Bulletin No. EPAX6-E

Drawing No. LP0539

Released 05/13

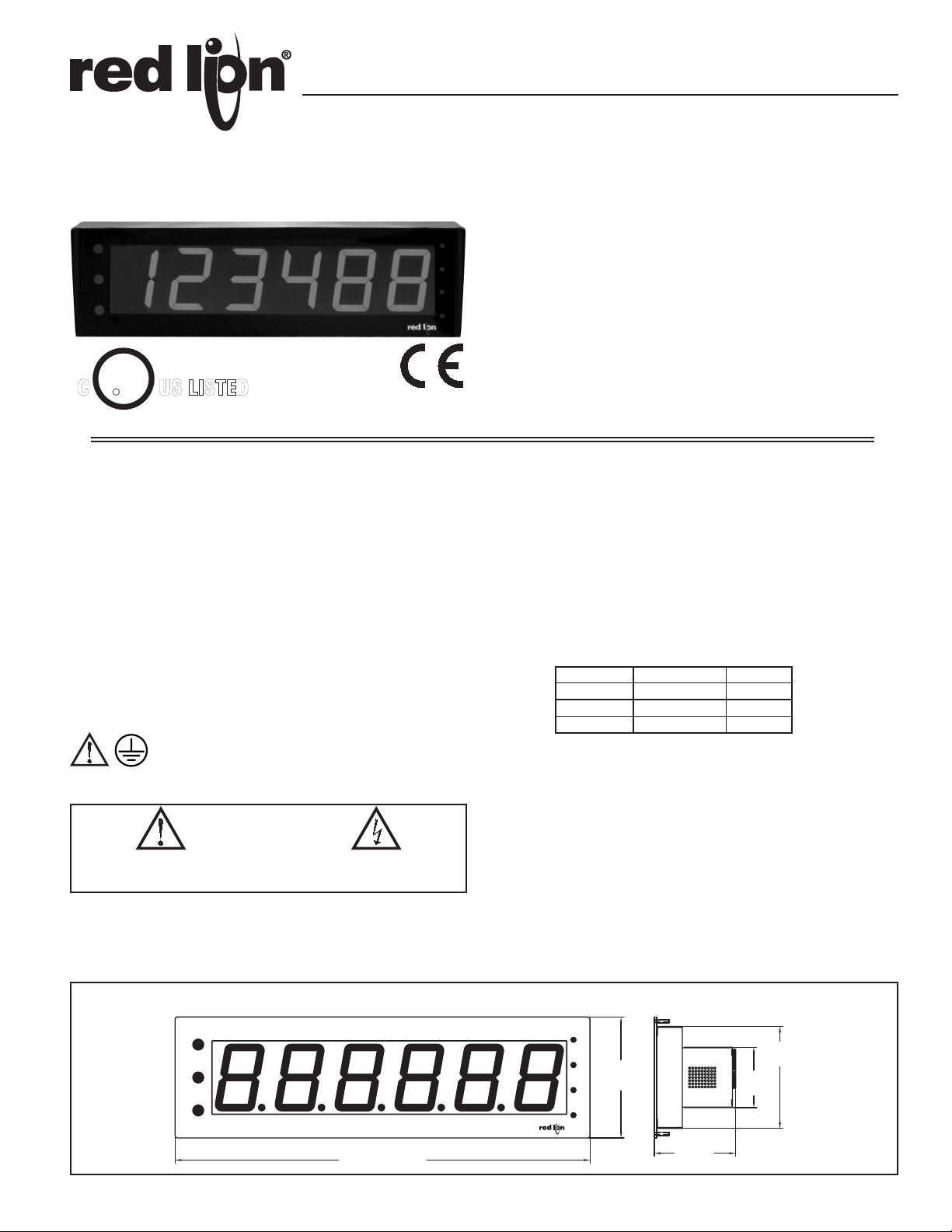

MODEL EPAX- 6 DIGIT EXTRA LARGE PAX DISPLAY FOR DIGITAL INPUTS

LARGE LED DISPLAY READABLE TO 180 FEET

VARIOUS DIGITAL INPUT MODULES;

COUNT AND RATE INPUT

CLOCK/TIMER

SERIAL SLAVE

ALARMS, ANALOG OUTPUT, AND COMMUNICATION

PROGRAMMABLE USER INPUTS

UNIVERSAL AC POWERED (85 to 250 VAC)

PC SOFTWARE FOR METER CONFIGURATION

C

U

R

L

US LISTED

IND. CONT. EQ.

51EB

NEMA 4X/IP65

GENERAL DESCRIPTION

The EPAX Display is a versatile display that can increase productivity by

offering the plant floor or production area a large visual display of their current

status. Whether your measurement is rate, count, or time, the EPAX can satisfy

your requirement. The EPAX displays accept various digital inputs through the

use of input modules (MPAX) which allow the unit to adapt to most any

application. The MPAX Modules offer the same features as our highly

successful PAX Series Panel Meters. Additional plug-in option cards can add

alarms, analog output, and communication/bus capabilities, making the EPAX a

truly Intelligent Panel Meter.

SAFETY SUMMARY

All safety regulations, local codes and instructions that appear in this and

corresponding literature, or on equipment, must be observed to ensure personal

safety and to prevent damage to either the instrument or equipment connected

to it. If equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

The protective conductor terminal is bonded to conductive

parts of the equipment for safety purposes and must be

connected to an external protective earthing system.

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

SPECIFICATIONS

Additional specifications, wiring, programming, and information for the

individual MPAX models are contained in the corresponding standard PAX

literature. This PAX literature is shipped with the ordered MPAX model.

1. DISPLAY: 4" (101 mm) Red LED

6-Digit (EPAX0600): (-99999 to 999999)

2. POWER REQUIREMENTS:

AC MPAX Modules: 85 to 250 VAC, 50/60 Hz, 18 VA

EPAX Display: 85 to 250 VAC, 50/60 Hz, 10 VA

3. INPUT: Accepts digital input modules, see “Selecting Your Display

Components and Option Cards.”

4. ANNUNCIATORS:

Display Indication: Three vertical dots on the left side of the unit identify

the displays for the following modules:

COUNT/RATE CLOCK

TOP Display A Timer

MIDDLE Display B Count

BOTTOM Display C Date

Setpoint Indication: Four vertical dots on the right side of the unit identify

the setpoint “ON” condition, with SP 1 being the top position through SP

4 at the bottom.

5. EPAX Programming: The unit is a large display, designed to be remotely

mounted. Therefore, the unit does not have a programming keypad. Unit

programming should be accomplished by one of the following methods:

Rear Terminal Block: External switches can be wired via the terminal block

to allow unit programming. A minimum of 3 switches would be required.

Optional Programming Remote (EPAXPGM0): This option provides a 10

foot interconnecting cable and programming box. The Programming

Remote contains buttons similar to the PAX, allowing easy programming

of the EPAX display.

Optional Serial Programming: Like all PAX units, you can purchase an RS232

or RS485 Comms Card and program the unit via Windows

software programs.

®

based

DIMENSIONS In inches (mm)

24.77 (629.2)

6.09

7.22

(183.4)

4.65

(118.1)

1

3.60

(91.5)

(154.7)

6. CERTIFICATIONS AND COMPLIANCES:

SAFETY

UL Recognized Component, File #E179259, UL61010A-1, CSA C22.2

No. 1010-1

Recognized to U.S. and Canadian requirements under the Component

Recognition Program of Underwriters Laboratories, Inc.

UL Listed, File #E137808, UL508, CSA C22.2 No. 14-M95

LISTED by Und. Lab. Inc. to U.S. and Canadian safety standards

Type 4X Indoor Enclosure rating (Face only), UL50

IECEE CB Scheme Test Certificate #US/8843/UL

CB Scheme Test Report #04ME11209-20041018

Issued by Underwriters Laboratories, Inc.

9. MODULE INSTALLATION:

24-pin shrouded connector on EPAX engages connector on MPAX module

upon installation. Shroud ensures proper alignment by providing a lead-in for

the module connector.

10. CONNECTIONS: Wiring connections are made to the EPAX terminal

block and MPAX module via high compression cage-clamp terminal blocks.

MPAX Module Wiring: Instructions are provided in the corresponding PAX

Bulletin.

EPAX Terminal Block Wiring:

Wire Strip Length: 0.3" (7.5 mm)

Wire Gage: 30-12 AWG copper wire

Maximum Torque: 5-7 inch-lbs (0.58-0.81 N-m)

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

IP65 Enclosure rating (Face only), IEC 529

CAUTION: DISCONNECT ALL POWER BEFORE

INSTALLING OR REMOVING MODULE

ELECTROMAGNETIC COMPATIBILITY

EMC specifications determined by the MPAX module.

7. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: Determined by the MPAX module

Storage Temperature Range: -40 to 60°C

Operating and Storage Humidity: 0 to 85% max. RH (non-condensing)

Altitude: Up to 2000 meters

11. CONSTRUCTION: Aluminum front panel, enclosure, and rear cover with

textured black polyurethane paint for scratch and corrosion resistance

protection. Sealed front panel meets NEMA 4X/IP65 specifications for

indoor use when properly installed. Installation Category II, Pollution Degree

2. Panel gasket and keps nuts included.

12. WEIGHT: 5 lbs (2.25 kg) (less module)

8. MOUNTING REQUIREMENTS:

Max. panel thickness is 0.375" (9.5 mm)

Min. panel thickness for NEMA 4/IP65 sealing is 0.060" (1.52 mm)

About the MPAX Input Modules

The MPAX Module serves as the input to the EPAX Display. There are several different modules to cover a variety of inputs. The MPAX module provides input

scaling which allows the EPAX to display most any engineering unit. Once the MPAX is inserted into the EPAX, the unit has the same functions and capabilities of

our PAX Series Intelligent Panel Meters. A full set of PAX programming instructions will be included with the MPAX module.

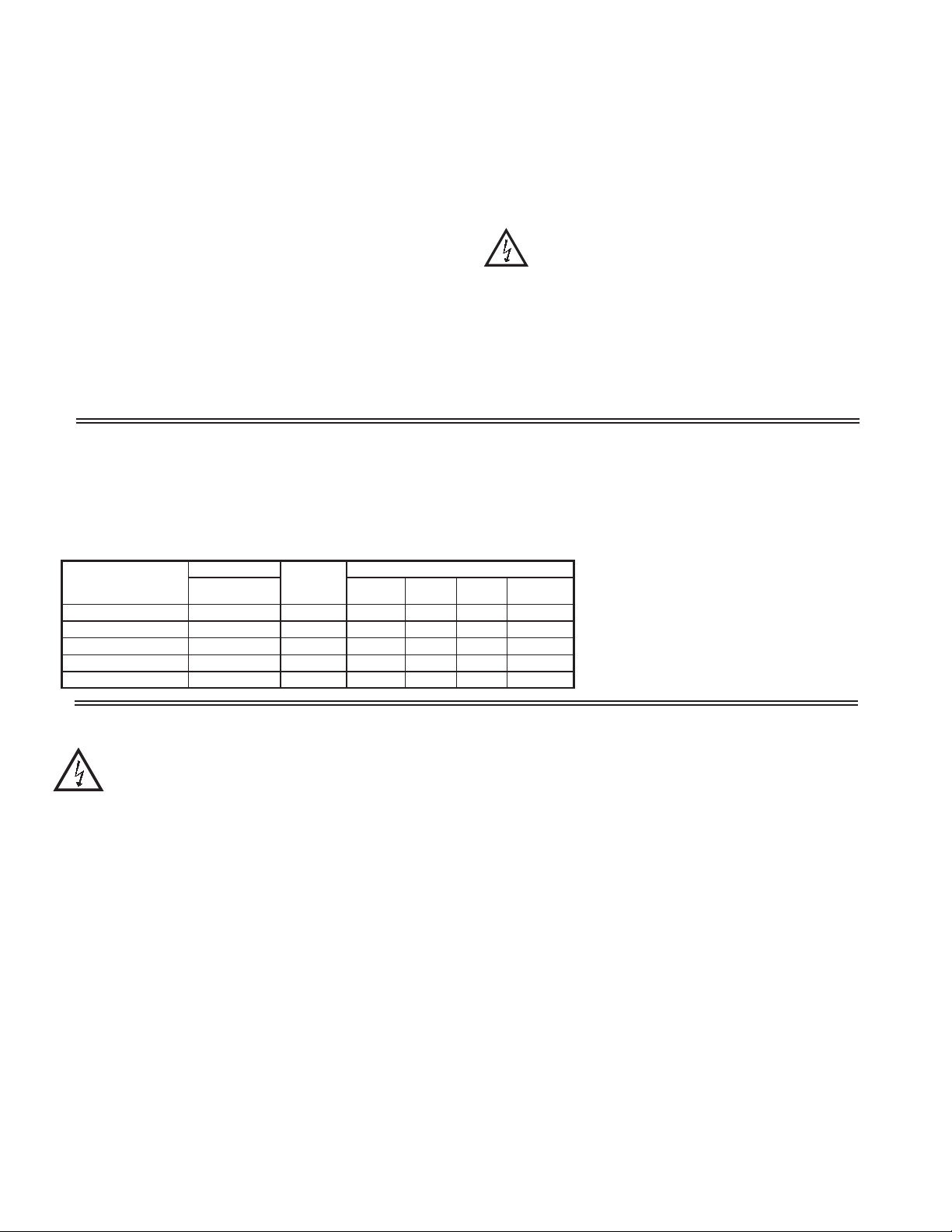

Selecting Your Display Components and Option Cards

To build a complete display unit, you will need an EPAX and an MPAX Input Module. The EPAX is only a display and will not operate without an MPAX module.

Please use the following chart to identify the appropriate MPAX module and EPAX Display that will satisfy your application.

SIGNAL TYPE

Count/Rate/Serial Slave

Count

Rate

Real-Time Clock/Timer

Timer

MPAX MODULES*

85-250 VAC

MPAXCK00

MPAXTM00

EPAX

DISPLAYS

EPAX0600MPAXI020

EPAX0600MPAXC020

EPAX0600MPAXR020

EPAX0600

EPAX0600

OPTIONAL PLUG-IN CARD COMPATABILITY

YES

-

-

-

-

REAL-TIME

CLOCK

SETPOINT

YES

YES

YES

YES

YES

COMMS

YES

-

-

YES

YES

ANALOG

-

-

-

YES

-

* For detailed module and plug-in card specifications,

see corresponding PAX literature. (i.e. For MPAXI

specifications, see the PAXI literature)

OPTIONAL PLUG-IN CARDS AND ACCESSORIES

WARNING: Disconnect all power to the unit before

installing Plug-in cards.

Adding Option Cards

The PAX and MPAX series meters can be fitted with up to three optional plug-

in cards. The details for each plug-in card can be reviewed in the specification

section of the PAX Bulletin. Only one card from each function type can be

installed at one time. The function types include Setpoint Alarms (PAXCDS),

Communications (PAXCDC), and Analog Output (PAXCDL). The plug-in cards

can be installed initially or at a later date.

SETPOINT ALARMS PLUG-IN CARDS (PAXCDS)

The PAX and MPAX series has 4 available setpoint alarm output plug-in

cards. Only one of these cards can be installed at a time. (Logic state of the

outputs can be reversed in the programming.) These plug-in cards include:

PAXCDS10 - Dual Relay, FORM-C, Normally open & closed

PAXCDS20 - Quad Relay, FORM-A, Normally open only

PAXCDS30 - Isolated quad sinking NPN open collector

PAXCDS40 - Isolated quad sourcing PNP open collector

ANALOG OUTPUT PLUG-IN CARD (PAXCDL)

Either a 0(4)-20 mA or 0-10 V retransmitted linear DC output is available

from the analog output plug-in card. The programmable output low and high

scaling can be based on various display values. Reverse slopes output is possible

by reversing the scaling point positions.

PAXCDL10 - Retransmitted Analog Output Card

COMMUNICATION PLUG-IN CARDS (PAXCDC)

A variety of communication protocols are available for the PAX and MPAX

series. Only one of these cards can be installed at a time. When programming the

unit via Crimson (for MPAXI) or SFPAX (for MPAXCK or MPAXTM), the

RS232 or RS485 Cards must be used.

MPAXI/C/R Note: For Modbus communications, use RS485 Communications

Output Card and configure Communication Type parameter (tYPE) for Modbus.

PAXCDC10 - RS485 Serial (Terminal) PAXCDC1C - RS485 Serial (Connector)

PAXCDC20 - RS232 Serial (Terminal) PAXCDC2C - RS232 Serial (Connector)

PAXCDC30 - DeviceNet

* PAXCDC40 - Modbus (Terminal) * PAXCDC4C - Modbus (Connector)

PAXCDC50 - Profibus-DP

* MPAXCK/MPAXTM only.

PROGRAMMING SOFTWARE

CRIMSON - MPAXI Only

Crimson is a Windows® based program that allows configuration of the

EPAX meter from a PC. Crimson offers standard drop-down menu commands,

that make it easy to program the EPAX meter. The EPAX program can then be

saved in a PC file for future use. A PAX serial plug-in card is required to

program the meter using the software.

SFPAX - MPAXCK and MPAXTM Only

The SFPAX is a Windows® based program that allows configuration of the

EPAX meter from a PC. Using the SFPAX makes it easier to program the EPAX

meter and allows saving the PAX program in a PC file for future use. On-line

help is available within the software. A PAX serial plug-in card is required to

program the meter using the software.

2

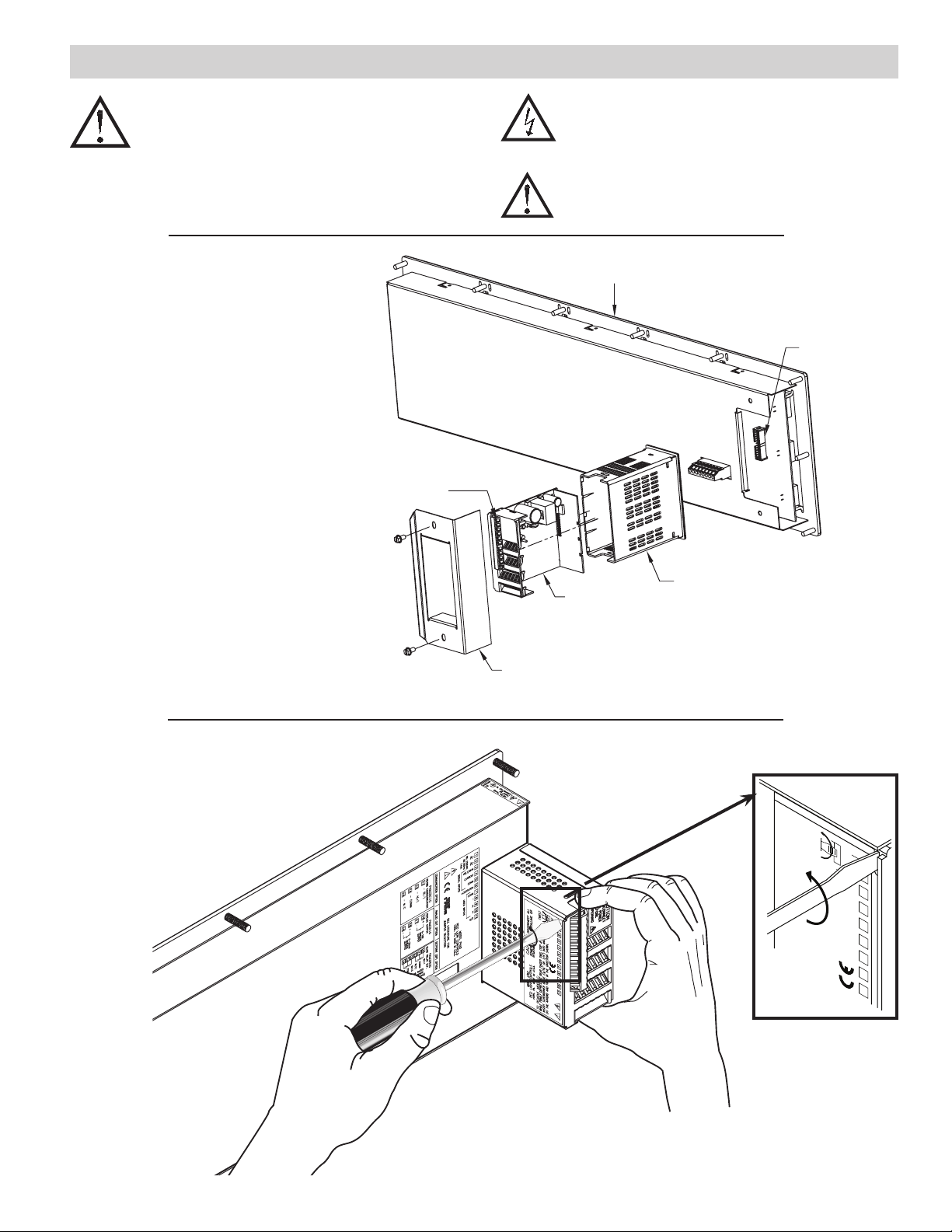

1.0 ASSEMBLING THE DISPLAY

CAUTION: The MPAX main circuit board and the option cards

contain static sensitive components. Before handling the module

or the cards, discharge static charges from your body by

touching a grounded bare metal object. Handle the module by

the rear plastic cover only, and the option cards by the board

edges. Dirt, oil or other contaminants that contact the circuit

boards or components can adversely affect circuit operation.

Prior to installing the EPAX Display, it is recommended

that the MPAX and any option cards be assembled first.

This will allow you the opportunity to insure all the boards

are fitted properly into their connectors.

Installing the Option Cards

If your application requires option cards, they should be

installed into the MPAX before it is installed into the

EPAX Display. Refer to the literature enclosed with the

option cards for installation instruction.

Installing the MPAX

Remove the MPAX case (plastic) from the rear of the

EPAX by removing the two screws and pulling off the

metal holding bracket. Install the MPAX into plastic case

by aligning the front connector of the MPAX with the hole

in the front of the plastic case. The module must be

oriented as shown with terminal #1 toward the top of the

EPAX case. Next, insert the MPAX case into the EPAX by

lightly pushing the connector of the MPAX into the

connector of the EPAX PC board. Place holding bracket

over the plastic case and install the two screws.

Installing the Labels

Each option card and the MPAX are shipped with a

connection label. These labels must be applied to the rear

of the EPAX in the positions shown in the drawing.

WARNING: Exposed line voltage exists on the MPAX main circuit

board and the option cards. DO NOT apply power to the

module OR load circuits until the module is properly installed

in the EPAX case.

NOTE: All module and option card labels must be installed as

shown for safety purposes.

EPAX

EPAX CONNECTOR

TERMINAL # 1

MPAX CASE

MPAX

HOLDING BRACKET

Figure 1, Installing an MPAX Module and Option Cards

Removing The MPAX Module

To remove the MPAX Module from the EPAX Display, first remove all

power and load circuits. Then insert a flat screwdriver blade (3/16" or

1

/4") into the narrow slot between the EPAX rear cover plate and

the module’s plastic cover as illustrated in Figure 2. Twist

the screwdriver in the direction shown to disengage the

internal connectors while firmly squeezing and

pulling back on the rear finger tabs (top and

bottom). Carefully slide the module

out of the EPAX case, keeping it

properly aligned with the

case opening.

Figure 2, Removing an MPAX Module

TWIST

SLOT

7 654 32

8

3

2.0 INSTALLING THE DISPLAY

2X

(123.3)

5X 4.85

(158.2 )

(170.8)

6.72

6.23

3.36

(85.4)

0.23 (5.9) DIA.

THRU, TYP.

(604.3 )

23.79

24.27 (616.5)

+.04

-.00

+1.01

-.00

+.03

-.00

+.76

-.00

EPAX DISPLAY INSTALLATION

The EPAX display is intended to be mounted

into a panel or enclosure. The display is provided

with a gasket to provide a water-tight seal. The

recommended minimum panel thickness for

NEMA 4/IP65 sealing is 0.060" (1.57 mm).

For panel mounting, prepare the panel

cut-out to the dimensions shown in

Figure 3. The supplied template may be

used to mark the cut-out and hole

locations on the panel. After the panel

cut-out has been deburred, slide the

panel gasket over the rear of the display

and onto the mounting studs. Insert the

display into the panel cut-out as

illustrated in Figure 4. Install 14 #

10-32 keps nuts (supplied) and tighten

evenly for uniform gasket compression.

Do not over-tighten the nuts.

By using additional mounting accessories,

the EPAX can be surface-wall mounted, suspended,

or bottom mounted. Separate installation instructions are

provided with the mounting accessories.

DIMENSIONS In inches (mm)

Figure 3, Panel Cut-out for the EPAX

Environment And Cleaning

The display should be installed in a location that does

not exceed the maximum operating temperature and

provides good air circulation. Placing the system near

devices that generate excessive heat should be avoided.

The bezel should be cleaned only with a soft cloth and

neutral soap product. Do NOT use solvents. Continuous

exposure to direct sunlight may accelerate the aging

process of the bezel.

FRONT

PANEL

MOUNTING

PANEL

GASKET

PANEL

MA2204X

E

CONNECTED TO

MUST BE

METAL PANEL

1

~~

85-250VAC

AC AC

50/60Hz

2 3 4 5 6 7

14VA

COMMUNICATION OPTION ANALOG OUT OPTION SETPOINT (SP) OPTION

SIGNAL INPUTS

!

VOLT/OHM

RS485 COMMUNICATION

CURRENT

12

OUTPUT

21

COMM

7

RST KEY

0-10V

ANALOG

- B(-)

ANALOG OUTPUT

+16

QUAD RELAY S.P.

20

RLY1

6

F2 KEY

PAXCDC10

PAXCDL10

PAXCDS20

5

F1 KEY

COMM

+EXCITATION

COMM

8 9

USER INPUTS

1

R

2

10 11

3

SEE LITERATURE FOR

JUMPER SELECTION

N/C

RED LION CONTROLS

YORK, PA. MADE IN U.S.A.

MODEL PAXD

CAUTION: DISCONNECT

ALL POWER BEFORE INSTALL-

ING OR REMOVING MODULE.

2

~

3 1

~

DSP KEY

AC AC

4

PAR KEY

85 - 250VAC

50/60Hz @ 5VA

RJ12

13

14

- A(+)

15

- COMM

- N/C

17

-

+18

-19

0-20mA

ANALOG

OUTPUT

22

23

24

25

RLY2

RLY3

COMM

RLY4

RELAYS RATED

3A @ 250VAC

(RESISTIVE LOAD)

8

COMM

!

MODEL EPAX

RED LION CONTROLS

YORK, PA.

MADE IN U.S.A.

MOUNTING STUDS AND NUTS

(14 PLACES)

CONNECT THIS STUD

TO A PROTECTIVE

EARTHING SYSTEM

!

CASE

VENT

HOLES

TWIST

SLOT

12

DISCONNECT ALL

3

456

CAUTION:

POWER BEFORE INSTALLING OR

REMOVING MODULE

7

89

MODEL LPAX

1011

RED LION CONTROLS

YORK, PA. MADE IN U.S.A.

TO REMOVE MODULE:

WHILE FIRMLY DEPRESSING REAR FINGER TABS (TOP & BOTTOM),

INSERT SCREWDRIVER BLADE (3/16" OR 1/4") INTO NARROW SLOT

(AT THE ARROW) AND TWIST IN THE DIRECTION SHOWN.

!

REAR COVER PLATE

OPENING

CAUTION

DISCONNECT

ALL POWER

BEFORE

MODULE

RETENTION

LATCH (TOP

AND BOTTOM)

MODULE RELEASE

FINGER TAB

(TOP & BOTTOM)

Figure 4, Installing The EPAX Into A Panel

4

3.0 WIRING AND PROGRAMMING THE DISPLAY

21

36

Note: Both the EPAX and the MPAX module require power. It is

recommended to connect the primary AC power to the EPAX terminal

block, then jumper to the MPAX module.

EPAX REAR VIEW

EPAX PROGRAMMING

The unit is a large display, designed to be remotely mounted. Therefore,

the unit does not have a programming keypad. Unit programming must be

accomplished by one of the following three methods:

8

RST KEY

COMM

F2 KEY

!

MODEL EPAX

RED LION CONTROLS

YORK, PA.

MADE IN U.S.A.

MPAX

MODULE

CAUTION:

ING OR REMOVING MODULE

ALL POWER BEFORE INSTALL-

M2967X

4576 123

DSP KEY

PAR KEY

F1 KEY

~

~

AC AC

85 - 250VAC

50/60Hz @ 5VA

DISCONNECT

RJ12

Optional Programming Remote (EPAXPGM0)

This optional programming remote

plugs into the EPAX through an

RJ12 connector and a 10 foot cable.

The buttons on the programming box

function the same as the PAX unit.

Simply program the EPAX exactly

as the PAX instructions indicate. The

programming box can be left

connected to the EPAX for future

programming changes or can be

disconnected and used to program

additional EPAX units.

RJ12 CONNECTOR ON BOTTOM OF UNIT

RJ12 FEMALE

PIN

1DSP KEY

2

3

4

5

6

NAME

PAR KEY

F1 KEY

F2 KEY

RST KEY

COMM

12 4

RJ12 CONNECTOR

ON BOTTOM OF UNIT

Rear Terminal Block

External normally open switches can be wired via the terminal block to allow

unit programming. A minimum of 3 switches would be required. Each

external switch must be wired between the key and the common terminal.

EPAX TERMINAL BLOCK

~

AC

85 - 250VAC

50/60Hz @ 5VA

~

AC

DSP KEY

PAR KEY

F1 KEY

67543

F2 KEY

RST KEY

8

COMM

Optional Serial Programming

5

Like all PAX units, you can purchase an RS232 or RS485 Comms Card and

program the unit via Windows® based software programs.

5

NEMA 4/IP65 LARGE DISPLAY ENCLOSURE & SHROUD FOR EPAX

LIGHT-WEIGHT ALUMINUM CONSTRUCTION

COMPLETELY SEALED FOR WASH-DOWN

MOUNTING CHANNELS FOR VERSATILE INSTALLATION

DESCRIPTION

The NEMA 4/IP65 Large Display Enclosure is designed to protect the EPAX

from dust and hose directed water, when properly installed. This light-weight

all aluminum unit utilizes welded seams and neoprene gaskets to meet NEMA

4/IP65 requirements. A textured, polyurethane coating protects against corrosion

Picture includes the EPAX, Nema Enclosure, and Shroud

and is scratch resistant. Figure 1 below shows the overall dimensions of the

Enclosure. The Display Enclosure with Mounting Channels weighs 9 pounds

(4.1 Kg).

DIMENSIONS In inches (mm) MOUNTING

21.00 (533.4)

1.25 (31.8)

27.50 (698.5)

10.00

(254)

.75

(19.1)

6.50*

(165.1)

7.11**

(180.6)

* Housing Only ** Overall Including Screwheads

Figure 1 Figure 3

Provided with the enclosure are two ¼-20 UNC x 1" hex

bolts, two ¼-20 UNC “strut nuts”, and two ¼" washers. The

“strut nuts” can be installed anywhere in the channel by

inserting them, spring side down, into the channels, then

rotating them 90 degrees clockwise until the notches engage

with the lips of the channel. The bolts and washers provided

allow mounting to surfaces ¼" to ½" thick (6.4 to 12.7 mm).

Use longer bolts for mounting to thicker surfaces. Bolts

fabricated from materials other than steel are not recommended.

1/4-20 UNC STEEL BOLT

WASHER

MOUNTING CHANNEL

STRUT NUT

TYPICAL INSTALLATIONS FOR NEMA 4/IP65 ENCLOSURE

Removing the rear panel of the enclosure allows access to the Display for

service. Either the rear panel or housing may be drilled to accept sealed conduit

fittings, liquid-tight cable fittings or other types of wiring connectors. The

enclosure may be attached to horizontal surfaces located above or below it,

using the mounting channels provided.

I-BEAM

ENCLOSURE

BASEMOUNT WITH WATERTIGHT

CABLE CONNECTOR ENTERING

THROUGH REAR PANEL.

SUSPENDED FROM CONDUIT

WITH SEALED FITTINGS.

(SHOWN WITH SHROUD).

Figure 2

6

BEAM MOUNT WITH SEALED

CONDUIT ENTERING FROM

RIGHT SIDE.

ASSEMBLY AND INSTALLATION PROCEDURE

1. Install the two mounting channels on the enclosure housing using

the four #8-32 screws provided and then insert the strut nuts

(provided). Invert enclosure if base mounting.

2. If the wiring is to be routed through the housing, make sure that

the mounting channels are oriented properly before drilling, so

the Display will be readable. Wiring is generally brought into the

right side of the housing or rear panel, closest to the terminals of

the MPAX module. Drill the proper size hole in the housing or

rear panel for the wiring connector or sealed conduit fitting and

attach the fitting(s)

3. Before installing the Display into the housing, be sure that the

mounting channels are oriented properly for the type of

installation planned. Place the gasket that is supplied with the

Display over the studs extending from the front panel of the

display.

4. If using the shroud, refer to the Shroud Installation Procedure.

Place the Display with gasket through the holes in the housing as

shown at right. Working back and forth across the stud pattern,

install the #10-32 keps nuts supplied with the Display on the

studs. Tighten firmly.

5. Mount the housing, using the strut nuts and steel ¼-20 UNC

bolts and washers, as shown in figure 4.

6. Connect the wires to the Display per the instructions included

with the personality board.

7. Remove the center section of the rear panel gasket. Apply the

gasket to the rear panel of the enclosure by inserting the #8-32

screws through the panel and into the holes in the gasket.

Position the panel on the housing, start all of the screws, then

firmly tighten them in a pattern working back and forth across

the rear panel.

1/4-20 x 1"

SCREW & WASHER

#8-32 SCREWS

TYP. 4

MOUNTING

CHANNEL

TYP. 2

EPAX

* Supplied with EPAX.

STRUT NUT

TYP. 2

#10-32

KEPS NUTS *

TYP. 14

Figure 4

#8-32 SCREWS

TYP. 16

REAR PANEL GASKET

HOUSING

FRONT PANEL GASKET *

REAR PANEL

DIMENSIONS FOR THE EPAX DISPLAY SHROUD

The optional EPAX Display Shroud enhances the readability of the

DIMENSIONS In inches (mm)

25.12 (637.9)

Displays that are installed in areas with high intensity overhead light

sources. The Shroud can be used with the EPAX Display in any

installation, (panel mount, NEMA 4/IP65 Enclosure, or Universal

Mounting Bracket). When properly assembled, the Shroud will not

affect the integrity of a NEMA 4/IP65 installation. The Shroud

weighs 1.0 pounds (0.45 Kg).

SHROUD INSTALLATION PROCEDURE

Installing The Shroud On An EPAX Display In A NEMA 4/IP65 Enclosure Or Panel

1. Place a gasket over the studs extending from the rear of the

front panel of the Display.

2. Orient the shroud as shown in Figure 6, and place it over the

display. The studs of the display should now be protruding

through the rear of the shroud.

3. Place the other gasket over the studs.

4. Install the unit into the panel or enclosure using the #10-32

keps nuts that are supplied with the Display. Tighten the nuts

firmly.

GASKET

SHROUD

Figure 5

3.65

(92.7)

7.60

(193)

PANEL OR NEMA 4 ENCLOSURE

#10-32

KEPS NUTS *

TYP. 14

EPAX

Nema 4/IP65 Shroud Installation

* Supplied with EPAX.

7

Figure 6

FRONT PANEL GASKET *

ORDERING INFORMATION

TYPE MODEL NO. DESCRIPTION PART NUMBERS

Display EPAX

Digital

Input

Module

Optional

Plug-In

Cards

Accessories

MPAX

PAXCDS

PAXCDC*

PAXCDL*

PAXUSB

PAXRTC*

PGM

SFCRD**

SFPAX** PC Configuration Software for Windows 95/98 on 3.5" disk (for MPAXCK00 and MPAXTM00 Modules)

ENC12

SHR

EN/SH

*Refer to “Selecting Your Display Components and Option Cards.”

**Available as a FREE download from the Red Lion website. www.redlion.net

6-Digit Extra Large Display for Digital MPAX Modules EPAX0600

Count/Rate Indicator Module, AC Powered MPAXI020

Count Indicator Module, AC Powered MPAXC020

Rate Indicator Module, AC Powered MPAXR020

Real-Time Clock Module, AC Powered MPAXCK00

Timer Module, AC Powered MPAXTM00

Dual Setpoint Relay Output Card PAXCDS10

Quad Setpoint Relay Output Card PAXCDS20

Quad Setpoint Sinking Open Collector Output Card PAXCDS30

Quad Setpoint Sourcing Open Collector Output Card PAXCDS40

RS485 Serial Communications Output Card with Terminal Block PAXCDC10

Extended RS485 Serial Communications Output Card with Dual RJ11 Connector PAXCDC1C

RS232 Serial Communications Output Card with Terminal Block PAXCDC20

Extended RS232 Serial Communications Output Card with 9 Pin D Connector PAXCDC2C

DeviceNet Communications Card PAXCDC30

Modbus Communications Card PAXCDC40

Extended Modbus Communications Card with Dual RJ11 Connector PAXCDC4C

Profibus-DP Communications Card PAXCDC50

Analog Output Card PAXCDL10

PAX USB Programming Card (Not included in PAX product UL E179259 file). PAXUSB00

Real-Time Clock Card (Replacement Only) PAXRTC00

Programming Remote for EPAX with 10 foot cable EPAXPGM0

Crimson 2 PC Configuration Software for Windows 98, ME, 2000 and XP (for MPAXI020 Module) SFCRD200

NEMA 4/IP65 Enclosure for EPAX ENC12000

Shroud for EPAX SHREPAX0

EPAX NEMA 4/IP65 Enclosure and Shroud EPAXENSH

SFPAX

TROUBLESHOOTING

For technical assistance, contact technical support.

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and workmanship for a

period limited to two years from the date of shipment, provided the products have been stored, handled,

installed, and used under proper conditions. The Company’s liability under this limited warranty shall

extend only to the repair or replacement of a defective product, at The Company’s option. The Company

disclaims all liability for any afrmation, promise or representation with respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products containing

components manufactured by RLC and based upon personal injuries, deaths, property damage, lost prots,

and other matters which Buyer, its employees, or sub-contractors are or may be to any extent liable,

including without limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and

liability imposed upon any person pursuant to the Magnuson-Moss Warranty Act (P.L. 93-637), as now in

effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those

expressly contained herein. The Customer acknowledges the disclaimers and limitations contained herein

and relies on no other warranties or afrmations.

Loading...

Loading...