Page 1

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

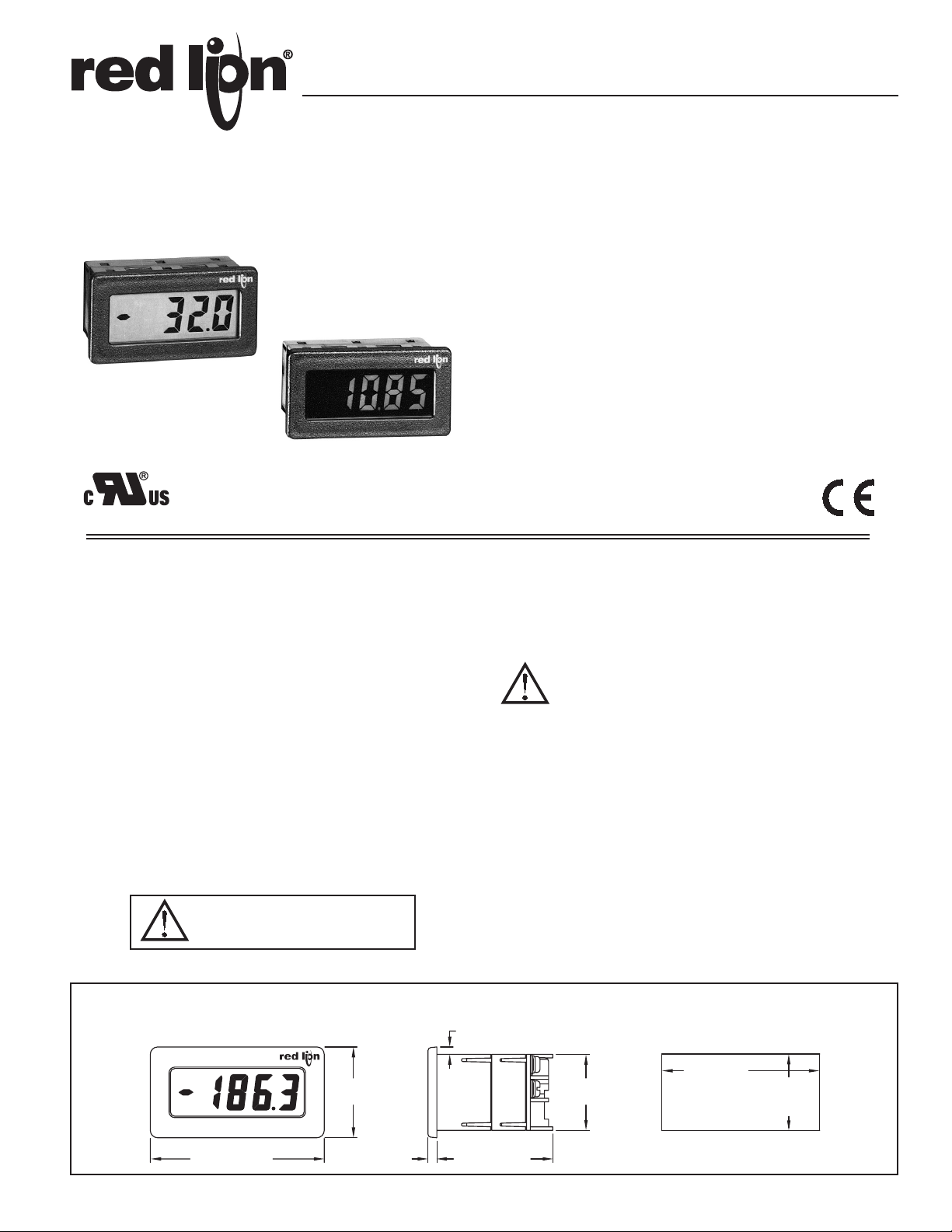

MODEL CUB4LP - LOOP POWERED PROCESS INDICATOR

MODEL CUB4CL - CURRENT LOOP INDICATOR

DUAL RANGE, 4 to 20 mA OR 10 to 50 mA

3½-DIGIT, 0.6" (15.2 mm) HIGH DIGITS

POSITIVE IMAGE TRANSFLECTIVE LCD WITH RED BACKLIGHT

OR POSITIVE IMAGE REFLECTIVE LCD (CUB4LP)

POSITIVE IMAGE TRANSFLECTIVE LCD WITH RED BACKLIGHT

OR NEGATIVE IMAGE TRANSMISSIVE WITH RED OR YELLOW/

GREEN BACKLIGHT (CUB4CL)

SPAN AND OFFSET CAPABILITY

NEGATIVE AND OVERRANGE INDICATION

SELECTABLE DECIMAL POINT POSITION

NEMA 4X/IP65 SEALED FRONT PANEL BEZEL

FITS DIN STANDARD CUT-OUT 2.68" (68 mm) X 1.30" (33 mm)

FOR USE IN HAZARDOUS LOCATIONS:

Class I, Division 2, Groups A, B, C, and D

Class II, Division 2, Groups F and G

Class III, Division 2

Bulletin No. CUB4LP-M

Drawing No. LP0318

Released 12/13

DESCRIPTION

The CUB4LP and CUB4CL are additions to the CUB4 product line. The

CUB4LP uses a 4 to 20 mA or a 10 to 50 mA input signal as operating power.

The input signal is also used to power the backlighting on the CUB4LP40 unit.

The CUB4CL uses a 4 to 20 mA or a 10 to 50 mA input signal to power the unit.

An external power supply is used to power the CUB4CL backlighting to provide

a brighter, more consistent display and a lower compliance voltage.

The units have a 3½-digit LCD display with 0.6" (15.2 mm) high digits and

a DIP switch selectable decimal point. The CUB4LP display is available in

positive image reflective (dark digits, reflective background) or positive image

transflective (dark digits, illuminated background) with red backlighting. The

CUB4CL display is available in positive image transflective (dark digits,

illuminated background) with red or yellow/green backlighting or negative

image transmissive (illuminated digits, dark background) with red or yellow/

green backlighting.

The ability to scale the display allows indication in any desired unit of

measurement such as temperature, pressure, humidity, fluid flow, etc. The unit

is calibrated at the factory with 0.0 displayed @ 4 mA input and 100.0 displayed

@ 20 mA input.

The units are contained in a lightweight, high impact plastic case with a clear

viewing window. When properly installed, the sealed front panel meets NEMA

4X/IP65 specifications for wash-down and dusty environments.

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

DIMENSIONS In inches (mm)

Note: Recommended minimum clearance (behind the panel) for

mounting clip installation is 2.15" (54.6) H x 3.00" (76.2) W.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

WARNING - EXPLOSION HAZARD - SUBSTITUTION

OF ANY COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2 / CLASS II, DIVISION 2 / CLASS III, DIVISION 2

SPECIFICATIONS

1. DISPLAY: 3½-digit (-1999 to 1999), 0.6" (15.2 mm) high digits.

The CUB4LP is available with a positive image reflective LCD or a red

backlit positive image transflective LCD. The intensity of the backlighting

will vary with the input signal.

The CUB4CL is available with a positive image transflective LCD with red

or yellow/green backlighting or a negative image transmissive with red or

yellow/green backlight.

A minus sign is displayed when the indicator is adjusted for a negative offset.

Overrange: Overrange is indicated by a “1” in the most significant digit and

the blanking of the three least significant digits.

2. EXTERNAL BACKLIGHT POWER: (CUB4CL only)

9 - 28 VDC, @ 35 mA typ., 50 mA max. Power Supplies must be Class 2

(NEC) or SELV rated. Above 26 VDC, derate the operating temperature to

50°C.

3. DECIMAL POINTS: Three DIP switch selectable, decimal point positions

allow the display to be read in tenths, hundredths or thousandths.

.13 (3.3)

PANEL CUT-OUT

2.95 (74.9)

1.54 (39.1)

+.025

2.68

-.000

1.29 (32.8)

+.8

(68 )

-.0

1.30

+.6

(33 )

-.0

+.024

-.000

1.96 (49.8).15 (3.8)

1

Page 2

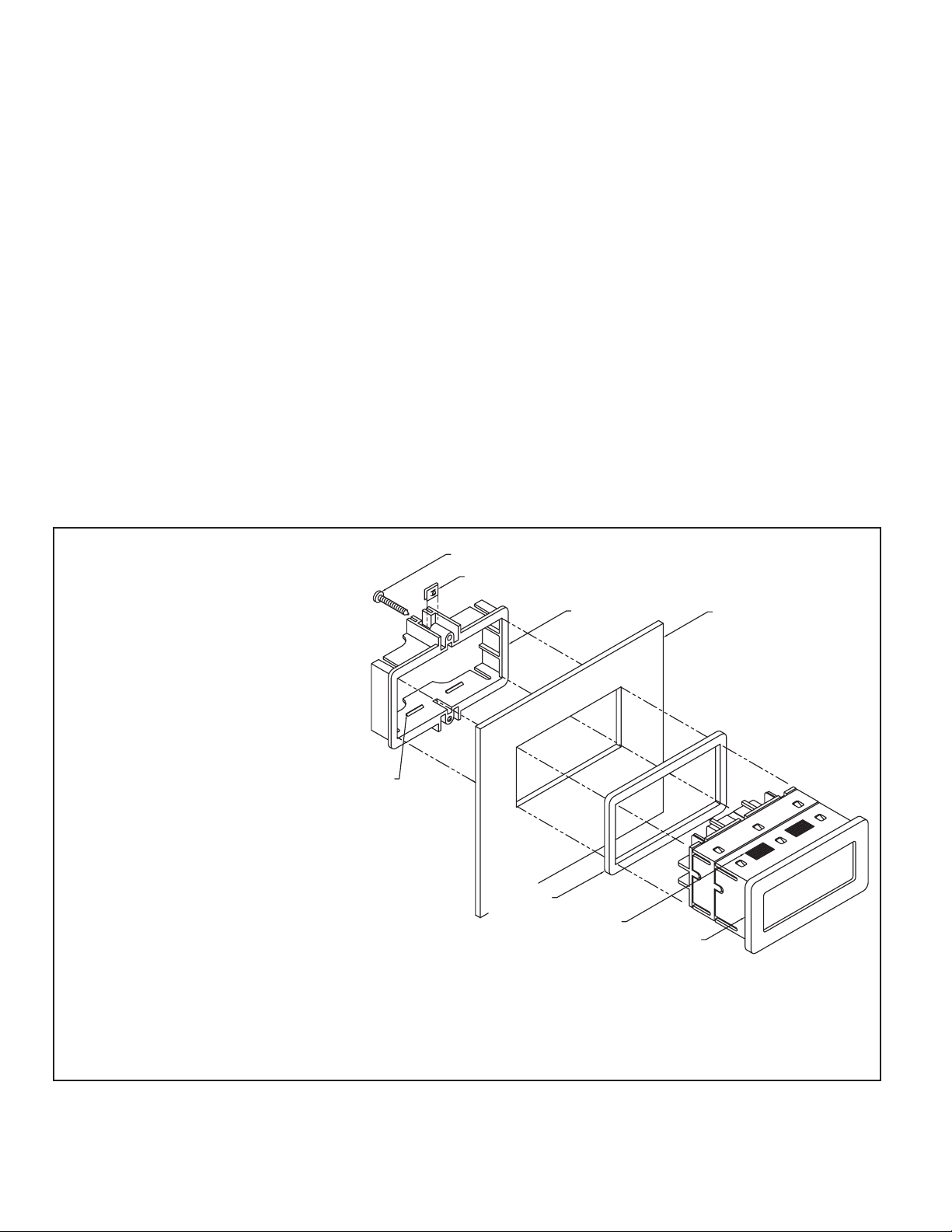

LATCHING

FEATURE

BEZEL

MOUNTING CLIP

NUT FASTENER

MOUNTING SCREW

GASKET

0.093" (2.4 mm)

THICK

LATCHING

FEATURE

EXISTING PANEL

.05" to .20"

(1.3 to 5.1mm)

THICK

SPECIFICATIONS (Cont’d)

4. MAXIMUM VOLTAGE DROP:

3.2 VDC for CUB4LP00

4.0 VDC for CUB4LP40

3.2 VDC for CUB4CL all models

5. EQUIVALENT RESISTANCE:

CUB4LP00: 800 Ω max. @ 4 mA; 160 Ω max. @ 20 mA

320 Ω max. @ 10 mA; 65 Ω max. @ 50 mA

CUB4LP40: 1000 Ω max. @ 4 mA; 200 Ω max. @ 20 mA

400 Ω max. @ 10 mA; 80 Ω max. @ 50 mA

CUB4CL (all models): 800 Ω max. @ 4 mA; 160 Ω max. @ 20 mA

320 Ω max. @ 10 mA; 65 Ω max. @ 50 mA

6. MAXIMUM ALLOWABLE INPUT CURRENT: 100 mA

7. SCALING RANGE:

Span: Two potentiometers provide a coarse and fine span adjustment. Span

range = 0 to 2000.

Offset: Two potentiometers provide a coarse and fine zero offset adjustment.

Offset range = -1999 to 1999.

8. LINEARITY: (@ 23°C, Less than 85% RH) ±(0.1% + 1 digit).

9. READING RATE: 2.5 per second, nominal.

10. RESPONSE TIME: 1.5 seconds to settle for a step change.

11. NORMAL MODE REJECTION: 60 dB 50/60 Hz

12. TEMPERATURE EFFECTS:

Span Temperature Coefficient: 100 PPM/°C

Offset Temperature Coefficient: 0.2 digits/°C

13. CONSTRUCTION: High impact plastic case with clear viewing window.

(Panel gasket and mounting clips included.) This unit is rated for NEMA 4X/

IP65 indoor use. Installation Category I, Pollution Degree 2

14. CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 Immunity to Industrial Locations

Emission CISPR 11 Class B

Safety requirements for electrical equipment for measurement, control, and

laboratory use:

EN 61010-1: General Requirements

RoHS Compliant

UL Hazardous: File #E184589

Type 4X Indoor Enclosure rating (Face only)

IP65 Enclosure rating (Face only)

Refer to the EMC Installation Guidelines of this bulletin for additional

information.

15. ENVIRONMENTAL CONDITIONS:

Operating Temperature: 0° to 60°C

(Derate backlight voltage to 26 VDC above 50°C.)

Storage Temperature: -40° to 80°C

Operating and Storage Humidity: 85% max. (non-condensing) from 0°C to

60°C.

Vibration to IEC 68-2-6: Operational 5 to 500 Hz, 5g

Shock to IEC 68-2-27: Operational 30 g

Altitude: Up to 2000 meters

16. WEIGHT: 3.3 oz. (93.5 g)

INSTALLATION

When properly installed, the CUB4LP/CL meets

NEMA 4X/IP65 requirements for indoor use. The

units are intended to be mounted into a suitably rated

enclosed panel. A sponge rubber gasket, mounting

clip, two screws, and nut fasteners are provided to

install and seal the unit in the panel cutout.

Installation Environment

The unit should be installed in a location that does

not exceed the maximum operating temperature and

provides good air circulation. Placing the unit near

devices that generate excessive heat should be

avoided.

The bezel should be cleaned only with a soft cloth

and neutral soap product. Do NOT use solvents.

Continuous exposure to direct sunlight may

accelerate the aging process of the bezel.

The following procedure assures proper installation:

1. Cut the panel opening to the specified dimensions.

Remove burrs and clean the panel opening.

2. Slide nut fastener into slot on mounting clip and then insert

mounting screw through nut on both sides of mounting clip. The

tip of mounting screw should not project through hole on clip.

3. Slide the panel gasket over the rear of the unit to the back of the bezel.

Install CUB4LP/CL unit through panel cutout.

4. Slide mounting clip over rear of unit until the clip is against back of panel.

The mounting clip and CUB4LP/CL housing have a latching feature to hold

the unit in place until tightened.

Note: Hold the CUB4LP/CL front bezel in place when sliding the mounting

5. Alternately tighten each mounting screw to ensure uniform gasket pressure.

Visually inspect the gasket for proper seal. The gasket should be compressed

to approximately 75 to 80% of its original thickness.

(Recommended torque is 28 to 36 in-oz.)

clip into position.

6. If the gasket is not adequately compressed and the mounting screws cannot

be tightened any further, loosen the mounting screws and insure that the clip

is latched as closely as possible to the panel.

7. Repeat Step #6 for tightening the mounting screws.

2

Page 3

EMC INSTALLATION GUIDELINES

Although Red Lion Controls Products are designed with a high degree of

immunity to Electromagnetic Interference (EMI), proper installation and wiring

methods must be followed to ensure compatibility in each application. The type

of the electrical noise, source or coupling method into a unit may be different

for various installations. Cable length, routing, and shield termination are very

important and can mean the difference between a successful or troublesome

installation. Listed are some EMI guidelines for a successful installation in an

industrial environment.

1. A unit should be mounted in a metal enclosure, which is properly connected

to protective earth.

2. Use shielded cables for all Signal and Control inputs. The shield connection

should be made as short as possible. The connection point for the shield

depends somewhat upon the application. Listed below are the recommended

methods of connecting the shield, in order of their effectiveness.

a. Connect the shield to earth ground (protective earth) at one end where the

unit is mounted.

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is over 1 MHz.

3. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors, feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run through metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter. Also, Signal or Control cables within

an enclosure should be routed as far away as possible from contactors, control

relays, transformers, and other noisy components.

4. Long cable runs are more susceptible to EMI pickup than short cable runs.

5. In extremely high EMI environments, the use of external EMI suppression

devices such as Ferrite Suppression Cores for signal and control cables is

effective. The following EMI suppression devices (or equivalent) are

recommended:

Fair-Rite part number 0443167251 (RLC part number FCOR0000)

Line Filters for input power cables:

Schaffner # FN2010-1/07 (Red Lion Controls # LFIL0000)

6. To protect relay contacts that control inductive loads and to minimize radiated

and conducted noise (EMI), some type of contact protection network is

normally installed across the load, the contacts or both. The most effective

location is across the load.

a. Using a snubber, which is a resistor-capacitor (RC) network or metal oxide

varistor (MOV) across an AC inductive load is very effective at reducing

EMI and increasing relay contact life.

b. If a DC inductive load (such as a DC relay coil) is controlled by a transistor

switch, care must be taken not to exceed the breakdown voltage of the

transistor when the load is switched. One of the most effective ways is to

place a diode across the inductive load. Most RLC products with solid state

outputs have internal zener diode protection. However external diode

protection at the load is always a good design practice to limit EMI.

Although the use of a snubber or varistor could be used.

RLC part numbers: Snubber: SNUB0000

Varistor: ILS11500 or ILS23000

7. Care should be taken when connecting input and output devices to the

instrument. When a separate input and output common is provided, they

should not be mixed. Therefore a sensor common should NOT be connected

to an output common. This would cause EMI on the sensitive input common,

which could affect the instrument’s operation.

Visit RLC’s web site at http://www.redlion.net/Support/InstallationConsiderations.

html for more information on EMI guidelines, Safety and CE issues as they

relate to Red Lion Controls products.

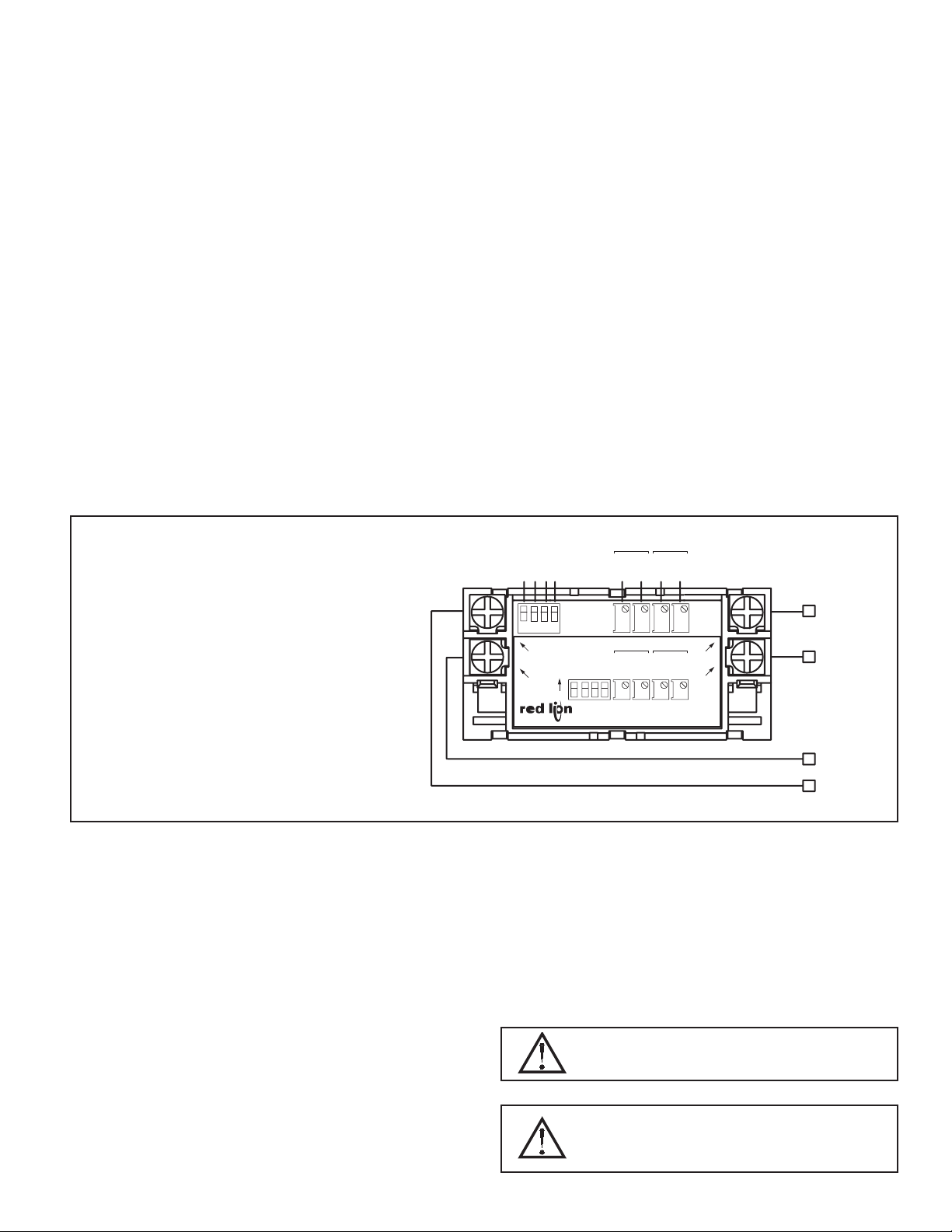

WIRING CONNECTIONS

All conductors should meet voltage and current ratings for

each terminal. Also cabling should conform to appropriate

standards of good installation, local codes and regulations. It is

recommended that power supplied to the unit (AC or DC) be

protected by a fuse or circuit breaker.

The electrical connections are made via screw-clamp terminals

located on the back of the unit. When wiring the unit, use the

label to identify the wire position with the proper function. Strip

the wire, leaving approximately ¼" of bare wire (stranded wires

should be tinned with solder). Insert the wire into the screwclamp terminal and tighten the screw until the wire is clamped

tightly. Each terminal can accept up to two #14 AWG wires.

CUB4LP/CL SIGNAL INPUT

The current range is selected by setting DIP switch S1 to the OFF position

for a 4 to 20 mA input or ON for a 10 to 50 mA input. Attach the signal wires

to terminals 3 (SIG-) and 4 (SIG+) observing the correct polarity. The (SIG-)

signal input circuit is not reverse polarity protected.

Backlight Power (CUB4CL only)

Attach a 9 to 28 VDC supply to terminals 1 (COM) and 2 (V+) to power the

backlight. Terminals 3 (SIG-) and 1 (COM) are AC coupled with a capacitor.

This limits the isolation between these terminals to 50 VDC maximum.

SPANOFFSET

COARSE

FINE

COARSE

0.0

0.00

0.000

10-50

1

2

34

CUB4LP/CL

3

SIG.-

ON

1 COM

(CL)

0.000

0.00

0.0

10-50

RED LION CONTROLS

YORK, PA.

COARSE

4321

MADE IN U.S.A.

FINE

SIG +

4

(SENSOR)

SPANOFFSET

FINE

4

SIG.+

COARSE

FINE

2

V+

(CL)

M1721C

2

1

3

VDC +

(CL ONLY)

COM

(CL ONLY)

SIG (SENSOR)

SPAN ADJUSTMENTS

Span is defined as the numerical range that the display traverses, disregarding

the decimal point, when the input signal is varied from minimum to maximum

(4 to 20 mA or 10 to 50 mA). For example; if a unit is to display 250 @ 4 mA

and 1000 @ 20 mA, the span is 750 (the difference between 250 and 1000). Had

the minimum display been -250, the span would be 1250 (1000 - (-250) = 1250).

The CUB4LP/CL can be set to operate over a wide span range by adjusting the

Coarse and Fine Span adjustment pots. The Coarse Span pot is used to get the

display to within a couple of counts of the desired reading, and the Fine Span

pot is used to adjust for the exact reading.

OFFSET ADJUSTMENTS

The minimum currents are not zero based with 4 to 20 mA and 10 to 50 mA

signals. To obtain a zero minimum display reading, the display must be offset.

The display on the CUB4LP/CL can be offset by adjusting the Coarse and Fine

Offset pots.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF

OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS EQUIPMENT IS SUITABLE FOR USE IN:

Class I, Division 2, Groups A, B, C, and D

Class II, Division 2, Groups F and G

Class III, Division 2 or Non Hazardous locations.

3

Page 4

DECIMAL POINT POSITION SELECTION

The decimal point position is DIP switch selectable for one of three locations.

The CUB4LP/CL can be set up to read in 10ths, 100ths, or 1000ths. If all the

DIP switches are set to the “OFF” position, no decimal point will appear on the

display. The DIP switches are located at the rear of the unit.

APPLICATION EXAMPLE

Operation of a refinery process required a local display of the position of a

remote pipeline valve. The display would indicate 0 (zero) when the valve was

fully closed with an input signal of 4 mA. When the valve was fully open the

display would indicate 100 with an input signal of 20 mA.

Both the CUB4LP and the CUB4CL meet the necessary requirements.

CALIBRATING THE DISPLAY

Calibrating the CUB4LP/CL requires either an accurate adjustable constant

current supply or the CUB4LP/CL can be installed and scaled with the process

sensor connected to the CUB4LP/CL. To calibrate the unit, proceed as follows.

1. Set DIP switching for the desired current range.

2. Select the desired decimal point position.

3. Apply the minimum input signal to the CUB4LP/CL and adjust the COARSE

OFFSET to display the approximate desired minimum value.

4. Apply the maximum input signal to the CUB4LP/CL and adjust the COARSE

SPAN to display the approximate desired maximum value.

5. Repeat steps 3 and 4 until the minimum and maximum values are within the

desired values.

6. Apply the minimum input signal to the CUB4LP/CL and adjust the FINE

OFFSET to display the exact desired minimum value.

7. Apply the maximum input signal to the CUB4LP/CL and adjust the FINE

SPAN to display the exact desired maximum value.

8. Apply the minimum input signal and verify that the display indicates

correctly.

9. Apply the maximum input signal and verify that the display indicates

correctly.

10. Repeat Steps 6 through 9 until display reads exact.

Note: The CUB4LP/CL display is factory calibrated to indicate 0.0 to 100.0

with an input of 4 to 20 mA at approximately 25°C.

COM

(CL ONLY)

+VDC

(CL ONLY)

SIG-

Connection for

CUB4LP40

SIG+

DEVICE

1

2

3

4

++

-

SIG +

COMM

(SIG -)

CUB4LP

VALVECONTROL

-

BLOCK DIAGRAM

BACKLIGHT

FINE

0.1 µf

OFFSET

12.7Ω

50 VDC

S1

8.25Ω

COARSE

SPAN

COARSE

OFFSET

FINE

SPAN

PROCESS

GND

-V

CIRCUITRY

+V

S4 S3 S2

TROUBLESHOOTING

For further technical assistance, contact technical

support at the appropriate company numbers listed.

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

NL - 3821 BN Amersfoort

Fax +31 (0) 334 893 793

Red Lion Controls

Europe

Softwareweg 9

Tel +31 (0) 334 723 225

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBERS

Reflective LCD Loop Powered Process Indicator CUB4LP00

CUB4LP

CUB4CL

MLPS

*Backlight intensity will vary depending on signal level.

201-B, 2nd Floor, Park Centra

Opp 32 Mile Stone, Sector-30

Gurgaon-122002 Haryana, India

Red Backlit LCD Loop Powered Process Indicator

Positive Image Transflective LCD

Yel/Grn Backlit LCD External Powered Process

Indicator Negative Image Transmissive LCD

Red Backlit LCD External Powered Process

Indicator Negative Image Transmissive LCD

Yel/Grn Backlit LCD External Powered Process

Indicator Positive Image Transflective LCD

Red Backlit LCD External Powered Process

Indicator Positive Image Transflective LCD

Micro Line/Sensor Power Supply

(Non-hazardous use only)

Red Lion Controls

India

Tel +91 984 487 0503

*CUB4LP40

CUB4CL10

CUB4CL20

CUB4CL30

CUB4CL40

MLPS1000

Red Lion Controls

Unit 302, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113 3688

Fax +86 21 6113 3683

China

Loading...

Loading...