Page 1

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

GRAPHITE™ SERIES

12" Color Touchscreen Operator Interface

Installation Guide

U

R

C

US LISTED

L

IND. CONT. EQ.

34AD

Drawing No. LP0910B

Released 04/14

See the Red Lion website at www.redlion.net or the enclosed

USB thumbdrive for full user manual, Crimson software and

software manual.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in this

literature or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired. Do not use this unit to directly

command motors, valves, or other actuators not equipped with safeguards. To

do so can be potentially harmful to persons or equipment in the event of a fault

to the unit.

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION:

Risk of electric shock.

ORDERING INFORMATION

DESCRIPTION PART NUMBER

12" color touch screen, indoor use, 24 VDC powered G12C0000

12" color touch screen, indoor use, 24 VDC powered,

additional ethernet and serial port

G12C1100

SPECIFICATIONS

POWER: +24 VDC ±20%

Typical Power HMI only: 16 W

Maximum Power HMI only: 23 W

HMI With Module(s): 56 W

Must use a Class 2 circuit according to National Electrical Code (NEC),

NFPA-70 or Canadian Electrical Code (CEC), Part I, C22.1 or a Limited

Power Supply (LPS) according to IEC 60950-1 or Limited-energy circuit

according to IEC 61010-1.

Power connection via removable three position terminal block.

ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -20 to 60 °C

Storage Temperature Range: -20 to 70 °C

Vibration to IEC 68-2-6: Operational 5-500 Hz, 4 g

Shock to IEC 68-2-27: Operational 40 g (10 g, modules w/relays)

Operating and Storage Humidity: 0 to 85% max. RH non-condensing

Altitude: Up to 2000 meters

CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 Immunity to Industrial Locations

Emission CISPR 11 Class A

IEC/EN 61010-1

RoHS Compliant

UL Listed: File #E302106

Type 4X Indoor / IP66 Enclosure rating (Face only) for all models

CONNECTIONS: High compression cage-clamp terminal block

Wire Strip Length: 0.3" (7.5 mm)

Wire Gauge Capacity: One 14 AWG (2.55 mm) solid,

two 18 AWG (1.02 mm) or four 20 AWG (0.61 mm)

CONSTRUCTION: Cast aluminum enclosure with NEMA 4X/IP66 rating for

indoor use only when correctly fitted with the gasket provided. Installation

Category II, Pollution Degree 2.

WEIGHT: 5.06 lb. (2.29 Kg)

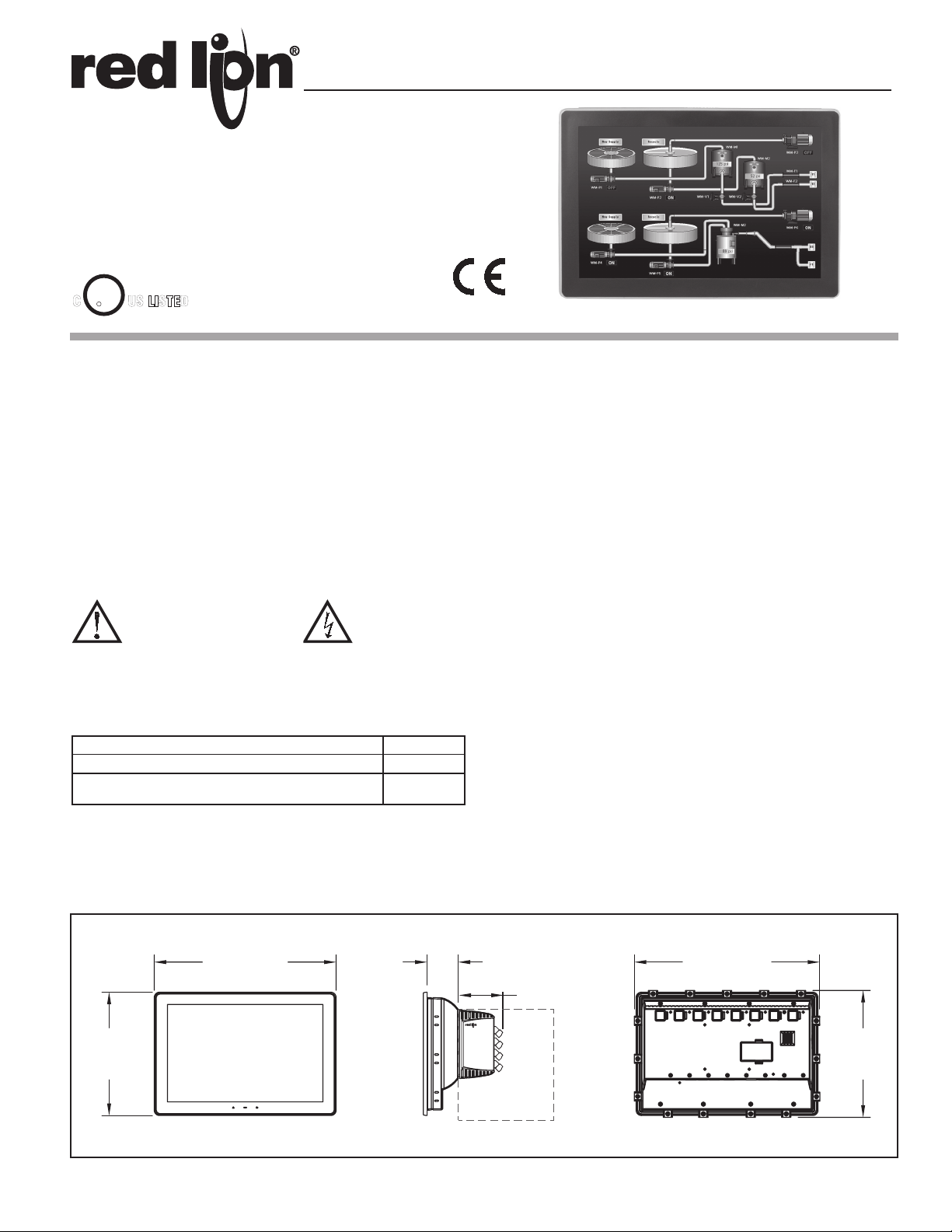

DIMENSIONS In inches (mm)

12.10 (307.3)

8.20

(208.3)

2.06 (52.4)

2.97 (76)

Module sold

separately

1

12.3 (314)

8.4

(215)

(MOUNTING CLIPS INSTALLED)

Page 2

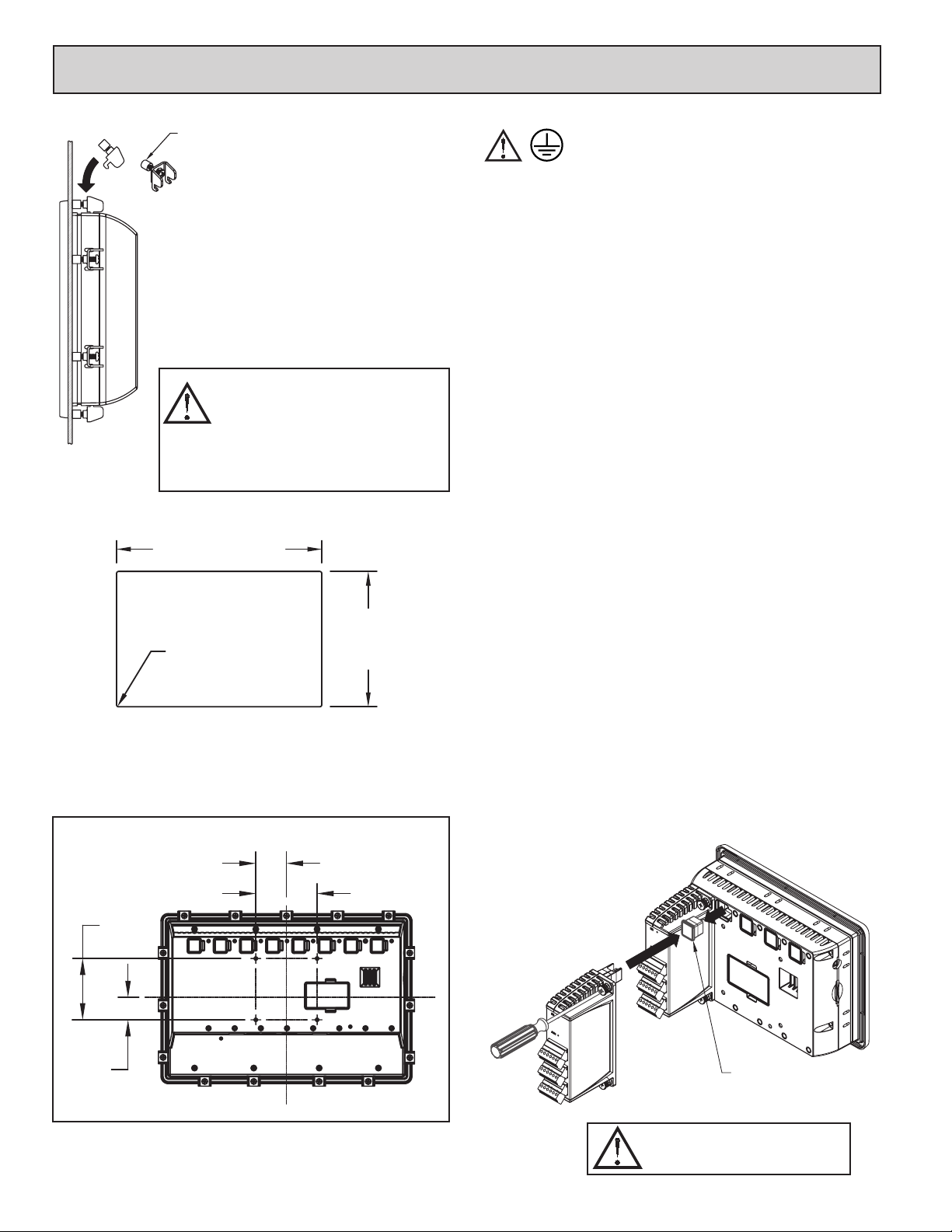

FOOT MAY BE REMOVED

FOR THICKER PANEL

INSTALLATIONS

A

OperatOr Interface InstallatIOn

MOUNTING INSTRUCTIONS

This operator interface is primarily designed for

through-panel mounting. Four VESA mount tapped screwholes (M4 x 0.7, 5 mm deep) are present on the rear of the

panels to allow for stand or wall mounting. Care should be

taken to remove any loose material from the mounting cutout to prevent that material from falling into the operator

interface during installation. A gasket is provided to enable

sealing to NEMA 4X/IP66 specification. Install the nine

mounting clips provided and tighten to 6.0 pound-force inch

(96 ounce-force inch) evenly for uniform gasket compression.

ALL NONINCENDIVE CIRCUITS MUST BE

WIRED USING DIVISION 2 WIRING

METHODS AS SPECIFIED IN ARTICLE 501-4

(b), 502-4 (b), AND 503-3 (b) OF THE

NATIONAL ELECTRICAL CODE, NFPA 70

FOR INSTALLATION WITHIN THE UNITED

STATES, OR AS SPECIFIED IN SECTION

19-152 OF CANADIAN ELECTRICAL CODE

FOR INSTALLATION IN CANADA.

PANEL CUT-OUT

11.458 (291.0)

4X R.10 (2.5)

MAX.

ll tolerances ±.059" (±1.5 mm)

7.561

(192.0)

CONNECTING TO EARTH GROUND

The protective conductor terminal is bonded to conductive

parts of the equipment for safety purposes and must be

connected to an external protective earthing system.

Each operator panel has a chassis ground terminal on the back of the unit.

Your unit should be connected to earth ground (protective earth).

The chassis ground is not connected to signal common of the unit.

Maintaining isolation between earth ground and signal common is not required

to operate your unit. But, other equipment connected to this unit may require

isolation between signal common and earth ground. To maintain isolation

between signal common and earth ground care must be taken when connections

are made to the unit. For example, a power supply with isolation between its

signal common and earth ground must be used. Also, plugging in a USB cable

may connect signal common and earth ground.

1

USB’s shield may be connected to earth ground at the host. USB’s shield in

turn may also be connected to signal common.

1

POWER SUPPLY REQUIREMENTS

The G12 requires a 24 VDC power supply. Your unit may draw considerably

less than the maximum rated power depending upon the features being used. As

additional features are used your unit will draw increasing amounts of power.

Items that could cause increases in current are modules, additional on-board

communications, SD card, and other features programmed through Crimson.

In any case, it is very important that the power supply is mounted correctly if

the unit is to operate reliably. Please take care to observe the following points:

– The power supply must be mounted close to the unit, with usually not more

than 6 feet (1.8 m) of cable between the supply and the operator interface.

Ideally, the shortest length possible should be used.

– The wire used to connect the operator interface’s power supply should be

at least 22-gage wire suitably rated for the temperatures of the environment

to which it is being installed. If a longer cable run is used, a heavier gage

wire should be used. The routing of the cable should be kept away from

large contactors, inverters, and other devices which may generate

significant electrical noise.

– A power supply with an NEC Class 2 or Limited Power Source (LPS) and

SELV rating is to be used. This type of power supply provides isolation to

accessible circuits from hazardous voltage levels generated by a mains

power supply due to single faults. SELV is an acronym for “safety extralow voltage.” Safety extra-low voltage circuits shall exhibit voltages safe

to touch both under normal operating conditions and after a single fault,

such as a breakdown of a layer of basic insulation or after the failure of a

single component has occurred.

I/O MODULE INSTALLATION

Modules must be installed beginning with slot 1 (left-most slot), with no

empty slots between the modules, and the order must match the modules order

VESA MOUNT (MIS-D 75) DIMENSIONS

1.48 (37.5)

2.95 (75)

2.95

(75)

1.08

(27.4)

in the Crimson database. Torque screws to 6.0 pound-force inch (96 ounceforce inch).

REMOVE RUBBER

MODULE PLUG

WARNING: Disconnect all power

to the unit before installing or

removing modules.

2

Page 3

cOmmunIcatIng WIth the g12

CONFIGURING A G12

The G12 is configured using Crimson® software. Crimson is available as a

free download from Red Lion’s website. Updates to Crimson for new features

and drivers are posted on the website as they become available. By configuring

the G12 using the latest version of Crimson, you are assured that your unit has

the most up to date feature set. Crimson® software can configure the G12 through

the RS232 PGM port, USB port, or SD.

The USB port is connected using a standard USB cable with a Type B

connector. The driver needed to use the USB port will be installed with Crimson.

The RS232 PGM port uses a programming cable made by Red Lion to connect

to the DB9 COM port of your computer. If you choose to make your own cable,

use the “G12 Port Pin Out Diagram” for wiring information.

The SD can be used to program a G12 by placing a configuration file and

firmware on the SD card. The card is then inserted into the target G12 and

powered. Refer to the Crimson literature for more information on the proper

names and locations of the files.

USB, DATA TRANSFERS FROM THE SD CARD

WARNING - DO NOT CONNECT OR DISCONNECT CABLES

WHILE POWER IS APPLIED UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS. USB PORT IS FOR SYSTEM SET-UP AND

DIAGNOSTICS AND IS NOT INTENDED FOR PERMANENT

CONNECTION.

In order to transfer data from the SD card via the USB port, a driver must be

installed on your computer. This driver is installed with Crimson and is located

in the folder C:\Program Files\Red Lion Controls\Crimson 3.0\Device\ after

Crimson is installed. This may have already been accomplished if your G12 was

configured using the USB port.

Once the driver is installed, connect the G12 to your PC with a USB cable,

and follow “Mounting the SD” instructions in the Crimson 3 user manual.

INSERTION/REMOVAL OF THE SD CARD

Insert the SD card into the slot provided with the card oriented as shown. The

card is inserted properly when the end of the card is flush with the Graphite

case. To remove the SD card, push in slightly on the card.

COMMON

+DC VOLTAGE

1

2

POWER

CONNECTOR

G12 PORT PIN OUTS

RS485

PORT B

AUXILIARY

ETHERNET

PORT A

PORT B

USB HOST

STATUS

STATUS

USB HOST

ETHERNET

ETHERNET

(NIC)

RS232

RS485

PORT A (PGM)

PORT A

COMM

RTS (PIN 6)TxCTS (PIN 1)

Rx

COMM

RS232

PORT B

TxA (PIN 8)

TxB

COMM

TxEN

RxB

RxA

TxA

RTS (PIN 6)

TxB (PIN 1)

Rx

COMMTxCOMM

CTS (PIN 1)

USB

POWER

-

+

DEVICE

USB

CHASSIS

TYPE B

3

TxB

TxA (PIN 8)

TxEN

COMM

RxB

TxB (PIN 1)

TxA

RxA

AUXILIARY

ETHERNET

(NIC)

[OPTIONAL]

AUXILIARY

RS485 COMMS PORTCOMMS PORTPGM PORT

COMMS PORT

RS232 RS485 RS232

[OPTIONAL]

3

Page 4

BATTERY & TIME KEEPING

+

-

WARNING - EXPLOSION HAZARD - THE AREA MUST BE

KNOWN TO BE NON-HAZARDOUS BEFORE SERVICING/

REPLACING THE UNIT AND BEFORE INSTALLING OR

REMOVING I/O WIRING AND BATTERY.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN DISCONNECTED

AND THE AREA IS KNOWN TO BE NON-HAZARDOUS.

A battery is used to keep time when the unit is without power. Typical

accuracy (at 25°C) of the Graphite time keeping is less than one minute per

month drift. The battery of a Graphite unit does not affect the unit’s memory, all

configurations and data is stored in non-volatile memory.

Changing the Battery

To change the battery of a Graphite, first remove power to the unit. Remove

the battery cover. Grasp the top edge of the battery and push to the left to remove

the battery from the holder. Lift the battery out and replace with a new battery.

Replace the battery cover, and re-apply power. Using Crimson or the unit’s

keypad, enter the correct time and date.

* Please note that the old battery must be disposed of in a manner that

complies with your local waste regulations. The battery must not be disposed of

in fire, or in a manner whereby it may be damaged and its contents could come

into contact with human skin.

The battery used by the panel is a lithium type BR2032.

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and

workmanship for a period limited to two years from the date of shipment, provided

the products have been stored, handled, installed, and used under proper conditions.

The Company’s liability under this limited warranty shall extend only to the repair or

replacement of a defective product, at The Company’s option. The Company disclaims

all liability for any afrmation, promise or representation with respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify

RLC against damages, claims, and expenses arising out of subsequent sales of RLC

products or products containing components manufactured by RLC and based upon

personal injuries, deaths, property damage, lost prots, and other matters which Buyer,

its employees, or sub-contractors are or may be to any extent liable, including without

limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and

liability imposed upon any person pursuant to the Magnuson-Moss Warranty Act (P.L.

93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products

except those expressly contained herein. The Customer acknowledges the disclaimers

and limitations contained herein and relies on no other warranties or afrmations.

20 Willow Springs Circle | York, PA 17406 USA

+1 (717) 767-6511 | info@redlion.net | www.redlion.net

4

Loading...

Loading...