Page 1

RED GOAT DISPOSERS

Installation • Operation • Maintenance

“H” Series “A” Series “A” Offset

“B” Series “C” Series

Ordering Instructions.......................................2

Safety..............................................................3

General Installation .........................................4

“H” Series Installation & Connection...............5

“A” Series Installation & Connection ...............6

“B” Series Installation & Connection ...............7

“C” Series Installation & Connection...............8

Typical Installation/Start-up & Run..................9

Operation/Troubleshooting............................10

Troubleshooting.............................................11

Red Goat Disposers

165 Independence Court • Lancaster, PA 17601

800.237.6628 • 717.397.5100 • FAX 717.397.1997

www.redgoat.com Red Goat Disposers 10/12

Maintenance .................................................12

Parts Replacement .......................................14

Motor Test Results ........................................15

“H” Replacement Parts .................................16

“A” Replacement Parts .................................18

“B” Replacement Parts .................................20

“C” Replacement Parts .................................22

“RAC1” Replacement Parts ..........................24

“RAC2” Replacement Parts ..........................25

Hostile Environment Table/Disposer.............26

Terms of Sale and Warranty..........................28

Page 2

ORDERING INSTRUCTIONS

Contact the Factory-authorized Parts Distributor for all parts orders or contact us directly for the name and phone

number of the parts distributor nearest you:

Call Toll Free: 800-237-6628

FAX: 717-397-1997

Page 2 Red Goat Disposers 10/12

Page 3

SAFETY

RECOGNIZE SAFETY INFORMATION. When you see this symbol on

your machine or in this manual, be alert to the potential for personal

injury.

UNDERSTAND SIGNAL WORDS. DANGER, WARNING and CAUTION

appear with the safety-alert symbol in this manual and on safety labels on

the machine to identify the level of hazard seriousness.

DANGER indicates a hazard that WILL result in severe personal injury or

death.

WARNING indicates a hazard or unsafe practice which COULD result in

severe personal injury or death.

CAUTION indicates a hazard or unsafe practice which COULD result in

minor personal injury or equipment damage.

READ ALL INSTRUCTIONS

Read this owner’s manual before using the machine. Failure to follow the

instructions provided could result in personal injury or equipment damage.

KEEP OUT OF REACH OF CHILDREN

This disposer is intended for commercial use only.

DO NOT PUT HANDS OR ANY IMPLEMENT IN THE DISPOSER

WHILE IN OPERATION.

NEVER FEED WASTE BY HAND PAST VINYL SILVER TRAP

SCRAPPING RING.

DO NOT OPERATE IF DAMAGED.

Do not install or operate this disposer if the disposer has been dropped

or damaged in any manner. Contact the nearest factory-authorized

service center for examination, repair or adjustment. (Refer to the service

center list included in the Owner ’s Information Packet.)

DO NOT LEAVE DISPOSER UNATTENDED.

SET THE POWER SWITCH TO OFF BEFORE CLEARING JAMS OR

REMOVING OBJECTS FROM DISPOSER.

When the disposer is wired to a Manual Control or Model RAC1 Control

Center, SHUT OFF the branch circuit main switch or disconnect.

When disposer is wired to a RAC2 Control Panel, TURN OFF emergency

disconnect.

Use long-handled tongs or pliers to remove objects.

TO REDUCE THE RISK OF INJURY BY MATERIALS THAT MAY BE

EXPELLED BY DISPOSER, DO NOT PUT THE FOLLOWING INTO

DISPOSER: drain cleaner; glass, china or plastic; large, whole bones;

metal (bottle cas, tin cans, aluminum foil, etc.); whole cornhusks.

ALWAYS KEEP VINYL SILVER TRAP SCRAPPING RING OR SINK

STOPPER IN PLACE ON SERIES “H-RSA”, EVEN WHEN NOT IN USE.

This reduces the risk of objects falling into the disposer .

WHEN CLEANING KITCHEN AND DISPOSER AREA, ONLY DAMP

WIPE OUTSIDE OF DISPOSER AND CONTROLS. DO NOT AT ANY

TIME HOSE DOWN THE EXTERIOR SURF ACES OF THE DISPOSER

AND CONTROLS.

SAVE THESE INSTRUCTIONS.

Keep this booklet in a convenient location for future reference.

Red Goat Disposers 10/12 Page 3

Page 4

GENERAL INSTALLATION

FABRICATING

1. Consult installation and connection data and installation diagrams on following pages for regular cone or regular

sink attachment dishtable cutout sizes.

2. For cone attachment, position cone so water swirl inlet fitting is nearest to operator .

3. Weld the total circumference of cone or sink attachment to prevent leakage.

4. Smooth grind and polish to match and blend weld seams.

NOTE: DO NOT PLACE CONTROL MOUNTING BRACKETS IN DIRECT WATER SPLASH AREAS.

PLUMBING

1. Consult installation and connection data and installation diagrams on following pages for mounting, hookups and

pipe sizes.

2. “H” Series is mounted by suspending from dishtable.

3. “A”, “B” and “C” Series use a floor leg support system with a neoprene connecting sleeve and two (2) stainless

steel clamps. Supplied sleeve (8” length) should be cut to required length for connection of disposer to dishtable.

4. Slide in, or position, disposer to connect to waste line, avoiding as many bends, elbows and tees as possible.

5. Flexible drain connection should be installed as follows:

A. Slip coupling over disposer outlet, then onto drain pipe.

B. Using a 5⁄16” nut driver, tighten to a torque of 60 in-lbs.

6. Perform power-rotor reaming of waste line whether connection is made to a new or old waste line. New lines

often contain foreign items left in the lines accidentally during construction.

7. Blow new water feed lines out before connections are made. Dirt, solder, or other foreign matter can lodge itself

in the flow controls, solenoid valve and vacuum breaker , causing malfunction.

8. Install solenoid valve. Check that inlet and outlet ports are in proper direction.

9. Check that disposer and dishtable opening are in line, level and true. This is visible when neoprene sleeve is

not kinked or partially collapsed. If level and in line adjustment is required, turn feet on bottom of legs.

10. Secure disposer to floor using the holes provided in the feet.

ELECTRICAL

NOTE: FOLLOW GUIDELINES SET FORTH BY NEC STANDARD AND LOCAL CODES.

1. Consult installation and connection data and diagrams on following pages for control placement and motor

wiring.

NOTE: DO NOT PLACE CONTROL IN DIRECT WATER SPLASH AREAS.

2. Follow supplied wiring schematics for all controls, solenoid valves and pre-wired custom control centers.

3. Size and fuse disposer branch circuit or use circuit breakers as required by motor nameplate rating.

4. Check that motor voltage wiring matches incoming voltage.

NOTE: ALL CONDUIT AND FITTINGS SHALL BE OF THE NEMA 4 WATERTIGHT TYPE.

5. All “H” and “A” disposers have thermal protection of the manual reset type, in motor . Check that reset button is

not jammed.

6. All “B” and “C” disposers must have thermal protection (heaters) in control. Check that heaters are sized properly

to prevent either motor burnout or nuisance tripping.

7. Check that all connections are tight, secure and well-grounded.

NOTE: Disposers are designed to operate in both a clockwise and counter-clockwise direction. Direction of rotation

does not have to be considered when wiring motor .

GROUNDING

Connect disposer to a grounded metal permanent wiring system or run a disposer grounding conductor with the circuit

conductors and connect it to the disposer grounding terminal or lead on the disposer .

Page 4 Red Goat Disposers 10/12

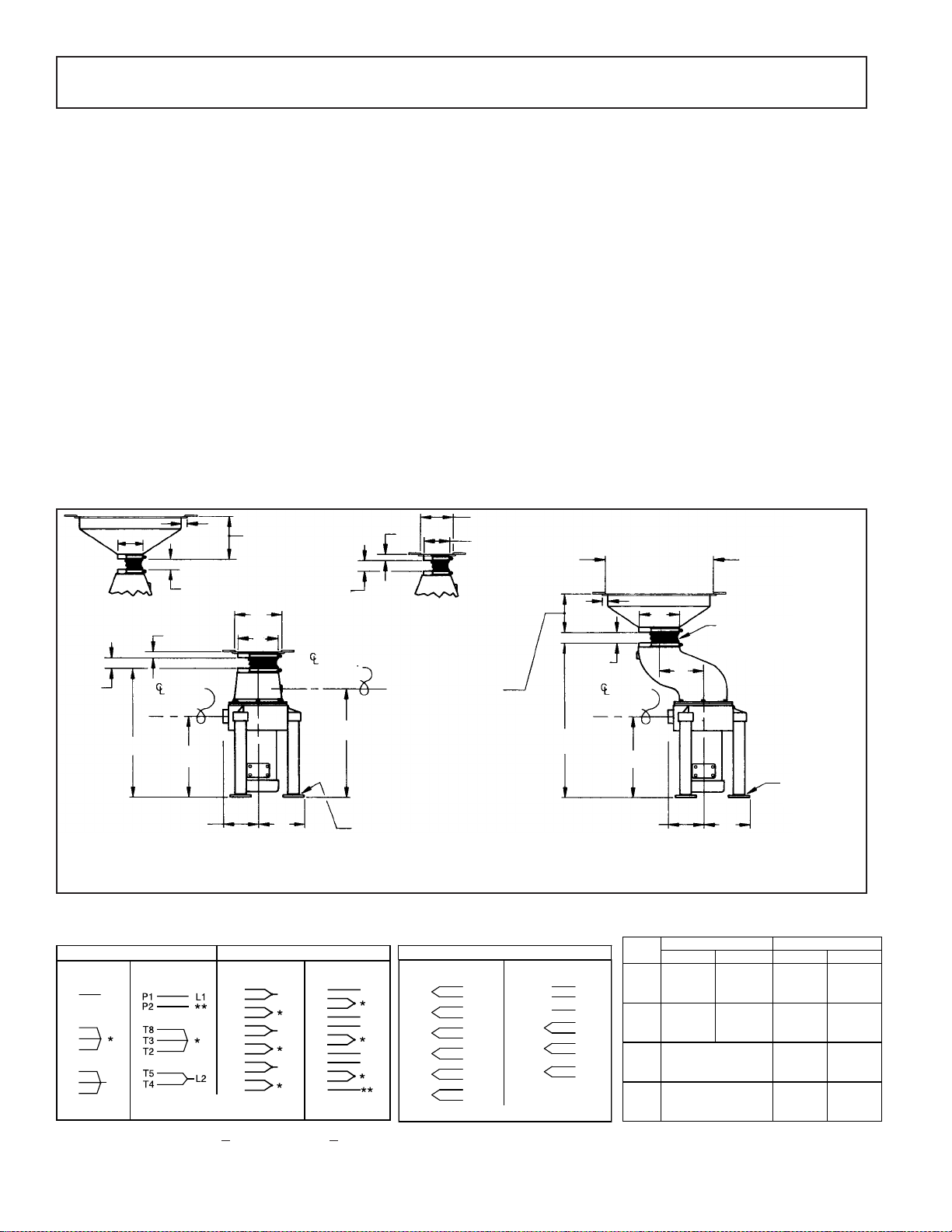

Page 5

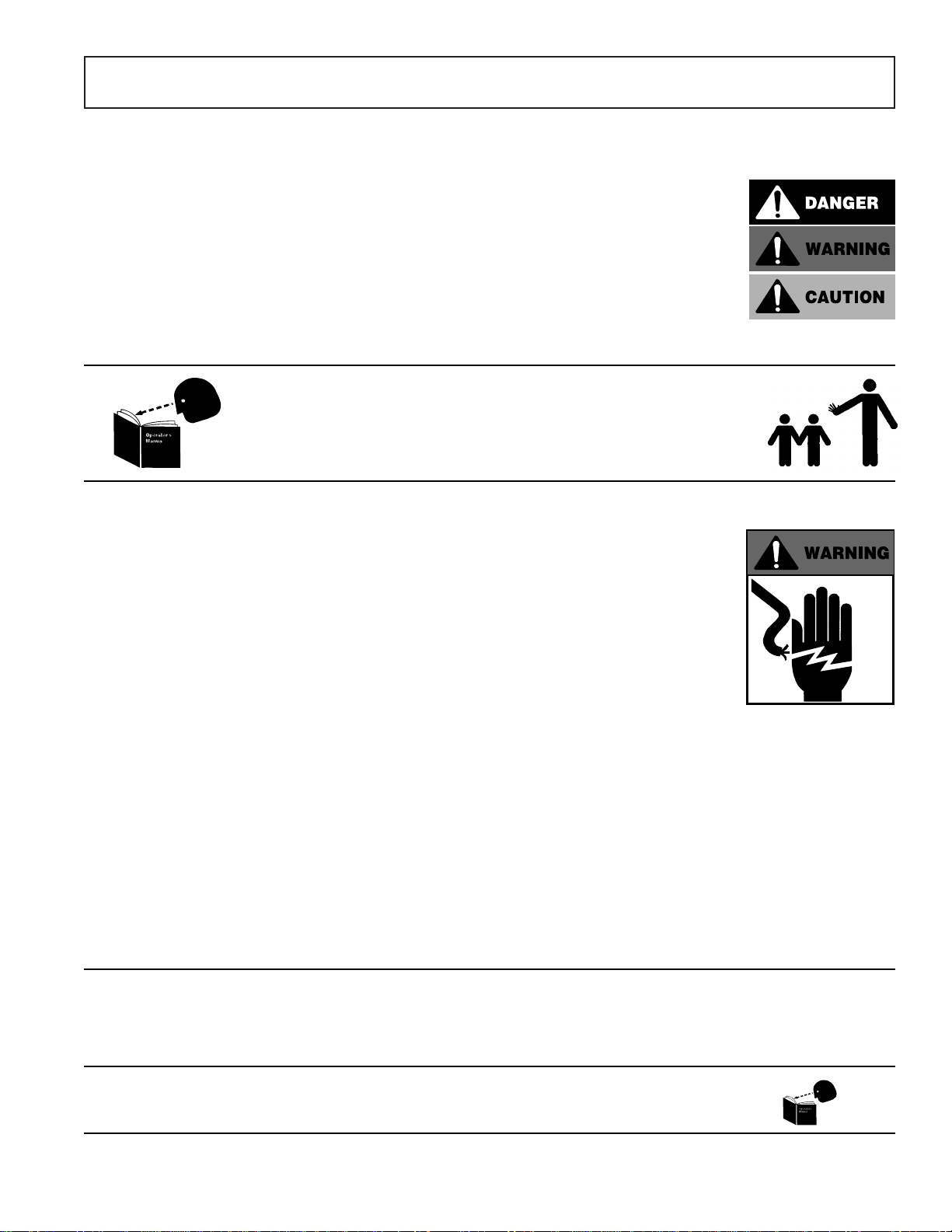

“H” SERIES - Installation and Connection

NOTE: PLUMBING AND ELECTRICAL CONNECTIONS SHALL BE MADE IN COMPLIANCE WITH APPLICABLE

LOCAL CONSTRUCTION CODES.

PLUMBING

Inlet: Cold water supply to disposer shall be 1⁄2" service line with a minimum of 20 lbs. flow pressure, piped as close to

disposer as possible. All disposer and control connections shall be 1⁄2" pipe size.

Sewer Outlet: 11⁄2" waste line should have trap with conveniently located clean out. Do not connect through a grease trap.

Avoid bends, elbows, tees, etc., to reduce the possibility of plumbing stoppage. . A globe valve, used for metering flow, must

be installed between solenoid valve and cone or sink. Water swirl inlet valves should be located nearest operator.

See Typical Installation Diagram.

ELECTRICAL

Follow guidelines set forth by NEC standards. Disposer branch circuit shall be sized and fused (circuit breakers) as

required by motor. The disposer must be connected to a grounded, metal, permanent wiring system; or a disposergrounding conductor must be run with the circuit conductors and connected to the disposer-grounding terminal or lead

on disposer. All connections, junction boxes and conduits must be watertight (NEMA 4).

TESTING See Start-up and Run Section.

INSTALLATION DIAGRAM

31⁄4” INSIDE

DIAMETER

7

7

DRAIN

SEE SPEC SHEET FOR

MOTOR SPECIFIC SIZES

⁄8”

DISPOSER SHOWN WITH SINK MOUNTING ASSEMBLY DISPOSER SHOWN WITH CONE MOUNTING ASSEMBLY

MOTOR WIRING DIAGRAMS

)RUXVHZLWK/HHVRQPRWRUV

SINGLE PHASE THREE PHASE

115 Volt, 60 Hz 230 Volts, 60 Hz 208/230 Volt, 60 Hz 460 Volt, 60 Hz

110 Volt, 50 Hz 220 Volts, 50 Hz 190-220 Volts, 50 Hz 380-440 Volts, 50 Hz

P1

L1

T8

P2

T3

T5

L2

T2

T4

Tied Together and Insulated

*

Insulated

**

6 = Six 9 = Nine

T1

T7

T4

P4

T2

T8

T5

P5

T3

T9

T6

P6

T1

L1

T7

T4

P4

T2

L2

T8

T5

P5

T3

L3

T9

T6

P6

SINK MOUNTING ASSEMBLY

WILL FIT STANDARD 3

TO 4” DIAMETER OPENING

WATER INLET

1

3

⁄4”

9”

1

5

⁄2”

)RUXVHZLWK%DOGRUPRWRUV

208-230 Volts, 60 Hz

190-220 Volts, 50 Hz

L1

**

L2

**

L3

THREE PHASE WITH THERMAL

L1

L2

L3

*

*

*

Tied Together and Insulated

*

1

⁄2

”

DRAIN

TABLE CUTOUT

13” FOR 12” CONE

16” FOR 15” CONE

19” FOR 18” CONE

5

⁄8”

6

6” FOR 12” CONE

5” FOR 15” CONE

7” FOR 18” CONE

SEE SPEC SHEET FOR

MOTOR SPECIFIC SIZES

65⁄8

”

VOLTAGE-AMPERAGE TABLE

460 Volts, 60 Hz

380 Volts, 50 Hz

1

7

2

8

9

3

10

4

11

5

12

6

L1 1

L2 2

L3 3

4

7

*

5

8

*

6

*

9

**10 **11 **12

Insulated

**

HP Volts Amps* Volts Amps*

3/4

1 1/2

SINGLE PHASE THREE PHASE

115 5.4 208 2.8

230 10.8 230 2.8

460 1.4

115 12.8 208 3.6

1

230 6.4 230 3.6

460 1.8

115 17.2 208 4.9

230 8.6 230 4.4

460 2.2

115 20.0 208 6.9

2

230 10.0 230 6.2

460 3.1

*Ratings are for 60 Hz operation

Red Goat Disposers 10/12

Page 5

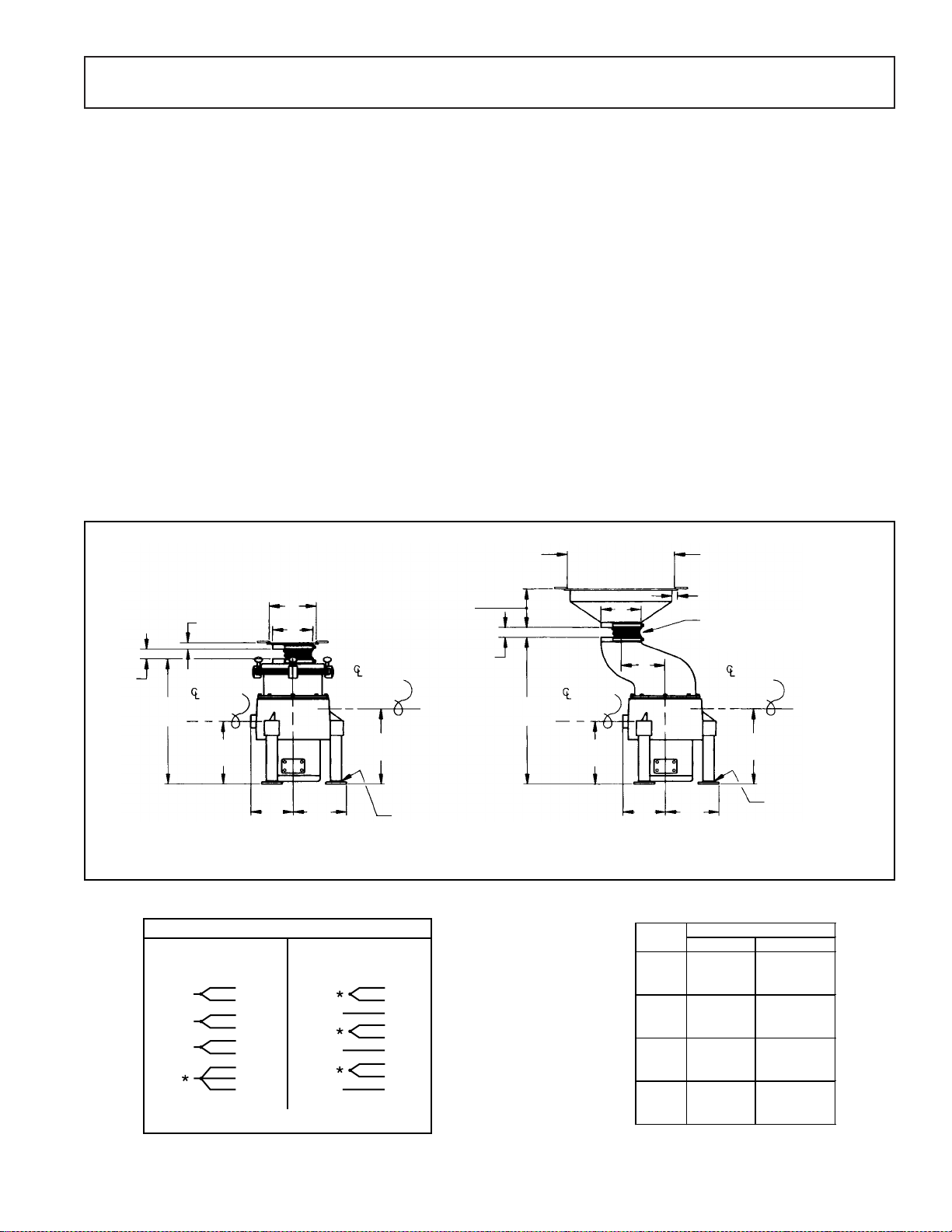

Page 6

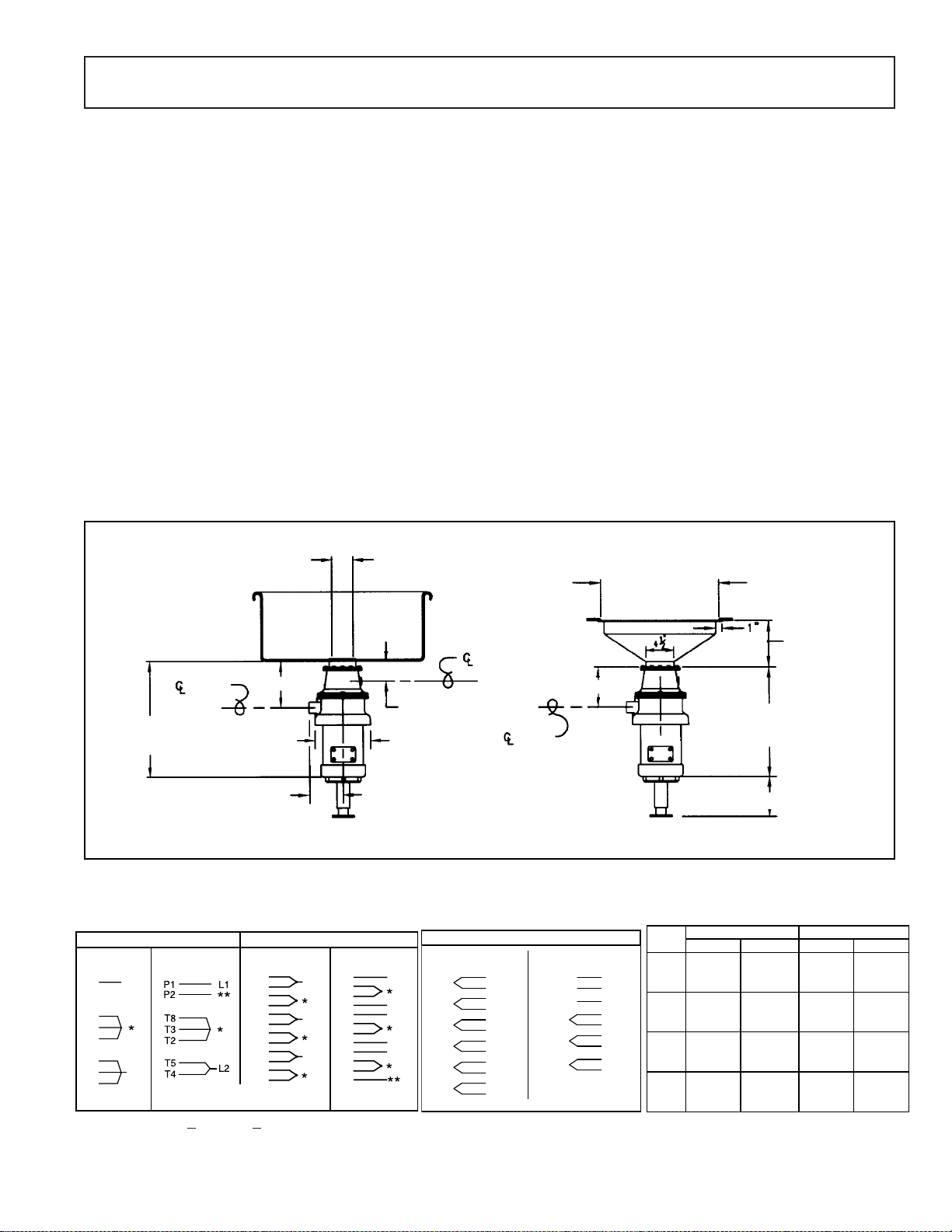

“A” SERIES - Installation and Connection

NOTE: PLUMBING AND ELECTRICAL CONNECTIONS SHALL BE MADE IN COMPLIANCE WITH APPLICABLE

LOCAL CONSTRUCTION CODES.

PLUMBING

Inlet: Cold water supply to disposer shall be 1⁄2" service line with a minimum of 20 lbs. flow pressure, piped as close to

disposer as possible. All disposer and control connections shall be 1⁄2" pipe size.

Sewer Outlet: 2" waste line should have trap with conveniently located clean out. Do not connect through a grease trap.

Avoid bends, elbows, tees, etc., to reduce the possibility of plumbing stoppage. A globe valve, used for metering flow,

must be installed between solenoid valve and cone or sink. Water swirl inlet valves should be located nearest operator.

See Typical Installation Diagram.

ELECTRICAL

Follow guidelines set forth by NEC standards. Disposer branch circuit shall be sized and fused (circuit breakers) as

required by motor. The disposer must be connected to a grounded, metal, permanent wiring system; or a disposergrounding conductor must be run with the circuit conductors and connected to the disposer-grounding terminal or lead

on disposer. All connections, junction boxes and conduits must be watertight (NEMA 4).

TESTING See Start-up and Run Section.

INSTALLATION DIAGRAM

1

1

⁄2”

4

1” MIN.

41⁄2” REGULAR DRUM WITH

6” MAX.

CONE MOUNTING ASSEMBLY

1”

1” MIN.

6” MAX.

DRAIN

1”

CUTOUT

6” FOR 12” CONE

5” FOR 15” CONE

7” FOR 18” CONE

1” MIN.

6” MAX.

8”

7”

WATER

1”

41⁄2” REGULAR DRUM WITH

SINK MOUNTING ASSEMBLY

INLET

6” FOR 12” CONE

5” FOR 15” CONE

7” FOR 18” CONE

CUTOUT 5

41⁄2

DIAMETER

” INSIDE

⁄2”

TABLE CUTOUT

13” FOR 12” CONE

16” FOR 15” CONE

19” FOR 18” CONE

1”

1” MIN.

6” MAX.

7”

8” LENGTH OF NEOPRENE

CONNECTOR SLEEVE FURNISHED.

MAY BE CUT TO DESIRED LENGTH.

8”

DRAIN

19”

23”

1

⁄2”

14

27”

141⁄2”

ADJUSTABLE

0” TO 2”

1

6

⁄4”

8”

ADJUSTABLE 0” TO 2 ”

DISPOSER SHOWN WITH REGULAR 7” DRUM

AND SINK MOUNTING ASSEMBLY

1

⁄4”

6

8”

DISPOSER SHOWN WITH OFFSET DRUM

AND CONE MOUNTING ASSEMBLY

NOTE: All dimensions shown at 0” foot height adjustment.

MOTOR WIRING DIAGRAMS

)RUXVHZLWK/HHVRQPRWRUV )RUXVHZLWK%DOGRUPRWRUV

SINGLE PHASE THREE PHASE

115 Volt, 60 Hz 230 Volts, 60 Hz 208/230 Volt, 60 Hz 460 Volt, 60 Hz

110 Volt, 50 Hz 220 Volts, 50 Hz 190-220 Volts, 50 Hz 380-440 Volts, 50 Hz

P1

L1

T8

P2

T3

T5

L2

T2

T4

Tied Together and Insulated

*

Insulated

**

T1

T7

T4

P4

T2

T8

T5

P5

T3

T9

T6

P6

T1

**

**

L1

L2

L3

L1

T7

T4

P4

T2

L2

T8

T5

P5

T3

L3

T9

T6

P6

6 = Six 9 = Nine

THREE PHASE WITH THERMAL

208-230 Volts, 60 Hz

190-220 Volts, 50 Hz

Tied Together and Insulated

*

1

L1

7

2

L2

8

9

L3

3

10

*

4

11

*

5

12

*

6

460 Volts, 60 Hz

380 Volts, 50 Hz

L1 1

L2 2

L3 3

4

7

*

5

8

*

6

*

9

**10 **11 **12

Insulated

**

VOLTAGE-AMPERAGE TABLE

HP Volts Amps* Volts Amps*

1 1/2

SINGLE PHASE THREE PHASE

115 17.2 208 4.9

230 8.6 230 4.4

115 18.4 208 6.9

2

230 9.2 230 6.2

3

N/A

5 N/A

*Ratings are for 60 Hz operation

460 2.2

460 3.1

208 9.7

230 8.8

460 4.4

208 14.8

230 13.4

460 6.7

Page 6 Red Goat Disposers 10/12

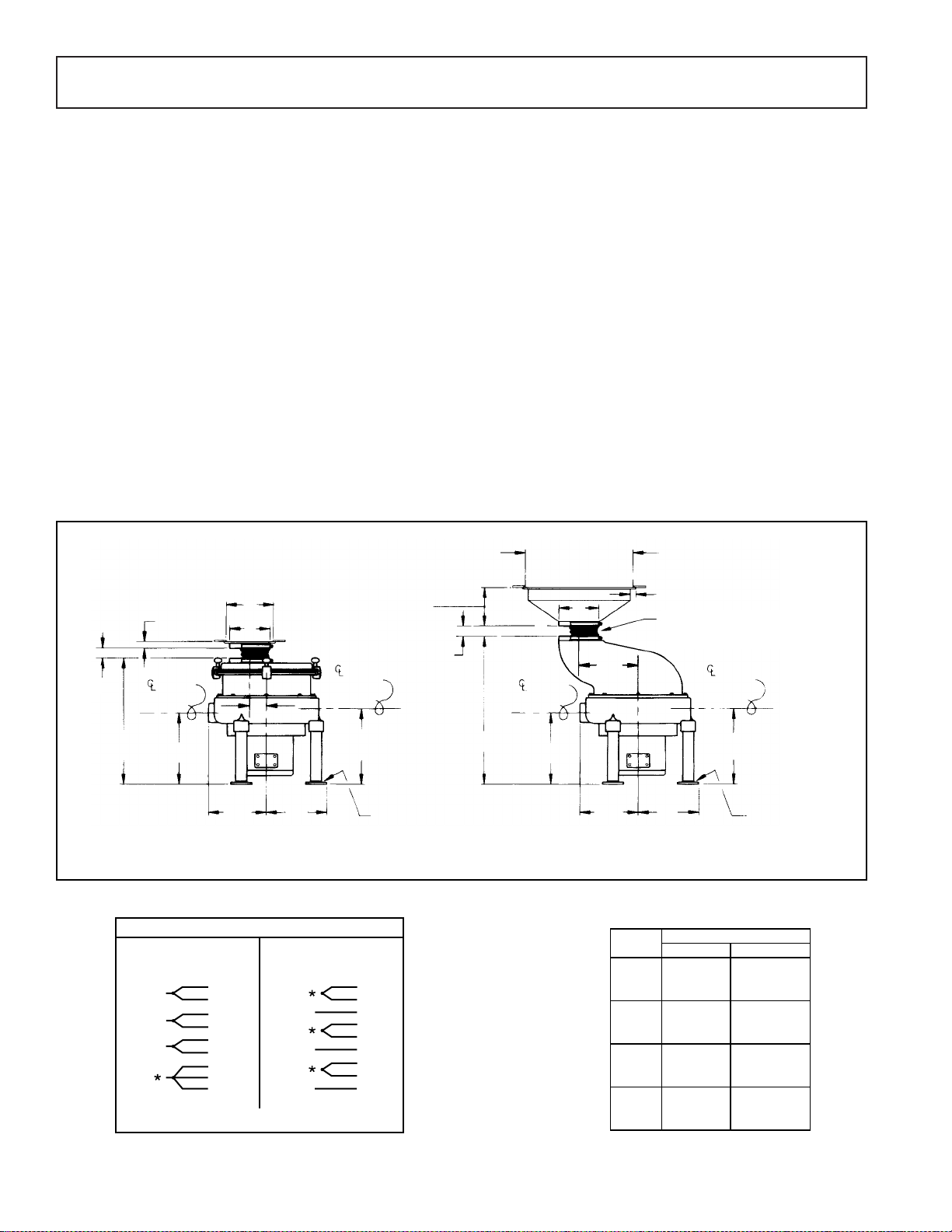

Page 7

“B” SERIES - Installation and Connection

THREE PHASE

208-230 Volts, 60 Hz 460 Volts, 60 Hz

190-220 Volts, 50 Hz 380 Volts, 50 Hz

Tied Together and Insulated

*

L1

L2

L3

1

7

2

8

3

9

4

5

6

4

7

1

5

8

2

6

9

3

L1

L2

L3

HP Volts Amps*

208 9.5

230 9.0

460 4.5

208 15.2

230 13.6

460 6.8

208 23

230 22

460 11

208 33

230 30

460 15

10

THREE PHASE

3

5

7 1/2

NOTE: PLUMBING AND ELECTRICAL CONNECTIONS SHALL BE MADE IN COMPLIANCE WITH APPLICABLE

LOCAL CONSTRUCTION CODES.

PLUMBING

Inlet: Cold water supply to disposer shall be 1⁄2" service line with a minimum of 20 lbs. flow pressure, piped as close to

disposer as possible. All disposer and control connections shall be 1⁄2" pipe size.

Sewer Outlet: 2" waste line should have trap with conveniently located clean out. Do not connect through a grease trap.

Avoid bends, elbows, tees, etc., to reduce the possibility of plumbing stoppage. A globe valve, used for metering flow,

must be installed between solenoid valve and cone or sink. Water swirl inlet valves should be located nearest operator.

See Typical Installation Diagram.

ELECTRICAL

Follow guidelines set forth by NEC standards. Disposer branch circuit shall be sized and fused (circuit breakers) as

required by motor. The disposer must be connected to a grounded, metal, permanent wiring system; or a disposergrounding conductor must be run with the circuit conductors and connected to the disposer-grounding terminal or lead

on disposer. All connections, junction boxes and conduits must be watertight (NEMA 4).

TESTING See Start-up and Run Section.

INSTALLATION DIAGRAM

TABLE CUTOUT

13” FOR 12” CONE

16” FOR 15” CONE

19” FOR 18” CONE

43⁄4” FOR 12” CONE

1

⁄2” FOR 15” CONE

5

1

⁄4” FOR 18” CONE

6

WATER

INLET

1

⁄2”

13

(141⁄2

”)

*

1” MIN.

6” MAX.

27”

(28)

7”

8”

DRAIN

1”

8” LENGTH OF NEOPRENE

CONNECTOR SLEEVE FURNISHED.

MAY BE CUT TO DESIRED LENGTH.

WATER

INLET

*

111⁄2”

(12

1

⁄2”)

*

131⁄2”

(14

1

⁄2

”)

*

1” MIN.

6” MAX.

221⁄2”

(23

⁄2”)

CUTOUT

8”

7”

*

1” MIN.

6” MAX.

1”

DRAIN

1

⁄2”)

*

111⁄2”

1

(12

Red Goat Disposers 10/12 Page 7

3

95⁄8”

⁄8”

7

DISPOSER SHOWN WITH REGULAR DRUM

AND SINK MOUNTING ASSEMBLY

ADJUSTABLE 0” TO 2 ”

3

7

DISPOSER SHOWN WITH OFFSET DRUM

AND CONE MOUNTING ASSEMBLY

5

9

⁄8”

⁄8”

ADJUSTABLE 0” TO 2 ”

NOTE: All dimensions shown at 0” foot height adjustment.

MOTOR WIRING DIAGRAM VOLTAGE-AMPERAGE TABLE

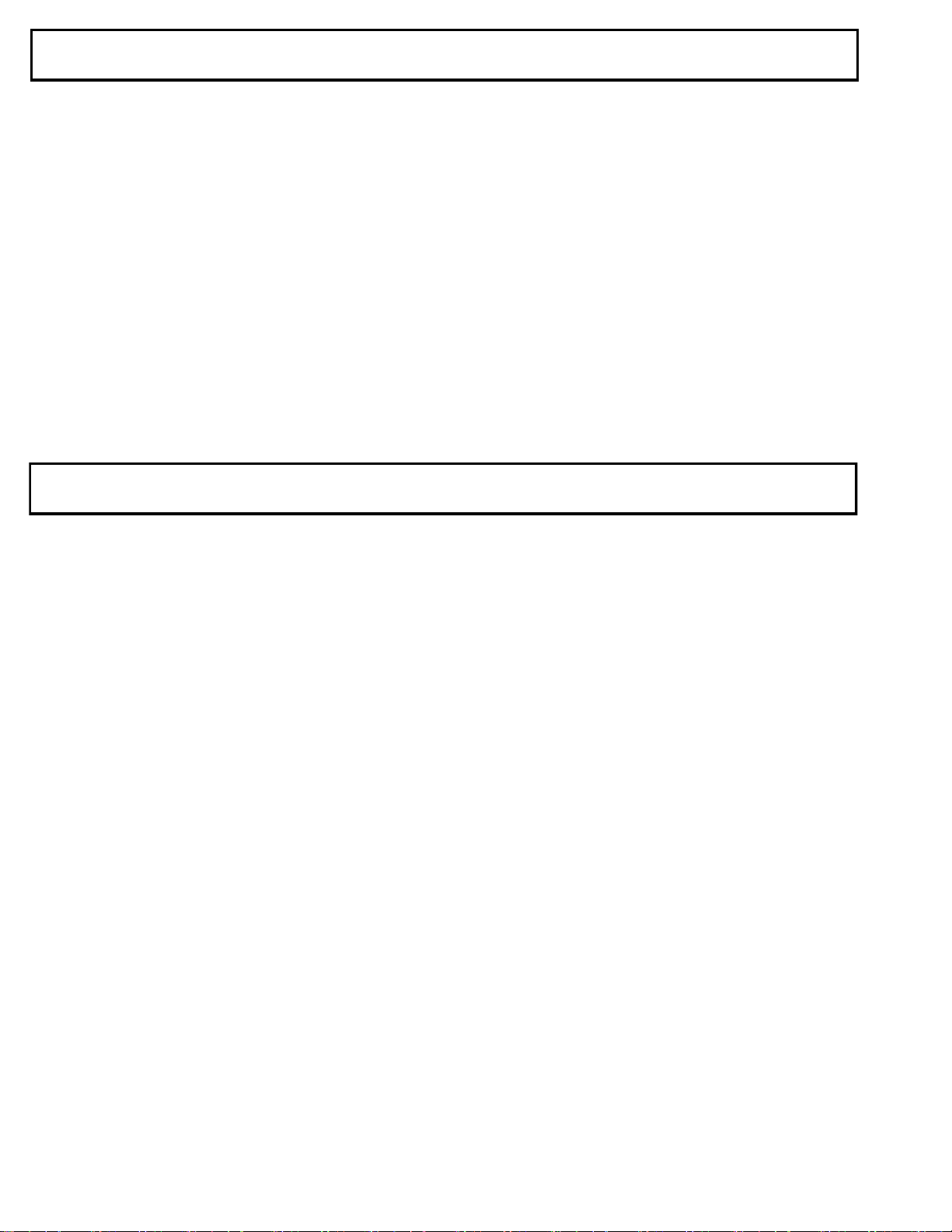

Page 8

“C” SERIES - Installation and Connection

THREE PHASE

208-230 Volts, 60 Hz 460 Volts, 60 Hz

190 Volts, 50 Hz 380 Volts, 50 Hz

Tied Together and Insulated

*

L1

L2

L3

1

7

2

8

3

9

4

5

6

4

7

1

5

8

2

6

9

3

L1

L2

L3

HP Volts Amps*

208 9.5

230 9.0

460 4.5

208 15.2

230 13.6

460 6.8

208 23

230 22

460 11

208 33

230 30

460 15

10

THREE PHASE

3

5

7 1/2

NOTE: PLUMBING AND ELECTRICAL CONNECTIONS SHALL BE MADE IN COMPLIANCE WITH APPLICABLE

LOCAL CONSTRUCTION CODES.

PLUMBING

Inlet: Cold water supply to disposer shall be 1⁄2" service line with a minimum of 20 lbs. flow pressure, piped as close to

disposer as possible. All disposer and control connections shall be 1⁄2" pipe size.

Sewer Outlet: 3" waste line should have trap with conveniently located clean out. Do not connect through a grease trap.

Avoid bends, elbows, tees, etc., to reduce the possibility of plumbing stoppage. A globe valve, used for metering flow,

must be installed between solenoid valve and cone or sink. Water swirl inlet valves should be located nearest operator.

See Typical Installation Diagram.

ELECTRICAL

Follow guidelines set forth by NEC standards. Disposer branch circuit shall be sized and fused (circuit breakers) as

required by motor. The disposer must be connected to a grounded, metal, permanent wiring system; or a disposergrounding conductor must be run with the circuit conductors and connected to the disposer-grounding terminal or lead

on disposer. All connections, junction boxes and conduits must be watertight (NEMA 4).

TESTING See Start-up and Run Section.

INSTALLATION DIAGRAM

TABLE CUTOUT

13” FOR 12” CONE

16” FOR 15” CONE

19” FOR 18” CONE

3

⁄4” FOR 12” CONE

4

1

⁄2” FOR 15” CONE

5

1

⁄4” FOR 18” CONE

6

WATER

INLET

1” MIN.

6” MAX.

DRAIN

7”

1”

8” LENGTH OF NEOPRENE

CONNECTOR SLEEVE FURNISHED.

MAY BE CUT TO DESIRED LENGTH.

1

10

⁄2”

WATER

INLET

1” MIN.

6” MAX.

1”

DRAIN

CUTOUT

8”

7”

221⁄2”

1

121⁄2”

⁄2

”)

(26

*

1

⁄4”

10

DISPOSER SHOWN WITH REGULAR DRUM

AND SINK MOUNTING ASSEMBLY

11”

1

⁄2”

13

ADJUSTABLE 0” TO 2 ”

27”

1

12

⁄2”

1

10

⁄4”

DISPOSER SHOWN WITH OFFSET DRUM

AND CONE MOUNTING ASSEMBLY

11”

1

13

⁄2”

ADJUSTABLE 0” TO 2 ”

NOTE: All dimensions shown at 0” foot height adjustment.

MOTOR WIRING DIAGRAM VOLTAGE-AMPERAGE TABLE

Page 8 Red Goat Disposers 10/12

Page 9

TYPICAL INSTALLATION

START-UP AND RUN CHECK

1. Check that vinyl silver trap scrapping ring is fully seated.

2. Check that all connections are secure.

3. Check that disposer is secured to floor.

4. Open terminal wiring box on motor; pull out and separate motor leads to permit ampere reading on each leg.

Leave all connections and insulation in place.

5. Clamp ammeter over input feed lead.

6. Turn on disposer.

8. Check for leaks, water flow, excessive noise or vibration, and regulate water flow if required.

7. Take ampere readings on each leg and verify against factory-checked motor test results.

NOTE: Before checking rotation reversal, be sure disposer is empty. Wear safety glasses or goggles. BE SURE POWER

SWITCH IS OFF SHOULD ADJUSTMENTS ON DISPOSER BE NECESSARY. NEVER REACH INTO DISPOSER WHEN DIS-

POSER IS RUNNING.

9. If disposer is connected to a reversing control, whether automatic or manual, check reversing.

10. If disposer is connected to a manual reversing drum switch or contactor, START motor in forward position and note rotation

through top opening as motor coasts to a stop. RESTART motor in reverse position. Verify that disposer restarted in opposite

direction.

11. If disposer is connected to a control center with automatic reversing (Model RAC1/ RAC2), verify if disposer reverses.

NOTE: Motor must be stopped or 30 seconds must have elapsed before pushing START; otherwise, motor will not reverse. This

is a safety cycle feature. Should START button be pressed prior to elapsed time, motor will run in same direction. Direction Test:

A.) Press Start- Disposer Run. B.) Press Stop (note coast down direction. C.) Wait 30 sec. after motor stops. D.) Press startDisposer should run is opposite direction.

12. If disposer is wired with a (RAC1/ RAC2), There are 3 trim-pots on the Control Module inside the controller that adjust operation. (To enable or disable clean out cycles) For more information about this Eco-Mizer: Electricity and Water Saver please

see the Instructions For Adjustable Timer With Auto Shut Down spec sheet in the control box. This timer is used to control the

shut down sequence of industrial garbage disposal units. When either the Stop input is activated or the Auto Shut Down timer

times out, the two stage shut down sequence begins. The first stage is Clean Out, where both the motor and water flow continue

for up to 2 minutes. The second stage is Positive Flush, where the motor is stopped, but the water flow is continued, also for up

to 2 minutes. The disposal may be restarted at any time, but if the motor has been off for more than 30 seconds, its direction will

be reversed.

13. In all shutdown phases, be sure water is being shut off by the closing of the solenoid valve.

14. Reinsert all wiring, close all covers and shut all doors that were open during run check.

Red Goat Disposers 10/12 Page 9

Page 10

OPERATION

1. Check that disposer is empty and clean from previous use.

2. Check that vinyl silver trap scrapping ring is in place and properly seated over throat opening in cone or sink.

3. Turn disposer ON. Note that water is flowing into top cone or into sink via the water swirl fitting.

WARNING: Never feed waste by hand past vinyl silver trap ring or reach inside running disposer .

NOTE: Do not feed metal, wood, cloth, rubber, corn husks, plastics, plastic sheets of bags, styrofoam, or other foreign

matter. A periodic clean out of such material from the disposer is advisable.

4. Proceed with dish cleanup, feeding waste gradually. DO NOT pack waste into disposer waste chamber .

5. After each use, if disposer is wired with manual controls, allow disposer to run (motor and water) for at least 2

minutes. This clean-out cycle will empty the disposer and flush the waste line, preventing potential drain

stoppage.

6. Should motor stop during use cycle, SHUT OFF POWER IMMEDIA TELY, via ON-OFF switch. If disposer is

connected to Model RAC2 Control Center , shut OFF power at black emergency disconnect handle; on manual

switches, turn branch circuit disconnect to OFF.

A. Remove vinyl silver saver scrapping ring and check waste chamber through top opening and remove foreign

objects that may have caused stoppage.

B. Check to see if rotor turns freely.

C. If rotor turns freely, replace vinyl silver saver scrapping ring and turn disposer ON.

If disposer fails to start and run, an obstruction may still be binding the rotor .

A. Turn disposer OFF. Using a wooden bar or wooden handle, pry and push against the impact bars on the

rotor to break it free; then remove object.

B. Turn disposer ON and if motor fails to start, the thermal protector, either in the motor (“H” and “A” Series) or

in the controls, may have tripped.

C. Push reset button on thermal protector.

If disposer still fails to start, check for blown fuses or tripped circuit breakers in the branch circuit (especially on

three-phase installations) to be sure that all power legs are feeding motor .

TROUBLESHOOTING

DISPOSER DOES NOT START WHEN NEW

Manual reset button of thermal protector is tripped. On “H” and “A” Series, reset button is on motor; on “B” and “C”

Series, reset button is in control box.

Fuses or circuit breaker on branch circuit feed line have tripped.

Electrical connectionf on motor, in panel or feed lines not tight.

Headers have not been installed in starter, if starter is used in circuit.

DISPOSER DOES NOT START AFTER STANDING UNUSED FOR A PERIOD OF TIME

Clean out cycle too short. When disposer is stopped too early, the remaining water slowly drains out carrying the

shattered waste particles into the very close clearance opening between sizing ring and rotor, where it hardens and

solidifies, acting as a binding agent between the two parts. The motor at start-up is unable to overcome the dried

blockage (usually on low horsepower disposers).

DISPOSER STALLS WHEN IN OPERATION

Large quantities of foreign material (rags, wood pieces, rubber bands, strings, pieces from floor mops, cellophane

and polyethylene) which will not disintegrate, cause the motor to overheat and the thermal protector to trip.

Not enough water volume flow (GPM) causing thermal protector to trip.

Thermal protectors (heaters) sized too small, causing nuisance tripping.

Page 10 Red Goat Disposers 10/12

Page 11

TROUBLESHOOTING

(continued)

DISPOSER OPERATES BUT DISINTEGRATION AND DISCHARGE IS SLOW

Not enough water volume flow (GPM).

Worn shattering mechanism (impact bars, sizing ring, rotor).

Large amounts of foreign material in waste chamber.

DISPOSER MOVES WHEN STARTED

Large amounts of unshattered waste in chamber.

Rotor unbalanced due to loose impact bar.

Disposer not anchored to floor.

DRAIN LINE CLOGS

Worn shattering mechanism (impact bars, sizing ring, rotor) permitting large waste particles to flow through.

Large amount of paper and non-food particles being fed into disposer .

Not enough water volume flow (GPM).

DISPOSER DOES NOT TURN OFF (AFTER CLEAN OUT CYCLE, IF WIRED WITH RAC2)

Stop button in switch or control defective.

Timer in Model RAC2 control center defective.

DISPOSER DOES NOT REVERSE

Contacts in manual reversing switch burned.

Contactor in auto reversing control center defective.

Reversing circuit in auto reversing control center defective.

Time lapse safety circuit in auto reversing control center defective.

Motor not wired as indicated in wiring diagram.

SEVERE VIBRATION DURING OPERATION

Loose or broken impact bars.

Unshattered waste lodged in rotor.

Severe rotor damage from metal objects being fed into disposer .

MOTOR RUNS BUT NO WATER FLOW

Solenoid valve improperly wired.

Defective solenoid valve coil.

No water flow in main feed line.

MOTOR NUT TURNING AT PROPER RPM

Low voltage on incoming feed line.

On three-phase hookups, no voltage on one feeder line (leg).

Motor not wired as indicated in wiring diagram (low to high, high to low voltsO.

LOUD NOISE FROM MOTOR AREA

Upper or lower or both bearings worn.

Leakage of disposer seals.

SMOKE OR BURNING ODOR FROM MOT OR

Incoming voltage not correct.

On three-phase hookups, no voltage on one feeder line (leg).

Water leaking into motor through faulty seals.

Disposer being overloaded, especially with foreign material.

Improper motor connections.

Page 12

TROUBLESHOOTING

MOTOR BURNS OUT

Internal winding short.

Water leaking into motor through faulty seals.

Disposer being overloaded.

Incoming voltage not correct.

Thermal protectors (heaters) not tripping, sized too large.

WATER LEAKING FROM BASE OR DISPOSER

Defective seals.

Hole worn in base.

Motor mounting screws not sealed on “H” and “A” Series units.

Leaking plumbing connections or leaking sink mounts.

WATER SPLASHING UP FROM DISPOSER

Building water pressure too high.

Globe valve not installed or needs adjustment.

WATER FLOWS BUT MOTOR DOES NOT RUN

Thermal protectors (heaters) not installed in starter.

Motor not wired as indicated on wiring diagram.

Control not wired correctly.

(continued)

MAINTENANCE

Waste disposer troubles usually involve plumbing. A preventative maintenance program is advisable to keep waste line

stoppage and disposer repair at a mininum. Any sewer problem occurring shortly after your disposer has begun

operation cannot be caused by the new machine. It will be the result of connecting to either an inadequate waste line,

or to one that has not been properly cleared before use. On the other hand, if waste line clogging occurs after the

disposer has been running trouble-free for a year or more, this indicates probable need for servicing.

The slurry leaving a new disposer contains no discernible solids, so there is nothing to clog the waste line. In regular

use, however, wearing of the working parts is to be expected. As the gradual wear occurs, the solid particles passing

through the wider gaps in the shatter mechanism will grow increasingly larger, until waste line stoppage may result.

See Figures.

MONTHLY WEAR CHECK

NOTE: The following should be performed every two weeks if waste is of a highly abrasive consistency .

1. Shut OFF branch circuit power, or emergency disconnect on control panel when disposer has completed its

clean out cycle.

2. Loosen stainless steel clamps on neoprene connector sleeve.

3. Twist neoprene sleeve loose and remove.

4. On “B” and “C” Series, loosen Quick-Release body clamps and lift of f aluminum lid.

5. Remove any foreign objects (rubber bands, metal, wood, plastics, etc.) from waste chamber .

6. Check free movement of rotor.

7. The two points of probable wear are the leading edges of the impact bars and the spacing between the outer

edges of the rotor and the inner diameter of the sizing ring teeth (Figure 1, Page 13). When one end of each

impact bar is worn rounded, as shown in Figure 2, Page 13, they need to be reversed (if disposer is wired to an

automatic reversing control).

A. Loosen four hex socket head cap Allen screws to release the bars. Should it be necessary, use liquid wrench

or a mixture of oil and kerosene to help loosen the screws.

Page 12

Red Goat Disposers 10/12

Page 13

MAINTENANCE

B. Reverse bars and reinstall Allen screws.

C.

When the edges of the reversed impact bars become rounded (Figure 3), the bars must be replaced.

See below and Page 14.

8. The second point of wear is the clearance between the outer edge of the rotor and the inner diameter of the

sizing ring teeth (Figure 3).

If the space between the rotor and sizing ring has grown to 3⁄32”, (.094) and the impact bars are worn (rounded)

as shown in Figure 3, replacement of total rotor and sizing ring is advisable. See below and Page 14.

NOTE: If 3⁄32” space between rotor sna sizing ring is left to continue to increase, waste line stoppage may result as

increasingly large whole sections of waste will pass through sizing ring without breaking up.

(continued)

FIG. 1

These bars are badly worn and need reversing. FIG. 2

Remove Allen screws and reverse bars.

When the rotor and sizing ring are new,

this spacing is 0.0 12” (less then

POINTS OF WEAR

When these impact bars are reversed,

presenting new working sides, this

disposer will function well even though

this space may have grown to 3⁄32”.

At this stage of wear, no new parts

are needed.

With uniform wear on the rotor and the

teeth, spacing between has increased,

but the new faces of the reversed bars

restore efficiency.

1

⁄

64”).

These bars have had their double life. FIG. 3

With both sides well worn, it is evident that this disposer was

properly cared for, getting maximum length of service from all parts.

Red Goat Disposers 10/12

At this stage of double wear on bars,

this space may be 3⁄32” (.094). Check

with feeler gauge or U.S. Std. #13 gauge

wire.

At this stage, bars only may be

renewed–provided spacing between

rotor and teeth has not grown to 3⁄32”

and if waste line appears capable of

handling the slurry output.

Page 13

Page 14

PARTS REPLACEMENT

WARNING: ALWAYS SHUT OFF MAIN POWER DISCONNECT BEFORE PERFORMING

MAINTENANCE OR PARTS REPLACEMENT.

IMPACT BARS (Series A, B and C)

1. Shut off main power disconnect.

2. Disconnect water line feeding into waste chamber, if applicable.

3. Loosen stainless steel clamps and remove neoprene sleeve.

4. On Series “A” disposers, remove 41⁄2” or 7 ” waste chamber by loosening and removing the six hex head bolts

holding chamber to base.

On Series “B” and “C” disposers, remove aluminum lid by loosening quick-release head clamps.

5. Insert wedge at impact bar between rotor and sizing ring to prevent rotor rotation.

6. Loosen hex socket head cap Allen screws and remove impact bars. Use liquid wrench or a solution of oil and

kerosene if necessary.

7. Install new impact bars in milled slots, after cleaning slots of foreign materials. Be sure new bars fit tightly into

slots and sit flatly, making metal to metal contact.

8. Remove anti-rotation wedge.

9. Replace removed components and reconnect disposer to sink or dishtable.

ROTOR AND/OR SIZING RING

1. Shut off main power disconnect.

2. Disconnect water line feeding into waste chamber, if applicable.

3. Loosen and disconnect disposer from sink or dishtable.

4. Remove waste chamber by loosening and removing the hex head bolts holding chamber to base.

5. Remove center cover bolt and plate.

6. Remove the two centering hold down studs from sizing ring and lift off sizing ring.

7. Remove old gaskets from base sizing ring or waste chamber .

8. Lift off rotor. On “B” and “C” Series, provisions for use of a wheel puller are cast into rotor. When using wheel

puller, thead back cover bolt onto motor shaft 1⁄2”. This will protect the threaded motor shaft.

9. Remove key from shaft.

10. Clean and inspect keyway.

11. Inspect motor seal system. If replacement is necessary , do so now. See Instructions on Page 13.

12. Oil motor shaft and slide on new rotor . Be sure rotor has seated fully on motor shaft shoulder and that shaft is

below machined surface on rotor.

13. Reinsert key. Series “B” and “C” use two keys. BE SURE the keys make metal to metal contact on all surfaces

in the rotor and motor shaft keyways and that the key is the full length of the keyway. Short keys will shear at

peak loads. Rotate rotor slightly to be sure there is no radial play between the rotor and motor shaft.

14. Insert cover gasket, plate and bolt to lock down rotor .

15. Torque cover bolt to 34 ft-lbs.

16. Install one new gasket on base.

17. Place sizing ring over gasket on base and thread in new centering studs.

18. Center sizing ring on rotor, turning rotor several complete turns. There should now be approximately 1⁄64” running

clearance between rotor and sizing ring.

19. Lock sizing ring into place with the centering studs. BE SURE sizing ring did not move and that running

clearance has been maintained.

20. Place the second gasket over centering studs and install waste chamber .

21. Lock waste chamber into place and reconnect parts removed earlier .

Page 14 Red Goat Disposers 10/12

Page 15

PARTS REPLACEMENT

(continued)

MOTOR SEALS AND/OR MOTOR

1. Shut off main power disconnect.

2. Disconnect disposer from dishtable and waste line; remove floor mount and disconnect electric line feeding

motor.

3. Slide out disposer.

4. Remove rotor and sizing ring, as described on Page 14.

5. Series “H” and “A”: Remove four (4) motor bolts.

Series “H” and “A”: Turn disposer over resting base, especially sizing ring clamping surface, on wooden blocks.

6. Series “B” and “C”: Remove four (4) motor bolts and lift of f motor.

Series “B” and “C”: Drive out the lip seal and cartridge seal; clean seal seating area.

Series “B” and “C”: Turn base over and set in the new lip seal (open side of seal facing up) and oil with SAE 30

oil.

7. Install cartridge seal.

A. Place light application of Permatex adhesive gasket sealant or equivalent in seal bore in base.

B. Fully immerse new cartridge seal in SAE 30 oil.

C Install new cartridge seal (rubber seal ring up), using installation tool (available separately) making sure seal

is fully seated in bore.

8. Turn base back onto the wooden blocks.

9. Clean motor shaft and oil shaft well with SEA 30 oil.

10. Slide motor back over seals and fasten motor. BE SURE motor is in same position as before for electrical

connections.

11. Turn base with motor back over and make sure rubber seal ring on cartridge seal is in place.

12. Re-install components, as listed on Page 14 and reconnect disposer .

TEST RESULTS

Red Goat Disposers 10/12

Page 15

Page 16

“H” SERIES REPLACEMENT PARTS LIST

KEY NO. PART NO. NAME: DESCRITION/ QTY PER MACH. KEY NO. PART NO. NAME: DESCRITION/ QTY PER MACH.

1 30-H-RSA RSA Head Assy1 1 28 30-A-436 Motor: 1.5 HP, 3PH 1

(Includes 2-9) (Includes 19-21 & 28)

2 06-H-8 Sink Stopper: "H" Series RSA 1 29 02-A-462 Thermal Protector: #MWJ57KB 1

3 27-H-15 Sink Mount: Threaded 1 28 30-A-480 Motor: 2 HP, 1PH 1

4 07-H-19 Gasket: RSA Rubber 1 (Includes 19-21 & 28)

5 07-H-20 Gasket: RSA Fiber 1 29 02-5-486 Thermal Protector: #BE J44DB 1

6 08-H-21 Screw, Hxhd 5/16-18 x 3/4 6 28 30-A-442 Motor: 2 HP, 3PH 1

7 08-HA-311 Washer: Lock Split 5/16 13 (Includes 19-21 & 28) 1

8 51-H-17 RSA Head 1 29 02-A-465 Thermal Protector:#CWJ58KB LEESON 1

9 07-H-18 Gasket: Splash Guard 1 31 06-5-505 Rubber Boot: Thermal Protector 1

10 06-HA-ST4

Silver Saver: 4 1/2"

1 33 08-HA-282 Key: Woodruff #606 1

11 07-H-34 Gasket: "H" Series cone 1 34 02-HA-521 V-Ring Seal LEESON 1

12 08-HA-22 Screw: Hxhd 5/16-18 x 1, SS 4 35 02-HA-522 Seal: Motor Shaft LEESON 1

13 51-H-12LD Drum 1 36 02-5-400 Bearing: #205 1

14 08-HA-17 Nut: Hex 5/16-18 2 41 02-HA-399 Bearing: #203 1

15 10-5-27. Pipe Plug: 1⁄2” 1 42 40-H-016 Center Support Leg Kit (H Model) 1

16 07-H-10 Gasket: Sizing Ring 2 (Includes 42-48)

17 08-HA-16 Centering Stud 2

18 30-H-9D Sizing Ring 1 40-H-504 H-Complete Renewal Kit 1

19 08-6-276 Nut: Hex Jam Nyloc, 5/8 x 18, SS 1 S/N 060185H01/ RG-1000 Forward

20 08-6-277 Washer: Flat H D5/8 x .134 thick 1 40-H-1DA H-Rotor Kit (Includes 19-22) 1

21 07-6-98. Gasket: Turntable Mounting 1 40-H-9DA H-Sizing Ring Kit 1

22 30-H-1D Rotor: With Cast-On Impact Bars 1 (Includes 7, 14 & 16-18)

23 07-HA-83 Cartridge Seal 1 40-HA-507 H-Motor Seal Kit (Includes 23 & 27) 1

04-HA-263 Install. Tool: HA Cartridge Seal 1 S/N 060185H01/ RG-1000 Forward

24 08-5-24. Screw: Skhd 3/8-16x3/4 Nyloc SS 4

25 30-H-1140 Base Assy: Includes Seals Installed 1 FOR USE WITH BALDOR MOTORS ONLY

26 06-5-849 Drain Coupling: “H” Series 1 19 08-H-21 Screw: Hxhd 5/16-18 x 3/4 SS Nyloc 1

27 07-HA-5 Gasket: Motor/Base 1 20 09-HA-2 Coverplate 1

28 30-H-431 Motor: 3/4 HP, 1PH 1 21 07-HA-3 Gasket: Coverplate 1

(Includes 19-21 & 28) 33 02-HA-100 Key 1

28 30-H-432 Motor: 3/4 HP, 3PH 1 29 02-A-475 Thermal Protector: #MYJ42WB 2HP 1

(Includes 19-21 & 28) 1

28 30-H-523 Motor: 1 HP, 1PH 1 (NON-STOCK ITEMS)

(Includes 19-21 & 28) 1 30, 32 & 37-40 PLEASE CONTACT OUR FACTORY

29 02-MC-6068 Thermal Protector: #CE J53CB 1

28 30-H-524 Motor: 1 HP, 3PH 1

(Includes 19-21 & 28)

28 30-H-435 Motor: 1.5 HP, 1PH 1

(Includes 19-21 & 28) 1

29 02-HA-459 Thermal Protector: #CE J50CA 1

Page 16 Red Goat Disposers 10/12

Page 17

“H” SERIES REPLACEMENT PARTS DIAGRAM

Red Goat Disposers 10/12 Page 17

Page 18

“A” SERIES REPLACEMENT PARTS LIST

KEY NO.

PART NO.

NAME: DESCRITION/ QTY PER MACH.

KEY NO. PART NO. NAME: DESCRITION/ QTY PER MACH.

1 06-HA-ST4 Silver Saver: 4 1⁄2” 1 26 02-5-400 Bearing: #205 LEESON 1.5 & 2HP UP 1

06-ABC-ST7 Silver Saver: 7” 1 27 02-HA-399 Bearing: #203 LEESON 1.5 & 2HP LOW 1

2 06-A-818 Connector Sleeve: 4 1⁄2” dia. x 8” 1 23 30-AB-448 Motor: 3 HP/3 PH Includes 14-16 &23 1

06-A-414 Connector Sleeve: 4 1⁄2” dia. x 4” 1 24 02-A-464 Thermal Protector: #BYJ36KF LEESON 1

06-ABC-834 Connector Sleeve: 7” dia. x 8” 1 26 02-BC-401 Bearing: #206 LEESON 1

06-ABC-434 Connector Sleeve: 7” dia. x 4” 1 27 08-SM-1418 Bearing: #204 LEESON 1

3 08-A-19 Clamp: Connector Sleeve 4 1⁄2” 2 23 30-A-481B Motor: 5 HP/3 PH Includes 14-16 &23 1

08-ABC-33 Clamp: Connector Sleeve 7” 2 24 02-A-488 Thermal Protector: #BYJ32KF LEESON 1

4 51-A-11AS Drum: 4 1⁄2” Throat 1 26 02-BC-401 Bearing: #206 LEESON 1

51-A-11S Drum: 7” Throat 1 27 08-SM-1418 Bearing: #204 LEESON 1

51-A-81 Offset Drum: 7” Throat 1 29 02-A-523 Seal: V-Ring 3 & 5 HP LEESON 1

5 08-HA-22 Screw: Hxhd 5/16-18 x 1, SS 4 30 02-A-524 Seal: Motor Shaft 3 & 5 HP LEESON 1

6 08-HA-311 Washer: Lock Split 5/16 6 28 08-HA-282 Key: Woodruff #606 LEESON 1

7 08-HA-17 Nut: Hex 5/16-18 2 29 02-HA-521 V-Ring Seal LEESON 1

8 10-5-27. Pipe Plug: 1⁄2” 1 30 02-HA-522 Seal: Motor Shaft 1.5 & 2 HP LEESON 1

9 07-A-10 Gasket: Sizing Ring 2 32 06-5-505 Rubber boot: Thermal Protector 1

10 08-HA-16 Centering Stud 2 34 09-A-928 Leg Assy w/Foot: 2" X 13.5, SS 3

11 30-A-9 Sizing Ring 1

12 08-5-24. Screw: Skhd 3/8-16 x3/4 Nyloc SS 2 40-A-503 A-Complete Renewal Kit 1

13 30-A-27 Impact Bar 2 S/N 060185A01/ RG-1000 Forward

14 08-6-276 Nut: Hex Jam Nyloc, 5/8-18, SS 1 40-A-1A A-Rotor Kit (Includes 12-17) 1

15 08-6-277 Washer: Flat, HD, 5/8 x.134 thick 1 40-A-9A A-Sizing Ring Kit 1

16 07-6-98. Gasket: Turntable Mounting 1 (Includes 6, 7 & 9-11)

17 51-A-1 Rotor 1 40-HA-507 A-Motor Seal Kit (Includes 19 & 22) 1

30-A-1 Rotor Assy: w/Impact Bars 1 S/N 060185A01/ RG-1000 Forward

(Includes 12, 13 & 17)

18 08-5-24. Screw: Skhd 3/8-16 x 3/4 Nyloc SS 4 FOR USE WITH BALDOR MOTORS ONLY

19 07-HA-83 Cartridge Seal 1 14 08-H-21 Screw: Hxhd 5/16-18 x 3/4 SS Nyloc 1

04-HA-263 Install. Tool: HA Cartridge Seal 1 15 09-HA-2 Coverplate 1

20 30-A-1141 Base Assy: Includes Seals Installed 1 16 07-HA-3 Gasket: Coverplate 1

21 06-5-851 Drain Coupling: “A” & “B” Series 1 28 02-HA-100 Key 1

22 07-HA-5 Gasket: Motor/Base 1 24 02-A-475 Thermal Protector: #MYJ42WB 2HP 1

MOTOR OPTIONS 24 CYJ52AB Thermal Protector: #CYJ52AB 3HP 1

23 30-H-435 Motor: 1.5 HP/1PH Includes 14-16 &23 1 24 BY J23WB Thermal Protector: #BY J23WB 5HP 1

24 02-HA-459 Thermal Protector: #CE J50CA 1 26 02-5-400 Bearing: #205 UPPER 2HP 1

23 30-A-436 Motor: 1.5 HP/3PH Includes 14-16 &23 1 27 02-HA-399 Bearing: #203 LOWER 2HP 1

24 02-A-462 Thermal Protector: #MWJ57KB 1 26 02-BC-401 Bearing: #206 UPPER 3 & 5HP 1

23 30-A-480 Motor: 2 HP/1PH Includes 14-16 &23 1 27 02-5-400 Bearing: #205 LOWER 3 & 5HP 1

24 02-5-486 Thermal Protector: #BE J44DB 1

23 30-A-442 Motor: 2 HP/3PH Includes 14-16 &23 1 (NON-STOCK ITEMS)

24 02-A-465 Thermal Protector:#CWJ58KB LEESON 1 25, 31, 33, & 35-38 PLEASE CONTACT OUR FACTORY

Page 18 Red Goat Disposers 10/12

Page 19

“A” SERIES REPLACEMENT PARTS DIAGRAM

Red Goat Disposers 10/12 Page 19

Page 20

“B” SERIES REPLACEMENT PARTS LIST

KEY NO. PART NO. NAME: DESCRITION/ QTY PER MACH. KEY NO. PART NO. NAME: DESCRITION/ QTY PER MACH.

1 06-ABC-ST7 Silver Saver: 7” 1 27 30-BC-151 Motor: 5 HP, 3PH Baldor 1

2 06-ABC-834 Connector Sleeve: 7” dia. x 8” 1 (Includes 19-21 & 28)

06-ABC-434 Connector Sleeve: 7” dia. x 4” 1

3 08-ABC-33 Clamp: Connector Sleeve 7” 2 27 30-BC-161 Motor: 7.5 HP, 3PH Baldor 1

4 01-B-36L Lid: 7” Aluminum 1 (Includes 19-21 & 28)

5 07-B-39 Gasket: Lid 1

6 51-B-36 Drum 1 27 30-BC-171 Motor: 10 HP, 3PH Baldor 1

51-B-80 Offset Drum 1 (Includes 19-21 & 28)

30-B-36 Drum Assy (includes 6 & 10-12 1

7 08-BC-71 Screw: Hxhd 3/8-16 x 1-1/2 6 29 08-5-24. Screw: Skhd 3/8-16 X 3/4, Nyloc SS 4

8 08-BC-312 Washer: Lock Split 5/16 13 30 08-BC-283 Key, Woodruff: #808 1

9 08-BC-1029 Nut: Hex 3/8-16 6 31 07-BC-903 Lip Seal: 1 7⁄8” OD Baldor 3-10 HP 1

10 08-BC-67 Thumb Screw: Lid Clamp 4 32 02-BC-403 Bearing: #306 1

11 51-BC-65 Lid Clamp 4 35 02-BC-401 Bearing: #206 1

12 08-BC-285 Screw: Hxhd 3/8-15 x 1-1/2 4 36 09-BC-927 Leg Assy w/Foot: 2” x 9.6, SS 3

13 07-B-32 Gasket: Sizing Ring 2

14 08-BC-1028 Centering Stud 2 40-B-501 B-Complete Renewal Kit 1

15 30-B-31 Sizing Ring 1 (S/N 060185B01/ RG-1000 Forward)

16 10-5-27. Pipe Plug: 1/2 1 40-B-1A B-Rotor Kit (Includes 17-22) 1

17 08-5-24. Screw: Skhd 3/8-16 X 3/4, Nyloc SS 4 40-B-31A B-Sizing Ring Kit 1

18 30-B-6 Impact Bar 2 (Includes 8-9 & 13-15)

19 08-6-280 Nut: Hex Jam Nyloc, 7/8-14, SS 1 40-B-502 B-Motor Seal Kit (Includes 23-24) 1

20 08-6-281 Washer: Flat, HD, 7/8 x .134 thick 1 (S/N 060185B01/ RG-1000 Forward)

21 07-BC-99 Gasket: Turntable Mounting 1

22 51-B-1 Rotor 1 (NON-STOCK ITEMS)

30-B-1 Rotor Assy: w/Impact Bars 1 28, 33, 34, & 37 PLEASE CONTACT OUR FACTORY

(Includes 17, 18 & 22)

23 07-BC-84 Cartridge Seal 1

04-BC-264 Install. Tool: BC Cartridge Seal 1

24 07-B-14 Lip Seal 1

25 30-B-1142 Base Assy: Includes Seals Installed 1

26 06-5-851 Drain Coupling: “A” & “B” Series 1

27 30-B-141 Motor: 3 HP, 3PH Baldor 1

(Includes 19-21 & 28)

Page 20 Red Goat Disposers 10/12

Page 21

“B” SERIES REPLACEMENT PARTS DIAGRAM

Red Goat Disposers 10/12 Page 21

Page 22

“C” SERIES REPLACEMENT PARTS LIST

KEY NO. PART NO. NAME: DESCRITION/ QTY PER MACH. KEY NO. PART NO.

NAME: DESCRITION/ QTY PER MACH.

1 06-ABC-ST7 Silver Saver: 7” 1 26 30-BC-161 Motor: 7.5 HP, 3PH 1

2 06-ABC-834 Connector Sleeve: 7” dia. x 8” 1 (Includes 17-19 & 33)

06-ABC-434 Connector Sleeve: 7” dia. x 4” 1

3 08-ABC-33 Clamp: Connector Sleeve 7” 2 26 30-BC-171 Motor: 10 HP, 3PH 1

4 01-C-1136 Lid: 7" Offset Opening 1 (Includes 17-19 & 33)

4A 07-C-1039 Gasket: Lid 1

5 51-C-1036 Drum 1 27 08-BC-283 Key, Woodruff: #808 1

51-C-1080 High Drum 1 28 07-BC-903 Lip Seal: 1 7⁄8” OD Baldor 3-10 HP 1

51-C-80 Offset Drum 1 29 02-BC-403 Bearing: #306 1

30-C-1036 Drum Assy (Includes 9-11) 1 32 02-BC-401 Bearing: #206 1

6 08-BC-71 Screw: Hxhd 3/8-16 x 1-1/2 6 34 08-5-24. Screw: Skhd 3/8-16 X 3/4, Nyloc SS 4

7 08-BC-312 Washer: Lock Split 3⁄8” 8 35 09-BC-927 Leg Assy w/Foot: 2” x 9.6, SS 3

8 08-BC-1029 Nut: Hex 3/8-16 2

9 08-BC-67 Thumb Screw: Lid Clamp 4 40-C-505 C-Complete Renewal Kit 1

10 51-BC-65 Lid Clamp 4 (S/N 060185C01/ RG-1000 forward)

11 08-BC-285 Screw: Hxhd 1/4-20 x 1-3/4, SS 4 40-C-500 C-Complete Renewal Kit 1

11A 08-BC-286 Nut: Hex Nyloc, 1/4-20, SS 4 (Thru S/N 053185C17)

12 07-C-1032 Gasket: Sizing Ring 2 40-C-1001A C-Rotor Kit (includes 15-20) 1

13 08-BC-1028 Centering Stud 2 40-C-1031A C-Sizing Ring Kit 1

14 30-C-1031 Sizing Ring Assy 1 (Includes 7-8 & 12-14)

15 08-5-24. Screw: Skhd 3/8-16 X 3/4, Nyloc SS 4 40-C-1012A C-Motor Seal Kit 1

16 30-C-1006 Impact Bar 2 40-B-502 B-Motor Seal Kit 1

17 08-6-280 Nut: Hex Jam Nyloc, 7/8-14, SS 1 (S/N 010191/ RG-1000 forward)

18 08-6-281 Washer: Flat, HD, 7/8 x .134 thick 1

19 07-BC-99 Gasket: Turntable Mounting 1 (NON-STOCK ITEMS)

20 51-C-1001 Rotor 1 30, 31, 33, & 36 PLEASE CONTACT OUR FACTORY

30-C-1001 Rotor Assy: w/Impact Bars 1

(includes 15, 16 & 20)

21 07-BC-84 Cartridge Seal 1

04-BC-264 Install. Tool: BC Cartridge Seal 1

22 07-B-14 Lip Seal S/N 010191/ RG-1000 forward 1

23 30-C-1143 Base Assy: Includes Seals Installed 1

24 10-5-27. Pipe Plug: 1⁄2” 1

25 06-5-851 Drain Coupling: “C” Series 1

26 30-BC-151 Motor: 5 HP, 3PH 1

(Includes 17-19 & 33)

Page 22 Red Goat Disposers 10/12

Page 23

“C” SERIES REPLACEMENT PARTS DIAGRAM

Red Goat Disposers 10/12 Page 23

Page 24

RAC1 REPLACEMENT PARTS LIST

KEY PART NO. NAME: DESCRIPTION KEY PART NO. NAME: DESCRIPTION

1

03-5-988

2

03-5-987

3

03-5-1023

4

03-5-1025

5

03-5-1042

6

03-5-1034

7

08-6-258

8

03-5-1000

9

03-HAB-940

10

03-HAB-995

03-HAB-911

03-HAB-912

11

08-6-250

12

03-HAB-906

03-BC-907

03-C-909

SPECIFY HP, VOLTAGE, PHASE, MODEL AND SERIAL NUMBER WHEN ORDERING CONTACTORS AND OVERLOAD RELAYS.

Pushbutton Assy: Red (N.C.)

Pushbutton Assy: Black (N.O.)

Legend Plate: “STOP”

Legend Plate: “RUN”

Enclosure: Non-Metallic, RAC1 & 2

Control Module

Screw: Php HD, 8-32 x 1

Wiring Harness: RAC1

Fuse: 2.5 Amp

Transformer: 24V/115, 230V 50VA

Transformer: 24V/208, 230, 460V 50VA

Transformer: 24V/380V 50VA

Screw: Php HD, 8-32 x 1/2

Contactor: Rev, 10A, 24V, 50/60HZ

(Use w/ 0H, 1.5L, 1.5H, 2L, 2H & 5H)

Contactor: Rev, 17.5A, 24V, 50/60HZ

(Use w/ 0L, 1H, 2.5H, 5L, 7H & 10H)

Contactor: Rev, 32A, 24V, 50/60HZ

(Use w/ 1L, 2.5L, 7L & 10L)

13

14

15

16

17

18

19

08-5-949

03-5-983

03-5-1067

03-5-1097

03-5-1002

03-5-1001

03-5-1085

08-6-251

03-5-1124

03-5-1125

03-5-1126

03-5-1127

Screw, Php HD, 10-32 x 1/2

Back Plate: RAC1 & 2

Track: Contactor Mounting

Grounding Lug

Terminal Strip: 9 Position

Terminal Strip: 6 Position

Terminal Strip: 13 Position

Screw, Php HD, 8-32 x 3/4

Overload Relay: 3-12 Amp

(Use with 1.5L, 1.5H & 5H)

Overload Relay: 11-16 Amp

(Use with 2.5H, 5L, 7H & 10H)

Overload Relay: 18-25 Amp

(Use with 2.5L & 7L)

Overload Relay: 22-32 Amp

(Use with 10L)

Page 24 Red Goat Disposers 10/12

Page 25

RAC2 REPLACEMENT PARTS LIST

KEY PART NO. NAME: DESCRIPTION KEY PART NO. NAME: DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

03-5-1036

03-5-1037

03-5-1023

03-5-1025

03-5-1049

03-5-1042

03-5-1034

08-6-258

03-5-999

03-HAB-940

03-HAB-995

03-HAB-911

03-HAB-912

08-6-250

03-5-1120

08-6-251

03-5-1041

03-HAB-906

03-BC-907

03-C-909

Pushbutton Assy: Lighted, Red

Pushbutton Assy: Lighted, Amber

Legend Plate: “STOP”

Legend Plate: “RUN”

Handle: Disconnect Switch (w/Shaft)

Enclosure: Non Metallic, RAC1 & 2

Control Module

Screw: Php HD, 8-32 x 1

Wiring Harness: RAC2

Fuse: 2.5 Amp

Transformer: 24V/115, 230V 50VA

Transformer: 24V/208, 230, 460V 50VA

Transformer: 24V/380V 50VA

Screw: Php HD, 8-32 x 1/2

Shaft: Disconnect Switch, RAC2

Screw, Php HD, 8-32 x 3/4

Disconnect Switch: 40 Amp, RAC2

Contactor: Rev, 10A, 24V, 50/60HZ

(Use w/ 0H, 1.5L, 1.5H, 2L, 2H & 5H)

Contactor: Rev, 17.5A, 24V, 50/60HZ

(Use w/ 0L, 1H, 2.5H, 5L, 7H & 10H)

Contactor: Rev, 32A, 24V, 50/60HZ

(Use w/ 1L, 2.5L, 7L & 10L)

17

18

19

20

21

22

08-5-949

03-5-983

03-5-1067

03-5-1097

03-5-1002

03-5-1001

03-5-1085

03-5-1124

03-5-1125

03-5-1126

03-5-1127

Screw, Php HD, 10-32 x 1/2

Back Plate: RAC1 & 2

Track: Contactor Mounting

Grounding Lug

Terminal Strip: 9 Position

Terminal Strip: 6 Position

Terminal Strip: 13 Position

Overload Relay: 3-12 Amp

(Use with 1.5L, 1.5H & 5H)

Overload Relay: 11-16 Amp

(Use with 2.5H, 5L, 7H & 10H)

Overload Relay: 18-25 Amp

(Use with 2.5L & 7L)

Overload Relay: 22-32 Amp

(Use with 10L

SPECIFY HP, VOLTAGE, PHASE, MODEL AND SERIAL NUMBER WHEN ORDERING CONTACTORS AND OVERLOAD RELAYS

Red Goat Disposers 10/12 Page 25

Page 26

HOSTILE ENVIRONMENT TABLE REPLACEMENT PARTS

1

2

3

4

KEY

NO.

1

2

3

4

5

6

PART NO.

A2P-THE

A3P-THE

A5P-THE

A2P-R7HE

A3P-R7HE

A5P-R7HE

10-H-303

05-5-154

RAC2-2L

RAC2-2H

RAC2-5LA

RAC2-5HA

40-HE-014

04-5-333

04-5-335

NAME: DESCRIPTION

Hostile Environment Table: 2HP 3 Phase 7” Throat

Hostile Environment Table: 3HP 3 Phase 7” Throat

Hostile Environment Table: 5HP 3 Phase 7” Throat

2 HP 3 Phase 7” Throat Disposer - Includes Chrome

Plated Option

3 HP 3 Phase 7” Throat Disposer - Includes Chrome

Plated Option

5 HP 3 Phase 7” Throat Disposer - Includes Chrome

Plated Option

(For H.E. Disposer Parts Breakdown, view Hostile Envi-

ronment Disposer “A” Series Rep. Parts page)

1/2” Flow Control Valve: 3 GPM (Qty. 2 per Unit)

1/2” 24 Volt Solenoid Valve

Control Panel - 2 HP, 3 Phase, 208/230 Volt

Control Panel - 2 HP, 3 Phase, 460 Volt

Control Panel - 3-5 HP, 3 Phase, 208/230 Volt

Control Panel - 3-5 HP, 3 Phase, 460 Volt

Optional Full Enclosure Stainless Panels (Complete Set)

Replacement Stainless Side Panel

Replacement Stainless Side Panel (Connection Side)

5 6

Page 26 Red Goat Disposers 10/12

Page 27

1

HOSTILE ENVIRONMENT DISPOSER

“A” SERIES REPLACEMENT PARTS

2

3

4

5

6

5

7

8

10

11

12

5

13

14

15

10

16

17

18

19

20

21

9

KEY

NO.

10

11

12

13

1

2

3

4

5

6

7

8

9

7

PART NO.

06-ABC-834

08-ABC-33

51-A-11S

08-HA-22

08-HA-311

08-HA-17

07-A-10

08-HA-16

30-A-9HC

08-5-24

30-A-27HC

08-HA-23

09-HA-2

NAME: DESCRIPTION

Connector Sleeve: 7” dia. x 8”…………………

Clamp: Connector Sleeve 7”…………………..

Drum: 7” Throat………………………………….

Screw: Hxhd 5/16-18 x1, SS…………………..

Washer: Lock Split 5/16………………………..

Nut: Hex 5/16-18………………………………..

Gasket: Sizing Ring……………………………..

Centering Stud…………………………………..

Sizing Ring: Chrome Plated……………………

Screw: Skhd 3/8-16 x 7/8………………………

Impact Bar: Chrome Plated…………………….

Screw: Hxhd 5/16 x 18 x 3/4, Nylock………….

Coverplate……………………………………….

QTY.

PER

MACH.

1

2

1

4

7

2

2

2

1

6

2

1

1

22

KEY

NO.

14

15

16

17

18

19

20

21

30-A-481B Motor: 5 HP, 3 PH, HE.................................. 1

22

PART NO.

07-HA-3

51-A-1HC

30-A-1HC

07-HA-83

04-HA-263

30-A-1141

06-5-851

07-HA-5

02-HA-100

30-A-442

30-AB-448

09-A-928

NAME: DESCRIPTION

Gasket: Coveplate…………………………….

Rotor: Chrome Plated…………………………

Rotor Assy: Chrome Plated…………………..

(Includes Items: (2)10, (2)11, 15)

Cartridge Seal………………………………….

Install Tool: HA Cartridge Seal……………….

Base Assy: Includes Seal Installed…………

Drain Coupling: “A” & “B” Series……………..

Gasket: Motor/Base…………………………..

Key………………………………………………

Motor: 2 HP, 3 PH, HE………………………..

Motor: 3 HP, 3 PH, HE………………………..

Leg Assy w/Foot: 2” x 13.5 SS……………….

Red Goat Disposers 10/12 Page 27

QTY.

PER

MACH.

1

1

1

1

1

1

1

1

1

1

3

1

Page 28

TERMS OF SALE

1. NATURE OF DOCUMENT. This document constitutes the acceptance of the RED GOAT Disposers Division of Somat Company (“Seller”) to sell the products specified on the reverse side

(the “Products”) on the terms and conditions contained herein, however, acceptance is made expressly conditional on the Buyer’s agreement to all of the terms and conditions contained

herein. Seller’s acceptance of a purchase order from the Buyer shall not constitute acceptance of any of the terms and conditions thereon which differ from these terms, except as the

Seller may otherwise specify in writing.

2. TERMINATION AND CANCELLATION. Seller shall have the right to terminate and cancel the contract for sale of the Products at any time Seller determines that Buyer’s credit is not

satisfactory. Any such termination or cancellation shall be effective upon notification (orally or in writing) to Buyer and shall be without liability to the Seller. Under no circumstances shall

Buyer have the right to terminate the contract or cancel its order to purchase the Products, without written authorization by the Seller. All cancelled orders and returned goods will be

subject to a minimum of 25% cancellation and/or restocking charge. Custom or modified units cannot be returned.

3. PRICES. Unless otherwise indicated, prices are F.O.B. Lancaster, PA and do not include any sales, use, excise or similar taxes or duties now or hereafter imposed. Errors or

omissions in prices are subject to correction.

4. PAYMENT. Unless otherwise indicated, payment terms are net cash 30 days from date of shipment. In the event that the Buyer fails to make payment on time, Buyer shall be liable to

Seller for the lesser of (a) 1.5% per month on the remaining balance or (b) the highest monthly interest rate which may lawfully be charged to Buyer. Buyer shall be liable for all expenses

(including reasonable attorneys’ fees) incurred by Seller in collecting or attempting to collect any amounts due to Seller under the contract.

5. TITLE; RISK OF LOSS. Title to, and risk of loss of, the Products shall pass to Buyer upon the delivery of the Products F.O.B. Lancaster, PA to an agent of Buyer or to a common

carrier.

6. INSPECTION. If, upon receipt of the Products by Buyer at the destination, the same shall appear not to conform to the order, Buyer shall within seven (7) days after receipt thereof,

notify Seller of such condition and afford Seller a reasonable opportunity to inspect the Products and make the appropriate adjustments, repair or replacement. The remedies afforded

under Section 7 below shall be exclusive for any defects discovered in the Products and which could have been discovered upon inspection. If the Seller is not so notified, the Buyer

waives any recourse for those defects, and all warranty obligations of Seller regarding such obvious defects or deficiencies shall terminate.

7. LIMITED WARRANTIES AND REMEDIES. Seller warrants that, at the time of shipment, the Products will be free from defects in material and workmanship for a period of one year

from the date of purchase by the initial user. Written notice of a claim under this warranty must be received by Seller before the expiration of such period in order for warranty coverage to

apply.

If notice of a claim is timely made, Seller will repair or replace the Product or part which is defective (at Seller’s sole option) either at the user’s facility or at Seller’s plant, as Seller shall

decide. If Seller decides that a Product or part should be returned to its plant, the Buyer or user shall have the following obligations:

(a) removal of any parts to be returned;

(b) identification of all parts with tags stating the model number and serial number of the Products on which the part is used;

(c) shipment of Products and/or parts, transportation prepaid, to Seller’s plant;

(d) installation of the repaired or replaced Product or parts at user’s facility.

This Warranty shall not apply to the extent that Products or parts have been used other than in conformance with operating or maintenance instructions, subjected to misuse or abuse,

damaged by accident, act of God, abnormal use or stress or any other matter unrelated to Seller and beyond its reasonable control or altered or modified by third parties.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PURPOSE. IN NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF USE, REVENUE OR PROFIT OR FOR ANY OTHER INCIDENTAL, SPECIAL OR

CONSEQUENTIAL DAMAGE INVOLVING THE PRODUCTS.

8. LIMITATION OF LIABILITY. The liability of Seller arising out of the manufacture, sale, delivery, repair, or use of any of the Products shall not, in any event, exceed the cost of

correcting defects or making replacement as required in the Limited Warranty and, upon the expiration of the Limited Warranty, all liability of Seller to Buyer shall terminate.

9. DELAYS. Neither party shall be liable for any delay or failure to perform any obligation to the other if such delay or failure shall be caused by an event or contingency beyond its

reasonable control, irrespective of the nature thereof, however, the delaying party shall endeavor to correct such delay as soon as reasonably practicable.

10. MODIFICATION; ASSIGNMENT; APPLICABLE LAW; ENTIRE AGREEMENT. No modification of the terms and conditions specified in the contract shall be binding upon Seller

unless agreed to by Seller in writing. The contract shall not be assigned by Buyer, nor may any of the duties of Buyer there under be delegated, without the written consent of Seller. Any

such assignment or delegation without such consent shall be void. The contract shall be governed by, and construed in accordance with, the laws of the State of Pennsylvania. The

provisions of the contract shall constitute the entire agreement of the parties with respect to the sale of the Products by Seller to Buyer and shall supersede all prior discussion and

writings between the parties.

11. BINDING EFFECT OF CONTRACT. The contract shall be binding upon, and shall inure to the benefit of, the parties hereto and their respective successors and assigns.

12. RETURNS. No returns will be accepted without the prior approval of the Seller. A Return Authorization Number must be given by Seller prior to Products being shipped, freight

prepaid, by Buyer. Any damage in transit to Products being returned is Buyer’s responsibility.

All accepted returns are subject to a 25% or $25.00 minimum restocking charge. Returns that have been approved by Seller must be received within thirty (30) days after approval.

Returns will not be considered after ninety (90) days from date of original notice.

13. INDEMNITY. Buyer agrees to indemnify, hold harmless and defend Seller from and against any and all liabilities and expenses arising out of any injury or damage which results from

Buyer’s use, misuse, misapplication, failure to inspect, maintain or repair the Products which are the subject of this agreement.

14. MINIMUM ORDER. $75.00 net.

WARRANTY

THE EXCLUSIVE ONE AND TEN YEAR WARRANTY

All products (and parts) manufactured and sold by RED GOAT DISPOSERS (the “Manufacturer”) are warranted to be free from

defects in material and workmanship for a period of one year following the date of its initial installation or eighteen months from

the date of shipment from the factory or factory warehouse, whichever expires first. Notice of a claim under this Warranty must be

RUBBER

HEAD GASKET

PARTS AND received by the Manufacturer at its offices before the expiration of such period in order for Warranty coverage of

to apply.LABOR

If notice of a claim is timely made, the Manufacturer will repair or replace the product or part which is defective either at the user’s

facility or at the Manufacturer’s plant, as the Manufacturer shall decide. In addition, the Manufacturer warrants that the basic body

components of every Red Goat Disposer will remain serviceable for a period of at least

TEN YEARS. Should any of these basic

SLOTTED

SIZING RING

body components require replacement during the first ten years of normal usage following installation the Manufacturer will furnish

new duplicate parts to the original user at no charge. Manufacturer cannot warrant products returned to the factory not properly

packaged, causing additional damage.

MOTOR SHAFT

SEAL SYSTEM

This Warranty shall not apply to the extent that products or parts have been used other than in conformance with operating and

R

maintenance instructions, subjected to misuse or abuse or damage by accident, act of God, abnormal use or stress or any other

matter unrelated to the Manufacturer, and beyond its reasonable control or otherwise altered or modified by third parties. In

ROTOR WITH

IMPACT BARS

addition, this Warranty does not cover normal wear items, such as sizing rings, impact bars and rotors. THIS WARRANTY IS

EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED AND IMPLIED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PURPOSE. In no event shall the Manufacturer be liable for loss of

use, revenue or profit or for indirect or consequential damages.

All Red Goat machines are packed in heavy corrugated shipping containers suitable for reshipment.

Red Goat Disposers is not responsible for any typographical errors.

Due to continued product improvement specifications are subject to change without notice.

STANDARD ONE YEAR WARRANTY

ALL RED GOAT disposer components ,

shown above in BLOCK print, are guaranteed

against all def ects for the initial ONE YEAR

period of use, as stated in the Warranty.

MOTOR

ALL RED GOAT basic body components ,

shown abo ve in

teed to remain ser v iceable at least TEN

YEARS as stated in the Warr anty.

Page 28 Red Goat Disposers 10/12

Heavy Cast

Aluminum Cover

Quick Release

Head Clamps

Cast Alloy

Waste Chamber

Cast Alloy

Base

Stainless Steel

Leg Supports

Adjustable Feet

TEN YEAR WARRANTY

italicized

print, are guar an-

Loading...

Loading...