Page 1

OPERATOR'S MANUAL

General Description

3

Cleaning

4

Electrical Requirements

7

Maintenance

11

Parts Replacement

and Service

12

MODEL ES12L SLICER

INTRODUCTION

The Model ES12L Slicer is designed for counter top use. It slices boneless products such as ham, poultry, beef and

cheese to desired thickness.

IMPORTANT: READ THIS MANUAL BEFORE USING THE SLICER.

It is important to read this manual thoroughly before using the slicer. This will help you obtain the full benefits of the

quality, convenience and safety built into this product. Used and maintained according to the following instructions,

the slicer will provide years of trouble-free service. Keep this booklet in a convenient location for future reference.

Safety

Unpacking 4

2

Operation 8

Lubrication 10

Page 2

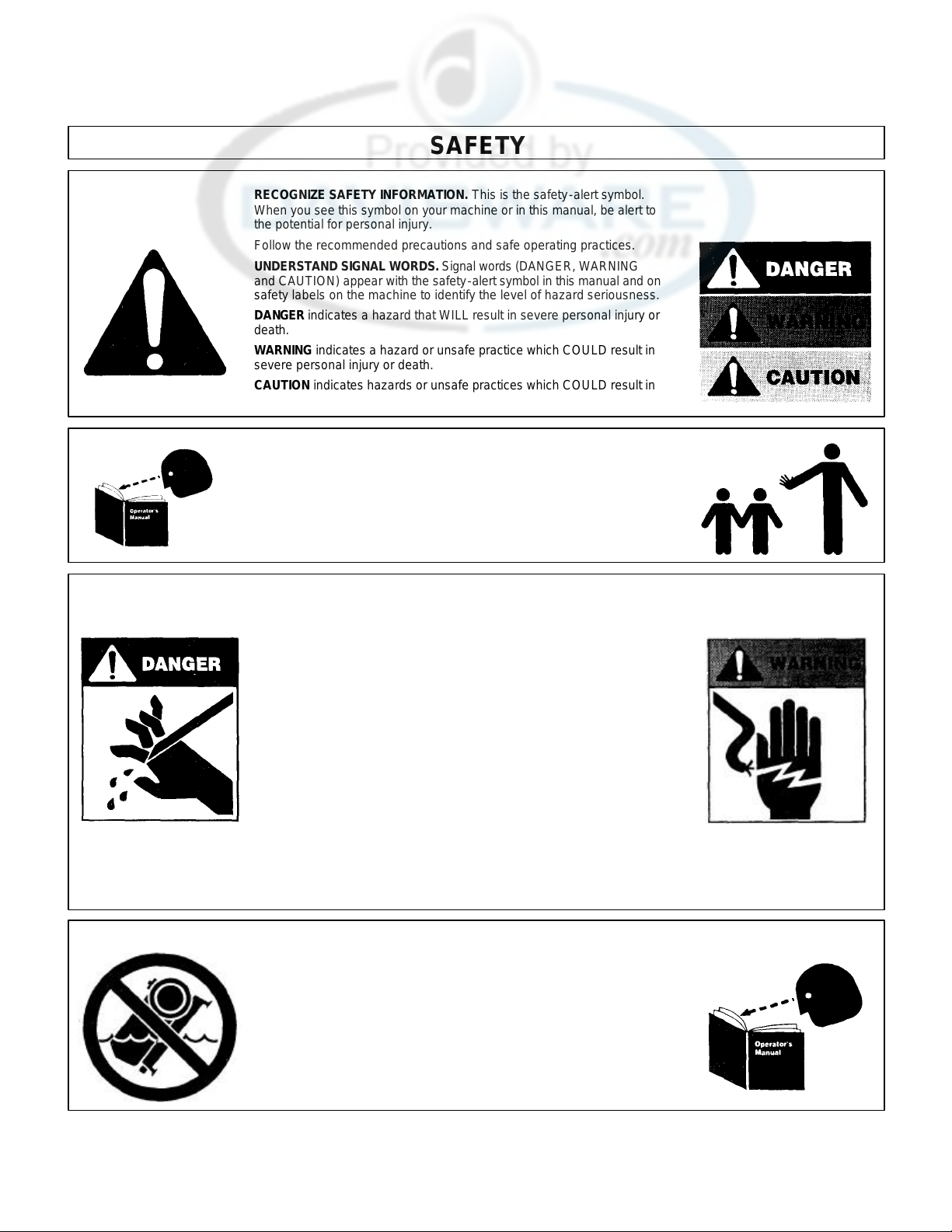

SAFETY

RECOGNIZE SAFETY INFORMATION. This is the safety-alert symbol.

When you see this symbol on your machine or in this manual, be alert to

the potential for personal injury.

Follow the recommended precautions and safe operating practices.

UNDERSTAND SIGNAL WORDS. Signal words (DANGER, WARNING

and CAUTION) appear with the safety-alert symbol in this manual and on

safety labels on the machine to identify the level of hazard seriousness.

DAN GER indicates a hazard that WILL result in severe personal injury or

death.

WARNING indicates a hazard or unsafe practice which COULD result in

severe personal injury or death.

CAUTION indicates hazards or unsafe practices which COULD result in

minor personal injury or equipment damage.

READ ALL INSTRUCTIONS

Read this operator's manual before using the machine. Failure to follow

the instructions provided could result in personal injury or equipment

damage.

KEEP OUT OF REACH OF CHILDREN

This slicer is intended for commercial use only.

DO NOT OPERATE WITHOUT KNIFE COVER. Do not turn the machine

on unless the knife cover is in place.

DO NOT FEED FOOD BY HAND. Always use the foodpusher.

KEEP HANDS AWAY FROM KNIFE. Never touch the knife with your hand.

DO NOT CATCH FOOD WITH YOUR HANDS. Let sliced food fall onto the

receiving area.

DO NOT OPERATE IF DAMAGED. Do not operate this slicer with a

damaged cord or plug, or if the slicer has been dropped or damaged in any

manner. Contact the nearest factory-authorized service center for

examination, repair or adjustment. (Refer to the service center list included

in the Owner's Information Packet.)

Do not allow the cord to touch hot surfaces. Do not allow the cord to hang

over the edge of a table or counter.

DO NOT LEAVE SLICER UNATTENDED. Never leave the slicer

unattended while the unit is operating.

UNPLUG SLICER. Set the regulator knob to "0" and unplug the slicer from

the outlet when not in use, before cleaning or removing jams, and before

attaching or removing this knife sharpener.

DO NOT IMMERSE

Do not place the slicer in water or any other liquid.

ATTACHMENTS

Do not use attachments not recommended by the manufacturer.

Follow the manufacturer's instructions for use of attachments.

SAVE THESE INSTRUCTIONS

Keep this manual in a convenient location for future reference.

2

Page 3

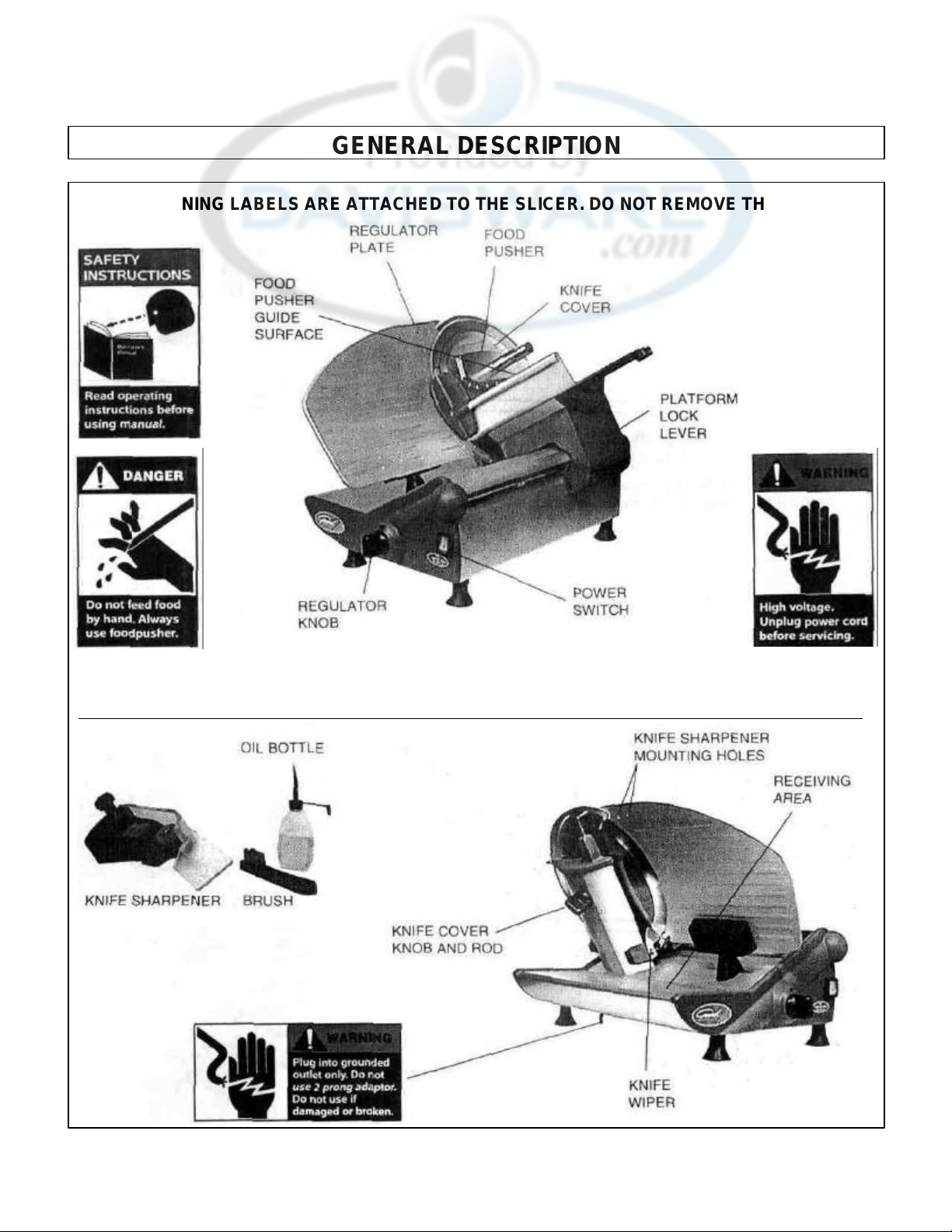

GENERAL DESCRIPTION

THESE WARNING LABELS ARE ATTACHED TO THE SLICER. DO NOT REMOVE THEM.

3

Page 4

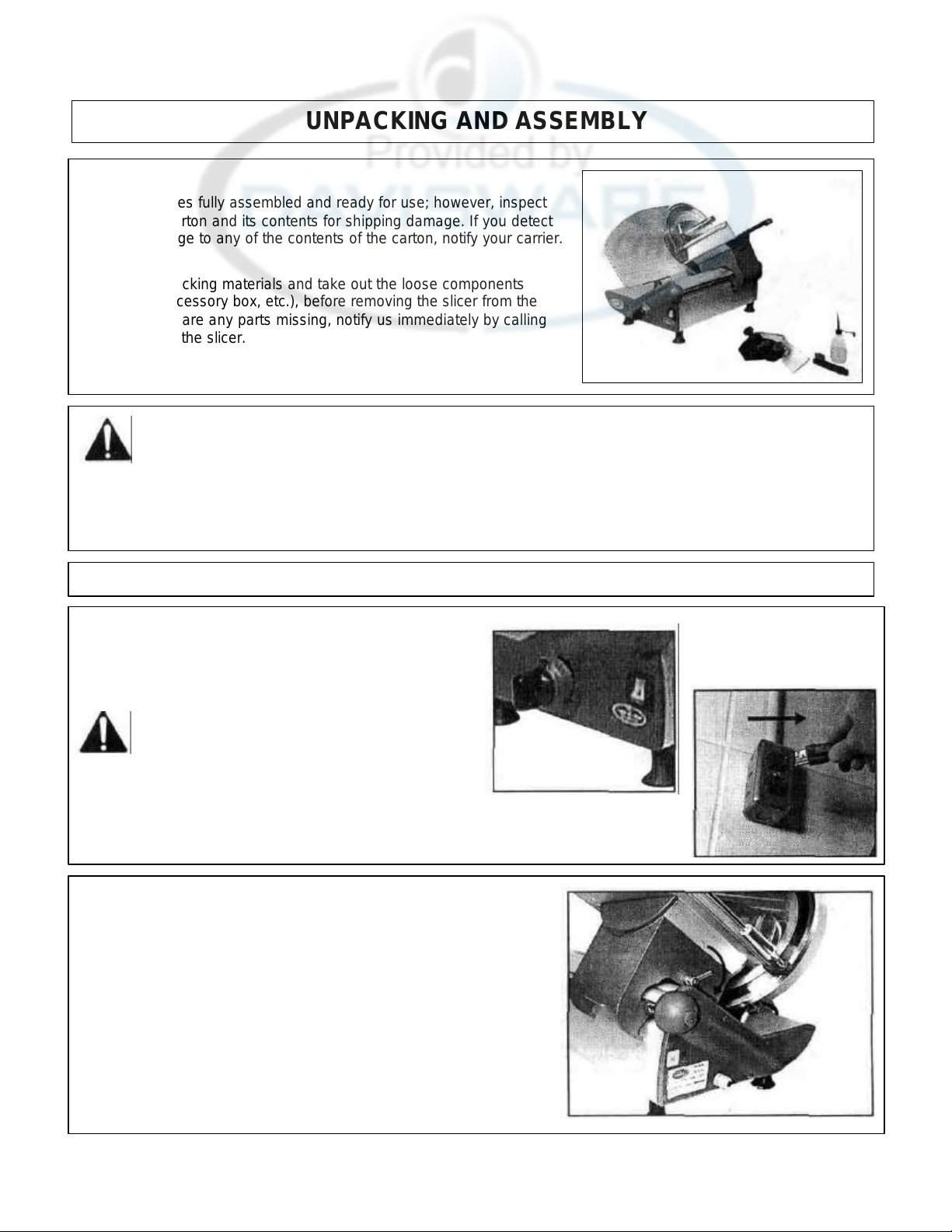

UNPACKING AND ASSEMBLY

UNPACKING

The slicer comes fully assembled and ready for use; however, inspect

the shipping carton and its contents for shipping damage. If you detect

shipping damage to any of the contents of the carton, notify your carrier.

Remove the packing materials and take out the loose components

(sharpener, accessory box, etc.), before removing the slicer from the

carton. If there are any parts missing, notify us immediately by calling

the number on the slicer.

CAUTION: The slicer should be installed on a level counter

top strong enough to safely support its weight.

The slicer should be thoroughly cleaned and sanitized (See below) before using to

ensure sanitary conditions.

CLEANING

Clean and sanitize the slicer before using the first time,

after each use, and before slicing different types of food

products. Follow company, local, and state

health/sanitation codes.

WARNING: Set the regulator knob to "0" and

unplug the slicer before cleaning or handling.

Do NOT use caustic or abrasive cleaners.

Do NOT spray cleaning materials or water toward the

power switch, the regulator knob, or the openings of the

machine.

DISASSEMBLY FOR CLEANING

Platform Assembly

1. Rotate cam lock lever clockwise.

4

Page 5

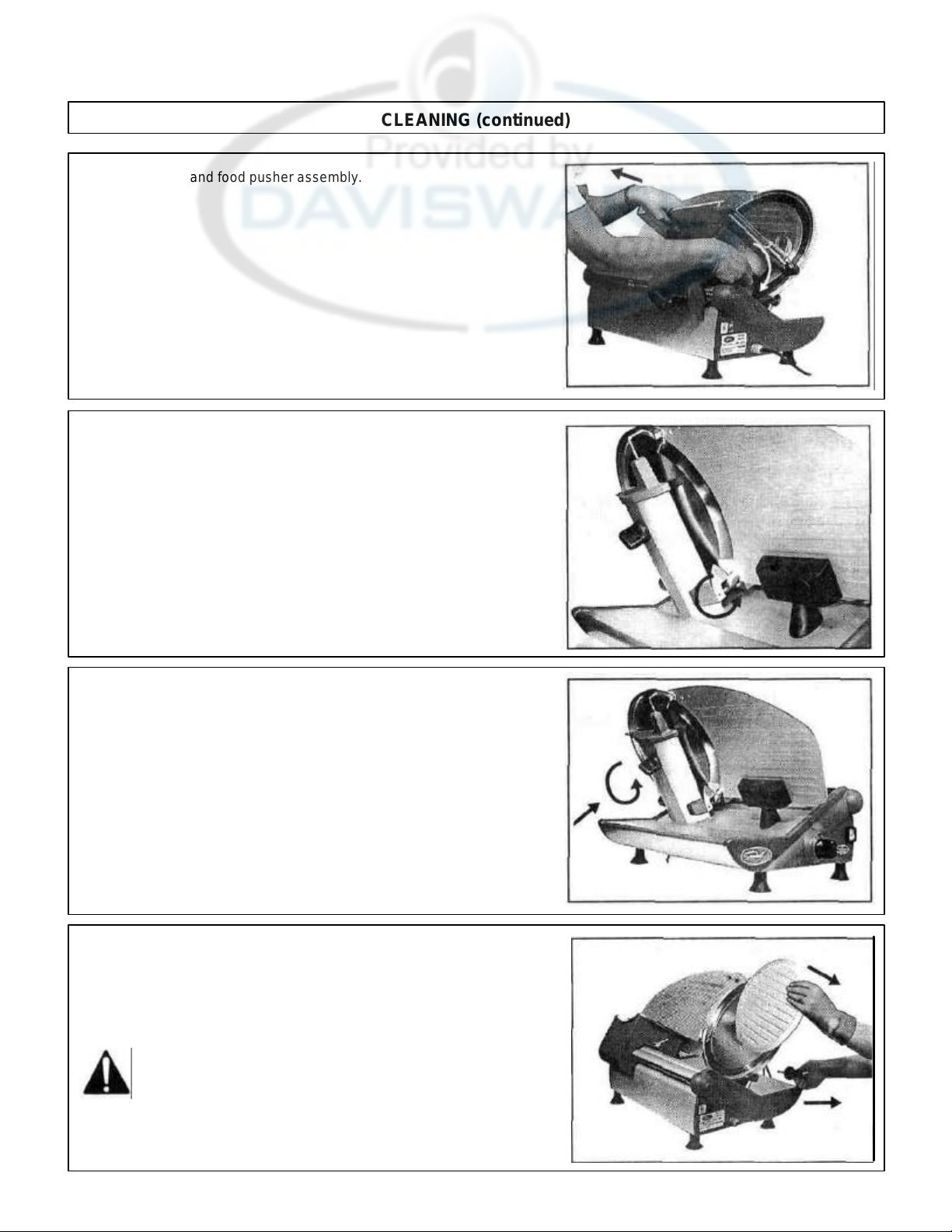

2.

Pull off platform and food pusher assembly.

CLEANING (continued)

Knife Wiper

1. Remove the thumbscrew by turning counter-clockwise.

2. Remove the knife wiper.

Knife Cover

1. Loose n the knife cover knob and rod assembly by turning it 2 turns

counter-clockwise.

2. Push the knob and rod assembly in against the knife cover to dislodge it.

3. Support the knife cover with the left hand.

4. Unscrew and remove the knob and rod assembly by continuing to turn it

counter-clockwise.

5. Remove the knife cover.

CAUTION: Always use protective cut -resistant gloves when

knife is exposed.

5

Page 6

CLEANING (continued)

WASH ALL SURFACES

1. Clean all surfaces and parts of the slicer with hot, soapy water and a

clean cloth.

2. Clean the foodpusher shaft to remove food juices and ensure smoot h

operation.

3. Clean the knife front and back with hot, soapy water and a clean cloth

by wiping outward from the center.

REASSEMBLY

Knife Wiper

1. Re-install the knife wiper by positioning it as close to the knife as

possible (the wiper should not touch the knife). Replace and

tighten the thumbscrew.

Knife Cover

1. Re-install the knife cover by positioning the space on the back

of the knife cover in the center of the knife hub.

Note: The grooves on the front of the knife cover should be

horizontal, as on the regulator plate.

2. Replace the knob and rod assembly, and tighten by turning it

clockwise.

6

Page 7

2.

Rotate cam lock level counter

-

clockwise until tight.

CLEANING (continued)

Platform Assembly

1. Slide on platform and food pusher assembly until positive stop is

reached.

ELECTRICAL REQUIREMENTS

Use a properly grounded three-prong outlet to reduce the hazard of

electrical shock.

The slicer should be placed close enough to the electrical power supply

so that an extension cord will not be needed. It is designed to be used

on 115 Volt, A.C., 60 Hz power source, as indicated on the Data Plate

affixed to the back of the unit. Be sure that the voltage is the same

before plugging the slicer into the outlet. To operate the unit on other

voltages, the slicer must be returned to the factory for modification.

All electrical connections must be made in compliance with all

applicable local electrical codes, as well as the latest edition of the

National Electrical Code (NFPA 70).

7

Page 8

OPERATION

Clean and sanitize the slicer before using the first time, after each

use, and before slicing different types of food products. Follow

company, local, and state health/sanitation codes. (See Page 4.)

CAUTION: Do not cut products that contain bone or frozen

product.

1. Plug the power cord into a grounded three-prong outlet. (See

Electrical Requirements, Page 7).

2. Pull the platform assembly to the front of the slicer (toward you).

3. Raise the foodpusher to its open position.

4. Place the product to be sliced on the platform against the

regulator plate and lower the foodpusher against the product.

5. Set the regulator knob to the desired slice thickness.

8

Page 9

6. Set the power switch to ON. (I)

OPERATION (continued)

DANGER: Do not feed food by hand. Always use the

foodpusher.

DANGER: Keep your hands away from the back of the

cutting edge of the knife.

7. Holding the food pusher handle with your right hand, move the

platform forward to complete the slice, and back until the product

clears the cutting edge of the knife. Repeat until desired quantity

is cut. (The slicer is gravity-fed, so it is not necessary to exert

force or pressure against the foodpusher.)

8. Set the power switch to OFF (0), turn the regulator knob to

"0", and unplug the slicer.

Clean the slicer after each operation, as described in the

Cleaning Section.

9

Page 10

2.

Remove platform.

LUBRICATION

To ensure continued smooth operation of sliding parts, use the oil

supplied in the accessory box or a light non-toxic mineral oil.

1. Apply 2-3 drops of oil to the foodpusher glide surface after each

cleaning.

2. Apply 1-2 drops of oil to the knife cover rod threads after each

cleaning.

MAINTENANCE

SHARPENING THE KNIFE

CAUTION: Always use protective cut -resistant gloves when

attaching or removing the sharpener, as this will leave a

portion of the knife exposed. Do not touch expos ed knife

edge.

Note: Inspect the sharpening stones to be sure they are clean and free of

cracks or chips. Clean, if necessary, with the wire brush provided.

Replace the stones if they are cracked or chipped.

1. Clean the knife, as described in the Cleaning Section, to remove all

food particles and grease.

3. Set the regulator knob to "15".

10

Page 11

4.

Remove the sharpener lock knob from the sharpener by

MAINTENANCE (continued)

turning it counter-clockwise.

5. Holding the sharpener by the housing base, attach it to the front

of the regulator plate with the alignment pin in the hole closest to

the knife.

6. Screw the sharpener lock knob through the back of the

regulator plate into the sharpener by turning it clockwise.

7. Set the power switch to ON (I).

8. Turn the regulator knob to "12" for 5 seconds.

9. Turn the regulator knob to "17" for 2-3 seconds.

10. Set the regulator knob back to "15".

11. Set the power switch to OFF (0) and unplug the slicer.

11

Page 12

12

Remove the sharpener and replace the

sharpener lock knob in the sharpener.

13

Set the regulator knob to "O".

MAINTENANCE (continued)

14

Clean both sharpening and deburring stones with the wire brush.

15

Remove the knife cover and clean the knife, as described in the

Cleaning Section.

16

Remove and clean the knife wiper, as described in the Cleaning

Section.

NOTE: Before slicing again be sure that all steel particles from grinding have

been removed to prevent contamination of food.

PARTS REPLACEMENT AND SERVICE

PARTS REPLACEMENT

Use the replacement parts list and the parts distributors list included in

the Owner's Information Packet to order spare parts. Specify the part

number and part name.

SERVICE CENTER LIST

For repair consult the factory -authorized service center list included in the

Owner's Information Packet for the closest service center.

12

Page 13

KEY

QTY

2

3

4

5

6

7

8

08-SM-1080 NUT: HEX

6MM 3

8a

8b

8c

9

10

09-SM-6316 SPRING: SHORT

1 11

12

13

14

08-SM-6196 NUT: JAM HEX 3MM

2 15

16

23-SM-6323 PLATFORM

1

17

09-SM-6324 GUARD: PLATFORM KNIFE

1 18

19

09-SM-6326 HANDLE: FOOD PUSHER

1

20

21

09-SM-6327 SHAFT: FOOD PUSHER

1 22

23

24

25

09-SM-6331 CLIP: REGULATOR BRKT

1

25c 08-SM-1080 NUT: HEX

6MM 2

26

27

27a 08-SM-6127 WASHER: STAR 5MM

2

28

08-SM-1761 SCREW: HXHD 8MA X

35

BRASS

2

29

30

30d 08-SM-1055 WASHER: FLAT

6MM 1

31

32

33

34

35

36

37

38

39

40

23-SM-6344 REGULATOR PLATE

1 41

43

44

KEY

45 09-SM-6348 WEAR ST

RIP: PLATFORM ROLLER

1

46

46a 08-SM-1010 WASHER: FLAT

8MM 2 46b 08-SM-1515 NUT: HEX

8MM 2

47

48

48a 08-SM-6377 S

CREW: SET

4MA X 4 4

49

50

54

55 23-SM-6356 BODY PANEL: CARRIAGE SIDE.

1 57

58

08-SM-6380 SCREW: SET 5MA X

20 4

59

60

61

62

05-SM-1894 BUSHING: STRAIN RELIEF

1 63

64

65

08-SM-1514 WASHER: STAR

8MM 1

66

05-SM-6304 CAPACITOR: 20UF/

450V;

ES12L

1

67

68

69

70

71

72

09-SM-6361 SHELF: KNIFE BACK

1 73

74

75

76

08-SM-1340 SPACER: KNIFE PULLEY SHAFT

1 79

80

09-SM-6364 SPRING SHARPENING STONE

1

81

82

83

84

09-SM-6367 SPRING: DEBURRING STONE

1 85

86

87

88

89

90

91

92

93

09-SM-6372 ROD: THREADED

& FORMED

1 94

95

Effective: April

1, 1999

REPLACEMENT PARTS LIST

MODEL: ES12L

NO.

1 09-SM-6308 BRACKET: PLATFORM 1

13a 08-SM-6320 SCREW: PNHD 3MAX 45 2

19a 08-SM-1264 SOCKET SET SCREW: M10 X 2 1

25a 08-SM-6373 SCREW: HXHD 6MAX 60 2

25b 08-SM-6076 WASHER: STAR 6MM 2

27b 08-SM-1073 SCREW: HXHD 5MAX10 2

28a 08-SM-1515 NUT: HEX 8MM 2

29a 08-SM-6118 SCREW: SET 5MAX 6 2

30a 08-SM-6374 SCREW: SOC HD 5MAX 10 4

30b 08-SM-6076 WASHER: STAR 6MM 2

30c 08-SM-6101 SCREW: SOC HD 6MAX 15 1

30e 09-SM-6336 SPACER, REG BKT HSG 1

42 23-SM-6345 SUPPORT: REGULATOR PLATE 1

PART NO.

09-SM-6309 BLOCK: CAM LOCK 1

06-SM-6310 ROLLER: PLATFORM BRACKET 2

09-SM-6311 SHAFT: ROLLER 2

08-SM-1055 WASHER: FLAT 6MM 6

08-SM-6312 RETAINING RING: EXTERNAL 1

30-SM-6313 CAM ASSY (INC: 6 & 7) 1

06-SM-6314 GLIDE: NYLON 1

08-SM-1515 NUT: HEX 8MM 2

08-SM-6076 WASHER: STAR 6MM 1

09-SM-6315 SPRING: LONG 1

01-SM-6317 PLATFORM: CARRIAGE 1

09-SM-6318 SHAFT: PLATFORM CARRIAGE 1

09-SM-6319 BLOCK: SHAFT RETAINING 2

09-SM-6322 CAP: PLATFORM (LEFT) 1

30-SM-6323 PLATFORM ASSY (INC: 13-23, 32 & 33)

09-SM-6325 CAP: PLATFORM (RIGHT) 1

23-SM-6307 FOOD PUSHER W/SPIKES 1

30-SM-6307 FOOD PUSHER ASSY (INC: 19-23)

06-SM-6328 NYLON RIDER: FOOD PUSHER 1

09-SM-6384 BUMPER: FOOD PUSHER 1

09-SM-6330 SPRING, REGULATOR TENSION 1

09-SM-6332 REGULATOR BRKT 1

04-SM-6333 ROD: REG BRKT SPANNER 1

09-SM-6334 REGULATOR CAM 1

09-SM-6335 HOUSING: REG BRKT 1

05-SM-6337 SWITCH: ROCKER 1

08-SM-6375 SCREW: PHL PNHD 4MA X 15 ST 25

09-SM-6338 PLUG: SCREW COVER 25

09-SM-6339 PLUG: SCREW COVER 2

08-SM-6340 SCREW: CSK SOC HD 8MAX 25 2

09-SM-6321 LENS: KNOB NUMBER 1

09-SM-6341 REGULATOR KNOB 1

08-SM-6342 WASHER: REGULATOR KNOB 1

09-SM-6343 CAP: SHELF END (LEFT) 1

09-SM-6128 KNOB & ROD ASSY: SHARPENER ATTACH 1

06-SM-6346 BOOT: REG PL SUPPORT 1

23-SM-6347 BODY: CENTER SECTION 1

NAME: DESCRIPTION MACH

NO.

49a 08-SM-6378 SCREW: KNIFE WIPER 1

51 09-SM-6353 SUPPORT: KNIFE GUARD STANDOFF (TOP) 1

52 09-SM-6354 STANDOFF: KNIFE GUARD (RIGHT) 1

53 09-SM-6301 KNOB & ROD ASSY: KNIFE COVER 1

65a 08-SM-1515 NUT: HEX 8MA 1

80a 08-SM-1055 WASHER: SPRING STOP 1

81 a 09-SM-6365 GUARD: SHARPENER 1

81 b 08-SM-6381 SCREW: CSK PHLHD 4MAX 10 ST 1

86a 08-SM-6363 WASHER: FIBER 6MM 2

86b 08-SM-1016 NUT: JAM HEX 6MA 2

90a 08-SM-1055 WASHER: FLAT 6MM 7

90b 08-SM-1080 NUT: HEX 6MM 7

95a 08-SM-1055 WASHER: FLAT 6MM 2

General Slicing/Red Goat Disposers • 1152 Park Avenue • P.O. Box 428 • Murfreesboro, TN 37133-0428 • (615) 893-4820

PART NO.

09-SM-6349 CAP: SCREW (REG PL SUPPORT) 1

09-SM-6350 STANDOFF: KNIFE GUARD (STRAIGHT) 2

09-SM-6351 SUPPORT: KNIFE GUARD STANDOFF (LEFT) 1

09-SM-6306 KNIFE WIPER 1

09-SM-6352 STANDOFF: KNIFE GUARD (TOP) 1

09-SM-6355 SUPPORT: KNIFE GUARD STANDOFF (RIGHT) 1

08-SM-6379 BUSHING: EXPANSION 5MM BRASS 4

06-SM-1463 FOOT: 45MM HW/6MA STUD 4

23-SM-6357 SHELF SECTION 1

09-SM-6358 CAP: SHELF END (RIGHT) 1

05-GSM-756 CORDSET 1

09-SM-6359 PLATE: MOTOR MTG 1

05-SM-6384 CAPACITOR: 8UF/450V; ES12H 1

30-SM-6136 MOTOR ASSY: 115V/60HZ; ES12L 1

30-SM-6376 MOTOR ASSY: 220V/50/60H; ES12H 1

23-SM-6302 KNIFE COVER 1

08-SM-1032 SCREW: CSK HD 5MA SS 3

09-SM-6001 KNIFE: 12" 1

09-SM-6360 KNIFE GUARD 1

06-SM-6305 BELT: TB2-34-660 1

30-SM-6362 KNIFE PULLEY ASSY 1

08-SM-1218 SPACER: KNIFE PULLEY 2.3MM 1

30-SM-6060 KNIFE SHARPENER ASSY (INC: 79-86b) 1

08-SM-1021 RING: RETAINING 2

09-SM-6366 SHAFT: SHARPENING STONE 1

09-SM-850 STONE: SHARPENING 1

09-SM-6368 SHAFT: DEBURRING STONE 1

09-SM-851 STONE: DEBURRING 1

23-SM-6369 BACK SUPPORT 1

08-SM-1217 WASHER: FLAT 14MM X 1 1

08-SM-1216 NUT: HEX 14MM X 1 1

08-SM-6382 SCREW: SOC HD 6MAX 35 2

09-SM-6370 BOTTOM COVER 1

09-SM-6371 BLOCK: MOTOR MOUNT 1

08-SM-6383 NUT: HEX NYLOC 6MM 2

08-SM-6090 SCREW: HEXHD 8MA X 45 2

QTY

NAME: DESCRIPTION MACH

Page 14

MODEL ES12L

Loading...

Loading...