Page 1

EXPLOSIONPROOF

RedMax - Revolution

Electrical, explosion proof rotary actuators - size S

On-off / 3-pos , 24..230 VAC/DC, 95° angle of rotation, potential free contacts, EEx-i circuit

5/10 Nm - 15/30 Nm without and 5/10 Nm - 15 Nm with safety operation (spring return)

PTB-tested in acc. with ATEX RL 94/9/EG for zone 2, 22.

RedMax- 15-BF

RedMax - ...-BF - VA

RedMax - ...-BF - CT

Subject to change

Compact - Easy installation - Universal - Cost effective - Safe

Type Torque Supply Motor running time Spring return Control mode Additional features Wiring diagram

RedMax-5.10-BF

RedMax- 5.10 - BF 5 Nm & 10 Nm 24..230VAC/DC 3/15/30/60/120 sec. at 90° 3 or 10 sec. at 90° On-off, 3-pos 2 contacts (5/85°

RedMax- 15 - BF 15 Nm 24..230VAC/DC 3/15/30/60/120 sec. at 90° 3 or 10 sec. at 90° On-off, 3-pos 2 contacts (5/85°

RedMax- ... - VA Type as above but with stainless steel housing (AISI 316) for aggressive ambient (12x12 shaft, shaft manual override, cable glands and hollow rivet nickel-plated)

RedMax- ... - CT Type as above but with Al housing and amercoat painting (12x12 shaft connenction, shaft manual override, cable glands and hollow rivet nickel-plated)

Application

Firedamper

Damper Ball valve, Throttle valve

) + EEx-i circuit SB 7.0/7.1

) + EEx-i circuit SB 7.0/7.1

Description size S

The new RedMax actuators are a revolution for safety, fire and shut-off

dampers, VAV systems, ball valves, throttle valves and other motorized

applications for HVAC systems, in chemical, pharmaceutical, industrial

and Offshore-/Onshore plants, for use in EEx-areas zone 2 (gas) and

zone 22 (dust).

Highest protection class (ATEX) and IP 66 protection, small dimensions,

only 3,5 kg weight, universal functions and technical data, an integrated

heater and an optional stainless steel housing guarantee safe operation

even under difficult environmental conditions. High quality brushless

motors guarantee long life.

All actuators are programmable and adjustable on site. Special tools

or equipment are not required. 5 motor running times and 2 torques as

well as 2 spring return times - according to the actuator type - are

selectable or adjustable on site. The integrated universal power supply

is self adaptable to input voltages in the range of 24 to 230 VAC / DC.

The actuators are 100% overload protected and self locking.

RedMax-...-BF actuators are equipped with spring return fail safe function,

with integrated aux. switches for end position indication and an intrinsic

safe circuit to connect an external passive potential free thermostat.

Standard shaft connection is a double squared direct coupling with

12 x 12 mm.

Different accessories are available to adapt aux. switches, terminal

boxes or adaptations for ball valves and throttle valves.

Highlights

u

For all type of gas, mixtures, vapours and dust for use in zone 2 and 22

u

Universal supply unit from 24 to 230 V - AC/DC

u

EEx-i circuit for directly connection of a passive potential free safety thermostat

u

2 integral aux. switches , switching at 5° and 85° angle of rotation

u

5 different motor running times (3-15-30-60-120 sec./90°), adjustable on site

u

2 different spring return running times (3-10 sec./90°), selectable on site

u

On-off and 3-pos control with spring return function

u

5 - 10 - 15 Nm actuators in the same size (S)

u

100 % overload protected, Self locking

u

Compact design and small dimension (l x w x h = 210 x 95 x 80 mm)

u

Direct coupling to the damper shaft with double-squared connection 12 x 12 mm

u

95° Angle of rotation incl. 5° pre-tention

u

Robust aluminium housing (optional stainless steel or amercoat painting)

u

IP 66 protection

u

Simple manual override include + preparation for comfortable manual override

u

Gear made of stainless steel and sinter metal

u

Only 3,5 Kg weight

u

Integral heater for ambient temperatures down to -40°C

u

Integral safety temperature sensor

u

Integral equipment for manual adjustment (push button, lamp, switch)

u

Preparation for adaptable aux. switches type RedSwitch

u

Range of accessories

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

www.schischek.com

Page 2

RedMax-5.10-BF RedMax-15-BF

Special makes RedMax-..-VA/-CT

Technical data RedMax-5.10-BF RedMax-15-BF

Torque motor 5 / 10 Nm selectable on site 15 Nm

Torque spring return (F) min. 10 Nm min. 15 Nm

Dimension of external torque above mentioned torques are min. torques in blocked position, eternal torque should be max. 80% of max. actuator torque but min. 3 Nm

Supply voltage/Frequency 24...230 VAC/DC, + 15 % / - 20% , self adaptable, Frequency 50...60 Hz +/- 20 %

Dimension max. starting currents see table (in acc. with voltage, I

Protection class class I (grounded)

Angle of rotation and indication 95°, incl. ~ 5° pre-tention, mechanical value indication

Working direction selectable by left/right mounting to the damper/valve shaft

Motor running time 3 / 15 / 30 / 60 / 120 sec. at 90° selectable on site

3 sec. mode - motor In acc. with the supply voltage rand external torque 3 to 4 sec at 90° angle of rotation

Motor brushless DC Motor

Spring return (F) spring return in the event of loss of power

Spring return running time (F) spring return in 3 sec., or 10 sec. at 90°, selectable on site

3 sec. mode - spring return in acc. with external torque 3 to 4 sec. at 90° angle of rotation

Safety operations at 10 sec (F) min. 10.000 in acc. with construction of damper and ambient

Safety operations at 3 sec (F) min. 1.000 in acc. with construction of damper and ambient

Response time spring return up to 1 sec. after power failure

Control mode On-off and 3-pos in acc. with wiring, selectable on site

Intrinsic safe circuit Additional EEx-i circuit to connect a passive potential free thermostat as a safety sensor, e.g. type FireSafe

Integratet aux. switches 2 aux. switches, switching at 5° and 85° Angle of rotation

Axle of the actuator double squared 12 x 12 mm, direct coupling, 100 % overload protected and 100 % self locking up to 15 Nm

Electrical connection cable, ~1 m, diameter of wires 0,5 mm² for connection inside hazardous areas an terminal box is required!

Diameter of cable ~ Æ 9,6 mm + ~ Æ 6,2 mm

Cable gland M16 x 1,5 standard - cable - and wire entries are integral part of explosions proof encapsulation; tested acc. to EN 50018

Manual override Use Manual override only if supply voltage is cut, use delivered socket wrench, slow motion, enough torque/force is required

Attention: with manual operation of the spring danger of injury exists, with release/let go the hexagonal spanner!

Integral heater integral heater, controlled, for ambient temperature down to - 40°C

Housing material Aluminium die cast housing, painted (optional in stainless steel version AISI 316 - type RedMax-...-VA, amercoat painting type RedMax ...-CT)

Dimensions l x w x h 210 x 95 x 80 mm, for diagramm see extra information ME

Weight ~ 3,5 Kg Aluminium housing (stainless steel ~ 7 Kg)

Ambients storage temp. - 40..+ 70°C, working temperature - 40..+ 40°C at T6 and - 40...+ 50°C at T5, humidity in acc. with EN 60335-1

Operation mode at

runningtime motor 3 sec at 3 sec. 10 % ED, max. 1 on-off cycle per minute (must be guaranteed by control system)

Operation mode ex

runningtime motor 15 sec at 15/30/60/120 sec. 100 % ED

Self adjustment if you select 3 sec. and 15 sec. mode for motor you need to start the self adjustment mode

Maintenance maintenance free, maintenance must be complied with regional standards, rules and regulations

Wiring diagrams (SB) SB 7.0 / 7.1 SB 7.0 / 7.1

start >> I rated), max. 20 W blocking position, approx. 16 W for heater

EXPLOSIONPROOF

Delivery 1 actuator, 1 m cable, double squared shaft connection 12x12 mm, 4 screws M 4 x 100, 4 nuts M 4

socket wrench for simple manual override

Parameter at delivery 5 Nm, 30 sec./90° 15 Nm, 30 sec./90°

Explosion proof RedMax actuators - size S

Certification PTP 04 ATEX 2106

ATEX Directive 94/9/EG (ATEX)

Approval for gas II3G EEx nC II T6 II3(1)G EEx [ia] IIC gas, mist, vapour,

zone 2

Approval for dust II3D IP66 T80°C dust, zone 22

Identification CE Nr. 0158

EMC EMC-directive 89/336/EG

Low voltage Low-voltage directive 72/23/EG

IP-Protection IP 66

Potential compensation external PA-terminal, 4 mm²

EEx-i circuit data see table below wiring diagrams

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

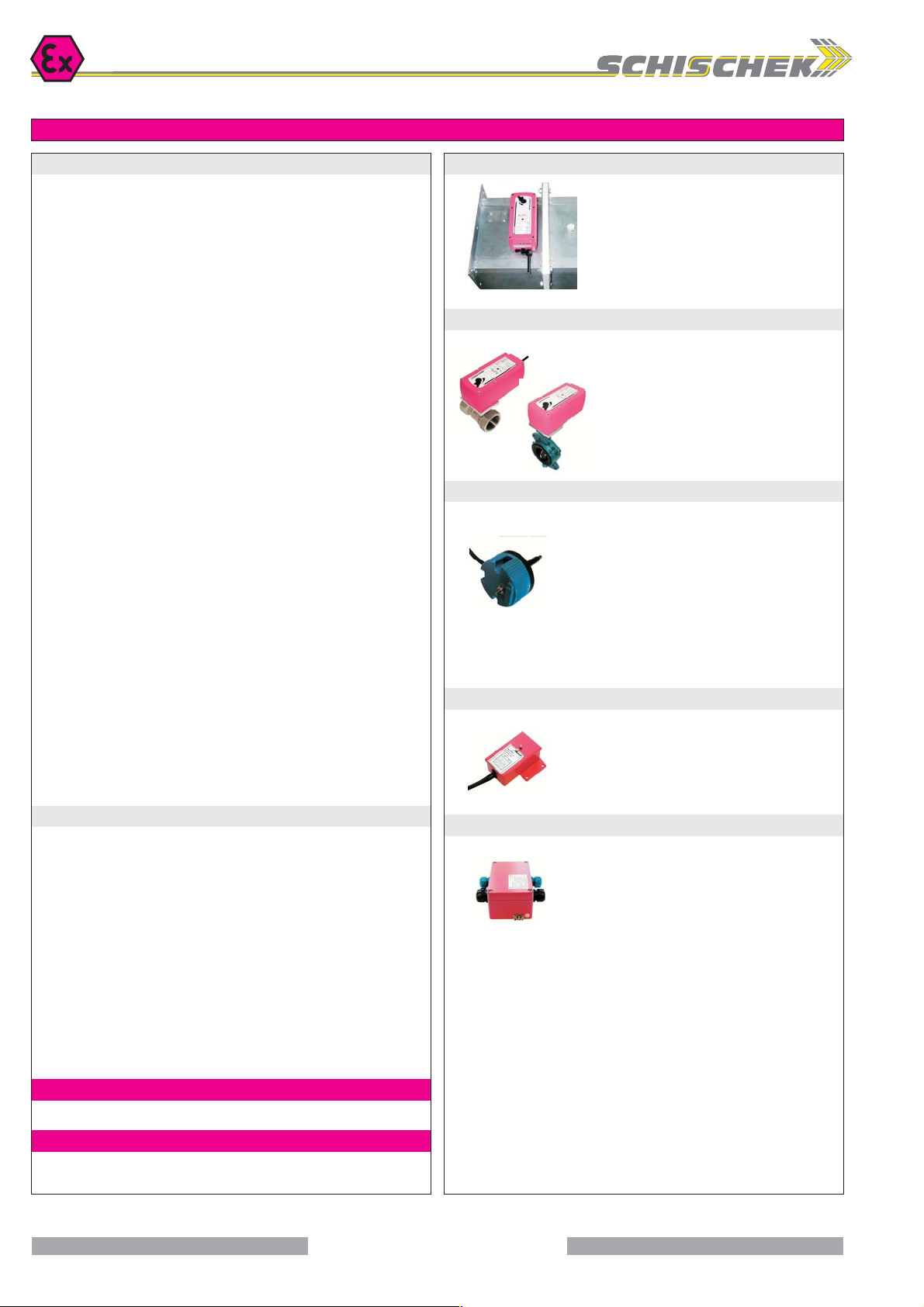

Accessories or special solutions - size S

RedMax-..-VAabove listed types in stainless steel version, housing AISI 316.

RedMax-..-CTabove listed types in Al-housing with amercoat painting, parts nickel-plated

RedBox-... Terminal box for zone 2, 22.

MKK-S mounting bracket for EEx-e terminal boxes type RedBox-... direct on actuator

RedSwitch 2 external aux. switches, 2 x EPU, adjustable, for zone 2, 22

KB-S clutch for damper shafts Æ 10...20 mm and

HV-S comfortable manual override for RedMax actuators size S

Adaptations various adaptations for dampers/valves on request

BFH-S Mounting holder for actuators at fire danger area

FireSafe Sensor with manufacturer certificate in acc. with ATEX.

AR-12-xx Reduction of square damper connection from 12 mm to 11, 10, 9, 8

10...16 mm.

www.schischek.com

Page 3

RedMax-5.10-BF RedMax-15-BF

Special makes RedMax-..-VA/-CT

Electrical connection

RedMax actuators are equipped with a universal supply unit working at a voltage range

from 24 to 230 VAC/DC. The supply unit is self adjustable to the connected voltage!

The safety operation of the spring return function works if the supply voltage is cut.

For electrical connection inside hazardous areas an t erminal box, certificated in acc. with

ATEX is required (e.g. RedBox).

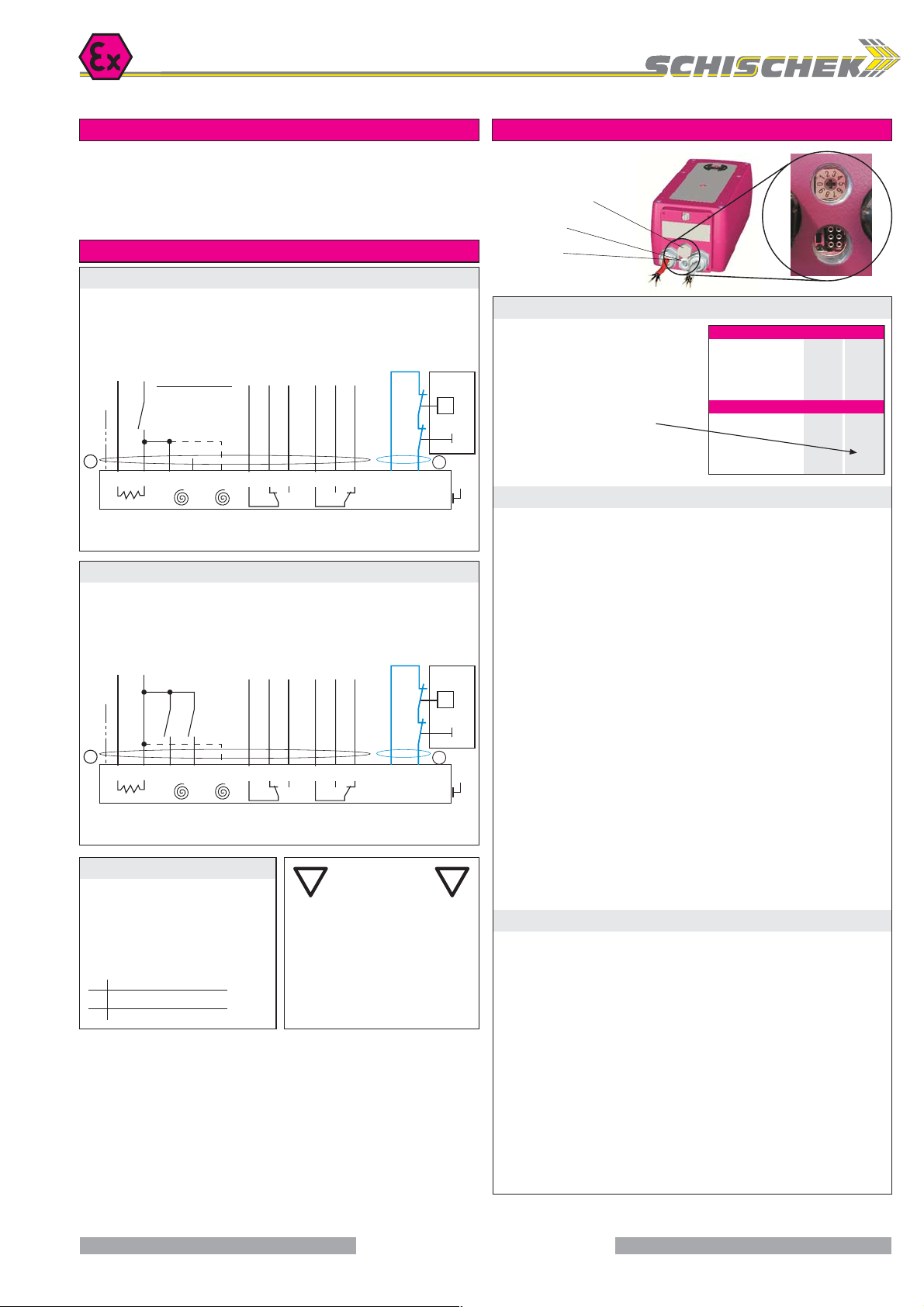

Wiring diagram RedMax-5.10-BF and RedMax-15-BF

On-off 1-wire- spring return + EEx-i circuit

Integrated aux. switches

max 24V/3A, 230V/0,5A

switching at 5° and 85°.

Supply at aux. switches must

24...230 VAC/DC

be the same like supply of the

actuator on same fuse.

+

~-~

! Attention !

If you use this type of

PE

A

Standard wiring = spring return in ~10 sec.

Additional wiring terminal 5 = spring return in ~ 3 sec.

wiring the heater does

not work in case of

open contact.

123

heater

4

5

< 5 °

67

8 910

On-off/3 pos - spring return + EEx-i circuit

Integrated aux. switches

max 24V/3A, 230V/0,5A

switching at 5° and 85°.

Supply at aux. switches must

24...230 VAC/DC

+

~

~

be the same like supply of the

actuator on same fuse.

< 5 °

> 85 °

PE

b

a

A

123

heater

Standard wiring = spring return in ~10 sec.

Additional wiring terminal 5 = spring return in ~ 3 sec.

5

4

67

8 910

EEx-i intrinsic safe data

U0 = 10,6 V

I

0 = 11 mA

P

0 = 30 mW

i = 0

C

L

i = 0

IIC IIB IIA

C

0 830 nF 3,7µF 4,5 µF

0 2 mH 5 mH 10 mH

L

! !

If 3 sec. mode is selected, the self adju

stment of Angle of rotation must be started

and operation mode of max. 10% ED

must be guaranteed.

Never use actuators in this mode without

external torque/force.

EEx-i circuit for

passive + potential free

push button on site

and sagfety temperatur sensor

(Type FireSafe accessories)

> 85

°

11

EEx-i circuit for

passive + potential free

push button on site

and sagfety temperatur sensor

(Type FireSafe accessories)

11

Attention!

SB 7.0

push button

12

SB 7.1

FireSafe

push button

12

FireSafe

°C

B

PA

°C

B

PA

EXPLOSIONPROOF

Parameter, Adjustment - Failure indication

Switch - Push button - Lamp

for adjustment,

behind the blancking plug

S

10-position switch (S)

Push button(T)

3-colour LED

T

Parameter selection

Example: RedMax-5.10-BF

Requested parameter:

Torque 10 Nm

Running time motor 60 sec/90°

Result: switch position (S) 08

Type Torques

RedMax -5.10-BF u 5 Nm 10 Nm

RedMax- 15-BF u 15 Nm 30 Nm

Running times Position of switch S

120 sec./90° u 04 09

qq

3 sec./90° u 00 05

15 sec./90° u 01 06

30 sec./90° u 02 07

60 sec./90° u 03 08

Function, adjustment and parameter

A) Self adjustment of Angle of rotation:

Switch (S) into position 02 (low torque) or 07 (high torque), then push button (T) for

minimum 3 seconds. The actuator will drive into both end positions to be adjusted.

LED indicates green.

Adjusmtent time needs approx. 60 sec. (30 sec. On, 30 sec. Off). After that, switch S

into position 00-09 in acc. with your required torque and running time.

B) Selection of running time and torque:

Put switch (S) into the correct/selected position in acc. to above table.

The selected parameter will work at next operation of the actuator.

Adjustment can be done even without supply voltage. If supply voltage is available turn

switch only if actuator is not running.

C) Running time spring return:

The running time of 3 or 10 sec. spring return is selected by wiring

(see wiring diagrams SB 7.0/7.1).

D) Additional information for 3-pos operation:

a closed, b open = direction I

b closed, a open = direction II

a and b closed = Motor doesn't work

a and b opened = Motor doesn't work

Direction (I and II) depends on left/right mounting of the actuator to the damper/valve.

You can change direction of the motor by changing electrical wiring terminal 3 and 4.

E) Function of a passive sensor in the EEx-i circuit:

If the sensor opens the EEx-i circuit the actuator runs into its safety end-position with

spring return

Error indication

See extra information EL

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

www.schischek.com

Page 4

RedMax-5.10-BF RedMax-15-BF

Special makes RedMax-..-VA/-CT

Mounting instructions and important information for operation and installation

EXPLOSIONPROOF

Important information for installation and operation

A. Installation, commissioning, maintenance

The cable of the actuator must be installed in a fixed position and protected against

mechanical and thermical damage. In acc. with operation RedMax actuators are

maintenance free. Nevertheless maintenace must comply with regional standards,

rules and regulations. The actuators must not be opened by the customer. For outdoor

installation a protective housing against rain, snow and sun should be applied to the

actuator, as well as a constant supply at terminal 1 and 2 for the integral heater. For

electrical connection inside hazardous areas an terminal box is requested (e.g. type

RedBox).

Example: you have to cut the supply voltage before opening an EEx-e terminal box

B. Shaft connection, selection of running time, heater

RedMax actuators are equipped with a direct coupling double squared shaft connection

of 12 x 12 mm. For round shafts an adaptor is available (Accessory type KB-S).

The housing of the actuator is axially symmetrically built to select open/close direction

of the spring return function by left/right mounting.

In acc. to the actuator type 5 different motor running times and 2 different spring return

running times can be selscted on site. The integral heater is for ambient temperatures

down to -40°C.

C. Working with 3 sec. motor running time

See extra information EL.

D. 3-pos control mode

See extra information EL.

E. Spring return

Spring return function works if the supply voltage (terminal 1 or 2) is cut. In the event

of an electrical interruption, the spring returns to its end position.

F. Operation at an ambient temperature below - 20°C

See extra information EL.

G. Excess temperature

In acc. to the ATEX rules and regulations EEx actuators must be protected against

excess temperature. An internal thermostat guarantees the temperature class in the

event of failure. If this thermostat is working the actuator must be sent to the factory.

RedMax actuators are equipped with an additional temperature sensor to stop the

actuator before reaching this max. temperature. In this case the failure must be

eliminated immediately on site.

Mounting on air dampers with double squared shaft connection

Details see extra information ME.

Mounting of quarter turn valves

Details see extra information ME.

EEx-i safety temperature sensor - FireSafe

The safety thermostat type FireSafe is passive and

potential free for use in intrinsic safe circuits, directly

connectable to the EEx-i circuit of the RedMax-...-BF

actuators. The sensor switches at an ambient temperature

of 72°C and starts the fail safe spring return function of

the actuator. Sensor with manufacturer certificate in acc.

with ATEX.

RedSwitch - adaptable external EEx-d aux. switches

RedSwitch is an accessory to RedMax actuators size

S, fixing directly onto the actuator. RedSwitch are aux.

switches with with 2 potential free contacts, adustable

on site. The electrical wiring needs an terminal box.

Important information for routine test

For periodic inspection of fire dampers cut of the the supply line (cut off the current

of the actuator)

The switch contact on FireSafe is only for test aims of actuators function.

RedBox - adaptable terminal box

For electrical connection of an RedMax inside the hazar

dous area an terminal box is required.

RedBox-BF for RedMax-5.10-BF and RedMax-15-BF.

To adapt the RedBox direct to the actuator housing an

additional accessory type MKK-S is required.

Extra information "EL" (see additional data sheet)

extra technical information, versions of circuit diagrams and failure indication

Extra information "ME" (see additional data sheet)

extra technical information, dimensions, installation instruction and illustration

D.EM-03.08-S-en-BF

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

2006-06-14

www.schischek.com

Page 5

ExMax-.. and RedMax-.. extra information EL - size S

EXPLOSIONPROOF

ExMax/RedMax - extra information EL

The "EL"-data sheet contains additional information for ExMax and

RedMax actuators of the size "S", for the optimization and simplification

in regard to planning, installation and initial startup. It provides

influences of external factors in reference to the safe initiation of

the actuators, as well as technical references and problem solutions

(error indication). With the error indication, functions can be examined

and different error/problems can be adjusted locally.

For additional mechanical data have a look at "extra information ME"

u Power supply design

u Design of line cross section 24...48 VAC/DC

u Wiring alternatives for on-off, 3-pos, BF actuators

u Wiring alternatives for modulating actuators

u Use at ambient temperatures down to -20°C / - 40°C ( )

u

Error indication - problem treatment/solution

Power input depending of supply voltage

Power supply design

The design of the on-site supply, depends on the selected motor running time and selected

supply voltage. Accompanying values are "about values", since there can be construction

unit dispersions within electronics. The power consumption in the blocking position is run

time independently with max. 20 W. The power consumption for the heater is approx. 16W.

The heading is running only if the motor is in idle position! The initial starting supply voltage

required by the actuators power supply unit is around 2,0 A for about 1 Sec.

(Please consider this while concepting the cross section ot the supply line)

Voltage Current 3/7,5s 15s 30s 60s 120s

230 V I

120 V I

48 V I

24 V I

Rated current in acc. with motor running time

rated 0,5 A 0,3 A 0,15 A 0,10 A 0,10 A

rated 0,75 A 0,4 A 0,3 A 0,25 A 0,25 A

rated 2,0 A 0,5 A 0,3 A 0,2 A 0,2 A

rated 4,7 A 1,45 A 0,52 A 0,4 A 0,4 A

Dimensioning of the line cross section with 24 ....48 VAC/DC supply voltages

Dimensioning/Design of the supply line

On long distances between voltage supply and drive, voltage drops occur due to line

resistances. As a consequence with 24 VAC/DC the actuator receives a too low tension

and does not start. In order to prevent this, the cross section of the inlet line is to be

designed/dimensioned accordingly. The accompanying formula allows the calculation of

the necessary line cross section, perhabs provides the maximally permitted conduit length

utilizing the existing line cross section. Alternatively the secondary voltage can be increased

by selecting a transformer. For calcualtion purposses, following characteristics are essential:

UV = supply voltage in [V]

A = line cross section in [mm²]

L = conduit length in [m]

Factor 0.0714 = drive-specific factor

[Vmm²/m] ( based on the electrical conductivity of electrolytic copper with a coefficient of

56m/Wmm²)

pannel

voltage

"Uv" [V]

Formula for max. cable length "L" at cable

cross section "A"

line cross section "A" [mm²]

length "L" [m]

L = A l (Uv-18V) : 0,0714

Example: A = 1,5 mm², Uv = 24 V

Lengthof cable L = 126 m

Formula of needed cable cross section

"A" at a cable length of "L"

A = 0,0714 l L : (Uv-18V)

Example: L = 250 m, Uv = 30 V

Cross section of A = 1,5 mm²

terminal box actuator

Uv [V]

28

27

26

25

24

23

22

21

20

50 100 150 200 250 300 350 400

Example:

24 V power supply with wire diameter 1,5 mm² = 126 m

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

1 mm² 1,5 mm² 2,5 mm²

4 mm²

L[m]

www.schischek.com

Page 6

ExMax-.. and RedMax-.. extra information EL - size S

EXPLOSIONPROOF

Wiring alternatives for on-off and 3-pos actuators with spring return

ExMax-...-F, ExMax-...-SF, RedMax-...-F, RedMax-...-SF

On-off and 3-pos

SB 2.0 SB 2.1

24 to 230 VAC/DC

+

~-~

PE

Standard wiring = spring return in ~10 sec.

Additional wiring terminal 5 = spring return in ~ 3 sec.

ab

123 4

heater

PA PA

5

On-off 1-wire

24 to 230 VAC/DC

+

~-~

! Attention !

If you use this type of

a

wiring the heater does

PE

123 4

heater

Standard wiring = spring return in ~10 sec.

Additional wiring terminal 5 = spring return in ~ 3 sec.

not work in case of

open contact.

Wiring alternatives for BF actuators

ExMax-...-BF, RedMax-...-BF

On-off 1-wire - spring return + EEx-i circuit

24...230 VAC/DC

+

~-~

PE

A

123

heater

! Attention !

If you use this type of

wiring the heater does

not work in case of

open contact.

5

4

Integrated aux. switches

max 24V/3A, 230V/0,5A

switching at 5° and 85°.

Supply at aux. switches must

be the same like supply of the

actuator on same fuse in case

that power is switched.

< 5 °

67

> 85 °

8 910

EEx-i circuit for

passive + potential free

push button on site

and safety temperature sensor

(Type FireSafe accessories)

11

12

5

SB 7.0

FireSafe

°C

push button

B

PA

! !

If 3 sec. mode is selected, the self adjustment of angel of rotation must be started

and operation mode of max. 10% ED

must be guaranteed.

Never operate actuator in the 3 sec mode

without an outside load of min. 3 Nm.

Engaging 1 wire On/Off controlls in the

3 sec. modus with spring return, the ac

tuator can only be operated with 1 On/Off

function per minute otherwise electronics

will be liable to overheating.

O-off/3-pos - spring return + EEx-i circuit

Integrated aux. switches

max 24V/3A, 230V/0,5A

switching at 5° and 85°.

Supply at aux. switches must

24...230 VAC/DC

+

~

~

PE

A

123

heater

b

a

4

be the same like supply of the

actuator on same fuse in case

that power is switched.

< 5 °

5

67

8 910

Attention!

EEx-i circuit for

passive + potential free

push button on site

and safety temperature sensor

(Type FireSafe accessories)

> 85 °

11

SB 7.1

FireSafe

push button

12

°C

B

PA

Standard wiring = spring return in ~10 sec.

Additional wiring terminal 5 = spring return in ~ 3 sec.

On-off 1-wire - spring return + EEx-d limiter

24...230 VAC/DC

+

! Attention !

~-~

If you use this type of

wiring the heater does

not work in case of

open contact.

PE

EXC-DS1/VA

°C

Limiter

Push button

Integrated aux. switches

max 24V/3A, 230V/0,5A

switching at 5° and 85°.

Supply at aux. switches must

be the same like supply of the

actuator on same fuse in case

that power is switched.

< 5 °

> 85 °

SB 7.2

The intrinsic safe circuit must

be closed otherwise the

actuator is unable to work!

Standard wiring = spring return in ~10 sec.

Additional wiring terminal 5 = spring return in ~ 3 sec.

Values of the EEx-i circuit

U0 = 10,6 V

0 = 11 mA

I

P

0 = 30 mW

C

i = 0

L

i = 0

IIC IIB IIA

C

0 830 nF 3,7µF 4,5 µF

L

0 2 mH 5 mH 10 mH

! !

Achtung!

If 3 sec. mode is selected, the self adjustment of angel of rotation must be started

and operation mode of max. 10% ED

must be guaranteed.

Never operate actuator in the 3 sec mode

without an outside load of min. 3 Nm.

Engaging 1 wire On/Off controlls in the

3 sec. modus with spring return, the ac

tuator can only be operated with 1 On/Off

function per minute otherwise electronics

A

123

heater

Standard wiring = spring return in ~10 sec.

Additional wiring terminal 5 = spring return in ~ 3 sec.

5

4

67

8 910

11

12

B

PA

will be liable to overheating.

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

www.schischek.com

Page 7

ExMax-.. and RedMax-.. extra information EL - size S

EXPLOSIONPROOF

Wiring alternatives for modulating actuators with or without spring return

ExMax-...-Y.., RedMax-...-Y..

Modulating or 3-pos with/without spring return

Self adjustment:

To adjust the signal input/output to the Angle

24...230 VAC/DC

+

~-~

of rotation of the damper/valve the button T

must be pushed for minimum 3 sec.

Y

mA

Y

VDC

VDC/mA

PE

ab

A

123 4

heater

Selection of running time for spring return:

Standard wiring = spring return in ~10 Sek

Additional wiring terminal 5 = spring return in ~ 3 Sek

Function of switch a and b:

- a closed, On (Off) - in acc. to left/right mounting ot the actuator

- b closed, Off (On) - in acc. to left/right mounting ot the actuator

5

1

I

2T3

Reverse function:

bridge 3--4 reverse input and output

signals.

45

Modulating with/without spring return, no feedback

Self adjustment:

To adjust the signal input/output to the Angle

of rotation of the damper/valve the button T

24...230 VAC/DC

+

~-~

must be pushed for minimum 3 sec.

Y

mA

Y

VDC

VDC/mA

SB 5.0 SB 5.1

U

mA

U

VDC

Modulating with/without spring rturn

Self adjustment:

To adjust the signal input/output to the Angle

24...230 VAC/DC

+

~-~

of rotation of the damper/valve the button T

must be pushed for minimum 3 sec.

Y

mA

Y

VDC

VDC/mA

PE

I

A

B

6

PA PA

I

123 4

heater

Selection of running time for spring return:

Standard wiring = spring return in ~10 Sek

Additional wiring terminal 5 = spring return in ~ 3 Sek

5

1

2T3

Reverse function:

bridge 3--4 reverse input and output

signals.

45

3-pos with/without spring return, plus feedback

Self adjustment:

To adjust the signal input/output to the Angle

of rotation of the damper/valve the button T

24...230 VAC/DC

+

~-~

must be pushed for minimum 3 sec.

VDC/mA

U

mA

U

VDC

B

6

I

SB 5.3SB 5.2

U

mA

U

VDC

PE

I

A

123 4

heater

Selection of running time for spring return:

Standard wiring = spring return in ~10 Sek

Additional wiring terminal 5 = spring return in ~ 3 Sek

5

1

2T3 45

Reverse function:

bridge 3--4 reverse input and output

signals.

I

B

6

3-sec. mode, 3-pos-operation, heating by low ambient temperatures

I. Operation with 3 sec. motor running time mode

While operating the ExMax actuator in 3 sec. mode following parameters have to be aligned:

1. Maximum cyclic duration 10% ED, maximum 1 cycle/min.

2. Exeeding above mentioned parameter the actuator will remain functionless until cooling

has occured. At 2 wire mode (circuit diagram SB 2.1 / 7.0 / 7.2) the cool down is

funtionless. The cool down must be guaranteed by control system.

3. The actuator must be operated with an outside load of at least 3 Nm.

4. After installing the actuator to the damper/armature an automatic alignment has to be

accomplished, in order to obtain a "gentle blockade/stop". This function protects the

damper/armature by reducing the end positions/blockade speed in order to avoid

mechanical overload. The actuator alignes specifically once with 30 Sec/90° onto each

position, recognizes the blockade position in order to reduce the motor performance

during operation briefly before reaching the end /blockade position.

II. 3-pos operation

ExMax (RedMax) actuators are in the best way suitable for the 3-pos operation.To protect

such elements as gears and mounting elements against harmful influences like minimum

pulse time, ExMax (RedMax) actuators are protectet via internal electronics. The internal

PE

ab

A

123 4

heater

Selection of running time for spring return:

Standard wiring = spring return in ~10 Sek

Additional wiring terminal 5 = spring return in ~ 3 Sek

Function of switch a and b:

- a closed, On (Off) - in acc. to left/right mounting ot the actuator

- b closed, Off (On) - in acc. to left/right mounting ot the actuator

5

1 2T3

I

45

Reverse function:

bridge 3--4 reverse input and output

signals.

6

I

B

PAPA

electronic permits 20 impulses with < 0.5 > sec. cyclic duration, afterwards at least

1 impulse > 1 sec. must follow. If clocked with more than 20 impulses each < 1 sec. the

actuator will adjust into a suspend mode.There after a reset is mandadory and will be

achieved by briefly switching of the supply voltage for about 2 sec..The controll unit has

to be parameterized in order to be set within the above mentioned duration limits.

III. Use at low ambient temparature below - 20°C

All ExMax (Redmax) actuators are equipped with a regulated integrated heating device

designed for employments down to -40°C ambient temperature.

The heater will be supplied automatically by connecting the constant voltage supply on

the clamps 1 and 2.

Following parameters are to be considered by ambient temperaure < 10°C:

1. After mounting the actuator must bei immediately electrically connected.

2. The actuator will only be activated after the operating temperature has reached at least

-20°C .

3. The adjustment options are only ensured after this heating up period.

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

www.schischek.com

Page 8

ExMax-.. and RedMax-.. extra information EL - size S

Error indication

Error/Symptom Reason Solution

EXPLOSIONPROOF

Actuator does not work

01

LED does not lights

Actuator does not work

02

LED lights red

Actuator does not work

03

LED lights green

Acuator does not work

04

LED is red blinking

l No power supply attached

l The actuator is operated beyond ex-prevention

ambient temperature specifications and the internal

temperature sensor did irreversibly shut down

operations

l The actuator is operated by a too high ambient

temperature and the internal temperature sensor

responded

l 3-Pos control signal is wired on both entrances

l Required torque is greater than actuators torque

l Control signals are not attached or attached on a

wrong conductor

l Actuator is incorrect mounted and is blocked by an

external stop unit

l Actuator is clocked with more than 20 impulses <0,5

per sec. and therefore adjusted into suspend mode

l Interchanged supply lines

l The actuator has been mounted by temperatures

of less than -20°C and did not reach is operating

temperatur of at least -20°C.

l Attache power supply and turn on

l Because of inadmissable operation the actuator drove out of safety

relevant reasons into an irreversible condition and must be exchanged.

Accompanying new installation the ambient temperature has to be

reduced accordingly

l Shut off actuator and let temperature decrease, reduce ambient

temperature by suitable measures e.g. ventilation or other mounting

position of the actuator

l Readjust/correct circuit

l Adjust a higher torque at the actuator if possible otherwise exchange

for a type with higher torque.

l Examine rule and adjusting signal in accordance with attached diagram

l Dismount actuator and testdrive without load for operability. Install

actuator accordingly that the power transmissions runs without external

blockade or torsion

l Switch off supply voltage for at least 2 sec. thereby a reset is conducted

Readjust controller in order to extend control pulses

l Wire 1 must be (-, N) and wire 2 (+, L)

l Ensure that a constant voltage supply on conductor 1--2 is existing.

l Wait until the required operating temperature is achieved by the actuators

internal heating system.The actuator will start operating independently

Spring return funktion is 10 sec./90°,

05

should however amount to 3 sec./90°

Spring return funktion is 3 sec./90°,

06

should however amount to 10 sec./90°

Actuator does not start after more than

07

2 briefly following adjusting functions

in the 3 sec. mode where set

Y-drive in the 3-pos mode can not gear

08

into intermediate positions

Actuator sits diagonally on the squared

09

damper shaft

Actuator is with clamp stand KBS

10

actuated installed onto damper shaft

and does only partly or not at all drive

A modulating actuator (Y) works with

11

reduced angle of rotation and already

reaches its end positions before O V/4

mA, respectively before 10V/20mA.

LED flashes irregularly and actuator

12

does not work

l Bridge 2 --5 is not established l Bridge conductor 2 of the constant voltage supply with conductor 5

l Bridge 2 --5 is established l Disconnect bridge

l The maximal permissable cyclic duration of 10%

ED was not complied to, the actuator is in a safety

disconnection mode

l The conversion of constant mode on 3-pos-modus

was not set

l The actuators have an angle of rotation of 95°

inclusive 5° pre-tention. While assembling the preloading was not considered

l Provided that the electrical basic conditions specified

above are fullfilled, the anti- twist plate could be so

installed that the actuator blocks itself due to the

twisted and not centric shaft connection and therefore

interlocks

l At start up no self adjustment of angle of rotation

was accomplished

l Actuator does not receive sufficient supply voltage

l Cable to long, voltage drop in the supply line to large

l Wait approx.1 minute until internal electronics cool down to operating

temperature.

l Recalibrate the actuator in accordance with assembly instructions

l Dismount actuator of the damper, use the enclosed socket wrench to

draw up approx. 5° over the hand operated control device before

remounting on the damper shaft. Consider additional information ME

of the assembly instructions

l Loosen the anti-twist plate and remount that the actuator can implement

an easy oscillationg motion over its angle of rotation

l Accomplish self adjustment of angle of rotation in accordance with

assembly instruction

l Increase line cross section or increase tension at the transformer/power

suply unit

l Increase line cross section or increase tension

M.EZ-01.05-S-en-Zusatzinfo EL

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

2006-04-05

www.schischek.com

Page 9

ExMax-.. and RedMax-.. extra information ME - size S

EXPLOSIONPROOF

ExMax/RedMax - extra information ME

The "ME"-data sheet contains additional information for ExMax and

RedMax actuators of the size "S", for the optimization and simplification

in regard to planning, installation and initial start up. It provides

influences of external factors in reference to the safe initiation of

the actuators. In particular it represents the installation, as well as

different flabs, fire protection flabs and armatures. Additionally

describing different accessory elements and their mounting to the

actuator.

For additional electrical data have a look at "extra information EL"

Dimensions - drill template

Dimension size S

Dimension in mm

Side R

60

inl. radius

of bend for

the cable

210

Side L

u

Dimension, drill template

u

Control elements: switch - push button - LED

u

Outdoor installation

u Mounting using form-fitting shaft connection (square shaft)

u

Mounting using clamp mounting (round shaft)

u

Mounting on butterfly valves and ball valves

u

Mounting on fire dampers

u

Mounting ExBox (RedBox), ExSwitch (RedSwitch)

118,5 30 30

80

6 x Æ 4,4

6 x M 4 Double sqaured 12 x 12 mm

14

74

95

Control elements: switch - push button - LED

Specification

All ExMax and RedMax actuators are equipped with a 10 position switch a push button

and a multicolor LED for calibration. These control elements are to be found cablelaterally behind the two middle sectioned dummy plugs. For operation these must be

removed. The calibration can be achieved despide lining up tension at the actuator.

The explosion prevention is not impaired thereby. However it has to be of great concern

that the dummy plugs must be rescrewed in order to comply with the IP-protection

class. The operation of the switch and button has to be done by means of a small

screwdriver. Force with strong pressure and /or rotation is to be avoided in any case,

since otherwise control electronics can be damaged irreparably. By bad visibilities a

flashlight (certified within the EX-range) should be used. Attitudes of torque and running

time can be achieved also before mounting. The adjustment of angle of rotation can

be started only with an outside load and accurate mounting.

Outdoor installation

Specification

When mounting actuator outdoors it has to be certain that the actuator is protected against

direct sun exposure (warmth and UV), rain and snow by employing an enclosure roof.

Supply voltage is to be applied immediately after mounting in order to assure integrated

heating at start. Since explosion proof actuators must have internal safety temperature

limiters, these may not be exposed neither at storage nor during operation to a too high

temperature. Otherwise the limiters could respond and switch of the actuator irreversibly.

Switch - push button - LED for programming,

behind dummy plug

S

10-position switch (S)

Push button (T)

3-colour LED

T

RST

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

www.schischek.com

Page 10

ExMax-.. and RedMax-.. extra information ME - size S

EXPLOSIONPROOF

Mounting instruction for ExMax and RedMax actuators size S on air dampers

Specification

ExMax and RedMax actuators size S are equipped with a 12 x 12 mm (double square) shaft connection. The form-fitting shaft connection is the securest connection between damper

shaft and actuator because slipping or slipping through is avoided compared to the force-fit clamp-connection. The actuator will be connected firmly by means of four screws

M 4 x 100 (scope of supply) to the damper. For the connection to round damper shaft or square damper shaft with smaller or larger 12x12 mm an optional mounting clamp

(type KB-S) for tensionally locked connections is available.

Form fitting mounting on square damper shaft Mounting clamp type KB-S

Dimension damper shaft

A

12 x 12 mm

M4 x 100

Length A

Dimension A in acc. with indicator

1. Actuator without indicator A = no limit

2. Actuator with indicator, no accessories A < 65 mm

HV

Dimension squared damper shaft Dimension round damper shaft

A

10..16 mm

1. Pre-assembly clamp

2 x

3. Pre-assembling mounting bracket

2. Fixing the clamp

4. Mounting to the damper

A

Æ 10...20 mm

Length A < 25 mmLength A < 25 mm

4 screws M4 x 100, as well as a socket wrench, are part of delivery for ExMax/RedMax

actuators size "S".

For damper shafts 9 x 9, 10 x 10 or 11 x 11 mm reducing bush are optional available.

Mounting instructions form-fitting shaft connection

It is to be considered that the actuators have a total angle movement of approx. 95°

in order to realize a pre-tention on the damper. Therefore the actuator sits tilted on the

damper shaft. In order to prevent this and to assure pre-tention to the damper the driving

shaft has to be adjusted mechanically before connecting to the damper shaft.

The provided socket wrench serves for the mechanical adjustment over the hand-operated

control socket HV. The actuators are axially symmetrically developed. In case of spring

return function the safety postion must be selected by turning the actuator 180°.

Mounting:

1. Affix tap hole M6 (in accordance with drill template) on the damper or to a mounting

bracket.

2. Adjust drive shaft of the actuator with the socket wrench that the drive stands

perpendicular to the damper before pluging actuator on to the damper shaft.

3. Plug actuator onto damper shaft and fix diagonally with 2 screws.

4. Remove the socket wrench.

5. Pivot and tighten the remaining screws.

Note: the drive shaft is selflockingly produced and may only be mechanically adjusted

either with the provided socket wrench or the optional accessory "HV-S" manual override.

External applied force to the shaft can lead to mechanical damage of the actuator.

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

Mounting instructions for mounting clamp

The actuators are axially symmetrically developed. In case of a spring return function

the safety position must be selected by turning the actuator 180°.

Mounting

1. Insert u-bold connection into drive-shaft and screw the bold from the opposite side

tight with the socket wrench.

2. Screw in two screws functioning as an anti twist locking device.

3. Install mounting bracket at the damper.

4. Plug the actuator to the damper shaft, adjust the actuator in the mounting brackets

position and tighten the damper shaft with a wrench socket via the u-bold connection.

Attention!

The actuator must be installed in such a way that it can implement an easy oscillating

motion in the mounting bracket for the reconciliation of the not centric connection.

Note: the drive shaft is selflockingly produced and may only be mechanically adjusted

either with the provided socket wrench or the optional accessory "HV-S" manual override.

External applied force to the shaft can lead to mechanical damage of the actuator.

www.schischek.com

Page 11

ExMax-.. and RedMax-.. extra information ME - size S

EXPLOSIONPROOF

Mounting instructions for ExMax and RedMax actuators size S

on butterfly valve and ball valve

Specification

ExMax and RedMax actuators of the size S are equiped with a 12x12 mm (double square) form-fitting shaft connection. For mounting to butterfly valves or ball valve a special mounting

bracket in acc. with DIN EN ISIO 5211 is required. Since this standard provides only certain basic conditions there can be substantial geometrical differences between armatures

which require a special adaption.

Mounting to a ball valve Mounting to a butterfly valve

4 x4 x

Mounting instructions for ExMax and RedMax actuators Size S on fire dampers

Specification

ExMax and RedMax actuators of the size S are equipped with a 12x12 mm (double square) form-fitting shaft connection. The form-fitting shaft connection is the securest connection

between damper shaft and actuator. The actuator is fixed with four screws directly to the fire damper and/or fixed to a mounting bracket. ExMax-...-BF and RedMax-...-BF actuators

integrate an intrinsically safe circuit in order to connect a FireSafe sensor which works like a temperature limiter.

Fire damper

Assembly

It is to be considered that the actuators have a total angle of rotation of approx. 95°

in order to realize a pre-tention on the damper. Therefore thr actuator sits tilted on the

damper shaft. In order to prevent this and to assure pre-tention to the damper the driving

shaft has to be adjusted mechanically before connecting to the damper shaft. The

provided socket wrench serves for the mechanical adjustment over the hand-operated

control socket HV.The actuators are axially symmetrically developed. In case of a spring

return function the safety postion must be selected by turning the actuator 180°.

Mounting:

1. Affix tap hole M6 (in accordance with drill drill template) on the damper or to a mounting

bracket.

2. Adjust drive shaft of the actuator with the socket wrench that the drive stands

perpendicular to the damper before pluging actuator on to the damper shaft.

3. Plug actuator onto damper shaft and fix diagonally with 2 screws.

4. Remove the socket wrench.

5. Pivot and tighten the remaining screws.

6. Mount temperatur limiter type Fire Safe

7. Mount terminal box

8. Wire connect actuator and sensor in the terminal box

Note: the drive shaft is selflockingly produced and may only be mechanically adjusted

either with the provided socket wrench or the optional accessory "HV-S" manual override.

External applied force to the shaft can lead to mechanical damage of the actuator.

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

www.schischek.com

Page 12

ExMax-.. and RedMax-.. extra information ME - size S

Mounting of terminal boxes type ExBox (RedBox)

via mounting bracket type MKK-S to the actuator (accessory)

Specification

1. Screw mounting bracket MKK-S to the actuator (A)

then terminal box to the mounting bracket (B) schrauben

(B)

2 x

(A)

2 x

Mounting bracket MKK-S can be mounted every 90°

EXPLOSIONPROOF

Terminal box mounted above the actuator Terminal box mounted beside the actuator

Mounting of ExSwitch (RedSwitch) accessory to the actuator

Specification

1. Put the squared connection part to the actuator, then mount ExSwitch(RedSwitch) and

fix it with 4 screws

4 x

2. ExMax (RedMax) with mounted ExSwitch (RedSwitch)

M.MZ-01.01-S-en-Zusatzinfo ME

Schischek GmbH Germany D-90579 Langenzenn, Mühlsteig 45, Gewerbegebiet V, Tel. ++49 (0)9101-90810, Fax ++49 (0)9101-908177, Email ExMax@schischek.de

www.schischek.com

Loading...

Loading...