LCR Meter

R5001

Instruction

Manual

www.GlobalTestSupply.com

Table of Contents

Introduction ................................................................................................ 3

Product Quality ........................................................................................... 3

Safety ......................................................................................................... 4

Features ...................................................................................................... 4

Included ...................................................................................................... 5

Specications ........................................................................................ 5-10

Accuracy ........................................................................................... 6-10

Instrument Description ............................................................................. 11

Operating Instructions ......................................................................... 12-19

Power ON/OFF .................................................................................... 12

Auto Power Off .................................................................................... 12

Beep Function ..................................................................................... 12

Backlight .............................................................................................. 12

Battery Charge .................................................................................... 12

Test Frequency Functions ................................................................... 13

Capacitance .................................................................................... 13

Inductance ...................................................................................... 13

Selecting Test Frequency .................................................................... 13

Primary Impedance with Secondary Parameter Test .......................... 14

Series or Parallel Functions ............................................................ 14-15

Capacitance .................................................................................... 15

Inductance ...................................................................................... 15

Series/Parallel Measurements ............................................................. 15

Data Hold ............................................................................................. 15

continued...

www.GlobalTestSupply.com

2

Relative Mode ...................................................................................... 16

Accuracy Discrepancies ................................................................. 16-17

Capacitance .................................................................................... 16

Inductance ...................................................................................... 16

Resistance ...................................................................................... 17

Guard Terminal .................................................................................... 17

Calibration Mode ............................................................................ 17-18

Sorting Mode .................................................................................. 18-19

Battery Replacement ................................................................................ 19

Accessories and Replacement Parts ....................................................... 20

Product Care ............................................................................................ 20

Product Warranty ..................................................................................... 21

Product Disposal and Recycling .............................................................. 21

Product Support ....................................................................................... 22

Introduction

Thank you for purchasing your REED R5001 LCR Meter. Please read the

following instructions carefully before using your instrument. By following the

steps outlined in this manual your meter will provide years of reliable service.

Product Quality

This product has been manufactured in an ISO 9001 facility and has

been calibrated during the manufacturing process to meet stated product

specications. If a certicate of calibration is required please contact the

nearest authorized REED distributor or authorized Service Center. Please

note an additional fee for this service will apply.

www.GlobalTestSupply.com

3

Safety

This manual should be read and well understood before the instrument is used.

• Never attempt to repair or modify your instrument. Dismantling your

product, other than for the purpose of replacing batteries, may cause

damage that will not be covered under the manufacturer's warranty.

Servicing should only be provided by an authorized service center.

• Do not operate in an explosive atmosphere.

• Do not operate in the presence of ammable gases or fumes.

• Keep away from live circuits.

• Do not remove the instrument cover.

• This meter is for indoor use, altitude up to 2000m.

• When measuring in-circuit components, rst de-energize the circuits

before connecting the test leads.

• Do not measure a capacitor that is not fully discharged.

•

When measuring within a circuit, the circuit must be de-energized before

connecting the test leads.

• Wipe the instrument clean when used in a dusty environment.

•

Do not leave the instrument exposed to direct heat for long periods of time.

• Before removing the battery cover, ensure that the instrument is

disconnected from any circuit and is powered OFF.

Features

• Measures inductance, capacitance and resistance

• Autoranging for AC impedance and DE resistance measurement

• Auto LCR smart check and measurement

• Series/Parallel modes

• Ls/Lp/Cp with D/Q/Ø/ESR parameters

• Support DCR mode 200Ω to 200MΩ

• High accuracy with 4/5 terminal Kelvin measurement

• 10kHz testing frequency and up to 100kHz output frequency

• Large backlit dual LCD display

• Data hold and relative functions

• Low battery indication with auto power off

www.GlobalTestSupply.com

4

Included

• Test Leads and Probes

• Tweezers

• Alligator Clips

• Batteries

Specifications

Test Frequencies: 100/120/1k/10k/100kHz

Test AC Signal Level: 0.6mVRMS typical

Test Range (F=1kHz): L: 200µH to 2000H

C: 2000pF to 2mF

R: 20Ω to 200MΩ

Primary Parameters Display: DCR: DC resistance

Ls: Serial inductance

Lp: Parallel inductance

Cs: Serial capacitance

Cp: Parallel capacitance

Rs: Serial resistance

Rp: Parallel resistance

Second Parameter Display: θ: Phase angle

ESR: Equivalence Serial Resistance

D: Dissipation factor

Q: Quality factor

Power Supply: 6 x 1.5 AA Batteries

Dimensions: 8.6 x 3.7 x 2.4" (220 x 96 x 60mm)

Weight: 0.8lb (360g)

www.GlobalTestSupply.com

continued...

5

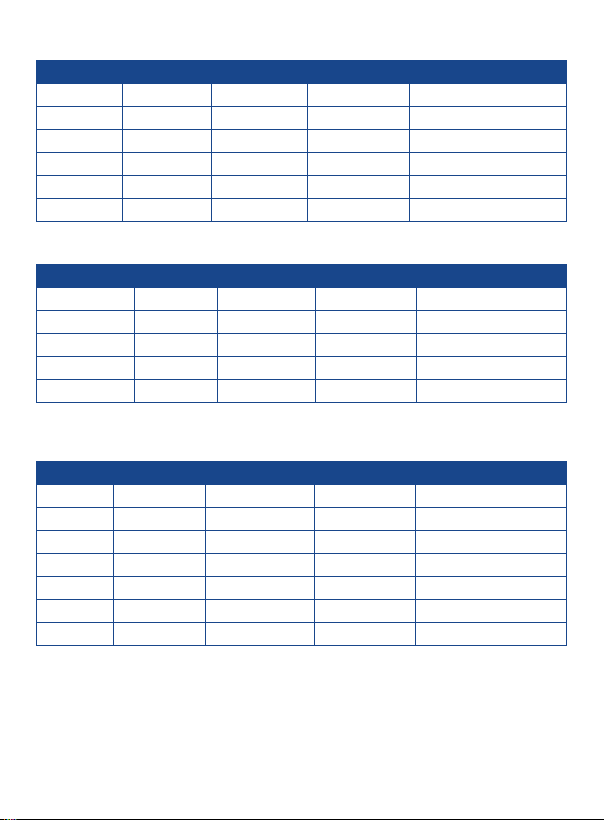

Accuracy

Notes:

• Measurement performed at the test socket.

• Measurements performed after correct open and short calibration.

• DUT and test leads must be properly shielded.

• Q value is the reciprocal of DF.

• Accuracies based within 10% to 100% of full scale of range; values

outside of range should be used as reference only.

• "---" means parallel or series measurement mode.

Inductance @ Ta = 18 to 28°C (De)

Frequency = 100 Hz/120 Hz

Range Resolution Lx Accuracy DF Accuracy

20.000mH 1µH 1.5% ±10d 1.5% ±50d Series

200.00mH 0.01mH 1.4% ±15d 1.4% ±50d Series

2000.0mH 0.1mH 1.5% ±15d 1.5% ±50d Series

20.000H 1mH 1.6% ±10d 1.6% ±50d ---

200.00H 0.01H 1.3% ±10d 1.3% ±50d Parallel

2000.0H 0.1H 2.0% ±15d 2.0% ±50d Parallel

20.000kH 0.001kH 2.5% ±15d 2.5% ±50d Parallel

Frequency = 1kHz

Range Resolution Lx Accuracy DF Accuracy Measurement Mode

2000.0µH 0.1µH 1.3% ±10d 1.3% ±50d Series

20.000mH 1µH 1.2% ±10d 1.2% ±50d Series

200.00mH 0.01mH 1.2% ±10d 1.2% ±50d Series

2000.0mH 0.1mH 1.5% ±15d 1.5% ±50d ---

20.000H 1mH 1.5% ±15d 1.5% ±50d Parallel

200.00H 0.01H 2.0% ±10d 2.0% ±50d Parallel

2000.0H 0.1H 2.5% ±15d 2.5% ±50d Parallel

Measurement Mode

www.GlobalTestSupply.com

continued...

6

Frequency = 10kHz

Range Resolution Lx Accuracy DF Accuracy Measurement Mode

200.00µH 0.01µH 1.8% ±10d 1.8% ±50d Series

2000.0uH 0.1µH 1.5% ±10d 1.5% ±50d Series

20.000mH 1µH 1.2% ±10d 1.2% ±50d Series

200.00mH 0.01mH 1.5% ±15d 1.5% ±50d ---

2000.0mH 0.1mH 2.0% ±10d 2.0% ±50d Parallel

20.000H 1mH 2.5% ±15d 2.5% ±50d Parallel

Frequency = 100kHz

Range Resolution Lx Accuracy DF Accuracy Measurement Mode

20.000µH 0.001µH 2.5% ±10d 2.5% ±50d Series

200.00µH 0.01µH 1.5% ±10d 1.5% ±50d Series

2000.0µH 0.1µH 1.3% ±15d 1.3% ±50d Series

20.000mH 1µH 2.0% ±15d 2.0% ±50d Parallel

200.00mH 0.01mH 2.5% ±15d 2.5% ±50d Parallel

Capacitance @ Ta = 18 to 28°C (De)

Frequency = 100Hz/120Hz

Range Resolution Cx Accuracy DF Accuracy Measurement Mode

20.000nF 1pF 2.5% ±10d 2.5% ±50d Parallel

200.00nF 0.01nF 1.2% ±10d 1.2% ±50d ---

2000.0nF 0.1nF 0.9% ±10d 0.9% ±50d ---

20.000µF 1nF 1.0% ±15d 1.0% ±50d Series

200.00µF 0.01µF 1.2% ±10d 1.2% ±50d Series

2000.0µF 0.1µF 2.5% ±10d 2.5% ±50d Series

20.00mF 0.01mF 5.0% ±10d 5.0% ±50d Series

www.GlobalTestSupply.com

continued...

7

Frequency = 1kHz

Range Resolution Cx Accuracy DF Accuracy Measurement Mode

2000.0pF 0.1pF 3.5% ±15d 3.5% ±50d Parallel

20.000nF 1pF 1.0% ±10d 1.0% ±50d ---

200.00nF 0.01nF 0.9% ±10d 0.9% ±50d ---

2000.0nF 0.1nF 1.0% ±10d 1.0% ±50d Series

20.000µF 1nF 1.2% ±15d 1.2% ±50d Series

200.00µF 0.01µF 2.5% ±10d 2.5% ±50d Series

2000µF 1µF 4% ±20d 4% ±50d Series

Frequency = 10kHz

Range Resolution Cx Accuracy DF Accuracy

200.00pF 0.01pF 3.0% ±8d 3.0% ±50d Parallel

2000.0pF 0.1pF 1.0% ±10d 1.0% ±50d ---

20.000nF 1pF 0.9% ±10d 0.9% ±50d ---

200.00nF 0.01nF 0.8% ±10d 0.8% ±50d Series

2000.0nF 0.1nF 1.0% ±8d 1.0% ±50d Series

20.000µF 1nF 2.0% ±8d 2.0% ±50d Series

200.0µF 0.1µF 4.5% ±15d 4.5% ±50d Series

Measurement Mode

Frequency = 100kHz

Range Resolution Cx Accuracy DF Accuracy Measurement Mode

200.00pF 0.01pF 2.5% ±15d 2.5% ±50d Parallel

2000.0pF 0.1pF 1.0% ±8d 1.0% ±50d Parallel

20.000nF 1pF 1.8% ±8d 1.8% ±50d Parallel

200.00nF 0.01nF 1.5% ±10d 1.5% ±50d Series

2000.0nF 0.1nF 2.5% ±15d 2.5% ±50d Series

www.GlobalTestSupply.com

continued...

8

Resistance @ Ta = 18 to 28°C (De)

Frequency = 100Hz/120Hz

Range Resolution Rx Accuracy Measurement Mode

200.00Ω 0.01Ω 1.2% ±10d ---

2.0000kΩ 0.1Ω 0.8% ±5d ---

20.000kΩ 1Ω 0.9% ±5d ---

200.00kΩ 0.01kΩ 0.7% ±3d ---

2.0000MΩ 0.1kΩ 1.0% ±5d ---

20.000MΩ 1kΩ 2.2% ±10d ---

200.0MΩ 0.1MΩ 2.5% ±10d ---

Frequency = 1kHz

Range Resolution Rx Accuracy Measurement Mode

20.000Ω 1mΩ 1.2% ±10d ---

200.00Ω 0.01Ω 0.8% ±5d ---

2.0000kΩ 0.1Ω 0.8% ±3d ---

20.000kΩ 1Ω 0.7% ±3d ---

200.00kΩ 0.01kΩ 1.0% ±5d ---

2.0000MΩ 0.1kΩ 1.5% ±10d ---

20.000MΩ 1kΩ 1.8% ±10d ---

200.0MΩ 0.1MΩ 6.0% ±50d ---

Frequency = 10kHz

Range Resolution Rx Accuracy Measurement Mode

20.000Ω 1mΩ 1.5% ±10d ---

200.00Ω 0.01Ω 0.8% ±10d ---

2.0000kΩ 0.1Ω 0.9% ±5d ---

20.000kΩ 1Ω 0.8% ±3d ---

200.00kΩ 0.01kΩ 1.0% ±5d ---

2.0000MΩ 0.1kΩ 2.5% ±10d ---

20.00MΩ 0.01MΩ 2.8% ±10d ---

www.GlobalTestSupply.com

continued...

9

Frequency = 100kHz

Range Resolution Rx Accuracy Measurement Mode

20.000Ω 1mΩ 2.3% ±10d ---

200.00Ω 0.01Ω 1.5% ±5d ---

2.0000kΩ 0.1Ω 0.8% ±20d ---

20.000kΩ 1Ω 0.8% ±20d ---

200.00kΩ 0.01kΩ 1.5% ±10d ---

2.000MΩ 1kΩ 2.5% ±30d ---

DC Resistance @ Ta = 18 to 28°C (De)

Frequency = 100Hz/120Hz/1kHz/10kHz/100KHz

Range Resolution Rx Accuracy Measurement Mode

200.00Ω 0.01Ω 1.8% ±10d ---

2.0000kΩ 0.1Ω 0.6% ±20d ---

20.000kΩ 1Ω 0.6% ±10d ---

200.00kΩ 0.01kΩ 0.5% ±3d ---

2.0000MΩ 0.1kΩ 1.5% ±5d ---

20.000MΩ 1kΩ 2.0% ±5d ---

200.0MΩ 0.1MΩ 2.5% ±5d ---

D Value Accuracy @ Ta =18 to 28°C (De)

Freq./Z 0.1 to 1Ω

100/120Hz ±0.03 ±0.01 0.009 ±0.010 ±0.02 ±0.04

1kHz ±0.03 ±0.01 0.009 ±0.010 ±0.02 ±0.09

10kHz ±0.03 ±0.01 0.009 ±0.009 ±0.01 ±0.04

100kHz ±0.04 ±0.03 0.010 ±0.010 ±0.02 ±0.04

1 to 10Ω

10 to 100kΩ

100k to 1MΩ

1 to 20MΩ

20 to 200MΩ

θ Value Accuracy @ Ta =18 to 28°C

Freq./Z

100/120Hz ±0.65° ±0.36° ±0.23° ±0.45° ±0.65° ±1.35°

1kHz ±0.65° ±0.36° ±0.23° ±0.45° ±0.65° ±3.63°

10kHz ±0.65° ±0.36° ±0.23° ±0.45° ±1.35° N/A

100kHz ±1.27° ±0.65° ±0.49° ±0.65° ±1.35° ±1.35°

0.1 to 1Ω

1 to 10Ω

10 to 100kΩ

100k to 1MΩ

1 to 20MΩ 20 to 200MΩ

www.GlobalTestSupply.com

10

Instrument Description

3

4

5

6

7

8

9

R5001

10

11

12

13

14

15

16

1. LCD Display

2. Function Button

3. Calibration Button

4. Sorting Button

5. Frequency Button

6. Secondary Display/

Left Button

7. Power Button

8. Relative/Down Button

9. Input Sockets

(Banana Jack Inputs) and

Terminals for Positive,

Negative, and Guard

www.GlobalTestSupply.com

10. Setup Button

11. Auto Power Off Button

12. Up Button

13. Enter Button

14. Hold Button

15. Parallel/Series/Right Button

16. Backlight Button

11

Operating Instructions

Power ON/OFF

To turn the meter on or off, press the power button. By default, the meter

is set to Auto LCR Smart mode with a test frequency of 1kHz.

Auto Power Off

To preserve battery life, the meter is programmed to turn off after 5 minutes of

inactivity and 3 warning beeps. If a button is pushed during the three beeps,

the meter will continue measuring. To turn this feature on and off, press the

APO button. When enabled, "APO" will appear on the display.

Beep Function

This meter will beep once if the function selected is available, and beep

twice if the function selected is unavailable.

u = Active Functions

Button FUNC HOLD

AUTOLCR

L

C

ACR

DCR

u u u u

u u u u u u u u

u u u u u u u u

u u u u u u u

u u u u u

Backlight

Press the Backlight Button to turn the backlight on or off. The backlight

will stay on for 60 seconds before turning off automatically.

Battery Charge

The three horizontal bars above the battery symbol on the LCD screen

indicate the charge left in the batteries. When the three bars are no longer

visible the batteries need replacement. See "Battery Replacement" for details.

S/P BKLIT SORT REL% FREQ

DQθ

www.GlobalTestSupply.com

continued...

12

Test Frequency Functions

Test frequency can greatly affect the results of measurement readings,

especially when measuring inductors and capacitors. This section provides

some recommendations and suggestions to consider.

Capacitance

When measuring capacitance, selecting the right frequency is important

in obtaining the most accurate results. Generally a 1kHz test frequency is

used to measure capacitors that are 0.01μF or smaller. For capacitors that

are 10μF or larger, a lower frequency of 120Hz is used. Following this trend,

high-test frequencies are best for testing very low capacitance components.

For large capacitance components, low frequency would be optimal.

For example, if the capacitance of the component is in the mF range, then

selecting 100Hz or 120Hz for the test frequency would give more accurate

results. The results will also be obvious because if the same component

was tested with 1kHz or 10kHz, the measured readings may look erroneous

on the display. In all cases, it is best to check with the manufacturer's data

sheet in order to determine the best test frequency to use for measurement.

Inductance

Typically a 1kHz or 10kHz test frequency is used to measure inductors

that are used in audio and RF circuits because these components operate

at higher frequencies. However, a 120Hz test signal is used to measure

inductors that are used for applications such as lter chokes in power

supplies, which are typically operated at 60Hz AC (in US) with 120Hz

lter frequencies. In general, inductors below 2 mH should be measured

at 1kHz frequency while inductors above 200H should be measured at

120Hz. In all cases, it is best to check with the manufacturer's data sheet

in order to determine the best test frequency to use for measurement.

Selecting Test Frequency

The meter has ve test frequencies: 100Hz/120Hz/1kHz/10kHz/100kHz. Press

the FREQ button to scroll through the ve frequencies sequentially.

Note: The test frequency can affect the accuracy of the results depending

on what frequency is selected as well as what type and value of component

is being measured or tested.

continued...

13

www.GlobalTestSupply.com

Primary Impedance with Secondary Parameter Test

The default test mode for this meter is Auto-LCR Mode, which checks the

type of impedance and automatically enters L/C/R Mode. The secondary

parameter will follow the L/C/R measurement, meaning that (L+Q), (C+D)*,

(R+θ)** are combined in one group respectively.

1. Press the FUNC button to switch from Auto-LCR Mode to Auto-Lp

Mode, Auto-Cp Mode, Auto-Rp Mode, and DCR Mode.

Note: When Auto-Lp or Auto-Cp Mode is selected, the impedance

measurement is auto ranging. The primary LCD display will show the

inductance or capacitance of DUT (device under test); while the secondary

LCD display will show the quality or dissipation factor.

2. Press the button to display the D/Q/θ/ESR value. When Auto-R

(ACR mode) or DCR mode is selected the secondary parameter

is omitted.

* When Auto-LCR mode is active,

Device Under Test Display

the secondary parameter will

show the equivalent resistance in

parallel mode (Rp) to replace the

D factor if the C measured value

of the DUT is less than 5pF.

** Auto-LCR mode only. During

Auto-R Mode or DCR Mode,

the secondary parameter is

not available.

Series or Parallel Functions

Just as test frequency can greatly affect measurement results, selecting

between series or parallel measurement mode can also affect the accuracy

of the meter, especially for capacitive and inductive components. This

section provides some recommendations and suggestions to consider.

www.GlobalTestSupply.com

continued...

14

Capacitance

Most capacitance measurements will obtain best results with parallel mode

selected. The majority of capacitors have a very low dissipation factor

(high internal resistance) compared to the impedance of the capacitance. In

these cases, the paralleled internal resistance has negligible impact on the

measurement. There will be some cases where series mode would be used

for a capacitance measurement, or the readings will appear inaccurate.

Series mode is useful when large capacitors have higher dissipation factor

and lower internal resistance.

Inductance

Most inductance measurements will obtain best results with series mode

selected. In series mode, accurate Q (quality factor) readings can be

obtained from reading low Q inductors and ohmic losses are signicant.

There will be some cases where parallel mode would be used for an

inductance measurement, for example iron core inductors operating at

higher frequencies where hysteresis and eddy currents become signicant.

Series/Parallel Measurements

When any L/C/R function is selected, the default measurement will be

automatically selected. If the impedance is greater than 10kΩ, parallel

mode will be selected, and "Lp/Cp/Rp" will display on the LCD screen. If

the impedance is less than 10kΩ, series mode will be selected, and

"Ls/Cs/Rs" will display on the LCD. When the Parallel/Series/Right Button

is pressed, the impedance measurement will be set in series mode or in

parallel mode sequentially.

Data Hold

1. While taking a measurement, press the HOLD button to freeze the

current readings on the display.

2. While in this mode a "HOLD" symbol will appear.

3. Press the button again to resume normal operation.

Note: When the Data Hold feature is active all buttons except the power &

backlight buttons are disabled.

www.GlobalTestSupply.com

continued...continued...

15

Relative Mode

1. To reserve the current DUT readings (DCUR) on the primary display

as a reference value (DREF), press the button.

2.

The ∆ symbol will then appear on the LCD screen indicating this function

is now active. The secondary display will show the percentage of the

relative value (REL%).

3. Press the button again to show the reference value (DREF) on the

primary display; the ∆ symbol will start to blink.

REL% = (DCUR – DREF) / DREF x 100%

Note: The percentage range is -99.9% to 99.9%. When the relative value

is larger than double the reference value (DREF), the "OL%" symbol will

appear on the secondary display.

4.

Press and hold down the button for approximately 3 seconds to

exit relative mode and resume normal operation.

Accuracy Discrepancies

In some special cases, inaccuracies may occur in the measurement of

capacitive, inductive, and resistive components. This section provides

some recommendations and suggestions to consider.

Capacitance

It is strongly recommended to have the dissipation factor low when measuring

capacitors. Electrolytic capacitors inherently have a higher dissipation factor

due to their normally high internal leakage characteristics. In some cases, if

D (dissipation factor) is excessive, measurement accuracy may degrade and

even read out of specication.

Inductance

Some inductors are intended to operate at a certain DC bias to achieve a

certain inductance value, however this meter cannot produce such a biasing

scheme. External biasing should not be attempted because external power

would be applied to the instrument and cause serious damage to the meter.

Therefore, in some cases, the inductance reading may not agree with

manufacturer's specication. It is important to check if the specication

pertains to DC biasing or not.

www.GlobalTestSupply.com

continued...

16

Resistance

When measuring resistance of devices, it is important to know that there are

two types or ways of measurement. One type is DC resistance measurement.

Another type is AC resistance measurement. The LCR meter provides both

types of measurement.

Before using the meter to measure resistance, please verify whether

the DUT (device under test) requires DC or AC resistance measurement

method. Depending on the method, results will vary greatly.

Guard Terminal

One of the input sockets and terminals is labeled as "GUARD". This

terminal does not have to be used in all instances for the meter to provide

measurements. But in some instances, it is very useful. Guard terminal

generally serves two purposes.

If user is using test leads, the guard terminal can be used to connect to

the shielding of the test leads. Doing so can be useful when making large

resistive component measurements. For example, when measuring a 10

MΩ resistor with test leads, at the high range the reading may seem to be

unstable as a few digits may continuously be changing. Having the shield

of the test leads connected to the guard terminal will help stabilize the

reading in some instances.

Guard terminal is also used to minimize noise and to help minimize parasitic

effects coming from the component being measured, thus allowing high

precision results.

Calibration Mode

It is recommended to regularly calibrate this meter to improve the accuracy

of high/low impedance measurements.

Note: You will need a shorting bar or a short piece of conductive metal

(i.e. paper clip) to complete the calibration procedure.

1. Be sure nothing is connected to the meter, and turn it on.

2. Press and hold down the CAL button for 2 seconds to enter

calibration mode.

3. The screen will display "OPEN", indicating the input terminals have

nothing connected.

continued...

17

www.GlobalTestSupply.com

4. Press the CAL button again and a 30 second countdown will appear

on the screen.

5. After the countdown is complete, a "PASS" or "FAIL" will show on

the display.

6. Press the CAL button a third time, and "SRT" will appear on the LCD

screen, indicating to the user to put the shorting bar across the "+"

and "-" input terminals.

7. Press the CAL button a fourth time, and a 30 second countdown will

appear on the screen.

8.

After the calibration procedure is nished a "PASS" or "FAIL" will appear

on the LCD screen.

9.

Press the CAL button a fth time and the calibration data will be saved

if "PASS" was displayed for both the Open & Short calibrations.

Open Calibration (left) and Short Calibration (right)

Sorting Mode

Sorting mode helps the user quickly sort through multiple components.

Select the primary measurement mode (L/C/R) based on the type of

components to be measured. Insert the component to be used as the

standard or good reference value that will be used for testing against all

other components.

Note: The meter needs a component connected to either the input sockets

or terminals for sorting mode to activate.

1. When ready, turn the meter on and press the SORTING button to

enter sorting mode.

2. The upper display will indicate "PASS" and the lower display will

indicate the value of the component.

Note: The default sorting % is +/- 1%.

continued...

18

www.GlobalTestSupply.com

3. Press the SETUP button and the "Range" symbol will ash on

the display.

4. Adjust the range setting by pressing the or buttons

5. Press the ENTER button save the range setting and proceed to the

value setting.

6. Press the or buttons to select the ashing digit required for

adjustment. Press the or button to adjust the value of the digit.

7. Press the ENTER button to save the value setting and proceed to the

Tolerance setting.

8.

Press the or buttons to scroll through following tolerance % values.

1)

±0.25%

2) ± 0.5%

3) ± 1%

4) ± 2%

9. Press the ENTER button to save the Tolerance setting.

10.

The upper display will now indicate "PASS" or "FAIL", depending on

whether the impedance measured exceeds tolerance range. The current

measurement result will display on the lower display.

11. Press the SORTING Button to exit Sorting Mode.

5) ±5%

6) ±10%

7) ±20%

8) -20% +80%

Battery Replacement

The battery icon indicates the power status of the batteries. As the

batteries weaken, the number of lines will decrease. When the battery icon

appears on the LCD, the batteries must be replaced.

To replace the batteries:

1. Remove the four screws under the ip stand located at the rear of

the meter.

2. Lift up the battery cover and replace the 6 x "AA" batteries

3. Secure the cover back into place with the four screws.

www.GlobalTestSupply.com

19

Accessories and Replacement Parts

• R1210 Alligator Clip Set

• R1020 Fused Test Lead Set

• R8888 Deluxe Hard Carrying Case

• CA-05A Soft Carrying Case

Don't see your part listed here? For a complete list of all accessories and

replacement parts visit your product page on www.reedinstruments.com.

Product Care

To keep your instrument in good working order we recommend the following:

• Store your product in a clean, dry place.

• Change the battery as needed.

• If your instrument isn't being used for a period of one month or longer

please remove the battery.

• Clean your product and accessories with biodegradable cleaner. Do not

spray the cleaner directly on the instrument. Use on external parts only.

www.GlobalTestSupply.com

20

Product Warranty

REED Instruments guarantees this instrument to be free of defects in

material or workmanship for a period of one (1) year from date of shipment.

During the warranty period, REED Instruments will repair or replace, at no

charge, products or parts of a product that proves to be defective because

of improper material or workmanship, under normal use and maintenance.

REED Instruments total liability is limited to repair or replacement of the

product. REED Instruments shall not be liable for damages to goods,

property, or persons due to improper use or through attempts to utilize the

instrument under conditions which exceed the designed capabilities. In

order to begin the warranty service process, please contact us by phone at

1-877-849-2127 or by email at info@reedinstruments.com to discuss the

claim and determine the appropriate steps to process the warranty.

Product Disposal and Recycling

Please follow local laws and regulations when disposing or recycling your

instrument. Your product contains electronic components and must be

disposed of separately from standard waste products.

www.GlobalTestSupply.com

21

Product Support

If you have any questions on your product, please contact your authorized

REED distributor or REED Instruments Customer Service by phone at

1-877-849-2127 or by email at info@reedinstruments.com.

Please visit www.REEDINSTRUMENTS.com for the most

up-to-date manuals, datasheets, product guides and software.

Product specifications subject to change without notice.

All rights reserved. Any unauthorized copying or reproduction of

this manual is strictly prohibited without prior written permission

from REED Instruments.

www.GlobalTestSupply.com

22

TEST & MEASURE

WITH CONFIDENCE

CHECK OUT OUR LATEST PRODUCTS!

www.GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...