Page 1

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

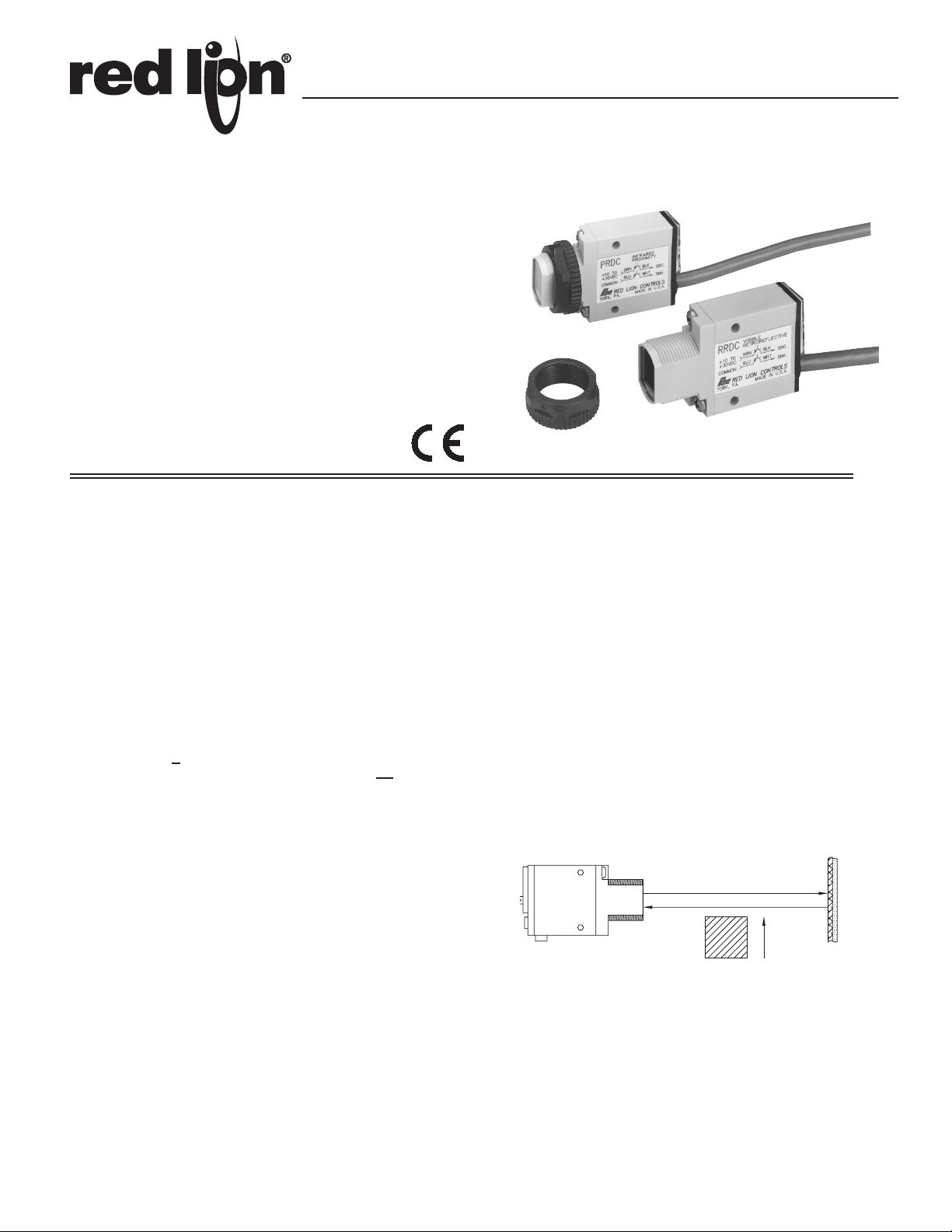

COMPACT DC POWERED PHOTO-ELECTRIC SENSORS

RETROREFLECTIVE, PROXIMITY (DIFFUSE) & OPPOSED BEAM

PAIRS

MODULATED LED LIGHT BEAMS FOR IMMUNITY TO AMBIENT

LIGHT

+10 to +30 VDC OPERATION WITH REVERSE POLARITY

PROTECTION

NPN & PNP (CURRENT SINKING AND SOURCING ) OUTPUTS

RUGGED VALOX HOUSING MEETS NEMA 1, 2, 3, 3S, 4, 4X, 12,

& 13 STANDARDS

LED SIGNAL STRENGTH INDICATOR MAKES ALIGNMENT EASY

& PROVIDES INDICATION OF LIGHT SIGNAL DETERIORATION

Bulletin No. PES/DC-C

Drawing No. LP0156

Released 04/13

DESCRIPTION

These compact self-contained and powerful Retroreflective, Proximity

(Diffuse) and Opposed Beam Pair Photo-electric Sensors provide application

flexibility in counting, positioning and object detection. All units are

interchangeable with conventional 18 mm threaded barrel-type photo-electrics

and inductive proximity sensors. Their small 2-1/8" x 1-1/4" x 1/2" size, in

addition to various mounting options, greatly increases alignment ease and

application possibilities.

All units can be powered from +10 to +30 VDC and are reverse polarity

protected. Current sinking NPN and current sourcing PNP Open Collector

Transistors are protected from continuous overload and inductive load transients

and are rated to 150 mA, with low saturation voltage and less than 1 µA offstate

leakage current. In addition, no false outputs are generated at power-up. A 6 foot

long 4 conductor PVC jacketed cable with strain relief provides supply input

and transistor outputs.

A gasketed removable back cover provides access to the LIGHT/DARK

Operate Mode Selector. When in the “Light Operate” (LO) position, outputs

turn on when light is received by the detector. When in the “Dark Operate”

(DO) position, the outputs are turned on when sensor light is not detected. Also

accessible is a 15-turn screwdriver adjustable GAIN potentiometer that enables

precise adjustment of system sensitivity. A rear mounted LED Signal Strength

Indicator “lights” whenever the sensor sees a light condition and “blinks” at a

rate proportional to the received signals strength (the stronger the signal, the

faster the rate). This LED allows for easy alignment and monitoring of signal

strength deterioration due to dirty optics or changes in alignment.

SPECIFICATIONS

1. POWER REQUIREMENTS: +10 to +30 VDC, 10% Ripple Max., Re verse

Polarity Protected, 25 mA max. (Model EMDC = 20 mA max.)

2. OUTPUTS: Current Sinking NPN and Current Sourcing PNP Open

Collector Transistors; Short Circuit Protected to +30 VDC, Internal Zener

Diode Protected;

I

= 150 mA each; VOH = 30 VDC max.

SNK

NPN V

PNP V

Offstate Leakage Current = Less than 1 µA

3. RESPONSE TIME: Responds to a “light” or “dark” signal duration of 1

msec. or greater.

4. OPERATING TEMPERATURE: -4° to+158°F (-20° to +70°C)

5. WEIGHT: 3.5 oz (99.2 g)

= 0.2 V @ 10 mA load; 1 V max. @ 150 mA max. load

SAT

= Less than 1 V @ 10 mA load; less than 2 V @ 150 mA max.

SAT

load

MOUNTING

Various mounting methods have been designed to simplify alignment and

provide versatility in any industrial environment. The integral 18 mm threaded

lense can be interchanged with existing threaded entries common to 18 mm

barrel sensors and inductive proximity switches. The threaded lense can also be

installed into panel thicknesses of 5/16" through a 0.71" diameter hole and

tightened into place with the supplied mounting nut. Two #4 screw clearance

through-holes on 0.95" centers are available for side mounting or side nesting

of multiple units on 1/2" centers for scanning large areas or for code reading

applications. Units may also be mounted using the stainless steel Bottom-Mount

or Side-Mount Bracket Kits (Models MB2 or MB3). These brackets allow 2

axes of movement & greatly simplify alignment.

MODEL RRDC - RETROREFLECTIVE SENSOR

The Model RRDC is a compact, DC powered, retroreflective photo-electric

sensor with maximum detection range of 15 feet (with 3" dia. reflector Model

RT2). The “visible” LED light beam allows for easy alignment and is modulated,

providing immunity to ambient light. The small beam size of 1/2" at 1 foot from

the lense, makes it a good choice for detecting relatively small objects.

In operation, the visible LED light beam is directed at a prismatic photo

transistor, amplified and demodulated. An object which then breaks this beam

will trigger the outputs.

RETRO TARGET

RRDC

RETRO-

REFLECTIVE

ALIGNMENT

Apply DC power to the RRDC and direct its visible light beam at a reflective

target (Models RT1 or RT2) while observing the Signal Strength LED on the

back of the unit. Optimum alignment occurs when the sensor is receiving the

maximum amount of reflected light and the GAIN (sensitivity) potentiometer is

adjusted for the highest pulse rate on the Signal Strength LED. Note that glass,

metallic objects, and other highly reflective surfaces may not be detected. In

these applications, mount the sensor and reflector at any angle to the object to

minimize direct reflections.

SENSING RANGE UP TO 15'

OBJECT

1

Page 2

MODEL PRDC - PROXIMITY SENSOR

The Model PRDC is a compact, DC powered, Proximity (Diffuse) photoelectric sensor with a 12" maximum detecting distance (as measured with a

90% reflective white test card). This sensor requires no special reflectors or

reflective tapes and the limited 12" sensing range reduces detection of

background reflections. It is ideally suited for detection of transparent or

translucent objects, parts ejected from presses, and rotating targets such as

pulley spokes. A modulated “infrared” LED light beam provides immunity to

ambient light.

In operation, the modulated light beam is reflected by the object to be

detected. Actual sensing range is determined by the surface area and the

amount of reflectivity of the object. This reflected light is sensed by a phototransistor, amplified, demodulated and then energizes the outputs.

SENSING RANGE UP TO 12"

PRDC

PROXIMITY

OBJECT

ALIGNMENT

With the PRDC in its sensing position, apply DC Power and direct the

infrared light beam at the object to be detected. While observing the Signal

Strength LED, adjust the GAIN (sensitivity) potentiometer for the highest LED

pulse rate. Now remove the sensed object. If the LED goes out, no further

adjustment is necessary. If the LED remains lit, the sensor is “seeing” reflected

light from the background. Reduce the GAIN by steps until the sensor “sees”

the object but not the background. Then turn the pot counter clockwise 2 more

full turns. If the background is still being sensed, it will be necessary to reduce

its reflectivity by either moving it back or painting it flat black.

MODELS EMDC & RCDC - OPPOSED BEAM

EMITTER/ RECEIVER SENSOR PAIR

The Models EMDC (Emitter) and the RCDC (Receiver) are compact, DC

powered, Opposed Beam photo-electric sensor pairs with a 10 foot sensing

range. The Emitter contains a high power modulated “infrared” LED. The

Receiver contains a sensitive photo-transistor, amplifier-demodulator and

output transistors. In operation, these outputs will be triggered when the

Receiver detects that an object begins to break the Emitter beam. Due to their

high gain, they are ideally suited for detecting opaque objects in dirty and dusty

areas or when condensation or oil film environments are present. The small

1/8" well defined beam size allows for sensing small parts accurately and

provides repeatable edge sensing of opaque objects to better than 0.01" for

accurate positioning applications. Greater accuracies can be achieved by

aperturing the Emitter, Receiver or both. However, aperturing will result in

reduced sensing distances. While the beam size is small, the Receiver has a

wide field of view which allows easy “line-of-sight” alignment.

SENSING RANGE UP TO 10'

EMDC

EMITTER

OBJECT

RCDC

RECEIVER

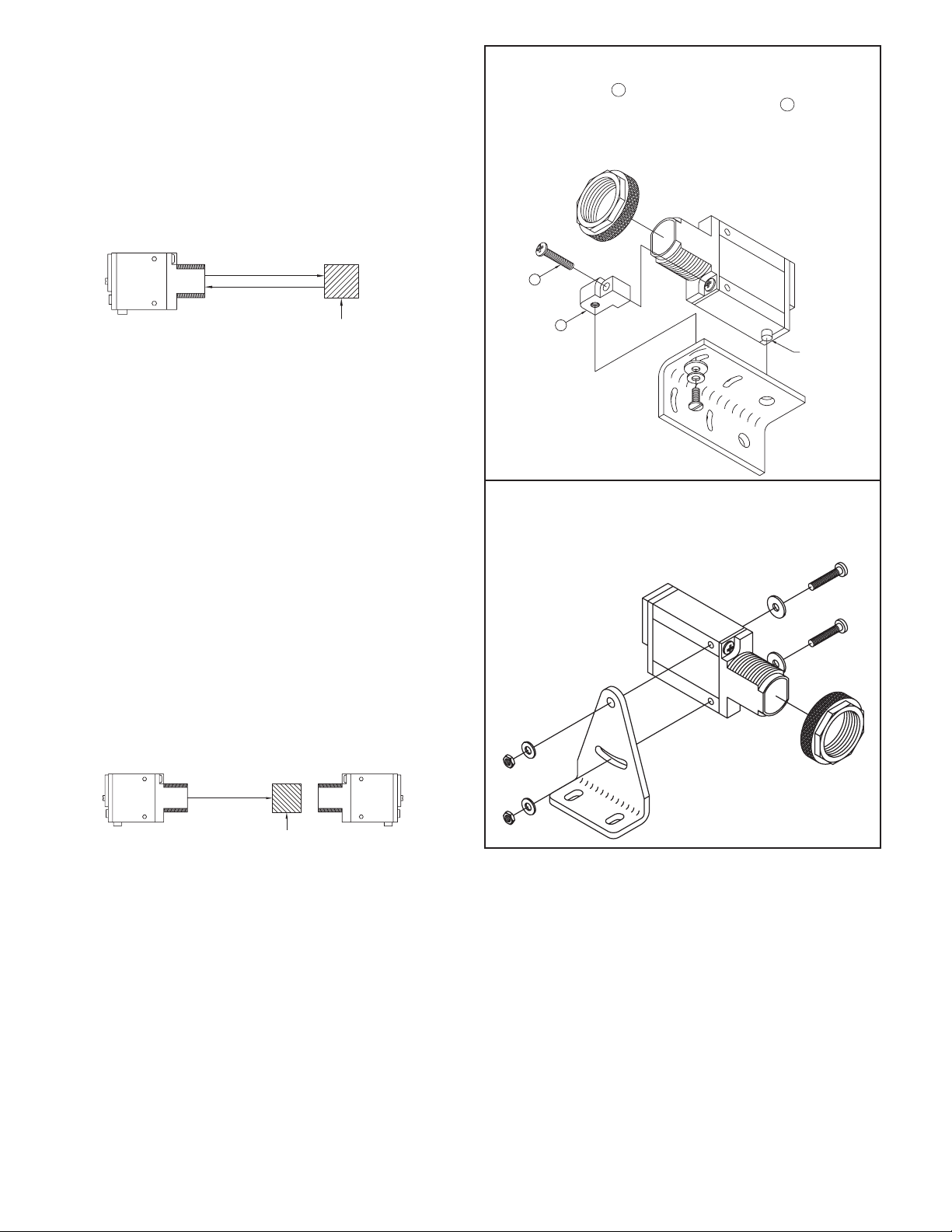

MB2 BOTTOM MOUNT BRACKET KIT INSTALLATION

1. Remove lense mounting nut on sensor and bottom lense screw.

2. Align mounting foot A under lense as shown with threaded insert facing

down and attach to lense with long kit supplied screw B .

3. Place sensor mounting peg into bracket hole.

4. Install screw, with washers, into long slotted bracket hole and into

mounting foot threaded insert.

B

A

MOUNTING

PEG

MB3 SIDE MOUNT BRACKET KIT INSTALLATION

1. Remove lense mounting nut from sensor.

2. Install screws with flat washers, through side clearance holes in sen sor

and through top hole and slot of bracket.

3. Install lockwashers and tighten hex nuts.

ALIGNMENT

Temporarily mount the Emitter-Receiver Pair opposite, and in line-of-sight,

to each other. Apply DC power to both and aim the Emitter at the Receiver.

Move the Receiver up-down-left-right until the Signal Strength LED lights.

Optimum alignment occurs when the Signal Strength LED flashes at the

highest rate obtainable with the GAIN (Sensitivity) potentiometer adjusted to

the lowest setting needed to light the LED. Mount the units in place. Opposed

Beam Pairs should be used at their highest possible gain. Therefore, have the

object to be detected in “sensing position” and adjust the GAIN potentiometer

fully clockwise (maximum gain). If the Signal Strength LED comes on, “burnthrough” is occurring, and will require that the GAIN pot be backed off

(counter clockwise) until the LED goes out and then backed off 2 more full

turns. Note that Opposed Beam Pairs must be aligned properly and mounted

securely. Excessive movement or vibration can cause loss of alignment and

intermittent or false operation.

2

Page 3

MOUNTING OPTIONS

DIMENSIONS In inches (mm)

MB2 BOTTOM MOUNTING BRACKET

MB3 SIDE MOUNTING BRACKET

C

L

0.61 (15.5)

90°

BRACKET

(STAINLESS STEEL)

0.10

(2.5)

0.34

(8.6)

0.47

(11.9)

Ø 0.27

(6.9)

0.34 (8.6)

0.59

(15)

Ø 0.27 (6.9)

0.95

(24.1)

2.00 (50.8)

0.92

(23.4)

R 0.70 (17.8)

R 0.70 (17.8)

ISOMETRIC VIEW

R 0.09 (2.2)

R 0.06 (1.5)

0.48

(12.2)

0.24 (6.2)

R 1.38 (35.1)

R 0.09 (2.2)

R 0.06 (1.5)

0.48

(12.2)

0.24 (6.2)

R 1.38 (35.1)

0.10 (2.5)

#4 MOUNTING

BOLTS (2)

C

L

1.12

(28.5)

90°

BRACKET ROTATES HORIZONTALLY

±10 DEGREES FROM POSITION

0.79

SHOWN

1.79

(45.5)

BRACKET

(STAINLESS STEEL)

(20.1)

FRONT OF SENSOR

TILTS VERTICALLY

±15 DEGREES

FROM HORIZONTAL

1.59

(40.4)

0.40

(10.2)

4X R 0.09

(2.2)

30.0°

1.25

(31.8)

ISOMETRIC VIEW

Ø 0.12

(3.0)

2X R 0.06

(1.5)

R 0.40

(10.2)

R 0.48

(12.1)

TYPICAL HOOKUP

DC

PHOTO ELECTRIC

CONTROLLER

BRN (+10 TO 30VDC)

BLK (PNP O.C.)

WHT (NPN O.C.)

BLUE (COMMON)

REMOTE

CUB

H.S. CNT.

L.S. CNT.

RMT. RST.

RST. EN.

COMMON

TYPICAL COUNTER

INPUT SWITCH SET-UP

A

+12V

COMM.

B

C

CNT.

SRC.

*

SNK.

LO FRQ.

321

HI

LO BIAS

* APPLICATION

HI

DEPENDENT

3

Page 4

DIMENSIONS In inches (mm)

.

48

FRONT REAR

VIEW VIEW

GAIN CONTROL

C

L

.61

(15.5)

.48

(12.2)

SIDE

VIEW

6' PVC-COVERED

4-CONDUCTOR CABLE

BROWN (+10 TO 30VDC)

BLACK (PNP SOURCING OUTPUT)

WHITE (NPN SINKING OUTPUT)

BLUE (COMMON)

(CIRCULAR, .25 (6.3) DIA.)

1.21

(30.7)

MOUNTING HOLES (2), #4 SCREW

CLEARANCE; USE FOR SIDE MOUNTING

GASKETED

ACRYLIC

COVER

MOUNTING PEG

.95

(24.1)

1.5 (38.1)

SIGNAL STRENGTH LED INDICATOR

LIGHT/DARK OPERATE SWITCH

1.08 (27.4)

.125

(3.2)

18 x 1 MM

THREAD

2.1 (53.3)

CABLE

.71

(18)

DIA.

(12.2)

+

-

D.O.

L.O.

.10 (2.5)

MOUNTING NUT

(SUPPLIED)

.95

(24.1)

.32 (8.1)

EMDC HOOKUP

BROWN

(+10 TO 30VDC)

BLUE (COMMON)

1. GAIN (sensitivity) control: rotate clockwise to increase gain.

2. “SIGNAL STRENGTH” LED indicator pulse at a rate proportional to received light signal

strength.

3. LIGHT/DARK OPERATE SELECT control: DARK OPERATE = fully counter clockwise;

LIGHT OPERATE = fully clockwise.

4. 6´ PVC-jacketed 4-wire cable supplied (2-wire, EMDC).

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBERS

RRDC Retroreflective DC Photo-Electric Sensor RRDC0000

PRDC Proximity (Diffuse) DC Photo-Electric Sensor PRDC0000

EMDC DC Emitter (Opposed Beam Pair) EMDC0000

RCDC DC Receiver (Opposed Beam Pair) RCDC0000

MB2 Bottom Mount Bracket Kit MB200000

MB3 Side Mount Bracket Kit MB300000

RT1 1-1/2" Dia. Prismatic Reflector (Model RRDC) RT100000

RT2 3" Dia. Prismatic Reflector (Model RRDC) RT200000

Do not dispose of unit in trash - Recycle

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls

Europe

Softwareweg 9

NL - 3821 BN Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

201-B, 2nd Floor, Park Centra

Opp 32 Mile Stone, Sector-30

Gurgaon-122002 Haryana, India

Tel +91 984 487 0503

Red Lion Controls

China

Unit 302, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113 3688

Fax +86 21 6113 3683

Loading...

Loading...