Page 1

MODEL MDMU - MINIATURE DISPLAY MODULE COUNTER/TIMER

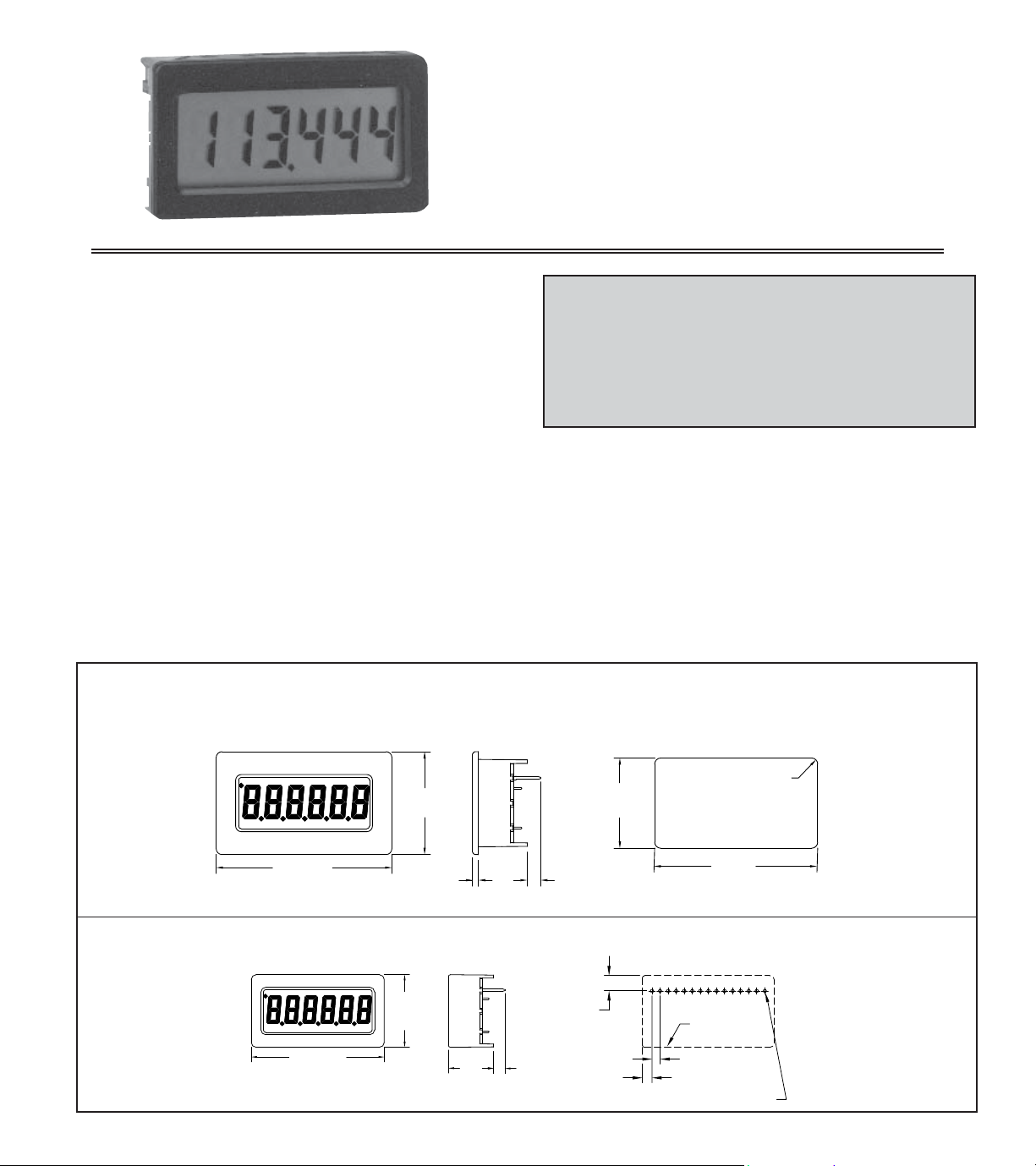

1.81 (46.0)

SEE

NOTE

0.06

(1.5)

1.06

(26.9)

0.2 (5.08) MAX.

0.14 (3.56) MIN.

1.68

-.02

+.03

0.93

-.02

+.03

(23.6 )

+.8

-.5

(42.7 )

+.8

-.5

(1.5)

R 0.06 MAX., 4PL.

NOTE: BACKLIGHT MODELS: 0.50" (12.7)

REFLECTIVE MODELS: 0.31" (8.0)

0.12 (3.1)

0.10 (2.5)

UNIT OUTLINE

THRU, 15 PL.

Ø 0.042 (1.07)

0.19 (4.8)

NOTE: BACKLIGHT MODELS: 0.56" (14.2)

REFLECTIVE MODELS: 0.37" (9.4)

1.65 (41.9)

0.90

(22.9)

SEE

NOTE

0.2 (5.08) MAX.

0.14 (3.56) MIN.

LCD, POSITIVE REFLECTIVE OR NEGATIVE TRANSMISSIVE

WITH YELLOW/GREEN OR RED BACKLIGHTING

COUNTER & TIMER ALL IN A SINGLE UNIT

COUNT POSITIVE OR NEGATIVE EDGE

9 RANGES IN TIMER MODE

SELECTABLE DECIMAL POINTS

5 VDC POWERED

PANEL MOUNT OR PC BOARD MOUNT

DESCRIPTION

The MDMU is a complete 6 digit Counter/Timer in a small panel or printed

circuit board mounted package. It is designed to operate from a 5 VDC power

supply. It has a 6 digit LCD, with 0.35" high digits, and 3 selectable decimal

points. In the timer modes, a flashing annunciator is supplied to indicate that the

signal input of the MDMU is active. The displays are available in positive image

reflective (black digits, reflective background) or negative image transmissive

(illuminated digits, dark background) with red or yellow/green backlighting.

The MDMU has four Mode Select and two Decimal Point Select inputs

This device contains CMOS circuitry which requires special anti-static

handling to the same degree required by standard CMOS integrated

circuits. Units should be stored in the conductive package used to ship the

device. Containers should be opened and units handled only on a

conductive table top by personnel wearing wrist-strap grounding equipment.

These devices have the same protection circuits as standard CMOS devices

to prevent damage to inputs due to nominal over-voltage.

CAUTION

available for determining the basic operation. In most applications, the MS and

DP inputs are hard wired to select the appropriate function (counter or timer)

and counter decimal point position.

The COUNTER mode is selected by setting the Mode select inputs to the

appropriate levels (Hardware selection). Decimal points may also be set using

the DP Inputs (Hardware selection).

The TIMER mode and range is selected by setting the Mode Select inputs to

the appropriate levels (Hardware selection). The timing range increments

available are

1 msec, 10 msec, 100 msec, 1 sec, 0.1 min, 1 min, 0.01 hr, 0.1 hr,

and 1 hr. The TIMER ACTIVE annunciator will flash at a 1 Hz rate when the

input to the timer is activated.

SPECIFICATIONS

1. DISPLAY: 6 Digit LCD, 0.35" (8.89 mm) high characters, available in

positive image reflective (black digits, reflective background) or negative

image transmissive (illuminated digits, dark background) with red or yellow/

green backlighting.

2. POWER REQUIREMENTS:

Reflective Versions: 5.0 VDC ±10% 100 μA max.

Backlight Versions: 5.0 VDC ±10% 25 mA max.

3. DECIMAL POINTS:

Timer: Determined by the timing mode selected.

Counter: 3 programmable positions.

DIMENSIONS Note: Recommended minimum clearance behind the panel for mounting clip installation is 2.25" (57.2)W x 1.5" (38.1)H

In inches (mm)

PANEL MOUNT UNIT PANEL CUT-OUT

PRINTED CIRCUIT BOARD MOUNT UNIT RECOMMENDED PCB LAYOUT

1

Page 2

4. ANNUNCIATOR: Flashes at a 1 Hz rate in the Timer mode when the signal

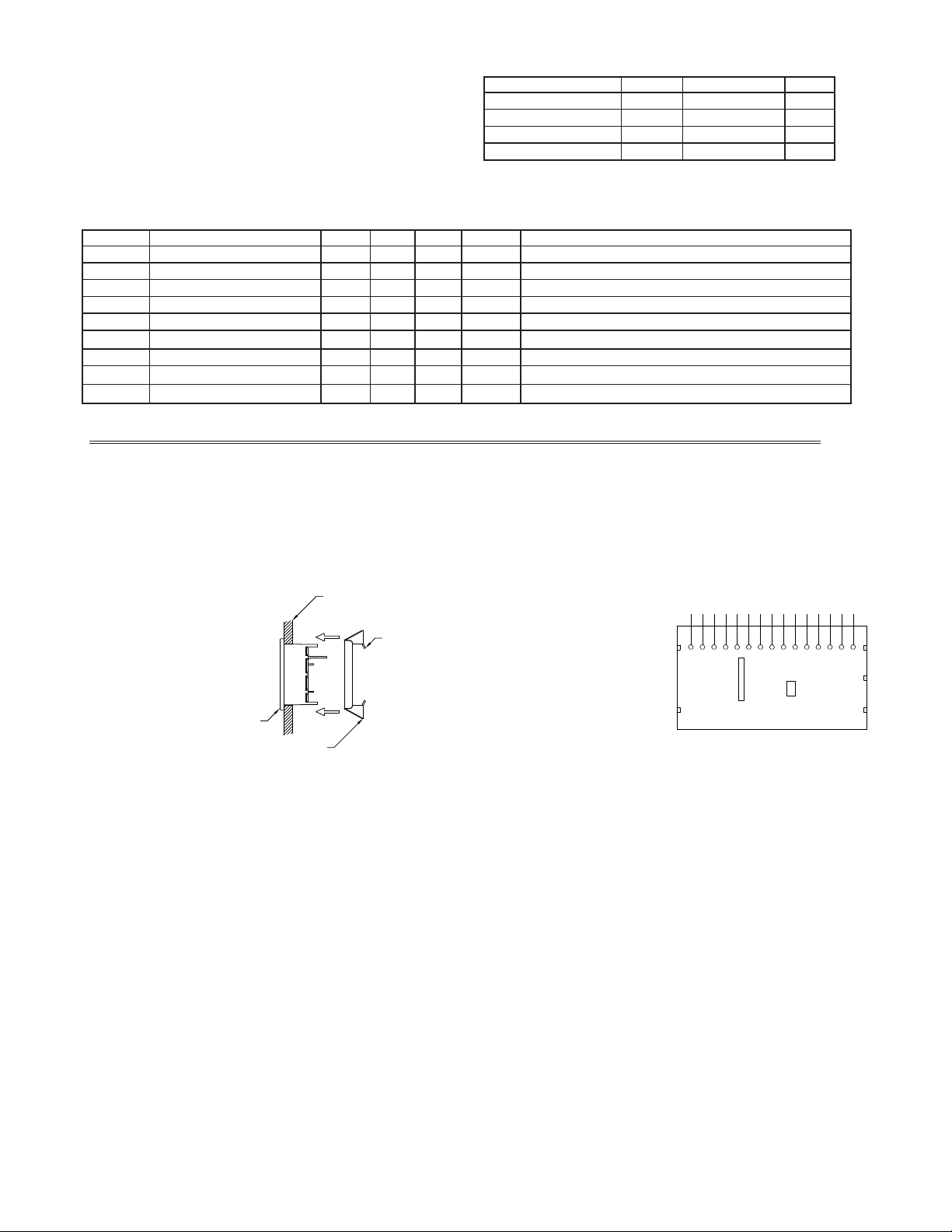

BEZEL

MOUNTING CLIP

EXISTING PANEL THICKNESS

0.031" to 0.125"

(0.79 to 3.18)

LOCKING

TAB

VSS (GND)

CNT

NO CONNECTION

NO CONNECTION

NO CONNECTION

LATCH

RST

MS1

MS2

MS3

MS4

NO CONNECTION

DP2

DP1

V

DD

input (CNT) is activated.

5. CONSTRUCTION: High impact black plastic case (mounting clip included

with panel mount models).

6 RELATIVE HUMIDITY: Less than 85% RH (non condensing)

7. WEIGHT:

Reflective Panel Mount: 0.275 oz (7.26 g)

Reflective PCB Mount: 0.26 oz (6.8 g)

MAXIMUM RATINGS

RATING SYMBOL VALUE UNITS

DC Supply Voltage VDD 5.5 VDC

Input Voltage, all inputs V

Operating Temperature T

Storage Temperature TSTG -40 to +85 °C

Transmissive Panel Mount: 0.38 oz (10.43 g)

Transmissive PCB Mount: 0.356 (9.75 g)

ELECTRICAL SPECIFICATIONS - VDD = 5.0 VDC = 10% @ 25 C unless otherwise specified.

SYMBOL PARAMETER MIN TYP MAX UNITS NOTES

VDD Supply Voltage 4.5 5.0 5.5 VDC Voltages outside these parameters may cause display problems

DD Supply Current - Transmissive 20 25 mA VDD = 5.0 VDC - 10 KHz Counting Rate.

I

IDD Supply Current - Reflective 50 100 AVDD = 5.0 VDC - 10 KHz Counting Rate.

IH Valid High Voltage 3.0 VDC

V

IL Valid Low Voltage 1.5 VDC

V

IN Input Leakage Current 0.1 1.0

I

Fc Count Frequency - CNT 9.9 KHz 50% Duty cycle

R,L RST, LATCH Pulse Width 30

T

CCTB Time Base Accuracy 0.025

A

A

sec

IN -0.5 to (VDD +0.5) VDC

A -35 to +85 °C

INSTALLATION

The MDMUs are available in either a panel mount or printed circuit board

mount design. The panel mount units are provided with a mounting clip to

securely hold the unit in the panel cutout.

Panel Mount Installation:

1. Cut panel opening to specified

dimensions. Remove burrs

and clean the panel opening.

2. Install MDMU through the

panel cutout as shown in

Figure 1.

3. Slide mounting clip over rear

of unit until clip is against the

back of panel. The unit has

slots for the locking tabs to

hold it in the panel opening.

Note: Hold the MDMU front

bezel in place when sliding the

mounting clip in to position

PCB Mount Installation:

1. Prepare printed circuit board hole pattern to the specifications.

2. Unit should be hand soldered using good soldering techniques and hand

cleaned if necessary.

Figure 1

WIRING CONNECTIONS

The electrical connections are

made via terminal pins located on

the back of the unit. The terminal

pins are on 0.100" center lines and

can be mated with the RLC Model

HWK7 cable assembly or many

standard 0.100" center line

connectors. When wiring the unit,

refer to Figure 2 to identify the

wire position with the proper

function.

There are certain considerations

that should be observed when

running the signal wires. A length

of wire can act like an antenna,

and the closer it is to a source of

electrical noise, the more it

becomes susceptible to that noise.

These are a few rules that should be followed when running these wires.

1. Never run signal wires in the same conduit or raceway with A.C. power lines,

conductors feeding motors, solenoids, SCR controls, heaters, etc.

2. Signal wires within enclosures should be routed as far away as possible from

contactors, control relays, transformers, and other noisy components.

3. When shielded wire is used, connect the shield to the common of the MDMU

unit, and leave the other end of the shield disconnected and insulated from

machine ground.

4. Connect common of the MDMU to machine ground at one point only.

Figure 2

2

Page 3

PIN DESCRIPTIONS

VSS (GND)

CNT

NO CONNECTION

NO CONNECTION

NO CONNECTION

LATCH

RST

MS1

MS2

MS3

MS4

NO CONNECTION

DP2

DP1

V

DD

RST

.0022 µf

220K

GND

+5 V

GND +5 V

0.15 (3.8)

12 (305)

CIRCUIT #1; BROWN

0.100 (2.54), TYP.

STRIPPED AND TINNED

COLOR CODED RIBBON CABLE

0.100 (2.54), TYP.

(All inputs are Schmidt trigger inputs)

: +5 VDC power

V

DD

V

: GND or common supply terminal

SS

DP1 & DP2: Counters - See Decimal Point Configuration Chart

Timers - Tie low

MS1-MS4: See Mode Select Inputs Chart

RST: Active low, will reset the display to zero

LATCH: Counters - A HIGH level will freeze the display, a LOW level will

allow the counter to update the display normally

Timers - Tie low

CNT: Counters - This is the count input (edge trigger determined by mode)

Timers - This is the run input (active low = timer runs)

DECIMAL POINT CONFIGURATION CHART

DP2 DP1 DISPLAY

000

0 1 0.0

1 0 0.00

1 1 0.000

TYPICAL APPLICATIONS

COUNTER - TTL signal input counting. Positive edge

incrementing (leading edge).

MODE SELECT INPUTS CHART

MODE MS4 MS3 MS2 MS1 MODE OF OPERATION

0 00000.001 Second Timer

1 00010.01 Second Timer

2 00100.1 Second Timer

3 00111 Second Timer

4 01000.1 Minute Timer

5 01011 Minute Timer

6 01100.01 Hour Timer

7 01110.1 Hour Timer

8 10001 Hour Timer

9 1001DO NOT USE

10 1010Negative Edge Counter

11 1011Positive Edge Counter

12 1100DO NOT USE

13 1101DO NOT USE

14 1110DO NOT USE

15 1111DO NOT USE

1 MINUTE TIMER - With Leading Zero Blanking

enabled. Time starts with the switch closed. Time

stops and holds the display with the switch open.

ACCESSORY: MDM CABLE ASSEMBLY - HWK70000

TTL SIGNAL

TIMER

RUN

VSS (GND)

CNT

NO CONNECTION

NO CONNECTION

NO CONNECTION

LATCH

RST

MS1

MS2

MS3

MS4

DP2

DP1

DD

V

RST

.0022 µf

220K

220K

ORDERING INFORMATION

MODEL NO DESCRIPTION PART NUMBER

Panel Mount W/Reflective Display MDMU0000

Panel Mount W/Yel-Grn Backlighting MDMU0010

MDMU

HWK7 MDM Cable Assembly HWK70000

3

Panel Mount W/Red Backlighting MDMU0020

PC Board Mount W/Reflective Display MDMU0100

PC Board Mount W/Yel-Grn Backlighting MDMU0110

PC Board Mount W/Red Backlighting MDMU0120

Page 4

The Company warrants the products it manufactures against defects in materials and workmanship

LIMITED WARRANTY

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC

against damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.

Loading...

Loading...