Page 1

OWNER'S/OPERATOR'S

MANUAL

MODE D’EMPLOI MANUAL DE

INSTRUCCIONES

BRUSHCUTTERS

DEBROUSSAILLEUSE

DESBROZADOR

848-J7G-93A0 (901)

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

Before using our products,

please read this manual carefully

to understand the proper use of

your unit.

Los gases de escape del motor de

este producto contienen

sustancias químicas conocidas

por el Estado de California como

causantes de cáncer,

malformaciones en recién nacidos

y otros problemas de

reproducción.

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.

Antes de usar nuestros productos,

lea detenidamente este manual a

fin de familiarizarse con el uso

correcto de este aparato.

Avant d’utiliser cette

ce produit

,

veuillez lire attentivement ce

manuel afin de bien comprendre le

bon fonctionnement de cet

appareil.

TR2350S

U

S

F

R

E

S

APPLICABLE SERIAL NUMBERS :

DRIVE UNIT 90200101 and up

ENGINE UNIT 90200101 and up

NUMEROS DE SERIE APPLICABLES :

BOITE DE COMMANDES 90200101 et au-delà

MOTEUR 90200101 et au-delà

NÚMEROS DE SERIE APLICABLES:

UNIDAD DE ACCIONAMIENTO

90200101

y superior

UNIDAD DE MOTOR

90200101

y superior

Page 2

Page 3

US-1

TR2350S

U

S

OWNER'S/OPERATOR'S

MANUAL

BRUSHCUTTERS

848-J7G-93A0 (901)

APPLICABLE SERIAL NUMBERS :

DRIVE UNIT 90200101 and up

ENGINE UNIT 90200101 and up

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING

Before using our products,

please read this manual carefully

to understand the proper use of

your unit.

TR2350S

Page 4

US-2

TR2350S

SAFETY FIRST

Instructions contained in warnings within

this manual marked with a symbol

concern critical points which must be

taken into consideration to prevent

possible serious bodily injury, and for this

reason you are requested to read all such

instructions carefully and follow them

without fail.

■ WARNINGS IN THE MANUAL

This mark indicates instructions which must

be followed in order to prevent accidents

which could lead to serious bodily injury or

death.

This mark indicates instructions which must

be followed, or it leads to mechanical failure,

breakdown, or damage.

This mark indicates hints or directions useful

in the use of the product.

NOTE

1. Parts location......................................................................3

2. Specifications .....................................................................3

3. Warning labels on the machine ..........................................4

4. Symbols on the machine ....................................................4

5. For safe operation ..............................................................5

6. Set up .................................................................................9

7. Fuel...................................................................................10

8. Operation..........................................................................12

9. Maintenance.....................................................................14

10. Storage.............................................................................16

11. Disposal............................................................................16

12. Optional blade usage........................................................17

13. Troubleshooting guide......................................................20

Contents

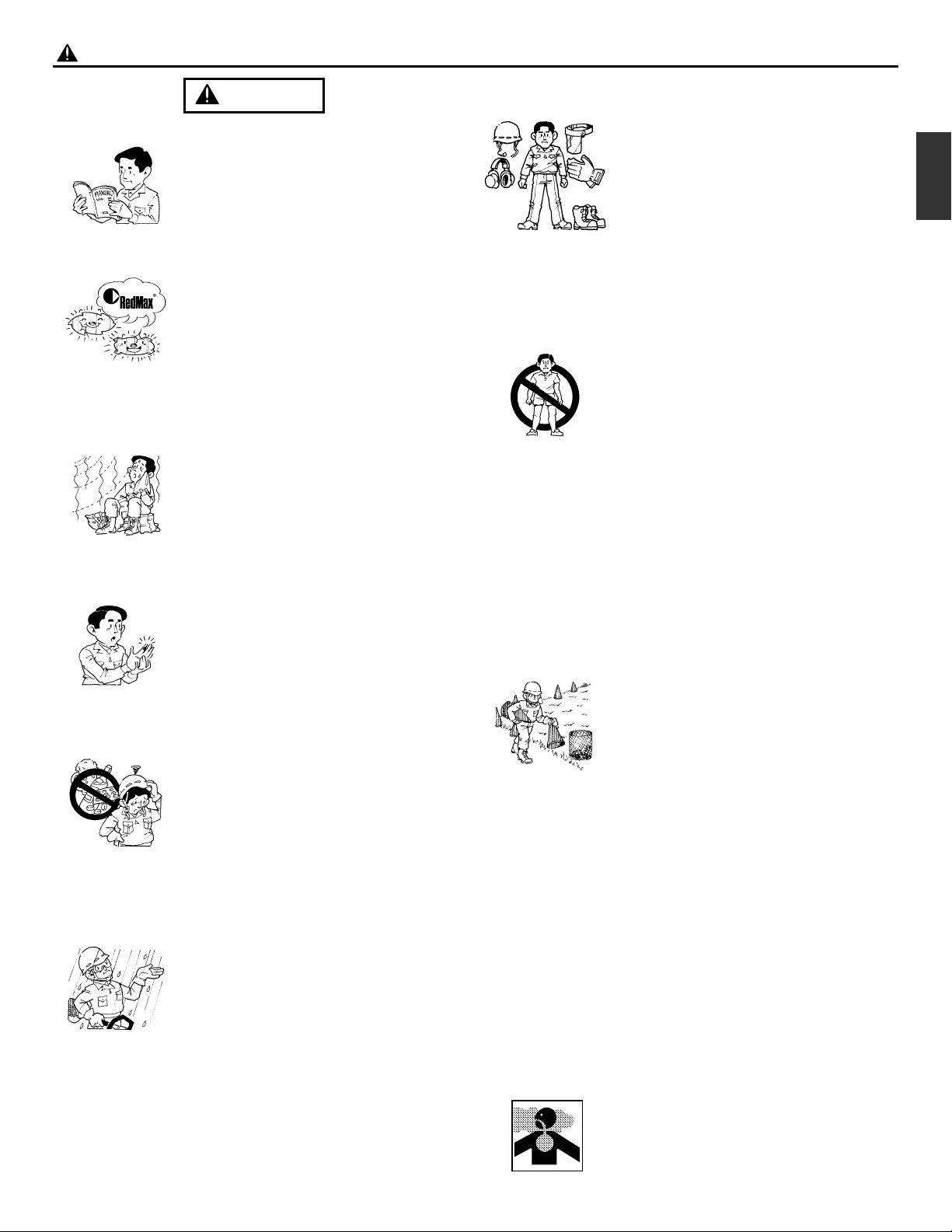

1. Read this brushcutter Owner/Operator

Manual carefully. Be sure you

understand how to operate this unit

properly before you use it. Failure to do

so could result in serious injury.

2. Be sure to keep this manual handy so

that you may refer to it later whenever

any questions arise. Also note that you

are requested to contact the dealer from

whom you purchased the product for

assistance the event that you have any

questions which cannot be answered

herein.

3. Always be sure to include this manual

when selling, lending, or otherwise

transferring the ownership of this

product.

4. Do not lend or rent your machine

without the owner's manual.

5. Be sure that anyone using your unit

understands the infomation contained in

this manual.

6. Never let a child under 13 years old use

the machine.

WARNING

WARNING

IMPORTANT

Page 5

US-3

TR2350S

U

S

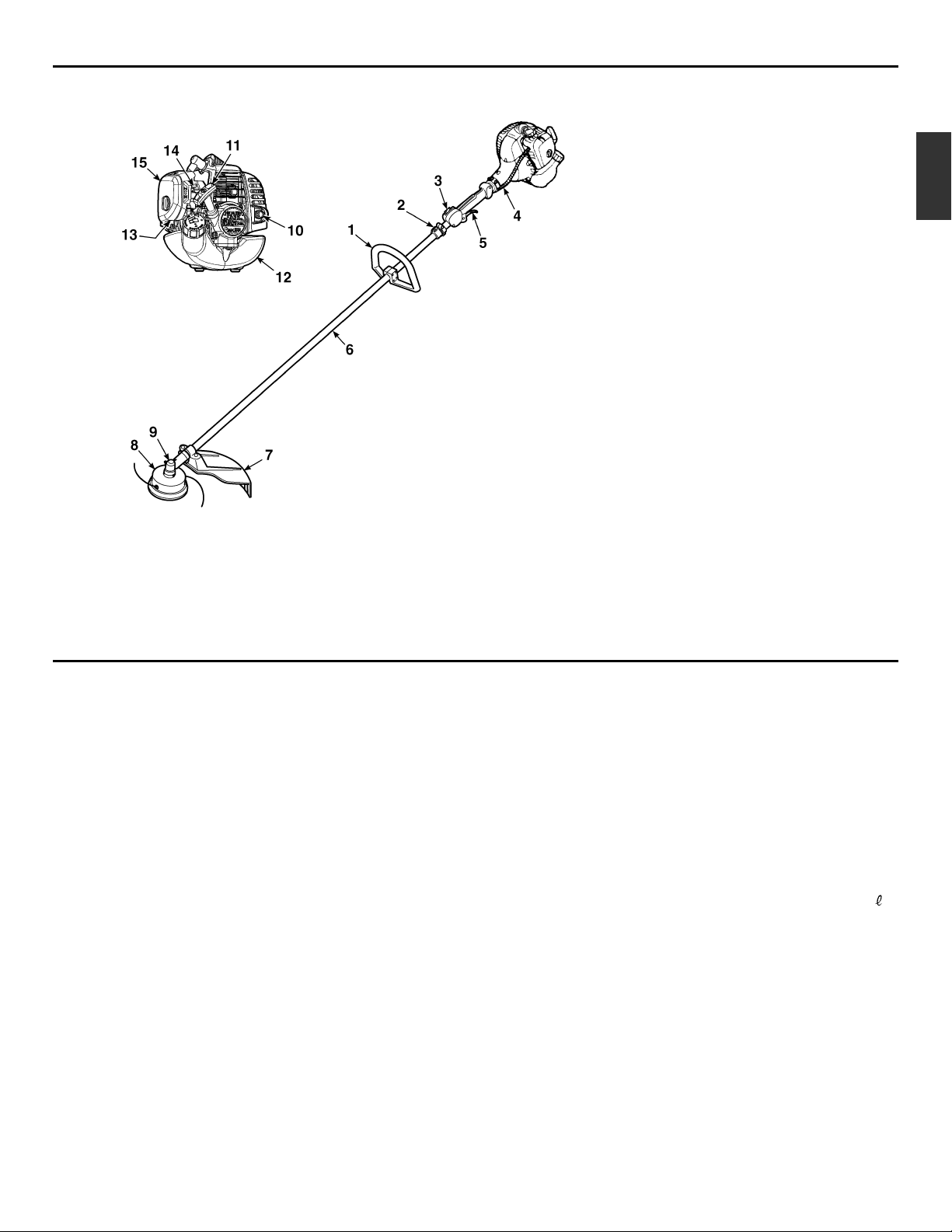

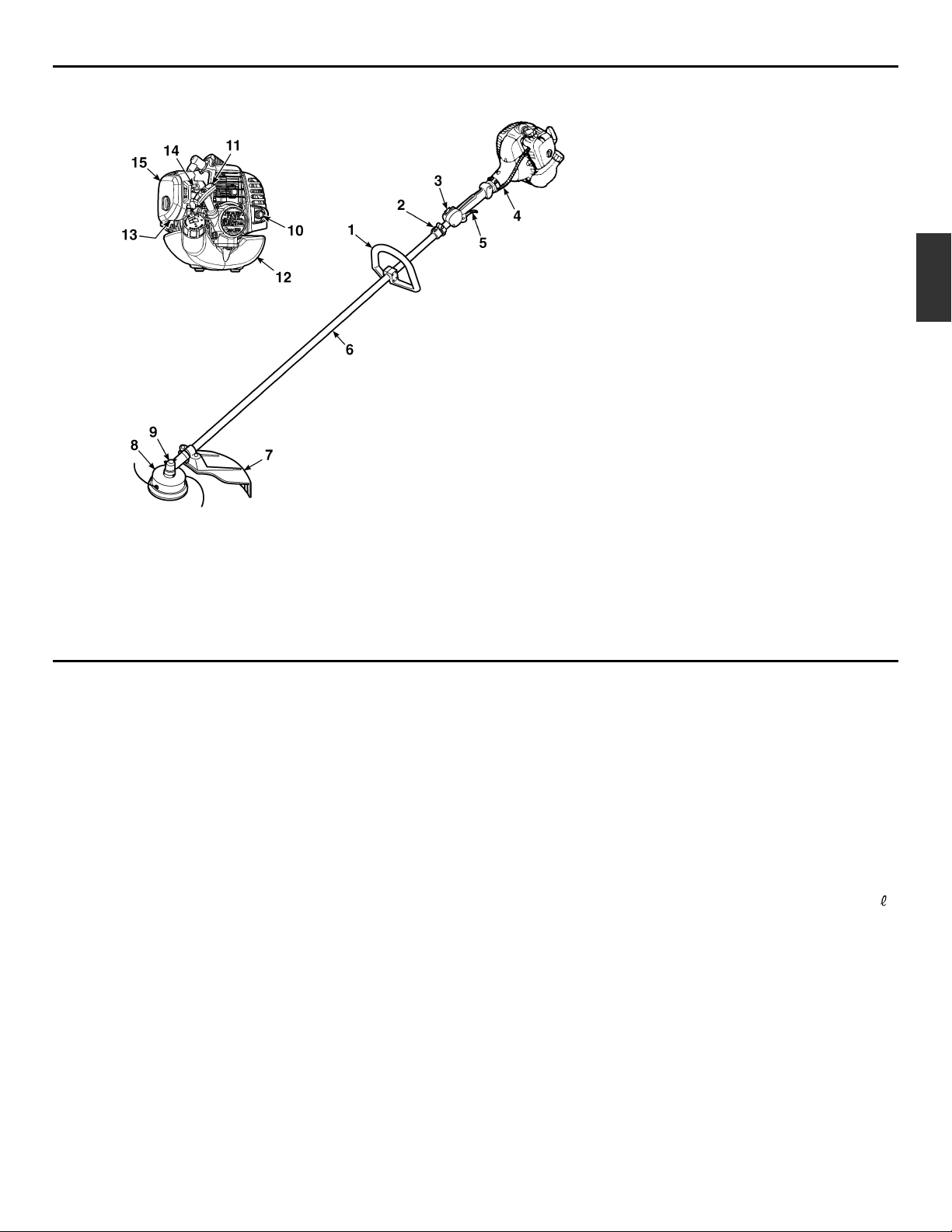

1. Parts location

■ TR2350S

Overall size(LxWxH) ····················································································· 69.0(1753)x8.9(226)x12.1(307) in(mm)

Dry weight ················································································· 9.3 lbs (4.2kg) (10.2 lbs (4.6kg) Including tap head)

Engine Type·················································································································· Air-cooled 2-stroke gasoline

Model ················································································································································· G20LS

Displacement ·················································································································· 1.3 cu-in (21.7cm

3

)

Max. output ························································································· 0.95 Hp (0.71 kW)at 7000/min

-1

(rpm)

Idle speed····················································································································3000 ± 200/min

-1

(rpm)

Fuel ·················································································································· Mixture (Gasoline 50 : Oil 1)

(when using RedMax/ZENOAH genuine oil)

Carburetor ··············································································································· Walbro Diaphragm type

Spark plug ······························································································································NGK BPMR7A

Fuel tank capacity····························································································································19.6 fl.oz (0.50 )

Transmission········································································································ Centrifugal clutch, Rigid driveshaft

Reduction ratio··················································································································································· 1.462

Cutting head rotating direction·············································································· Counter-clockwise(Operator view)

Standard Accessories

4 in. 2-line Head ···································································································································· 1 pc.

Goggle··················································································································································· 1 pc.

Tool Kit ·················································································································································· 1 pc.

Specifications are subject to change without notice.

1. Loop handle

2. Suspention point

3. Stop switch

4. Throttle cable

5. Throttle trigger

6. Shaft tube

7. Cutting attachment guard

8. Cutting line head

9. Gear case

10. Spark arrester

11. Starter knob

12. Fuel tank

13. Primer

14. Choke lever

15. Air cleaner cover

2. Specifications

Page 6

US-4

TR2350S

3. Warning labels on the machine

For safe operation and maintenance, symbols

are carved in relief on the machine. According

to these indications, please be careful not to

take a mistake.

(a) The port to refuel the "MIX GASOLINE"

Position: FUEL TANK CAP

(b) The direction to close the choke

Position: AIR CLEANER COVER

(c) The direction to open the choke

Position: AIR CLEANER COVER

(1) Read owner/operator manual before operating this machine.

(2) Wear head, eye and ear protection.

(3) Warning! Danger of kickback.

(4) Beware of thrown objects.

(5) Warning/Attention

(6) Keep all children, bystanders and helpers 15 meters away from the brushcutter

If warning label peel off or become soiled and impossible to read, you should contact the dealer from

which you purchased the product to order new labels and affix them in the required location(s).

Never modify your brushcutter.

We won't warrant the machine, if you use the remodeled brushcutter or you don't observe the

proper usage written in the manual.

WARNING

4. Symbols on the machine

15

m

(50ft)

(1)(

2

)(

3

)(

4

)(

5

)(

6

)

*1: The year will be changed every year of manufacturing.

*2: The initial number will be changed every year of

manufacturing.

*3: SP : Sealed tank made of HDPE or PE.

USE JASO FD OR ISO L-EGD GRADE 50:1 OIL

MANUFACTURED:

THIS ENGINE MEETS U.S. EPA AND CALI FORNIA EXH / EVP REGS FOR

2009*1

S.O.R.E.

ENGINE FAMILY :

9HQZS.0224BF*2 DISPL.:

22cc

EMISSION CONTROL SYSTEM :

EXH;EM/EVP;SP*

3

COMPLIANCE PERIOD : 50 HOURS

REFER TO OPERATOR'S MANUAL FOR MAINTENANCE, SPECIFICATIONS AND ADJUSTMENTS.

EMISSION CONTROL INFORMATION

ZENOAH AMERICA INC.

■ EMISSION CONTROL

An emission control label is located on the engine.

IMPORTANT

Page 7

US-5

TR2350S

U

S

•A brushcutter or trimmer can be

dangerous if used incorrectly or

carelessly, and can cause serious or

fatal injury to the operater or others. It

is extremely important that you read

and understand the contents of this

Owner's manual.

• Under no circumstances may the

design of the machine be modified

without the permission of the

manufacturer. Always use genuine

accessories and parts. Non-authorized

modifications and/or accessories or

parts can result in serious personal

injury or the death of the operator or

others.

• When planning your work schedule,

allow plenty of time to rest. Limit the

amount of time over which the product

is to be used continuously to

somewhere around 30 ~ 40 minutes per

session. Also try to keep the total

amount of work performed in a single

day under 2 hours or less.

• If you don’t observe the working time,

or working manner (See p5), Repetitive

Stress Injury(RSI) could occur.

If you feel discomfort, redness and

swelling of your fingers or any other

part of your body, see a doctor before

getting worse.

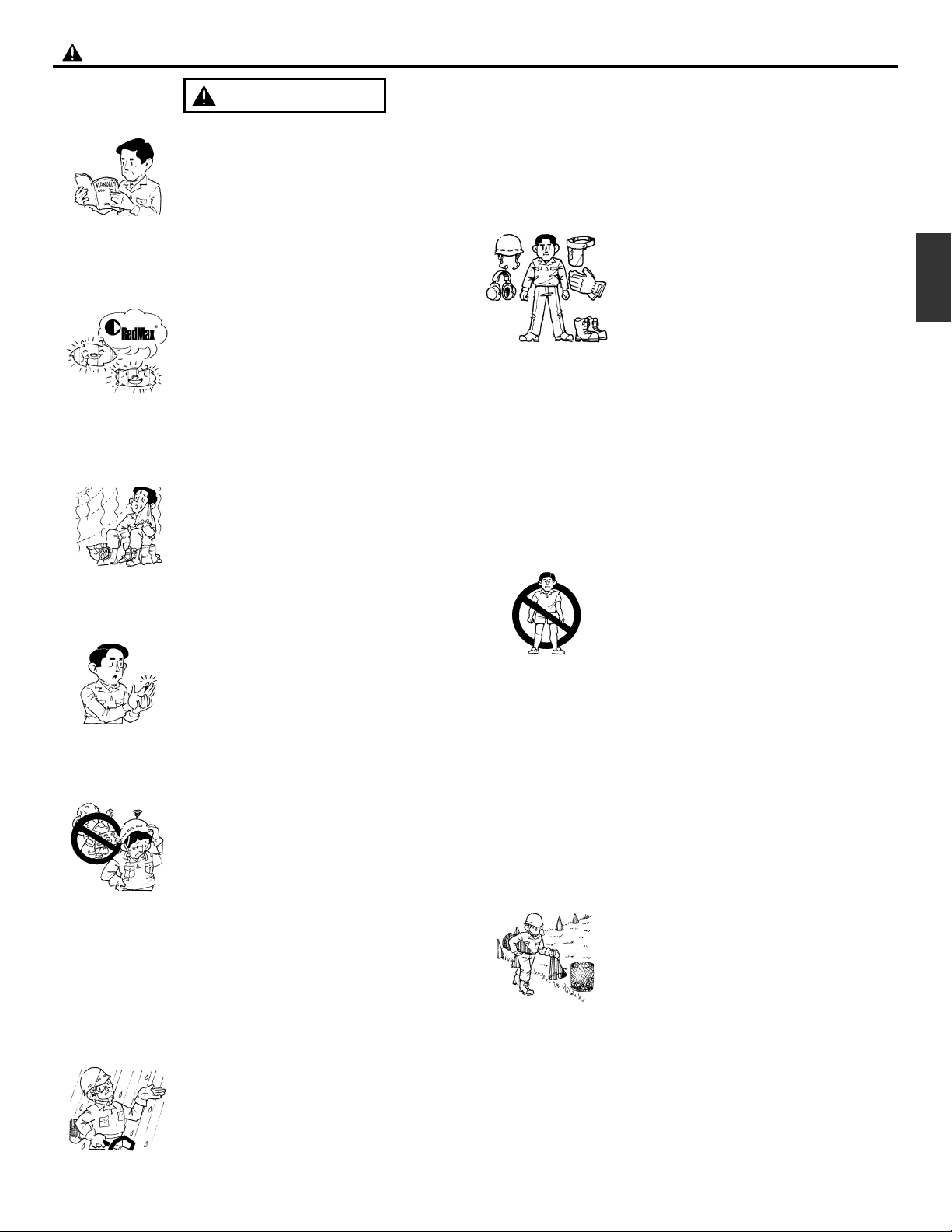

■ Basic safety rules

1. Never operate the product when you are

fatigued, ill, or upset, or under the

influence of madication that may make you

drowsy, or if you are under the influence

of alcohol or drugs.

2. Never use the product;

a: When the ground is slippery or when

you can't maintain a steady posture.

b: At night, at times of heavy fog, or at any

other times when your field of vision

might be limited and it would be difficult

to gain a clear view of the working area.

c: During rain storms, during lightning

storms, at times of strong or gale-force

winds, or at any other times when

weather conditions might make it

unsafe to use the product.

3. Wear the following protective equipments

when operating the product.

a: Approved helmet to reduce the risk of

falling objects.

WARNING

5. For safe operation

b: Approved ear protection to reduce the

risk of hearing loss.

c: Approved (ANSI Z87.1.) eye protection

and foot protection to reduce the risk of

injury associated with thrown objects.

d: Face filter mask in dusty conditions to

reduce the risk of injury associated with

the inhalation of dust.

e: Wear sturdy rubber-soled shoes or

shoes with some other form of anti-slip

protection to help protect you against

falling.

f: Wear thick anti-vibration gloves to

reduce the risk of whitefinger disease.

g: Do not wear loose clothing, scarves,

neck chains, unconfineed long hair, and

like to reduce the risk of injury

associated with objects being drawn into

air intake and rotating parts.

Personal protective equipment cannot

eliminate the risk of injury but it will reduce

the degree of injury.

4. The ignition system of your unit produces

an electromagnetic field of a very low

intensity. This field may interfere with some

pacemakers. To reduce the risk of serious

or fatal injury, persons with pacemaker

should consult their physician and the

pacemaker munufacturer before operating

this tool.

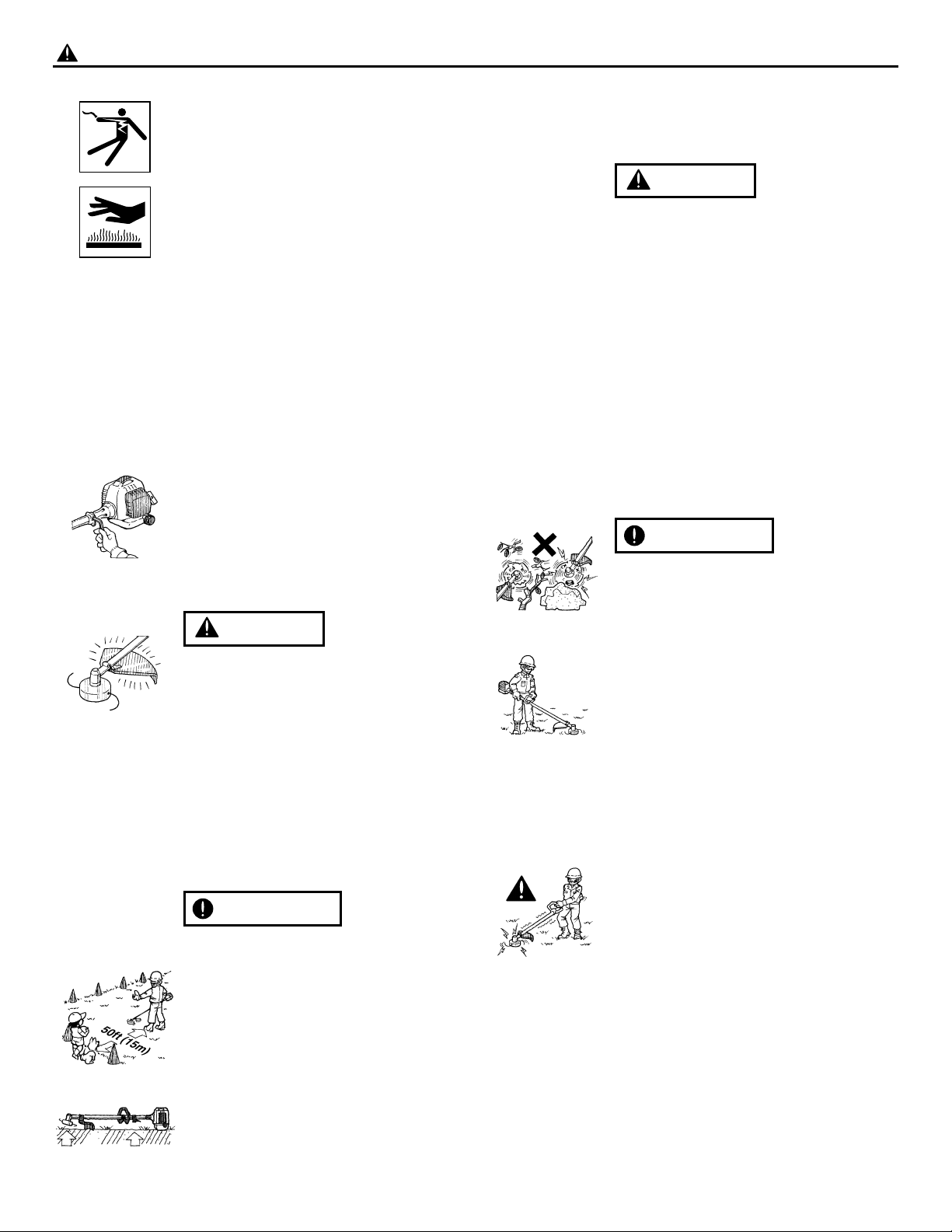

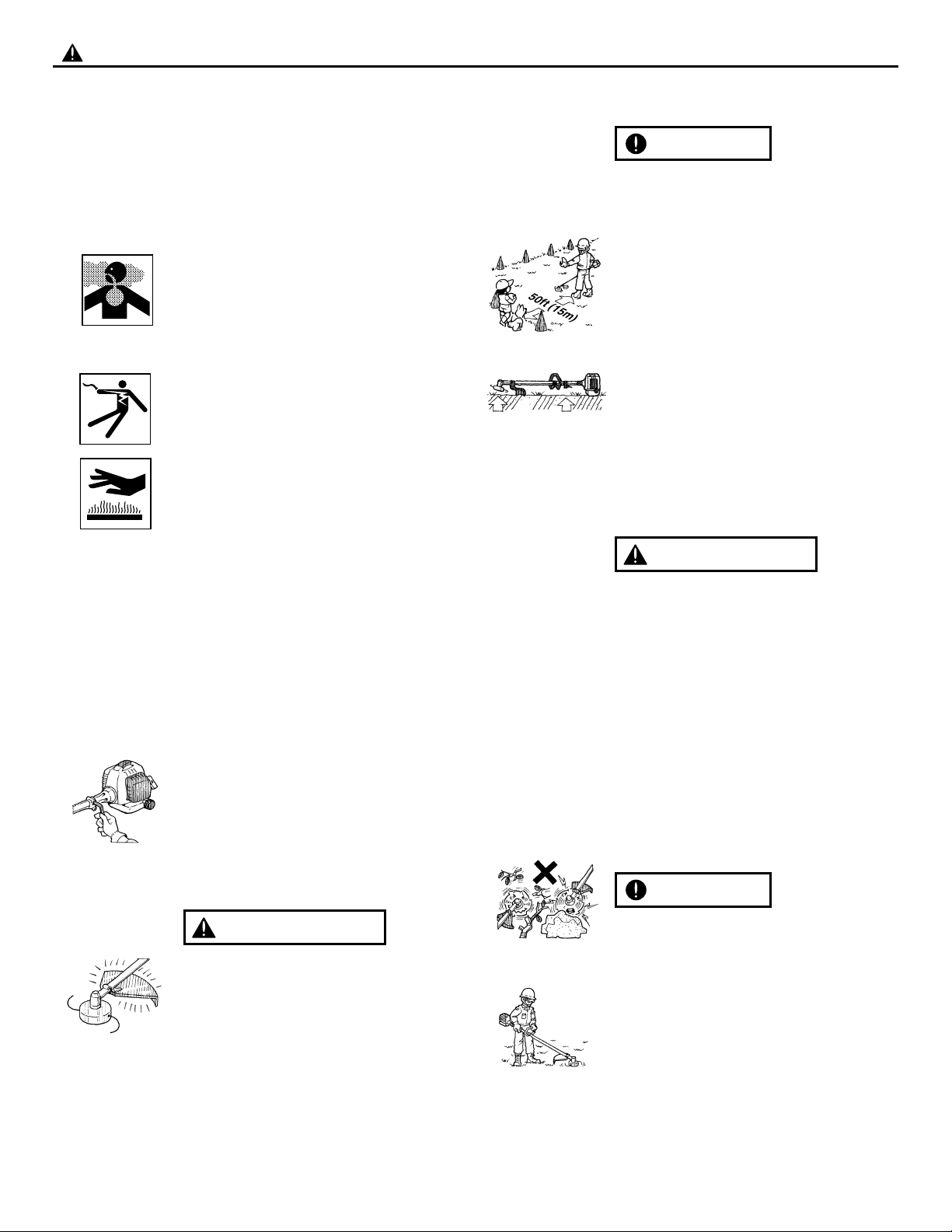

5. The area within a perimeter of 50 feet (15

meters) of the person using the product

should be considered a hazardous area

into which no one should enter. If

necessary yellow warning rope, warning

signs should be placed around the

perimeter of the area.

When work is to be performed

simultaneously by two or more persons,

care should also be taken to constantly

look around or otherwise check for the

presence and locations of other people

working so as to maintain a distance

between each person sufficient to ensure

safety.

6. Avoid using the product where stable

footing and balance are not assured.

7. All product service, other than the items

listed in the Owner's Manual, should be

performed by competent service

personnel.

8. Always shut off the engine before setting it

down.

9. Start the engine only in well ventilated

areas. Never start or run the engine inside

a closed room or building and potentially

explosive atmosphere. Exhaust fumes

Page 8

US-6

TR2350S

contain dangerous carbon monoxide.

10. Never to touch the spark plug or plug cord

while the engine is in operation Doing so

may result in being subjected to an

electrical shock.

11.Never to touch the muffler, spark plug,

other metallic parts of the engine or

engine cover while the engine is in

operation or immediately after shutting

down the engine. These metallic parts

and engine cover reach high

temperatures during operation and doing

so could result in serious burns.

12.To reduce the risk of injury associated

with contacting rotating parts, stop the

engine before installing or removing

attachments. Always disconnect the spark

plug before performing maintenance or

accessing movable parts.

■ Before use

1. Each time before starting the engine,

inspect the entire unit to see if every part

is in good order and is securely tightened

in place. If any damage is found in the fuel

line, the exhaust line, or the ignition wiring,

do not use the product until it has been

repaired.

2. Before starting operation, always make

sure that the cutting attachment and the

debris guard are properly installed and

securely fastened.

3. If the cutting head is the metal blade,

change the guard and handle as shown in

the Owner's manual (see P17).

4. Check the condition of working area to

avoid any accident by hitting hidden

obstacles such as stumps, stones, cans, or

broken grass.

Remove any obstacle before beginning work.

■ Starting the engine

1. Keep bystanders and animals at least 50

feet (15 meters) away from the operating

point. If you are approached, immediately

stop the engine.

2. The product is equipped with centrifugal

clutch mechanism, so the cutting

attachment could rotate as soon as the

engine is started. When starting the

engine, place the product onto the ground

in a flat clear area and hold it firmly in

IMPORTANT

5. For safe operation

place so as to ensure that neither the

cutting part nor the throttle come into

contact with any obstacle when the engine

starts.

Make sure the throttle is at idle position.

Never place the throttle into the high

speed position or half throttle position

(throttle lock position) when starting the

engine.

3. After starting the engine, check to make

sure that the cutting attachment stops

rotating when the throttle is moved fully

back to its original position (idle position). If

it continues to rotate even after the throttle

has been moved fully back, turn off the

engine and take the unit to your authorized

RedMax servicing dealer for repair.

■ Using the product

Cut only materials recommended by the

manufacturer. And use only for tasks

explained in the manual.

1. Grip the handles firmly with both hands

using your whole hand. Place your feet

slightly apart (slightly further apart than the

width of your shoulders) so that your

weight is distributed evenly across both

legs, and always be sure to maintain a

steady , even posture while working.

2. Keep cutting attachment below waist level.

3. Maintain the speed of the engine at the

level required to perform cutting work, and

never raise the speed of the engine above

the level necessary.

4. If you detect abnormal vibration or noise

during operation, promptly stop the product

and check whether something has broken.

If a breakedown has occurred, do not

operate the product until the problem is

fixed.

5. Keep all parts of your body away from

rotating cutting attachment.

6. Guard against hazardous situations at all

times. Warn adults to keep pets and

children away from the area. Be careful if

you are approached. Injury may result from

flying debris.

7. If someone calls out or otherwise interrupts

you while working, always be sure to turn

off the engine before turning around.

8. After using the product and other

IMPORTANT

WARNING

WARNING

Page 9

US-7

TR2350S

U

S

5. For safe operation

equipment, CLEAN UP!

■ Transport

1. Drain the fuel from the fuel tank before

transporting or storing the product.

2. When hand-carrying the product, cover

over the cutting part, lift up the product and

carry it paying attention to the blade.

3. Secure the unit carefully to prevent

movement when it is transported.

4. A unit that receives a strong shock during

transport and unloading may malfunction.

■ Fuel safety

1. Always use caution when handling fuel. It

is highly flammable. Wipe up all spills,

screw the fuel cap back tightly, and then

move the product at least 10 feet (3

meters) from the fueling point before

starting the engine.

2. Eliminate all sources of sparks or flame

(i.e. smoking, open flames, or work that

can cause sparks) in the areas where fuel

is mixed, poured, or stored.

3. Do not smoke while handling fuel or while

operating the product.

4. Do not refuel a hot engine.

5. Do not refuel a running engine.

6. Keep the handles dry, clean and free of oil

or fuel mixture.

7. Always store fuel in an approved container

designed for that purpose.

■ Storage

1. Always store the product and fuel so that

there is no risk of leakages or fumes

coming into contact with sparks or naked

flames from electrical equipment, electric

moters, relays/switches, boilers and the

like.

2. When storing the product, the fuel tank

should be emptied.

3. When storing the product, choose a space

indoors free from moisture and out of the

reach of children.

■ Avoid noise problem

Check and follow the local regulations as to

sound level and hours of operations for the

product.

1. Operate power equipment only at

reasonable hours not early in the morning

or late at night when people might be

disturbed. Comply with times listed in local

ordinances.

IMPORTANT

2. To reduce sound levels, limit the number of

pieces of equipment used at any one time.

3. Operate the product at the lowest possible

throttle speed to do the job.

4. Check your equipment before operation,

especially the muffler, air intakes and air

filters.

■ For protecting your body from vibration

Prolonged use of the product, exposing

the operater to vibrations and cold may

produce whitefinger disease (Raynaud's

phenomenon), which symptoms are

tingling and burning sensations followed

by loss of color and numbness in the

fingers.

All factors which contribute to whitefinger

disease are not known, but cold weather,

smoking diseases or physical conditions

as well as long periods of exposure to

vibration are mentioned as factors. In

order to reduce the risk of whitefinger

disease, the following precautions are

strongly recommended.

a: Keep your body warm. Never use the

product during rains.

b: Wear thick anti-vibration gloves.

c: Take more than 5 minutes of break in

warm place frequently.

d: Maintain a firm grip at all times, but do not

squeeze the handles with constant,

excessive pressures.

e: If you feel discomfort, redness and swelling

of your fingers or any other part of your

body, see a doctor before getting worse.

■ Maintenance

1. In order to maintain your product in proper

working order, perform the maintenance

and checking operations described in the

manual at regular intervals.

2. Always be sure to turn off the engine and

disconnect the spark plug before

performing any maintenance or checking

procedures.

The metallic parts and engine cover reach

high temperatures immediately after

stopping the engine.

3. Examine the product at intervals for loose

fasteners and rusted or damaged parts.

Use special care around the fuel line, the

WARNING

WARNING

Page 10

US-8

TR2350S

5. For safe operation

muffler, and the ignition wiring.

4. When replacing the any other part, or

any lubricant, always be sure to use

only RedMax products or products

which have been certified by RedMax

for use with the RedMax product.

5. In the event that any part must be

replaced or any maintenance or repair

work not described in this manual must

be performed, please contact a

representative from the store nearest

RedMax authorized servicing dealer for

assistance.

6. Do not use any accessory or

attachment other than those bearing

the RedMax mark and recommended

for the unit.

7. Under no circumstances should you

ever take apart the product or alter it in

any way. Doing so might result in the

product becoming damaged during

operation or the product becoming

unable to operate properly.

■ Disposal

When disposing your machine, fuel or oil

for the machine, be sure to allow your

local regulations.

Page 11

US-9

TR2350S

U

S

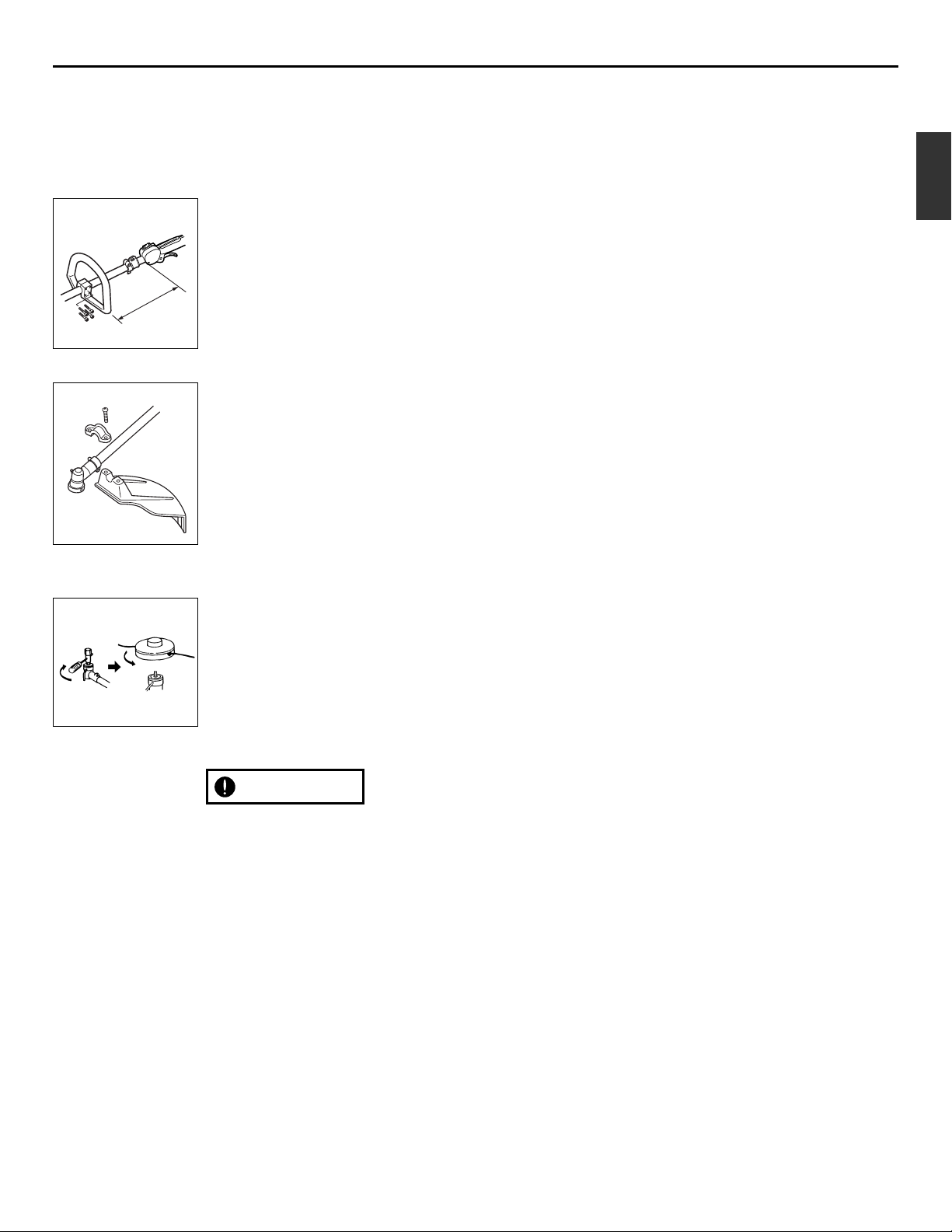

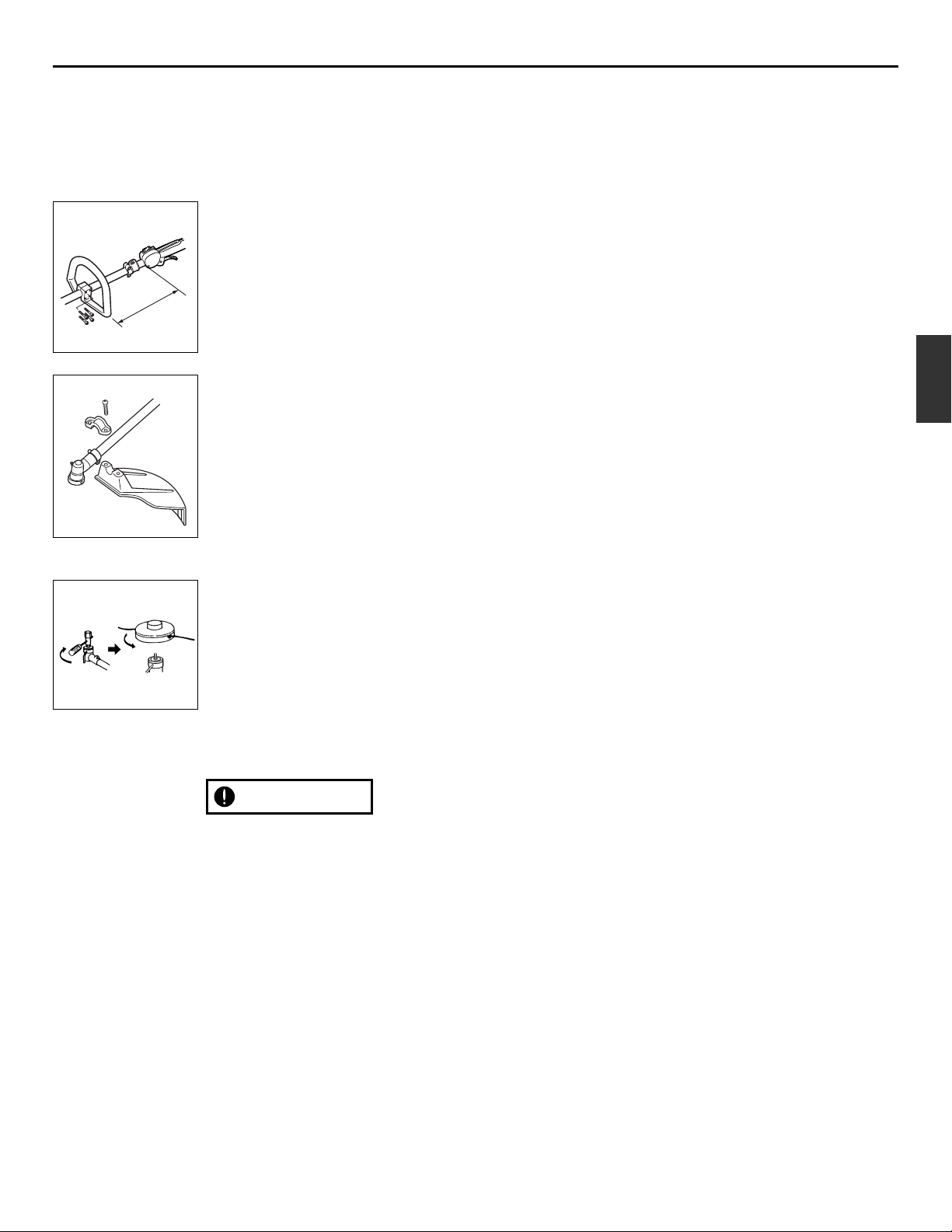

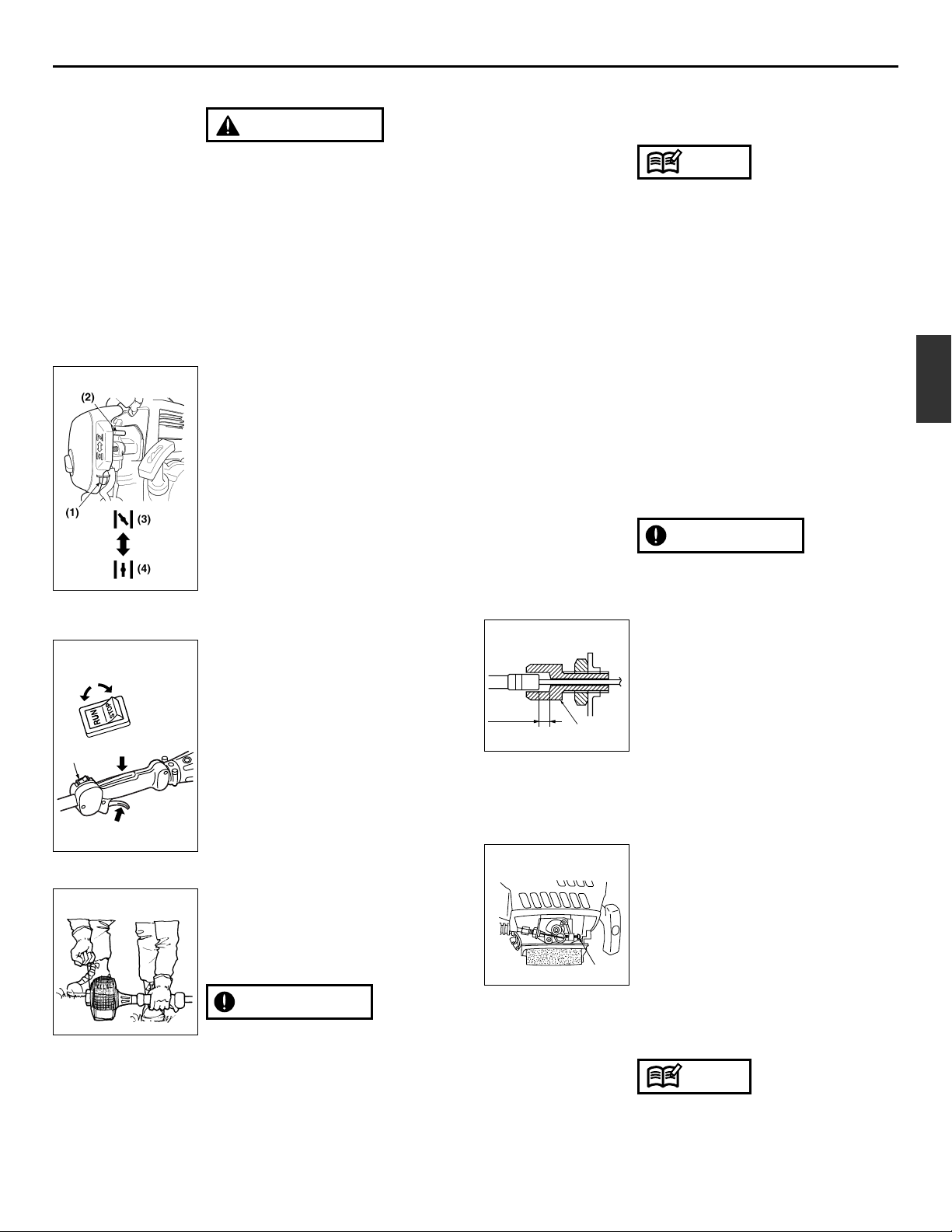

6. Set up

(1)

SE1

SE2

SE3

■ CONNECTING SWITCH WIRES

• Connect the switch wires between the

engine and the main unit. Pair the wires

of the same color.

■ INSTALLING HANDLE

• Mount the handle to the shaft tube and

clamp it at a location that is comfortable

to you. (SE1)

(1) About 11 inches (28cm)

■ INSTALLING DEBRIS GUARD

• Put the debris guard on the gear box,

attach it with the screws and hardware

provided. (SE2)

■ INSTALLING CUTTING HEAD (SE3)

1. While locking the gear shaft, by

inserting the supplied tool into the

upper holder on the gear box, loosen

and remove the hexagon nut(lefthanded)

2. Fit the line head assembly to the gear

shaft over the holders. Hand-tighten it

securely.

You need not holder (B) and nut when

installing the cutting head.

IMPORTANT

Page 12

US-10

TR2350S

lines or fuel tank of the engine.

• Failures caused by operating engines on gasoline with octane

rating lower than 89 are not covered

by the RedMax Two-

Stroke engine warranty.

•Alternative Fuels (Not Gasoline)

Alternative fuels, such as E-15 (15% ethanol), E-20 (20%

ethanol), E-85 (85% ethanol) are NOT classified as gasoline

and are NOT approved for use in RedMax 2-stroke gasoline

engines. Use of alternative fuels will cause major engine

performance and durability problems such as: improper

clutch engagements, overheating, vapor lock, power loss,

lubrication deficiency, deterioration of fuel lines, gaskets

and internal carburetor components, etc... Alternative fuels

cause high moisture absorption into the fuel/oil mixture

leading to oil and fuel separation.

■ OIL REQUIREMENTS

• Use only RedMax "Max Life", Synthetic blend Premium AirCooled two-stroke engine oil or oil certified to ISO-L-EGD

(ISO/CD1378) standard AND

one that is JASO-FD

registered.

RedMax Air-Cooled "Max Life", Synthetic blend Premium two

stroke engine oil and ISO-L-EGD

(ISO/CD1378) AND

JASO-FD

oils are fully compatible

with gasoline's containing 10% Ethanol.

RedMax Air-Cooled "Max Life", Synthetic blend Premium two

stroke engine oil and ISO-L-EGD

(ISO/CD1378) AND

JASO-FD

oils are Universal and should be mixed at 50:1 ratio for all 2

stroke air cooled engines sold in the past regardless of mixing

ratios specified in those manuals.

• If the oil is registered with JASO, the JASO Logo with FD

and

registration number

will be displayed on the container. The

highest JASO rating is "FD", which equals the ISO-L-EGD

rating. Lower ratings are "FC", "FB", and "FA".

• Engine problems due to inadequate lubrication caused by

failure to use ISO-L-EGD

certified and JASO FD registered oil

such as "MaxLife", RedMax Synthetic blend Premium 2-stroke

oil WILL VOID THE REDMAX TWO-STROKE ENGINE

WARRANTY.

• Do not use NMMA (National Marine Manufacturers

Association), BIA (Boating Industry Association), and TCW (two

cycle water cooled) oils designed for MoPeds or Outboard,

water cooled Marine Engines. Do not use API (American

Petroleum Institute), TC (Two Cycle) labeled oils. The API-TC

WARNING

7. Fuel

FUEL

• Gasoline is very flammable. Avoid smoking or bringing any

flame or sparks near fuel. Make sure to stop the engine and

allow it cool before refueling the unit. Select outdoor bare

ground for fueling and move at least 10 ft (3 m) away from

the fueling point before starting the engine.

■ GASOLINE REQUIREMENTS

• All 2-Stroke RedMax Products are powered by Zenoah

Professional-Commercial Duty, Hi-Performance, Hi-RPM, Air

Cooled 2-Stroke engines.

RedMax/Zenoah – Hi-Performance 2-stroke engines produce

higher HP outputs as compared to standard Home Owner Duty

or Light Commercial Duty production engines offered by most

manufacturers.

• Exhaust emission are controlled by the fundamental engine

parameters and components (eq., carburation, ignition timing

and port timing) without addition of any major hardware or the

introduction of an inert material during combustion.

• The RedMax/Zenoah Engines are registered and certified with

CARB (California Air Resources Board) and EPA

(Environmental Protection Agency) to operate on CLEAN Midgrade 89 octane or Premium, unleaded (lead-free) gasoline and

RedMax Air-Cooled "Max Life", Synthetic blend Premium twostroke engine oil mixed at 50:1 ratio.

• Unleaded gasoline is recommended to reduce the

contamination of the air for the sake of your health and the

environment.

• This Hi-Performance Air Cooled 2-stroke Engine requires the

use of Minimum

89 Octane (Mid grade or Premium)

clean gasoline. Gasoline may contain maximum of 10% Ethanol

(grain alcohol) or up to 15% MTBE (Methyl tertiary-butyl ether).

Gasoline containing Methanol (Wood Alcohol) is NOT

approved.

• IF octane rating of the Mid Grade

gasoline in your area is lower

than 89 Octane use Premium Unleaded Gasoline. The majority

of all 2-stroke engine manufacturers in the USA and Canada

recommend using gasoline with 89 Octane or higher.

• Gasoline with an octane rating lower than 89 will greatly

increase the engines operating temperature. Low octane

gasoline will cause detonation (knock) resulting in piston

seizures and major internal engine components damage.

• Poor quality gasolines or oils may damage sealing rings, fuel

WARNING

[ R+M ]

2

WARNING

NOTE

WARNING

NOTE

Page 13

US-11

TR2350S

U

S

7. Fuel

test standard has been discontinued by API in 1995 and it no

longer exists.

• Gasoline/Oil mixture Storage Recommendations

Store your gasoline or gasoline/oil mixture in a cool dry area in

a tightly sealed approved container to limit the entry of moisture

and additional air (oxygen). Moisture and air cause the

development of varnish and gum, making the fuel stale. Stored

gasoline and gasoline/oil mixture ages and loses its octane

rating and volatility. Do not mix more gasoline/oil than you

intend to use in 30 days, and 60 days when fuel stabilizer is

added. RedMax Air-Cooled "Max Life" Synthetic blend

Premium two-stroke engine oil "Contains fuel stabilizer"

and

will automatically extend your gasoline/oil mixture life up to 60

days.

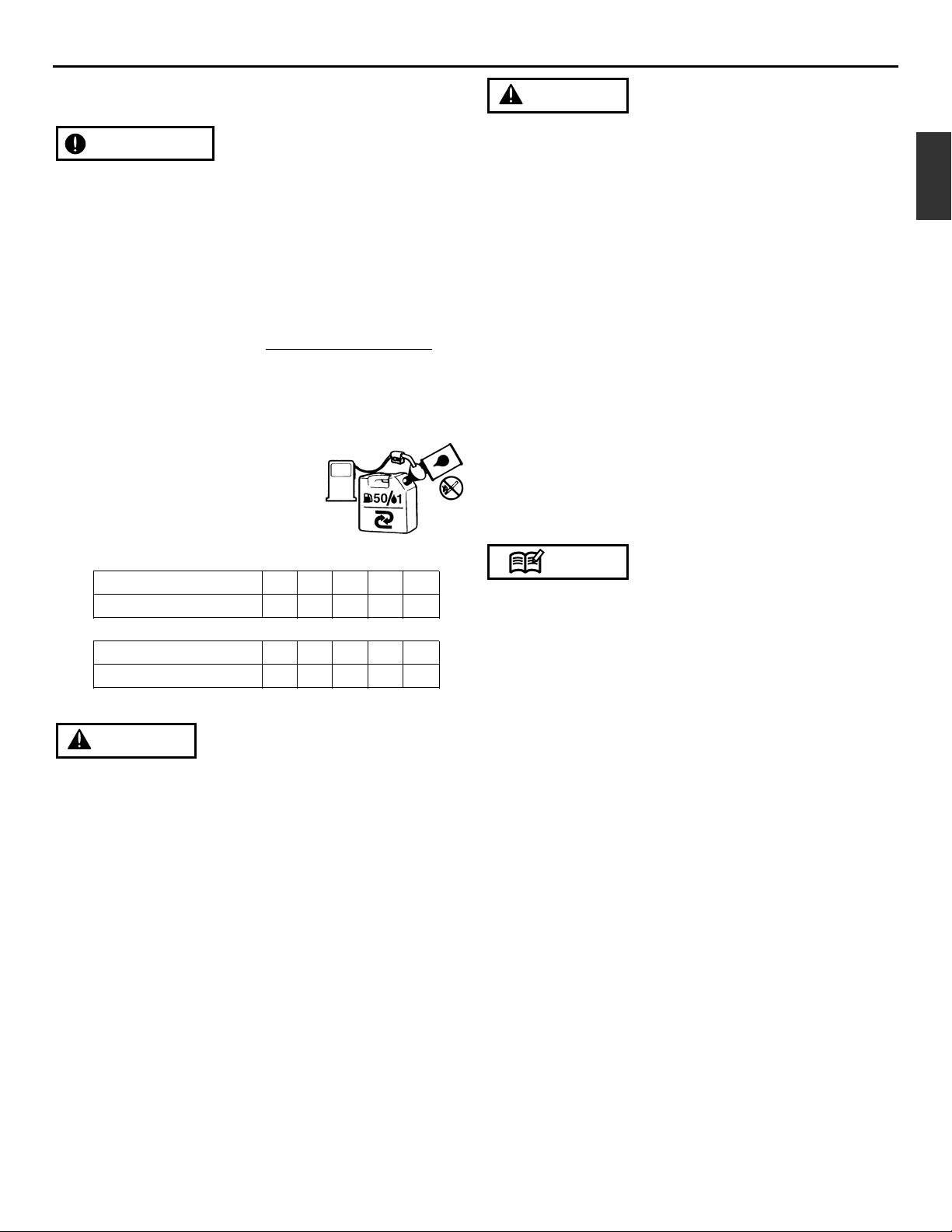

■ HOW TO MIX FUEL

RECOMMENDED MIXING RATIO

GASOLINE 50 : OIL 1

(when using RedMax Air-Cooled "Max

Life")

• Pay attention to agitation.

1. Measure out the quantities of gasoline and oil to be mixed.

2. Put some of the gasoline into a clean, approved fuel container.

3. Pour in all of the oil and agitate well for 10seconds.

4. Pour in the rest of gasoline and agitate again for at least one

minute. As some oils may be difficult to agitate depending on oil

ingredients, sufficient agitation is necessary. Be careful that, if

the agitation is insufficient, there is an increased danger of early

piston seizure due to abnormally lean mixture.

5. Place a clear indication on the outside of the container to avoid

mixing up with gasoline or other containers that dont contain oil.

6. Indicate the contents on outside of container for easy

identification.

■ FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the cap on a clean

surface.

2. Put fuel into the fuel tank to 80% of the full capacity.

3. Fasten the fuel cap securely and wipe up any fuel spillage

around the unit.

WARNING

1. Select flat and bare ground for fueling.

2. Move at least 10 feet (3 meters) away from the fueling point

before starting the engine.

3. Stop the engine before refueling the unit. At that time, be

sure to sufficiently agitate the mixed gasoline in the

container.

■ FOR YOUR ENGINE LIFE, AVOID

1. FUEL WITH NO OIL (RAW GASOLINE) – It will cause severe

damage to the internal engine parts very quickly.

2. GASOHOL – It can cause deterioration of rubber and/or plastic

parts and disruption of engine lubrication.

3. OIL FOR 4-CYCLE ENGINE USE – It can cause spark plug

fouling, exhaust port blocking, or piston ring seizure.

4. Mixed fuels which have been left unused for a period of

one month or more may clog the carburetor and result in the

engine failing to operate properly.

5. In the case of storing the product for a long period of time,

clean the fuel tank after rendering it empty. Next, Start the

engine and run the carburetor dry residual fuel.

6. In the case of scrapping the used mixed oil container, scrap it

only at an authorized depository site.

• As for details of quality assurance, read the description in the

section Limited Warranty carefully. Moreover, normal wear and

change in product with no functional influence are not covered

by the warranty. Also, be careful that, if the usage in the

instruction manual is not observed as to the mixed gasoline,

type of oil or fuel to be used. described therein, it may not be

covered by the warranty.

NOTE

50:1 MIXING CHART

GASOLINE gal. 1 2 3 4 5

2-CYCLE OIL fl.oz 2.6 5.2 7.8 10.4 13

GASOLINE liter 1 2 3 4 5

2-CYCLE OIL ml 20 40 60 80 100

IMPORTANT

WARNING

Page 14

US-12

TR2350S

8. Operation

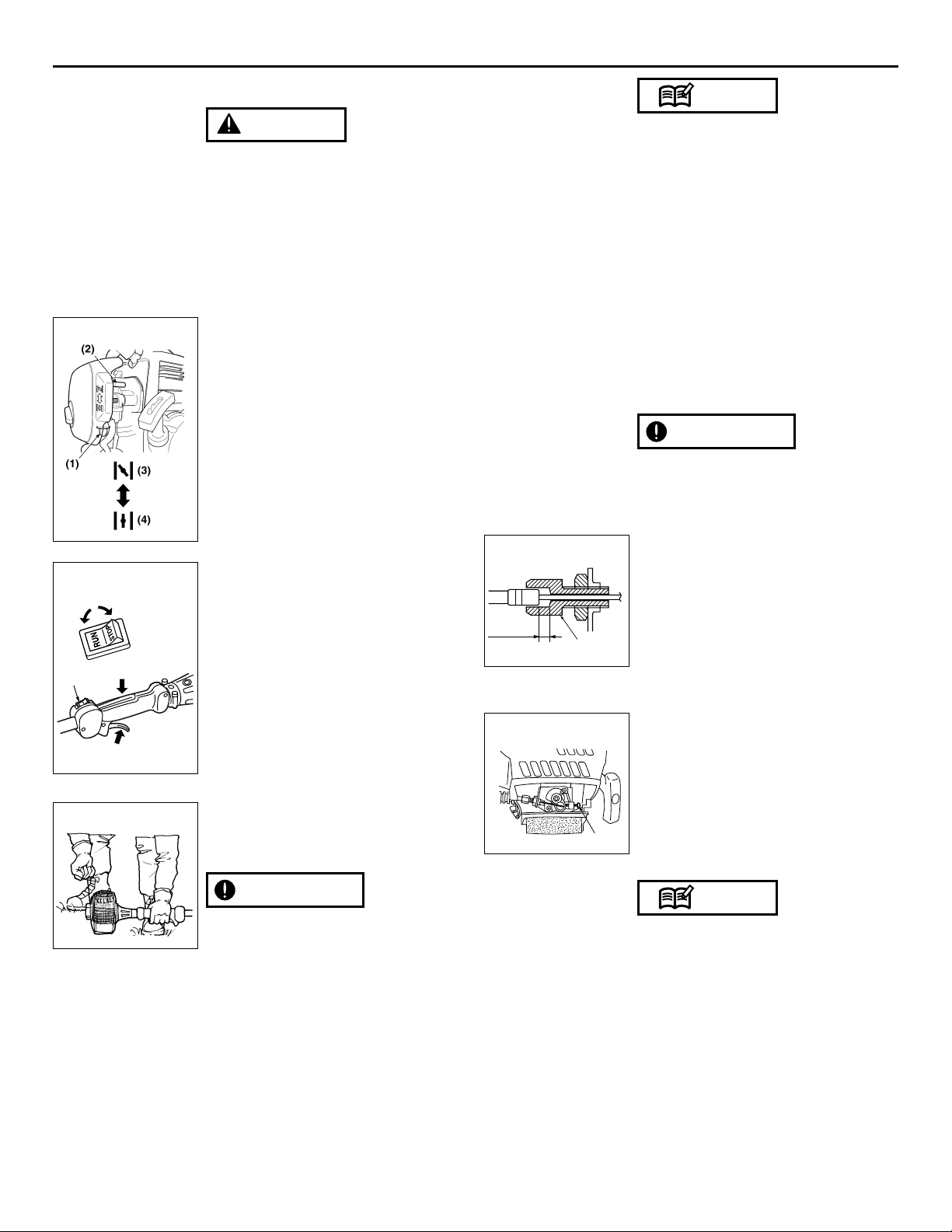

■ STARTING ENGINE

The cutting head will start rotating

upon the engine starts.

1. Rest the unit on a flat, firm place. Keep

the cutting head off the ground and

clear of surrounding objects as it will

start rotating upon starting of the

engine.

2. Push the primer pump several times

until overflown fuel flows out in the

clear tube. (OP1)

3. Move the choke lever to the closed

position. (OP1)

(1) primer pump

(2) choke lever

(3) close

(4) open

4. Set the stop switch to the "RUN"

position. Place the unit on a flat, firm

place. Keep the cutting head clear of

everything around it. (OP2)

(1) stop switch

(2) RUN

(3) STOP

(a) lockout lever

(b) throttle trigger

5. Firmly grasp (a) and (b) with left hand,

pull the starter knob quickly until engine

fires. (OP3)

• Avoid pulling the rope to its end or

returning it by releasing the knob. Such

actions can cause starter failures.

6. Move the choke lever downward to

open the choke. And restart engine.

(OP1)

7. Allow the engine to warm up for several

minutes before starting operation.

IMPORTANT

OP1

(1)

(3)

(a)

(b)

(2)

OP2

OP3

.04 in

(1~2mm)

(1)

OP4

1. When restarting the engine

immediately after stopping it, leave the

choke open.

2. Overchoking can make the engine hard

to start due to excess fuel. When the

engine failed to start after several

attempts, open the choke and repeat

pulling the rope, or remove the spark

plug and dry it.

■ STOPPING ENGINE (OP2)

1. Release the throttle lever and run the

engine for a half minute.

2. Shift the stop switch to the "STOP"

position.

• Except for an emergency, avoid

stopping the engine while pulling the

throttle lever.

■ ADJUSTING THROTTLE CABLE

• The normal play is 1 or 2mm when

measured at the carburetor side end.

Readjust with the cable adjuster as

required. (OP4)

(1) cable adjuster

■ ADJUSTING IDLING SPEED (OP5)

1. When the engine tends stop frequently

at idling mode, turn the adjusting screw

clockwise.

2. When the cutting head keeps rotating

after releasing the trigger, turn the

adjusting screw counter-clockwise.

(1) idle adjusting screw

• Warm up the engine before adjusting

the idling speed.

NOTE

OP5

NOTE

WARNING

IMPORTANT

(1)

Page 15

US-13

TR2350S

U

S

8. Operation

OP6

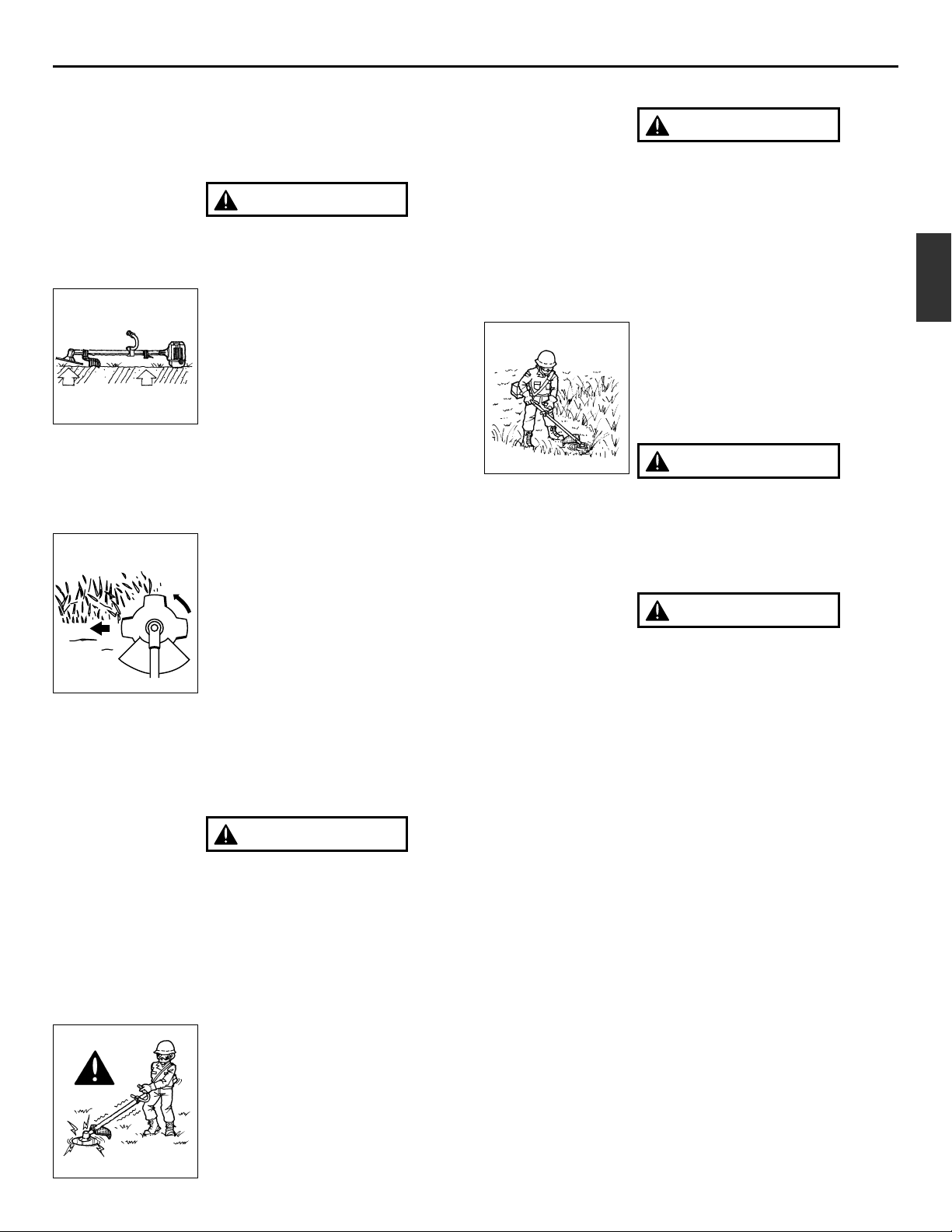

■ CUTTING WORK (LINE HEAD

USAGE)

1. Always wear eye protection such as

safety goggles. Never lean over the

rotating cutting head. Rocks or other

debris could be thrown into eyes

and face and cause serious personal

injury.

2. Keep the debris guard in place at all

times when the unit is operated.

TRIMMING GRASS AND WEEDS

• Always remember that the TIP of the

line does cutting. You will achieve

better results by not crowding the line

into the cutting area. Allow the unit to

trim at its own pace.

1. Hold the unit so the head is off the

ground and is tilted about 20 degrees

toward the sweep direction. (OP6)

2. You can avoid thrown debris by

sweeping from your left to the right.

3. Use a slow, deliberate action to cut

heavy growth. The rate of cutting

motion will depend on the material

being cut. Heavy growth will require

slower action than will light growth.

4. Never swing the unit so hard as you

are in danger of losing your balance or

control of the unit.

5. Try to control the cutting motion with

the hip rather than placing the full

workload on the arm and hands.

6. Take precautions to avoid wire, grass

and dead, dry, long-stem weeds from

wrapping around the head shaft. Such

materials can stall the head and cause

the clutch to slip, resulting in damage to

the clutch system if repeated

frequently.

ADJUSTING THE LINE LENGTH

• Your brushcutters is equipped with a

semi- auto type nylon line head that

allows the operator to advance the line

without stopping the engine. When the

line becomes short, lightly tap the head

on the ground while running the engine

at full throttle.

• Each time the head is bumped, the line

advance about 1 inch(25.4 mm). For

better effect, tap the head on bear

ground or hard soil. Avoid bumping in

thick, tall grass as the engine may stall

by overload.

WARNING

Page 16

US-14

TR2350S

every every every

25 50 100

system/compornent procedure before hours hours hours note

use after after after

fuel leaks, fuel spillage wipe out ✔

fuel tank, air filter, fuel filter inspect/clean ✔✔ replace, if necessary

see ■ADJUSTING replace carburetor

idle adjusting screw ✔

IDLING SPEED (p.12) if necessary

clean and readjust GAP: .025in(0.6~0.7mm)

spark plug ✔

plug gap replace, if necessary

cylinder fins, intake air cooling vent clean ✔

muffler, spark arrester, cylinder exhaust port

clean ✔

throttle lever, ignition switch check operation ✔

replace if

cutting parts ✔

something's wrong

debris guard make sure to attach ✔

gear case grease ✔

screws/nuts/bolts tighten/replace ✔✔not adjusting screws

ENGINE

SHAFT

■ MAINTENANCE CHART

Maintenance, replacement, or repair of the emission control device and

systems may be performed by any non-road engine repair establishment or

individual.

9. Maintenance

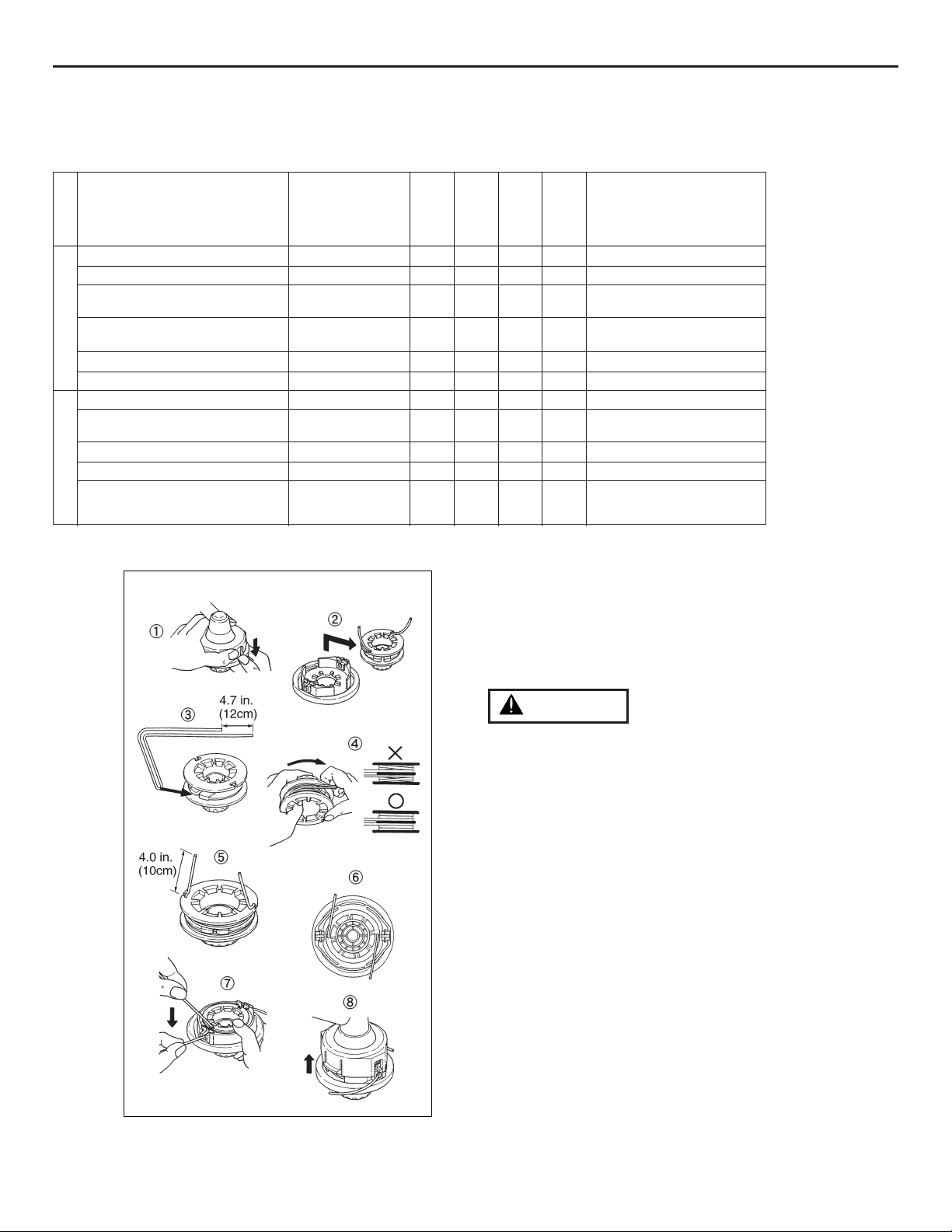

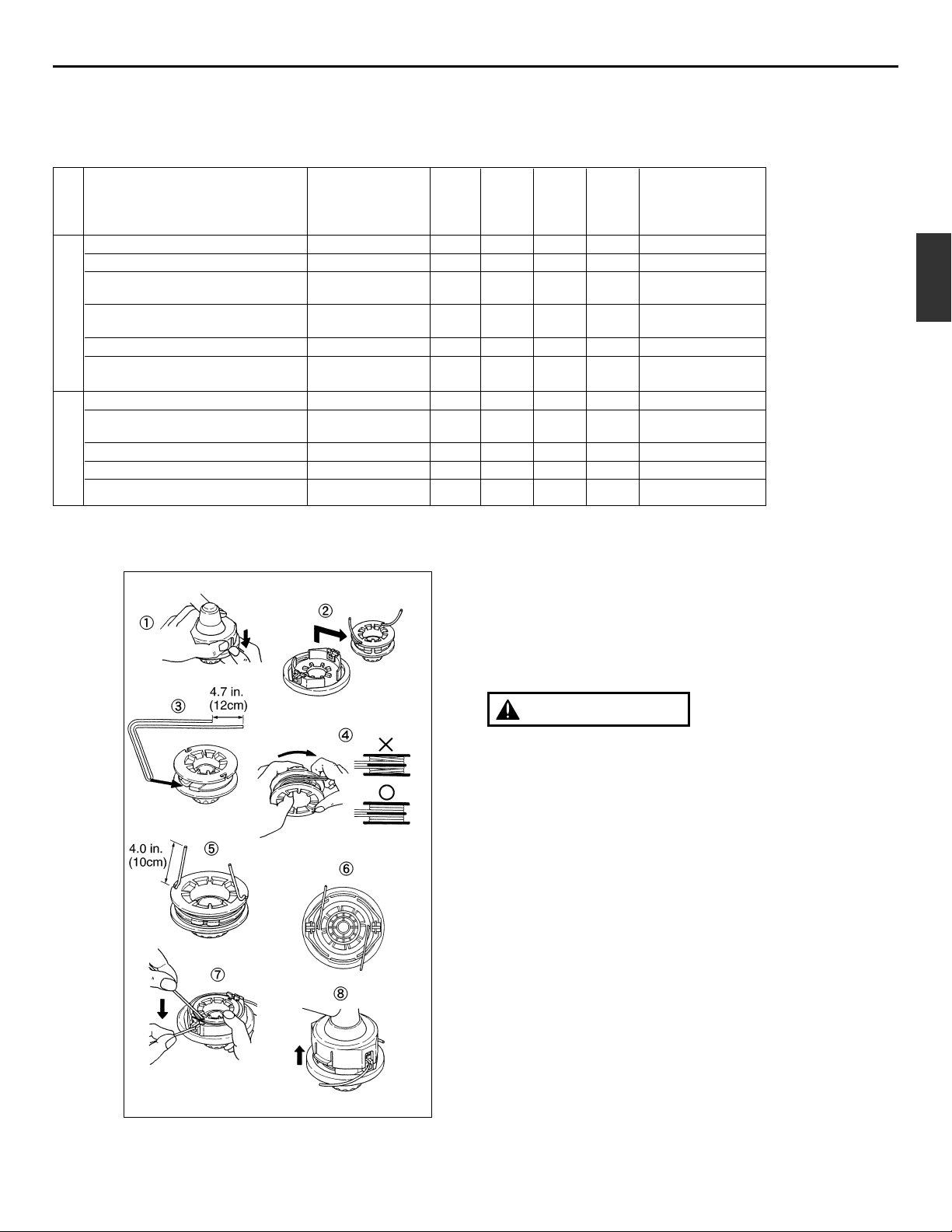

■ REFILLING TRIMMING LINE (MA1)

1. For replacement line, use a diameter of .095in (2.4mm). The

spool is capable for a line upto 20ft (6m) on the 4” head. Avoid

using a larger line as it may cut down the trimming

performance.

For safety reasons, do not use metalreinforced line.

2. Pinch the slotted area on the both sides of the spool housing to

unhook the bottom cap.

3. Take out the spool and pull off the old line. Fold new line so that

one half line is 4.7in.(12cm) shorter than another half. And then,

hook bended end in the slot of the spool.

4. Wind up the line in the correct direction as indicated on the

spool.

5. Hook each end of the line in the slot on the edge of the spool,

and then put the ends through the eyelets on the housing. Make

sure that the spring and the washers are in place.

6. While holding the spool against the housing, pull the line ends

to release them from the slot.

7. Line up the slot on the bottom cap with the hook on the housing,

press the cap against the housing until it clicks.

WARNING

MA1

Page 17

US-15

TR2350S

U

S

■ MUFFLER

• Inspect periodically, the muffler for

loose fasteners, any damage or

corrosion. If any sign of exhaust

leakage is found, stop using the

machine and have it repaired

immediately.

•Note that failing to do so may result

in the engine catching on fire.

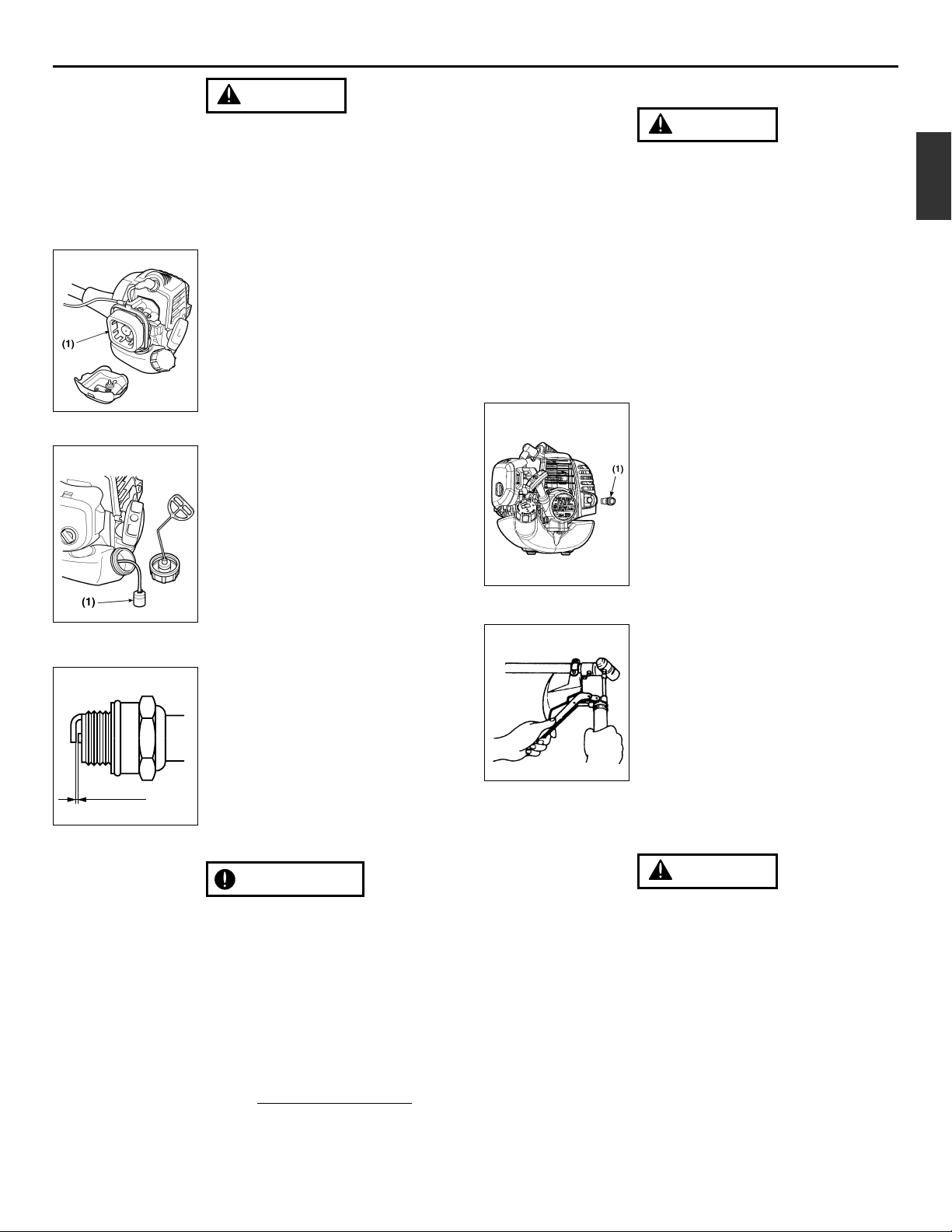

■ SPARK ARRESTER

• The muffler is equipped with a spark

arrester to prevent red hot carbon from

flying out of the exhaust outlet.

Periodically inspect and clean as

necessary with a wire brush.

In the State of California it is required

by law (Section 4442 of the California

Public Resources Code) to equip a

spark arrester when a gas powered tool

is used in any forest covered, brush

covered, or grass covered unimproved

land. (MA5)

(1) spark arrester

■ GEAR CASE (MA6)

• The reduction gears are lubricated by

multipurpose, lithium-based grease in

the gear case. Supply new grease

every 25 hours of use or more often

depending on the job condition.

• Remove the side bolt in gear case

opposite of grease nipple before

installing new grease to arrange for old

grease to exit.

■ INTAKE AIR COOLING VENT

• Never touch the cylinder, muffler, or

spark plugs with your bare hands

immediately after stopping the

engine. The engine can become

very hot when in operation, and

doing so could result in severe

burns.

• When checking the machine to make

sure that it is okay before using it,

check the area around the muffler

and remove any wood chips or

leaves which have attached

themselves to the brushcutter.

Failing to do so could cause the

muffler to become overheated, and

WARNING

• Make sure that the engine has

stopped and is cool before

performing any service to the

machine. Contact with moving

cutting head or hot muffler may

result in a personal injury.

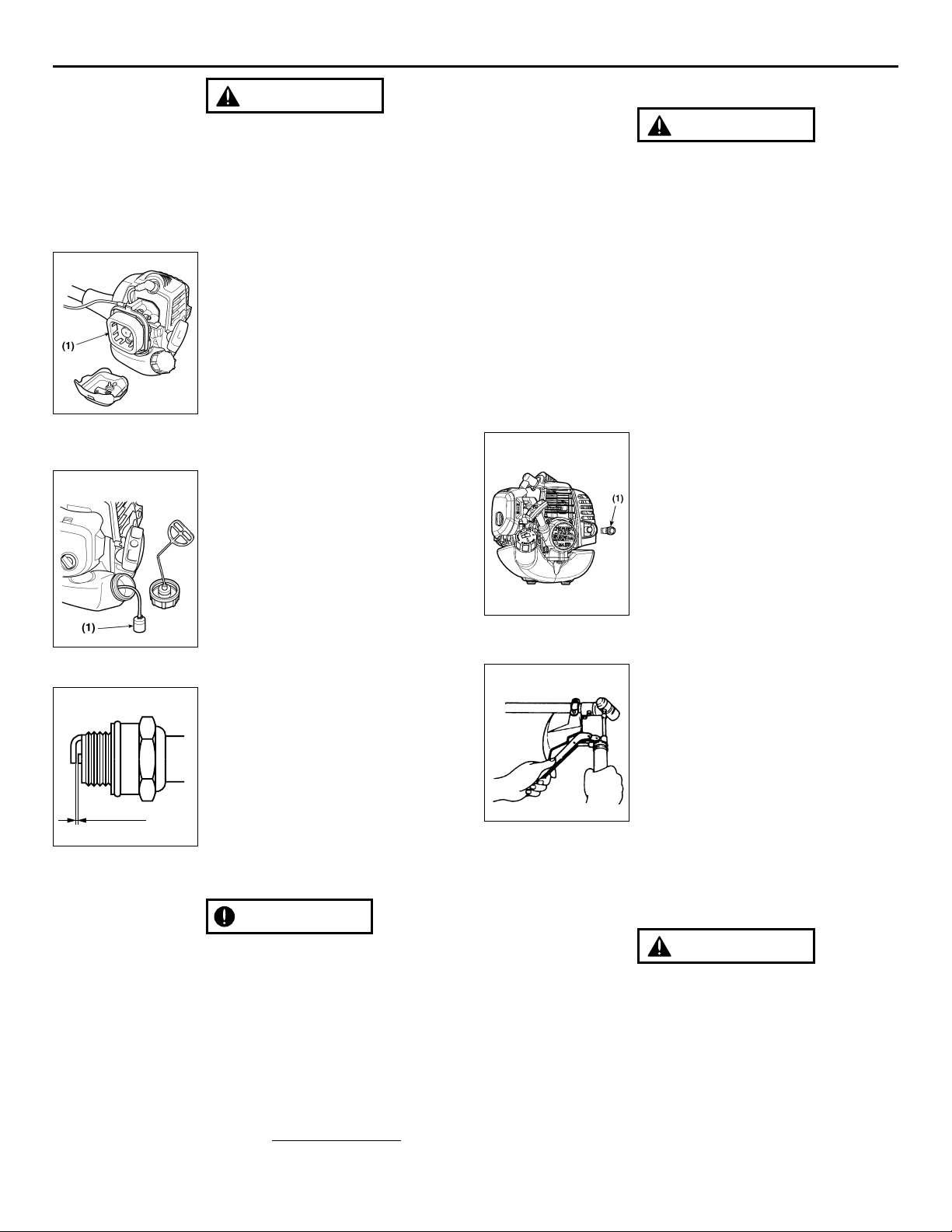

■ AIR FILTER

• The air filter, if clogged, will reduce the

engine performance. Check and clean

the filter element in warm, soapy water

as required. Dry completely before

installing. If the element is broken or

shrunk, replace with a new one. (MA2)

(1) air filter

■ FUEL FILTER

• When the engine runs short of fuel

supply, check the fuel cap and the fuel

filter for blockage. (MA3)

(1) fuel filter

■ SPARK PLUG

• Starting failure and mis-firing are often

caused by a fouled spark plug. Clean

the spark plug and check that the plug

gap is in the correct range. For a

replacement plug, use the correct type

specified by RedMax. (MA4)

• REPLACEMENT PLUG IS A NGK

BPMR7A.

• Note that using any spark plug other

than those designated may result in the

engine failing to operate properly or in

the engine becoming overheated and

damaged.

• To install the spark plug, first turn the

plug until it is finger tight, then tighten it

a quarter turn more with a socket

wrench.

TIGHTENING TORQUE:

126~185 in-lbs

(14.7~21.6 N.m.)

IMPORTANT

MA4

MA5

9. Maintenance

MA2

MA3

MA6

WARNING

WARNING

.025 in

0.655mm

Page 18

US-16

TR2350S

9. Maintenance

MA8

MA7

• Aged fuel is one of major causes of

engine starting failure. Before storing

the unit, empty the fuel tank and run

the engine until it uses all the fuel left in

the fuel line and the carburetor. Store

the unit indoor taking necessary

measures for rust prevention.

10. Storage

11. Disposal

• When disposing your machine, fuel or

oil for the machine, be sure to allow

your local regulations.

that this in turn could cause the

engine to catch on fire. Always

make sure that the muffler is clean

and free of wood chips, leaves, and

other waste before use.

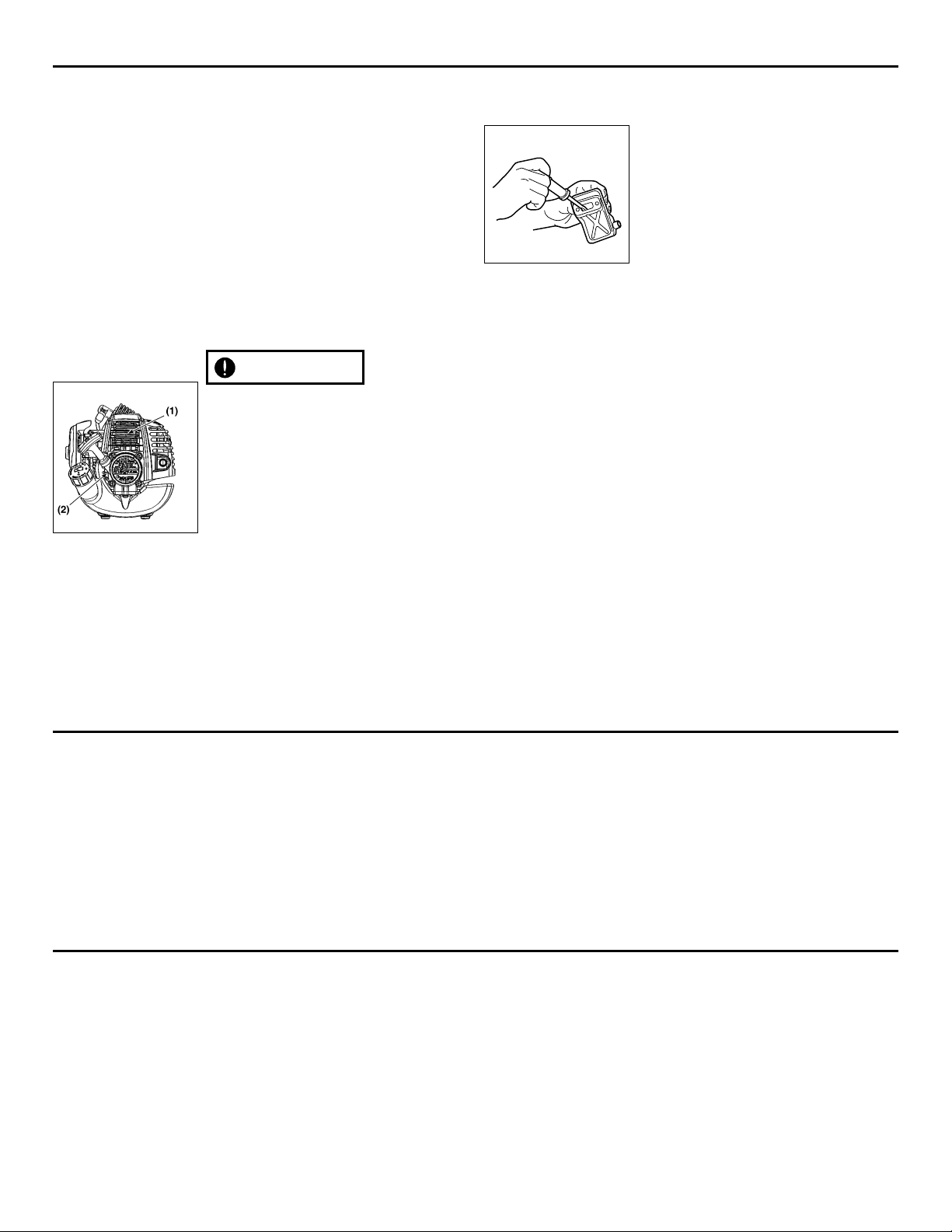

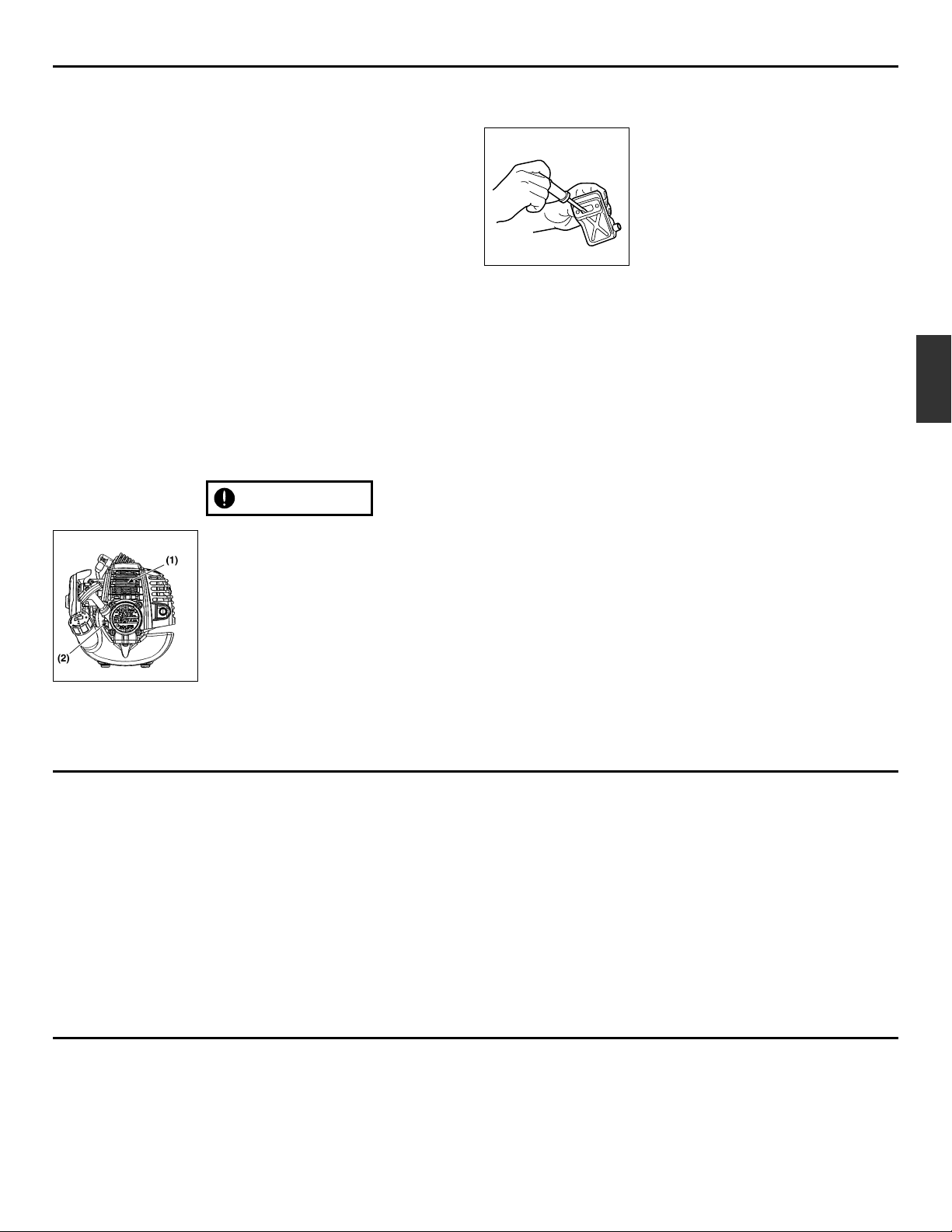

• Check the intake air cooling vent and

the area around the cylinder cooling

fins after every 25 hours of use for

blockage, and remove any waste which

has attached itself to the brushcutter.

Note that it is necessary to remove the

engine cover shown in (MA7) in order

to be able to view the upper part of the

cylinder.

• If waste gets stuck and causes

blockage around the intake air cooling

vent or between the cylinder fins, it may

cause the engine to overheat, and that

in turn may cause mechanical failure

on the part of the brushcutter. (MA7)

(1) cylinder

(2) intake air cooling vent (back)

IMPORTANT

■ PROCEDURES TO BE PERFORMED

AFTER EVERY 100 HOURS OF USE

1. Remove the muffler, insert a

screwdriver into the vent, and wipe

away any carbon buildup. Wipe away

any carbon buildup on the muffler

exhaust vent and cylinder exhaust port

at the same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has

worked its way in between the clutch

lining and drum, and if it has wipe it

away using oil-free, lead-free gasoline.

Page 19

US-17

TR2350S

U

S

•When sharpening, removing, or reattaching the blade, be

sure to wear thick, sturdy gloves and use only proper tools

and equipment to prevent injury.

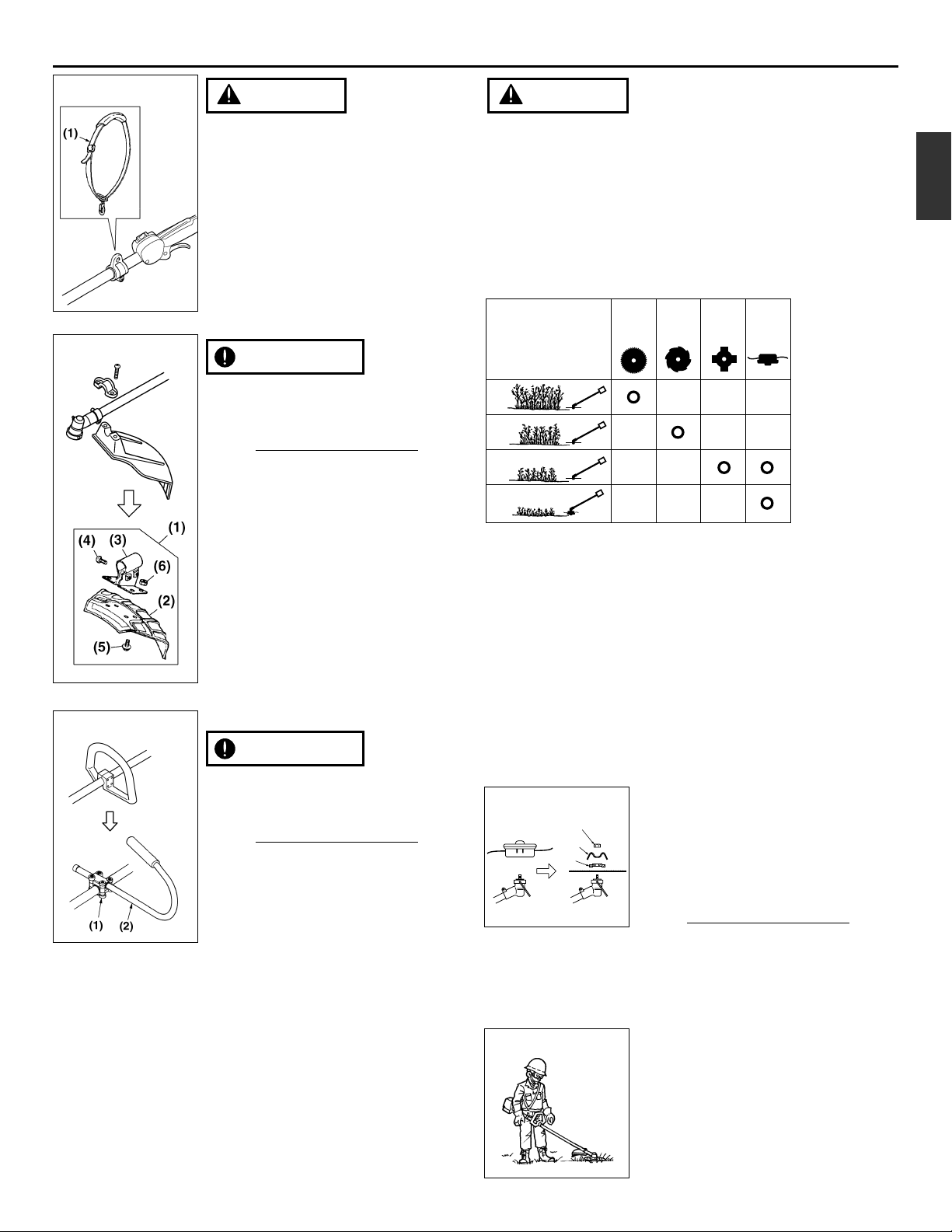

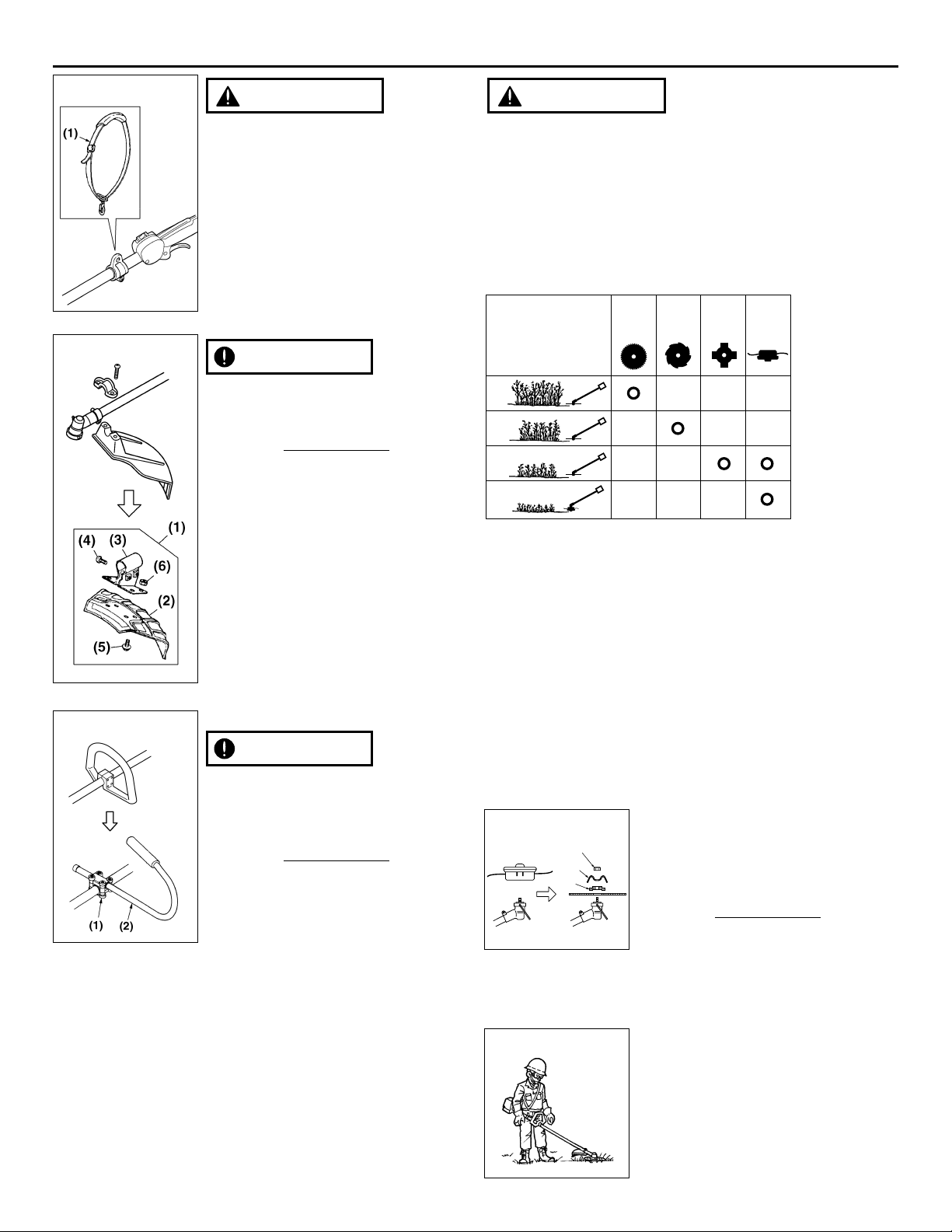

■ CHOOSE THE BLADE

Choose a suitable recommended cutting attachment according to

the object to be cut. (OPT4)

• When replacing blade always be sure to use products which

have been certified by RedMax.

(1) 9” 22-tooth : SST229

(2) 9” 24-tooth : SST249

(3) 8” 8-tooth : SGB088

(4) 9” 8-tooth : SGB089

(5) 8” 4-tooth : SGB048

(6) 9” 4-tooth : SGB049

(7) Nylon line head

(A) Under growth

(B) Heavy weeds

(C) Light weeds

(D) Grass

WARNING

■ SET UP THE BLADE

1. Detach the line head assembly. (OPT5)

2. Put on the blade, making the marked

side face the shaft side, put the holder

and the cover on, and fasten the blade

with the nut. (OPT5)

TIGHTENING TORQUE :

130~174 in-lbs

(14.7~19.6 N.m.)

(1) Cover : 3540-13283

(2) Holder (B) : 6019-13250

(3) Nut : T3002-13260 (STANDARD)

■ BALANCE UNIT

1. Put on strap and attach unit to strap.

2. Slide clamp up or down until unit

balances with head just touching on the

ground. (OPT6)

OPT6

(1)

(3)

(2)

OPT5

12. Optional blade usage

OPT1

OPT3

OPT2

• For security reason, in case of

mounting the blade on this product

and use it, purchase the blade kit

(X375000948) and change guard,

handle from the original ones, and

use shoulder strap.

(1) Shoulder strap : 848-J82-3610

Change to the debris guard which is

suitable for the metal blade. (OPT2)

TIGHTENING TORQUE :

for (4) Bolt, (5) Screw

130~174 in-lbs

(14.7~19.6 N.m.)

(1) Guard-A : 5764-24000

(2) Guard : 5766-24110

(3) Bracket : 3250-24120

(4) Bolt : 0225-10620

(5) Screw : 0263-30614

(6) Nut : 0280-10605

Change the loop handle to the J-handle

for safe operation. (OPT3)

TIGHTENING TORQUE :

42~78 in-lbs

(4.7~8.8 N.m.)

(1) Bracket : 3583-14101

(2) J-handle : 6367-14200

IMPORTANT

OPT4

WARNING

IMPORTANT

(1)

(3)

(4)

(5)

(6)

(7)

(2)

(A)

(B)

(C)

(D)

Page 20

US-18

TR2350S

OPT9

OPT8

OPT7

12. Optional blade usage

■ STARTING THE ENGINE

Please refer 5.For safe operation (P.6),

8.Operation (P.12).

• The product is equipped with a

centrifugal clutch mechanism, so

the cutting attachment could rotate

as soon as the engine is started.

When starting the engine, place the

product onto the ground in a flat

clear area and hold it firmly in place

so as to ensure that neither the

cutting part nor the throttle come

into contact with any obstacle when

the engine starts. (OPT7)

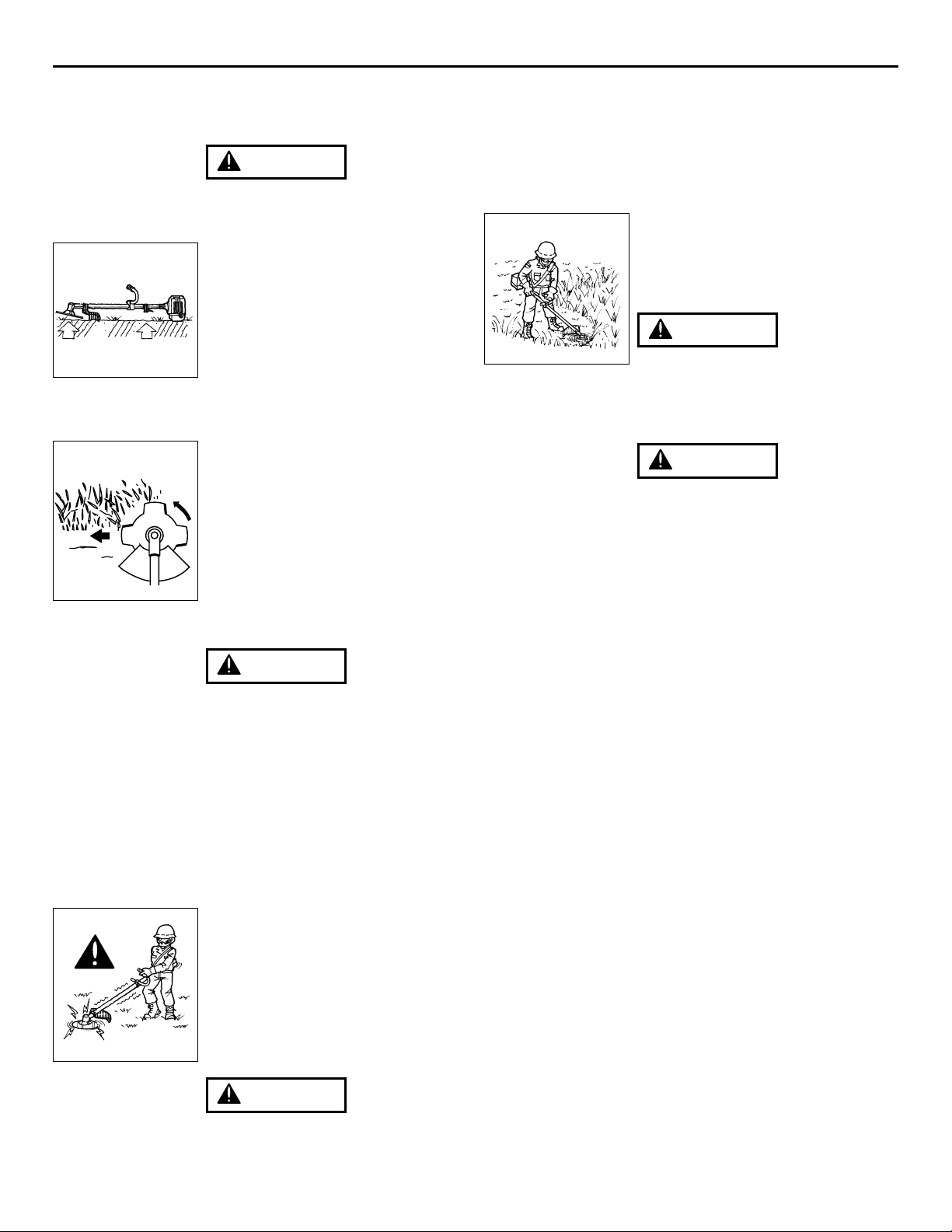

■ CUTTING METHOD

a) Use the front left side cutting.

b) Guide the blade from your right to left

with it tilted slightly to your left. (OPT8)

c) When mowing a wide area, start

working from your left end to avoid

interference of cut grass.

d) The blade may be seized by weeds if

the engine speed is too low, or the

blade cuts too deep into weeds. Adjust

the engine speed and cutting depth

according to the condition of object.

• If the grass or other object gets

caught in the blade, or if the unit

starts to shake or vibrate, turn off

the engine and check the whole unit.

Change the blade if it has been

damaged.

• Turn off the engine and make sure

the blade has completely stop

before checking the blade, and

removing any object got caught in.

■ OPERATION

1. Check the bolt to fasten the blade and

be sure the bolt has no fault, and no

abrasion.

2. Be sure that the blade and the holder

have been fastened according to

instruction and the blade turns

smoothly without abnormal noise.

(OPT9)

• The rotating parts fastened

incorrectly may cause serious

accident to the operator.

WARNING

•Make sure that the blade is not bent,

warped, cracked, broken or

damaged.

• If you find any error to the blade,

discard it and change new one

which is certified by RedMax.

■ By using the shoulder strap, hang the

unit on your right side. Adjust the strap

length so that the cutting head may

become parallel to the ground.

(OPT10)

Make sure to use shoulder strap and

debris guard. If not, it is very

dangerous when you slip or lose your

balance.

■ CONTROLLING BLADE THRUST

• Blade thrust can cause serious

personal injury. Carefully study this

section. It is important that you

understand what causes blade thrust,

how you can reduce the chance of

blade thrust and how you can remain in

control of the unit if blade thrust does

occur.

1. What causes blade thrust:

• Blade thrust can occur when the

moving blade contacts an object that it

cannot cut. This contact causes the

blade to stop for an instant and then

suddenly move or ”bounce” away from

the object that was hit. The operator

can lose control of the unit and the

blade can cause serious personal injury

to the operator or any person nearby if

the blade contacts any part of the body.

2.

How you can reduce the chance of blade

thrust:

a. Recognize that blade thrust can

happen. By understanding and

knowing about bounce, you can

help eliminate the element of

surprise.

b. Cut fibrous weeds and grass

only. Do not let the blade contact

materials it cannot cut such as hard,

woody vines and brush or rocks,

fences, metal, etc

c. Be extra prepared for blade thrust if

you must cut where you cannot see

the blade making contact such as in

WARNING

OPT10

WARNING

WARNING

WARNING

Page 21

US-19

TR2350S

U

S

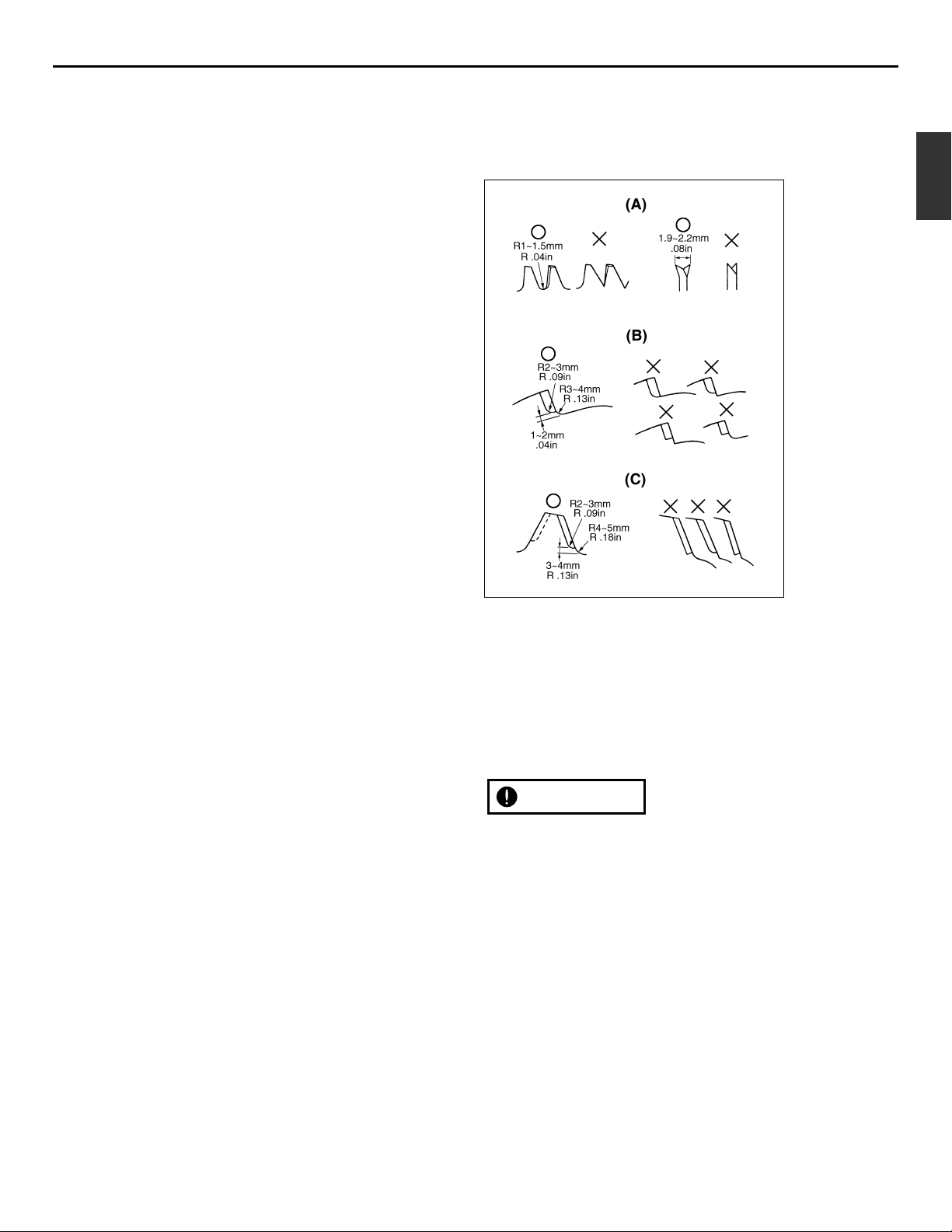

■ MAINTENANCE

BLADE

• Check the blade and the fasteners for looseness, cracking, or

bending.

• Check the cutting edges and reform with a flat file.

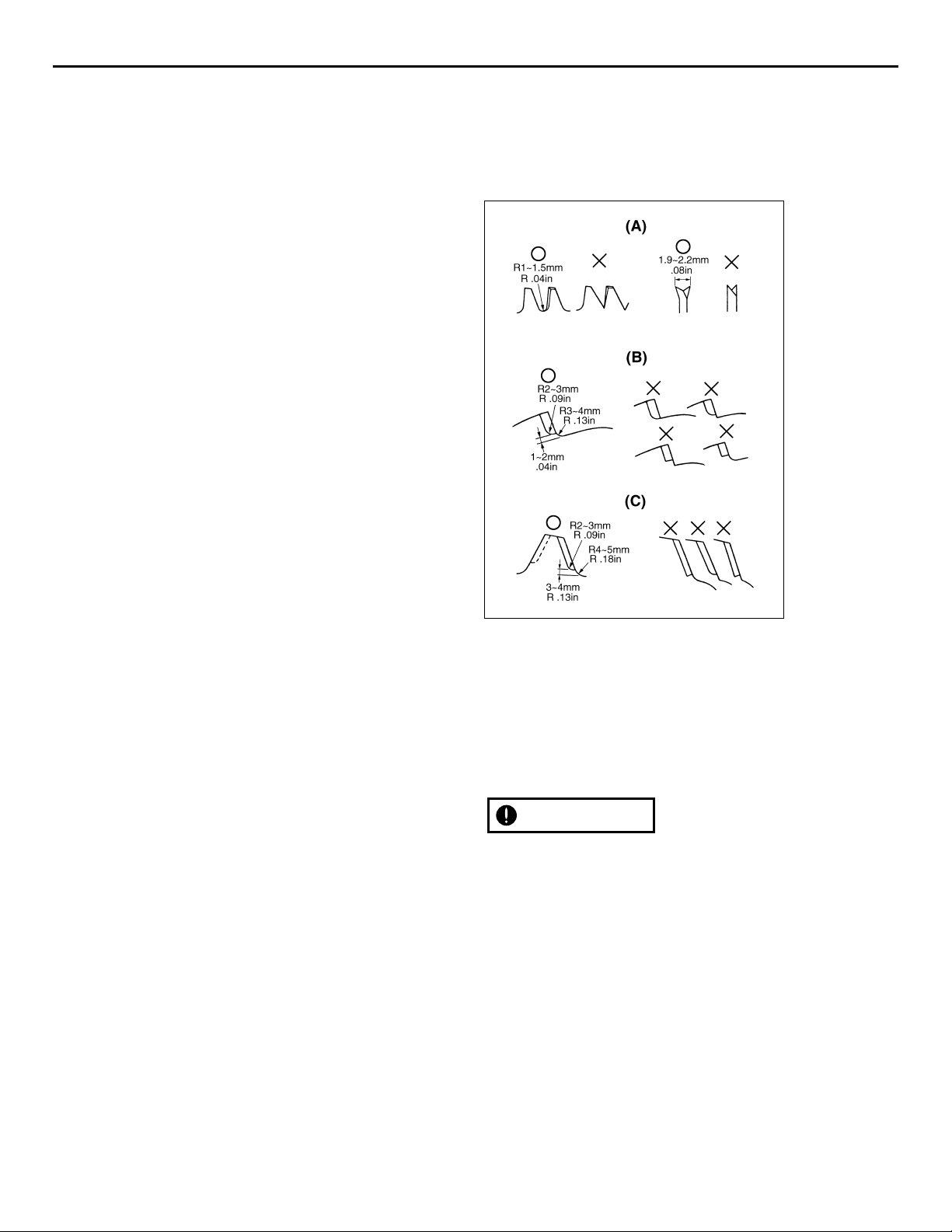

(A) 22, 24-tooth blade

(B) 8-tooth blade

(C) 4-tooth blade

Point (OPT11) :

1. Keep the end corner sharp.

2. Round the root of the edge, using round file.

3. Do not use water when using a grinder.

• It is recommended that filing should be done by professionals.

• Especially regarding filing the 22,24-tooth blade, Leave it to the

professionals.

■ TRANSPORTING THE UNIT

• When you finish cutting in one location and wish to continue

work in another spot, turn off the engine, and lift up the unit and

carry it paying attention for the blade.

• Never forget to place the protective cover over the blades.

• When transporting the unit over long distances, detach the

blade fix the unit by ropes.

IMPORTANT

OPT11

12. Optional blade usage

areas of dense growth.

d. Keep the blade sharp. A dull blade

increase the chance of blade thrust.

e. Avoid feeding the blade too rapidly.

The blade can bounce away from

material being cut if the blade is fed

faster than its cutting capability.

f. Cut only from your right to your left.

g. Keep your path of advance clear of

material that has been cut and other

debris.

3. How you can maintain the best

control:

a. Keep a good, firm grip on the unit

with both hands. A firm grip can

help neutralize bounce. Keep your

right and left hands completely

around the respective handles.

b. Keep both feet spread apart in a

comfortable stance and yet braced

for the possibility that the unit could

bounce. Do not overreach. Keep

firm footing and balance.

Page 22

US-20

TR2350S

13. Troubleshooting guide

Case 1. Starting failure

CHECK PROBABLE CAUSES ACTION

fuel tank ➞ incorrect fuel ➞ drain it and with correct fuel

fuel filter ➞ fuel filter is clogged ➞ clean

carburetor adjustment screw ➞ out of normal range ➞ adjust to normal range

sparking (no spark) ➞ spark plug is fouled/wet ➞ clean/dry

➞ plug gap is incorrect ➞ correct (GAP: 0.6 – 0.7 mm)

spark plug ➞ disconnected ➞ retighten

Case 2. Engine starts but does not keep running/Hard re-starting.

CHECK PROBABLE CAUSES ACTION

fuel tank ➞ incorrect fuel or staled fuel ➞ drain it and with correct fuel

carburetor adjustment screw ➞ out of normal range ➞ adjust to normal range

muffler,cylinder (exhaust port) ➞ carbon is built-up ➞ wipe away

air cleaner ➞ clogged with dust ➞ wash

cylinder fin, fan cover ➞ clogged with dust ➞ clean

When your unit seems to need further service, please consult with our service shop in your area.

Page 23

Page 24

Page 25

FR-1

TR2350S

F

R

MODE D’EMPLOI

DEBROUSSAILLEUSE

848-J7G-93A0 (901)

AVERTISSEMENT

AVERTISSEMENT

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.

Avant d’utiliser cette

ce produit

,

veuillez lire attentivement ce

manuel afin de bien comprendre le

bon fonctionnement de cet

appareil.

TR2350S

NUMEROS DE SERIE APPLICABLES :

BOITE DE COMMANDES 90200101 et au-delà

MOTEUR 90200101 et au-delà

Page 26

FR-2

TR2350S

SECURITE

Les instructions contenues dans les

mises en garde de ce mode d’emploi

portant le symbole concernent les

points critiques qui doivent être pris en

considération pour éviter les blessures

corporelles graves, c’est pourquoi ces

précautions doivent être rigoureusement

suivies.

■ DIFFERENTS TYPES

D’AVERTISSEMENT DE CE MODE

D’EMPLOI

Les instructions repérées par ce symbole

doivent être rigoureusement suivies afin

d’éviter tout accident pouvant entraîner des

blessures corporelles graves ou la mort.

Les instructions repérées par ce symbole

doivent être suivies afin d’éviter tout incident

mécanique, panne ou endommagement de la

débroussailleuse.

Remarques utilisées dans des instructions ou

conseils supplémentaires pour l’utilisation de

cette débroussailleuse.

REMARQUE

1. Emplacement des composants ..........................................3

2. Caracteristiques..................................................................3

3. Etiquettes d’avertissement placées sur la machine............4

4. Symboles utilises sur la machine .......................................4

5. Consignes de securite........................................................5

6. Assemblage........................................................................9

7. Carburant..........................................................................10

8. Fonctionnement................................................................13

9. Entretien ...........................................................................15

10. Rangement.......................................................................17

11. Mise au rebut....................................................................17

12. Utilisation de la lame optionnelle......................................18

13. Guide de localisation des pannes.....................................21

Tables des matieres

1. Lire ce manuel attentivement jusqu’à

une compréhension totale et suivre

toutes les instructions de sécurité et

d’utilisation.

2. Conserver ce mode d’emploi à portée de

la main pour le consulter au moindre

doute. Si une question reste sans

réponse, contacter le revendeur où vous

avez acheté la produit.

3. Ne pas oublier de donner le manuel

avec la machine en cas de revente ou de

prêt.

4. Joignez toujours le manuel du

propriétaire quand vous prêtez ou louez

votre machine.

5. Assurez-vous que les personnes qui

utilisent l’appareil connaissent les

informations contenues dans le manuel.

6. Ne laissez jamais les enfants de moins

de 13 ans se servir de la machine.

AVERTISSEMENT

AVERTISSEMENT

IMPORTANT

Page 27

FR-3

TR2350S

F

R

1. Emplacement des pieces

1. Poignée

2. Point de suspension

3. Interrupteur d’arrêt

4. Câble d’accélérateur

5. Gâchette de la commande de vitesse

6. Tube d’arbre

7. Protection d’accessoire de coupe

8. Tête avec fil de coupe

9. Boîtier du renvoi d’angle

10. Pare-étincelles du silencieux

11. Poignée de démarrage

12. Réservoir de carburant

13. D’amorçage

14. Levier de starter

15. Capot du filtre à air

2. Fiche technique

■ TR2350S

Dimensions totales (L x L x H) ································································································· 1753 x 226 x 307 mm

Poids à vide ···········································································································4,2 kg ((4,6 kg) contenir Tête à fil)

Moteur Type ········································································································· 2 temps à essence refroidi par air

Modèle ··············································································································································· G20LS

Cylindrée ··········································································································································21,7 cm

3

Puissance maximale····················································································· 0,95 CV (0,71kW) à 7000 t/mn

Vitesse de ralenti················································································································· 3000 ± 200 t/mn

Carburant ····································································································· Mélange (essence 50 : huile 1)

(Lors de l’utilisation de la véritable huile RedMax/ZENOAH)

Carburateur················································································································· Walbro à diaphragme

Bougie d’allumage ················································································································· NGK BPMR7A

Contenance du réservoir de carburant ············································································································· 0,50

Transmission············································································· Embrayage centrifuge, arbre de transmission rigide

Rapport de réduction ········································································································································· 1,462

Sens de rotation de la tête de coupe ······································································· Anti-horaire (vue de l’opérateur)

Accessoires standards

Tête à 2 fils, 4 po ······························································································································· 1 pièce

Lunettes de sécurité ···························································································································1 pièce

Trousse à outils ································································································································· 1 pièce

Ces spécifications peuvent être modifiées sans préavis.

Page 28

FR-4

TR2350S

3. Etiquettes d’avertissement sur la machine

(1) Lire le mode d’emploi avant d’utiliser cette machine.

(2) Porter un casque de sécurité, des lunettes de sécurité et un casque antibruit.

(3) Avertissement! Phénomène de rebond dangereux.

(4) Attention aux objets qui volent ou ricochent.

(5) Avertissement/Attention

(6) Interdire aux enfants ou à toute personne de s’approcher dans un rayon de 15 mètres de la

débroussailleuse.

Si les étiquettes d’avertissement se décollent, deviennent sales ou impossible à lire, commander de

nouvelles étiquettes auprès du revendeur pour les remplacer.

Ne pas modifier la débroussailleuse.

La garantie sera annulée si la débroussailleuse a été modifiée ou utilisée de manière non

conforme aux instructions de ce mode d’emploi.

AVERTISSEMENT

Des symboles en relief ont été placés sur la

machine pour assurer la sécurité à l’usage et faciliter

l’entretien. Prendre soin d’observer les indications

suivantes afin d’éviter les erreurs.

(a) Emplacement de remplissage du “MELANGE”

Emplacement: BOUCHON DU RESERVOIR DE

CARBURANT

(b) Position fermée du starter

Emplacement: CAPOT DU FILTRE A AIR

(c) Position ouverte du starter

Emplacement: CAPOT DU FILTRE A AIR

4. Symboles utilises sur la machine

*1: L'année changera chaque année de la fabrication.

*2: Le nombre initial changera chaque année de la fabrication.

*3: SP : Réservoir hermétique en HDPE ou PE.

■ MESURES DE LUTTE CONTRE LES EMISSIONS

Une étiquette de mesures de lutte contre les émissions se trouve

sur le moteur.

15

m

(50ft)

(1)(

2

)(

3

)(

4

)(

5

)(

6

)

Information de controle des émissions

Utilise JASO FD ou ISO L-EGD 50:1 Huile.

Ce moteur est conforme aux règlements sur les émissions

de gaz U.S. EPA et californie EXH / EVP pour

2009*1

S.O.R.E.

Type de moteur :

9HQZS.0224BF*2 Cylindree :

22cc

Système de contrôle des émissions :

EXH;EM / EVP;SP*

3

Période de conformité : 50 heures

Se référer au manuel de l’opérateur pour l’entretien, les

spécifications et les réglages.

Fabrique Par:

ZENOAH AMERICA INC.

IMPORTANT

Page 29

FR-5

TR2350S

F

R

• Utilisés de manière négligente ou

erronée, les débroussailleuses et les

coupe-herbes peuvent devenir des

outils dangereux pouvant occasionner

des blessures graves, voire mortelles

pour l'utilisateur ou d'autres. Il est très

important de lire attentivement et de

bien comprendre les instructions

contenues dans ce mode d'emploi.

• Ne jamais modifier sous aucun prétexte

la machine sans l'autorisation du

fabricant. N'utiliser que des accessoires

et des pièces d'origine. Des

modifications non-autorisées et l'emploi

d'accessoires non-homologués peuvent

provoquer des accidents graves et

même mortels, à l'utilisateur ou d'autres

personnes.

• Lorsque vous tracez votre plan de

travail, prévoyez suffisamment de

pauses. Limitez les durées d’utilisation

prolongée de l’appareil à 30 ou 40

minutes par séance, avec des temps de

pause de 10 à 20 minutes entre

chacune. Essayez également de ne pas

utiliser la machine plus de 2 heures par

jour en tout.

•Si ce plan de travail et cette méthode de

travail ne sont pas respectés, un

accident dû au stress répétitif peut se

produire (voir p5).

Si l’on ressent un malaise ou si les

doigts ou tout autre membre rougissent

et enflent, consulter un docteur avant

que cela ne s’aggrave.

■ Règles de sécurité élémentaires

1. N’utilisez jamais le produit si vous êtes

fatigué(e), malade ou contrarié(e), ou

encore sous l’influence de l’alcool, de

drogues ou de médicaments provoquant

un état de somnolence.

2. Ne jamais utiliser la machine dans les

conditions suivantes:

a) Lorsque le sol est glissant ou lorsqu’il

est impossible de se maintenir dans

une position correcte.

b) La nuit, par temps de brouillard ou

lorsque la visibilité ou le champ de

vision empêche de voir clairement la

zone de travail.

c) Pendant les averses, les orages avec

éclairs, par grands vents ou toute autre

condition climatique rendant l’utilisation

de la machine dangereuse.

AVERTISSEMENT

5. Consignes de securite

3. Portez le matériel de protection suivant

lorsque vous utilisez le produit :

a) Un casque homologué pour vous

protéger des chutes d’objets

hasardeuses.

b) Un protège-oreilles homologué afin de

réduire le risque de perte d’audition.

c) Des lunettes et des chaussures de

protection homologuées (ANSI Z87.1.)

pour réduire le risque de blessures

associé à la projection des objets

balayés par le produit.

d) Un masque de protection anti-

poussières pour éviter les risques de

problèmes liés a l’inhalation de

poussières.

e) Portez des chaussures robustes avec

des semelles en caoutchouc ou

composées d’autres matières

antidérapantes, limitant ainsi les risques

de chute.

f) Portez des gants anti-vibrations épais

pour réduire le risque de développer la

maladie des doigts blancs.

g) Ne portez pas de vêtements larges,

foulards, colliers et attachez vos

cheveux s’ils sont longs, etc. afin

d’éviter le risque d’aspiration vers

l’entrée d’air et les parties rotatives de

l’appareil. Le matériel de protection

n’élimine pas totalement les risques de

blessures mais contribue à limiter leur

gravité.

4. Le système d’allumage de votre appareil

émane un champ électromagnétique de

très faible intensité, mais qui peut dérégler

les stimulateurs cardiaques. Avant

d’utiliser l’appareil, les personnes munies

d’un simulateur cardiaque sont priées de

consulter un médecin et le fabricant du

simulateur afin de se renseigner sur les

risques d’accidents mortels.

5. La zone dans un rayon de 15 mètres

autour de l’opérateur est considérée

comme dangereuse et personne ne doit

s’y trouver. Si nécessaire, délimiter le

périmètre de la zone de travail avec du

ruban de marquage (rouge fluorescent et

blanc par exemple) et poser des panneaux

d’avertissement. Lorsque deux ou

plusieurs personnes travaillent ensemble

ou à proximité, chacune doit constamment

faire attention et garder ses distances par

rapport aux autres pour assurer une

sécurité satisfaisante.

6. Evitez d’utiliser la produit lorsque vous

n’êtes pas sur un support ferme ou lorsque

Page 30

FR-6

TR2350S

vous êtes en déséquilibre.

7. Tout entretien du produit autre que celui

décrit dans le mode d’emploi doit être

effectué par du personnel compétent

(l’entretien inapproprié du ventilateur ou de

l’échappement du produit risque de causer

une panne de l’appareil).

8. Toujours arrêter le moteur avant de poser

la produit.

9. La produit ne doit être utilisée qu’en plein

air ou dans un local bien ventilé. Ne jamais

mettre en marche ou laisser tourner le

moteur dans un local fermé. Les gaz

d’échappement sont dangereux car ils

contiennent du monoxyde de carbone.

10. Ne touchez pas la bougie d’allumage ou

le fil de la prise lorsque le moteur tourne.

Vous risquez de recevoir un choc

électrique.

11.Ne touchez pas le silencieux, la bougie

d'allumage, les autres pièces métalliques

ou le capot moteur lorsque le moteur

tourne ou vient d'être arrêté. Ces pièces

et le capot moteur atteignent des

températures élevées et vous risqueriez

de vous brûler sérieusement.

12. Arrêtez le moteur avant de poser ou

déposer un accessoire, afin d’éviter les

risques de blessure dus au contact des

pièces rotatives de l’appareil. N’oubliez

pas de débrancher la bougie d’allumage

avant d’entamer une opération d’entretien

ou de retirer une pièce mobile.

■ AVANT DE FAIRE DEMARRER LE

MOTEUR

1. Chaque fois que vous utilisez l’appareil

avant de faire démarrer le moteur vérifiez

que tous les organes sont en bon état de

marche et bien fixés. N’utilisez pas la

produit avant d’avoir fait réparer les

anomalies que vous aurez pu constater sur

le circuit de carburant, le circuit

d’échappement ou les fils électriques.

2. Avant de mettre l’appareil en marche,

assurez-vous que l’accessoire de coupe

et la protection contre les débris soient

installés correctement et attachés

fermement.

3. Si la tête de coupe est la lame en métal,

changez la protection et utilisez comme

indiqué dans le mode d’emploi (voir p. ??).

4. Vérifier constamment l’état de la zone de

travail pour éviter tout accident dû aux

impacts avec des obstacles tels que les

AVERTISSEMENT

5. Consignes de securite

souches, les pierres, les boîtes de

conserves ou débris de verre.

Retirer tout obstacle avant de commencer le

travail.

■ DEMARRAGE DU MOTEUR

1. Empêcher toute personne ou animal de

s’approcher à moins de 15 mètres. Si

quelqu’un s’approche trop près, arrêter

aussitôt le moteur.

2. La machine est équipée d’un embrayage

centrifuge et l’outil de coupe se met à

tourner dès que le moteur est mis en route

en plaçant l’accélérateur en position de

démarrage. Pour mettre le moteur en

route, poser et maintenir fermement la

machine à plat sur le sol dans un endroit

dégagé où aucun obstacle ne peut entrer

en contact avec l’outil de coupe ou la

manette d’accélérateur une fois que le

moteur sera en marche.

Veiller à ce que la manette de

l’accélérateur est au ralenti.

Ne jamais mettre la manette de

l’accélérateur à fond ou à moitié

enclenchée (Position de verrouillage de la

manette) lors de la mise en marche.

3. Une fois le moteur en marche, vérifier que

l’outil de coupe s’arrête de tourner lorsque

l’accélérateur est remis à zéro. Si l’outil de

coupe continue à tourner, couper le moteur

et rapporter l’appareil chez votre revendeur

Red Max agréé afin de le faire réparer.

■ UTILISATION DU PRODUIT

Ne couper avec la machine que les

matériaux recommandés par le fabricant.

1. Tenir les poignées de la machine

fermement des deux mains. Ecarter

légèrement les jambes (pour que les pieds

reposent sur une largeur un peu plus

importante que celle des épaules) et avoir

une posture de travail stable et répartir le

poids du corps également sur chaque

jambe.

2. Maintenir l’outil de coupe toujours plus bas

que le niveau de la taille.

3. Faire tourner le moteur à la vitesse

IMPORTANT

IMPORTANT

AVERTISSEMENT

Page 31

FR-7

TR2350S

F

R

5. Consignes de securite

appropriée à la coupe sans jamais

accélérer inutilement au dessus du niveau

nécessaire.

4. Arrêtez immédiatement le produit si vous

détectez des vibrations ou des bruits

anormaux en cours d’utilisation et vérifiez

que rien ne soit cassé. Si une panne se

produit, n’utilisez plus l’appareil jusqu'à ce

qu’il soit réparé.

5. Se tenir à distance de l’outil de coupe ou

des parties chaudes de la machine.

6. Il faut se préserver des situations

dangereuses à tout moment. Avertir les

adultes de maintenir les enfants et les

animaux à distances car le risque de

recevoir des projections d’objet est

important.

7. Si quelqu’un appelle ou interrompt le

travail d’une manière ou d’une autre,

arrêter le moteur avant de se tourner vers

la personne.

8. NETTOYEZ la produit et les accessoires

après usage.

■ TRANSPORT

1. Vidanger le carburant avant de transporter

ou stocker la produit.

2. Lorsque vous transportez l’appareil à la

main, recouvrir la partie coupante si

nécessaire, soulever le produit et le porter

en faisant attention à la lame.

3. Bien mettre la produit en place durant son

transport.

4. La produit risque d’être endommagée ou

de tomber en panne si elle subit des chocs

violents durant le transport ou lorsqu’elle

est chargée et déchargée.

■ Sécurité carburant

1. Observer les précautions d’usage avec le

carburant. Essuyer immédiatement

l’essence répandue et éloigner le bidon

d’essence d’au moins 3 mètres avant de

mettre le moteur de la produit en marche.

2. Ne tolérer aucun flamme ou source

d’étincelles à proximité de l’endroit où est

entreposée l’essence et pendant la

préparation du mélange ou le remplissage

du réservoir. (S’abstenir de fumer, de faire

du feu ou d’utiliser un outil produisant des

étincelles.)

3. Ne jamais fumer en manipulant l’essence

ou en utilisant la produit.

4 Ne faites pas le plein quand le moteur est

chaud.

5 Ne faites pas le plein quand le moteur

tourne.

6. Veillez à ce que les manettes soient

sèches, propres, et tenues à l’écart de

l’huile et du carburant.

7. Stockez toujours le carburant dans un

réservoir homologué prévu à cet effet.

■ Rangement

1. Rangez toujours le produit et le carburant

après chaque utilisation afin d’éviter les

risques de fuite ou que des vapeurs

entrent en contact avec des étincelles ou

des flammes provenant d’appareils

électriques, de moteurs électriques, de

relais/commutateurs, de chauffe-eau, etc.

2. Videz le réservoir à carburant avant de le

ranger pour une période de longue durée.