Red-White Valve 5020AB Installation Manual

1

2-PIECE BALL VALVES

How to use your RWV 2-piece ball valve.

(Installation, Operation and Maintenance Instructions).

INDEX

• GENERAL INFORMATION

• CHOICE OF THE VALVE

• PRESSURE AND TEMPERATURE RATINGS

• VALVE INSTALLATION

• USE AND MAINTENANCE

Red-White Valve Corp. assumes no responsibility for any damages or injuries

resulting from non-compliance with installation instructions or standard good

practice when installing, operating or maintaining the valves, even if not

explicitly mentioned in these installation instructions.

GENERAL INFORMATION

RWV ball valves are produced in a wide range of ratings and connections. RWV portfolio includes models

suitable for HVAC systems, oil, compressed air or gas distribution.

Instructions apply to the following RWV valve models:

2412

2415

2417

2419

4550

4880

5020

5024

5042

5060

5063

5070

5081

5082

5083

5084

5200

5581

5586

2417AB

2419AB

2420F

2422F

3300AB

3320AB

3330AB

5004AB

5006AB

5007AB

5008AB

5009AB

5014AB

5015AB

5016AB

5017AB

5017SMW

5018AB

5019AB

5020AB

5020ABS

5020ABX

5044AB

5044F

5049AB

5049F

5060AB

5063AB

5070AB

5080B

5080BSS

5081AB

5082AB

5083AB

5084AB

5200S

5200T

5414AB

5415AB

5416AB

5417AB

5418AB

5520AB

5520ABX

5544AB

5544DAB

5549AB

5549DAB

5586AB

5592AB

5592F

5595AB

5595F

92UBP

92UBS

92UBT

92UDP

92UDS

92UDT

99IBV

Please contact RWV for models not listed above.

CHOICE OF THE VALVE

RWV offers ball valves made of different materials: brass, lead free* brass, Dezincification Resistant (DZR)

brass, lead free DZR brass, bronze, and stainless steel. We recommend using valves made of a material

suitable for the specific application. Stainless steel, bronze and DZR brasses are recommended to reduce risk

of de-zincification and stress corrosion. Details of the materials used for each model are listed in the specific

valve technical sheet. Please refer to your local water authority for compatibility with brass products. RWV

cannot be held responsible for failures caused by the quality of the water in combination with an unsuitable

material chosen for the valve.

*

Federal Safe Drinking Water Act – SDWA 2011 standards have determined “lead free” as having less than 0.25% of wetted surface area.

MV3000000.39-0 [200714]

RWV – RED-WHITE VALVE CORP. IOM

2

PRESSURE AND TEMPERATURE RATINGS

Specific information on pressure and temperature ratings of each valve model are provided in the RWV

technical sheets, those can be obtained through RWV site or by contacting RWV. All contact information is

provided in the last page of these instructions.

The operative conditions given in the tech sheets are intended for non-shock operating conditions: water

hammer, impacts, stress loads, corrosive or erosive external environmental elements and the transport of

fluids with abrasive properties should be avoided.

VALVE INSTALLATION

Prior to installation, verify the valve is suitable for the pressures, temperatures, operating fluids and

environment in which it will be installed. It is the responsibility of the installer and/or of the facility designer to

ensure that the application does not exceed the limits of pressure and temperature of the valve and is carried

out in accordance with local current laws and regulations.

All models referred to in the above table can be installed in any position (vertical, horizontal, inclined), with

flow going in both directions. The position chosen for the installation should allow for accessibility to the valve

during operation, inspection and maintenance.

Pipe ends should be void of any burrs and not protrude inside the bore or obstruct any part of the flow (it’s

advisable to flush the line after installation or after performing maintenance on the system).

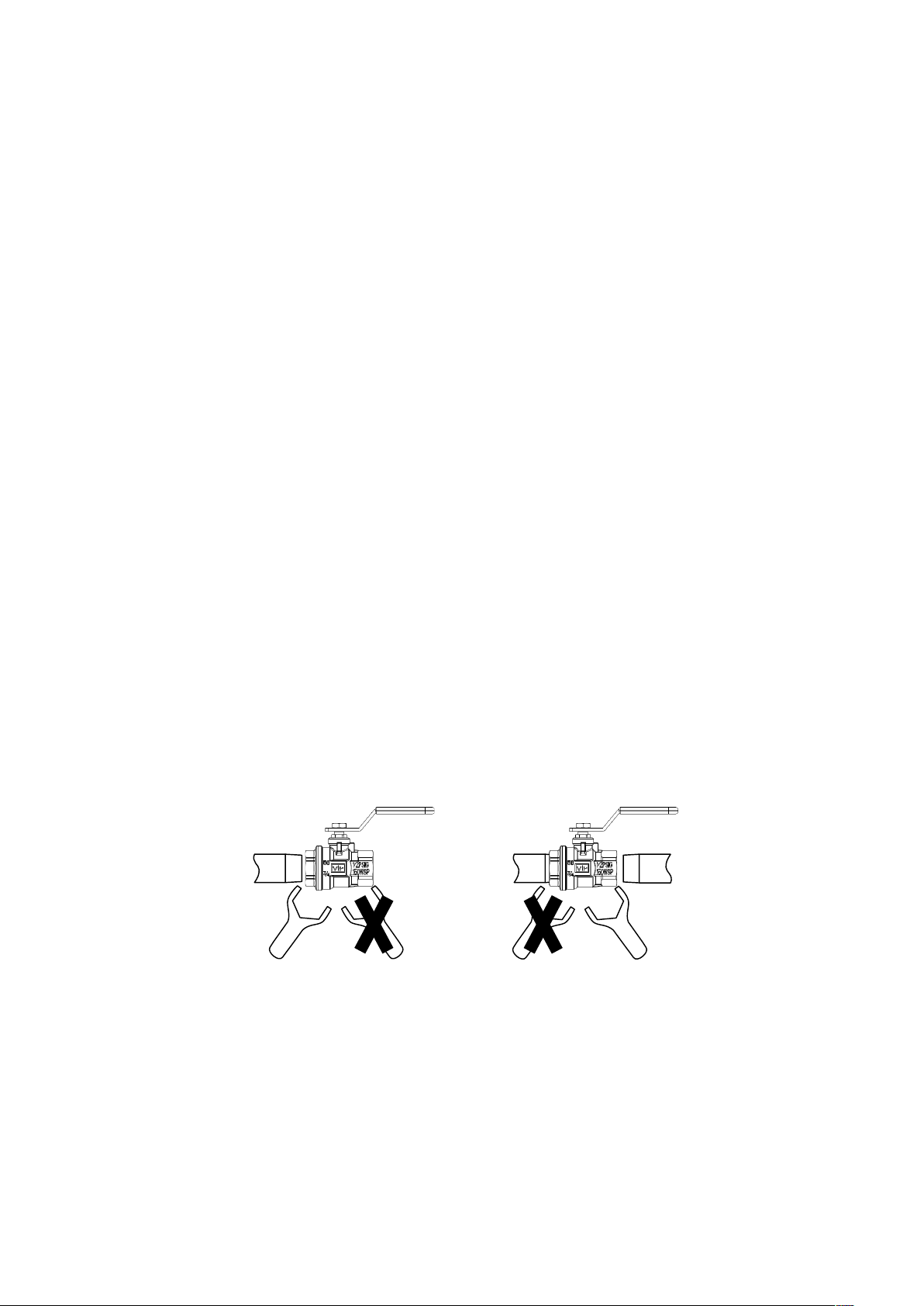

Do not subject the valve to any torsion, bending or tension. We recommend the use of pipe brackets. Pipe

brackets should be installed at a distance suitable to properly support the valve. Do not to overload the valve

with any unexpected additional stresses

Threaded connections

The valves shall be installed on pipes using, if necessary, a sealant suitable for the application and the

expected type of fluid.

• The pipe threading shall be in accordance with the applicable standard requirements (please refer to the

valve technical sheet). The pipe threading must be free of damage that could impair the correct coupling

with the valve and the outward seal.

• Additional stresses on the body to body-end junction must be avoided during installation. A pipe clamp or

key wrench must always grasp onto the hexagon/octagon portion of the threaded end that needs to be

screwed to the pipe. In order to avoid additional stress on the valve be careful not to tighten the pipe at an

excessive distance from the threaded area.

• Avoid screwing male threaded pipes too far into the valve. This could result in damage to the valve seats,

resulting in leakage once the valve is operational.

• When installing a tailpiece, slide the union nut over the pipe before mounting to prevent interference

between the tailpiece and union. Make sure all seals/o-rings are in place and not damaged.

Sweat connections

RWV sweat connections are designed to be soft soldered.

• Valves contain polymer materials such as o-rings and PTFE seals. These seals can be damaged by

excessive heat, therefore the use of heat sinks (for example a wet towel around the valve) is required. The

flame must be directed away from the center of the valve body.

• Ball valves must be placed in the closed position prior to soldering. After the installation wait for the valve

to cool to room temperature before operating it.

• Make sure that the cut on the pipe is as square as possible and no burrs or rough edges are present. Clean

both the valve socket and pipe end with a suitable tool until they are made bright.

• Coat both the valve socket and pipe with non-corrosive solder flux. In cold weather this should be done with

the parts at ambient temperature. After applying the flux, slide the pipe to the shoulder of the socket then

rotate a few times to insure flux properly covers the connection prior to soldering

Loading...

Loading...