1000A AC/DC

True RMS

Clamp Meter

R5040

Instruction

Manual

www.GlobalTestSupply.com

Table of Contents

Introduction ................................................................................................... 3

Product Quality .............................................................................................. 3

Safety .........................................................................................................3-4

Features ......................................................................................................... 4

Included ......................................................................................................... 4

Specications ............................................................................................. 5-6

Instrument Description .................................................................................. 7

Display Description ....................................................................................... 7

Operating Instructions .............................................................................. 8-11

AC/DC Current Measurements ................................................................ 8

AC/DC Voltage Measurements ................................................................. 8

Resistance Measurements ....................................................................... 8

Diode and Continuity Measurements ....................................................... 9

Capacitance Measurements ..................................................................... 9

Frequency or % Duty Cycle Measurements ............................................. 9

Temperature Measurements ................................................................... 10

Non-Contact AC Voltage Measurements ............................................... 10

Min/Max Recording ................................................................................ 10

Relative Mode ......................................................................................... 10

Data Hold ............................................................................................... 11

Auto and Manual Range ......................................................................... 11

Battery Replacement ................................................................................... 11

Applications ................................................................................................. 11

Accessories and Replacement Parts .......................................................... 12

Product Care ............................................................................................... 12

Product Warranty ........................................................................................ 13

Product Disposal and Recycling ................................................................. 13

Product Support .......................................................................................... 13

www.GlobalTestSupply.com

2

Introduction

Thank you for purchasing your REED R5040 1000A AC/DC True RMS

Clamp Meter. Please read the following instructions carefully before using

your instrument. By following the steps outlined in this manual your meter

will provide years of reliable service.

Product Quality

This product has been manufactured in an ISO 9001 facility and has

been calibrated during the manufacturing process to meet stated product

specications. If a certicate of calibration is required please contact the

nearest authorized REED distributor or authorized Service Center. Please

note an additional fee for this service will apply.

Safety

• Never attempt to repair or modify your instrument. Dismantling your

product, other than for the purpose of replacing batteries, may cause

damage that will not be covered under the manufacturer's warranty.

Servicing should only be provided by an authorized service center.

• Do not exceed the maximum allowable input range of any function.

• Do not apply voltage to the meter when resistance function is selected.

• Set the function switch OFF when the meter is not in use.

• Set the function switch to the appropriate position before measuring.

• When measuring volts do not switch to current/resistance modes.

• When changing ranges using the selector switch always disconnect the

test leads from the circuit under test.

• Do not exceed the maximum rated input limits.

• Improper use of this meter can cause damage, shock, injury or death.

• Read and understand this user manual before operating the meter.

• Always remove the test leads before replacing the battery.

• Inspect the condition of the test leads and the meter itself for any

damage before operating.

www.GlobalTestSupply.com

continued...

3

• Repair or replace any damage before use.

• Use great care when taking measurements if the voltages are greater

than 25VAC RMS or 35VDC as they are considered a shock hazard.

• Remove the battery if the meter is to be stored for long periods.

• Always discharge capacitors and remove power from the device under

test before performing diode, resistance, or continuity tests.

• Voltage checks on electrical outlets can be difcult and misleading

because of the uncertainty of connection to the recessed

electrical contacts.

• If the equipment is used in a manner not specied by the manufacturer,

the protection provided by the equipment may be impaired.

Features

• Measures AC/DC current/voltage, resistance, capacitance, frequency,

duty cycle, and temperature

• 50,000-count backlit LCD display and analog bargraph

• Low battery and overrange indicators

• Built-in non-contact voltage detector with LED indicator

• True RMS AC measurements

• Min/Max, display hold and relative mode

• Diode test and continuity check functions

• Durable double molded plastic housing

• Cat. III 600V safety rating

Included

• Test Leads

• Thermocouple Wire Probe

• Thermocouple Adapter

• Soft Carrying Case

• Battery

www.GlobalTestSupply.com

4

Specifications

AC/DC Current

Range: 500, 1000A

Accuracy: AC: ±(2.8% rdg. +30 dgt.)

DC: ±(2.5% rdg. +30 dgt.)

Resolution: 0.01, 0.1, 1A

AC/DC Voltage

Range: AC: 500mV, 5, 50, 500, 750V

DC: 500mV, 5, 50, 500, 1000V

Accuracy: AC: ±(1.0% rdg. +30 dgt.)

DC: ±(0.1% rdg. +4 dgt.)

Resolution: AC/DC: 0.1mV, 0.001, 0.01, 0.1, 1V

Resistance

Range: 500Ω, 5, 50, 500kΩ, 5, 50MΩ

Accuracy: ±(1.0% rdg. +4 dgt.)

0.1Ω, 0.001, 0.01, 0.1kΩ, 0.001, 0.01MΩ

Capacitance

Range: 500, 5000nF, 50, 500µF, 5mF

Accuracy: ±(3.5% rdg. +10 dgt.)

Resolution: 0.01, 0.1nF, 0.01, 0.1μF, 0.1mF

Frequency

Range: 10kHz

Accuracy: ±(0.3% rdg. +2 dgt.)

Resolution: 0.001Hz

Temperature

Range: -148 to 1832°F (-100 to 1000°C)

Accuracy: ±(1.0% rdg. + 4.5°F)

±(1.0% rdg. + 2.5°C)

Resolution: 1°F, 1°C

www.GlobalTestSupply.com

continued...

5

General Specifications

Range Selection: Autoranging/Manual

True RMS: Yes

Display: 50,000 count LCD display

Display Hold: Yes

Max/Min: Yes

Relative Mode: Yes

Diode Test: Yes

Backlit Display: Yes

Analog Bargraph: Yes (61-segment)

Continuity Check: Audible signal if resistance <35Ω

Duty Cycle: Yes

Non-Contact Voltage Detector: Yes

Autoshut Off: Yes (after 15 minutes)

Power Supply: 9V Battery

Low Battery Indicator: Yes

Jaw Opening: 1.5" (40mm), up to 500 MCM

Overvoltage Category: CAT. III 600V

Product Certications: CE

Operating Temperature: 32 to 122°F (0 to 50°C)

Storage Temperature: -4 to 140°F (-20 to 60°C)

Dimensions: 9.1 x 3.0 x 1.5" (232 x 77 x 39mm)

Weight: 9.6oz (271g)

www.GlobalTestSupply.com

6

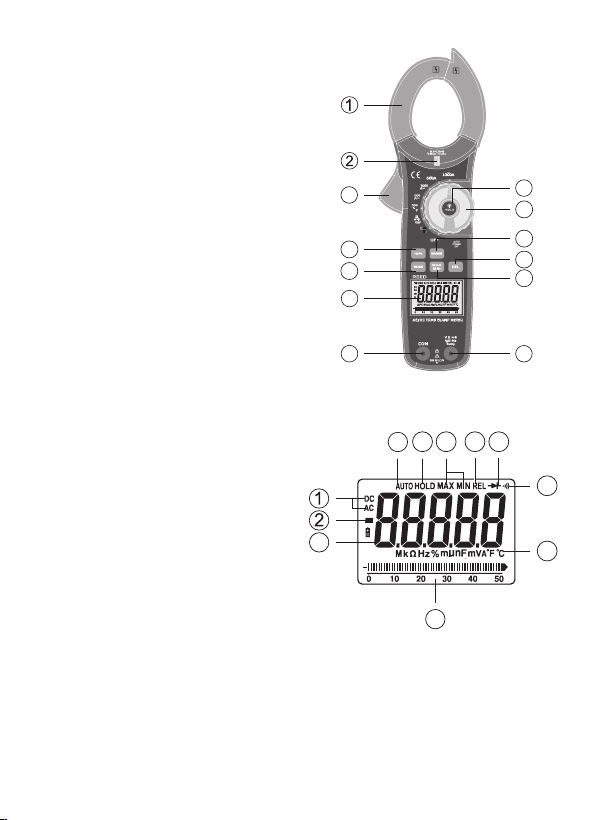

Instrument Description

1. Current Clamp

2. Non-Contact AC Voltage

Indicator Light

3. Clamp Trigger

4. Data Hold and Backlight Button

5. Rotary Function Switch

6. Hz% Hold Button

7. RANGE Select Button

8. MODE Select Button

9. Relative Button

10. MIN/MAX Hold Button

11. LCD Display

12. COM Input Jack

13. Positive Input Jack

Display Description

1. AC/DC Indicator

2. Negative Reading Indicator

3. 50,000 Count Main Display

4. Analog Bargraph

5. Units of Measurement

6. Audible Continuity Indicator

7. Diode Test Mode Indicator

8. Relative Mode Indicator

9. Max/Min Mode Indicator

10. Data Hold Indicator

11. Auto Range Mode Indicator

3

6

8

11

12

11

R5040

10

4

5

7

9

10

13

89

7

6

3

5

4

www.GlobalTestSupply.com

7

Operating Instructions

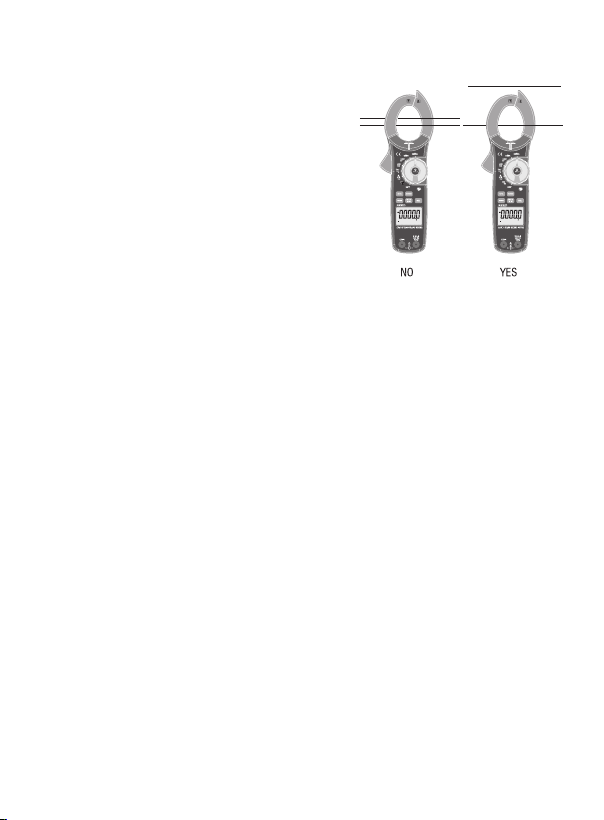

AC/DC Current Measurements

1. Set the rotary function switch to the

1000ADC, 600ADC, 1000AAC, or

600AAC range. If the range needed

is not known, select the higher range

rst then move to the lower range if

necessary.

2. Press the trigger to the open jaw and

fully enclose one conductor.

3. The LCD will display the reading.

AC/DC Voltage Measurements

1. Insert the black test lead into the negative COM terminal and the red

test lead into the positive V terminal.

2. Set the rotary function switch to the V position, and select either AC

or DC with the MODE button.

3. Select Hz% or ACV with the Hz% button.

4. Connect the test leads in parallel to the circuit under test.

5. The LCD will display the reading.

Resistance Measurements

1. Insert the black test lead into the negative COM terminal and the red

test lead into the positive V terminal.

2. Set the rotary function switch to the Ω position.

3. Touch the test probe tips across the circuit or component under test.

It is best to disconnect one side of the device under test so the rest

of the circuit will not interfere with the reading.

4. The LCD will display the reading.

R5040

R5040

www.GlobalTestSupply.com

continued...

8

Diode and Continuity Measurements

1. Insert the black test lead into the negative COM terminal and the red

test lead into the positive V diode terminal.

2. Turn the rotary function switch to the Ω position. Press the MODE

button until the Diode Test indicator appears on the display.

3. Touch the test probes to the diode under test. Forward voltage will

indicate 0.4V to 0.7V. Reverse voltage will be indicated by "OL".

Shorted devices will indicate near 0mV and an open device will be

indicated by "OL" in both polarities. For continuity tests, if the

resistance is <40Ω, a tone will sound.

Capacitance Measurements

1. To avoid electric shock, disconnect power to the unit under test and

discharge all capacitors before taking any capacitance measurements.

Remove the batteries and unplug the line cords.

2. Set the rotary function switch to the CAP position.

3. Insert the black test lead into the negative COM terminal and the red

test lead into the positive V terminal.

4. Touch the test leads to the capacitor under test.

5. The LCD will display the reading.

Frequency or % Duty Cycle Measurements

1. Set the rotary function switch to the V position.

2. Select ACV with the MODE button and press the Hz/% button to

indicate "Hz" in the display.

3. Insert the black test lead into the negative COM terminal and the red

test lead into the positive V terminal.

4. Touch the test probe tips to the circuit under test.

5. The LCD will display the reading.

continued...

www.GlobalTestSupply.com

9

Temperature Measurements

1. To avoid electric shock, disconnect both test probes from any source

of voltage before making a temperature measurement.

2. Set the function switch to TEMP. Press the MODE button to change

between °C and °F.

3. Insert the Temperature Probe into the negative COM and the

positive V terminals, making sure to observe the correct polarity.

4. Touch the Temperature Probe head to the area to be measured. Keep

the probe touching the part under test until the reading stabilizes

(about 30 seconds).

5. The LCD will display the reading.

Note: To avoid electric shock, be sure the thermocouple has been removed

before changing to another function.

Non-Contact AC Voltage Measurements

1. Set the rotary function switch to the V position.

2. Touch the probe tip to the hot conductor or insert into the hot side of

the electrical outlet. If AC voltage is present, the detector will light up.

3. The conductors in electrical cord sets are often twisted. For best

results, rub the probe tip along a length of the cord to assure placing

the tip in close proximity to the live conductor.

4. The detector is designed with high sensitivity. Static electricity or

other sources of energy may randomly trip the sensor.

Min/Max Recording

While in Manual Range, select the proper range before selecting MIN/MAX

to ensure that the MIN/MAX reading will not exceed the testing range.

Press the MIN/MAX button to select the minimum reading. Press the

MIN/MAX button again to select the maximum reading. Press the MIN/

MAX button again to exit and resume normal measuring.

Relative Mode

Press the REL button for Capacitance Zero & Offset Adjustment.

www.GlobalTestSupply.com

continued...

10

Data Hold

1. While taking a measurement, press the HOLD button to freeze the

current reading on the display.

2. While in this mode, a HOLD symbol will appear.

3. Press the HOLD button again to exit and resume normal operation.

Auto and Manual Range

When the meter is rst turned on, it automatically goes into AutoRanging.

This automatically selects the best range for the measurements being

made and is generally the best mode for most measurements. For

measurement situations requiring that a range be manually selected,

perform the following:

1. Press the RANGE button. The "Auto Range" display indicator will

turn off and "Manual Range" display indicator will turn on.

2. Press the RANGE button to step through the available ranges until

you select the range you want.

3. Press and hold the RANGE button for 2 seconds to exit "Manual

Ranging" mode and return to "AutoRanging".

Battery Replacement

1. Remove the Phillips screw on the back of the meter.

2. Open the battery compartment.

3. Replace the 1 x 9V battery and secure the battery compartment.

Applications

• Industrial maintenance teams performing scheduled and preventative

maintenance on electro-mechanical equipment and systems.

• Facilities, building maintenance and electricians looking to troubleshoot

electrical equipment installation problems.

www.GlobalTestSupply.com

11

Accessories and Replacement Parts

• R2990 Thermocouple Adapter

• R5400 Line Splitter

• R1000 Safety Test Lead Set, Double Insulated

• R1020 Fused Test Lead Set

• TP-01 Type K Thermocouple Wire Probe

• R2920 Surface Thermocouple Probe

• R2930 Right Angle Thermocouple Surface Probe

• R2940 Air/Gas Thermocouple Probe

• R2950 Immersion Thermocouple Probe

• R2960 Needle Tip Thermocouple Probe

• CA-05A Soft Carrying Case

• R9940 Hard Shell Carrying Case

Don't see your part listed here? For a complete list of all accessories and

replacement parts visit your product page on www.reedinstruments.com.

Product Care

To keep your instrument in good working order we recommend the following:

• Store your product in a clean, dry place.

• Change the battery as needed.

• If your instrument isn't being used for a period of one month or longer

please remove the battery.

• Clean your product and accessories with biodegradable cleaner. Do not

spray the cleaner directly on the instrument. Use on external parts only.

www.GlobalTestSupply.com

12

Product Warranty

REED Instruments guarantees this instrument to be free of defects in

material or workmanship for a period of one (1) year from date of shipment.

During the warranty period, REED Instruments will repair or replace, at no

charge, products or parts of a product that proves to be defective because

of improper material or workmanship, under normal use and maintenance.

REED Instruments total liability is limited to repair or replacement of the

product. REED Instruments shall not be liable for damages to goods,

property, or persons due to improper use or through attempts to utilize the

instrument under conditions which exceed the designed capabilities. In

order to begin the warranty service process, please contact us by phone at

1-877-849-2127 or by email at info@reedinstruments.com to discuss the

claim and determine the appropriate steps to process the warranty.

Product Disposal and Recycling

Please follow local laws and regulations when disposing or recycling your

instrument. Your product contains electronic components and must be

disposed of separately from standard waste products.

Product Support

If you have any questions on your product, please contact your authorized

REED distributor or REED Instruments Customer Service by phone at

1-877-849-2127 or by email at info@reedinstruments.com.

Please visit www.REEDInstruments.com for the most

up-to-date manuals, datasheets, product guides and software.

Product specifications subject to change without notice.

All rights reserved. Any unauthorized copying or reproduction of

this manual is strictly prohibited without prior written permission

from REED Instruments.

www.GlobalTestSupply.com

13

TEST & MEASURE

WITH CONFIDENCE

CHECK OUT OUR LATEST PRODUCTS!

www.GlobalTestSupply.com

Loading...

Loading...