Page 1

1

z LCD, REFLECTIVE OR GREEN/RED LED BACKLIGHTING

z 0.46" (11.7 mm) HIGH DIGITS

z OPTIONAL RELAY OUTPUT MODULE

z OPTIONAL SERIAL COMMUNICATIONS MODULE (RS232 or RS485)

z COUNT SPEEDS UP TO 20 KHz

z OPERATES FROM 9 TO 28 VDC POWER SOURCE

z PROGRAMMABLE SCALING FOR COUNT AND RATE

z BI-DIRECTIONAL COUNTING, UP/DOWN CONTROL

z QUADRATURE SENSING (UP TO 4 TIMES RESOLUTION)

z DISPLAY COLOR CHANGE CAPABILITY AT PRESET OUTPUT

z NEMA 4X/IP65 SEALED FRONT BEZEL

MODEL CUB5 - MINIATURE ELECTRONIC 8-DIGIT DUAL

COUNTER AND RATE INDICATOR

GENERAL DESCRIPTION

The CUB5 provides the user the ultimate in flexibility, from its complete user

programming to the optional relay output capability. The meter can be

programmed as a single or dual counter with rate indication capability. The

display can be toggled either manually or automatically between the

selected displays.

The CUB5 display has 0.46" (11.7 mm) high digits. The LCD is available in

two versions, reflective (CUB5R000) and backlight (CUB5B000). The

backlight version is user selectable for green or red backlighting with variable

display intensity.

The counter is programmable for one of eight different count modes,

including bi-directional and quadrature. When programmed as a dual counter,

each counter has a separate scale factor and decimal points. In the counter/rate

indicator mode, each have their own scaling and decimal point read-outs in

different engineering units.

The meter has two separate inputs which provide different functions

depending on which operating mode is selected. Input A accepts the signal for

the Count and/or Rate displays, while Input B accepts the signal for the Count

display or direction control. In the anti-coincidence mode, both inputs are

monitored simultaneously so that no counts are lost. The resulting display can

be chosen as the sum or difference of the two inputs. The Rate Indicator has

programmable low (minimum) and high (maximum) update times to provide

optimal display response at any input frequency. There is a programmable user

input that can be programmed to perform a variety of functions.

The capability of the CUB5 can be easily expanded with the addition of an

option module. Setpoint capability is field installable with the addition of the

CUB5RLY0, relay output module. Serial communications capability for RS232

or RS485 is added with a serial option module.

The CUB5 can be powered from an optional Red Lion Micro-Line/Sensor

Power Supply (MLPS1000), which attaches directly to the back of a CUB5. The

MLPS1 is powered from 85 to 250 VAC and provides up to 400 mA to drive the

unit and sensors.

COUNTER

The CUB5 receives incoming pulses and multiplies them by the Count Scale

Factor to obtain the desired reading for the count display. Input A accepts the

signal for the count and Input B is used for quadrature, dual counter, anticoincidence counting, or up/down control counting.

RATE

The rate indicator utilizes the signal at Input A to calculate the rate value

using a time interval method (1/tau). The unit counts on the negative edge of the

input pulses. After the programmed minimum update time elapses and the next

negative edge occurs, the unit calculates the input rate based on the number of

edges that occurred during the elapsed time. The input rate is then multiplied by

the rate scaling value to calculate the rate display.

At slower rates, averaging can be accomplished by programming the rate

minimum update time for the desired response. Extensive scaling capabilities

allow practically any desired reading at very slow count rates.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in this

literature or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use this meter to directly command motors, valves, or other actuators

not equipped with safeguards. To do so can be potentially harmful to persons or

equipment in the event of a fault to the meter.

Bulletin No. CUB5-E

Drawing No. LP0584

Released 3/07

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

CAUTION: Risk of Danger.

Read complete instructions prior to

installationand operation of the unit.

CAUTION: Risk of electric shock.

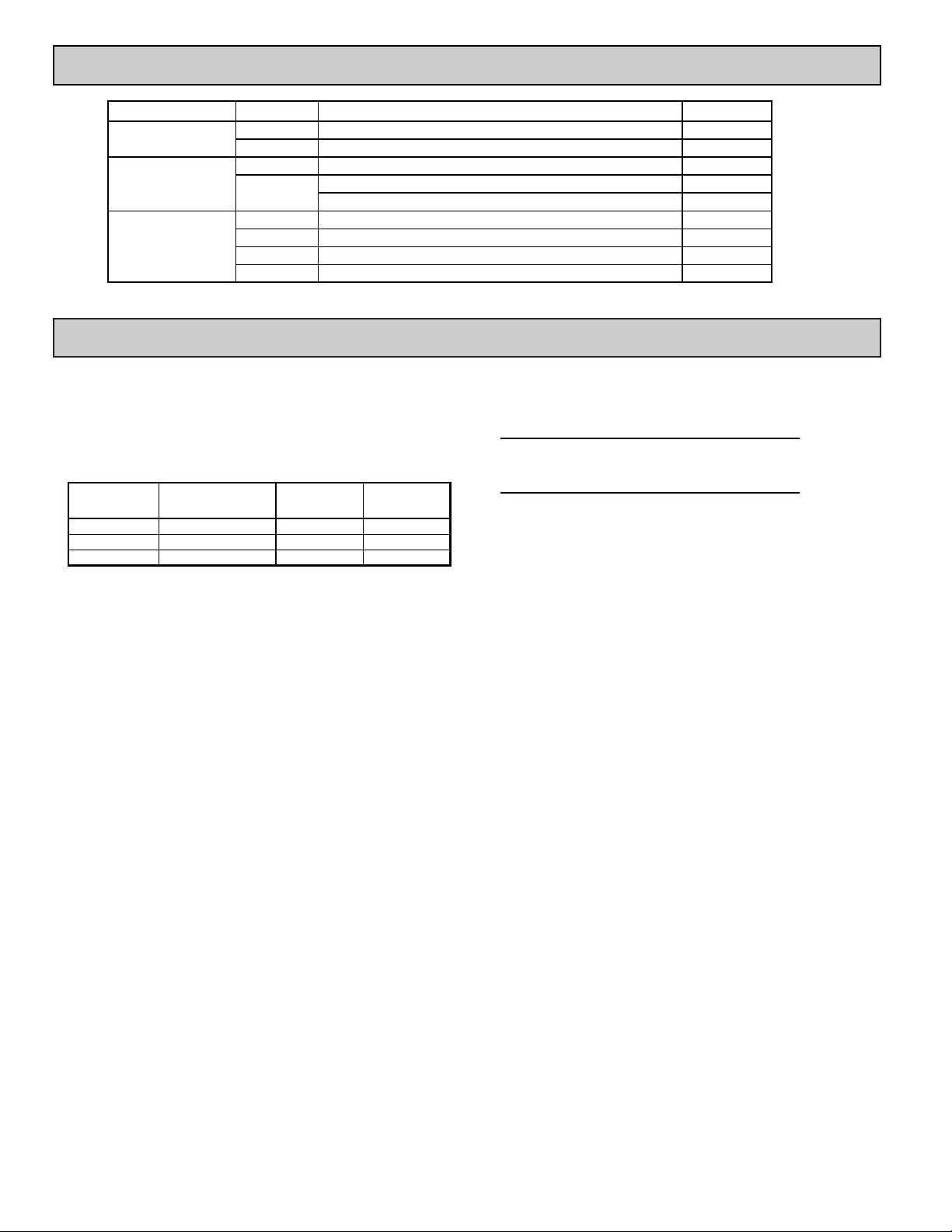

DIMENSIONS In inches (mm)

Note: Recommended minimum clearance (behind the panel) for mounting clip installation is 2.15" (54.6) H x 3.00" (76.2) W.

C

US LISTEDUS

LISTED

U

L

R

IND. CONT.EQ.

51EB

Page 2

1. DISPLAY: 8 digit LCD 0.46" (11.7 mm) high digits

CUB5R000: Reflective LCD with full viewing angle

CUB5B000: Selectable transmissive red or green backlight LED with

viewing angle optimized. Display color change capability at preset when

using a relay module.

2. POWER: Input voltage range is +9 to +28 VDC with short circuit and input

polarity protection. Must use an RLC model MLPS1 or a Class 2 or SELV

rated power supply.

3. COUNTER DISPLAYS:

Counter A: 8-digits, enabled in all count modes

Display Range: -9999999 to 99999999

Overflow Indication: Display flashes “Cnt OVEr”

Counter B: 7-digits, enabled in Dual Counter mode only

Display Designator: “b” to the left side of the display

Display Range: 0 to 9999999 (positive count only)

Overflow Indication: Display flashes “bCntOVEr”

Maximum Count Rates: 50% duty cycle

Without setpoint option card: 20 KHz (all count modes)

With setpoint option card: 20 KHz for any count mode except Quadrature

x4 (18 KHz) and Dual Counter (17 KHz)

4. RATE DISPLAY: 6-digits, may be enabled or disabled in any mode

Display Designator: “R” to the left side of the display

Display Range: 0 to 999999

Over Range Display: “R OLOLOL”

Maximum Frequency: 20 KHz

Minimum Frequency: 0.01 Hz

Accuracy: ±0.01%

5. COUNT/RATE SIGNAL INPUTS (INP A and INP B):

Input A: DIP switch selectable to accept pulses from a variety of sources.

See Section 2.0 Setting the DIP Switches for Input A specifications.

Input B: Logic signals only

Trigger levels: VIL= 1.0 V max; VIH= 2.4 V min; V

MAX

= 28 VDC

Current sinking: Internal 10KΩ pull-up resistor to +9 to 28 VDC

Filter (LO Freq.): Damping capacitor provided for switch contact bounce.

Limits input frequency to 50 Hz and input pulse widths to 10 msec min.

6. USER INPUT (USR): Programmable input. Connect terminal to common to

activate function. Internal 10KΩ pull-up resistor to +9 to 28 VDC.

Threshold Levels: VIL= 1.0 V max; VIH= 2.4 V min; V

MAX

= 28 VDC

Response Time: 5 msec typ.; 50 msec debounce (activation and release)

7. MEMORY: Nonvolatile E

2

PROM memory retains all programming

parameters and count values when power is removed.

8. CONNECTIONS: Wire clamping screw terminals

Wire Strip Length: 0.3" (7.5 mm)

Wire Gage: 30-14 AWG copper wire

Torque: 5 inch-lbs (0.565 N-m) max.

9. CONSTRUCTION: This unit is rated for NEMA 4X/IP65 requirements for

indoor use. Installation Category I, Pollution Degree 2. High impact plastic

case with clear viewing window. Panel gasket and mounting clip included.

10. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range for CUB5R000: -35 to 75°C

Operating Temperature Range for CUB5B000 depends on display color

and intensity level as per below:

Storage Temperature: -35 to 85°C

Operating and Storage Humidity: 0 to 85% max. relative humidity (non-

condensing)

Altitude: Up to 2000 meters

11. CERTIFICATIONS AND COMPLIANCES:

SAFETY

UL Recognized Component, File #E179259, UL61010A-1, CSA 22.2 No. 61010-1

Recognized to U.S. and Canadian requirements under the Component

Recognition Program of Underwriters Laboratories, Inc.

UL Listed, File # E137808, UL508, CSA C22.2 No. 14-M95

LISTED by Und. Lab. Inc. to U.S. and Canadian safety standards

Type 4X Indoor Enclosure rating (Face only), UL50

IECEE CB Scheme Test Certificate #US/9257/UL

CB Scheme Test Report #E179259-V01-S02

Issued by Underwriters Laboratories, Inc.

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

IP65 Enclosure rating (Face only), IEC 529

ELECTROMAGNETIC COMPATIBILITY

Emissions and Immunity to EN 61326: Electrical Equipment for

Measurement, Control and Laboratory use.

Notes:

1. Criterion A: Normal operation within specified limits.

Refer to EMC Installation Guidelines for additional information.

12. WEIGHT: 3.2 oz (100 g)

2

GENERAL METER S

PECIFICATIONS

ORDERING INFORMATION

TYPE MODEL NO. DESCRIPTION PART NUMBER

CUB5

CUB5R CUB5R000

CUB5B CUB5B000

Optional Plug-in Cards

CUB5RLY

CUB5COM

RS232 Serial Communications Card

RS485 Serial Communications Card

Single Relay Option Card

CUB5COM2

CUB5COM1

CUB5RLY0

Accessories

SFCRD

CBLPRO

CBPRO

MLPS1

Crimson 2 PC Configuration Software for Windows 98, ME, 2000, XP

*

Programming Cable RS232 (RJ11-DB9)

Programming Cable RS485 (RJ11-DB9)

Micro-Line Power Supply, 85 to 250 VAC

SFCRD200

CBLPROG0

CBPRO007

MLPS1000

Dual Counter & Rate Indicator with Reflective Display

Dual Counter & Rate Indicator with Backlight Display

MODEL

NO.

DISPLAY COLOR

INPUT CURRENT

WITHOUT

CUB5RLY0

INPUT CURRENT

WITH

CUB5RLY0

CUB5R000 --- 10 mA 30 mA

CUB5B000 Red (max intensity) 85 mA 115 mA

CUB5B000 Green (max intensity) 95 mA 125 mA

TEMPERATURE

1 & 2 -35 to 75°C

3 -35 to 70°C

4 -35 to 60°C

5 -35 to 50°C

1 & 2 -35 to 75°C

3 -35 to 65°C

5

4

-35 to 35°C

-35 to 50°C

INTENSITY LEVEL

Class AEN 55011Emissions

Emissions:

30 A/m

3 V/rms

Criterion A

Criterion A

EN 61000-4-8

EN 61000-4-6RF conducted interference

1 kV L-L,

Criterion AEN 61000-4-5Surge

1 kV signal

2 kV power

Criterion AEN 61000-4-4Fast transients (burst)

2 kV L&N-E power

10 V/m

Criterion AEN 61000-4-3Electromagnetic RF fields

8 kV air discharge

4 kV contact discharge

Criterion AEN 61000-4-2Electrostatic discharge

Immunity to Industrial Locations:

Power frequency magnetic fields

Green Display

*Crimson 2 software is available for download from http://www.redlion.net/

Red Display

Page 3

3

ADDING OPTION CARDS

The CUB5 meters can be fitted with optional relay card and/or serial

communications cards. The details for the plug-in cards can be reviewed in the

specification section below. The plug-in cards, that are sold separately, can be

installed initially or at a later date.

RELAY CARD

Type: Single FORM-C relay

Isolation To Sensor & User Input Commons: 1400 Vrms for 1 min.

Working Voltage: 150 Vrms

Contact Rating: 1 amp @ 30 VDC resistive; 0.3 amp @ 125 VAC resistive

Life Expectancy: 100,000 minimum operations

Response Time:

Turn On Time: 4 msec max.

Turn Off Time: 4 msec max.

Time Accuracy: ± 0.01%

WARNING: Disconnect all power to the unit before

installing Plug-in card.

RS485 SERIAL COMMUNICATIONS CARD

Type: RS485 multi-point balanced interface (non-isolated)

Baud Rate: 300 to 19.2k

Data Format: 7/8 bits; odd, even, or no parity

Bus Address: 0 to 99; max 32 meters per line

Transmit Delay: Selectable (refer to CUB5COM bulletin)

RS232 SERIAL COMMUNICATIONS CARD

Type: RS232 half duplex (non-isolated)

Baud Rate: 300 to 19.2k

Data Format: 7/8 bits; odd, even, or no parity

OPTIONAL P

LUG-IN

CARDS

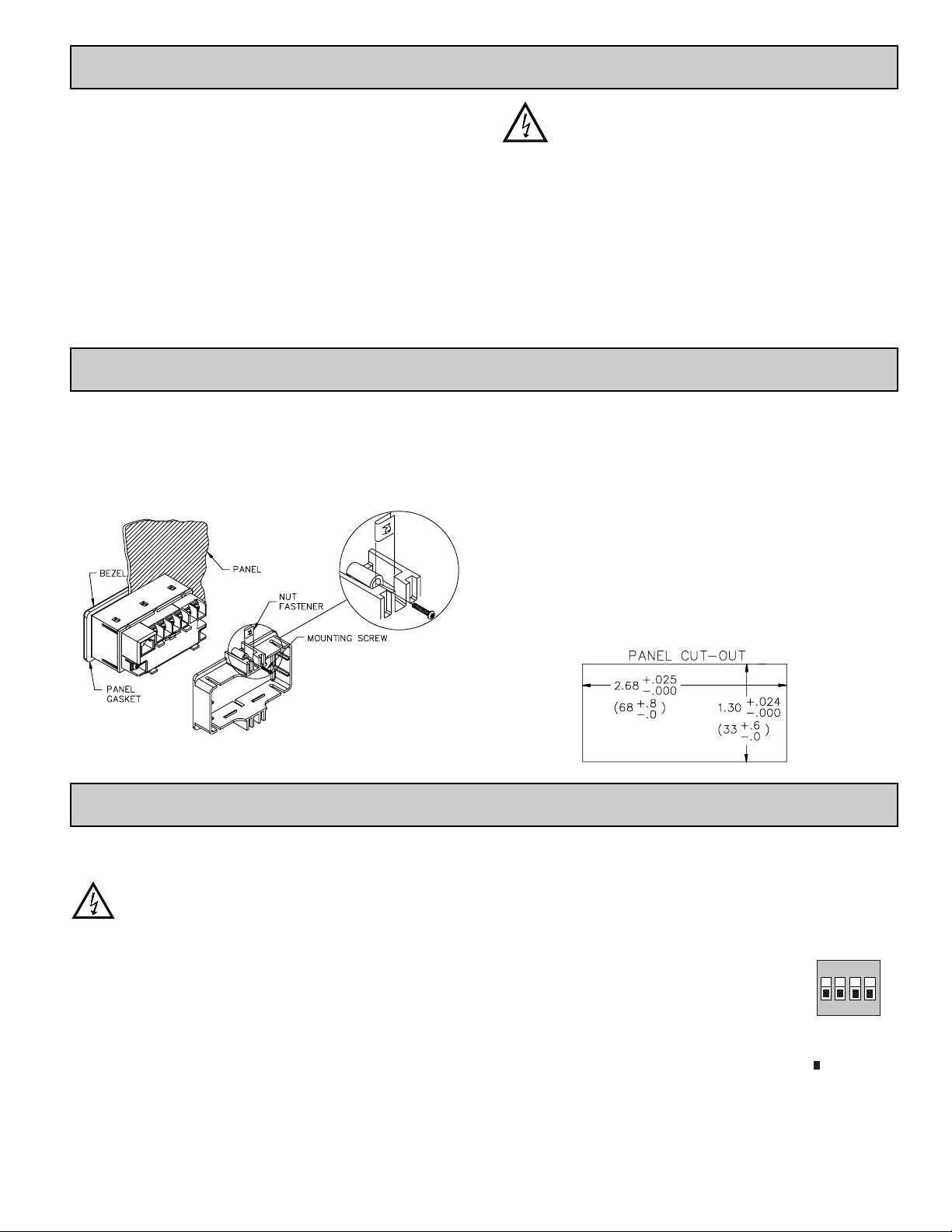

1.0 INSTALLING THE METER

INSTALLATION

The meter meets NEMA 4X/IP65 requirements when properly installed. The

unit is intended to be mounted into an enclosed panel. Prepare the panel cutout

to the dimensions shown. Remove the panel latch from the unit. Slide the panel

gasket over the rear of the unit to the back of the bezel. The unit should be

installed fully assembled. Insert the unit into the panel cutout.

While holding the unit in place, push the panel latch over the rear of the unit

so that the tabs of the panel latch engage in the slots on the case. The panel latch

should be engaged in the farthest forward slot possible. To achieve a proper seal,

tighten the latch screws evenly until the unit is snug in the panel (Torque to

approx. 28 to 36 in-oz [0.202 to 0.26 N-m]). Do not over-tighten the screws.

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the operating

temperature and provides good air circulation. Placing the unit near devices that

generate excessive heat should be avoided.

The bezel should only be cleaned with a soft cloth and neutral soap product.

Do NOT use solvents. Continuous exposure to direct sunlight may accelerate the

aging process of the bezel.

Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to operate the

keypad of the unit.

2.0 SETTING THE DIP SWITCHES

SETTING THE INPUT DIP SWITCHES

The meter has four DIP switches for Input A and

Input B that must be set before applying power.

SWITCH 1

LOGIC: Input A trigger levels VIL= 1.25 V max.;

VIH= 2.75 V min.; V

MAX

= 28 VAC

MAG: 200 mV peak input sensitivity; 100 mV

hysteresis; maximum voltage: ±40 V peak

(28 Vrms); Must also have SRC switch ON.

(Not recommended with counting applications.)

SWITCH 2

SNK.: Adds internal 7.8 KΩ pull-up resistor to +9 to

28 VDC, I

MAX

= 3.8 mA.

SRC.: Adds internal 3.9 KΩ pull-down resistor,

7.2 mA max. @ 28 VDC max.

SWITCHES 3 and 4

HI Frequency: Removes damping capacitor and allows max. frequency.

LO Frequency: Adds a damping capacitor for switch contact bounce. Limits

input frequency to 50 Hz and input pulse widths to 10 msec.

To access the switches, remove the rear cover of the meter. A bank of 4

switches is located in the upper right hand corner.

Warning: Exposed line voltage exists on the circuit boards.

Remove all power to the meter and load circuits before accessing

inside of the meter.

REMOVING THE REAR COVER

To remove the rear cover, locate the cover locking tab below the 2nd and 3rd

input terminals. To release the tab, insert a small, flat blade screwdriver between

the tab and the plastic wall below the terminals. Inserting the screwdriver will

provide enough pressure to release the tab locks. To replace the cover, align the

cover with the input terminals and press down until the cover snaps into place.

4

3

2

1

ON

Input B LO Freq.

Input A LO Freq.

Input A SRC.

Input A MAG.

HI Freq.

HI Freq.

SNK.

Logic

Factory Setting

Page 4

WIRING OVERVIEW

Electrical connections are made via screw-clamp terminals located on the

back of the meter. All conductors should conform to the meter’s voltage and

current ratings. All cabling should conform to appropriate standards of good

installation, local codes and regulations. It is recommended that the power

supplied to the meter (DC or AC) be protected by a fuse or circuit breaker.

Strip the wire, leaving approximately 0.3" (7.5 mm) bare lead exposed

(stranded wires should be tinned with solder.) Insert the lead under the correct

screw-clamp terminal and tighten until the wire is secure. (Pull wire to verify

tightness.) Each terminal can accept up to one #14 AWG (2.55 mm) wire, two

#18 AWG (1.02 mm), or four #20 AWG (0.61 mm).

EMC INSTALLATION GUIDELINES

Although this meter is designed with a high degree of immunity to ElectroMagnetic Interference (EMI), proper installation and wiring methods must be

followed to ensure compatibility in each application. The type of the electrical

noise, source or coupling method into the meter may be different for various

installations. The meter becomes more immune to EMI with fewer I/O

connections. Cable length, routing, and shield termination are very important

and can mean the difference between a successful or troublesome installation.

Listed below are some EMC guidelines for successful installation in an

industrial environment.

1. The meter should be mounted in a metal enclosure, which is properly

connected to protective earth.

2. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the panel where the unit is mounted to earth

ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the meter and leave the other end of the

shield unconnected and insulated from earth ground.

3. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be ran in metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

4. Signal or Control cables within an enclosure should be routed as far as possible

from contactors, control relays, transformers, and other noisy components.

5. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional protection.

Install line filters on the power input cable to the unit to suppress power line

interference. Install them near the power entry point of the enclosure. The

following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC# FCOR0000)

TDK # ZCAT3035-1330A

Steward # 28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC# LFIL0000)

Schaffner # FN670-1.8/07

Corcom # 1 VR3

Note: Reference manufacturer’s instructions when installing a line filter.

6. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

7. Switching of inductive loads produces high EMI. Use of snubbers across

inductive loads suppresses EMI.

Snubber: RLC# SNUB0000.

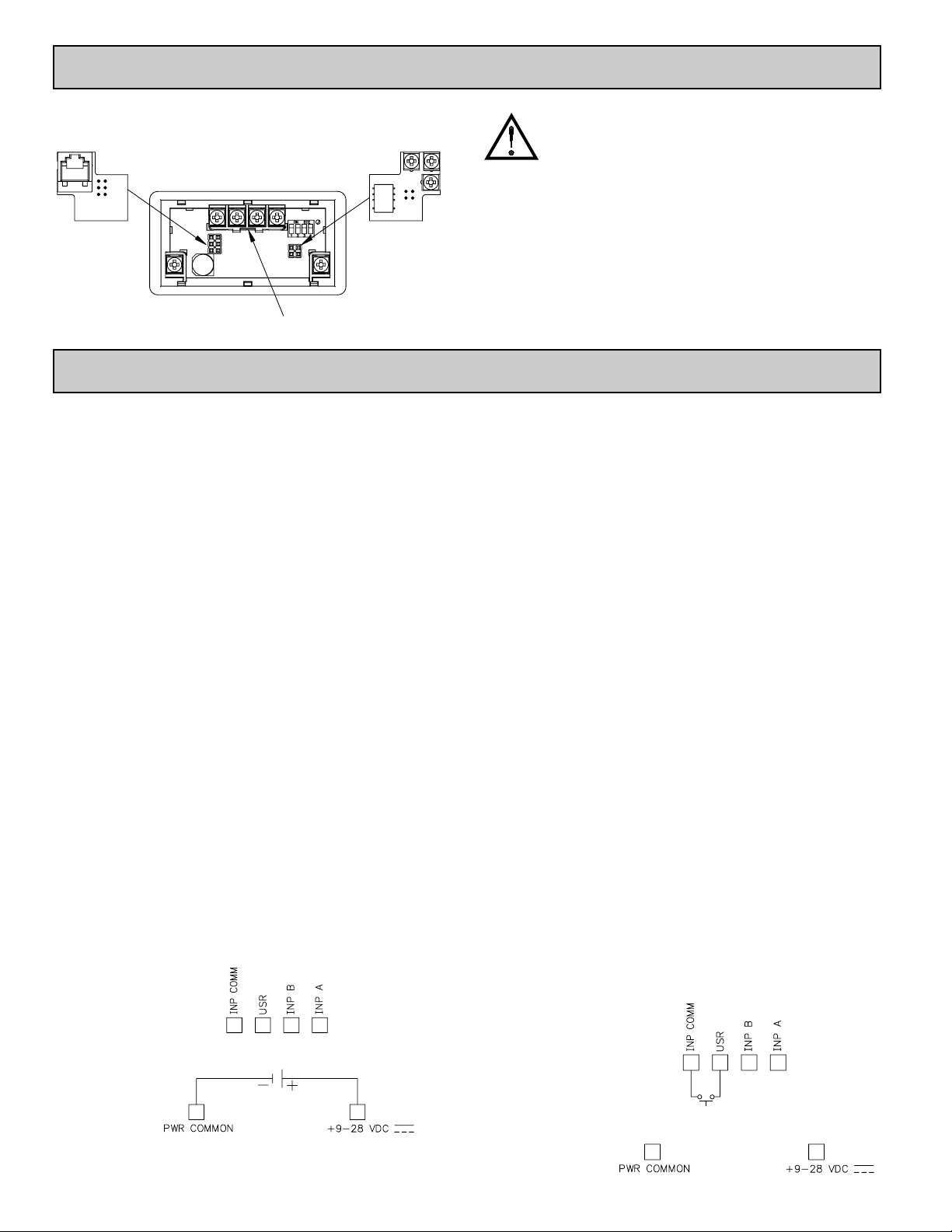

4.0 WIRING THE METER

4.1 POWER WIRING

DC Power

+9 to +28 VDC: +VDC

Power Common: -VDC

4.2 USER INPUT WIRING

Sinking Logic

INP COMM

USR

The user input of the meter is

internally pulled up to +9 to +28 V

with 10 K resistance. The input is

active when it is pulled low (<0 .7 V).

Connect external switching device between the

User Input terminal and Input Common.

}

4

The Plug-in cards are separately purchased option cards that perform specific

functions. The cards plug into the main circuit board of the meter

CAUTION: The Plug-in cards and main circuit board contain static

sensitive components. Before handling the cards, discharge

static charges from your body by touching a grounded bare

metal object. Ideally, handle the cards at a static controlled

clean workstation. Also, only handle the cards by the edges.

Dirt, oil or other contaminants that may contact the cards can

adversely affect circuit operation.

REMOVING THE REAR COVER

To remove the rear cover, locate the cover locking tab below the 2nd and 3rd

input terminals. To release the tab, insert a small, flat blade screwdriver between

the tab and the plastic wall below the terminals. Inserting the screwdriver will

provide enough pressure to release the tab locks. To replace the cover, align the

cover with the input terminals and press down until the cover snaps into place.

3.0 INSTALLING P

LUG-IN

CARDS

Comms Card

Setpoint Card

Locking Tab

Page 5

5

4.3 INPUT WIRING

CAUTION: Power input common is NOT isolated from user input common. In order to preserve the safety of the meter application, the power input

common must be suitably isolated from hazardous live earth referenced voltage; or input common must be at protective earth ground potential. If not,

hazardous voltage may be present at the User Inputs and User Input Common terminals. Appropriate considerations must then be given to the potential

of the user input common with respect to earth ground; and the common of the plug-in cards with respect to input common.

AC Inputs From Tach Generators, Etc.

Input A

Two Wire Proximity, Current Source

Input A

Magnetic Pickup

Input A

Current Sourcing Output

Input A

Interfacing With TTL

Input A

Current Sinking Output

Input A

Switch or Isolated Transistor; Current Sink

Input A

Switch or Isolated Transistor; Current Source

Input A

Switch position is application dependent.

Current Sink Output; Quad/Direction

Shaded areas not recommended for counting applications.

4.4 SETPOINT (OUTPUT) WIRING

4.5 SERIAL COMMUNICATION WIRING

ELECTRICAL CONNECTIONS

SETPOINT RELAY PLUG-IN CARD

SERIAL COMMUNICATIONS PLUG-IN CARD

RJ11 CONNECTOR PIN OUTS

Page 6

6

5.0 REVIEWING THE

FRONT B

UTTONS AND DISPLAY

PROGRAMMING MODE ENTRY (SEL KEY)

It is recommended all programming changes be made off line, or before

installation. The meter normally operates in the Display Mode. No parameters

can be programmed in this mode. The Programming Mode is entered by

pressing and holding the SEL key. If it is not accessible then it is locked by

either a security code, or a hardware lock.

MODULE ENTRY (SEL & RST KEYS)

The Programming Menu is organized into four modules. These modules group

together parameters that are related in function. The display will alternate between

Pro and the present module. The RST key is used to select the desired module.

The displayed module is entered by pressing the

SEL key.

MODULE MENU (SEL KEY)

Each module has a separate module menu (which is shown at the start of each

module discussion). The SEL key is pressed to advance to a particular parameter

to be changed, without changing the programming of preceding parameters.

After completing a module, the display will return to Pro NO. Programming

may continue by accessing additional modules.

SELECTION / VALUE ENTRY

For each parameter, the display alternates between the present parameter and

the selections/value for that parameter. The RST key is used to move through the

selections/values for that parameter. Pressing the

SEL key, stores and activates the

displayed selection/value. This also advances the meter to the next parameter.

For numeric values, press the

RST key to access the value. The right hand

most digit will begin to flash. Pressing the

RST key again increments the digit

by one or the user can hold the

RST key and the digit will automatically scroll.

The SEL key will advance to the next digit. Pressing and holding the SEL key

will enter the value and move to the next parameter.

PROGRAMMING MODE EXIT (SEL KEY)

The Programming Mode is exited by pressing the SEL key with Pro NO

displayed. This will commit any stored parameter changes to memory and

return the meter to the Display Mode. (If power loss occurs before returning to

the Display Mode, verify recent parameter changes.)

PROGRAMMING TIPS

It is recommended to start with Module 1 for counting or Module 2 for rate.

When programming is complete, it is recommended to record the parameter

programming and lock out parameter programming with the user input or

programming security code.

FACTORY SETTINGS

Factory Settings may be completely restored in Module 3. This is useful

when encountering programming problems.

Pressing the

RST key on power-up will load the factory settings and display

rESEt. This allows operation in the event of a memory failure or corrupted data.

ALTERNATING SELECTION DISPLAY

In the explanation of the modules, the following dual display with arrows will

appear. This is used to illustrate the display alternating between the parameter

on top and the parameter’s Factory Setting on the bottom. In most cases,

selections and values for the parameter will be listed on the right.

6.0 PROGRAMMING THE METER

OVERVIEW

PROGRAMMING MENU

Indicates Program Mode Alternating Display

Factory Settings are shown.

Parameter

Selection/Value

KEY DISPLAY MODE OPERATION ENTERING PROGRAM MODE PROGRAMMING MODE OPERATION

SEL Index display through selected displays Press and hold for 2 seconds to activate Store selected parameter and index to next parameter

RST Resets count display Press SEL to enter programming mode

Advances through the program menu/Increments

selected parameter value or selection

OPERATING MODE DISPLAY DESIGNATORS

“R” - To the left of the display is the rate value.

- Counter A has no designator.

“b” - To the left of the display is the Counter B value.

“1” - To the left of the display indicates the setpoint status.

Pressing the SEL button toggles the meter through the selected displays. If display scroll is enabled, the display will toggle automatically approximately every four

seconds between the rate and count values.

ª

«

Cnt ud

INP A-b

Page 7

7

6.1 MODULE 1 - I

NPUT SETUP PARAMETERS (

1-INPUt)

PARAMETER MENU

COUNTER A DECIMAL POSITION

This selects the decimal point position for Counter A and the setpoint value,

if assigned to Counter A. The selection will also affect Counter A scale

factor calculations.

COUNTER A SCALE FACTOR

The number of input counts is multiplied by the scale factor to obtain the

desired process value. A scale factor of 1.0000 will result in the display of the

actual number of input counts. (Details on scaling calculations are explained at

the end of this section.)*

00.0001 to 99.9999

COUNTER RESET AT POWER-UP

yES

NO

COUNT MODE

Select the count mode that corresponds with your application. The input

actions are shown in the boxes below. For simple counting applications, it is

recommended to use Count with Direction for the count mode. Simply leave the

direction input unconnected.

COUNTER B DECIMAL POSITION

This selects the decimal point position for Counter B. The selection will also

affect Counter B scale factor calculations.

COUNTER B SCALE FACTOR

The number of input counts is multiplied by the scale factor to obtain the

desired process value. A scale factor of 1.0000 will result in the display of the

actual number of input counts. (Details on scaling calculations are explained at

the end of this section.)*

00.0001 to 99.9999

Count bNO

both A-bCount A

Cnt ud qUAd 1 Add Add

dUAL Cnt

RAtE Cnt

qUAd 4

qUAd 2 Add Sub

SCALING FOR COUNT INDICATION

The CUB5’s scale factor is factory set to 1, to provide one count on the

display for each pulse that is input to the unit. In many applications, there will

not be a one-to-one correspondence between input pulses and display units.

Therefore, it is necessary for the CUB5 to scale or multiply the input pulses by

a scale factor to achieve the desired display units (feet, meters, gallons, etc.)

The Count Scale Factor Value can range from 00.0001 to 99.9999. It is

important to note that the precision of a counter application cannot be improved

by using a scale factor greater than one. To accomplish greater precision, more

pulse information must be generated per measuring unit. The following formula

is used to calculate the scale factor.

Scale Factor =

Desired Display Units

x Decimal Point Position

Number of Pulses

WHERE:

Desired Display Units: Count display units acquired after pulses that occurred.

Number of Pulses: Number of pulses required to achieve the desired

display units.

Decimal Point Position:

0=1

0.0 = 10

0.00 = 100

0.000 = 1000

0.0000 = 10000

0.00000 = 100000

EXAMPLE: The counter display is used to indicate the total number of feet

used in a process. It is necessary to know the number of pulses for the desired

units to be displayed. The decimal point is selected to show the resolution in

hundredths.

Scale Factor =

Desired Display Units

x Decimal Point Position

Number of Pulses

Given that 128 pulses are equal to 1 foot, display total feet with a onehundredth resolution.

Scale Factor =

1.00

x 100

128

Scale Factor = 0.007812 x 100

Scale Factor = 0.7812

0.000000.0000.0

0.00000.000

0.000000.0000.0

0.00000.000

ª

«

Cnt ud

INP A-b

ª

«

0

CntA dP

ª

«

01.0000

CmtA ScF

ª

«

0

Cntb dP

ª

«

01.0000

ª

«

NO

RSt P-UP

Shaded area selections only apply when programmed for dual count mode.

Counter A SubtractCounter A Add

Counter A AddCounter A Add

Quad ACount A

Quad ACount A

Quad ACount A

Counter B AddCounter A Add

Counter A AddRate only

Counter A DirectionCounter A

INPUT B ACTIONINPUT A ACTION

Add Sub

2 Input Add/Subtract

Add Add

2 Input Add/Add

qUAd 4

Quadrature x4

qUAd 2

Quadrature x2

qUAd 1

Quadrature x1

dUAL Cnt

Dual Counter

RAtE Cnt

Rate/Counter

Cnt ud

Count with Direction

DISPLAY MODE

*For value entry instructions, refer to selection/value entry in the Programming

The Meter section.

Note: The Rate indicator signal is derived from Input A in all count modes.

Cntb ScF

Page 8

8

6.2 MODULE 2 - RATE

SETUP PARAMETERS

(

2-rAtE)

PARAMETER MENU

RATE ENABLE

Module 2 is the programming for the Rate parameters. For maximum input

frequency, Rate Enable should be set to NO when not in use. When set to NO, the

remaining rate parameters are not accessible. The Rate value is shown with an

annunciator of “R” in the Display Mode.

This selects the decimal point position for rate displays and any setpoint

value assigned to these displays. This parameter does not affect rate scaling

calculations.

RATE DECIMAL POINT

0.000000.0000.0

0.00000.000

RATE SCALING INPUT VALUE

RATE SCALING DISPLAY VALUE

Enter the desired Rate Display Value for the Scaling Point.*

Enter the corresponding Rate Input Value for the Scaling Point.*

0 to 999999

0.1 to 99999.9

*For value entry instructions, refer to selection/value entry in the Programming

The Meter section.

USER INPUT ASSIGNMENT

The User Input Assignment is only active if the meter is programmed in the

Dual Count Mode and a selection of reset, store, store and reset, or inhibit is

selected in the User Input Function menu.

USER INPUT FUNCTION

MODEDISPLAY

No Function

NO

DESCRIPTION

User Input disabled.

Program Mode Lock-out

Pro Loc

Display Select

(Edge triggered)

d-SELECt

Advance once for each activation.

Maintained Reset

rESEt

Level active reset of the selected counters.

Store

StorE

Store and Reset

Stor-rSt

Inhibit

Inhibit

Inhibit counting for the selected counter(s).

d-LEVEL

Edge triggered reset of the selected

counter(s) after storing the count.

Count A

Count b

both A-b

See Programming Mode Access chart.

(Module 3)

Display Intensity Level

(Edge Triggered)

Freeze display of selected counter(s) while

allowing counts to accumulate internally.

ª

«

NO

USEr INP

ª

«

Count A

USEr ASN

ª

«

YES

RAtE Enb

ª

«

001000

RAtE dSP

ª

«

O

RAtE dP

ª

«

01000.0

RAtE INP

Shaded area selections only apply when programmed for dual count mode.

YESNO

Increase intensity one level for each

activation. (backlight version only)

MODE DESCRIPTIONDISPLAY

Print and Reset

Same as Print Request followed by a

momentary reset of the selected counter(s).

Prnt-r5t

Print Request

Serial transmit of the active parameters

selected in the Print Options menu

(Module 5).

Print

SCALING FOR RATE INDICATION

To scale the Rate, enter a Scaling Display value with a corresponding Scaling

Input value. These values are internally plotted to a Display value of 0 and Input

value of 0 Hz. A linear relationship is formed between these points to yield a

rate display value that corresponds to the incoming input signal rate. The meter

is capable of showing a rate display value for any linear process.

SCALING CALCULATION

If a display value versus input signal (in pulses per second) is known, then

those values can be entered into Scaling Display (RAtE dSP) and Scaling Input

(RAtE INP). No further calculations are needed.

If only the number of pulses per ‘single’ unit (i.e. # of pulses per foot) is

known, then it can be entered as the Scaling Input value and the Scaling Display

value will be entered as the following:

NOTES:

1. If # of pulse per unit is less than 10, then multiply both Input and Display

values by 10.

2. If # of pulse per unit is less than 1, then multiply both Input and Display

values by 100.

3. If the Display value is raised or lowered, then Input value must be raised

or lowered by the same proportion (i.e. Display value for per hour is

entered by a third less (1200) then Input value is a third less of # of pulses

per unit). The same is true if the Input value is raised or lowered, then

Display value must be raised or lowered by the same proportion.

4. Both values must be greater than 0.0.

EXAMPLE:

1. With 15.1 pulses per foot, show feet per minute in tenths. Scaling Display

= 60.0 Scaling Input = 15.1.

2. With 0.25 pulses per gallon, show whole gallons per hour. (To have greater

accuracy, multiply both Input and Display values by 10.) Scaling Display

= 36000 Scaling Input = 2.5.

RATE PER

DISPLAY (RAtE dSP) INPUT (RAtE INP)

Second 1 # of pulses per unit

Minute 60 # of pulses per unit

Hour 3600 # of pulses per unit

Page 9

9

INPUT FREQUENCY CALCULATION

The meter determines the input frequency by summing the number of falling

edges received during a sample period of time. The sample period begins on the

first falling edge. At this falling edge, the meter starts accumulating time

towards Low Update and High Update values. Also, the meter starts

accumulating the number of falling edges. When the time reaches the Low

Update Time value, the meter looks for one more falling edge to end the sample

period. If a falling edge occurs (before the High Update Time value is reached),

the Rate display will update to the new value and the next sample period will

start on the same edge. If the High Update Time value is reached (without

receiving a falling edge after reaching Low Update Time), then the sample

The Low Update Time is the minimum amount of time between display

updates for the Rate display. Values of 0.1 and 0.2 seconds will update the

display correctly but may cause the display to appear unsteady.

RATE LOW UPDATE TIME

0.1 to 99.9 seconds

The High Update Time is the maximum amount of time before the Rate

display is forced to zero. (For more explanation, refer to Rate Value

Calculation.) The High Update Time must be higher than the Low Update Time

and higher than the desired slowest readable speed (one divided by pulses per

second). The factory setting of 2.0, will force the display to zero for speeds

below 0.5 Hz or a pulse every 2 seconds.

RATE HIGH UPDATE TIME

0.2 to 99.9 seconds

ª

«

01.0

LO-Udt

ª

«

02.0

HI-Udt

period will end but the Rate display will be forced to zero. The High Update

Time value must be greater than the Low Update Time value. Both values must

be greater than 0.0. The input frequency calculated during the sample period, is

then shown as a Rate value determined by the scaling calculation.

6.3 MODULE 3 - DISPLAY AND FRONT PANEL KEY

PARAMETERS

(

3-dSPLAY)

PARAMETER MENU

The yES selection allows the SEL button to toggle through the enabled

displays.

FRONT PANEL DISPLAY SELECT ENABLE (SEL)

The yES selection allows the RST button to reset the selected counter(s). The

shaded selections are only active when the meter is programmed for Dual

Count Mode.

FRONT PANEL COUNTER RESET ENABLE (RST)

The yES selection allows the display to automatically scroll through the

enabled displays. The scroll rate is about every 4 seconds.

DISPLAY SCROLL ENABLE

NOyES

Count b

both A-b

dSPLAy

yES

NO

NO

Count A

NOyES

ª

«

yES

SEL Enb

ª

«

YES

RSt Enb

ª

«

NO

d-ScroLL

Enter the desired display color, red or green. This parameter is active for

backlight units only.

DISPLAY COLOR (BACKLIGHT UNIT ONLY)

6rnrEd

ª

«

rEd

d-COLOr

Enter the desired Display Intensity Level (1-5). The display will actively dim

or brighten as levels are changed. This parameter is active for backlight units only.

DISPLAY INTENSITY LEVEL (BACKLIGHT UNIT ONLY)

ª

«

5

d-LEVEL

1 to 5

Page 10

10

6.4 MODULE 4 - SETPOINT OUTPUT PARAMETERS (4-SEtPt)

PARAMETER MENU

The Setpoint Output Parameters are only active when the optional relay

module is installed in the meter. Some parameters will not appear depending on

the Setpoint Assignment and Setpoint Output Action selected.

Select the display the Setpoint is to be assigned.

SETPOINT OUTPUT ACTION

SETPOINT ASSIGNMENT

SETPOINT OUTPUT TIME-OUT

The Security Code determines the programming mode and the accessibility

of programming parameters. This code can be used along with the Program

Mode Lock-out (Pro Loc) in the User Input Function parameter (Module 1).

Two programming modes are available. Full Programming mode allows all

parameters to be viewed and modified. Quick Programming mode permits only

the Setpoint value to be modified, but allows direct access to this value without

having to enter Full Programming mode.

Programming a Security Code other than 0, requires this code to be entered

at the Pro CodE prompt in order to access Full Programming mode. Depending

on the code value, Quick Programming may be accessible before the Pro CodE

prompt appears (see chart).

PROGRAMMING SECURITY CODE

The yES selection will return the meter to the factory default settings. The

meter will display rESEt and then return to Pro, at which time all settings have

been changed.

Pressing the RST key on power-up will load the factory settings and display

rESEt. This allows operation in the event of a memory failure or corrupted data.

LOAD FACTORY DEFAULT SETTINGS

This parameter selects the action of the Setpoint output.

rAtECount A

SPT ACTION DESCRIPTION OUTPUT ACTIVATES OUTPUT DEACTIVATES

LAtCH

Latched Output Mode

When Count =

Setpoint

At Manual Reset

(if

SPt rSt=YES)

t-OUt

Timed Output Mode

When Count =

Setpoint

After Setpoint

Output Time-Out

bOUNd

Boundary Mode

When Count ≥

Setpoint

When Count

< Setpoint

LAtCH

t-OUt

bOUNd

SETPOINT OUTPUT ACTIONS

This parameter is only active if the Setpoint Action is set to time out (t-OUt).

Enter the value in seconds that the Setpoint will be active, once the Setpoint

Value is reached.

0.01 to 99.99 seconds

0 to 999

yESNO

ª

«

000

Pro CodE

ª

«

MO

FACt SEt

ª

«

Count A

SPt ASN

ª

«

LAtCH

SPt ACt

ª

«

01.00

SPt tOUt

USER INPUT

FUNCTION

USER INPUT

STATE

SECURITY

CODE

MODE WHEN “SEL”

KEY IS PRESSED

FULL PROGRAMMING

MODE ACCESS

0 Full Programming Immediate Access

not Pro Loc

______

1-99

Quick

Programming

After Quick Programming

with correct code entry

at

Pro CodE prompt *

100-999

Pro CodE prompt

With correct code entry

at

Pro CodE prompt *

0

Programming

Lock

No Access

Active

1-99

Quick

Programming

No Access

Pro Loc

100-999

Pro CodE prompt

With correct code entry

at

Pro CodE prompt *

Not Active 0-999 Full Programming Immediate Access

* Entering Code 222 allows access regardless of security code.

Page 11

11

6.5 MODULE 5 - SERIAL S

ETUP PARAMETERS

(

5-SERIAL)

SAVE will restore the output to the same state it was at before the meter was

powered down. ON will activate the output at power up. OFF will deactivate the

output at power up. This parameter is not active when the Setpoint Action is

selected for timed output mode.

SETPOINT OUTPUT POWER-UP STATE

When Counter Ais reset, it returns to zero or the Setpoint Value. When the Reset

Action is selected for to SPt (Reset to Setpoint), the output activates at zero.

Boundary Mode is only active when Programmed for to ZErO (Reset to Zero).

COUNTER A RESET ACTION

SETPOINT VALUE

Enter the desired Setpoint value. To enter a negative setpoint value,

increment digit 8 to display a “-” sign.

This automatically resets the display value of Counter A each time the

Setpoint Value is reached. The automatic reset occurs at output start or end. The

Out-End is only active when setpoint output action is selected for t-OUt.

COUNTER A AUTO RESET

Select yES, so the Setpoint output will deactivate (reset) when a manual reset

is applied to the meter. Manual reset can occur by the RST button or the User

Input, if programmed for that function. When the Setpoint Assignment,

(SPt ASN) is set to Count A, this parameter only applies to Count A reset.

SETPOINT OUTPUT RESET WITH MANUAL RESET

This parameter enables the backlight CUB5 to switch the backlight color when

the Setpoint Value is reached. A reset will revert the backlight color to the normal

operating mode color. This parameter is only active for the backlight version.

CHANGE DISPLAY COLOR w/SETPOINT OUTPUT STATE

Count A: -9999999 to 99999999

Rate: 0 to 999999

ª

«

00000100

SPt VAL

ª

«

OFF

SPt P-UP

ª

«

to ZErO

CmtA rSt

ª

«

NO

AUtO rSt

ª

«

YES

SPt rSt

ª

«

NO

Ch-COLOr

to SPtto ZErO

NO

Out-Strt

Out-End

NOYES

YESNO

OFF

ON

SAVE

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and workmanship for a period limited to two years

from the date of shipment, provided the products have been stored, handled, installed, and used under proper conditions. The

Company’s liability under this limited warranty shall extend only to the repair or replacement of a defective product, at The

Company’s option. The Company disclaims all liability for any affirmation, promise or representation with respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against damages, claims, and expenses

arising out of subsequent sales of RLC products or products containing components manufactured by RLC and based upon personal

injuries, deaths, property damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be to

any extent liable, including without limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and liability

imposed upon any person pursuant to the Magnuson-Moss Warranty Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those expressly contained herein.

The Customer acknowledges the disclaimers and limitations contained herein and relies on no other warranties or affirmations.

The Serial Setup Parameters are only active when the optional RS232 or RS485 serial communications module is installed in the meter. Refer to the CUB5COM

bulletin for complete details on CUB5 serial communications.

PARAMETER MENU

Page 12

CUB5 PROGRAMMING QUICK OVERVIEW

Shaded area selections are dependent on parameter mode selected.

Press and hold SEL key to

enter Programming Mode.

Loading...

Loading...