Red Valve WATERFLEX SERIES WF-3 Installation, Operation And Maintenance Manual

The revolutionary design of the Series WF-3 InLine

Check V alve provides reliable backflow prevention.

The valve solely operates on differential pressure

and has no moving mechanical parts. The valve

exhibits low headloss, high backpressure ratings and

a short face-to-face dimension.

The valve is only intended for clean flow media or

media with only fine particulates.

The Series WF-3 is constructed with ANSI, DIN, BS

or special flange drillings for easy installation.

IMPORTANT

Please take a moment to review this manual. Before performing any maintenance on the

valve be sure the pipeline has been de-pressurized. The improper installation or use of this

product may result in personal injury, product failure, or reduced product life. Red Valve Co., Inc.

can accept NO liability resulting from the improper use or installation of this product. If you have

any questions or problems, please call the customer service department at (412) 279-0044. We

appreciate your comments. And thank you for choosing Red Valve.

WATERFLEX SERIES WF-3

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

™

Flow

Flow

2

1. PIPE AND INSPECTION OF VALVE:

Check flange faces of pipe for rough/damaged

areas. Pipeline flanges must be flat, properly spaced,

and parallel to achieve proper seal. PVC flanges may

not seal properly, and are not recommended by Red

Valve. If PVC flanges are used, metal back up rings

should be placed behind the PVC flanges in order to

prevent yielding. Grind or file any sharp edges of pipe

flanges to prevent damage to the gaskets.

2. GASKETS:

Two flange gaskets by others are required, one on

each side of the disc. (See Figure 2.)

3. INSTALLING FLANGE BOLTS:

Tighten all bolts uniformly to distribute pressure

evenly around the sleeve flange. (For bolting sequence refer to the back page of this IOM).

4. VALVE ORIENTATION:

The membrane must be on the downstream side of

the disc when properly installed in a pipe line.

(See Figure 2.)

Make sure membrane is concentric with pipe I.D.

When installed in a horizontal pipeline, the rod must

be in the vertical position. (See Figure 3.)

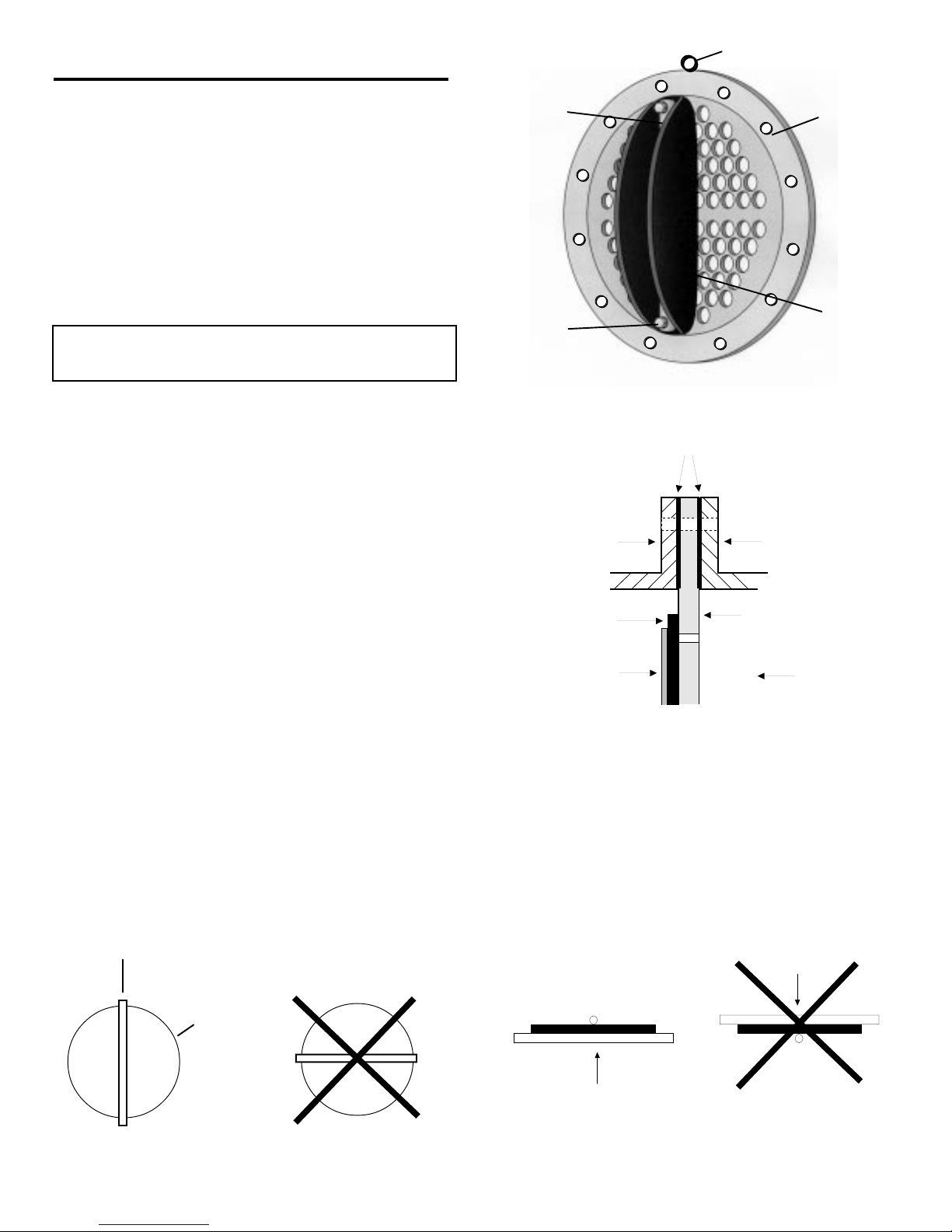

GENERAL DESCRIPTION

Terms used in this I.O.M. to refer to various parts of the

valve are described below.

(See Figure 1.)

1.

Disc

2.

Membrane

3.

Mounting Rod

4.

Rod Fasteners with Lock Nuts

5.

Lifting Eye (sizes 10" and up)

INSTALLATION

It is acceptable to install the valve in a vertical pipeline

provided normal flow direction is bottom to top.

(See Figure 4.)

It is not recommended to install the valve in a vertical

pipeline where the flow direction is from top to bottom. The membrane may tend to come away from the

disc and may not seal with minimal backpressure.

(See Figure 4.)

1

2

3

5

4

(Figure 1)

(Figure 2)

Flow

WF3 Disc

Pipe Flange

Pipe Flange

Gaskets

Membrane

Mounting Rod

Mounting Rod

Membrane

(Figure 3)

(Figure 4)

Loading...

Loading...