Red Valve TF-1, TF-2 Installation Manual

Division of Red Valve,Inc.

®

TIDEFLEX

TF-1 AND TF-2 ALL-RUBBER CHECK VALVES

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

The revolutionary design of the all-rubber Tideflex® Check Valve

provides reliable backflow protection. This unique duck bill

design eliminates costly back-flow from oceans, rivers or storm

water and is the ideal valve for effluent diffuser systems.

Tideflex® Valves seal on entrapped solids and debris without

jamming. Unlike traditional flap gates there are no hinged

gates to hang open and no warping or freezing. It’s virtually

maintenance-free.

The Tideflex® Check Valve is available in a wide variety of elastomers and is designed to meet your exact flow

specifications.

TF-1

TF-2

IMPORTANT

Please take a moment to review this manual. Before performing any maintenance on the valve be sure the

pipeline has been de-pressurized. The improper installation or use of this product may result in personal

injury, product failure, or reduced product life. Tideflex® Technologies can accept NO liability resulting from the

improper use or installation of this product. If you have any questions or problems, please call the customer service

department at (412) 279-0044. We appreciate your comments. Thank you for choosing Tideflex® Technologies.

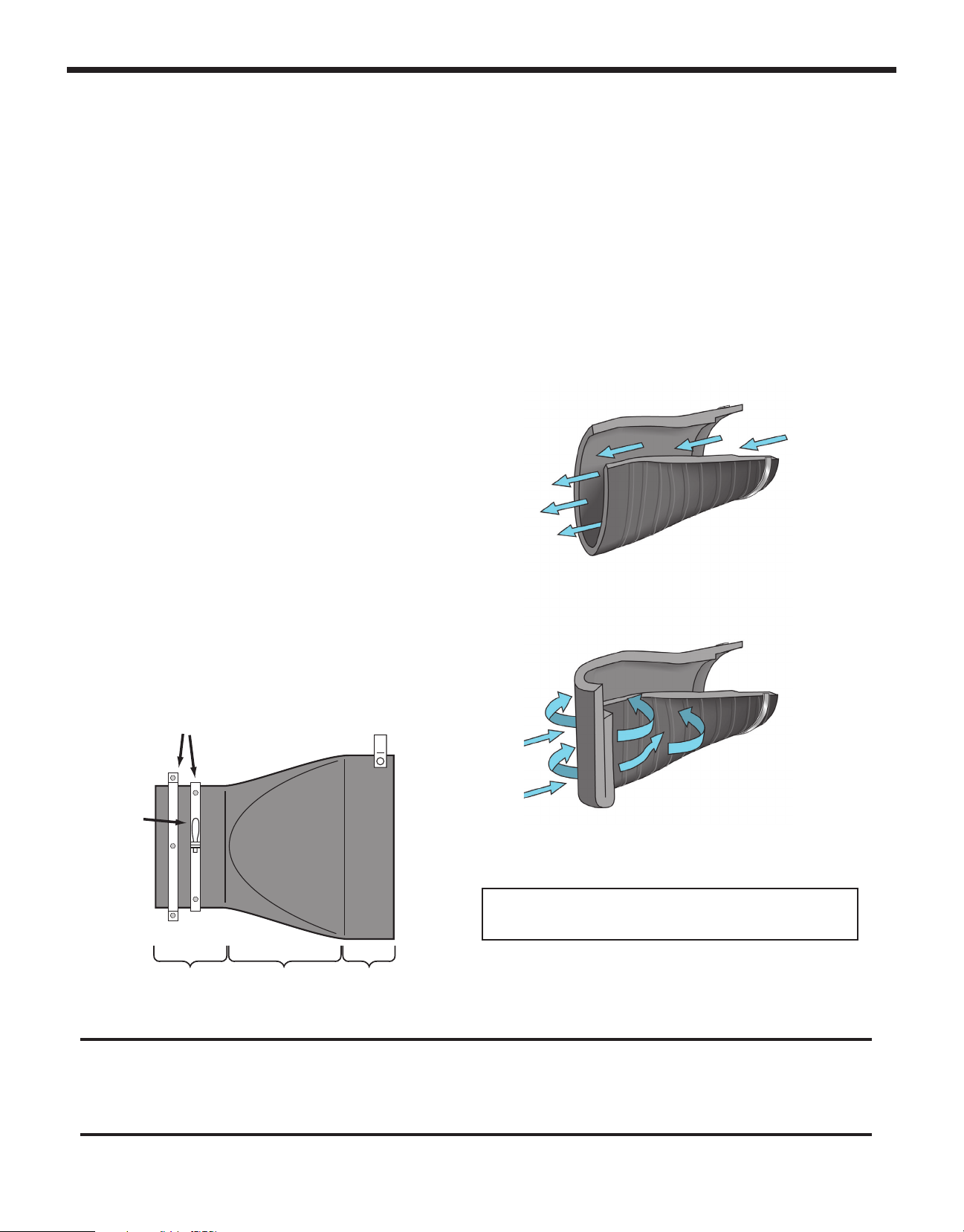

Saddle Bill

Lifting

Clevis

Cuff

Clamps

Lifting

Eyebolt

GENERAL DESCRIPTION

The Tideflex® Technologies' Check Valve is an all-elastomer, onepiece check valve. Terms used in this IOM to refer to various parts

of the valve are described below.

1.

Cuff

- the cuff is designed with a full round bore and slips over

the end of the pipe.

2.

Saddle from the round cuff to the flat bill. The saddle directs the flow

to the bill, and is flexible to sustain increased flow conditions.

3.

Bill

to allow flow to discharge, yet is stiff enough to prevent the

valve from opening without line pressure.

Backpressure, the pressure created on the exterior of the

valve by reverse flow or submersion, will seal the lips of the

bill tightly together, preventing backflow into the valve.

4.

Clamps

cuff has been slipped over the end of the discharge pipe. These

clamps are normally furnished by Red Valve Company. Hose

clamps are supplied for valves up to 12". Valves 14" and up

are supplied with fabricated clamps. 14"-20" are supplied with

one set, 20"-54" are supplied with two sets and sizes 60" and

up are supplied with three sets.

5.

Lifting clevis

valve for valves 36" and up. This clevis is used during

installation to assist in lifting the valve, and may be used to

attach a line to the bill to help support the valve after

installation.

The saddle is the middle part of the valve, tapering

- t

he bill is the discharge end of the valve. The bill flexes

- The clamps are tightened around the cuff after the

- lifting clevis is attached to the bill of the check

OPERATION

Tideflex® Check Valves are custom made products intended for a

specific application and have been designed to respond to criteria

unique to that purpose, such as line pressure, minimum and

maximum back pressure and chemical compatibility. Should the

conditions for which the valve has been designed be altered or change

in any way, it could affect the normal operation of the valve.

Tideflex® Check Valves work on backpressure exerted on the bill area to

seal the valve. The bill may appear to be slightly open when installed.

This slight opening does not affect the operation of the valve, as the valve

depends on backpressure to seal.

Forward Pressure Opens Valve

NEVER...

Cut or modify

check valve.

DO...

Use a soapy water solution to slide

check valve on pipe.

Reverse Pressure Seals Valve

IMPORTANT

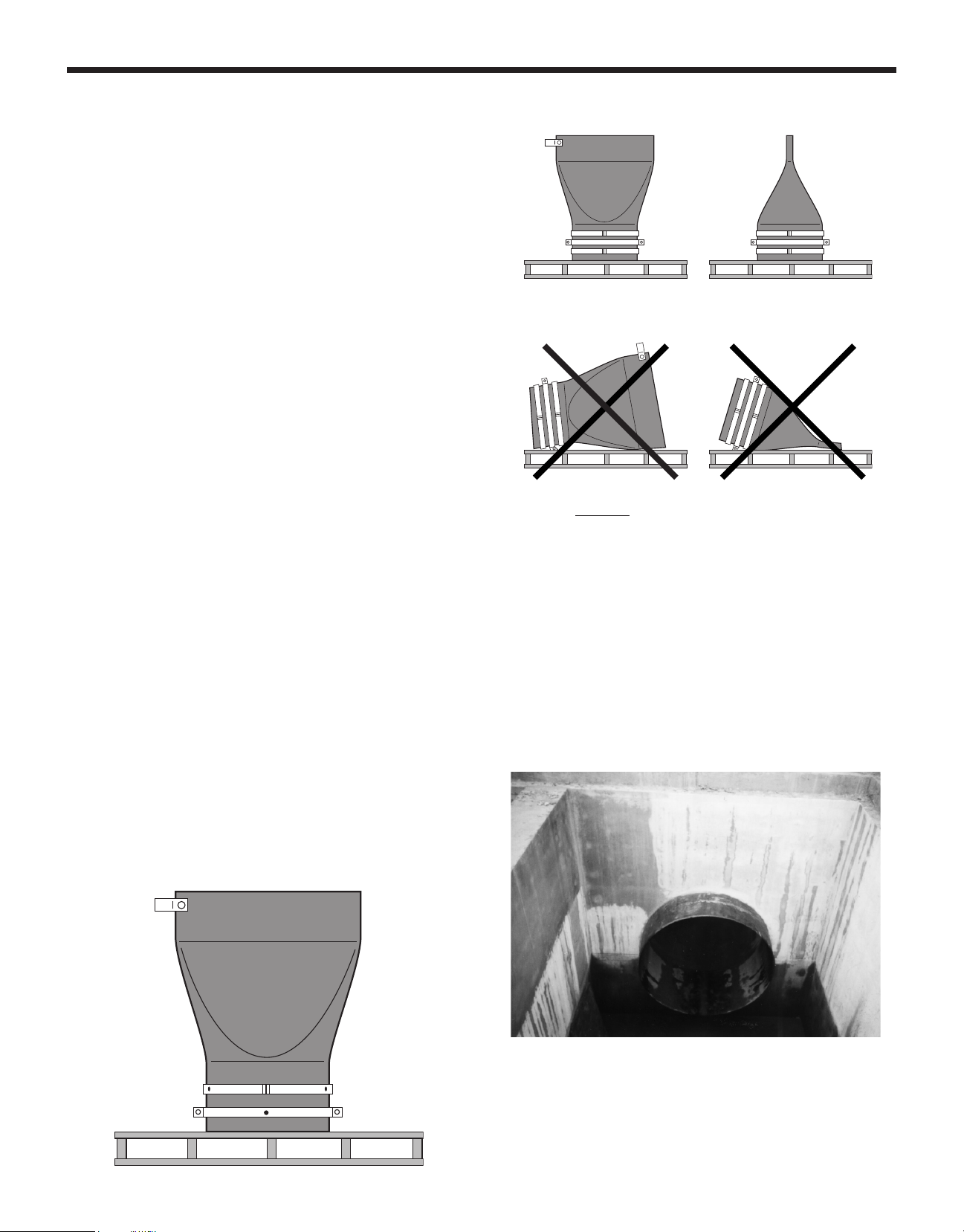

The valve shall be installed with the bill in the vertical

position.

DO...

Keep valve on pallet until

ready to install.

2

DO...

Tighten clamp

bolts evenly.

STORAGE

Tideflex® Check Valves should be stored in a cool, dry location

on original shipping pallet with the bill facing upward, not on its

side (see Figure 2). Do not drop, bend or twist check valve, or

damage may occur.

1. Store valve in a cool, clean, dry location.

2. Avoid exposure to light, electric motors, dirt or chemicals.

Resilient check valves are subject to deterioration when

exposed to ozones and non-compatible chemicals. Ozone

especially causes age hardening of the elastomer.

3. Store Installation Operation Manual with product so it will be

readily available for installation.

4. Do not remove wooden brace or metal shipping ring (36"+)

until valve is installed.

Figure 2

STORE VERTICALLY

NEVER STORE HORIZONTALLY

INSTALLATION INSTRUCTIONS

TIDEFLEX® CHECK VALVES

1. INSPECTION OF CHECK VALVE

Check the inside diameter of the cuff of the Tideflex® Check Valve

to compare it to the O.D. of the outfall pipe. Inspect the outfall pipe

for sharp or damaged areas. The pipeline should be in a smooth

condition to prevent cutting the rubber check valve.

Lifting clevis and lifting eye bolts are provided only for sizes 36"

and over.

Imperfections on the inside of the cuff area can be filled with a

silicone sealant prior to installing the valve on the pipe. This will

ensure a seal in the cuff area after clamps are tightened.

2. INSPECTION OF THE PIPE

Check the outside diameter of the pipe to determine if it

matches the I.D. of the cuff of the Tideflex® Check Valve. The

cuff of the check valve is usually made slightly larger to permit

ease of installation.

3

Loading...

Loading...