Red Valve Flexgate D series Installation, Operation And Maintenance Manual

IMPORTANT

Please take a moment to review this manual. Before performing any maintenance on the

valve be sure the pipeline has been de-pressurized. The improper installation or use of this

product may result in personal injury, product failure, or reduced product life. Red Valve Company,

Inc. can accept NO liability resulting from the improper use or installation of this product. If you

have any questions or problems, please call the customer service department at (412) 279-0044.

We appreciate your comments. Thank you for choosing Red Valve.

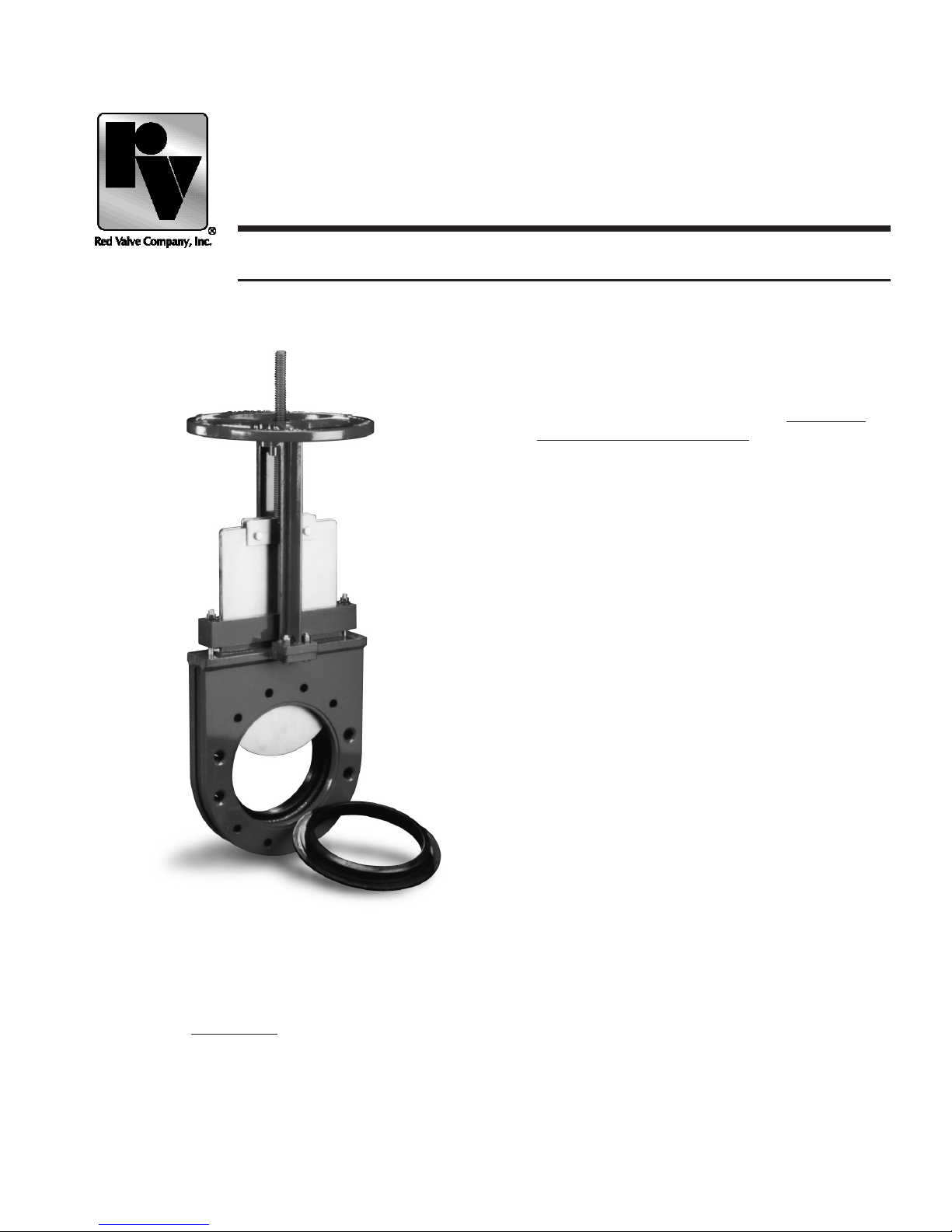

The Red Valve Series D Flexgate Slurry

Knife Gate Valve is a 100% full bore, truly

bi-directional valve designed for tough slurry

applications. The Flexgate features heavyduty elastomer seat cartridges which provide

droptight closure and are replaced WITHOUT

ANY VALVE DISASSEMBLY, for ease of

maintenance.

The Series D Flexgate is designed to meet

MSS-SP81 face-to-face dimensions, so that

it can be readily placed in service replacing

conventional knife-gate products.

Flush ports are provided to allow the valve to

be ushed with water and/or air. With a variety

of actuators available, limit switches, and other

options, the Red Valve Series D Flexgate can

be built to t your special applications.

SERIES D FLEXGATE

SLURRY KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

INSTALLATION

NEVER...

Use bolts which bottom out in body.

NEVER...

Install with gate up.

DO...

Lubricate seats and gate.

DO...

Use at-faced falnges and ighten bolts evenly.

1. When your Red Valve order arrives, check the contents

carefully to assure no damage or loss occured in transit.

2. Check ange faces of pipe for rough /damaged areas. Pipe-

line anges must be at, properly spaced, and parallel to

achieve proper seal. DO NOT mate Flexgate valves directly

to expansion joints or other exible connections. The ID of

the mating pipe ange must not exceed the nominal steel

pipe OD by .12" for sizes 12" and smaller, or .25" for sizes

14" and larger. Consult Red Valve if the ange ID exceeds

these dimensions. Std slip-on steel anges meet the criteria.

Slip-on adaptor anges for ductile iron pipe can create a

sealing problem.

The Flexgate can be used for end of line service if a at

face ange is bolted to the downstream side so that the

downstream seat is retained. When the Flexgate is used to

isolate equipment for future removal from the line, a spool

piece needs to be installed between the valve and equipment if the end of line condition will result upon removal of

the equipment.

3. The rubber seat acts as a gasket and separate ange

gaskets are normally not required. Installations where the

mating ange has a "slick" surface may require a metal

serrated or combination metal gasket serrated gasket and

contractor supplied standard gasket materials to assist in

creating a seal. All gaskets used on "LOW TORQUE" ange

material such as FRP and PVC should be approved by the

pipe manufacturer for compatibility. (Often the torque rat-

ing of the composite mating ange may be less than the

minimum torque required to install the valve

4. Actuate valve to the full CLOSED position for installation.

Lubricate seat cartridges and gate liberally with a grease

compatible with the seat material. Red Grease is recommended for all seat materials.

5. Insert seat cartridges. Flange gaskets are not required.

Make sure that cartridges are of the correct size and prop-

erly centered on valve ange.

6. Installing Flange Bolts:

CAUTION: Only use ange bolts of the correct length in

such manner that the BOLTS CAN NOT BOTTOM OUT

IN TAPPED HOLES. The use of bolts which are too long

and bottom out in tapped holes can distort body, create a

leak path and cause permanent valve damage. Red Valve

recommends the use of studs in the chest area of the

Flexgate in lieu of bolts.

Tighten each bolt uniformly on both sides of

the valve (upstream and downstream side of

the valve). This will distribute compression

evenly on seat ring. Torque all the ange

bolts and/or studs in a star pattern (as shown

in Figure 1), rst to 50% of tabulated values,

then retorque to 100% of 100% of tabulated

values. If greater torque is required, continue retorquing in

increments of 50% of tabulated values. Improper or uneven

torquing of ange bolts can cause premature seat cartridge

failure and a leak between the mating ange and valve. Use

of high quality anti-sieze compound on all bolt and/or stud

thread is recommended.

7. Apply grease liberally to stem. Red Grease from Red Valve

is the recommended lubricant for the stem and seats and

is available by contacting customer service at Red Valve.

8. Some leakage may occur at packing when line is pressur-

ized. The factory does not tighten packing to overcome

such leakage, as this can shorten packing life when valve

is in storage. Simply tighten the packing nuts until the leakage ends.

9. Over tightening ange bolts to stop a leak can fracture or

distort a composite ange such as a FRP or PVC ange.

Steel back-up rings should be considered to try to seal a

ange against a leak. Caution should be used to not overtorque FRP or PVC anges when using steel back-up rings.

Consult with the pipe and/or ange manufacturer.

10. Fill out and attach the enclosed VALVE MAINTENANCE

CARD to the valve. This has been provided for maintenance

convenience.

CAUTION: VALVES EQUIPPED WITH THE FLUSHPORT

DESIGN CAN BE PLUGGED OR PIPED TO A SUITABLE

DRAIN. REMOVAL OF PLUG(S) WILL CAUSE LEAKAGE OF LINE MATERIALS. CONSULT YOUR SYSTEMS

ENGINEER FOR PROPER PLUMBING OF FLUSHPORT

FOR YOUR INSTALLATION.

NOTE: It is recommended that valves with actuators be

installed in the vertical position. If actuated knife gates

must be installed horizontally, it is recommended that the

actuator be supported with a hanger or bracket.

1

2

3

4

5

6

78

Figure 1

Loading...

Loading...