Page 1

3892-93120

()RedMax"

AG431

Ovvner/Operator

Manual

and

Service Parts List

)

1M

PORT

ANT: Before operating your RedMax < product, read this manual carefully and completely.

This manual will provide you with a full understanding of the

necessary

instructions

for assembly, operation and maintenance of the equipment. For continued safe and

c.-)

reliable operation, use only parts supplied by manufacturer.

Adhere

to

all notes and

warnings.

Page 2

..........

r

or

Safe Operation

Know Your Unit

Read this Owner's Manual carefully until

you completely understand and can follow

all safety rules, precautions, and operating

instructions before operating the unit.

1

i

Restrict

you

r unit to users who understand

r

and follow

aJi

safety rules, precautions, and

i

operating instructions found in this manual.

J

1

Children should not be allowed

to

operate

this unit.

Plan Ahead

Dress

in

long pants and wear boots or safety

shoes. Use protection gears for your eyes

and ears.

Do

not wear Ibose clothing, jewelry, short pants or sandals. Do not go

barefoot.

)

Guard against hazardous situations at

all

times. Warn adults to keep pets and children away from the work area. Establish a

safe method for gaining your attention during operation.

Be

careful if you are ap-

proached.

Do not operate the unit when you are tired,

ill,

or

upset; or if you are under the influence

of alcohol, drugs, or medication.

Inspect the work site before each use.

Remove

all

debris and objects that could be

thrown, become entangled

in

the drill, or

cause damage during operation.

Handle Fuel with Caution

Eliminate

all

sources of sparks or flame

(including smoking, open flames, or work

that could cause sparks)

in

the area where

fuel is mixed, poured, or stored.

Mix, pour, and store fuel in

an

approved,

\

.,

marked container and

in

a well ventilated

area.

\J

Be sure

to

stop the engine before refueling

the unit.

Do

not smoke while handling fuel or while

operating the unit.

Wipe up

all

spills before starting the engine.

Move at least

10

feet

(3

meters) away from

fuel and fueling site before starting the

engine

..

Operate Your Unit Saiely

Inspect the entire unit before each use for

worn, loose, or damaged parts.

Do

not

use

until the unit

is

in

proper working order.

Keep the handles free of oil

and

fuel.

Never start or

run

the engine inside a closed

room or building. Exhaust fumes contain

dangerous carbon monoxide.

Keep the engine idle speed adjusted prop-

erly

so

that the drill comes

to

a complete

stop when trigger

is

released.

Be

sure to stop the engine before refueling,

inspecting or leaving the auger un-attended.

Always use both hands

to

hold the auger.

Do

not use any accessory

or

attachment

other than those supplied or authorized by

the manufacturer for use with this particular

unit.

Maintain Your Unit Properly

Disconnect spark plug before performing

maintenance except for carburetor adjust-

ment.

Use only recommended, genuine replacement parts

to

avoid creating hazard and/or

voiding your warranty.

Page 3

Do not store the unit or fuel in a closed area

Wear

protective gloves when handling or

where fuel vapors can reach an open flame

performing maintenance

on

the drill.

from hot water heaters, furnaces, etc.

When transporting or storing the auger, drain

Store in a dry area out of the reach

of

fuel from the fuel tank.

children.

Fueling

Mix a regular grade gasoline (leaded

or

un-

leaded, alcohol-free) and

RedMax~

motor oil

or

a quality-proven air cooled 2-cycle engine oil.

Recommended

mixing ratio is 32 to 1.

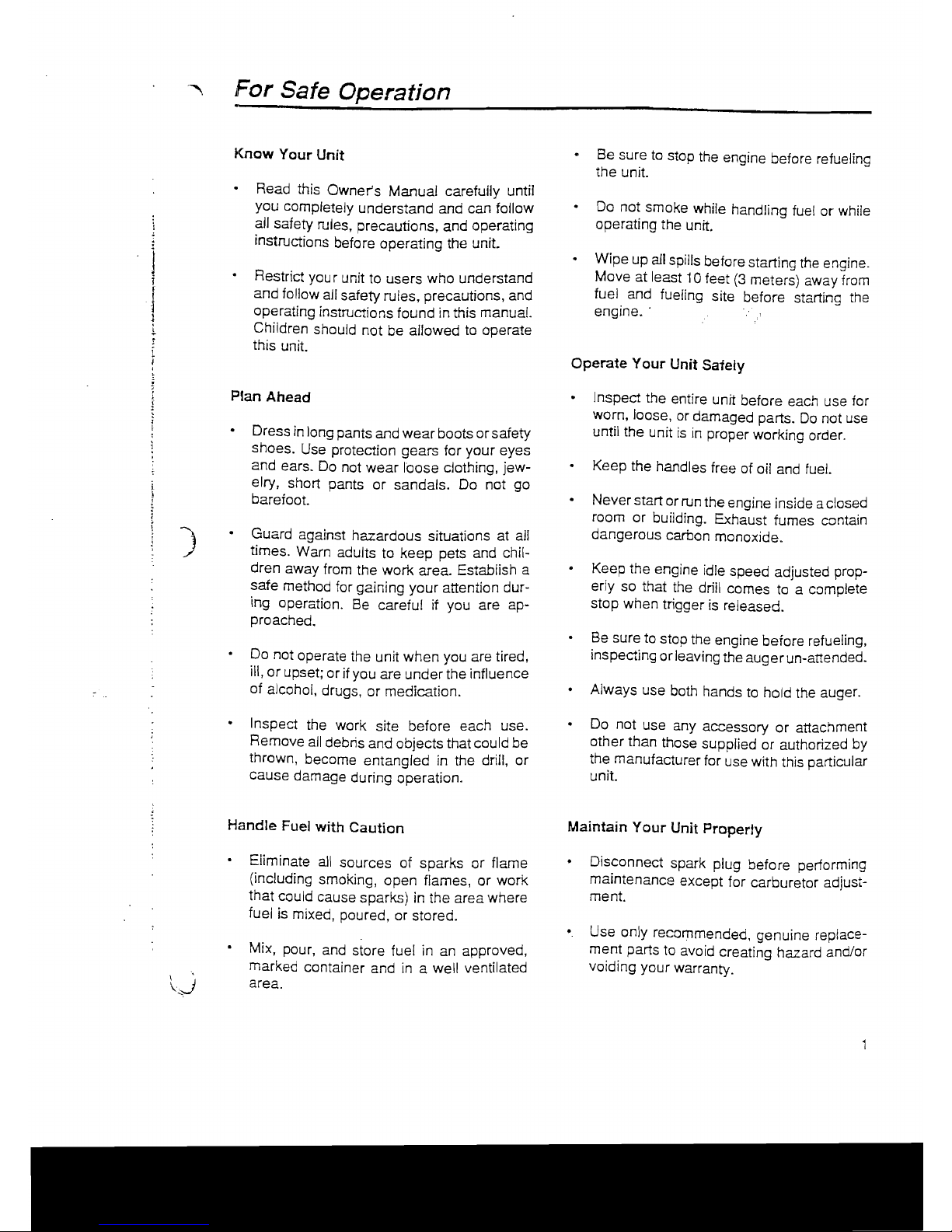

32:1

Mix

Chart

5

-g_a~I_lo_n_s

I

2

3

4

i

I Gasoline

I

1

I

,

!

__

---'_-'-_'----:---j

'!

[ 2-cycle oil -ounces

L1

8

112!

16

20

I

: I

I

A'

Keep open flames away from the

area where fuel

is

handled or stored.

• Mix and store fuel only

in

an ap-

proved gasoline container.

Make sure to use the proper fuel as most engine

failures are caused by

or

closely related to the

fuel used at

that

time. For example;

If

no oil

is

mixed

in

the fuel, the engine will

undergo a poor lubrication, resulting

in

heavy

damage to the piston and cylinders in a very

short time.

2

An alcohol-mixed fuel can deteriorate the

rubber parts used

in

the fuel supply system.

The use

of

a motor oil for 4-cycle engines

will lead to the spark plug fouling, carbon

accumulation, and the piston ring sticking.

The use of an aged fuel can

cause

a starting

failure and lack of power.

Water-contaminated fuel can cause a fluctuated engine revolution and a carburetor

corrosion.

Page 4

Operation

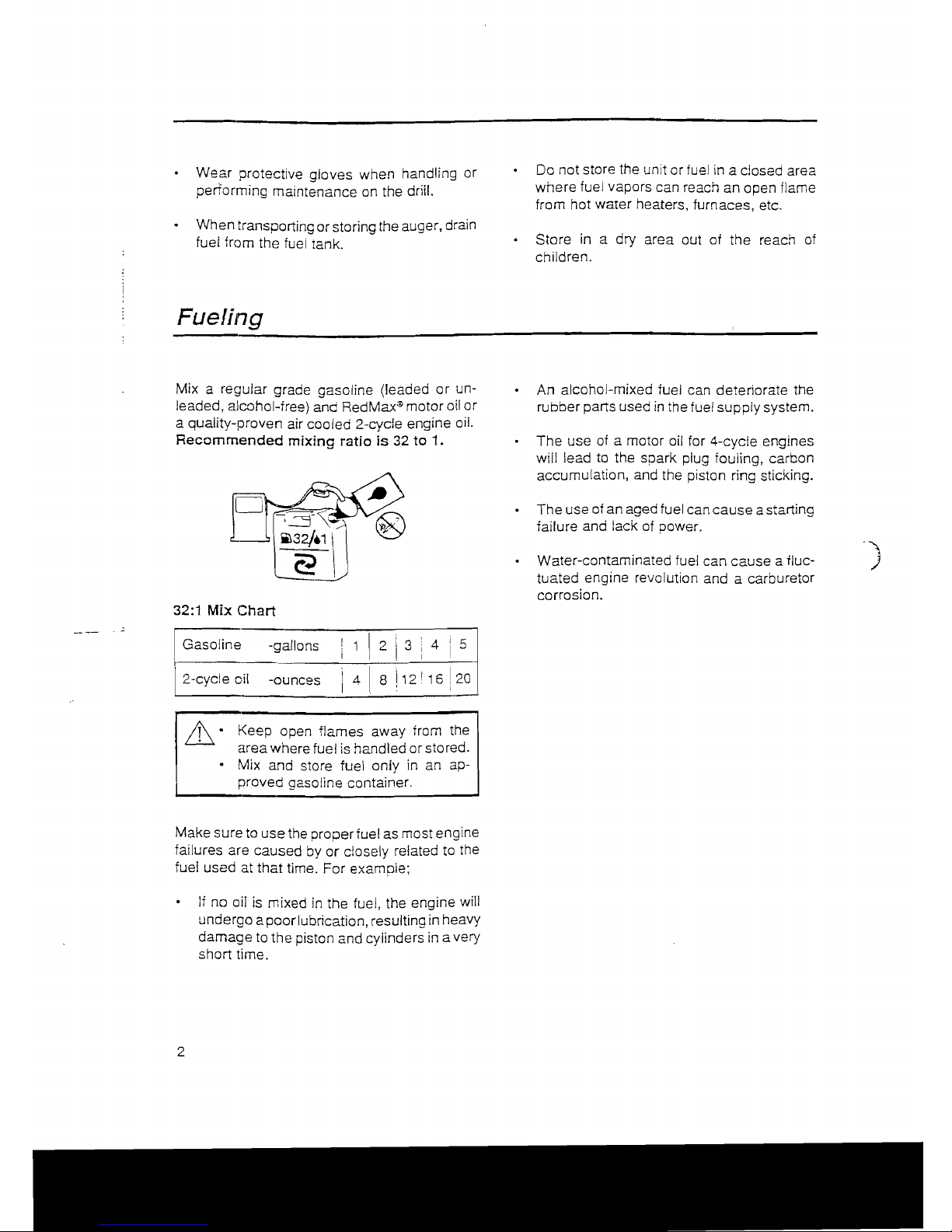

Installing Left Grip

Starting Engine

Screw

in

the left grip to the bracket provided on

1.

Open the fuel shut off.

the frame

and

tighten securely.

Fuel

vaJve

2. Press

on

the tickler lever until fuel flows out

Installing Drill

in the ovetilow pipe.

1.

Slide the ring clip and remove the lock pin

from the drill.

2. Put the drill onto the auger output shaft and

)

insert the lock pin. Cover it with the ring clip.

L3--

PTO shaft

Cc;p

b,"d

~

c:::::::,/

--+

I III

3.

Close the choke (shift the lever upward). It

Drill-----l

!I Pin

can

be

kept open when restarting the engine

right after stopping

it.

Throttle Cable Play

Check the throttle cable play and adjust

to

.04 or

.aEl

in. as necessary.

Big

I •

V

3

Page 5

4. Hook

up

the throttle lever in the starting

position.

L.ock

spring

5.

While supporting the auger with your left

waist and left hand as shown

in

the figure,

pull the starter rope, first lightly and add

force when compression is felt.

I!\

Keep the drill

clear

of everything

.

a.

round it

as

it will start rotating upon

starting of engine.

~

6.

When the engine has started. gradually open

the choke and release the throttle lever.

7. Allow the engine to warm up for a half

minutes before starting operation.

4

When re-starting immediately after stopping the engine. keep the choke open.

If the engine won't start after repeated attempts,

it may be overfed with fuel.

Remove and dry the spark plug, and try

to start again with the choke open.

Stopping Engine

Release the throttle lever and press on the red

button until the engine comes

to

a complete

stop.

Drilling

Keep a firm grip of the auger at all times

on

a wide stance and by holding the handle with

both hands.

A reacting motion may occur on the auger

when spinning drill has hit on stones or tree

roots under the ground. Always hold the

auger securely

to

control such motion.

Page 6

Start drilling with haJf-throttle, and gradually

increase the engine speed so that the drill

may get into the ground smoothly.

I

1

When the drill has been caught

in

the ground

and cannot

be

pulled out, stop the engine

and rotate the auger counter-clockwise.

1

J

jWaintenance

Adjustment of Idling

Spee<:i

The engine idling speed has been preset at the

factory

to

the

normal condition.

When it

is

too

low

or

too

high, adjust the idle

adjustment screw

on

the carburetor.

\

Idle adjusting screw

)

J

,

..

Before cleaning, inspecting or

re-

pairing the auger, make sure that the

engine has stopped and cooled

down. Disconnect the spark plug

terminal to avoid accidental engine

starts.

Daily Inspection

Check

all

nuts and screws are securely

tightened and no parts are missing.

Check for leakage of fuel.

Periodical Inspection

Check the air filter every 50 hours of use or

more frequently

if

used under very dusty

condition, and clean the element

in

warm

soapy water

as

necessary. Dry completely

before installing.

Check the spark plug every 50 hours of use

and clean the gap with a wire brush. The gap

should

be

set

to

.025 in. When replacing with

a new plug, use a

Champion RCJ 8Y or

NGK

BPMR

6A.

.024'

5

Page 7

Fuel Filter

Check oil level of the gear box every

50

hours of use and change with new oil

as

A clogg,:d fuel filter can cause lack of power and

necessary. (SAE #80 - 90).

poor pickup. Check the fuel filter every

25

use

hours.

1.

With a small wire hook, pull the fuel line

and

filter out of tank.

2.

Disconnect the

fi1ter

assembly.

3.

If

necessary, replace with new filter

or

clean

by blowing air inside out after spraying a

carburetor cleaning solvent.

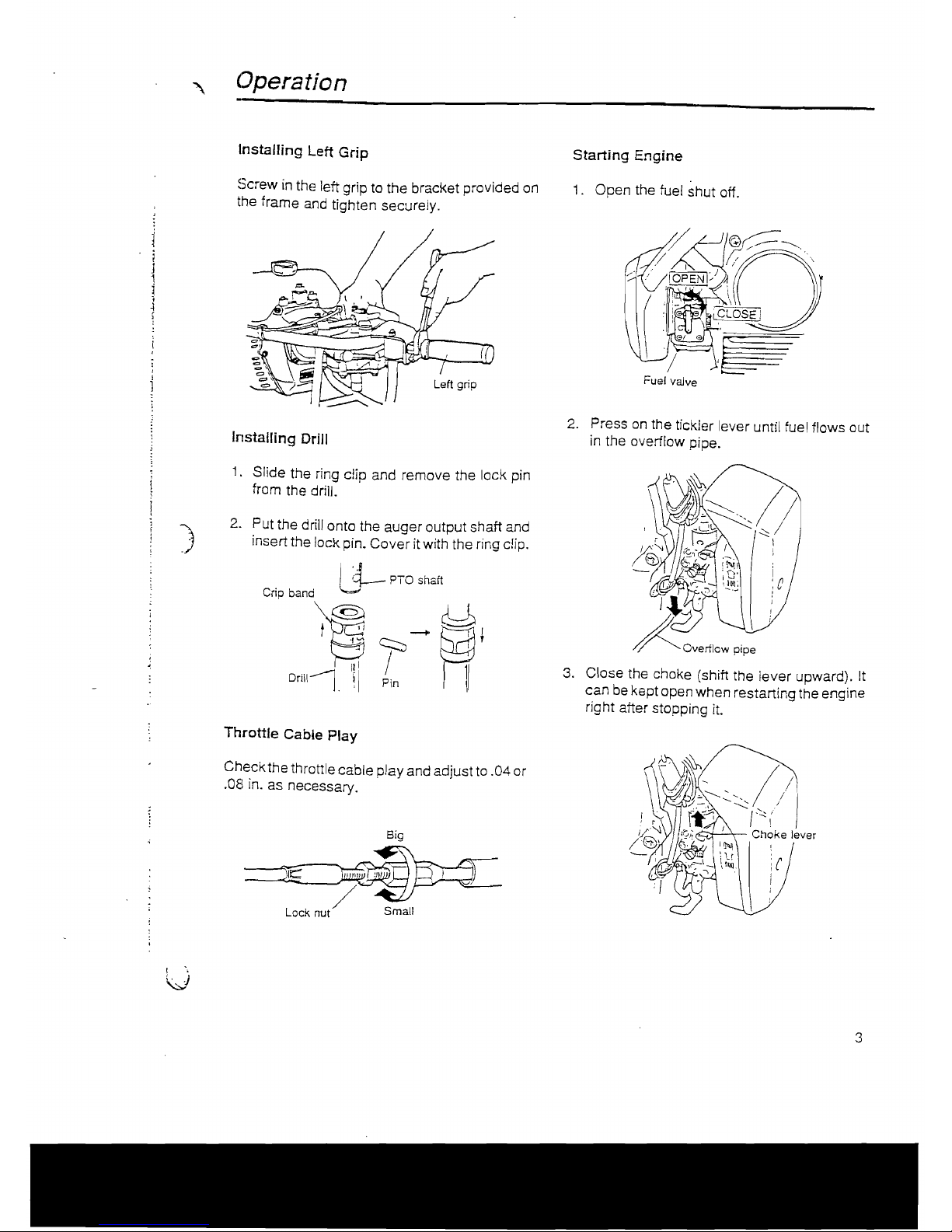

Spark Arrester

This en!;line

is

equipped with a spark arresting

screen at the exhaust port. Check periodically

to

see if it

is

in

good condition, especially when

your machine

is

to be used on any forest covered, brush covered, or grass covered unimproved land.

In

the State of California the above

is

required

by

law (Section 4442 of the California

Public Resources Code).

1.

Remove the muffler guard and pry off the

spark arrester from the exhaust port.

2.

Clean the metal screen with a wire brush.

If

damaged, replace with new one.

~~

rr

~

!I~

~

.. I

c:=I[)

?3:\~

======;!J

©

-=~==::rJ==/

\ /

Muffler

auard

"--

Spark

arreSI~r

6

Recommended change interval:

1st : After 50 hours of use

2nd and on : Every 100 hours of use.

Disconnect the engine from the gear box

and check the clutch condition every 100

hours of use. Wipe off oil attached

to

the

drum and shoes, and replace parts with a

new

one if found to be worn.

Before

Long~term

Storage

Drain fuel tank and run the engine out until

all fuel

in

the carburetor

is

used up.

Remove the spark plug and drop a spoon of

2 cycle oil into the cylinder.

Crank

the engine

several times and replace the plug. Pull

starter until compression is felt.

Page 8

Specifications

..

~

I

Model Name

I

I

Engine:

I

I

Displacement

cu.

in

(cc)

Maximum power

HP

Carburetor

I

Ignition system

Spark plug

Starter

I

i

Fuel

i

i

Fuel tank capacity

fl.QZ

(lit)

I

Transmission

Gear box lubricant

I

Reduction ratio

I

Grip span

in

(mm)

I

Overall dimension:

Length

Width

Height

in

(mm)

in

(mm)

in

(mm)

Dry

weight w/o drill

Ibs

(kg)

,

I

Adaptable drill size:

I

Diameter

in

(mm)

I

AG431

2.53 (41.5)

2.02 at 7000

rpm

Diaphragm type (TK)

Electronic (T.C.!.)

Champion RCJ-8Y

Recoil starter

2 cycle oil premixed gasoline (32:1)

34

(1.0)

Centrifugal clutch,

worm gear reduction

Gear

oil SAE#80-90

45:

1

22.8 (580)

24.8 (630)

11.3 (287)

11.7 (298)

20.0 (9.1)

1.6

to

8 (40

to

200)

Specifications are subject

to

change without notice.

7

Page 9

Service Parts

Ust

Fig. 1

ENG

INE

GROU

P

. not

jncrvldu~

Numoar

COlumn

are supplied.

an

numOer.

Those

Nota:

an

assam

Oly.

... in

Iha

column

Pat1

ara nol

lor

assemoly

p

rd

uOll.

Out

Tha

pans 5indlcata

marl<s

seePlaase suppllad

ally

out

a

'OP'

in Ina

Re

@--'17

. d oy Ihe Remarxs . wrth

stanoa

pans

WIth

saoarara orcer.

:...

avauaDle

by

0+-118

125 @l

©-J

129

:.

.---,'

.

116

' "

'1/

;n

,,---,"

~

4138

/>--",

'

./«

/

~

/\~,y;.

:

II

/,

~/'i,

"

~<Q

-

'17@!%

/~.c-=

<

"~\:".

'~-J

",[('

"'"

" " "

if

'",

142

~o

,:"~-

I Vi'

(!j'"

L-",

",

I

34

~

39

42

" .

"\

'::A"",

'

"i&C/:uG~

// "

16

r:,' a

fc:,;~[7\I5\"

,,/

'~:i

-----~~

\ \

46

55

3~

~

• ,

"

F-

'" ", @

,,-"

I'Cl

"\'

_:

........

I

l}-"

\~

(y ,•.

"

'r-U

c::",

\\

'

//~,.

~74

\

~

"':;,'i~f~4;~'~,

-\'

28~

29

'00-

-1

's--...;

~>O,

-

'"

4

_

30

>0

""

''-'

'---Oftt-~-

//

-

-v"'...-

11;-----105 I '

'.

>0'

, /

'.

:gj~::

~lt~:~lLr-~6

1

97

(!l)

~

113

.

51

~-84

/.

_"

I"/,,,

\

"

~'K-96

.~.

'~~~

",~~

",

'

...

' 110

I

.2---25

11'

Page 10

.~

.,

1

~

I

I

lnaex

I

PartNU_!

101'(

1*'1

Re_

Descr1ptJon

Iie_

1

Index

I

f>artNumber

OMo1pt1on

0

';:.:'1

Remeno

No.

"nn

I

117'9-7527 I

SCREW

66

1

1

1400-12112

1

CYUNDER

1400-75160

67

ROPE

2

1

1400-13121

.1

GASKET

1400-75170

KNOB

ea

3 1

1420-131

:JO

1

GASKET

1179-75340

CAP

69

4

I

1400-13150

1

GASKET

1400-.5211

70

PULLEY,

Sla11er

1

5

1

1420-13160

INSULATOR

1428--.5411

71

LABEL

1

6

3310-12280

4

BOLT

1400-75510

SCREW

72

4

138

0260-:30525 2

SCREW

7

0260-30540

2

SCREW

14:iD-81

000

CARBURETOR

ASS'Y

1

7410108

8

1421-15110

I

MUFFLE:R

74

BODY. c:arnurelor

·142Q-810oo

'139

I

1421-15120

1

SPARK ARRESTER

CAp,boay

1650-81122

75

I

9

1400-15410

I

COVER. mutfler

1420--81480

76 DIAPHRAGM ASS'Y

I

10

1400-13142

1

GASKET

1101-81950

n PACKING. diaohragm

11

1

1140-51230

2

WASHER

1420-81150

78

YALVE. tI1mltle

I

12

0212-50665

BOLT

1335-81070

79 RECEIVE, lhrottle spnng

I

I

13

4

1400-15510

SCREW

2

I

103:8-81001-29

80

SCREW, aojUst

I

I

1650-81250

81

SPRING. adjust

=-ew

'14

1

I

1400-21100

CRANK

CASE

COMp

1420-81271

82 SCREW, M.J

adjust

"5

1

1400-21140

1

GASKET

1420-81370

83 SPRING. M,J

adjust

screw

1

'16

06030-06202

2

BEARING

1420-81490

COVER.

diapn"'llm

84 1

'17

1520--21220

1

SEAL

1420-81420

85 HOLDER. needle

Jel

I

'Ill

1

04065--C3515 RING

1420-81410

JET, needle

86

1

19

1400-21220

1

SEAL

1420-81730

PACKING, pumo

87

1

~~O

4

0260-00530

SCREW

1420-81720

DIAPHRAGM,

~mp

8B

1

1101-81190

89

CUP.

jot needle

1

~~1

1400-31111

I

COVER. t3n

1420-81180

NEDl£,jet

1

90

~2

4

0263-60520

SCREW

,

1325-81060

91 SPRING, Ihrottle

I

23

1100-72120

GROMMET

OZSO-10310

92

SCREW

2,4

4

1400-32110

1

COYER, "Yonder

1420-81801

93

PUMP COVER ASS'Y

1

25

1400-15510

2

SCREW

3422-81130

CAP'

S4

1

26

I

1633-31120

LABEl

1130-81170

95

YALYE ASS'Y

1

1

1400-15510

"lQ

SCREW

0260-103C8

SCREW

96

4

142

I

1600-86130

CLAMP, pipe

1420-81510

97

LEVER, lid<Ier

1

1420--8

1520

98

SPRING.

tlcI<Je,

I

27

1400-41111

1

PISTON

0260-00408

99

SCREW

1

28

1400-41220

2

RING, piston

1420-81530

100

COU..AR

1

Z9

1400-41310

1

P'N.

piston

103

0260-00306

SCREW

I

3iJ

33-SO-41320 2

RING

104

1100-81461

PIN, hinge

1

31

1

1400-41410

BEARING

1100-81440

105

YALYE, needle

1

3:2

2616-41510

2

WASHER. thrust

106

1420-814:30

SP RING, hinge

1

3:3

1400-4ZOO1 1

CRANK

SHAFT

COMp.

1420-81450

107

HINGE, valve

I

:J.l

0-1

1300-42410

SHIM

1420-81620

108

CAP,

M.J

saew

I

3S

1000-43240

I

KEY

1420--85180

109

PIPE

3lj

I

0290-21025

I

WASHER

3:1'

01641-21016

WASHER 2

1421-8:2002

Cl..E.ANER

ASS'Y

11010

113

1

311

11ClO-43231

NUT 2

110

BODY, Cleaner

"1421-82002

I

,

11

140C---321

:JO

ELEMENT

1

3~1

1400-511'0

SHOE 2

112

"1421-82002

COYER. cleaner

4(1 I

1200-5121

I

SCREW 2

113

1133--82060

LABEL

41

I

1400·51220

1

SPRING. clutch

114

0260-30422

SCREW

4"

..

2

1200-51230

WASHER 2

1423--831

00

llS

CABLE

CaMP.

4;;1

1

1200-51240

WASHER 2

142O-a5OCl3

TANK

ASS'Y

11610

121

4-ol.

1

1400-71110

I

ROTOR

116

TANK

"1420-85003

I

4S to

41 &.14

1650-71200

1

COILASS'Y

1~

4S

-'650-71200

1

1117

&

118

I

COIL

I

CAP

ASS-Y

117

CAP

46

1

\"1600-85202

1400-71220

1

CORD

1600-8$302

YALVECOMp.

118

47

I

1400-71230

1

CAP

FILTER COMp,

119

3306--a5400

14'1

1

I

I

1650-71241

1

CORD

\ 420--85400

pIPECOMp.

120

46

1400-71311

UNIT 1

1260-85450

121

CUP

I

49

3320-7221

I

1

GROMMET

I

1063--861

:JO

122

CUP

50

1100-72120

1

I

GROMMET

125

16ClO-86120

SCREW

51

3

1400·721

I 1

1

CAP, plug

1400-86213

127

SUPPORT. tanK

52

1

1400-72121

SPRING I

14lJ()-85250

128

COU..AR

53

I

1216-73110

Champion

1

SPARK PLUG

14lJ()-8B250

129

COLLAR

Re.;

8Y

2

54

1400-75510

SCREW

3

55

0250-30516

SCREW

2

56

2031-81610

SWITCH

1

57

1400-72250

BRACKET.

swnCJ1

1

14(}()-72310

58

CLAMP 1

1400-75100

591069

1

RECOIL

ASS'Y

59

·,400-75100

CASE I

60

1400-75120

REEL I

61

1400-75130

SPRING,

SPiral

1

62

1400·75140

RATCHET

1

63

1180-75251

SPRING, Inetlon

1

64

1179-75320

SPRING. return 1

65

I

1400-75180

RETAINER I

I

9

Page 11

Fig.2

A7TACHMENT GROUP

t-

3Q

~2B

r

Z9

/

2S

102

~

~

0",,-

~

--.~/

10'

~

@------90

~~

..

a8

..

f'i!

https://manualmachine.com/

\;

103

les

I

@

©-------93

c_

92

)

'-.~

91

0--S7

~~as

't-"

~i

-05

10

Page 12

1r::

x

j

P1lrt

r-!um""r

!

Dl!t~cr1pttcn

I

:Q'ty

per!

R.mark.3

i unrt !

2

1

1

1

,

6

1

1

1

I

1

I

,

I

,

1

1

1

1

1

1

1

2

0-3

4

1

2

2

2

4

4

1

1

I

2

2

2

<1

1

1

1

I

1

1

1

1

I

1

1

1

1

,

1

1

1

1

1

2

2

2

1

1

1

,

1

1

2

2

2

1

,

,

1

I

I

I

I

I

I

1321030

I

I

!37 to 39

1.320

....

31300

I

141

to

44

I

I

lop

461049

'3206,51100

I

lOP

50 to 57

'3206-52100

lOP

581055

1'3206.52200

I

I

lnaex ,

Pllrtllum_!

Oescrl

pllon

1

0

'1'1

per!

Romark>

No.

I

, urNt 1

65

I

3200·51140

CUP

1

320&-52:300

S'5O

DRILL

ASS'y

1

I

{5.S

In

.dlal

I

I

I

loe~."

BODY, dnll

I

1

'3206-52300

67

66

3206-52320 TIP. S150

1

01225-40620 SCREW

3

69

68

0280-10605

NUT

3

70

WASHeR

0290-206'5

3

BIT

3206-52330

1

71

PIN

3200-51130 1

73

72

CLIP

3200-51140

1

3206-52400

S200

DRILL

ASS'Y

OP

1410

5'

1

(7.9 In

,dis)

74

SODY, dnll

1

1'3206-52400

75

3202·52<120 TIP, 5200

1

76

01225-40625

SCREW

3

77

NUT

0280-10605

3

76

0290-20615

WASHER

3

79

BIT

1

80

3206·5=

PIN

3200-51130

1

al

3200-511

dO

CUI'

1

,

32ll6-<I, 1

00

OP 82

to

B7

1150

DRILL

ASS'y

(5.9

In

.dla)

I

BODY,dnll

1

'3206-51100

82

3206-61120

BLADE

1

83

BOLT

0225-5OE20

2

84

0280-10605

NUT

2

86

85

:3200-51130 PIN

1

87

3200-51140

CUP

1

L1DO

JOllfT

ASS')'

OPasto90

as

1

3204-53'00

'320<1-531

00

89

EXTENSION ROO

13.9

1

PIN

3200-51130 1

90

CLIP

3200·51140 1

lops,

to

93

L300

JOIIfT

ASS'Y

3204-53200 1

.

"XTENS10N

ROD

1

1'3204-53200

91

111.8 in.)

92

3200-51130

PIN

1

3200-511

dO

l CUP 1

93

1075-96100 i PULLER

ASS'Y

OP

102

101

1

1400-56210

SE"" BLOCK

01'

1

1400·96300

:

ROO

ASS"Y

01'

103 1

3206·91610

SPANNER

,04

1

lOP

:

1

.OP

3206·51620 ROO

105

i

I

I

!

:

!

:

I

1

~

,

i

1

I

i

1

t

j

)

I

\

1

i

l

1

1

I

1

1

i

...

1

1

J.

J

130

,

2

3

4

5

6

7

a

9

10

11

12

13

14

15

16

17

11~

lH

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

:l5

36

37

38

39

40

41

42

43

d4

45

46

47

48

49

50

51

52

53

54

55

56

57

5a

59

60

61

62

63

64

1400-86271

320!Hl102

3200-11202

1800-21261

3202-11260

0260-30620

06000-00304

3202-11311

3202'11320

3200-11330

07000-02012

04<)65-06220

3202-11361

2510-23230

0224..{)0610

3010-313S0

3205-21110

3200-21121

3200-21130

3206-21210

3205-21220

3200-21230

3202-21240

3200-21250

0225-50620

3204-31110

0225-10616

01642-20608

3209·31122

n06-31130

0225-50630

3206-14410

:l2O&-31201

3206-31211

3206-31220

1000-15150

0280-10605

0290·20615

3:204-31300

.

3541-14220

0281-11411

3892·41110

3206-91001

1820·91111

1030-91340

323S-91310

3540-91120

3SAD-93120

320&-51100

3202-51121

.3200-5

11

30

3200-51140

:\206-521

00

.

3206-52121

01225-40620

0280-10605

0290-20015

3206-52330

3'!00-51130

3200-51140

3206-52200

..

3206-52220

01

225-40620

028,"-10605

0290·20615

3206-52:>;30

320<J·5113O

CUSHION

GEAR

CASE COMP

COVERCOMP.

OIL SEAL

GASKET

SCREW

BEARING

RETAINER

OIL

SEAL

O-RING

O-RING

SNAP RING

PLUG

O-RING

BOLT

GASKET

WORM

COLLAR

DRUM

SHAFT

WHEi"L

WASHER

WASHER

SHIM

BOLT

HANDLE

BOLT

WASHER

HOLDER

SPACER

BOLT

L"VER,

THROTTLE

BRACKET

ASS'Y

BRACKET

MOUNT

NUT

NUT

WASHER

LEFT

HANDLE

COMP,

HANDLE, Ian

GRIP

NUT

NAMEPLATE

Toolsel

BAG

SCREWDRIVER

SOCKET

SPANNER

BAND

540

DRILL

ASS'Y

(1.6 In.

dla,j

BODY, drill

BIT

PIN

CLlP

560

DRILL

ASS'Y

(2.4 In

dis.)

BODY, anll

TIP.

560

SCREW

NUT

WASHER

BIT

PIN

CLIP

500

DRILL

ASS'Y

(3-5

In.

dla,)

BODY,

dnU

TIP,

590

SCREW

NUT

WASHER

BIT

PIN

11

Page 13

RedMaX':Bl

POWER

AUGER

MODEL

AG431

2-YEAR LIMITED WARRANTY

For two

(2)

years

[1

year if used commercially] from the date of original purchase of the model

AG431 unit, KOMATSU

ZENOAH

AMERICA INC. (the "Company"), through any RedMax:»

dealer, will repair or replace, free

of

charge, for the original purchaser, any part found to

be

defective

in

material and/or workmanship.

This

is

the

exclusive

remedy.

The purchaser shall bear costs

of

transporting the model AG431

to

and from the

RedMax~

dealers.

This warranty does not apply

to

those units which have been damaged by accident, mishan-

dling, alteration, abuse, improper lubrication, the use

of

any parts or accessories other than

those specified by the Company, or other causes beyond our control.

This warranty does not

coverthose

parts replaced for normal

wear

or harmless changes

in

their

appearance.

There

are

no

other

express

warranties.

IMPLJED WARRANTIES inclUding those of merchantability and fitness for a particular purpose

ARE

UMITED

to

one

(1)

year

from the original purchase date.

Liabilities

for

incidental

or

consequential

damages

under

any

and

all

warranties

are

excluded.

Some states do not allow limitations on how long an implied warranty lasts

orthe

exclusion or

limitation of incidental or consequential damages, so the above lim itation

or

exclusion may not

apply

to

you.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

IMPORTANT:

You will receive a Warranty Registration Card at time of purchase.

Please keep the card and return

it

when sending your machine for a repair.

t)RedMar

KOMATSU

ZENOAH

AMERICA

INC.

1505

Pavilion

Place

Suite

A

Form

No.

21F-0312-70100-05

Norcross,

Georgia,

30093

Printed

in

Japan

11/90

Loading...

Loading...