Page 1

COMMERCIAL MIXERS

R

MODEL:GEM120

INSTRUCTION MANUAL

3355 Enterprise Avenue, Suite 160

Fort Lauderdale, Florida 33331

Tel: 954.202.7419 Fax: 954.202.7337

www.asburyfoodservice.com

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE USING YOUR MIXER

Page 2

GEW120 Mixer Operation Instruction edition a

GEW120 Mixer Operation Instruction

Index

1、 General Description ……………………………………………………………. 1

2、 Technical parameters …………………………………………………………. 2

3、 Main External Parts of Mixer …………………………………………………… 3

4、 Operation Instruction ……………………………………………………………. 3

5、 Accessories and Functions ………………………………………………………. 4

6、 Notes …………………………………………………………………………….. 4

7、 Maintenances ……………………………………………………………………. 5

8、 Problems and solutions ………………………………………………………….. 5

9、 exploded assembly drawing ……………………………………………………... 5

10、 electrical diagram ………………….…………………………………………… 7

11、 list of part number …………………….………………………………………. 8

1、General Description

This is a kind of three-speed gear mixer. With its planetary stirring design, it

has a compact structure, high efficiency, power saving and easy operation. It will

be provided to you as an ideal assistant for bread and cake making.

1 of 9

Page 3

GEW120 Mixer Operation Instruction edition a

2、Technical parameters

Name Barrel

Volume

(L)

SM-20 20 1.1 102 108 195 355

Power

(KW)

Weight

(Kg)

Speed Of Stirring Shaft

(r/min)

st

1

Speed

2ndSpeed 3

rd

Speed

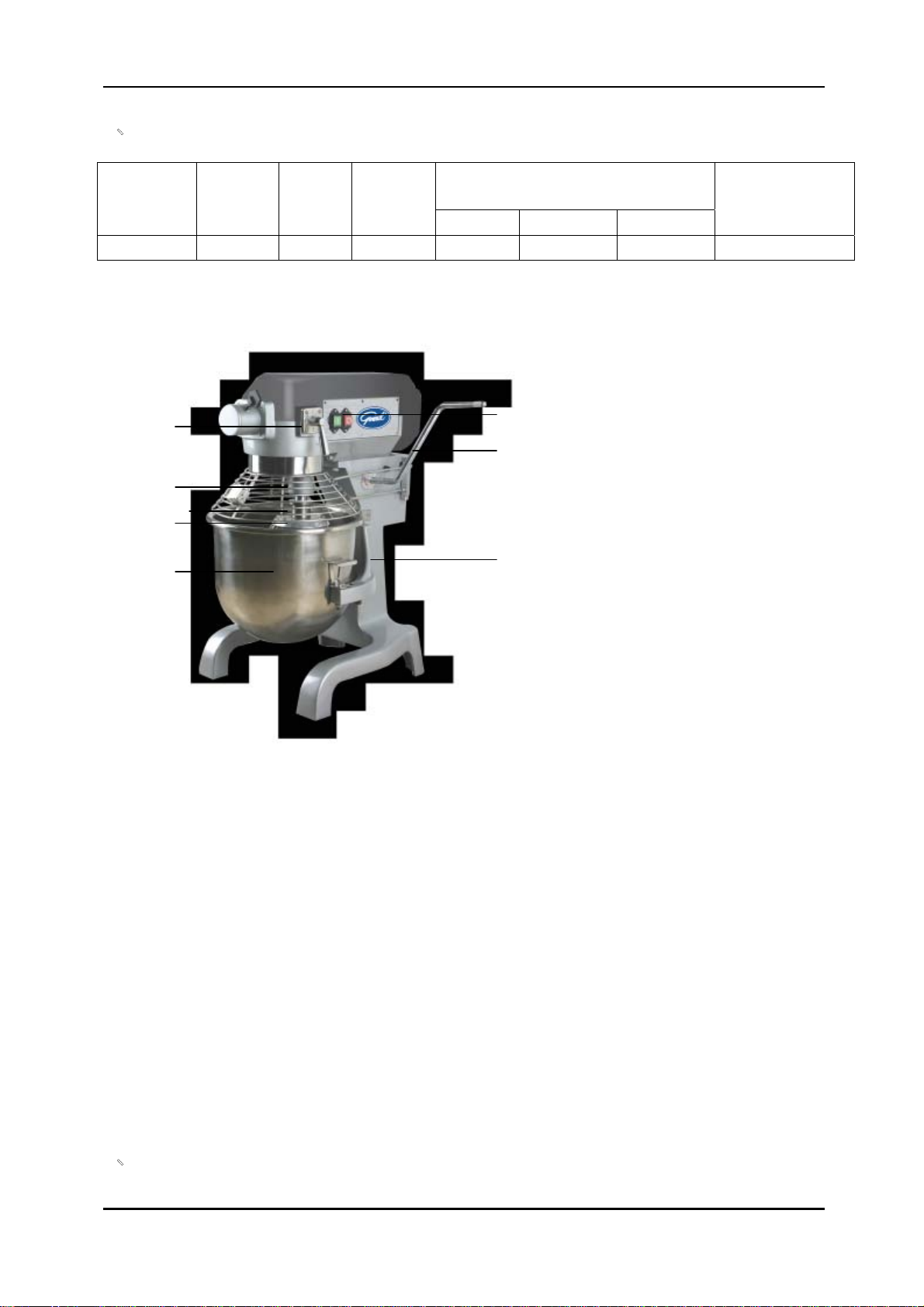

3、Main External Parts of Mixer

⑤

①

⑥

②

③

④ ⑦

Overall

Dimensions

(mm)

560×530×800

① Gear change hand lever

② Stirring shaft

③ Mixer

④ Stainless bowl

⑤ Power switch

⑥ Bent lever

⑦ Support

4、

Operation Instruction

2 of 9

Page 4

GEW120 Mixer Operation Instruction edition a

① Standard power supply 110V/60Hz AC.(Please use a plug with 3 wide

contacts and good grounding.)

② Installation of Mixer: Put the stirring shaft 2 in Mixer 3 and rotate it in

clockwise direction.

③ Starting procedure: Pull the gear change hand lever 1 to position 1 before

staring, Safe hood is in closed state. Then turn on the power switch 5, after

the mixer is in normal operation, set the speed required.

④ Speed transformation: If you want to change the speed, please pull the

bent lever 6 to the lowest point ,after pull the gear change hand lever 1 to the

position required, then pull the bent lever 6 to the highest point and lift the

support 7 to the highest position. The machine can be in normal operation at

this time.

⑤Installation procedures for meat Mincer head: stop operation first ,loose

stud bolt and lift the top cover of its head. Then put on the mincer and tighten

st

the stud bolt.1

speed should be used for mincing meat.

⑥Shutting down: When the operation is completed, turn off the power switch

5 first, then pull the gear change hand lever 1 to position 1, and pull back the

hand lever 6 to the lowest point and finally disconnect power supply.

5、Accessories and Functions

① Spherical mixer: Used for stirring of liquid materials, such as cream and

egg.

② Plate mixer: Used for stirring of paste, powder, and fragmental materials,

3 of 9

Page 5

GEW120 Mixer Operation Instruction edition a

such as stuffing.

③ Hook mixer: Used for stirring of more sticky materials, such as dough .

6、Notes

① The power socket must be provided with a good ground wire to guarantee

the mixer’s good grounding through it. There will be a electric shock if no

ground wire or an improper grounding mounted. The ground wire can never

be connected with gas pipe, water pipe, lightning rod or telephone line.

Electric leakage should be checked after installation.

② Don’t put your hand into the stirring barrel during operation. Power

supply should be disconnected before the mixer is going to be installed.

③ Don’t operate the mixer beyond the time limit to prevent reduction of its

service life.

④ The mixer should be mounted on a stable and clean place. Keep it away

from overheated or over wet places and away from equipment which has

strong electromagnet or can produce strong electromagnet.

⑤ Keep the machine clean constantly. Disconnect power supply before

maintenance. Clean it with a piece of soft and a bit wet cloth. Don’t clean it

with liquid or spraying detergent.

*** Warning: Do not use medium or high speed for kneading dough.

7、 Maintenances

a. After using, you should clean the bowl and agitator ect, make sure to keep the

4 of 9

Page 6

GEW120 Mixer Operation Instruction edition a

machine clean.

b. The transmission gear box is packed with special grease, it could be used for

six mouths in normal condition. If it need to add or replace the grease, please

open the top cover , then pour the grease from aperture or replace the grease

directly.

8、Problems and solutions

Problems Causes Solutions

The mixing shaft doesn’t rotate

after starting the machine

Oil leakage The oil seals are worn

The temperature of the motor

becomes higher and the

rotating speed becomes lower

Electric connectors are

loose

out

Too low voltage

Over-load Lessen the quantity

The speed of mixing is

too high or the mixing is

not suitable

Check the electric

circuit, tighten those

loose connects

Replace those oil

seals

Check the power

supply

of the mixture

Select a suitable

speed and mixing

The mixing knocks with the

bowl

The noise of the gearbox is

serious, its temperature is too

The mixing or the bowl

is deformed

Lubrication is

insufficient

repair or replace the

mixing or bowl

Add or replace the

grease

high

9. exploded assembly drawing

5 of 9

Page 7

GEW120 Mixer Operation Instruction edition a

6 of 9

Page 8

GEW120 Mixer Operation Instruction edition a

10. electrical diagram

A1

A2

7 of 9

Page 9

GEW120 Mixer Operation Instruction edition a

11. list of part number

GEW120 Planetary Mixer Spare Parts List

# PART # DESCRIPTION

SM20-01-19 COVER

1

GB54 NUT

2

GB97.1 CLAMP PLATE

3

SM20-01-15

4

Pressing plate 45

REMARK

43

44

# Part # DESCRIPTION

42

SM20-01-06

GB119

SM20-DQ-09

SM20-01-02

WORM WHEEL

SPRING

MOTOR

BACK CASING

TRANSMISSION

SM20-01-07

5

SM20-01-14 SPACER-LOWER

6

SM20-01-13

7

SUPPORT

Taper gear wheel 1

46

47

SM20-01-01

SM20-01-25

BACK COVER

PLUG ATT ACHMENT HUB

48 SM20-01-38 PLUG

SM20-01-18

-01

8

tooth GEAR

49 SM20-01-24 ATTACHMENT HUB

SM20-01-18

-02

9

GEAR

10 SM20-01-20 GEAR

SM20-01-21 BUSHING

11

SM20-01-22 SLEEVE

12

SM20-01-16 MAIN SHAFT

13

54

50 SM20-01-26 RING

51 SM20-01-23 PINION

SM20-01-30

52

53

SM20-01-32

SM20-01-34

GEAR BOX

INTERNAL GEAR

DRIP RING

PLUNGER-SHIFTER

SM20-01-44

14

SM20-01-43 SPRING

15

SM20-01-42 RETAINER-SPRING

16

SM20-01-21 BUSHING

17

201 BEARING

18

19

SM20-01-09 SHAFT WORM GEAR

20

SM20-01-08 GEAR

201 BEARING

21

YOKE

57

61

22 SM20-01-27 Claw type gear wheel 63

55 SM20-06-01 BEATER

56 SM20-04-00 BOWL

GB591.1

SM20-01-33

58

203

59

SM20-01-35

60

SM20-01-36

204

62

HG4-692

WASHER

GEAR

BEARING

PLANETARY

WORKING SHAFT

BUSHING

OIL SEAL

SM20-01-39-

205 BEARING

23

HG-692 OIL SEAL

24

64

65

01 CAM-GEAR SHIFTER

SM20-01-39-

02

PLATE-SHIFTER

INDEX

SM20-01-39-

GB54 NUT

25

GB54 NUT

26

201 BEARING

27

28 SM20-06-02 Wire Whip

SM20-01-11 GEAR

29

SM20-01-05 BUSHING

30

SM20-01-04 GEAR

31

201 BEARING

32

66

04 HANDLE-SHIFTER

SM20-05-01

67

SM20-05-12

68

SM20-05-11

69

SM20-05-13

70

GB97.1

71

GB97.1

72

SM20-05-10

73

PEDESTAL

ARM-BOWL LIFT

ROD-BOWL LIFT

LIFT HANDLE

SPRING

WASHER

WASHER

8 of 9

REMARK

Page 10

GEW120 Mixer Operation Instruction edition a

33 SM20-06-03 HOOK

PLUNGER-SHIFTER

SM20-01-44

34

SM20-01-43 SPRING

35

SM20-01-42 RETAINER-SPRING

36

SM20-01-41 SHIFTING YOKE

37

SM20-01-40

38

GB6171 NUT

39

YOKE

DECLUTCH SHIFT

SHAFT

40 SM20-01-12 GEAR SHAFT

SM20-01-03 CASE

41

electrical

GB6171

74

SM20-05-05

75

76

SM20-05-06 BASE

203

77

78 SM20-03-00 SAFETY GUARD

SM20-3-05-07Z

79

Z

SM20-3-05-07Z

80

Y

81

101(

1\2\3

) SM20-DQ-01

102(

10) SM20-DQ-02

103(

7) SM20-DQ-03

104(

8)

SM20-DQ-04

105(

8) SM20-DQ-05

106(

4) SM20-DQ-06

107(

5)

SM20-DQ-07

108(

6) SM20-DQ-08

RING

BOWL SUPPORT

BEARING

Bowl locker, left

Bowl locker, right

Back cover, electrical

Distance switch

Power cord

Contact switch

Green button

Red button

Overload switch

Capacitor 300uf

Capacitor 40 uf

9 of 9

Loading...

Loading...