Page 1

115 37 30-10 (003)

U

S

F

R

E

S

OWNER'S/OPERATOR'S

MANUAL

MODE D’EMPLOI MANUAL DE

INSTRUCCIONES

SHORT REACH

TRIMMER

TAILLE HAIE DE

COURTE PORTÉE

PODADERA DE

CORTO ALCANCE

SRTZ2460F

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

Before using our products,

please read this manual carefully

to understand the proper use of

your unit.

Los gases de escape del motor de

este producto contienen

sustancias químicas conocidas

por el Estado de California como

causantes de cáncer,

malformaciones en recién nacidos

y otros problemas de

reproducción.

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.

Antes de usar nuestros productos,

lea detenidamente este manual a

fin de familiarizarse con el uso

correcto de este aparato.

Avant d’utiliser cette

ce produit

,

veuillez lire attentivement ce

manuel afin de bien comprendre le

bon fonctionnement de cet

appareil.

This spark ignition system complies with

the Canadian standard ICES-002.

Ce système d’allumage par étincelle de véhicule

est conforme à la norme NMB-002 du Canada.

Este sistema de ignición por chispa de vehículo

es conforme con la norma ICES-002 del Canadá.

Page 2

US-1

SRTZ2460F

U

S

115 37 30-10 (003)

OWNER'S/OPERATOR'S

MANUAL

SHORT REACH

TRIMMER

SRTZ2460F

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING

Before using our products,

please read this manual carefully

to understand the proper use of

your unit.

This spark ignition system complies with

the Canadian standard ICES-002.

Page 3

US-2

SRTZ2460F

SAFETY FIRST

Instructions contained in warnings within

this manual marked with a symbol

concern critical points which must be

taken into consideration to prevent

possible serious bodily injury, and for this

reason you are requested to read all such

instructions carefully and follow them

without fail.

■ WARNINGS IN THE MANUAL

This mark indicates instructions which must

be followed in order to prevent accidents

which could lead to serious bodily injury or

death.

This mark indicates instructions which must

be followed, or it leads to mechanical failure,

breakdown, or damage.

This mark indicates hints or directions useful

in the use of the product.

NOTE

1. Parts location......................................................................3

2. Specifications .....................................................................3

3. Warning labels on the machine ..........................................4

4. Symbols on the machine ....................................................4

5. For safe operation ..............................................................5

6. Set up .................................................................................8

7. Fuel.....................................................................................9

8. Operation..........................................................................11

9. Maintenance.....................................................................13

10. Storage.............................................................................15

11. Disposal............................................................................15

12. Troubleshooting guide......................................................16

Contents

1. Read this Owner/Operator Manual

carefully. Be sure you understand how

to operate this unit properly before you

use it. Failure to do so could result in

serious injury.

2. Be sure to keep this manual handy so

that you may refer to it later whenever

any questions arise. Also note that you

are requested to contact the dealer from

whom you purchased the product for

assistance the event that you have any

questions which cannot be answered

herein.

3. Always be sure to include this manual

when selling, lending, or otherwise

transferring the ownership of this

product.

4. Do not lend or rent your machine

without the owner's manual.

5. Be sure that anyone using your unit

understands the infomation contained in

this manual.

6. Never let a child under 13 years old use

the machine.

WARNING

INFORMATION

This machine is equipped with an Overload

Cancellation Mechanism.

When the cutting blades have got into metal

wires or twigs difficult to cut, the mechanism

works as a shock absorber, and protects the

gears and the blades from severe reaction

which could give damage to those parts.

When the blades are frequently caught by

twigs, please check the following points:

1. Size of the twigs. Never try to cut twigs

thicker than 3/16" (5 mm).

2. Condition of the blade edges. Replace

the worn-out blades.

Thank you for choosing our product.

WARNING

IMPORTANT

Page 4

US-3

SRTZ2460F

U

S

1. Parts location

2. Specifications

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1. Loop handle

2. Shoulder strap hanger

3. Stop switch

4. Throttle cable

5. Throttle trigger

6. Shaft tube

7. Blade

8. Gear case

9. Spark arrester

10. Starter knob

11. Fuel tank

12. Primer

13. Choke lever

14. Air cleaner cover

■ SRTZ2460F

Overall size ( L x W x H )····································································68.3 (1735) x 8.9 (225) x 10.0 (255) in. (mm)

Dry Weight w/o acc. ······················································································································13.6 (6.2) lbs (kg)

Engine Type·············································································Air cooled 2-stroke gasoline engine

Model······················································································································· GZ23N

Displacement ······················································································1.5 (23.6) cu-in (cm

3

)

Max. output ····························································1.15 Hp (0.858 kW) at 8000/min

-1

(rpm)

Idle speed····························································································3000±200/min

-1

(rpm)

Fuel ·························································································Mixture (Gasoline 50 : Oil 1)

(when using RedMax genuine oil)

Carburetor ······················································································Walbro Diaphragm type

Spark Plug······································································································NGK CMR7H

Fuel tank capacity ·························································································································21.3 fl.oz (0.63 )

Transmission ··················································································Centrifugal clutch, spiral bevel gear, cam crank

Reduction ratio ·····················································································································································4.0

Durability period·············································································································································300hrs.

Standard operation speed················································································································6000~9000 rpm

Cutting head Type·························································································Reciprocating Double blade

Tooth·······················································································································26 teeth

Pitch·········································································································1.38 (35) in. (mm)

Effective cut width··················································································16.5 (420) in. (mm)

Standard Accessories Shoulder strap ···············································································································1 pc

Goggle···························································································································1 pc

Tool Kit ··························································································································1 pc

Blade Cover···················································································································1 pc

Specifications are subject to change without notice.

Page 5

US-4

SRTZ2460F

3. Warning labels on the machine

For safe operation and maintenance, symbols

are carved in relief on the machine. According

to these indications, please be careful not to

take a mistake.

(a) The port to refuel the "MIX GASOLINE"

Position: FUEL TANK CAP

(b) The direction to close the choke

Position: AIR CLEANER COVER

(c) The direction to open the choke

Position: AIR CLEANER COVER

4. Symbols on the machine

*1: The year will be changed every year of manufacturing.

*2: The initial will be changed every year of manufacturing.

*3: SP : Sealed tank made of HDPE or PE.

USE JASO FD OR ISO L-EGD GRADE 50:1 OIL

MANUFACTURED:

THIS ENGINE MEETS U.S. EPA AND CALI FORNIA EXH / EVP REGS FOR

2010*1

S.O.R.E.

ENGINE FAMILY :

AHQZS.0244BV*2 DISPL.:

24cc

EMISSION CONTROL SYSTEM :

EXH;EM/EVP;SP*

3

COMPLIANCE PERIOD : 300 HOURS

REFER TO OPERATOR'S MANUAL FOR MAINTENANCE, SPECIFICATIONS AND ADJUSTMENTS.

EMISSION CONTROL INFORMATION

■ EMISSION CONTROL

An emission control label is located on the engine.

(1) Read owner's manual before operating this machine.

(2) Wear head, eye and ear protection.

(3) Warning/Attention

If warning label peel off or become soiled and impossible to read,

you should contact the dealer from which you purchased the

product to order new labels and affix them in the required

location(s).

Never modify your machine.

We won't warrant the machine, if you use the remodeled

machine or you don't observe the proper usage written in the

manual.

WARNING

IMPORTANT

Page 6

US-5

SRTZ2460F

U

S

•A brushcutter or trimmer can be

dangerous if used incorrectly or

carelessly, and can cause serious or

fatal injury to the operater or others. It

is extremely important that you read

and understand the contents of this

Owner's manual.

• Under no circumstances may the

design of the machine be modified

without the permission of the

manufacturer. Always use genuine

accessories and parts. Non-authorized

modifications and/or accessories or

parts can result in serious personal

injury or the death of the operator or

others.

• When planning your work schedule,

allow plenty of time to rest. Limit the

amount of time over which the product

is to be used continuously to

somewhere around 30 ~ 40 minutes per

session. Also try to keep the total

amount of work performed in a single

day under 2 hours or less.

• If you don’t observe the working time,

or working manner (See p5), Repetitive

Stress Injury(RSI) could occur.

If you feel discomfort, redness and

swelling of your fingers or any other

part of your body, see a doctor before

getting worse.

■ Basic safety rules

1. Never operate the product when you are

fatigued, ill, or upset, or under the

influence of madication that may make you

drowsy, or if you are under the influence

of alcohol or drugs.

2. Never use the product;

a: When the ground is slippery or when

you can't maintain a steady posture.

b: At night, at times of heavy fog, or at any

other times when your field of vision

might be limited and it would be difficult

to gain a clear view of the working area.

c: During rain storms, during lightning

storms, at times of strong or gale-force

winds, or at any other times when

weather conditions might make it

unsafe to use the product.

3. Wear the following protective equipments

when operating the product.

a: Approved helmet to reduce the risk of

falling objects.

WARNING

5. For safe operation

b: Approved ear protection to reduce the

risk of hearing loss.

c: Approved (ANSI Z87.1.) eye protection

and foot protection to reduce the risk of

injury associated with thrown objects.

d: Face filter mask in dusty conditions to

reduce the risk of injury associated with

the inhalation of dust.

e: Wear sturdy rubber-soled shoes or

shoes with some other form of anti-slip

protection to help protect you against

falling.

f: Wear thick anti-vibration gloves to

reduce the risk of whitefinger disease.

g: Do not wear loose clothing, scarves,

neck chains, unconfineed long hair, and

like to reduce the risk of injury

associated with objects being drawn into

air intake and rotating parts.

Personal protective equipment cannot

eliminate the risk of injury but it will reduce

the degree of injury.

4. The ignition system of your unit produces

an electromagnetic field of a very low

intensity. This field may interfere with some

pacemakers. To reduce the risk of serious

or fatal injury, persons with pacemaker

should consult their physician and the

pacemaker munufacturer before operating

this tool.

5. The area within a perimeter of 50 feet (15

meters) of the person using the product

should be considered a hazardous area

into which no one should enter. If

necessary yellow warning rope, warning

signs should be placed around the

perimeter of the area.

When work is to be performed

simultaneously by two or more persons,

care should also be taken to constantly

look around or otherwise check for the

presence and locations of other people

working so as to maintain a distance

between each person sufficient to ensure

safety.

6. Avoid using the product where stable

footing and balance are not assured.

7. All product service, other than the items

listed in the Owner's Manual, should be

performed by competent service

personnel.

8. Always shut off the engine before setting it

down.

9. Start the engine only in well ventilated

areas. Never start or run the engine inside

a closed room or building and potentially

explosive atmosphere. Exhaust fumes

Page 7

US-6

SRTZ2460F

contain dangerous carbon monoxide.

10. Never to touch the spark plug or plug cord

while the engine is in operation Doing so

may result in being subjected to an

electrical shock.

11.Never to touch the muffler, spark plug,

other metallic parts of the engine or

engine cover while the engine is in

operation or immediately after shutting

down the engine. These metallic parts

and engine cover reach high

temperatures during operation and doing

so could result in serious burns.

12.To reduce the risk of injury associated

with contacting rotating parts, stop the

engine before installing or removing

attachments. Always disconnect the spark

plug before performing maintenance or

accessing movable parts.

■ Before use

1. Each time before starting the engine,

inspect the entire unit to see if every part

is in good order and is securely tightened

in place. If any damage is found in the fuel

line, the exhaust line, or the ignition wiring,

do not use the product until it has been

repaired.

Remove any obstacle before beginning work.

■ Starting the engine

1. Keep bystanders and animals at least 50

feet (15 meters) away from the operating

point. If you are approached, immediately

stop the engine.

2. The product is equipped with centrifugal

clutch mechanism, so the cutting

attachment could move as soon as the

engine is started. When starting the

engine, place the product onto the ground

in a flat clear area and hold it firmly in

place so as to ensure that neither the

cutting part nor the throttle come into

contact with any obstacle when the engine

starts.

Make sure the throttle is at idle position.

Never place the throttle into the high

speed position or half throttle position

(throttle lock position) when starting the

engine.

3. After starting the engine, check to make

sure that the cutting attachment stops

WARNING

5. For safe operation

moving when the throttle is moved fully

back to its original position (idle position). If

it continues to move even after the throttle

has been moved fully back, turn off the

engine and take the unit to your authorized

RedMax servicing dealer for repair.

■ Using the product

Cut only materials recommended by the

manufacturer. And use only for tasks

explained in the manual.

1. Maintain the speed of the engine at the

level required to perform cutting work, and

never raise the speed of the engine above

the level necessary.

2. If you detect abnormal vibration or noise

during operation, promptly stop the product

and check whether something has broken.

If a breakedown has occurred, do not

operate the product until the problem is

fixed.

3. Keep all parts of your body away from

moving cutting attachment.

4. Guard against hazardous situations at all

times. Warn adults to keep pets and

children away from the area. Be careful if

you are approached. Injury may result from

flying debris.

5. If someone calls out or otherwise interrupts

you while working, always be sure to turn

off the engine before turning around.

6. After using the product and other

equipment, CLEAN UP!

■ Transport

1. Drain the fuel from the fuel tank before

transporting or storing the product.

2. When hand-carrying the product, cover

over the cutting part, lift up the product and

carry it paying attention to the blade.

3. Secure the unit carefully to prevent

movement when it is transported.

4. A unit that receives a strong shock during

transport and unloading may malfunction.

■ Fuel safety

1. Always use caution when handling fuel. It

is highly flammable. Wipe up all spills,

screw the fuel cap back tightly, and then

move the product at least 10 feet (3

meters) from the fueling point before

starting the engine.

2. Eliminate all sources of sparks or flame

(i.e. smoking, open flames, or work that

can cause sparks) in the areas where fuel

IMPORTANT

IMPORTANT

Page 8

US-7

SRTZ2460F

U

S

5. For safe operation

is mixed, poured, or stored.

3. Do not smoke while handling fuel or while

operating the product.

4. Do not refuel a hot engine.

5. Do not refuel a running engine.

6. Keep the handles dry, clean and free of oil

or fuel mixture.

7. Always store fuel in an approved container

designed for that purpose.

■ Storage

1. Always store the product and fuel so that

there is no risk of leakages or fumes

coming into contact with sparks or naked

flames from electrical equipment, electric

moters, relays/switches, boilers and the

like.

2. When storing the product, the fuel tank

should be emptied.

3. When storing the product, choose a space

indoors free from moisture and out of the

reach of children.

■ Avoid noise problem

Check and follow the local regulations as to

sound level and hours of operations for the

product.

1. Operate power equipment only at

reasonable hours not early in the morning

or late at night when people might be

disturbed. Comply with times listed in local

ordinances.

2. To reduce sound levels, limit the number of

pieces of equipment used at any one time.

3. Operate the product at the lowest possible

throttle speed to do the job.

4. Check your equipment before operation,

especially the muffler, air intakes and air

filters.

■ For protecting your body from vibration

Prolonged use of the product, exposing

the operater to vibrations and cold may

produce whitefinger disease (Raynaud's

phenomenon), which symptoms are

tingling and burning sensations followed

by loss of color and numbness in the

fingers.

All factors which contribute to whitefinger

disease are not known, but cold weather,

smoking diseases or physical conditions

as well as long periods of exposure to

vibration are mentioned as factors. In

WARNING

order to reduce the risk of whitefinger

disease, the following precautions are

strongly recommended.

a: Keep your body warm. Never use the

product during rains.

b: Wear thick anti-vibration gloves.

c: Take more than 5 minutes of break in

warm place frequently.

d: Maintain a firm grip at all times, but do not

squeeze the handles with constant,

excessive pressures.

e: If you feel discomfort, redness and swelling

of your fingers or any other part of your

body, see a doctor before getting worse.

■ Maintenance

1. In order to maintain your product in proper

working order, perform the maintenance

and checking operations described in the

manual at regular intervals.

2. Always be sure to turn off the engine and

disconnect the spark plug before

performing any maintenance or checking

procedures.

The metallic parts and engine cover reach

high temperatures immediately after

stopping the engine.

3. Examine the product at intervals for loose

fasteners and rusted or damaged parts.

Use special care around the fuel line, the

muffler, and the ignition wiring.

4. When replacing the any other part, or any

lubricant, always be sure to use only

RedMax products or products which have

been certified by RedMax for use with the

RedMax product.

5. In the event that any part must be replaced

or any maintenance or repair work not

described in this manual must be

performed, please contact a representative

from the store nearest RedMax authorized

servicing dealer for assistance.

6. Do not use any accessory or attachment

other than those bearing the RedMax mark

and recommended for the unit.

7. Under no circumstances should you ever

take apart the product or alter it in any

way. Doing so might result in the product

becoming damaged during operation or the

product becoming unable to operate

properly.

■ Disposal

When disposing your machine, fuel or oil for

the machine, be sure to allow your local

regulations.

WARNING

IMPORTANT

Page 9

US-8

SRTZ2460F

6. Set up

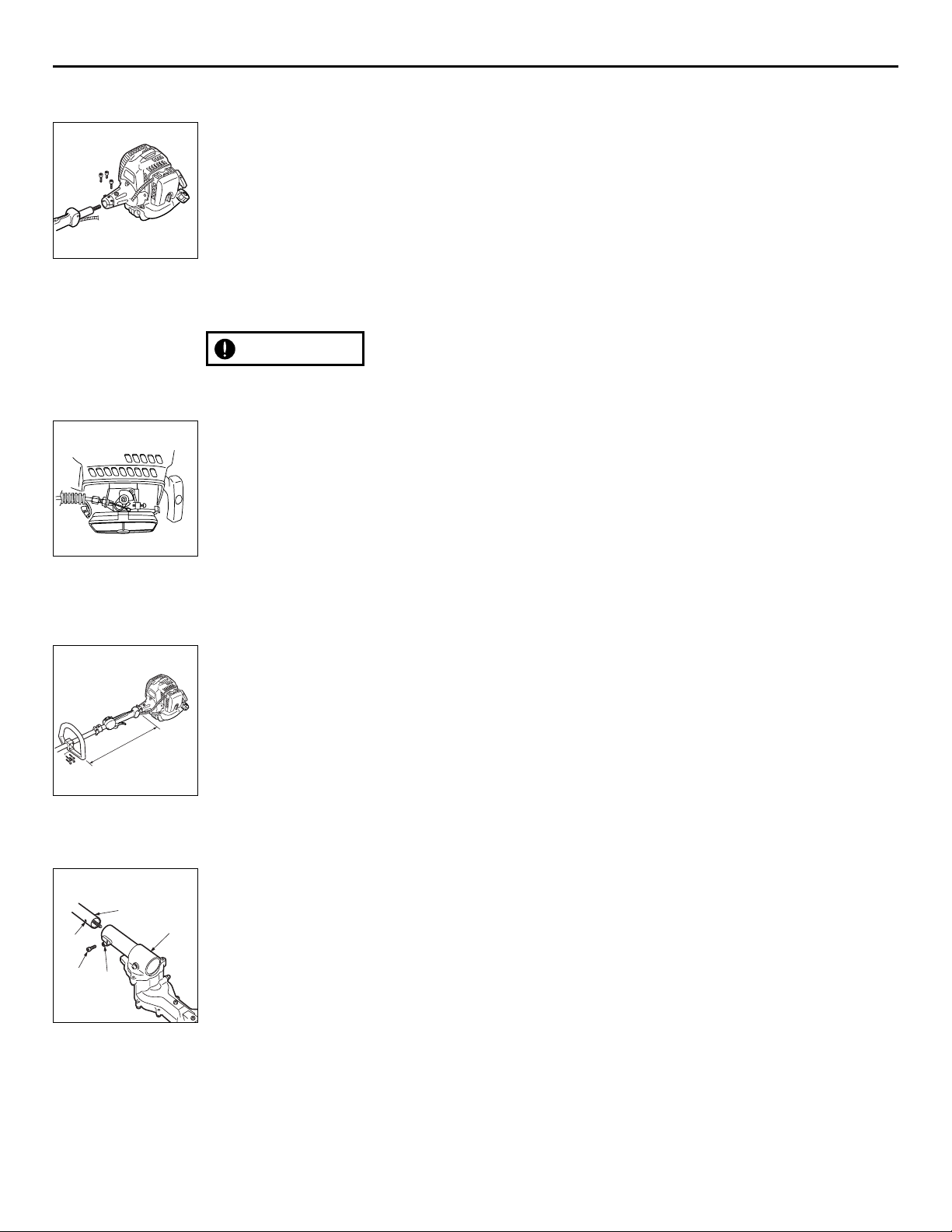

■ MOUNTING ENGINE (SE1)

1. Push the driveshaft housing toward the

clutch housing and rotate it by hand to

check that the driveshaft is engaged

with the gears.

2. Insert the driveshaft housing into the

clutch housing until it bottoms, and

align the positioning holes on the clutch

housing and the shaft tube and install

the screw. When difficult to engage,

twist the engine slightly.

3. Fasten the clamp securely with two

screws.

Tighten the screws gradually by turns.

■ CONNECTING THROTTLE WIRE

1. Remove the air cleaner cover.

2. Connect the end of the throttle wire to

the joint on the top of the carburetor.

(SE2)

■ CONNECTING SWITCH WIRES

• Connect the switch wires between the

engine and the main unit. Pair the wires

of the same color.

■ INSTALLING HANDLE

• Mount the handle to the shaft tube and

clamp it at a location that is comfortable

to you. (SE3)

(1) About 19 inches (48cm)

■ ATTACHING THE TRIMMING

MECHANISM (SE4)

1. Remove the screw screwed into the

end of the trimming mechanism.

2. Insert the end of the trimming

mechanism into the shaft tube.

3. Line up the hole on the end of the

trimming mechanism into which the

screw is to be inserted with the hole on

the shaft tube, and screw the screw

firmly in.

4. Using a wrench, screw in the bolt

provided to fix the trimming mechanism

into place.

(1) Shaft tube

(2) Trimming mechanishm

(3) Screw hole

(4) Bolt

(5) Fastening bolt

IMPORTANT

SE1

SE2

(1)

SE3

(5)

(4)

(3)

(2)

(1)

SE4

■ BALANCE UNIT

1. Put on strap and attach unit to strap.

2. Depending on the working posture,

slide clamp up or down until unit

balances and the strap fits your body.

Page 10

US-9

SRTZ2460F

U

S

lines or fuel tank of the engine.

• Failures caused by operating engines on gasoline with octane

rating lower than 89 are not covered

by the RedMax Two-

Stroke engine warranty.

•Alternative Fuels (Not Gasoline)

Alternative fuels, such as E-15 (15% ethanol), E-20 (20%

ethanol), E-85 (85% ethanol) are NOT classified as gasoline

and are NOT approved for use in RedMax 2-stroke gasoline

engines. Use of alternative fuels will cause major engine

performance and durability problems such as: improper

clutch engagements, overheating, vapor lock, power loss,

lubrication deficiency, deterioration of fuel lines, gaskets

and internal carburetor components, etc... Alternative fuels

cause high moisture absorption into the fuel/oil mixture

leading to oil and fuel separation.

■ OIL REQUIREMENTS

• Use only RedMax "Max Life", Synthetic blend Premium AirCooled two-stroke engine oil or oil certified to ISO-L-EGD

(ISO/CD1378) standard AND

one that is JASO-FD

registered.

RedMax Air-Cooled "Max Life", Synthetic blend Premium two

stroke engine oil and ISO-L-EGD

(ISO/CD1378) AND

JASO-FD

oils are fully compatible

with gasoline's containing 10% Ethanol.

RedMax Air-Cooled "Max Life", Synthetic blend Premium two

stroke engine oil and ISO-L-EGD

(ISO/CD1378) AND

JASO-FD

oils are Universal and should be mixed at 50:1 ratio for all 2

stroke air cooled engines sold in the past regardless of mixing

ratios specified in those manuals.

• If the oil is registered with JASO, the JASO Logo with FD

and

registration number

will be displayed on the container. The

highest JASO rating is "FD", which equals the ISO-L-EGD

rating. Lower ratings are "FC", "FB", and "FA".

• Engine problems due to inadequate lubrication caused by

failure to use ISO-L-EGD

certified and JASO FD registered oil

such as "MaxLife", RedMax Synthetic blend Premium 2-stroke

oil WILL VOID THE REDMAX TWO-STROKE ENGINE

WARRANTY.

• Do not use NMMA (National Marine Manufacturers

Association), BIA (Boating Industry Association), and TCW (two

cycle water cooled) oils designed for MoPeds or Outboard,

water cooled Marine Engines. Do not use API (American

Petroleum Institute), TC (Two Cycle) labeled oils. The API-TC

WARNING

7. Fuel

FUEL

• Gasoline is very flammable. Avoid smoking or bringing any

flame or sparks near fuel. Make sure to stop the engine and

allow it cool before refueling the unit. Select outdoor bare

ground for fueling and move at least 10 feet (3 m) away

from the fueling point before starting the engine.

■ GASOLINE REQUIREMENTS

• All 2-Stroke RedMax Products are powered by RedMax

Professional-Commercial Duty, Hi-Performance, Hi-RPM, Air

Cooled 2-Stroke engines.

RedMax – Hi-Performance 2-stroke engines produce higher HP

outputs as compared to standard Home Owner Duty or Light

Commercial Duty production engines offered by most

manufacturers.

• Exhaust emission are controlled by the fundamental engine

parameters and components (eq., carburation, ignition timing

and port timing) without addition of any major hardware or the

introduction of an inert material during combustion.

• The RedMax Engines are registered and certified with CARB

(California Air Resources Board) and EPA (Environmental

Protection Agency) to operate on CLEAN Mid-grade 89 octane

or Premium, unleaded (lead-free) gasoline and RedMax AirCooled "Max Life", Synthetic blend Premium two-stroke engine

oil mixed at 50:1 ratio.

• Unleaded gasoline is recommended to reduce the

contamination of the air for the sake of your health and the

environment.

• This Hi-Performance Air Cooled 2-stroke Engine requires the

use of Minimum

89 Octane (Mid grade or Premium)

clean gasoline. Gasoline may contain maximum of 10% Ethanol

(grain alcohol) or up to 15% MTBE (Methyl tertiary-butyl ether).

Gasoline containing Methanol (Wood Alcohol) is NOT

approved.

• IF octane rating of the Mid Grade

gasoline in your area is lower

than 89 Octane use Premium Unleaded Gasoline. The majority

of all 2-stroke engine manufacturers in the USA and Canada

recommend using gasoline with 89 Octane or higher.

• Gasoline with an octane rating lower than 89 will greatly

increase the engines operating temperature. Low octane

gasoline will cause detonation (knock) resulting in piston

seizures and major internal engine components damage.

• Poor quality gasolines or oils may damage sealing rings, fuel

WARNING

[ R+M ]

2

WARNING

NOTE

WARNING

NOTE

Page 11

US-10

SRTZ2460F

7. Fuel

test standard has been discontinued by API in 1995 and it no

longer exists.

• Gasoline/Oil mixture Storage Recommendations

Store your gasoline or gasoline/oil mixture in a cool dry area in

a tightly sealed approved container to limit the entry of moisture

and additional air (oxygen). Moisture and air cause the

development of varnish and gum, making the fuel stale. Stored

gasoline and gasoline/oil mixture ages and loses its octane

rating and volatility. Do not mix more gasoline/oil than you

intend to use in 30 days, and 60 days when fuel stabilizer is

added. RedMax Air-Cooled "Max Life" Synthetic blend

Premium two-stroke engine oil "Contains fuel stabilizer"

and

will automatically extend your gasoline/oil mixture life up to 60

days.

■ HOW TO MIX FUEL

RECOMMENDED MIXING RATIO

GASOLINE 50 : OIL 1

(when using RedMax Air-Cooled "Max

Life")

• Pay attention to agitation.

1. Measure out the quantities of gasoline and oil to be mixed.

2. Put some of the gasoline into a clean, approved fuel container.

3. Pour in all of the oil and agitate well for 10seconds.

4. Pour in the rest of gasoline and agitate again for at least one

minute. As some oils may be difficult to agitate depending on oil

ingredients, sufficient agitation is necessary. Be careful that, if

the agitation is insufficient, there is an increased danger of early

piston seizure due to abnormally lean mixture.

5. Place a clear indication on the outside of the container to avoid

mixing up with gasoline or other containers that dont contain oil.

6. Indicate the contents on outside of container for easy

identification.

■ FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the cap on a clean

surface.

2. Put fuel into the fuel tank to 80% of the full capacity.

3. Fasten the fuel cap securely and wipe up any fuel spillage

around the unit.

WARNING

1. Select flat and bare ground for fueling.

2. Move at least 10 feet (3 meters) away from the fueling point

before starting the engine.

3. Stop the engine before refueling the unit. At that time, be

sure to sufficiently agitate the mixed gasoline in the

container.

■ FOR YOUR ENGINE LIFE, AVOID

1. FUEL WITH NO OIL (RAW GASOLINE) – It will cause severe

damage to the internal engine parts very quickly.

2. GASOHOL – It can cause deterioration of rubber and/or plastic

parts and disruption of engine lubrication.

3. OIL FOR 4-CYCLE ENGINE USE – It can cause spark plug

fouling, exhaust port blocking, or piston ring seizure.

4. Mixed fuels which have been left unused for a period of

one month or more may clog the carburetor and result in the

engine failing to operate properly.

5. In the case of storing the product for a long period of time,

clean the fuel tank after rendering it empty. Next, Start the

engine and run the carburetor dry residual fuel.

6. In the case of scrapping the used mixed oil container, scrap it

only at an authorized depository site.

• As for details of quality assurance, read the description in the

section Limited Warranty carefully. Moreover, normal wear and

change in product with no functional influence are not covered

by the warranty. Also, be careful that, if the usage in the

instruction manual is not observed as to the mixed gasoline,

type of oil or fuel to be used. described therein, it may not be

covered by the warranty.

NOTE

50:1 MIXING CHART

GASOLINE gal. 1 2 3 4 5

2-CYCLE OIL fl.oz 2.6 5.2 7.8 10.4 13

GASOLINE liter 1 2 3 4 5

2-CYCLE OIL ml 20 40 60 80 100

IMPORTANT

WARNING

Page 12

US-11

SRTZ2460F

U

S

8. Operation

■ STARTING ENGINE

The cutting head will start rotating

upon the engine starts.

1. Rest the unit on a flat, firm place. Keep

the cutting head off the ground and

clear of surrounding objects as it will

start rotating upon starting of the

engine.

2. Push the primer pump several times

until overflown fuel flows out in the

clear tube. (OP1)

3. Move the choke lever to the closed

position. (OP2)

(1) choke lever

(2) close

(3) open

4. Set the stop switch to the "RUN"

position. Place the unit on a flat, firm

place. Keep the cutting head clear of

everything around it. (OP3)

(1) stop switch

(2) RUN

(3) STOP

(a) lockout lever

(b) throttle trigger

5. Firmly grasp (a) and (b) with left hand

(OP3), pull the starter knob quickly until

engine fires. Release throttle trigger

after engine starts. (OP4)

• Avoid pulling the rope to its end or

returning it by releasing the knob. Such

actions can cause starter failures.

6. Move the choke lever downward to

open the choke. And restart engine.

(OP2)

7. Allow the engine to warm up for several

minutes before starting operation.

IMPORTANT

OP1

(2)

(3)

(1)

OP2

(1)

(3)

(a)

(b)

(2)

OP3

OP4

.04 in

(1~2mm)

(1)

OP5

1. When restarting the engine

immediately after stopping it, leave the

choke open.

2. Overchoking can make the engine hard

to start due to excess fuel. When the

engine failed to start after several

attempts, open the choke and repeat

pulling the rope, or remove the spark

plug and dry it.

■ STOPPING ENGINE (OP3)

1. Release the throttle lever and run the

engine for a half minute.

2. Shift the stop switch to the "STOP"

position.

• Except for an emergency, avoid

stopping the engine while pulling the

throttle lever.

■ ADJUSTING THROTTLE CABLE

• The normal play is 1 or 2mm when

measured at the carburetor side end.

Readjust with the cable adjuster as

required. (OP5)

(1) cable adjuster

■ ADJUSTING IDLING SPEED (OP6)

1. When the engine tends stop frequently

at idling mode, turn the adjusting screw

clockwise.

2. When the cutting head keeps rotating

after releasing the trigger, turn the

adjusting screw counter-clockwise.

(1) idle adjusting screw

• Warm up the engine before adjusting

the idling speed.

• This product is equipped with

extremely sharp blades, and when

used improperly these blades can be

extremely dangerous, and improper

handling can cause accidents which

may in turn lead to serious injury or

death. For this reason, you should

always be careful to follow the

WARNING

OP6

NOTE

WARNING

IMPORTANT

(1)

NOTE

Page 13

US-12

SRTZ2460F

8. Operation

following instructions when using

your trimmer.

• Never hold the trimmer in a way in

which the blades are pointed

towards someone else.

• Never allow the blades to come into

proximity with your body while the

engine of the trimmer is in operation.

• Always be sure to turn off the engine

before changing the angle of the

blades, removing branches which

have become stuck in the blades, or

at any other time when coming into

close proximity with the blades.

• Always wear work gloves made of

leather or some other sturdy material

when using the trimmer.

• Always place the blade cover

provided with the trimmer over the

blades when not in use.

• Falling branches may fall onto the

face or into the eyes, resulting in

injuries, scratches, and cuts, and

for this reason you should always

be sure to wear a helmet and face

protector when using your

trimmer.

• The thickness of branches which may

be cut using this trimmer is limited to up

to approximately 3/16" (4.8mm). Never

try to cut branches thicker than this, as

doing so may result in damage to the

trimmer.

IMPORTANT

Page 14

US-13

SRTZ2460F

U

S

MA1

(1)

MA2

9. Maintenance

■ BLADES (MA1)

• When refilling the tank or resting, it is

often a good idea to use the time to oil

the cutting blades.

• If a gap exists between the upper and

lower blades, follow the procedure

below to adjust them so that they fit

more closely together.

1. Loosen lock nut (A) as shown in the

diagram.

2. Tighten screw (B) fully, and then turn

one-third to one-half of a rotation

backward.

3. While holding onto the screw to keep it

in position, tighten the lock nut.

4 .Check to make sure that the flat

washer (C) is loose enough so that it

may be turned by pressing on it with a

finger.

(1) Upper blade

(2) Lower blade

• Screwing in the screw too tightly may

make it impossible for the blades to

move. Conversely, not screwing in the

screw tightly enough may make the

blades of the trimmer feel dull and

cause leaves and branches to become

caught in the blades of the trimmer.

NOTE

QUICK TIP

If the blades become so worn down that it

is no longer possible to eliminate the gap

between them, you should contact the

authorized RedMax servicing dealer from

which you purchased your RedMax

trimmer to have the blades resharpened

or replaced.

■ GEAR CASE

The reduction gears are lubricated by

multipurpose, lithium-based grease in the

gear case. Supply new grease every 25

hours of use or more often depending on

the job condition.

When adding lubricant, use a grease gun

to insert lubricant into the three grease

nipples located on the gear case. (MA2)

TYPE OF LUBRICANT TO BE USED

Always be sure to use #2 lithium

heat-resistant lubricant.

(1) Grease fitting

■ MAINTENANCE CHART

Maintenance, replacement, or repair of the emission control device and systems may be performed by any

non-road engine repair establishment or individual.

every every every

25 50 100

system/compornent procedure before hours hours hours note

use after after after

fuel leaks, fuel spillage wipe out ✔

fuel tank, air filter, fuel filter inspect/clean ✔✔ replace, if necessary

see ■ADJUSTING replace carburetor

idle adjusting screw ✔

IDLING SPEED (p.11) if necessary

clean and readjust GAP: .025in(0.6~0.7mm)

spark plug ✔

plug gap replace, if necessary

cylinder fins, intake air cooling vent clean ✔

muffler, spark arrester, cylinder exhaust port

clean ✔

throttle lever, ignition switch check operation ✔

replace if

cutting parts ✔

something's wrong

gear case grease ✔

screws/nuts/bolts tighten/replace ✔✔not adjusting screws

ENGINESHAFT

Page 15

US-14

SRTZ2460F

■ MUFFLER

• Inspect periodically, the muffler for

loose fasteners, any damage or

corrosion. If any sign of exhaust

leakage is found, stop using the

machine and have it repaired

immediately.

•Note that failing to do so may result

in the engine catching on fire.

■ SPARK ARRESTER

• The muffler is equipped with a spark

arrester to prevent red hot carbon from

flying out of the exhaust outlet.

Periodically inspect and clean as

necessary with a wire brush.

In the State of California it is required

by law (Section 4442 of the California

Public Resources Code) to equip a

spark arrester when a gas powered tool

is used in any forest covered, brush

covered, or grass covered unimproved

land. (MA6)

(1) spark arrester

■ INTAKE AIR COOLING VENT

• Never touch the cylinder, muffler, or

spark plugs with your bare hands

immediately after stopping the

engine. The engine can become

very hot when in operation, and

doing so could result in severe

burns.

• When checking the machine to make

sure that it is okay before using it,

check the area around the muffler

and remove any wood chips or

leaves which have attached

themselves to the brushcutter.

Failing to do so could cause the

muffler to become overheated, and

that this in turn could cause the

engine to catch on fire. Always

make sure that the muffler is clean

and free of wood chips, leaves, and

other waste before use.

• Check the intake air cooling vent and

the area around the cylinder cooling

fins after every 25 hours of use for

blockage, and remove any waste which

has attached itself to the brushcutter.

Note that it is necessary to remove the

WARNING

MA6

.026 in

0.65 mm

MA5

9. Maintenance

(1)

MA3

(1)

MA4

• Make sure that the engine has

stopped and is cool before

performing any service to the

machine. Contact with moving

cutting head or hot muffler may

result in a personal injury.

■ AIR FILTER

• The air filter, if clogged, will reduce the

engine performance. Check and clean

the filter element. If the element is

broken or clogged, replace with a new

one. (MA3)

(1) air filter

■ FUEL FILTER

• When the engine runs short of fuel

supply, check the fuel cap and the fuel

filter for blockage. (MA4)

(1) fuel filter

■ SPARK PLUG

• Starting failure and mis-firing are often

caused by a fouled spark plug. Clean

the spark plug and check that the plug

gap is in the correct range. For a

replacement plug, use the correct type

specified by RedMax. (MA5)

• REPLACEMENT PLUG IS A NGK

CMR7H.

• Note that using any spark plug other

than those designated may result in the

engine failing to operate properly or in

the engine becoming overheated and

damaged.

• To install the spark plug, first turn the

plug until it is finger tight, then tighten it

a quarter turn more with a socket

wrench.

TIGHTENING TORQUE:

87~104 in-lbs

(9.8~11.8 N.m.)

IMPORTANT

WARNING

WARNING

(1)

Page 16

US-15

SRTZ2460F

U

S

9. Maintenance

MA8

(1)

(2)

MA7

• Aged fuel is one of major causes of

engine starting failure. Before storing

the unit, empty the fuel tank and run

the engine until it uses all the fuel left in

the fuel line and the carburetor. Store

the unit indoor taking necessary

measures for rust prevention.

10. Storage

11. Disposal

• When disposing your machine, fuel or

oil for the machine, be sure to allow

your local regulations.

engine cover shown in (MA7) in order

to be able to view the upper part of the

cylinder.

• If waste gets stuck and causes

blockage around the intake air cooling

vent or between the cylinder fins, it may

cause the engine to overheat, and that

in turn may cause mechanical failure

on the part of the brushcutter. (MA7)

(1) cylinder

(2) intake air cooling vent (back)

■ PROCEDURES TO BE PERFORMED

AFTER EVERY 100 HOURS OF USE

1. Remove the muffler, insert a

screwdriver into the vent, and wipe

away any carbon buildup. Wipe away

any carbon buildup on the muffler

exhaust vent and cylinder exhaust port

at the same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has

worked its way in between the clutch

lining and drum, and if it has wipe it

away using oil-free, lead-free gasoline.

IMPORTANT

Page 17

US-16

SRTZ2460F

12. Troubleshooting guide

Case 1. Starting failure

CHECK PROBABLE CAUSES ACTION

fuel tank ➞ incorrect fuel ➞ drain it and with correct fuel

fuel filter ➞ fuel filter is clogged ➞ clean

carburetor adjustment screw ➞ out of normal range ➞ adjust to normal range

sparking (no spark) ➞ spark plug is fouled/wet ➞ clean/dry

➞ plug gap is incorrect ➞ correct (GAP: 0.6 – 0.7 mm)

spark plug ➞ disconnected ➞ retighten

Case 2. Engine starts but does not keep running/Hard re-starting.

CHECK PROBABLE CAUSES ACTION

fuel tank ➞ incorrect fuel or staled fuel ➞ drain it and with correct fuel

carburetor adjustment screw ➞ out of normal range ➞ adjust to normal range

muffler,cylinder (exhaust port) ➞ carbon is built-up ➞ wipe away

air cleaner ➞ clogged with dust ➞ replace

cylinder fin, fan cover ➞ clogged with dust ➞ clean

When your unit seems to need further service, please consult with our service shop in your area.

Page 18

US-17

SRTZ2460F

U

S

The EPA (U.S. Environmental Protection Agency), CARB (California Air Resources Board), Environment

Canada and RedMax are pleased to explain the emissions control system's warranty on your 2009 and later

small off-road engine. In U.S. and Canada, new equipment that use small off-road engines must be designed,

built, and equipped to meet the applicable Federal or Californian stringent anti-smog standards. RedMax must

warrant the emissions control system on your small off-road engine for the period listed below provided there

has been no abuse, neglect or improper maintenance of your equipment. Your emissions control system may

include parts such as carburetor, ignition system, catalytic converter, fuel tank, filters and other associated

components. Also, included may be hoses, belts, connectors, sensors, and other emission-related assemblies.

Where a warrantable condition exists, RedMax will repair your small off-road engine at no cost to you including

diagnosis, parts and labor.

MANUFACTURER'S WARRANTY COVERAGE

This emissions control system is warranted for two years or if the product qualifies for a longer warranty period

resulting from the type of use, that period shall prevail. If any emissions-related part on your equipment is

defective, the part will be repaired or replaced by RedMax.

OWNER'S WARRANTY RESPONSIBILITIES

As the small off-road engine owner, you are responsible for performance of the required maintenance listed in

your Owner's Manual. RedMax recommends that you retain all receipts covering maintenance on your small offroad engine, but RedMax cannot deny warranty solely for the lack of receipts or your failure to ensure the

performance of all scheduled maintenance. As the small off-road engine owner, you should however be aware

that the RedMax may deny you warranty coverage if your small off-road engine or a part has failed due to

abuse, neglect, or improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine to a RedMax distribution center or service center

as soon as the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to

exceed 30 days. If you have any questions regarding your warranty coverage, you should contact RedMax at 1800-291-8251 or via e-mail at service@redmax.com.

WARRANTY COMMENCEMENT DATE

The warranty period begins on the date the engine or equipment is delivered to an ultimate purchaser.

LENGTH OF COVERAGE

RedMax warrants to the ultimate purchaser and each subsequent owner that the engine or equipment is

designed, built, and equipped so as to conform with all applicable regulations adopted by EPA and CARB, and

is free from defects in materials and workmanship that causes the failure of a warranted part for a period of two

years.

WHAT IS COVERED

REPAIR OR REPLACEMENT OF PARTS Repair or replacement of any warranted part under the warranty

must be performed at no charge to the owner at a warranty station. Warranty services or repairs will be provided

at all RedMax distribution centers that are franchised to service the subject engines. Throughout the emissions

warranty period of two years, RedMax must maintain a supply of warranted parts sufficient to meet the expected

demand for such parts.

WARRANTY PERIOD Any warranted part that is scheduled for replacement as required in the maintenance

schedule, is warranted for the period of time prior to the first scheduled replacement point for that part. If the

part fails prior to the first scheduled replacement, the part will be repaired or replaced by RedMax at no cost.

Any such part repaired or replaced under warranty is warranted for the remainder of the period prior to the first

scheduled replacement point for the part. Any warranted part that is not scheduled for replacement as required

in the maintenance schedule, is warranted for two years or if the product qualifies for a longer warranty period

resulting from the type of use, that period shall prevail. If any such part fails during the period of warranty

coverage, it will be repaired and replaced by RedMax at no cost. Any such part repaired or replaced under the

FEDERAL AND CALIFORNIA EMISSIONS CONTROL WARRANTY

STATEMENT YOUR WARRANTY RIGHTS AND OBLIGATIONS

Page 19

US-18

SRTZ2460F

warranty is warranted for the remaining warranty period. Any warranted part that is scheduled only for regular

inspection in the maintenance schedule will be warranted for a period of two years. A statement in such written

instructions to the effect of "repair or replace as necessary" will not reduce the period of warranty coverage. Any

such part repaired or replaced under warranty will be warranted for the remaining warranty period.

DIAGNOSIS The owner must not be charged for diagnostic labor that leads to the determination that a

warranted part is in fact defective, provided that such diagnostic work is performed at a warranty station.

CONSEQUENTIAL DAMAGES RedMax is liable for damages to other engine components proximately caused

by a failure under warranty of any warranted part.

EMISSION WARRANTY PARTS LIST

1. Air-induction system*

2. Fuel system*

3. Ignition system*

4. Fuel tank, cap and lines as applicable*

*some components only covered up to point specified by maintenance schedule

WHAT IS NOT COVERED

All failures caused by abuse, neglect or improper maintenance are not covered.

ADD-ON OR MODIFIED PARTS

Add-on or modified parts that are not exempted by CARB or EPA may not be used. The use of any nonexempted add-on or modified parts will be grounds for disallowing a warranty claim. RedMax will not be liable to

warrant failures of warranted parts caused by the use of a non-exempted add-on or modified part.

HOW TO FILE A CLAIM

If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest

authorized servicing dealer or contact RedMax at 1-800-291-8251 or via e-mail at service@redmax.com.

WHERE TO GET WARRANTY SERVICE

Warranty services or repairs are provided through all RedMax authorized servicing dealers.

MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION-RELATED PARTS

Any replacement part may be used in the performance of any warranty maintenance or repairs and must be

provided without charge to the owner. Such use will not reduce the warranty obligations of the manufacturer.

MAINTENANCE STATEMENT

The owner is responsible for the performance of all required maintenance, as defined in the operator's manual.

Loading...

Loading...