Red Lion Data Station Plus Sales Brochure

Data Station Plus

The Complete

Data Management Solution

> Multiple protocol converter allows

complete system integration

> IT-ready data logging for process

tracking and improvement

> Remote asset management and

control via built in web server

> Reduce downtime with email

and SMS alarm capability

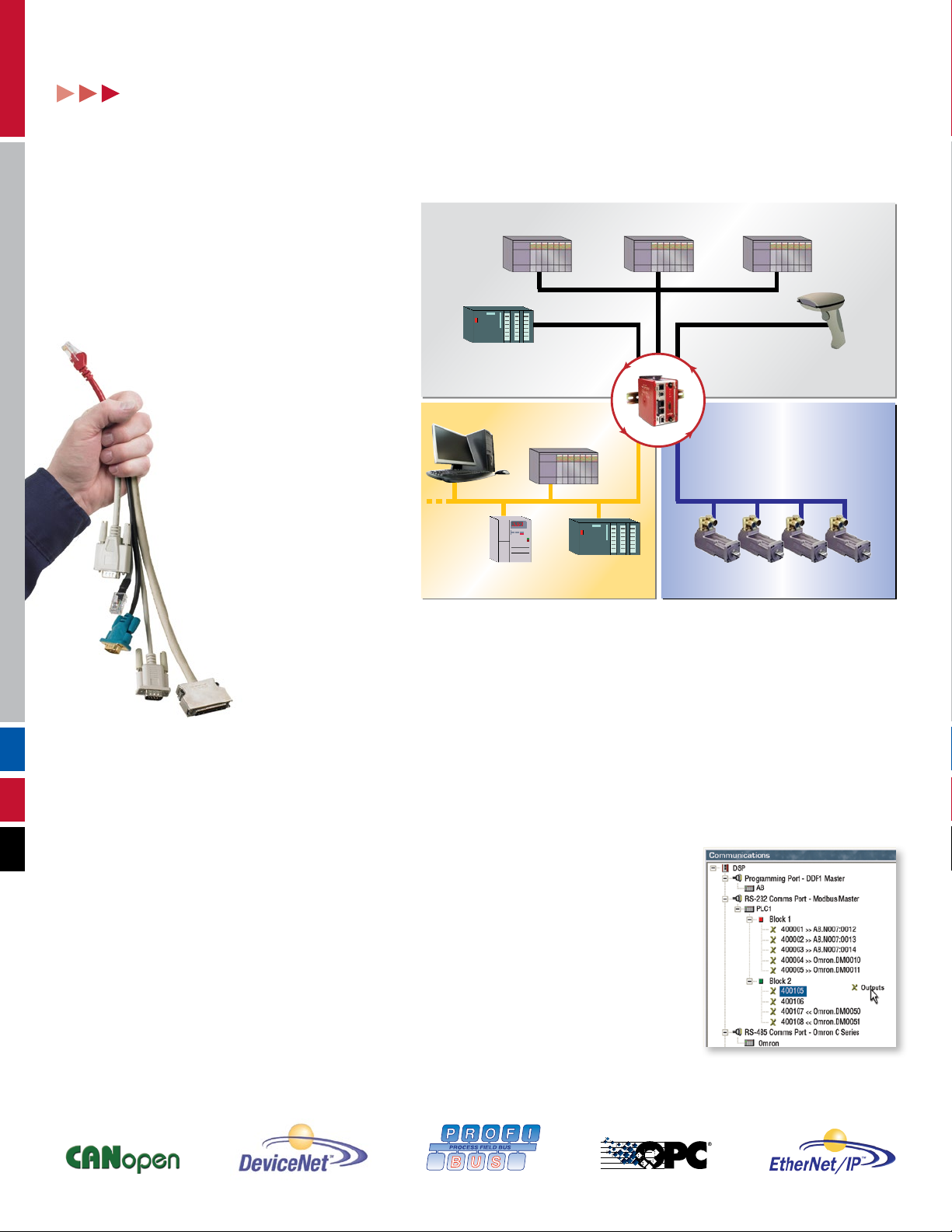

Seamless integration of multi-vendor systems

Now it’s easy to get all your devices

on the same page.

Red Lion’s Data Station Plus is the single-device

solution for protocol conversion. The DSP bridges

the communication gap between disparate

serial, Ethernet and fieldbus devices—unlocking

untold information from PLCs, drives,

motion controllers, etc., orphaned

by incompatible communications

standards. Drag and drop register

mapping allows a Siemens PLC

to talk to an Allen Bradley drive in

just seconds. With a growing list

of over 300 serial, Ethernet and

fieldbus drivers, the DSP allows

you to choose the best-in-class

automation components, without

worrying over whether or not

they’ll communicate with

one another.

Serial Communication

Ethernet

COM2

COM1 COM3

Y

A

W

E

T

A

G

Up to four protocols.

Data Station Connectivity

P

R

O

T

O

C

O

L

C

O

N

V

E

R

T

E

R

FieldBus

Network your existing equipment to avoid risk.

Getting legacy machines onto a common communications backbone used to be largely impossible,

sometimes requiring a complete replacement of the automation components. The Data Station Plus allows you to convert

your old PLC’s and drive’s proprietary protocol into a modern and open standard. By unlocking information hidden in these

legacy devices, you save money while avoiding a risky upgrade to equipment that is otherwise working perfectly.

OEMS—Add Ethernet and OPC connectivity to all of your machines.

Add a Data Station Plus to your equipment, and you can offer your customers out-of-box

connectivity to their SCADA systems, while providing yourself the means to remotely support

the machine. The DSP’s ability to support ten Ethernet protocols simultaneously, while offering

OPC compatibility, means you don’t have to worry about how the system will be integrated

at the user’s facility. And that’s just the beginning. The “port sharing” facility allows the Data

Station Plus to act as a remote serial port to your PC, meaning you can reprogram any

connected serial device from virtually anywhere in the world.

Drag and Drop Gateway Blocks in

Crimson 3.0

2

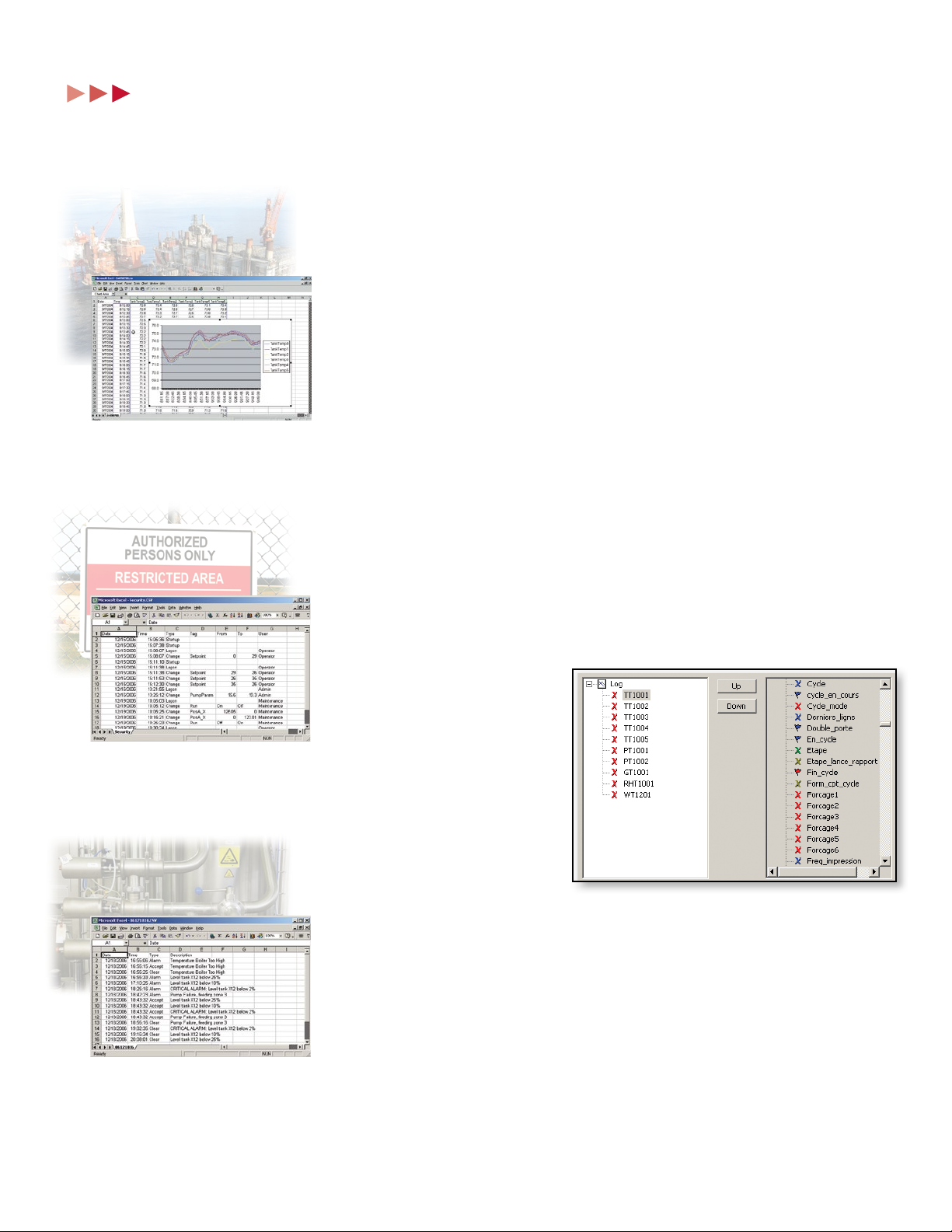

Reduce costs using data management.

Data Logging

Security Logging

Monitor the vital signs of your machines and processes.

Data points logged from devices, machines and processes provide a performance

baseline for analysis, and can be used to trigger PLC functions, alarms or

notifications when points stray from nominal parameters. These variables

can be used as reliable predictors of impending machine failure, monitoring

for preventative maintenance, as well as general performance monitoring of

distributed processes or discrete production throughput. Reliable data can be

used to identify process vulnerabilities, abnormal conditions or wear trending.

Data Logging can be used for real-time monitoring of process activities, product

traceability and quality control issues, TPM, downtime,OEE (overall equipment

effectiveness), or be used to generate virtually unlimited data sets for statistical

analysis and control decisions.

Know more. Do more.

One Data Station Plus allows a user to quickly set up monitoring of a number of

disparate devices in a control application, collect performance data, display it,

store it for evaluation, or trigger PLC functions, either live or remotely. The Data

Station Plus’ built-in math capability also allows probability calculations to preanalyze hard point data to provide only relevant information. An integrated OPC

server allows easy SCADA connectivity using Red Lion’s OPCWorx.

The multiple Data, Alarm,

Event and Security loggers in

Crimson® 3.0 provide data in

“IT ready” CSV (comma

separated values) files

that can be easily opened

with applications such

as Microsoft® Excel. No

software plug-ins are

required to access your

application data. And a

built-in CompactFlash® card

slot provides unlimited data

storage as well as secure and immediate retrieval of the DSP’s configuration.

All the requirements for quality traceability, production tracking or maintenance are

now embedded into one platform. The ability to monitor your process can be set

up in just minutes with the DSP’s connectivity and logging tools.

Set up for one data log in Crimson 3.0

Alarms and Events Logging

3

Loading...

Loading...