Temperature

Simulator

R2800

Instruction

Manual

www.GlobalTestSupply.com

Table of Contents

Introduction ................................................................................................ 3

Product Quality ........................................................................................... 3

Safety ......................................................................................................... 3

Features ...................................................................................................... 4

Included ...................................................................................................... 4

Specications .......................................................................................... 4-6

Output Functions ................................................................................4-5

General Specifications ........................................................................... 6

Instrument Description ............................................................................... 7

Display Description .................................................................................... 8

Operating Instructions ........................................................................... 8-12

Power ON/OFF ...................................................................................... 8

Auto Power-Off ...................................................................................... 9

Output Function ..................................................................................... 9

Simulating Output from DC Voltage ..................................................9-10

Simulating Output from Thermocouple (TC) ................................... 10-11

Simulating output from thermal resistance or RTD ......................... 11-12

Battery Replacement ................................................................................ 12

Applications .............................................................................................. 13

Accessories and Replacement Parts ....................................................... 13

Product Care ............................................................................................ 13

Product Warranty ..................................................................................... 13

Product Disposal and Recycling .............................................................. 14

Product Support ....................................................................................... 14

www.GlobalTestSupply.com

2

Introduction

Thank you for purchasing your REED R2800 Temperature Simulator. Please

read the following instructions carefully before using your instrument. By

following the steps outlined in this manual your meter will provide years of

reliable service.

Product Quality

This product has been manufactured to meet the stated product specications.

If a certicate of calibration is required please contact the nearest authorized

REED distributor or authorized Service Center. Please note an additional fee for

this service will apply.

Safety

Never attempt to repair or modify your instrument. Dismantling your

product, other than for the purpose of replacing batteries, may cause

damage that will not be covered under the manufacturer's warranty.

Servicing should only be provided by an authorized service center. To

avoid injury to the user or damage to the instrument, please read the

safety information below before initial use:

• Do not operate the instrument around ammable or explosive gas,

vapor or dust.

• Never apply more than 30V between any two terminals, or between any

terminal and ground terminal.

Note: For optimal accuracy, allow the instrument to warm up 5 minutes

before operating. If the automatic reference-junction temperature

compensation of the instrument deviates from its designed accuracy,

contact an Authorized REED Service Center.

www.GlobalTestSupply.com

3

Features

• Source 8 thermocouple types, including R, S, B, E, K, J, T, N; and 7

RTD types, including Pt 10 (385), Pt100 (385), Pt200 (385), Pt500 (385),

Pt1000 (385), Cu10, Cu50; plus volts and ohms

• Basic accuracy of 0.05%

• Internal cold junction compensation

• Easy-to-read 6-digit LCD display

• Zero adjustment button

• User selectable unit of measure (°F/°C)

• Low battery indicator and auto shut off

Included

• Test Leads

• Alligator Clips

• Thermocouple Adapter

• Protective Holster

• Batteries

Specifications

Output Functions

Accuracy specied at 23°C ±5°C & 75% RH for a period of one year

after calibration.

Output Range Output Range Resolution Accuracy

DCV

OHM

100mV -10.00 to 110.00mV 0.01mV 0.05% rdg. + 30mV

1000mV -100.00 to 1100.00mV 0.1mV 0.05% rdg. + 0.3mV

400Ω 0.0 to 400.0Ω 0.1Ω ±0.05% rdg. + 0.2Ω

400Ω 0 to 4000Ω 1Ω ±0.05% rdg. + 2Ω

www.GlobalTestSupply.com

continued...

4

Output Range Output Range Resolution Accuracy

R -40 to 1760°C 1°C

S -20 to 1760°C 1°C

B 400 to 1800°C 1°C

TC

RTD

E -200.0 to 1000.0°C 0.1°C

K -200.0 to 1370.0°C 0.1°C

J -200.0 to 1200.0°C 0.1°C

T -200.0 to 400.0°C 0.1°C

N -200.0 to 1300.0°C 0.1°C

Cu10 -10.0 to 250.0°C 0.1°C

Cu50 -50.0 to 150°C 0.1°C

Pt10 385 -200.0 to 850°C 0.1°C

Pt100 385 -200.0 to 850°C 0.1°C

Pt200 385 -200.0 to 630°C 0.1°C

Pt500 385 -200.0 to 630°C 0.1°C

Pt1000 385

-200.0 to 630°C 0.1°C

±0.05% rdg. +3°C

(≤100°C) ±0.05% rdg.

+2°C (>100°C)

±0.05% rdg. +3°C

(400 to 600°C);

±0.05% rdg. +2°C

(>600°C)

±0.05% rdg. +2°C

(≤-100°C) ±0.05%

rdg. +1°C (>-100°C)

±0.05% rdg. +0.6°C

±0.05% rdg. +0.6°C

±0.05% rdg. +0.6°C

Notes

• Excludes accessory lead resistance

• Range of excitation current: 0.5mA to 3mA; Max. output voltage: ≤2V

•

The accuracies indicated do not include the error of internal temperature

compensation caused by a sensor. The range of the internal temperature

compensation sensor is from -10 to 50°C with its compensating error up

to 0.5°C.

www.GlobalTestSupply.com

continued...

5

General Specifications

Display: 6-Digit LCD

Zero Adjustment Button: Yes

Kick Stand: Yes

Power Supply: 2 x AA Batteries

Cold Junction Compensation: Yes

Auto Shut Off: Yes (after 15 minutes/off)

Low Battery Indicator: Yes

Replaceable Test Leads: Yes

Product Certications: CE

Operating Temperature: 32 to 122°F (0 to 50°C)

Operating Humidity Range: 0 to 85%

Storage Temperature: 14 to 122°F (-10 to 50°C)

Dimensions: 7.1 x 3.5 x 1.9" (180 x 90 x 47mm)

Weight: 8.2oz (500g)

www.GlobalTestSupply.com

6

Instrument Description

R2800

OUTPUT

Pt1000 Pt200 Pt500 Cu50 Cu10

1

2

3

4

SIMULATOR

RJ-ON

Ω°C°F

mV

5

6

7

8

9

10

1. LCD Display

2. ON/OFF Button

3. °C/°F Selection Button

4. RJ-ON Button (T/C Reference Junction Compensation Button)

5. Function Selection Output Button

6. Range Selection Button

7. Zero Reset Button

8. Output Value Setting Button

9.

Output Digit Selection Button

10. Output Terminals

www.GlobalTestSupply.com

7

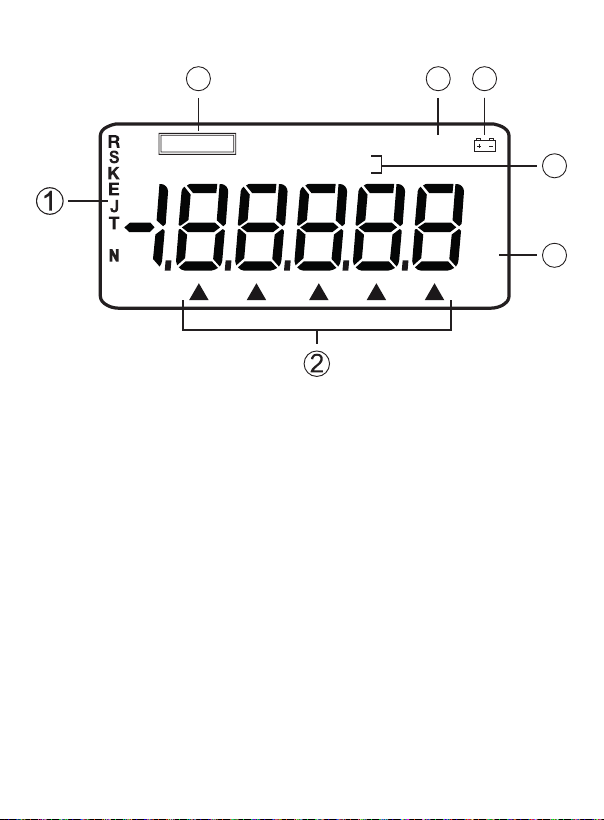

Display Description

567

OUTPUT

Pt1000 Pt200 Pt500 Cu50 Cu10

B

1. Thermocouple Type Indicator

2. Indicates which output value is being set

3. Current output value (unit of measure)

4. RTD Type Indicator

5. Low Battery Indicator

6. Instrument is performing its reference-cold junction compensation

7. Output State Indicator

RJ-ON

Ω°C°F

mV

4

3

Operating Instructions

Power ON/OFF

Press the POWER button to turn the instrument on. Press and hold the

POWER button to turn the instrument off. When the instrument is on, it

will begin an internal self-diagnosis at which time the full screen will be

displayed. When complete, the instrument is ready to take measurements.

www.GlobalTestSupply.com

continued...

8

Auto Power-Off

As a default the instrument will automatically turn off after 15 minutes of

inactivity. To turn off this feature:

1. Turn the meter off.

2. Press the POWER button (to display the full screen).

3. Quickly press the RANG button when the instrument is in the

maintenance state as indicated by "1.8.8.888".

4. "AP-XX" will now appear on the display.

5. Press the button to toggle between "AP-ON" & "AP-OF". "AP-OF"

indicates that the no automatic power-off function is disabled, while

"AP-ON" indicates the automatic power-off function is enabled.

6. Press the ZERO button to save the required setting.

7. Press and hold the POWER button to exit the maintenance state and

turn the instrument off.

Output Function

• The output terminal of the instrument can produce DC voltages set by

the user or can simulate resistance.

Do not apply any voltage to the output terminal during the operation.

If any improper voltage is applied to the output terminal, it will cause

damage to the internal circuit.

Simulating Output from DC Voltage

1. Insert one end of the test lead into

the output (TC/mV) jack of the

meter and connect the other end

to the input of the instrument under

test, as shown in the diagram to

the right.

2. Press the FUNC button to select

"DC Voltage Output". "V" will

appear on the display.

www.GlobalTestSupply.com

continued...

9

3. Press the RANG button to select the range of 1.0000V or 100.00mV.

"V" or "mV" will appear on the display.

4. Press the and buttons to move the on-screen cursor in order to

select the desired digit on the display.

5. Press the and buttons to change the numerical value of each

digit. (Numerical value cannot be changed beyond range maximum.)

6. Press the ZERO button and the output will be set to 00.00mV

or 0.0000V.

Simulating Output from Thermocouple (TC)

1. Insert one end of the test lead into the output (TC/mV) jack of the

meter and connect the other end to the input of the instrument under

test, as shown in the above diagram.

2.

Press the FUNC button to select "Thermocouple Output". "R" and

"°C" will appear on the display.

3. Press the RANG button to select the type of thermocouple.

4. Press the and buttons to move the on-screen cursor in order to

select the desired digit on the display.

5. Press the and buttons to change the numerical value of each

digit. (Numerical value cannot be changed beyond range maximum.)

6. Automatic compensation for reference-junction temperature.

7. Press the ZERO button and the output will be directly set to 0000°C

(R or S type), 400°C (B type) or 0000.0°C (other type).

8. Press the °C/°F button to select the unit °C or °F.

Note: During the direct calibration of an instrument with reference-junction

temperature compensation, it is recommended to press the RJ-ON button

so that the instrument can start the function of automatic referencejunction compensation. Thus providing the required thermo-electromotive

force for output followed by displaying the symbol "RJ-ON" where:

Output thermoelectric force = corresponding emf of set

temperature – emf of room temperature

•

It takes two seconds for the instrument to start its internal referencejunction

temperature. After this, each automatic compensation occurs at

10 second intervals.

continued...

10

www.GlobalTestSupply.com

• If there is a change in the operating ambient temperature, do not start

the operation until the built-in compensating sensor has become stable

(approx. 10 minutes).

• If there is no need for the simulator to perform the function of automatic

reference-junction compensation, press the RJ-ON button and the

symbol "RJ-ON" will no longer appear in the display.

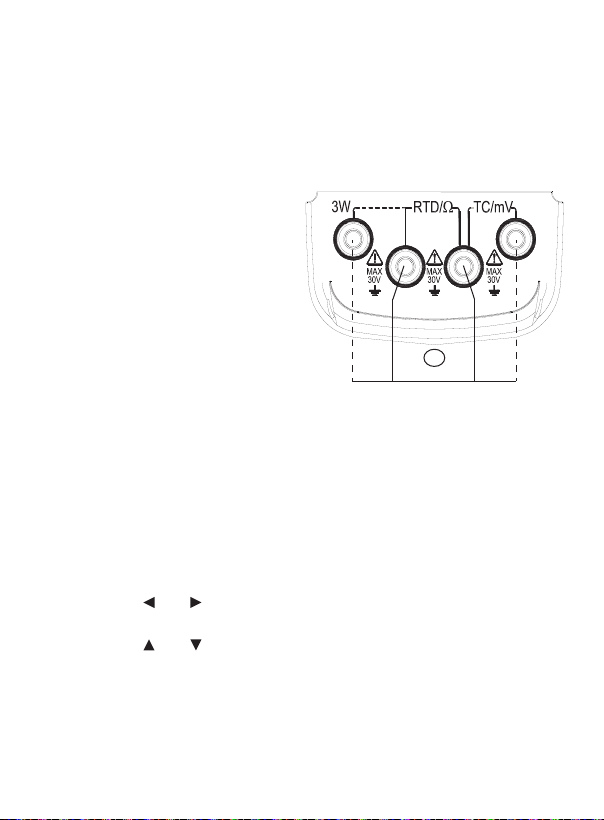

Simulating output from thermal resistance or RTD

1. Insert one end of the test lead

into the output (RTD/Ω) jack

of the meter and connect

the other end to the input of

the instrument under test as

shown in the diagram to the

right. The dedicated test leads

supplied with the simulator are

intended for a 2-wire system

for testing output according to

RTD

2w

user's requirement.

Note: An additional set of test leads are required for 3-wire or

4-wire systems.

2. The display of the symbol "OUTPUT" denotes the instrument is in an

output state.

3. Press the FUNC button to select thermal resistance output or RTD

output as indicated by "Ω" or "°C" and "Cu10" (Copper 10 ohm RTD)

on the LCD display.

4. While RTD function is selected, press the RANG button to select the

type of RTD.

5. Press the

and buttons to move the on-screen cursor in order to

select the desired digit on the display.

6. Press the and buttons to change the numerical value of each

digit. (Numerical value cannot be changed beyond range maximum.)

7. Press the ZERO button and the output will be directly set to 000.0°C.

8. Press the °C/°F button to select the unit °C or °F.

4w3w

www.GlobalTestSupply.com

continued...

11

Note: The instrument produces a simulation resistance up to 400Ω at

its output terminal (RTD /Ω). The method of simulating resistance output

is to send out an appropriate voltage 'Vx' according to the excitation

current 'Ix' produced by the calibrated instrument. Because R (set

resistance) = Vx (output voltage) / Ix (excitation current), the calibrated

device must provide an excitation current tothe simulator. The excitation

current should range from 0.5mA to 2mA.

Note:

When testing the resistance output of a 4-wire system while

employing a 2-wire connection, you should take into consideration the

error (approx. 0.1Ω) arising from the lead resistance of the test leads. If

the capacitance between the resistance output terminal of the simulator

and the tested instrument is more than 0.1μf, the simulator will produce

improper resistance.

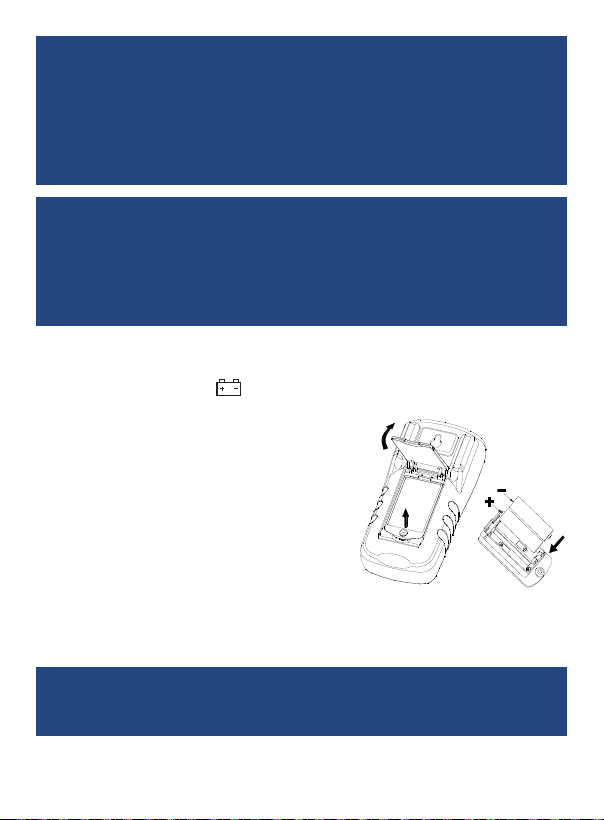

Battery Replacement

When the battery symbol, , appears on the display, the battery needs to

be replaced. In order to replace the battery, proceed with the following steps.

1. Ensure that the meter is turned OFF

and remove any test leads from the

meter's terminals.

2. Lift the tilt stand on the back of the unit

to access the battery compartment

door which can be removed using a

Phillips head screwdriver.

3. Replace the 2 x AA batteries in the lid

of the battery compartment.

4. Reinstall the compartment lid by ensuring that battery terminals

touch the unit's contact points and snap into place.

5. Tighten the screw to secure the battery compartment cover.

Note: Ensure battery door is closed and secured in place before using

the meter. To ensure proper operation, please wait 5 seconds before

turning meter on after changing batteries.

www.GlobalTestSupply.com

12

Applications

• Verication and calibration of temperature instruments including

thermocouple and RTD thermometers.

Accessories and Replacement Parts

R2920 Surface Thermocouple Probe

R2930 Right Angle Thermocouple Probe

R2940 Air/Gas Thermocouple Probe

R2950 Immersion Thermocouple Probe

R2960 Needle Tip Thermocouple Probe

CA-05A Soft Carrying Case

R9940 Hard Shell Carrying Case

AD-1 Thermocouple Adapter

R1000 Safety Test Lead

FC-300 Fused Test Lead Set

Don't see your part listed here? For a complete list of all accessories and

replacement parts visit your product page on www.reedinstruments.com.

Product Care

To keep your instrument in good working order we recommend the following:

• Store your product in a clean, dry place.

• Change the battery as needed.

• If your instrument isn't being used for a period of one month or longer

please remove the battery.

• Clean your product and accessories with biodegradable cleaner. Do not

spray the cleaner directly on the instrument. Use on external parts only.

www.GlobalTestSupply.com

13

Product Warranty

REED Instruments guarantees this instrument to be free of defects in

material or workmanship for a period of one (1) year from date of shipment.

During the warranty period, REED Instruments will repair or replace, at no

charge, products or parts of a product that proves to be defective because

of improper material or workmanship, under normal use and maintenance.

REED Instruments total liability is limited to repair or replacement of the

product. REED Instruments shall not be liable for damages to goods,

property, or persons due to improper use or through attempts to utilize the

instrument under conditions which exceed the designed capabilities. In

order to begin the warranty service process, please contact us by phone at

1-877-849-2127 or by email at info@reedinstruments.com to discuss the

claim and determine the appropriate steps to process the warranty.

Product Disposal and Recycling

Please follow local laws and regulations when disposing or recycling your

instrument. Your product contains electronic components and must be

disposed of separately from standard waste products.

Product Support

If you have any questions on your product, please contact your authorized

REED distributor or REED Instruments Customer Service by phone at

1-877-849-2127 or by email at info@reedinstruments.com.

Please visit www.REEDInstruments.com for the most

up-to-date manuals, datasheets, product guides and software.

Product specifications subject to change without notice.

All rights reserved. Any unauthorized copying or reproduction of

this manual is strictly prohibited without prior written permission

from REED Instruments.

www.GlobalTestSupply.com

14

TEST & MEASURE

WITH CONFIDENCE

CHECK OUT OUR LATEST PRODUCTS!

www.GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...