Page 1

Bulletin No. CUB5I-K

.13 (3.3)

(43.4)

1.71

2.95 (74.9)

SEL

.15 (3.8)

1.54 (39.1)

RST

(68 )

+.025

-.000

+8

1.29 (32.8)

2.68

-.000

1.30

(33 )

-0

+6

+.024

C

US LISTED

Drawing No. LP0658

Released 02/13

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

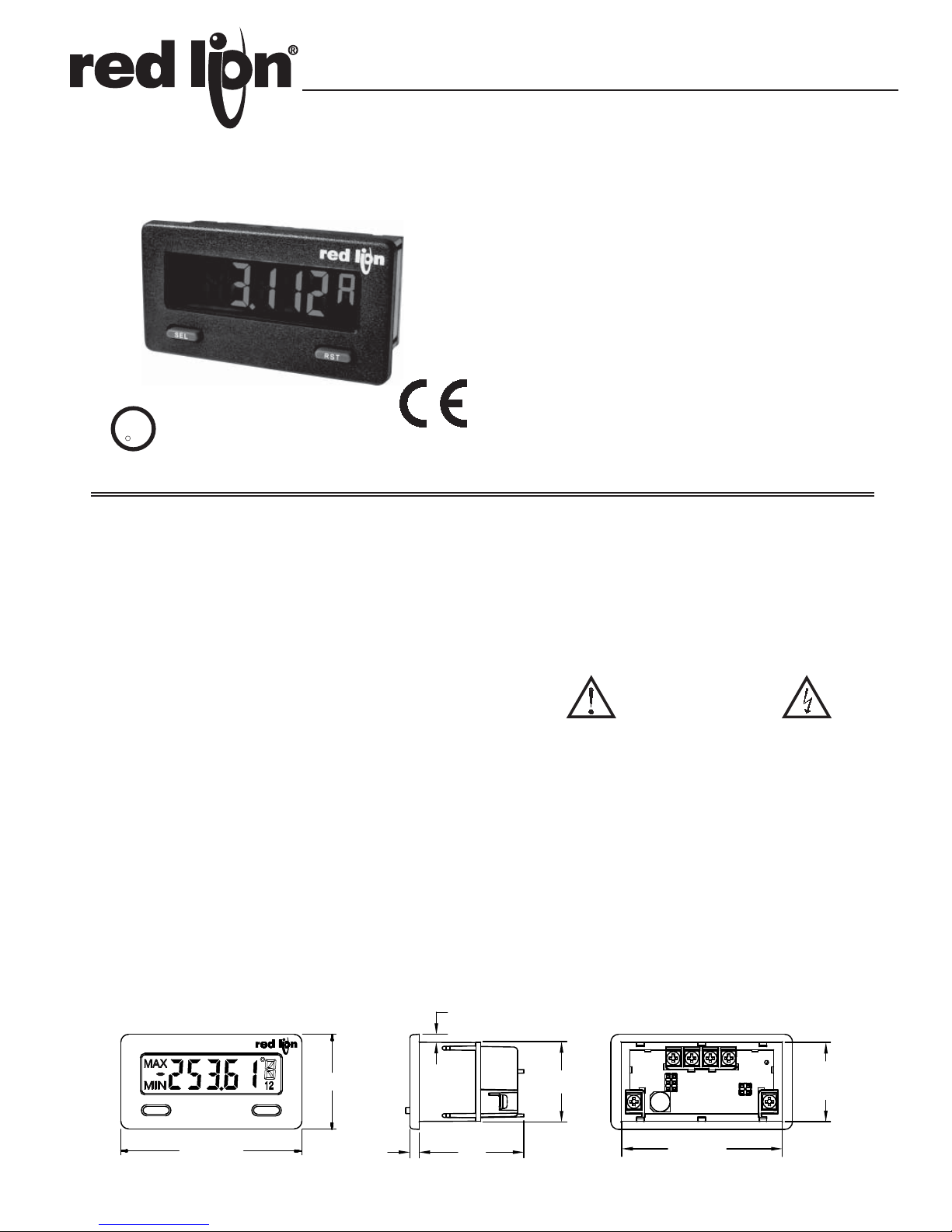

MODEL CUB5I - MINIATURE ELECTRONIC 5-DIGIT DC CURRENT METER

FOUR SELECTABLE D.C. RANGES

200 A, 2 mA, 20 mA, 200 mA

MINIMUM AND MAXIMUM DISPLAY CAPTURE

LCD, REFLECTIVE OR RED/GREEN LED BACKLIGHTING

0.48" (12.2 mm) HIGH DIGITS

OPTIONAL SETPOINT OUTPUT CARD

OPTIONAL SERIAL COMMUNICATIONS CARD (RS232 or RS485)

OPTIONAL USB PROGRAMMING CARD

OPERATES FROM 9 TO 28 VDC POWER SOURCE

FRONT PANEL OR CRIMSON PROGRAMMABLE

U

R

C

L

US LISTED

IND. CONT. EQ.

51EB

DISPLAY COLOR CHANGE CAPABILITY AT SETPOINT OUTPUT

NEMA 4X/IP65 SEALED FRONT BEZEL

GENERAL DESCRIPTION

The CUB5 provides the user the ultimate in flexibility, from its complete user

programming to the optional setpoint control and communication capability.

The CUB5I accepts a DC Current input signal and provides a display in the

desired unit of measure. The meter also features minimum and maximum

display capture, display offset, units indicator, and programmable user input.

The display can be toggled either manually or automatically between the

selected displays.

The CUB5 display has 0.48" (12.2 mm) high digits. The LCD is available in

two versions, reflective and red/green backlight. The backlight version is user

selectable for the desired color and also has variable display intensity.

The capability of the CUB5 can be easily expanded with the addition of

option cards. Setpoint capability is field installable with the addition of the

setpoint output cards. Serial communications capability for RS232 or RS485 is

added with a serial option card.

The CUB5 can be powered from an optional Red Lion Micro-Line/Sensor

Power Supply (MLPS), which attaches directly to the back of a CUB5. The

MLPS is powered from 85 to 250 VAC and provides up to 400 mA to drive the

unit and sensors.

CURRENT

The CUB5I is the DC Current meter. It features 4 current input ranges, that

are selected by the user via a programming jumper and software input range

selection. The ranges consist of following: 200 A, 2 mA, 20 mA, or 200 mA.

Users should select the appropriate current range that covers their maximum

signal input.

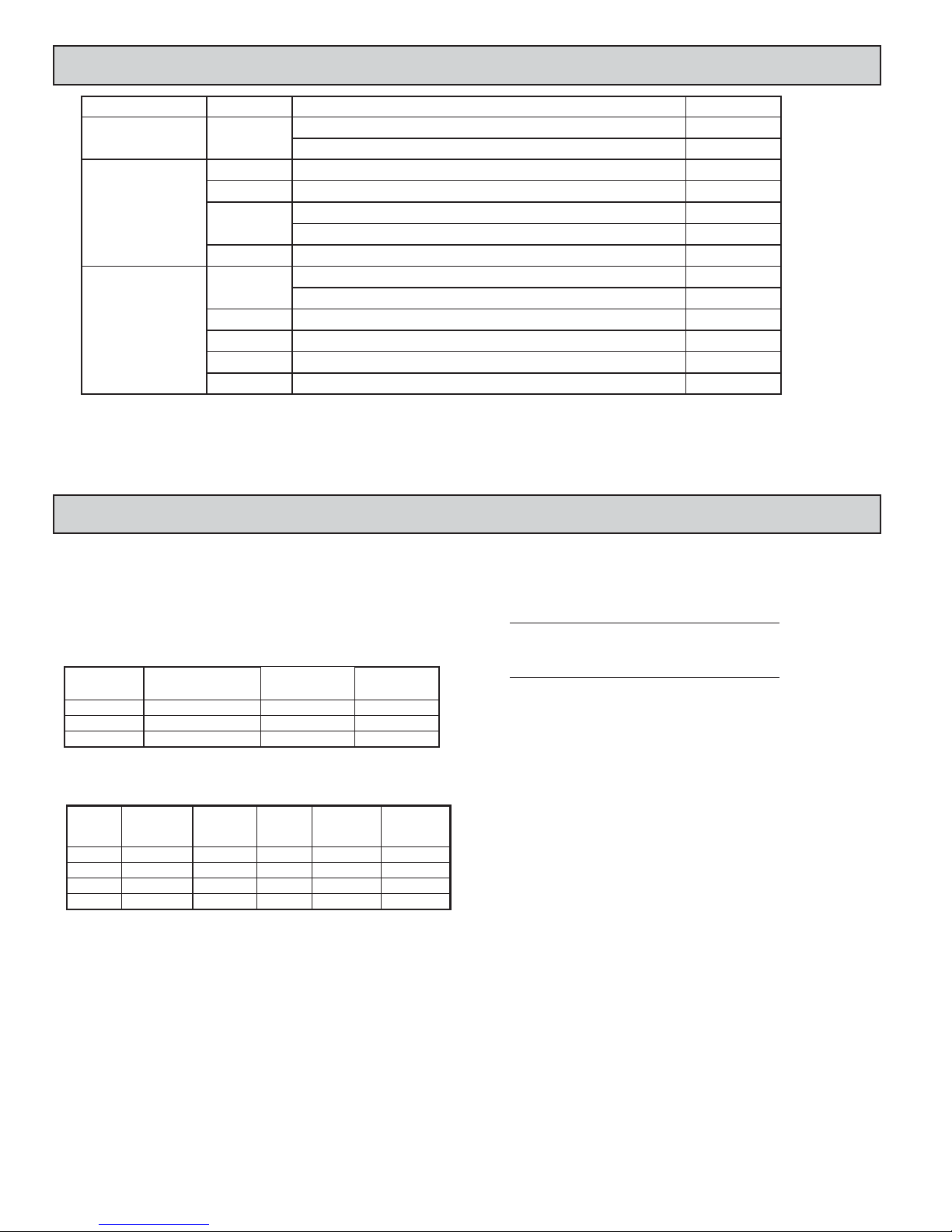

DIMENSIONS In inches (mm)

Note: Recommended minimum clearance (behind the panel) for mounting clip installation is 2.15" (54.6) H x 3.00" (76.2) W.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in this

literature or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use this meter to directly command motors, valves, or other actuators

not equipped with safeguards. To do so can be potentially harmful to persons or

equipment in the event of a fault to the meter.

CAUTION: Risk of Danger.

Read complete instructions prior to

installationand operation of the unit.

CAUTION: Risk of electric shock.

1

Page 2

ORDERING INFORMATION

TYPE MODEL NO. DESCRIPTION PART NUMBER

CUB5 CUB5I

CUB5RLY Single Relay Option Card CUB5RLY0

CUB5SNK Dual Sinking Open Collector Output Card CUB5SNK0

Optional Plug-in Cards

Accessories

1

Crimson software is a free download from http://www.redlion.net

CUB5COM

CUB5USB USB Programming Card CUB5USB0

MLPS

CBLPROG Programming Cable RS232 (RJ11-DB9) CBLPROG0

CBPRO Programming Cable RS485 (RJ11-DB9) CBPRO007

SFCRD Crimson PC Configuration Software for Windows 98, ME, 2000, XP

CBLUSB USB Programming Cable CBLUSB00

DC Current Meter with Reflective Display CUB5IR00

DC Current Meter with Backlight Display CUB5IB00

RS485 Serial Communications Card CUB5COM1

RS232 Serial Communications Card CUB5COM2

+12 VDC Micro-Line Power Supply, 85 to 250 VAC source, 400 mA max out MLPS1000

+24 VDC Micro-Line Power Supply, 85 to 250 VAC source, 200 mA max out MLPS2000

GENERAL METER SPECIFICATIONS

1

SFCRD200

1. DISPLAY: 5 digit LCD 0.48" (12.2 mm) high digits

CUB5IR00: Reflective LCD with full viewing angle

CUB5IB00: Transmissive LCD with selectable red or green LED backlight,

viewing angle optimized. Display color change capability with output state

when using an output module.

2. POWER: Input voltage range is +9 to +28 VDC with short circuit and input

polarity protection. Must use an RLC model MLPS or an NEC Class 2 or

Limited Power Source (LPS) rated power supply.

MODEL

NO.

CUB5IR00 --- 10 mA 40 mA

CUB5IB00 Red (max intensity) 85 mA 115 mA

CUB5IB00 Green (max intensity) 95 mA 125 mA

DISPLAY COLOR

INPUT CURRENT

@ 9 VDC WITHOUT

CUB5RLY0

INPUT CURRENT

@ 9 VDC WITH

CUB5RLY0

3. INPUT RANGES: Jumper Selectable

D.C. Currents: 200 A, 2 mA, 20 mA, or 200 mA

4. SIGNAL INPUTS:

INPUT

RANGE

200 A

2 mA 0.1% of span 50 mA 0.1 μA 70 ppm / °C

20 mA 0.1% of span

200 mA 0.1% of span

ACCURACY

@23 °C, less

than 85% RH

0.1% of span

INPUT

IMPEDANCE

1.111 K

111

11

1

MAX

INPUT

SIGNAL

150 mA 1 μA 70 ppm / °C

500 mA 10 μA 70 ppm / °C

RESOLUTION

15 mA 10 nA 70 ppm / °C

TEMP.

COEFFICIENT

5. OVERRANGE RATINGS, PROTECTION & INDICATION:

9 to 28 VDC power circuit is not isolated from the signal circuit.

Input Overrange Indication: “

OLOL”.

Input Underrange Indication: “ULUL”.

Display Overrange/Underrange Indication: “.....”/“-.....”

6. RESPONSE TIME:

Display: 500 msec min.

Output: 800 msec max (with input filter setting of 0)

7. NORMAL MODE REJECTION: 60 dB 50/60 Hz

8. USER INPUT (USR): Programmable input. Connect terminal to common

(USR COMM) to activate function. Internal 10K pull-up resistor to +9 to

28 VDC.

Threshold Levels: V

Response Time: 5 msec typ.; 50 msec debounce (activation and release)

= 0.7 V max; VIH = 2.4 V min; V

IL

= 28 VDC

MAX

9. MEMORY: Nonvolatile E2PROM memory retains all programming

parameters and max/min values when power is removed.

10. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range for CUB5IR00: -35 to 75°C

Operating Temperature Range for CUB5IB00 depends on display color

and intensity level as per below:

INTENSITY LEVEL TEMPERATURE

Red Display 1 & 2 -35 to 75°C

3 -35 to 70°C

4 -35 to 60°C

5 -35 to 50°C

Green Display 1 & 2 -35 to 75°C

3 -35 to 65°C

4 -35 to 50°C

5 -35 to 35°C

Storage Temperature: -35 to 85°C

Operating and Storage Humidity: 0 to 85% max. relative humidity (non-

condensing)

Vibration to IEC 68-2-6: Operational 5-500 Hz, 5 g

Shock to IEC 68-2-27: Operational 30 g

Altitude: Up to 2000 meters

11. CONNECTIONS: Wire clamping screw terminals

Wire Strip Length: 0.3" (7.5 mm)

Wire Gage: 30-14 AWG copper wire

Torque: 5 inch-lbs (0.565 N-m) max.

12. CONSTRUCTION: This unit is rated for NEMA 4X/IP65 requirements for

outdoor use. Installation Category I, Pollution Degree 2. High impact plastic

case with clear viewing window. Panel gasket and mounting clip included.

13. CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 Immunity to Industrial Locations

Emission CISPR 11 Class A

IEC/EN 61010-1

RoHS Compliant

UL Recognized Component: File #E179259

UL Listed: File #E137808

Type 4X Outdoor Enclosure rating (Face only)

IP65 Enclosure rating (Face only)

IP20 Enclosure rating (Rear of unit)

Refer to EMC Installation Guidelines for additional information.

14. WEIGHT: 3.2 oz (100 g)

2

Page 3

OPTIONAL PLUG-IN CARDS

INPUT RANGE JUMPERS

MAIN CIRCUIT

BOARD

INPUT RANGE

JUMPER LOCATIONS

2mA

200mA

200µA

20mA

2.68

(68 )

+.8

1.30

-.0

(33 )

-.000

+.6

-.0

-.000

+.024

+.025

PANEL

GASKET

BEZEL

PANEL

MOUNTING SCREW

NUT FASTENER

MOUNTING CLIP

ADDING OPTION CARDS

The CUB5 meters can be fitted with optional output cards and/or serial

communications cards. The details for the plug-in cards can be reviewed in the

specification section below. The plug-in cards, that are sold separately, can be

installed initially or at a later date.

WARNING: Disconnect all power to the unit before installing

Plug-in card.

Note: Measurement errors may occur if signal input common is shared with

another circuit common (ie, serial common, Dual Sinking Output option card,

or Power Supply common) on multiple units.

SINGLE RELAY CARD

Type: Single FORM-C relay

Isolation To Sensor & User Input Commons: 1400 Vrms for 1 min.

Working Voltage: 150 Vrms

Contact Rating: 1 amp @ 30 VDC resistive; 0.3 amp @ 125 VAC resistive

Life Expectancy: 100,000 minimum operations

DUAL SINKING OUTPUT CARD

Type: Non-isolated switched DC, N Channel open drain MOSFET

Current Rating: 100 mA max.

V

: 0.7 V @ 100 mA

DS ON

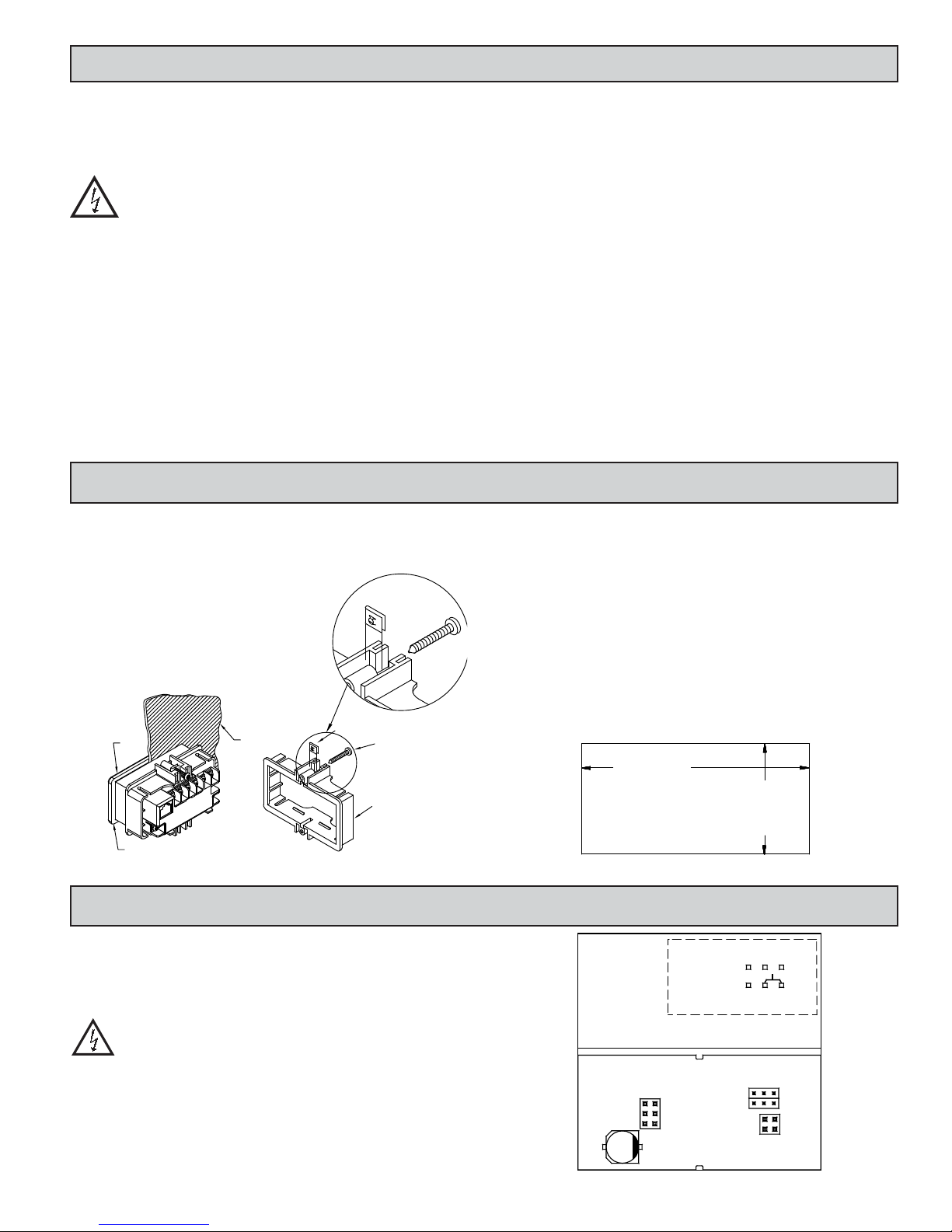

1.0 INSTALLING THE METER

INSTALLATION

The meter meets NEMA 4X/IP65 requirements when properly installed. The

unit is intended to be mounted into an enclosed panel. Prepare the panel cutout

to the dimensions shown. Remove the panel latch from the

unit. Slide the panel gasket over the rear of the unit to

the back of the bezel. The unit should be installed

fully assembled. Insert the unit into the panel

cutout.

While holding the unit in place, push the panel

latch over the rear of the unit so that the tabs of the

panel latch engage in the slots on the case. The

: 30 VDC

V

DS MAX

Offstate Leakage Current: 0.5 mA max.

RS485 SERIAL COMMUNICATIONS CARD

Type: RS485 multi-point balanced interface (non-isolated)

Baud Rate: 300 to 38.4k

Data Format: 7/8 bits; odd, even, or no parity

Bus Address: 0 to 99; max 32 meters per line

Transmit Delay: Selectable (refer to CUB5COM bulletin)

RS232 SERIAL COMMUNICATIONS CARD

Type: RS232 half duplex (non-isolated)

Baud Rate: 300 to 38.4k

Data Format: 7/8 bits; odd, even, or no parity

USB PROGRAMMING CARD

Type: USB virtual comms port

Connection: Type B

Baud Rate: 300 to 38.4k

Unit Address: 0 to 99

panel latch should be engaged in the farthest forward slot possible. To achieve a

proper seal, tighten the latch screws evenly until the unit is snug in the panel

(Torque to approx. 28 to 36 in-oz [0.202 to 0.26 N-m]). Do not over-tighten the

screws.

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the operating

temperature and provides good air circulation. Placing the unit near devices that

generate excessive heat should be avoided.

The bezel should only be cleaned with a soft cloth and neutral soap product.

Do NOT use solvents. Continuous exposure to direct sunlight may accelerate the

aging process of the bezel.

Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to operate the

keypad of the unit.

2.0 SETTING THE JUMPERS

INPUT RANGE JUMPER

This jumper is used to select the proper input range. The input range selected

in programming must match the jumper setting. Select a range that is high

enough to accommodate the maximum signal input to avoid overloads. To

access the jumper, remove the rear cover of the meter.

Warning: Exposed line voltage exists on the circuit boards. Remove

all power to the meter and load circuits before accessing inside of

the meter.

REMOVING THE REAR COVER

input terminals. T o release the tab, insert a small, flat blade screwdriver between

the tab and the plastic wall below the terminals. Inserting the screwdriver will

provide enough pressure to release the tab locks. To replace the cover, align the

cover with the input terminals and press down until the cover snaps into place.

To remove the rear cover, locate the cover locking tab below the 2nd and 3rd

3

Page 4

USR COMM

USR

+9-28 VDC

COMM

INP +

PWR COMMON

+

-

USR COMM

USR

+9-28 VDC

COMM

INP +

PWR COMMON

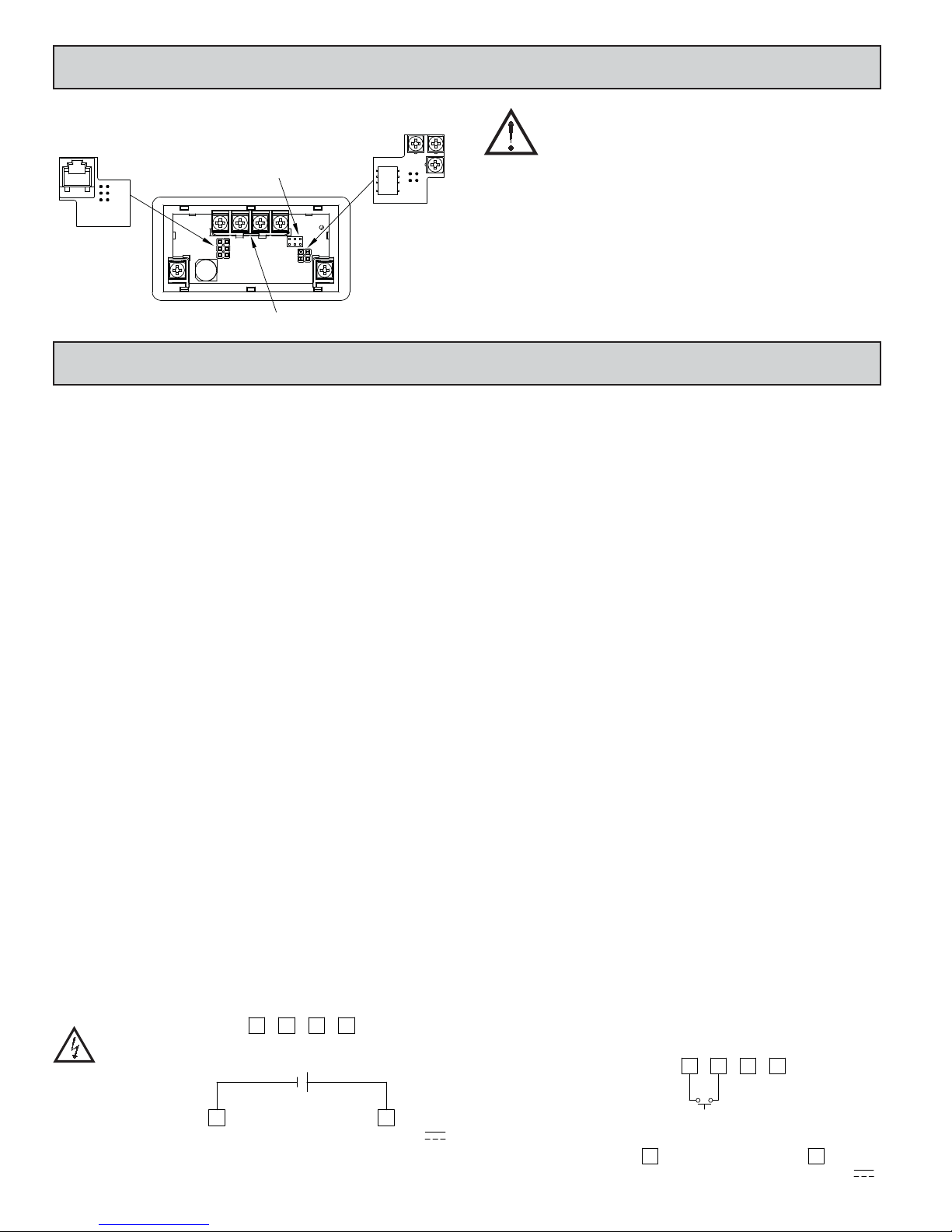

3.0 INSTALLING PLUG-IN CARDS

The Plug-in cards are separately purchased option cards that perform specific

functions. The cards plug into the main circuit board of the meter

Range Jumpers

Setpoint Card

Comms or

Programming

Card

Locking Tab

4.0 WIRING THE METER

WIRING OVERVIEW

Electrical connections are made via screw-clamp terminals located on the

back of the meter. All conductors should conform to the meter’s voltage and

current ratings. All cabling should conform to appropriate standards of good

installation, local codes and regulations. It is recommended that the power

supplied to the meter (DC or AC) be protected by a fuse or circuit breaker.

Strip the wire, leaving approximately 0.3" (7.5 mm) bare lead exposed

(stranded wires should be tinned with solder.) Insert the lead under the correct

screw-clamp terminal and tighten until the wire is secure. (Pull wire to verify

tightness.) Each terminal can accept up to one #14 AWG (2.55 mm) wire, two

#18 AWG (1.02 mm), or four #20 AWG (0.61 mm).

EMC INSTALLATION GUIDELINES

Although Red Lion Controls Products are designed with a high degree of

immunity to Electromagnetic Interference (EMI), proper installation and wiring

methods must be followed to ensure compatibility in each application. The type

of the electrical noise, source or coupling method into a unit may be different

for various installations. Cable length, routing, and shield termination are very

important and can mean the difference between a successful or troublesome

installation. Listed are some EMI guidelines for a successful installation in an

industrial environment.

1. A unit should be mounted in a metal enclosure, which is properly connected

to protective earth.

2. Use shielded cables for all Signal and Control inputs. The shield connection

should be made as short as possible. The connection point for the shield

depends somewhat upon the application. Listed below are the recommended

methods of connecting the shield, in order of their effectiveness.

a. Connect the shield to earth ground (protective earth) at one end where the

unit is mounted.

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is over 1 MHz.

3. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors, feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run through metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

CAUTION: The Plug-in cards and main circuit board contain static

sensitive components. Before handling the cards, discharge

static charges from your body by touching a grounded bare

metal object. Ideally, handle the cards at a static controlled

clean workstation. Also, only handle the cards by the edges.

Dirt, oil or other contaminants that may contact the cards can

adversely affect circuit operation.

REMOVING THE REAR COVER

To remove the rear cover, locate the cover locking tab below the 2nd and 3rd

input terminals. T o release the tab, insert a small, flat blade screwdriver between

the tab and the plastic wall below the terminals. Inserting the screwdriver will

provide enough pressure to release the tab locks. To replace the cover, align the

cover with the input terminals and press down until the cover snaps into place.

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter. Also, Signal or Control cables within

an enclosure should be routed as far away as possible from contactors,

control relays, transformers, and other noisy components.

4. Long cable runs are more susceptible to EMI pickup than short cable runs.

5. In extremely high EMI environments, the use of external EMI suppression

devices such as Ferrite Suppression Cores for signal and control cables is

effective. The following EMI suppression devices (or equivalent) are

recommended:

Fair-Rite part number 0443167251 (RLC part number FCOR0000)

Line Filters for input power cables:

Schaffner # FN2010-1/07 (Red Lion Controls # LFIL0000)

6. T o protect relay contacts that control inductive loads and to minimize radiated

and conducted noise (EMI), some type of contact protection network is

normally installed across the load, the contacts or both. The most effective

location is across the load.

a. Using a snubber, which is a resistor-capacitor (RC) network or metal oxide

varistor (MOV) across an AC inductive load is very effective at reducing

EMI and increasing relay contact life.

b. If a DC inductive load (such as a DC relay coil) is controlled by a transistor

switch, care must be taken not to exceed the breakdown voltage of the

transistor when the load is switched. One of the most effective ways is to

place a diode across the inductive load. Most RLC products with solid

state outputs have internal zener diode protection. However external diode

protection at the load is always a good design practice to limit EMI.

Although the use of a snubber or varistor could be used.

RLC part numbers: Snubber: SNUB0000

Varistor: ILS11500 or ILS23000

7. Care should be taken when connecting input and output devices to the

instrument. When a separate input and output common is provided, they

should not be mixed. Therefore a sensor common should NOT be connected

to an output common. This would cause EMI on the sensitive input common,

which could affect the instrument’s operation.

Visit RLC’ s web site at http://www.redlion.net/Support/InstallationConsiderations.

html for more information on EMI guidelines, Safety and CE issues as they

relate to Red Lion Controls products.

4.1 POWER WIRING

DC Power

+9 to +28 VDC: +VDC

Power Common: -VDC

CAUTION: 9 to 28 VDC

power circuit is not isolated

from the signal circuit.

4.2 USER INPUT WIRING

Sinking Logic

USR COMM

USR

The user input of the meter is

internally pulled up to +9 to +28 V

with 10 K resistance. The input is

active when it is pulled low (<0 .7 V).

4

Connect external switching device between the

}

User Input terminal and User Input Common.

Page 5

4.3 INPUT WIRING

COM

N.C.

N.O.

COM

N.O.

N.C.

OSNK1

OSNK2

COM

COM

OSNK 1(2)

(30 V MAX.)

N/C

RS485

2

COMM

A+

B-

N/C

534

N/C

RS232

5

N/C

TX

N/C

43

COMM

COMM

2

RX

61 61

CAUTION: Power input common is NOT isolated from user and input

commons. In order to preserve the safety of the meter application, the

power input common must be suitably isolated from hazardous live

earth referenced voltage; or input common must be at protective earth

or user inputs and input common terminals. Appropriate considerations must then

be given to the potential of the user and input commons with respect to earth

ground; and the common of the plug-in cards with respect to input common.

Before connecting signal wires, the Input Range Jumper should be verified for

proper position.

Input Signal (self powered)

Series Loop (must use separate supply for sensor power

and each CUB5)

ground potential. If not, hazardous voltage may be present at the signal

COMM

-

JUMPER

POSITION

INP+

200 μA

2 mA

+

20 mA

200 mA

EXTERNAL POWER

COMM

MAX INPUT

CURRENT

+VDC

15 mA

50 mA

150 mA

500 mA

+

_

2 WIRE TRANSMITTER

2 Wire With External Power

_

2 WIRE TRANSMITTER

+

INP +

COMM

COMM

COMM

+VDC

+VDC

EXTERNAL POWER

2 Wire With MLPS Power Supply

_

2 WIRE TRANSMITTER

+

INP +

COMM

RED LION CONTROLS

YORK, PA. MADE IN U.S.A.

+12V

AC INPUT

TERMINAL

!

M3424B

DC COMMON

MODEL

MLPS1

INPUT POWER:

85-250 VAC, 50/60Hz, 14VA

OUTPUT POWER:

12VDC UNREG. @ 400mA

OPERATING TEMP: 0° TO 60°C

2 Wire With Separate Sensor And CUB5 Power

EXTERNAL POWER

COMM

+VDC

+

2 WIRE TRANSMITTER

_

COMM

+12V

AC INPUT

TERMINAL

INP +

!

M3424B

DC COMMON

RED LION CONTROLS

YORK, PA. MADE IN U.S.A.

MODEL

MLPS1

INPUT POWER:

85-250 VAC, 50/60Hz, 14VA

OUTPUT POWER:

12VDC UNREG. @ 400mA

OPERATING TEMP: 0° TO 60°C

COMM

+12V

AC INPUT

TERMINAL

INP +

DC COMMON

RED LION CONTROLS

!

M3424B

YORK, PA. MADE IN U.S.A.

MODEL

MLPS1

INPUT POWER:

85-250 VAC, 50/60Hz, 14VA

OUTPUT POWER:

12VDC UNREG. @ 400mA

OPERATING TEMP: 0° TO 60°C

4.4 SETPOINT (OUTPUT) WIRING

SINGLE SETPOINT RELAY PLUG-IN CARD

DUAL SETPOINT N-FET OPEN DRAIN PLUG-IN CARD

INP +

COMM

RED LION CONTROLS

YORK, PA. MADE IN U.S.A.

+12V

AC INPUT

TERMINAL

!

M3424B

DC COMMON

MODEL

MLPS1

INPUT POWER:

85-250 VAC, 50/60Hz, 14VA

OUTPUT POWER:

12VDC UNREG. @ 400mA

OPERATING TEMP: 0° TO 60°C

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

Output Common is not isolated from DC Power Common. Load

must be wired between OSNK terminal and V+ of the load supply.

4.5 SERIAL COMMUNICATION WIRING

SERIAL COMMUNICATIONS PLUG-IN CARD

RJ11 CONNECTOR PIN OUTS

4.6 USB PROGRAMMING

USB PROGRAMING PLUG-IN CARD

5

Page 6

5.0 REVIEWING THE FRONT BUTTONS AND DISPLAY

SEL RST

Parameters

Output

Setpoint

Parameters

Signal Input

Pro

DISPLAY

MODE

Panel Key

Function

Parameters

3-dSP

Parameters

Display and Front

NO

SEL

RST

SEL SEL SEL SEL

2-SEC

1-INP

4-SPt

5-SEr

SEL

Serial

Setup

Parameters

Secondary

BUTTON DISPLAY MODE OPERATION ENTERING PROGRAM MODE PROGRAMMING MODE OPERATION

SEL Index display through enabled values Press and hold for 2 seconds to activate Store selected parameter and index to next parameter

RST Resets values (MIN/MAX) or outputs

Advances through the program menu

Increments selected parameter value or selection

OPERATING MODE DISPLAY DESIGNATORS

MAX - Maximum display capture value

MIN

- Minimum display capture value

Pressing the SEL button toggles the meter through the selected displays. If display scroll is enabled, the display will toggle automatically every four seconds between

the enabled display values.

6.0 PROGRAMMING THE METER

PROGRAMMING MODE ENTRY (SEL BUTTON)

It is recommended all programming changes be made off line, or before

installation. The meter normally operates in the Display Mode. No parameters

can be programmed in this mode. The Programming Mode is entered by

pressing and holding the

either a security code, or a hardware lock.

MODULE ENTRY (SEL & RST BUTTONS)

The Programming Menu is organized into separate modules. These modules

group together parameters that are related in function. The display will alternate

between Pro and the present module. The RST button is used to select the desired

module. The displayed module is entered by pressing the SEL button.

MODULE MENU (SEL BUTTON)

Each module has a separate module menu (which is shown at the start of each

module discussion). The SEL button is pressed to advance to a particular

parameter to be changed, without changing the programming of preceding

parameters. After completing a module, the display will return to Pro NO.

Programming may continue by accessing additional modules.

SELECTION / VALUE ENTRY

For each parameter, the display alternates between the present parameter and

the selections/value for that parameter. The RST button is used to move through

the selections/values for that parameter. Pressing the SEL button, stores and

activates the displayed selection/value. This also advances the meter to the next

parameter.

For numeric values, press the

most digit will begin to flash. Pressing the RST button again increments the

digit by one or the user can hold the

scroll. The

SEL button will enter the value and move to the next parameter.

SEL button will advance to the next digit. Pressing and holding the

SEL button. If it is not accessible then it is locked by

RST button to access the value. The right hand

RST button and the digit will automatically

“1” - To the right of the display indicates setpoint 1 output activated.

“2” - To the right of the display indicates setpoint 2 output activated.

OVERVIEW

PROGRAMMING MENU

PROGRAMMING MODE EXIT (SEL BUTTON)

The Programming Mode is exited by pressing the SEL button with Pro NO

displayed. This will commit any stored parameter changes to memory and

return the meter to the Display Mode. (If power loss occurs before returning to

the Display Mode, verify recent parameter changes.)

PROGRAMMING TIPS

It is recommended to start with Module 1 and proceed through each module in

sequence. When programming is complete, it is recommended to record the

parameter programming and lock out parameter programming with the user input

or programming security code.

FACTORY SETTINGS

Factory Settings may be completely restored in Module 2. This is useful

when encountering programming problems.

ALTERNATING SELECTION DISPLAY

In the explanation of the modules, the following dual display with arrows will

appear. This is used to illustrate the display alternating between the parameter

on top and the parameter’s Factory Setting on the bottom. In most cases,

selections and values for the parameter will be listed on the right.

6

Indicates Program Mode Alternating Display

Parameter

USrIN

Factory Settings are shown.

N0

Selection/Value

Page 7

Display

Decimal

Point

Filter

Setting

Filter

Band

Input Value

for Scaling

Point 1

Display Value

For Scaling

Point 1

User Input

Assignment

Input

Range

SEL

rANGE

dECPt

FILtr

bANd

INP 1

dSP 1

INP 2

U-ASN

1-INP

Pro

User Input

Function

dSP 2

USrIN

Input Value

for Scaling

Point 2

Display Value

For Scaling

Point 2

StYLE

Scaling

Style

OFSEt

Display

Offset

Value

6.1 MODULE 1 - SIGNAL INPUT PARAMETERS (1-INP)

PARAMETER MENU

CUB5I INPUT RANGE

SELECTION

rAN6E

Select the input range that corresponds to the external signal. This selection

should be high enough to avoid input signal overload but low enough for the

desired input resolution. This selection and the position of the Input Range

Jumper must match.

dECPt

Select the decimal point location for the Input, MIN and MAX displays. This

selection also affects the dSP1 and dSP2 parameters and setpoint values.

OFSEt

The display can be corrected with an offset value. This can be used to

compensate for signal variations or sensor errors. This value is automatically

updated after a Zero Display to show how far the display is offset. A value of

zero will remove the effects of offset.

FILtr

If the displayed value is difficult to read due to small process variations or

noise, increased levels of filtering will help to stabilize the display. Software

filtering effectively combines a fraction of the current input reading with a

fraction of the previous displayed reading to generate the new display.

Filter values represent no filtering (0), up to heavy filtering (3). A value of 1

for the filter uses 1/4 of the new input and 3/4 of the previous display to generate

the new display. A filter value of 2 uses 1/8 new and 7/8 previous. A filter value

of 3 uses 1/16 new and 15/16 previous.

0.02A

0.000

0.000

200uA

0.002A

DISPLAY DECIMAL POINT

DISPLAY OFFSET VALUE

1

RANGE

RESOLUTION

200.00 A

2.0000 mA

-19999 to 19999

FILTER SETTING

0,1 2 3

SELECTION

0.02A

0.2A

RANGE

RESOLUTION

20.000 mA

200.00 mA

0.000 0.00000.000.00

SCALING STYLE

StYLE

If Input Values and corresponding Display Values are known, the Key-in

(KEY) scaling style can be used. This allows scaling without the presence or

changing of the input signal. If Input Values have to be derived from the actual

input signal source or simulator, the Apply (APLY) scaling style must be used.

INP 1

For Key-in (KEY) style, enter the first Input Value using the front panel buttons.

(The Input Range selection sets the decimal location for the Input Value).

For Apply (APLY) style, the meter shows the previously stored Input Value. To

retain this value, press the SEL button to advance to the next parameter. To

change the Input Value, press the RST button and apply the input signal to the

meter. Adjust the signal source externally until the desired Input Value appears.

Press the SEL button to enter the value being displayed.

dSP 1

Enter the first Display Value by using the front panel buttons. This is the same

for

KEY and APLY scaling styles. The decimal point follows the dECPt selection.

INP 2

For Key-in (KEY) style, enter the known second Input Value using the front

panel buttons.

For Apply (

Scaling Point 2. T o retain this value, press the SEL button to advance to the next

parameter. To change the Input Value, press the RST button and apply the input

signal to the meter. Adjust the signal source externally until the desired Input

Value appears. Press the SEL button to enter the value being displayed.

KEy APLY

KEy

INPUT VALUE FOR SCALING POINT 1

0 to 29999

0.000

DISPLAY VALUE FOR SCALING POINT 1

-19999 to 99999

0.000

INPUT VALUE FOR SCALING POINT 2

0 to 29999

10.000

APLY) style, the meter shows the previously stored Input Value for

FILTER BAND

bANd

The filter will adapt to variations in the input signal. When the variation

exceeds the input filter band value, the filter disengages. When the variation

becomes less than the band value, the filter engages again. This allows for a

stable readout, but permits the display to settle rapidly after a large process

change. The value of the band is in display units, independent of the Display

Decimal Point position. A band setting of ‘0’ keeps the filter permanently

engaged at the filter level selected above.

10

0 to 199 display units

DISPLAY VALUE FOR SCALING POINT 2

dSP 2

Enter the second Display Value by using the front panel buttons. This is the

same for

General Notes on Scaling

1. When using the Apply (APLY) scaling style, input values for scaling points

must be confined to the range limits shown.

2. The same Input Value should not correspond to more than one Display Value.

(Example: 20 mA can not equal 0 and 20.)

3. For input levels beyond the programmed Input Values, the meter extends the

Display Value by calculating the slope from the two coordinate pairs (

-19999 to 99999

10.000

KEY and APLY scaling styles.

dSP1 & INP2 / dSP2).

7

INP1 /

Page 8

SEL

Max Capture

Delay Time

Max Display

Enable

Min Display

Enable

Access Code

For Service

Operations

Min Capture

Delay TIme

Factory

Service

Operations

2-SEC

HI-En HI-t

LO-En LO-t FCS

CodE

Pro

USrIN

P-Loc

ZErO

rESEt

d-HLd

d-SEL

d-LEV

COLOr

USER INPUT FUNCTION

NO

MODEDISPLAY

No Function

NO

Program Mode Lock-out

Zero Input

(Edge triggered)

Reset (Edge triggered)

Display Hold

Display Select

(Edge Triggered)

Display Intensity Level

(Edge Triggered)

Backlight Color

(Edge Triggered)

DESCRIPTION

User Input disabled.

See Programming Mode Access chart

(Module 3).

Zero the Input Display value causing

Display Reading to be Offset.

Resets the assigned value(s) to the

current input value.

Holds the assigned display, but all other

meter functions continue as long as

activated (maintained action).

Advance once for each activation.

Increase intensity one level for each

activation (backlight version only).

Change backlight color with each

activation (backlight version only).

U-ASN

Input Assignment only applies if a selection of reset, display hold, or print and

reset is selected in the User Input Function menu.

MODE DESCRIPTIONDISPLAY

Print Request

Print

Print and Reset

P-r5t

Setpoint 1 Reset

rSt-1

Setpoint 2 Reset

rSt-2

Setpoint 1 and 2 Reset

rSt12

USER INPUT ASSIGNMENT

dSP

Select the value(s) to which the User Input Function is assigned. The User

Serial transmit of the active parameters

selected in the Print Options menu

(Module 5).

Same as Print Request followed by a

momentary reset of the assigned value(s).

Resets setpoint 1 output.

Resets setpoint 2 output.

Reset both setpoint 1 and 2 outputs.

HI-LO HI

dSPLO

6.2 MODULE 2 - SECONDARY FUNCTION PARAMETERS (2-SEC)

PARAMETER MENU

MAX DISPLAY ENABLE

HI-En

Enables the Maximum Display Capture capability.

HI-t

When the Input Display is above the present MAX value for the entered

delay time, the meter will capture that display value as the new MAX reading.

A delay time helps to avoid false captures of sudden short spikes.

LO-En

Enables the Minimum Display Capture capability.

LO-t

When the Input Display is below the present MIN value for the entered delay

time, the meter will capture that display value as the new MIN reading. A delay

time helps to avoid false captures of sudden short spikes.

FCS

Select yES to perform either of the Factory Service Operations shown below.

YESNO

NO

MAX CAPTURE DELAY TIME

0.0 to 999.9 seconds

2.0

MIN DISPLAY ENABLE

YESNO

NO

MIN CAPTURE DELAY TIME

0.0 to 999.9 seconds

2.0

FACTORY SERVICE OPERATIONS

yESNO

NO

8

RESTORE FACTORY DEFAULT SETTINGS

CodE

CodE

CodE

calibration values no longer accurately define the input circuit. For most

applications, recalibration every 1 to 2 years should be sufficient.

Calibration of the CUB5I involves a current calibration which should only be

performed by individuals experienced in calibrating electronic equipment.

Allow 30 minute warm up before performing any calibration related procedure.

The following procedures should be performed at an ambient temperature of 15

to 35 °C (59 to 95 °F).

CAUTION: The accuracy of the calibration equipment will directly affect the

Current Calibration

1. Connect the negative lead of a precision DC current source with an accuracy

of 0.01% or better to the COMM terminal. Leave the positive lead of the DC

current source unconnected.

2. With the display at

Unit will display CAL NO

3. Press the RST button to select the range to be calibrated.

4. Press the SEL button. Display reads 0.0A

5. With the positive lead of the DC current source unconnected, press SEL.

Display reads

6. When the display reads the selected range, connect the positive lead of the DC

current source to INP+ and apply full-scale input signal for the range. (Note:

For 200 mA range, apply 100 mA as indicated on the display.)

7. Repeat steps 3 through 6 for each input range to be calibrated. When display

reads

66

50

48

accuracy of the CUB5I.

CAL NO, press the SEL button to exit calibration.

Entering Code 66 will overwrite all user settings with

the factory settings. The meter will display

return to CodE 00. Press the SEL button to exit the module.

VIEW VERSION DISPLAY

Entering Code 50 will display the version (x.x) of the

meter. The display then returns to CodE 00. Press the SEL

button to exit the module.

CALIBRATION

The CUB5I uses stored current calibration values to

provide accurate current measurements. Over time, the

electrical characteristics of the components inside the

CUB5I will slowly change with the result that the stored

CodE 48, press and hold the SEL button for 2 seconds.

CALC for about 8 seconds.

rESEt and then

Page 9

6.3 MODULE 3 - DISPLAY AND FRONT PANEL BUTTON

SEL

Pro

Front Panel

Display

Select Enable

Display

Update Time

Front Panel

Reset Enable

Programming

Security Code

Zero Display

W/Display

Reset

Display

Color

Units

Indicator

Selection

Backlight Unit Only

3-dSP

dSP-t SEL rSt ZErO UNItS COLOr CodE

Display

Intensity

Level

d-LEVScroL

Display

Scroll

Enable

P

ARAMETERS (3-dSP)

PARAMETER MENU

DISPLAY UPDATE TIME

dSP-t

This parameter sets the display update time in seconds.

SEL

The yES selection allows the SEL button to toggle through the enabled

displays.

0.5

1

2

seconds

1

FRONT PANEL DISPLAY SELECT ENABLE (SEL)

yES

NOyES

COLOr

backlight units only.

d-LEV

DISPLAY COLOR (BACKLIGHT UNIT ONLY)

rEd

Enter the desired display color, red or green. This parameter is active for

DISPLAY INTENSITY LEVEL (BACKLIGHT UNIT ONLY)

FRONT PANEL RESET ENABLE (RST)

rSt

This selection allows the RST button to reset the selected value(s).

HI

dSP

LO

HI-LO

dSPNO

Enter the desired Display Intensity Level (1-5). The display will actively dim

or brighten as levels are changed. This parameter is active for backlight units only.

CodE

ZERO DISPLAY WITH DISPLAY RESET

ZErO

This parameter enables the RST button or user input to zero the input display

value, causing the display reading to be offset.

Note: For this parameter to operate, the

must be set to dSP and the Input value must be displayed. If these conditions are

not met, the display will not zero.

NO

NOyES

RST button or User Input being used

The Security Code determines the programming mode and the accessibility

of programming parameters. This code can be used along with the Program

Mode Lock-out (P-Loc) in the User Input Function parameter (Module 1).

Two programming modes are available. Full Programming mode allows all

parameters to be viewed and modified. Quick Programming mode permits only

the Setpoint values to be modified, but allows direct access to these values

without having to enter Full Programming mode.

Programming a Security Code other than 0, requires this code to be entered

at the

code value, Quick Programming may be accessible before the CodE prompt

appears (see chart).

000

CodE prompt in order to access Full Programming mode. Depending on the

6rnrEd

1 to 5

5

PROGRAMMING SECURITY CODE

000 to 999

DISPLAY SCROLL ENABLE

ScroL

The yES selection allows the display to automatically scroll through the

enabled displays. The scroll rate is every 4 seconds. This parameter only appears

when the MAX or MIN displays are enabled.

UNItS

This parameter activates the Units Indicator on the display. There are two

methods of selecting the Indicator. List will present a group of Units

preprogrammed into the meter. Segments allows the user to choose which of the

segments should light.

NO

OFF

NOyES

UNITS INDICATOR SELECTION

LISt SEGSOFF

USER INPUT

FUNCTION

not P-Loc

* Entering Code 222 allows access regardless of security code.

9

P-Loc

USER INPUT

STATE

______

Active

Not Active 0-999

SECURITY

CODE

0

1-99

100-999

0

1-99

100-999

MODE WHEN “SEL”

BUTTON IS PRESSED

Full Programming Immediate Access

Quick Programming

CodE prompt

Programming Lock No Access

Quick Programming No Access

CodE prompt

Full Programming Immediate Access

FULL PROGRAMMING

MODE ACCESS

After Quick Programming

with correct code entry

CodE prompt *

at

With correct code entry

CodE prompt *

at

With correct code entry

CodE prompt *

at

Page 10

6.4 MODULE 4 - SETPOINT OUTPUT PARAMETERS (4-SPt)

SEL

Setpoint

Action

Setpoint

Select

Setpoint

Value

Output Reset

Action

Hysteresis

Value

Off Time

Delay

On Time

Delay

Output Reset

W/Display

Reset

Change Display

Color with

Output State

Backlight

Unit Only

SPSEL

4-SPt

Act-n SPt-n HYS-n tON-n tOF-n rSt-n rEn-n ChC-n

Pro

Standby

Operation

Stb-n

OUTPUT

STATE

OFF

ON

Hys

SP + ½Hys

SP

SP - ½Hys

OFF

TRIGGER POINTS

OUTPUT

STATE

OFF

ON

Hys

SP + Hys

SP

OFF

TRIGGER POINTS

OUTPUT

STATE

OFF

ON

Hys

SP + ½Hys

SP

SP - ½Hys

OFF

TRIGGER POINTS

OUTPUT

STATE

OFF

ON

Hys

SP

SP - Hys

OFF

TRIGGER POINTS

PARAMETER MENU

The Setpoint Output Parameters are only active when an optional output

module is installed in the meter.

SETPOINT SELECT

SPSEL

Enter the setpoint (output) to be programmed. The n in the following

parameters will reflect the chosen setpoint number. After the chosen setpoint

is completely programmed, the display will return to SPSEL. Repeat steps for

each setpoint to be programmed. Select

setpoints available is setpoint output card dependent.

NO

NO to exit the module. The number of

SP-2SP-1NO

SETPOINT 2 ENABLE

Enb-2

Select YES to enable Setpoint 2 and access the setup parameters. If NO is

selected, the unit returns to SPSEL and setpoint 2 is disabled.

NO

NOYES

SETPOINT ACTION

Act-n

Enter the action for the selected setpoint (output). See Setpoint Output

Figures for a visual detail of each action.

HI-Ub

HI-bL

LO-UbHI-UbLO-bL

SETPOINT VALUE

SPt-n

Enter the desired setpoint value. The decimal point position for the setpoint

and hysteresis values follow the selection set in Module 1.

10000

-19999 to 99999

HYSTERESIS VALUE

HYS-n

Enter desired hysteresis value. See Setpoint Output Figures for visual

explanation of how setpoint output actions (balanced and unbalanced) are

affected by the hysteresis. When the setpoint is a control output, usually

balanced hysteresis is used. For alarm applications, usually unbalanced

hysteresis is used. For unbalanced hysteresis modes, the hysteresis functions on

the low side for high acting setpoints and functions on the high side for low

acting setpoints.

Note: Hysteresis eliminates output chatter at the switch point, while time delay

can be used to prevent false triggering during process transient events.

1 to 59999

2

ON TIME DELAY

tON-n

Enter the time value in seconds that the output is delayed from turning on

after the trigger point is reached. A value of 0.0 allows the meter to update the

output status per the response time listed in the Specifications.

0.0

0.0 to 599.9 seconds

=

HI-bL

LO-bL

HI-Ub

LO-Ub

High Acting (Balanced Hys) = HI-bL

High Acting (Unbalanced Hys) = HI-Ub

High Acting, with balanced hysteresis

=

Low Acting, with balanced hysteresis

=

High Acting, with unbalanced hysteresis

=

Low Acting, with unbalanced hysteresis

Low Acting (Balanced Hys) = LO-bL

Low Acting (Unbalanced Hys) = LO-Ub

OFF TIME DELAY

tOF-n

Enter the time value in seconds that the output is delayed from turning off

after the trigger point is reached. A value of 0.0 allows the meter to update the

output status per the response time listed in the Specifications.

0.0

0.0 to 599.9 seconds

OUTPUT RESET ACTION

rSt-n

Auto

LAtCHAuto L-dLY

Enter the reset action of the output. See figure for details.

Auto = Automatic action; This action allows the output to automatically reset of f

at the trigger points per the Setpoint Action shown in Setpoint Output

Figures. The “on” output may be manually reset (off) immediately by the

front panel RST button or user input.The output remains off until the trigger

point is crossed again.

LAtCH = Latch with immediate reset action; This action latches the output on at

the trigger point per the Setpoint Action shown in Setpoint Output Figures.

Latch means that the output can only be turned off by the front panel RST

10

Page 11

SEL

Data BitBaud Rate Parity Bit Print

Options

Meter

Address

Abbreviated

Printing

5-SEr

bAUd dAtA

PAr Addr Abbr

OPt

Pro

button or user input manual reset, serial reset command or meter power

OUTPUT

STATE

OFF

ON

Hys

SP

Auto

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

MANUAL

RESET

LAtCH

L-dLY

SP - Hys

( )

( )

( )

{

cycle. When the user input or

the corresponding “on” output is reset immediately and remains off until the

trigger point is crossed again. (Previously latched alarms will be off if power

up Display Value is lower than setpoint value.)

RST button is activated (momentary action),

L-dLY = Latch with delay reset action; This action latches the output on at the

trigger point per the Setpoint Action shown in Setpoint Output Figures. Latch

means that the output can only be turned off by the front panel

or user input manual reset, serial reset command or meter power cycle. When

the user input or

delays the event until the corresponding “on” output crosses the trigger off

point. (Previously latched outputs are off if power up Display Value is lower

than setpoint value. During a power cycle, the meter erases a previous L-dLY

reset if it is not activated at power up.)

RST button is activated (momentary action), the meter

RST button

OUTPUT RESET WITH DISPLAY RESET

rEn-n

This parameter enables the RST button or user input to reset the output when

the display is reset.

Note: For this parameter to operate, the RST button or User Input being used

must be set to dSP and the Input value must be displayed. If these conditions are

not met, the output will not reset.

YES

YESNO

STANDBY OPERATION

Stb-n

When YES, the output is disabled (after a power up) until the trigger point is

crossed. Once the output is on, the output operates normally per the Setpoint

Action and Output Reset Action.

ChC-n

This parameter enables the backlight CUB5 to switch the backlight color when

the output state changes. This parameter is only active for the backlight version.

NO

CHANGE DISPLAY COLOR w/OUTPUT STATE

NO

Setpoint Output Reset Actions

6.5 MODULE 5 - SERIAL SETUP PARAMETERS (5-SEr)

PARAMETER MENU

YESNO

YESNO

The Serial Setup Parameters are only active when one of the optional serial communications/programming cards is installed in the meter.

Refer to the CUB5COM bulletin for details and setup for the CUB5 RS232 or RS485 serial communications.

Refer to the CUB5USB bulletin for details on the CUB5 USB programming and programming requirements.

The Company warrants the products it manufactures against defects in materials and workmanship for a period limited to two years

from the date of shipment, provided the products have been stored, handled, installed, and used under proper conditions. The

Company’s liability under this limited warranty shall extend only to the repair or replacement of a defective product, at The

Company’s option. The Company disclaims all liability for any affirmation, promise or representation with respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against damages, claims, and expenses

arising out of subsequent sales of RLC products or products containing components manufactured by RLC and based upon personal

injuries, deaths, property damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be to

any extent liable, including without limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and liability

imposed upon any person pursuant to the Magnuson-Moss Warranty Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those expressly contained herein.

The Customer acknowledges the disclaimers and limitations contained herein and relies on no other warranties or affirmations.

LIMITED WARRANTY

11

Page 12

Setpoint

Action

Setpoint

Select

Setpoint

Value

Output Reset

Action

Hysteresis

Value

Off Time

Delay

On Time

Delay

Output Reset

W/Display

Reset

Change Display

Color with

Output State

Backlight

Unit Only

SPSEL

4-SPt

Act-n SPt-n HYS-n tON-n tOF-n rSt-n rEn-n ChC-n

Standby

Operation

Stb-n

Front Panel

Reset Enable

Front Panel

Display

Select Enable

Display

Update Time

dSP-t SEL rSt

3-dSP

Display

Intensity

Level

COLOr

Units

Indicator

Selection

UNItS

Display

Color

d-LEV

Backlight Unit Only

Programming

Security Code

CodE

Filter Band

Input

Range

rANGE

Display

Decimal Point

dECPt

1-INP

Filter Setting

FILtr

bANd

USrIN

User Input

Function

Input Value

for Scaling

Point 1

INP 1 dSP 1

INP 2

U-ASN

User Input

Assignment

LO-En

Min Display

Enable

Max Capture

Delay Time

Max Display

Enable

HI-En HI t2-SEC

Min Capture

Delay TIme

LO-t

Factory

Service

Operations

FCS

Access Code

For Service

Operations

CodE

PAr

Parity BitBaud Rate

bAUd

Data Bit

dAtA

5-SEr

Meter

Address

Addr

Abbreviated

Printing

Abbr

Print

Options

OPt

SEL

RST

NO

Pro

Exit

Programming

End

SEL

RST

RST

RST

RST

RST

SEL

SEL

SEL

SEL

Display Value

for Scaling

Point 1

Input Value

for Scaling

Point 2

Display Value

for Scaling

Point 2

dSP 2

OFSEt

Display Offset

Value

StYLE

Scaling Style

Zero Display

W/Display

Reset

ZErO ScroL

Display

Scroll

Enable

CUB5I PROGRAMMING QUICK OVERVIEW

Press and hold SEL button to

enter Programming Mode.

Loading...

Loading...