Page 1

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

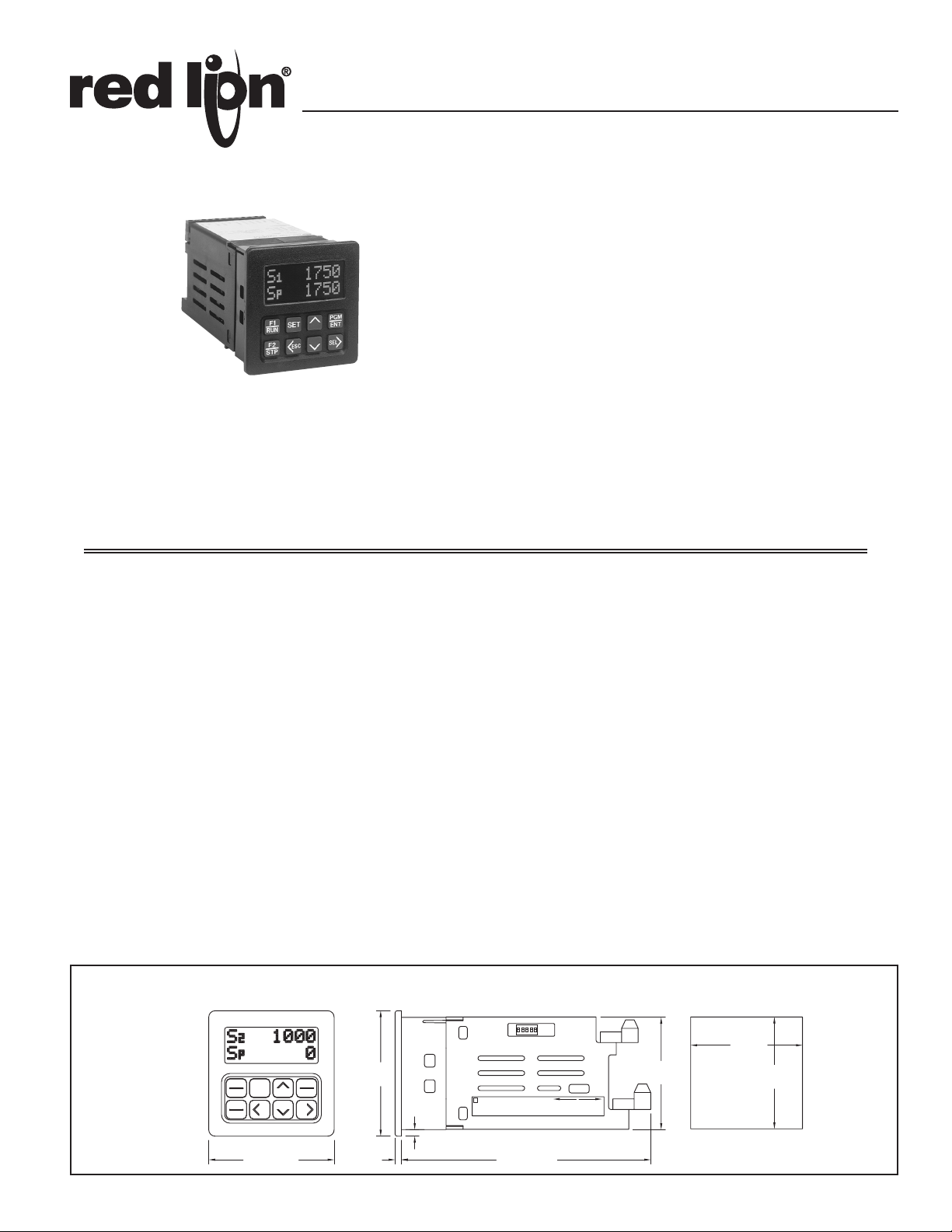

MOTOR DRIVE CONTROLLER

MASTER AND FOLLOWER MODES OF OPERATION

PROGRAMMABLE SETPOINTS:

TWO SPEED (Master)

TWO RAMP RATE (Master)

TWO RATIO (Follower)

TWO RATIO RAMP RATE (Follower)

ONE JOG SPEED

ONE JOG RAMP RATE

8 CHARACTER BY 2 LINE ALPHANUMERIC DISPLAY

FOUR PROGRAMMABLE INDICATION DISPLAYS

Bulletin No. MDC-D

Drawing No. LP0306

Released 04/14

ON LINE SETPOINT INCREMENT/DECREMENT

SELECTABLE DISPLAY SCROLLING

ABILITY TO LIMIT OPERATOR ACCESS TO PROGRAMMING

PARAMETERS

ENGLISH PROGRAMMING MENUS

FREQUENCY INPUTS ARE SWITCH SELECTABLE FOR A

VARIETY OF SOURCES

PROGRAMMABLE CONTROL INPUTS

THREE SOLID STATE OUTPUTS

VARIABLE SPAN (5 TO 15 VDC) ISOLATED DRIVE OUTPUT

FEEDBACK LOSS DETECTION

PROGRAMMABLE ALARM TYPES

INTERNAL OR EXTERNAL DRIVE OUTPUT REFERENCE

DIAGNOSTICS MODE

115/230VAC SWITCH SELECTABLE

NON-VOLATILE MEMORY

NEMA 4X/IP65 SEALED FRONT PANEL BEZEL

DESCRIPTION

The Motor Drive Controller (MDC) regulates motor speed by varying an

isolated DC control signal to a motor drive system. There are two modes of

operation, Master and Follower.

Master Mode provides control of a motor directly via programmed speed

setpoints in the MDC. Regulation is maintained by a feedback frequency to the

MDC taken from the motor shaft or a downstream shaft pulse encoder. Follower

Mode controls a motor’s speed as a ratio to a second motor’s speed or outside

frequency source. Ratio setpoints are programmed into the MDC causing the

motor to “follow” the lead motor or frequency at a fixed speed ratio.

Master Mode has two speed setpoints and two ramp setpoints. Follower

Mode has two ratio setpoints and two ramp setpoints. Both modes share a jog

speed setpoint and a jog ramp setpoint. All setpoints are retained in non-volatile

memory when the unit is powered down.

The Motor Drive Controller has the added feature of allowing real time

adjustment of the Speed (Master Mode) or Ratio (Follower Mode) setpoint

while the unit is operating a motor drive system. The setpoint may be adjusted

via the front panel keypad using the “Up” or “Down” arrow keys, or via 2 User

Inputs programmed for increment setpoint and decrement setpoint.

User flexibility is provided through the two-line by eight-character

alphanumeric display. The display features English language menus for easy

viewing and simplified programming. The four scroll-through indication

displays can be programmed to show various parameters and to automatically

scroll, if desired. A program disable DIP switch used with an external User Input

can be utilized to protect the settings and guarantee that no unwanted changes

occur during operation.

DIMENSIONS In inches (mm)

Note: Recommended minimum clearance (behind the panel) for

mounting clip installation is 3.0" (76.2) H x 4.0" (101.6) W.

There are five dedicated control inputs on the MDC:

RUN

RAMP STOP

FAST STOP

JOG

OPEN LOOP

There are six programmable control inputs: two front panel function keys and

four remote user inputs. The F1 and F2 keys are factory programmed for RUN

and R-STOP respectively. This eliminates the need for external switches in

some applications.

There are three solid state outputs, two are programmable alarms and one is

a dedicated Drive Enable output. Programmable alarm functions include:

High Alarm

Low Alarm

Deviation Alarm

Zero Speed

Disabled

These may be programmed for boundary or latching operation, high or low

acting.

Changing speed setpoints and programming information is easily

accomplished by scrolling through menus and selecting the correct parameter.

There are three main modules or menu loops:

Display Module

User Setpoint Module

Programming Module

Scaling is accomplished by entering the desired values for feedback pulses

per revolution (PPR), the maximum RPM, and the maximum display value.

PANEL CUT-OUT

2.95

F1

RUN

F2

STP

2.95 (74.9) 5.87 (149.1)

PGM

SET

ENT

SELESC

(74.9)

.15

(3.8)

.155 (3.8)

E

CAUTION:

SELECT PROPER VOLTAGE

BEFORE APPLYING POWER

1

115 VAC230 VAC

50/60 HZ, 10 VA

+.03

2.68

-.01

+.8

(68 )

2.64

(67.1)

LB01269

-.3

2.68

(68)

Page 2

DESCRIPTION (Cont’d)

The unit is factory configured for an isolated 0 to 10 VDC drive output

signal. The output drive signal can be adjusted to span from 0 to 15 VDC via an

accessible potentiometer. The drive output is jumper selectable for an external

reference. To use the external reference, the MDC is connected to the drive in

place of an external potentiometer.

The Motor Drive Controller has a light weight, high impact plastic case with a

clear viewing window. The sealed front panel meets NEMA 4X/IP65 specifications

for wash-down and/or dusty environments, when properly installed. Plug-in style

terminal blocks simplify installation and wiring change-outs.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use this unit to directly command motors, valves, or other actuators

not equipped with safeguards. To do so, can be potentially harmful to persons

or equipment in the event of a fault to the unit.

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

SPECIFICATIONS:

1. DISPLAY: 2x8, 0.3" (7 mm) high characters, negative image transmissive

LCD, with red LED backlighting.

2. POWER: 115/230 VAC ±10%, 50/60 Hz, 10 VA, switch selectable.

3. MEMORY: Non-volatile E2PROM retains all programming information and

values when power is removed or interrupted.

Power Cycles(ON/OFF): 100,000 min.

Data Retention: 10 years min.

4. SENSOR POWER: +12 VDC ±25% @ 100 mA.

5. INPUTS (LEAD AND FEEDBACK): DIP Switch selectable to accept input

pulses from a variety of sources including outputs from CMOS or TTL

circuits and all standard RLC sensors.

Input Freq:

1 Hz to 20 KHz (Master Mode), 1 Hz to 12 KHz (Follower Mode).

Logic: Input trigger levels VIL= 1.5 V

Current Sinking: Internal 7.8 KΩ pull-up to +12 VDC, I

Current Sourcing: Internal 3.9 KΩ pull-down, 7.3 mA @ 28 VDC

Magnetic Pickup:

Sensitivity: 200 mV PEAK.

Hysteresis: 100 mV.

Input impedance: 3.9 KΩ @ 60 Hz.

Maximum input voltage: ±50 V PEAK.

Note: For magnetic pickup input, the Sink/Source DIP switch must be in the

SRC position.

6. CONTROL LOOP RESPONSE: 10 msec (Master Mode), 20 msec

(Follower Mode).

7. CONTROL ACCURACY:

0.01% of Speed Setpoint (Master Mode)

0.02% of Ratio Setpoint (Follower Mode)

Minimum Frequency Resolution: 0.00125 Hz

8. ERROR TRIM: ±4095 BITS.

9. ERROR GAIN: 0 to 99%.

10. RAMP RATE: (Ramp 1, Ramp 2, and Jog Ramp)

1 Hz to 20 KHz/sec, set in user units/sec.

0.0001 to 1.9999 ratio units/sec (Ramp 1 & 2 in Follower Mode).

11. CONTROL INPUTS:

Internal 10 KΩ pull-up to +5 VDC. VIL = 1.0 V

Response time = 10 msec nominal, 30 msec max.

INPUTS SWITCH CONNECTIONS

RUN Momentary N.O.

FAST STOP Momentary N.C.

RAMP STOP Momentary N.C.

JOG Sustained N.O.

OPEN LOOP Maintained

USER INPUTS(4) Function Specific

12. OUTPUTS:

Drive Enable, Alarm 1, and Alarm 2:

Solid state, current sinking NPN Open collector transistor.

VCE = 1.1 V

(Internal zener diode protection.)

@ 100 mA max., V

SAT

; V

MAX

= 3.75 V

IH

MAX

= 30 VDC max.

OH

.

MIN

MAX

, VIH = 4.0 V

= 1.6 mA.

MAX

.

MIN

.

Response Time:

Drive Enable: 10 msec nominal; 30 msec max.

Alarm 1&2: Programmable

Normal: 1 sec nominal, 2 sec max.

Fast: 20 msec nominal, 40 msec max.

Isolated Drive Output: Jumper selectable internal/external reference 5 mA max.

Internal Reference: Pot adjustable from 0 to 5 VDC min. through 0 to 15

VDC max. span.

External Reference: 15 VDC max. (positive polarity only).

Isolation: 2300 Vrms for 1 minute

250 V working

13. ENVIRONMENTAL CONDITIONS:

Operating Temperature: 0 to 50°C

Storage Temperature: -40 to 70°C

Operating and Storage Humidity: 85% max. RH (non-condensing) from

0°C to 50°C.

Altitude: Up to 2000 meters

14. CONSTRUCTION: High impact plastic case with clear viewing window.

The front panel meets NEMA4 X/IP65 requirements for indoor use when

properly installed. Installation Category II, Pollution Degree 2. Panel gasket

and mounting clips included.

15. WEIGHT: 1.5 lbs. (0.68 Kg).

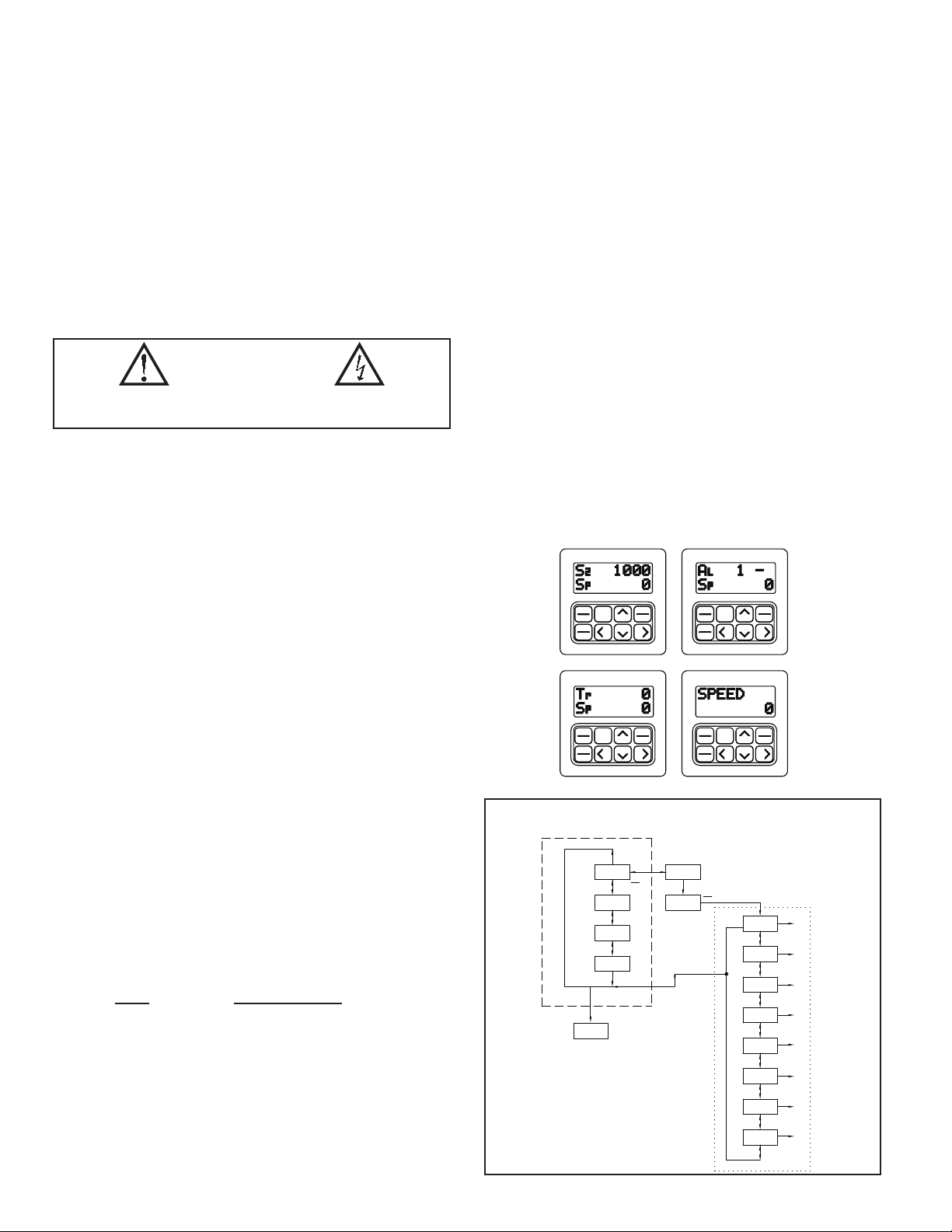

PROGRAMMING

Programming the MDC unit is accomplished through the front panel keypad,

which allows the user to enter into Main Menus, Sub-Menus, and Edit Menus.

The English language prompts, the flashing parameter values, and the front panel

keypad aid the operator during programming. In the normal run mode, the main

display loop allows the user to scroll through the four programmable indication

displays, using the direction keys. From the main loop, setpoints, alarm values

and a gain value may be accessed directly for changes, without entering the

programming loop. All other parameters are accessed through the pro-gramming

loop, which can be set to require an access code number for loop entry. In the

programming loop, parameters can be viewed or changed and the operator can

exit anywhere in the loop.

F1

RUN

F2

STP

F1

RUN

F2

STP

INDICATION DISPLAY

MODULE

SET

USER

SETPOINTS

*** - ACTIVE ONLY WHEN THE PROGRAM

DISABLE FUNCTION IS ENABLED.

1-4 - THE FOUR INDICATION DISPLAYS

--DASHED LINE:

MAIN DISPLAY LOOP

... DOTTED LINE:

PROGRAMMING LOOP

SET

ESC SEL

SET

SPEED

1

>

S R

1 1

p

S

2

AL

- -

p 500

S

3

Tr

Sp

4

>>>

PGM

ENT

PGM

ENT

SELESC

>

ESC

<

500

PGM

>

ENT

RUN

500

>>>

102

500

PROGRAM

MODE

PRO.CODE

***

0000

F1

RUN

F2

STP

F1

RUN

F2

STP

SEL

>

PGM

ENT

0

ESC

<

PGM

SET

ENT

ESCSEL

PGM

SET

ENT

ESCSEL

PROGRAMMING

MODULE

>

MASTER

MODE

PROGRAM

SCALING

> >

PROGRAM

USER

>>>>>>

PROGRAM

ALARMS

PROGRAM

DISPLAY

PROGRAM

OPTIONS

PROGRAM

DIAGNOST

PROGRAM

SECURITY

>>>>>>>>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

>

SEL

>

2

Page 3

PROGRAMMABLE FUNCTIONS

MODES

Master

Follower

SCALING

Pulses per Revolution Feedback (PPR FB) ranges from 1 to 59999

Maximum RPM Feedback (MAX RPM FB) ranges from 1 to 59999

Display Decimal Point (DSP DP) ranges from 0 to 0.00000

Maximum Display Units (DSP UNIT) ranges from 1 to 99999

*Pulses per Revolution Lead (PPR LD) ranges from 1 to 59999

*Maximum RPM Lead (MAX RPM LD) ranges from 1 to 59999

*These parameters are available in Follower Mode only.

Note: Values may be programmed in the range listed, provided that the

maximum equivalent frequency does not exceed 20971 Hz. If this occurs,

“OVFLW” will flash and a new entry will be required.

SETPOINTS

2 SPEED (Master Mode) - ranges from 0 to 99999 (or Display Unit Max.).

2 RAMP RATE (Master Mode) - ranges from 1 to 99999.

2 RATIO (Follower Mode) - ranges from 0.0000 to 1.9999.

2 RAMP RATE (Follower Mode) - ranges from 0.0001 to 1.9999 ratio units.

1 JOG SPEED - ranges from 0 to 99999 (or Display Unit Maximum).

1 JOG RAMP RATE - ranges from 1 to 99999.

2 ALARM - ranges from 0 to 99999.

1 GAIN - ranges from 0 to 99.

Note: Values may be programmed in the ranges listed, provided that the

maximum equivalent frequency does not exceed 20,971 Hz ( 20 KHz/sec for

Ramp Rate). If this occurs, a message will flash and the maximum is

automatically entered by the unit.

USER INPUTS

There are four programmable external user inputs and two programmable

front panel function keys. The options for each user input are the same, except

for the two function keys (F1/RUN & F2/STP), which have additional options.

No Mode:

If a user input terminal or a function key is activated, it will be ignored.

View Display 1-4:

Causes the selected indication display (1, 2, 3, or 4) to be displayed and held

from anywhere in the main display loop.

Change Display:

Causes the indication display to toggle to the next indication display.

Reset Alarm(s) Output:

Places the alarm(s) output(s) in its inactive state.

Setpoint Select/Toggle:

Selects Setpoint 1 or Setpoint 2 for the active speed (or ratio) setpoint. This

is a maintained select action for User Inputs 1 to 4, and a momentary toggle

action for F1 or F2.

Ramp Select/Toggle:

Selects Ramp 1 or Ramp 2 for the active acceleration and deceleration ramp

rate. This is a maintained select action for User Inputs 1 to 4, and a

momentary toggle action for F1 or F2.

Ramp Override:

Overrides the acceleration/deceleration ramp routine causing the unit to jump

to the ramp endpoint.

Setpoint Increment:

Only an external User Input can be used for this option. The currently active

speed or ratio setpoint is incremented when the User Input is made active. If

the input remains active for more than 5 display unit increments, the scroll

rate will progressively increase.

Setpoint Decrement:

Only an external User Input can be used for this option. The currently active

speed or ratio setpoint is decremented when the User Input is made active. If

the input remains active for more than 5 display unit increments, the scroll

rate will progressively increase.

Program Disable:

Only an external user input can be used for this option. When used with the

program disable DIP switch, this option can limit operator access to

programmable parameters.

Run (F1 only):

Pressing the F1 button causes the MDC to accelerate the motor from Stop

mode to the active speed setpoint using the active ramp rate.

R-Stop(F1 or F2 only):

Pressing the function key programmed for R-Stop causes the unit to

decelerate the motor from its active speed to Stop mode using the active ramp

rate.

F-Stop(F1 or F2 only):

Pressing the function key programmed for F-Stop causes the unit to execute

a fast stop, taking the motor from its current speed immediately to the stop

mode. The deceleration is limited only by the motor and drive.

Jog(F1 or F2 only):

This function is only available from the Stop mode. Pressing and holding the

function key programmed for Jog causes the unit to accelerate the motor to

the jog speed setpoint using the jog ramp rate.

ALARMS

Type Of Alarm:

High Alarm: Alarm output activates when the feedback input is greater than

or equal to the alarm value.

Low Alarm: Alarm output activates when the feedback input is less than or

equal to the alarm value.

Deviation Alarm: The alarm output activates when the feedback input is

outside a ± band.

Zero Speed Alarm: Alarm output activates when the feedback input receives

no input pulse for at least one second.

Disabled: The alarm output is inactive when disabled.

Phase:

Each output can have its active logic state set for Positive phase (ON) or

Negative phase (OFF).

Latched Or Boundary:

An alarm programmed for a latched output stays active until it is manually

reset by a User Input. An alarm programmed for boundary output stays active

as long as the alarm condition exists, after which the output returns to its

inactive state.

Fast Or Normal Update:

The normal update rate for the alarm outputs is once each second. The fast

update rate occurs at an interval less than or equal to 40 msec.

INDICATION DISPLAYS

If an indication display is to show two different numeric values, one for each

line, there will be a single or dual character mnemonic to the left of the numeric

value. Each line of each indication display can be programmed to show

mnemonics or a numeric value. The following list shows the single or dual

character mnemonics that will be displayed when value is selected and the

mnemonics for each programmable option.

VAL MNE DESCRIPTION

S1 99999 SETPT. 1 Speed or ratio setpoint 1

S2 99999 SETPT. 2 Speed or ratio setpoint 2

Sp 99999 SPEED Actual speed in user display units (feedback)

R 1.999 RATIO Actual ratio (follower mode)

%D 100.0 % DEV. % deviation of actual speed from target speed

%O 100.0 % OUTPUT Analog drive output- % of full scale voltage

FB 20971 FB. FREQ Feedback frequency in pulses/sec (Hz.)

LD 12000 LD. FREQ Lead frequency in pulses/sec (Hz.)

A1 99999 ALARM 1 Alarm 1 setpoint

A2 99999 ALARM 2 Alarm 2 setpoint

Tr 4095 TRIM Error correction in bits (-4095 to +4095)

STATUS DISPLAYS

Operating Status:

Setpoint 1, ramp rate 1, Stop mode

Alarm Output Status:

Alarm 1 active, alarm 2 inactive

Operating Status:

The operating status display indicates the currently active speed or ratio

setpoint (S1 or S2), the currently active ramp rate (R1 or R2), and the mode

of operation (RUN, STP, or JOG). An arrow will replace the “R” for the

currently active ramp rate indication when an actual ramp up or down is in

progress.

Alarm Status:

The alarm status display indicates that an alarm output is active when the

corresponding output number (1 or 2) is displayed. When an alarm output is

inactive, a dash is displayed.

3

Page 4

OPERATOR ACCESS

This is used with the program disable DIP switch or an external user input

that is selected for the program disable function. When a setpoint is selected as

NO, it can be viewed, but NOT changed from the front panel keypad. The

following setpoint values can be disabled from front panel access programming:

Speed/Ratio Setpoint 1 and 2 Jog Speed

Ramp Rate 1 and 2 Jog Ramp

Alarm Setpoint 1 and 2 Gain

Setpoint Scroll Menu

USER SETTINGS

The operator can reset ALL parameters to the factory settings if desired.

PROGRAM DIAGNOSTICS

This allows testing of the various MDC inputs and outputs. It is especially

useful after unit installation to independently test the operation of external

switches, relays, the feedback transducer, and the motor drive system.

Inputs - The MDC displays an alphanumeric character to indicate a Dedicated

Function Input or a User Input is active. This allows the user to check switch

operation and wiring connections to the Inputs.

Alarm Outputs - The up and down arrow keys are used to select an alarm

output and set it to the active or inactive state. This allows the user to check

the operation of devices wired to the alarm outputs and the wiring

connections.

Drive Output - This function allows the user to test the Drive System. A %

Output value is entered through the front panel keypad causing the motor to

run at the corresponding open loop speed. The display indicates the motor’s

feedback frequency.

PROGRAM SECURITY

The programmable code number is used in conjunction with the program

disable DIP switch and/or a user input programmed for the program disable

function to limit operator access to programming.

FOLLOWER MODE APPLICATION

A fertilizer production facility is mixing pellets containing Nitrogen with

pellets that contain Phosphorus. A chemical ratio of 1:1 is determined by the

speed of two different conveyors. Because of differences in the gearing of

the conveyor and concentration of the pellets, the Nitrogen conveyor motor

must run at 3 times the speed of the Phosphorus conveyor motor in order to

produce a 1:1 mixture. The maximum speed of both motors is 2000 RPM.

Set the follower MDC scaling to produce a 1:1 mixture of Nitrogen and

Phosphorus when a setpoint of 1.0000 is entered. Display speed units are in

RPM’s. Both the lead and feedback frequency are taken from 60 tooth gears

on each motor shaft.

1) Choose the Phosphorus conveyor motor for the follower MDC. It runs

slower than the Nitrogen conveyor motor.

2) Set the Pulses per revolution feedback to 60.

3) Set the MAX RPM feedback to 2000. This is the conveyor motor’s

maximum operating speed.

4) Set display decimal point to 0.

5) Set display unit to 2000. The display speed unit maximum is 2000 at a

MAX RPM FB of 2000. If the display units wanted were conveyor feet/

minute or Phosphorus pellets in lbs/sec, the equivalent display value for

2000 RPM would be entered.

6) Set the pulses per revolution lead to 60.

7) Setting the MAX RPM Lead:

This is the Lead RPM that would be necessary to have a 1:1 mixture if

the Follower Speed was MAX RPM FB (2000 RPM). Since the Nitrogen

conveyor motor must run 3 times as fast as the Phosphorus motor, MAX

RPM LD = 3 * 2000 = 6000 RPM. Set MAX RPM LD = 6000 RPM. This

is the correct value, even though the Nitrogen conveyor motor would never

actually run at 6000 RPM. A ratio setpoint of 1.0000 on the MDC is now

equal to a 1:1 mixture of Phosphorus and Nitrogen.

LEAD INP

WHITE

FEEDBACK INP

COMM.

(SEE SIDE

AC PWR

USR.INP. 1

4321 12111098765

LABEL)

RED

USR.INP. 2

+12VDC OUT

USR.INP. 3

COMM.

BLACK

USR.INP. 4

AL-1 SNK

RUN

AL-2 SNK

R-STOP

DRIVE ENABLE OUT

OPEN LOOP

JOG

F-STOP

ISOLATED

DRIVE

OUTPUT

-+REF.

COMM.

10 1167894321 5

MOTOR

DRIVE

EMERGENCY

STOP

STOP

MOTOR

START

MOTOR

MASTER MODE APPLICATION

A pump delivers a maximum of 30.0 gallons per minute with a shaft speed of

1750 RPM. A shaft pulse encoder generates 60 pulses/revolution. Set the MDC

scaling to control and display pumping speed in tenths of a gallon/minute. In the

Program Scaling Module:

1) Set the pulses per revolution feedback to 60.

2) Set the maximum RPM feedback to 1750. This is the pump shaft’s maximum

operating speed.

3) Set display decimal point to 0.0. Display units are in 0.1 gpm.

4) Set max display units to 30.0. The display speed unit maximum is 30.0 at a MAX

RPM FB of 1750.

MOTOR

ORDERING INFORMATION

MODEL NO. DESCRIPTION

MDC Motor Drive Controller with Red Backlighting MDC00100

4

PART NUMBERS

115/230VAC

Loading...

Loading...