Classic Range Cooker

OIL

Instructions for

Installation and Servicing

For use in Great Britain & Ireland

IMPORTANT

Redfyre Cookers, Osprey Road, Sowton Industrial Estate, Exeter, Devon, England EX2 7JG

Tel: (01392) 444070 Fax: (01392) 444804 E-mail: redfyre@gazco.com

A division of Gazco Ltd

This appliance must be installed and commissioned by an experienced oil heating engineer.

PR0655 Issue 2 (November 2006)

TECHNICAL SPECIFICATION

TECHNICAL DATA:

Burner Specification Don 8" Natural Draught

Vaporising Type

ppliance Type/Fuel Oil Fired Kerosene to BS2869

A

1988 Class 2

Country of Origin United Kingdom

Oil Flow Rates Low – 4ml/min.

High – 10ml/min.

Flue Draught Min. 0.02" wg (0.5mm wg)

Max. 0.04" wg (1.0mm wg)

Heat Input Low – 2.55kw (8.721 Btu/hr)

High – 6.37kw (21.734 Btu/hr)

Size of hot plates: 346mm diameter

Size of main oven: 507mm depth x 384mm width

x 310mm height

Size of warming oven 507mm depth x 384mm width

x 249mm height

Gross weight Approx. 397kg

Electrical Supply 230V 50Hz supplying

transformer 12VAC 1.5A

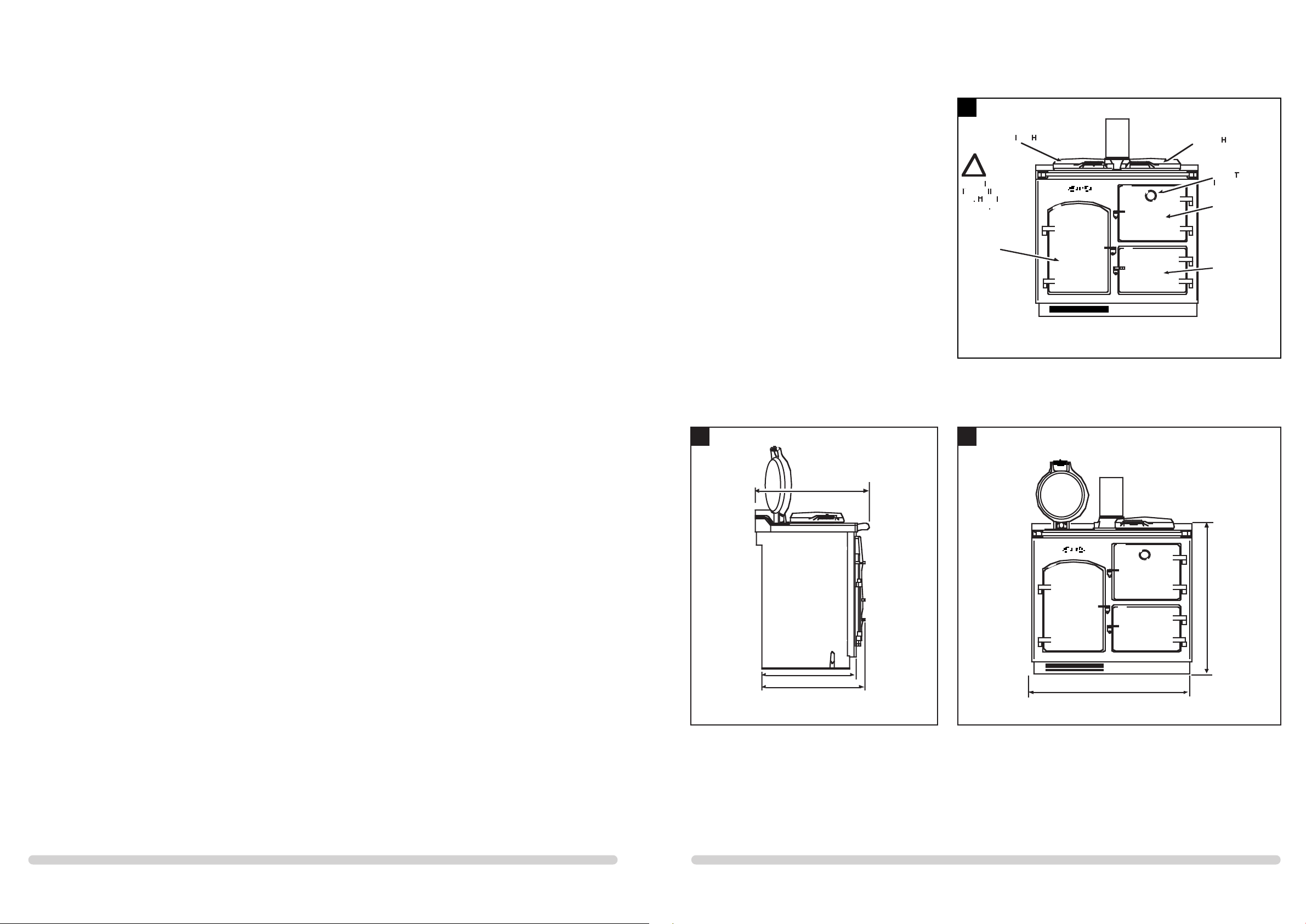

1

724mm

583mm

643mm

32

940mm

1007mm

17

2

INSTALLATION INSTRUCTIONS

WARNING

CONTROL OF SUBSTANCES HARMFUL TO HEALTH

It is the responsibility of the user and installer to ensure that protective clothing is worn when materials known to be injurious to

ealth and safety are being handled.

h

Avoid inhalation when working with insulation materials such as ceramic board, glass fibre or mineral wool.

•

se disposable protection for the eyes, skin and throat.

U

•

Use disposable gloves when handling fuels, fire cement and firebricks.

•

ALWAYS ENSURE THAT WORKING AREAS ARE WELL VENTILATED DURING INSTALLATION AND COMMISSIONING.

1. IMPORTANT INFORMATION

To ensure optimum performance from this range cooker, it

must be installed and commissioned by a REDFYRE/OFTEC

approved engineer.

Installation must be carried out to accepted standards, and

comply with all regional and national regulations. Redfyre

Cookers will accept no responsibility or liability for any faults

arising from poor or incorrect installation.

Any alteration not approved by Redfyre Cookers could

invalidate the approval of the appliance and the operation of

its warranty, as well as adversely affecting the purchaser’s

statutory rights.

It is recommended that a qualified OFTEC engineer should

carry out servicing once, or preferably twice, a year.

It is a requirement under OFTEC regulations that the

installation is recorded on a CD 10 form (a copy is attached at

the end of this book). Once completed, a copy is to be given to

the end user and one copy sent to Gazco Ltd. Failure to do so

may invalidate the guarantee.

The appliance is delivered fully assembled, with the exception of

the following items packed in a box in the Simmering Oven.

Set of Burner Shells

•

Burner Lid – 2 parts

•

Burner Ring

•

Vapour Chamber Lid

•

Flue Collar & Filler Plate

•

KBB Fire Valve

•

Set of Wicks

•

The location for the appliance must fit in with the layout and style

of the kitchen, and have:

access to services (oil and electricity);

enough space for the appliance, allowing access for

installation and maintenance;

3. DELIVERY

Astonish Cleaner

•

Shelves (3)

•

Cold Shelf

•

Roasting Dish (Lge)

•

Roasting Dish (Smll)

•

Cookbook

•

Instructions

•

4. LOCATION

EVIDENCE OF FAULT CAUSE

Burner soots up 1. Too little primary air.

2. Too low a flue pull.

3. Downdraught in flue. Fit suitable anti-downdraught cowl.

4. Vapourising Chamber lid not fully seated.

5. Shells not correctly seated.

6. Incorrect or contaminated fuel. Very little can cause

trouble. Clean out tank and refill with a new fuel.

COOKERS

Not reaching required temperature 1. Too little primary air.

2. To high a flue pull.

3. Flue partly or fully blocked.

4. High fire screw set too low.

Overheating 1. Too low a flue pull.

2. Low fire screw set too high.

Variations in temperature 1. Variations in flue draught. Fit suitable stabiliser.

2. COMPLIANCE

Installation must comply with these regulations:

The Building Regulations: Part J England and Wales; Part F,

Section III Scotland; Part L Northern Ireland; Part J Eire.

BS5440 Parts 1 & 2 installation of Flues and Ventilation.

BS5410 Part 1.

D.M.2. Installation in Timber Frame Buildings.

All OFTEC Codes of Practice.

Where a Standard or a Code of Practice is quoted, the current

version must be used.

a satisfactory flue;

a solid non-combustible hearth capable of supporting the

weight of the appliance.

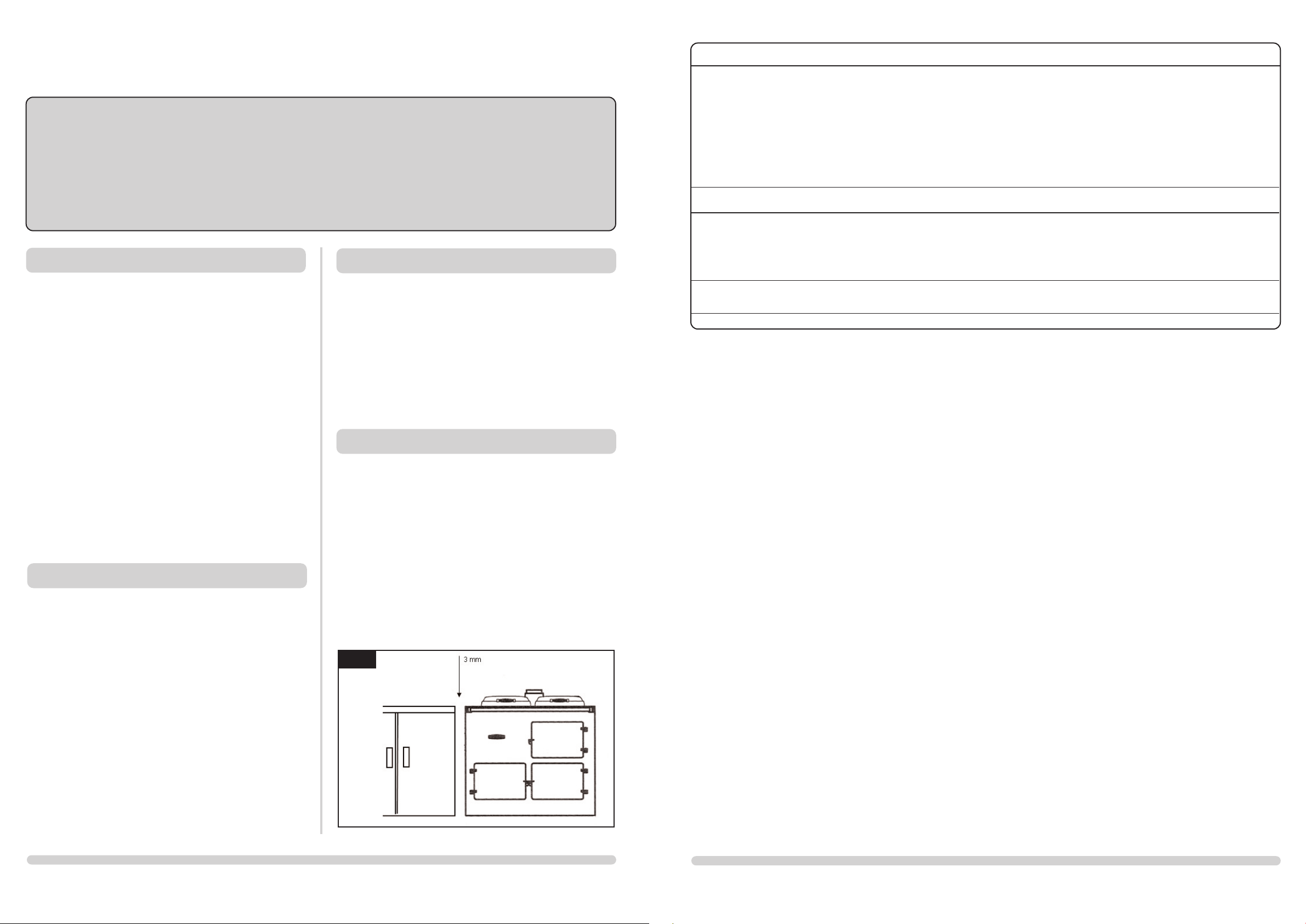

You need to allow at least a 3 mm gap between the

kitchen surfaces, cupboards or walls for expansion and

services.

4

3

16

EVIDENCE OF FAULT CAUSE

Black stain around any door 1. Too little primary air.

. Too low a flue pull.

2

3. Downdraught in flue. Fit suitable anti-downdraught cowl.

4. Flue partly or fully blocked.

. High fire screw set too high.

5

Burner carbons up after short period 1. Low fire screw set too low.

2. Oil Control filter blocked. Remove and clean with boiling

water and dry thoroughly before replacing.

. Incorrect or contaminated fuel. Very little can cause

3

trouble. Clean out tank and refill with a new fuel.

Unable to light burner 1. Control metering stem slot obstructed. To clear, turn

Control Knob from OFF to full ON several times.

2. Oil Control filter blocked. Remove and clean with boiling

water and dry thoroughly before replacing.

3. Metering stem in oil control sticking. Replace control.

4. Fuel inlet blocked. Service.

5. Oil depth in burner base too shallow.

6. Oil level in tank too low.

7. Air lock in oil line tank – burner – control.

8. Incorrect or contaminated fuel. Very little can cause

trouble. Clean out tank and refill with a new fuel.

9. Electrical supply failed or turned off. Check power supply. If there is

a power cut, switch control to manual. See User’s Instructions.

Burner goes out after burning 1-2 hours 1. Too little primary air.

2. Downdraught in flue. Fit suitable anti-downdraught cowl.

3. Low fire screw set too low.

4. Control metering stem slot obstructed. To clear, turn Control

Knob from OFF to full ON several times.

5. Fuel inlet blocked. Service.

6. Oil depth in burner base too shallow.

7. Oil level in tank too low.

8. Air lock in oil line tank – burner – control.

9. Incorrect or contaminated fuel. Very little can cause

trouble. Clean out tank and refill with a new fuel.

Burner goes out for no apparent reason 1. Too little primary air.

2. Downdraught in flue. Fit suitable anti-downdraught cowl.

3. Flue partly or fully blocked.

Low fire screw set too low.

4.

5. Control metering stem slot obstructed. To clear, turn

Control Knob from OFF to full ON several times.

6. Trip lever operated.

7. Oil Control filter blocked. Remove and clean with boiling

water and dry thoroughly before replacing.

Fuel inlet blocked. Service.

8.

9. Oil level in tank too low.

10. Air lock in oil line tank – burner – control.

Incorrect or contaminated fuel. Very little can cause trouble.

11.

Clean out tank and refill with a new fuel.

12. Electrical supply failed or turned off. Check power supply. If there is

a power cut, switch control to manual. See User’s Instructions.

5

. ELECTRICAL SUPPLY

All electrical work must be carried out by competent persons.

his cooker requires an electrical supply 230V 50Hz. A 3Amp

T

fused spur is to be positioned within 90cm of the LH side of the

cooker, See diagram 14.

In addition, the supply can be wired in via an optional timer

control, see diagram 14.

This supply needs a transformer which connects to the oil valve

thermostat control fitted inside the cooker. Easy access is provided

ia a magnetic access panel on the LH side of the cooker.

v

The cooker has a manual overide in the event of a power cut. See

ser’s Instructions.

U

6. FLUE SYSTEMS

5

Approved anti-downdraught

Min Height

This appliance is designed to operate with a Class 2 flue,

nominally 125mm (5") diameter. To ensure correct performance,

both flue and termination should conform to the relevant British

Standard.

NOTE: COMBUSTION TESTING, FLUE GAS ANALYSIS AND

DRAUGHT MEASUREMENT MUST BE CARRIED OUT ON SITE

BY THE APPROVED COMMISSIONING ENGINEER.

The quality of the flue is vital for satisfactory operation. A thorough

pre-installation check by a flue specialist is advisable. If an existing

flue is to be used, the specialist will advise on re-lining and the

correct choice of cowl or terminal for site wind conditions etc.

Before installing the appliance into an existing flue, check that:

the flue is clear of obstructions. Repair any structural damage.

•

the flue pipe is continuous. Any breaks in seals, flue liners etc.

•

must be rectified. A flexible steel liner (oil grade), BS4543 Parts

1 & 3 is highly recommended.

the flue diameter is uniform over its entire length.

•

the flue is not serving another appliance. Never connect to a

•

shared flue.

the flue is not constructed wholly of a single-skin pipe. This

•

must not be used under any circumstances. It has minimal heat

Typical Flue Arrangements

25mm (5") Diameter Flue

1

flue terminal

ermiculite

V

Clay liner

Sealing and

clamping plate

toBend

=600mm

NOTE: THESE DRAWINGS ARE SCHEMATIC REPRESENTATIONS ONLY

ermiculite or

V

similar filter

Flexible flue liner

Closure plate

5" diameter flue

Cleaning hatch

etention properties, and will lead to an overall loss of

r

efficiency, as well as condensation in flue and ovens.

vermiculite backfill, or the equivalent, is used whenever a

•

lexible liner is installed. It must be sealed top and bottom.

f

salt-glazed clay or pre-cast liners are acceptable.

•

the most appropriate cowl depends entirely on conditions at

•

he site. Several may have to be tried before one is found that

t

gives good all-year performance. In some circumstances it

may not be possible to entirely exclude downdraughts

aused by surrounding buildings or trees, so fit an anti-

c

downdraught cowl, preferably of the O-H type.

A ‘Chinaman’s Hat’ is not sufficient.

7. FLUE HEIGHT

A minimum of 4 metres (15 feet) is required between cowl and

round level.This ensures that the flue gases are vented into

g

relatively non-turbulent air, and will be less affected by nearby

buildings or trees etc. In certain circumstances, trees or other

bstructions may need to be removed.

o

Installation with flues in excess of 10M in height is not

recommended. Very tall flues are likely to exceed the maximum

flue draught specified in the technical data. High flue draughts can

cause problems with oven and hob temperatures and increase

running costs.

The cowl must be at least 1 metre above any obstruction within

600mm, and the siting of the flue should comply with OFTEC

regulations.

8. HORIZONTAL RUNS

Horizontal runs of greater than 450mm (18") should be avoided.

If the flue has to be offset, the recommended angle is 60° and the

legal minimum 45°. Never use a bend of 90°.

If the installation is using an existing flue, horizontal runs should be

avoided. A vertical rise of 600mm is the mandatory minimum

before turning into the flue. If it is necessary to exhaust into an

extended flue after the mandatory 600mm rise, the horizontal run

must not exceed 450mm.

NOTE: ALL FLUE CONNECTIONS MUST BE FULLY SEALED

AND INSPECTED BY THE INSTALLER ON COMPLETION.

9. FLUE CLEANING

Annual inspection and cleaning of the flue is recommended.

Therefore a cleaning door, or some other means of access, should

be incorporated into the system.

10. HEARTH CONSTRUCTION

The cooker must be installed on a non-combustible surface

designed to take its weight. For example, concrete slabs or similar.

11. CLEARANCE TO COMBUSTIBLES

Allow 15mm to the rear of the unit for the circulation of air and

the escape of cooking vapours. Do not tile down as far as the top

plate surface – if the top plate has to be removed at some time in

the future, the tiles would be damaged.

Allow 20mm to either side. Vertical filler pieces can be used.

15

4

12. OIL TANK SUPPLY PIPING

The appliance must be supplied by an oil tank and pipework of an

OFTEC approved standard, and installed to current OFTEC Codes

f Practice. Mild steel tanks should conform to BS541, plastic

o

tanks to OFT100.

14. FLUE DRAUGHT INTERFERENCE

ppliances with the ability to extract air should not be located in

A

the same room as the oil-fired Range Cooker. If this proves to be

impracticable, then additional air inlets to should be provided to

ompensate. A Flue Draught Interference Test will determine

c

whether or not there is an adequate air supply.

FAULT FINDING

GENERAL FAULT FINDING CHART FOR SINGLE, COMBINATION AND

DOUBLE OIL BURNERS

5

A = 450mm minimum height above the Cooker Oil Control Valve

H = Head of oil not more than 3m above the Cooker Oil Control Valve

It is important that the oil supply pipe and the height of the tank

are sufficient to enable 0.8 litres of oil per hour to pass freely into

the burner. Calculate the size taking into account the total friction

losses in the pipe, including bends etc.

Run the oil supply pipe to the rear LH side of the cooker, where it

will join with the Preformed 8mm Feed Pipe, which connects to

the Oil Valve. Easy access is gained to this pipe via a magnetic

access panel.

NOTE: A FUEL SHUT-OFF VALVE MUST BE FITTED AS CLOSE

TO THE APPLIANCE AS POSSIBLE – AND BE ACCESSIBLE AT

ALL TIMES. IT SHOULD BE CLOSED WHEN THE PROPERTY IS

VACANT FOR ANY LENGTH OF TIME.

Oil tank and pipe installation

13. AIR SUPPLY

Whenever a flued appliance is installed, a permanent air vent

must be provided. It must be located to take its air either from an

external source, or from an adjacent room which itself must have

a permanent external air vent of at least the same size.

For oil fired appliances, British Standard Code of Practice BS

5410: Part 1: 1997 requires that combustion air must be provided

into the room containing the appliance through purpose made

non-closable openings, having a total free area of 550mm

of the appliance maximum output rating above 5 kW.

This requirement does not apply if a room sealed balanced flue

appliance is used.

The Building Regulation for England, Wales, Scotland require that

an air supply to each appliance is provided, in accordance with

the requirement of BS 5410: Part 1: 1997. In the Republic of

Ireland, the Regulations advise that an air supply of 550mm

each kW of appliance output above 5 kW is provided.

This appliance requires a minimum of 755m2.

2

per kW

2

for

LUE DRAUGHT INTERFERENCE TEST

F

When the extractor is in the same room as the appliance – all

doors, windows and additional ventilation openings to the room

ust first be closed.

m

When the extractor is elsewhere in the building – all doors,

windows and additional ventilation openings must be closed, and

internal doors left open. The extractor should then be run at

maximum speed. As soon as the normal airflow pattern has been

established, the appliance should be set to maximum.

Combustion condition readings should then be taken with and

without the extractor fan running. The appliance should work

satisfactorily in either case. If not, additional ventilation must be

provided.

VENTILATION RESTRICTIONS

Where the appliance has a Vaporising Burner, the mechanical

extract rate from the area in which it is installed must not exceed

20 litres per second.

In the case of a Pressure Jet Burner, the rate must not exceed 40

litres per second.

OTHER INTERFERENCE WITH AIR SUPPLY

Other appliances like tumble driers, which discharge air to the

outside, have the same effect as extractor fans.

Other heating appliances in the same area using different fuels can

also have an adverse effect. They must have their own air supply

complying with Building Regulations for that particular fuel.

15. BURNER INSTALLATION

6

Burner Assembly

When the appliance is in its final position and has been levelled,

connect the 10mm Oil Feed Pipe to the KBB Remote Acting Fire

Valve, 8mm connection to the Preformed Feed Pipe on the LH

side of the cooker, and then to the inlet of the Oil Control Valve.

Purge the Oil Feed Pipe to remove air locks, then open all valves

to allow oil into the Oil Control Valve.

EVIDENCE OF FAULT CAUSE

Trip/Reset lever operates repeatedly 1. Oil level in control too high.

2. Top of tank over 10 feet above oil control unit.

Yellow flame on high fire only 1. High fire screw set too high.

2. Burner out of level.

Yellow flame on low fire only 1. Low fire screw set too low.

2. Burner out of level.

Yellow flame at all Control Knob positions 1. Too much primary air.

2. Too little secondary air.

3. Vapourising Chamber lid not fully seated.

4. Shells not correctly seated.

5. Burner out of level.

Yellow flame at one point of burner only 1. Wicks incorrectly positioned or upside down.

2. Vapourising Chamber lid not fully seated.

3. Shells not correctly seated.

4. Lighting flap not correctly seated.

5. Burner out of level.

Flame funnelling at centre of burner 1. Wicks incorrectly positioned or upside down.

Flame appears to leave top of burner 1. Too little primary air.

2. Too low a flue pull.

3. Flue partly or fully blocked.

Burner Popping 1. Too little primary air.

2. Too much secondary air.

3. Too low a flue pull.

4. Downdraught in flue. Fit suitable anti-downdraught cowl.

5. Wicks incorrectly positioned or upside down.

6. Oil depth in burner base too deep.

7. Vapourising Chamber lid not fully seated.

Burner surging 1. Variations in flue draught. Fit suitable stabiliser.

2. Fuel inlet overheating. Insulate with fireproof material.

3. Oil depth in burner base too deep.

Impossible to set high fire high enough 1. Too little primary air.

Flue partly or fully blocked.

2.

Impossible to set high fire low enough 1. Too much primary air.

Impossible to set low fire high enough 1. Too little primary air.

Too much primary air.

Impossible to set low fire low enough

Oil smell apparent 1. Too little primary air.

1.

2. Too low a flue pull.

Downdraught in flue. Fit suitable anti-downdraught cowl.

3.

4. Flue partly or fully blocked.

5. High fire screw set too high.

5

14

SERVICE RECORDS

1ST SERVICE 2ND SERVICE

Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Signed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer’s Stamp Dealer’s Stamp

NOTE: AVOID KINKING IN THE OIL FEED PIPE, IT CAUSES AIR

LOCKS. ALWAYS RUN THE PIPE TO A LOW POINT, THEN

PROVIDE A GRADUAL UPWARD SLOPE TO THE BURNER.

Open the Burner Door, and remove the Burner Cover.

Adjust the front support levelling screws of the Burner Assembly

until it is level in all directions by using a Cross Test Level. Then

tighten the locknuts on the levelling screws, and re-check for level.

Check that the oil depth in the burner base is between 5 to 6mm.

Correct if necessary by adjusting the position of the Oil Control

Valve.

3RD SERVICE 4TH SERVICE

Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Signed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer’s Stamp Dealer’s Stamp

5TH SERVICE 6TH SERVICE

Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Signed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer’s Stamp Dealer’s Stamp

7TH SERVICE 8TH SERVICE

Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signed:

Dealer’s Stamp Dealer’s Stamp

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signed:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NOTE: The Burner Base must be level in all directions.

It is a requirement under OFTEC regulations that the

installation is recorded on a CD 10 form (a copy is attached at

the end of this book). Once completed, a copy is to be given to

the end user and one copy sent to Gazco Ltd. Failure to do so

may invalidate the guarantee.

Complete this form now.

9TH SERVICE

Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date of Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Next Service due: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer’s Stamp Dealer’s Stamp

10TH SERVICE

Signed:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

6

COMMISSIONING

16. FITTING THE BURNER WICKS

Fit the Burner wicks, and check that the ‘cut-outs’ face downwards

nd line up with the radial oilways in the Burner Base.

a

Now fit the Vapour Chamber Lid with its machined face

ownwards, and turn, pressing down to get a mechanical seal.

d

Also check that each Perforated Shell Assembly has a near-airtight

eal with the Burner Base – and that the seams are arranged

s

approximately at right angles to each other, with the Lighting Port

at the bottom facing forward. Take care not to trap a wick thread

between the Shell and the Base.

8

icks

W

Galleries

ross Ports

C

18. ADJUSTING THE OIL CONTROL VALVE

– BM30 SERIES

The BM30 Oil Control Valve is a safety component, and so must

e handled carefully. Installation, adjustment and servicing can

b

only be performed by authorised personnel, and must conform to

Local Authority codes and requirements.

NOTE: BEFORE ADJUSTING THE OIL CONTROL VALVE,

CHECK THE VALVE AND FILTER FOR CONTAMINATION.

9

The performance of the Oil Control Valve is governed by an

adjustable Control Rail. It is mounted on a toothed rack, moved by

a pinion connected to the Oil Control Knob. Before adjusting the

rates, remove the punched section of the Cover Plate.

10

Low fire limit screw (F)

Control Valve Adjustment

Control rail

Control Oil Knob

High and Low fire adjusting

screw position (E)

24

Carefully remove the mineral wool insulation to reveal the

Cleaning Door, then remove it.

Removal of the mineral

wool insulation

25

Removal of the flueway cover plate

Remove both top Flueway Cover Plates – and thoroughly clean all

combustion products from the flueways with a wire brush.

Replace the Cover Plates, making sure the gaskets are sound and

form a gas-tight joint. Replace the insulation.

Fit the Burner Shells, starting with the inner one and working

utwards. Arrange the seams at 90˚ to one another, with the outer

o

shell Lighting Port facing forwards. Check that each shell is

accurately located on its spigot, and has not trapped a strand of

ick material.

w

it the Cast Iron Flame Ring, taking care not to disturb the Outer

F

Shell, then fit the Burner Lids.

eplace the Boiling and Simmering Hotplates, using the tool

R

provided. When in place, tighten the fixing screws – making sure

both hobs are uniformly bedded on the rope seal, and level after

inal tightening.

f

Replace the Inner Control Box Assembly, and re-fit the Tempomat

o the Oil Control Valve.

t

Re-fit the Oil Control Box Casing, and the control knobs.

Turn on the electrical supply, press the Safety Button to turn on

the oil supply – allowing 10-15 minutes for sufficient oil to enter

the Burner.

Then turn the Oil Control Knob to ‘High +’ setting, and switch on

the Thermostat.

Lift the Lighting Port Cover, light the Burner, and then replace the

Burner Cover.

With the Thermostat at the mid-position, let the cooker get back

up to its working temperature.

The Servicing Procedure is now complete.

17. CHECKING THE BURNER OIL LEVEL

Open the Oil Control Box Cover.

After making sure that all valves have been opened, press down

the Trip/Reset Lever, and turn the Oil Control Knob to the

‘Number 6’ setting.

8

Oil Control Knob

Trip/Reset Lever

High fire position

Control knob (A)

Low fire position

To adjust the minimum flow rate turn the Oil Control Knob to

‘position 1’ and turn the Adjustment Screw, which is visible

through the knockout in the cover, anti-clockwise to increase the

flow, clockwise to decrease it.

To adjust the maximum flow rate turn the Oil Control Knob to

‘position 6’ and turn the Adjustment Screw, which is visible

through the knockout in the cover, anti-clockwise to increase the

flow, clockwise to decrease it.

Actuating pin

Check that the integral Draught Stabiliser is free from obstruction

and can move freely.

Thoroughly clean the passages across the top of the cooker before

the Boiling and Simmering Hotplates are replaced.

25. RE-ASSEMBLY

First, replace the Burner Assembly in the Combustion Chamber

and lightly tighten the 2 retaining nuts.

Using a Cross Test Level, make sure the base is level in all

directions by adjusting the Jacking Screws – then tighten the two

retaining nuts. Re-check that the Burner is level.

Re-connect the Oil Supply Pipe to the Oil Control Valve, checking

all joints for leaks.

Allow oil to enter the Burner and check the oil depth is between

5 to 6mm.

Replace the Vapour Chamber Lid, and turn, pressing down, to get

a mechanical seal.

Insert new wicks, making sure the cut-outs are facing downwards

and in line with the radial ports.

7

12

urner Cover fixing nut

9

1

B

23. CLEANING BURNER AND FILTERS

19. CHECKING AND ADJUSTING BURNER

12

FLOW RATES

urner

B

over

C

lean the Burner Base thoroughly, paying particular attention to

C

the cross ports and galleries. Make sure the annular shell location

spigots are clean and undamaged, and that the Vapour Chamber

id seating is flat and unmarked.

L

fter making sure that the Burner is level, and that the oil is at the

A

correct depth, disconnect the feed pipe from the Oil Control Valve

to the Burner and measure the flow rate by the Drip Feed Method.

Burner Door

Remove the Burner Cover by releasing the hexagonal nut with the

ool provided, and lifting the door clear.

t

20

Check the machined face of the Vapour Chamber Lid to make

ure the surface is flat and free of inclusions.

s

Make sure the carbon leg (fuel inlet) is free from any carbon

o not use

eposits. When re-assembling it into the Burner Base

d

PTFE tape as a seal

, always use a jointing compound like Foliac.

22

d

apour Chamber Lid

V

achined face

m

Annular shell location

spigots

apour Chamber Lid

V

seating

Thoroughly clean soot deposits from all burner components.

Remove the Oil Filter Element from the Oil Control Valve, wash

out with clean kerosene, and re-assemble. Check that the

neoprene gasket makes a leak-proof seal.

NOTE: ALLOW 10 MINUTES FOR THE FLOW RATE TO

STABILISE BEFORE MEASURING. AFTER RESETTING, ALLOW

MINUTES BEFORE THE NEXT MEASUREMENT.

2

To check the low setting

ontrol Valve to ‘position 1’, and check the flow. It should be

C

- turn the Oil Control Knob on the Oil

4.0ml/min. If it needs adjusting, turn the Low Setting Screw in

the direction shown on the cover plate to increase or decrease

he flow.

t

To check the high setting - turn the Oil Control Knob to ‘position

’, allow time for the flow to settle, then check. It should be

6

10.0ml/min. If it needs adjusting, turn the High Setting Screw in

the direction shown on the cover plate to increase or decrease

the flow.

When adjusting the burner flow rates, the screws musrt only be

turned a quarter of a turn at a time and the flow allowed to

stabilise before turning further.

20. LIGHTING THE OIL BURNER

WARNING

NEVER try to re-light a hot burner! The burner MUST

be cool before you turn on the oil!

nner burner door

I

Lift up the Burner Cover, and remove it.

13

O

T

ven Heat

hermostat

Lift the Oil Control Valve Cover

Oil Control

Thermostat

Over-ride

ower Indicator

P

il control

O

alve cover

v

afety Button

S

Lift up the Controls cover. Push down the Safety Button to turn on

the oil supply, and turn the Oil Control Knob to ‘High +’.

Carefully dismantle the Burner, Flame Ring, Burner Lids, Shells,

Vapour Chamber Lid, and Wicks.

21

Withdrawal of the assembly

Check that the oil supply has been isolated, then disconnect the

Oil Supply Pipe from the Oil Control Valve, avoiding spillage.

Remove the Burner Assembly by undoing the two nuts securing it

to the Combustion Chamber and lifting it out.

In exceptional cases, it may be necessary to remove the Oil

Control Valve metering stem. This must be done with great care,

avoiding any damage to the slot – which must be cleaned with a

wooden cocktail stick, or similar. Never use anything metallic, as it

could increase the slot width and seriously affect flow rates.

24. CLEANING THE FLUEWAYS

23

Removal of the

right side panel

11

Burner Door

Burner Cover fixing nut

Burner

Cover

Open the Burner Door, then unscrew large hexagonal nut on the

Burner Cover using the tool provided.

Remove the right-hand panel in the Combustion Chamber.

11

8

14

Optional Timer Control

3A Fused Spur

Indicator

Neon

2VAC

1

1 2 3 4

Thermostat

with detail

Element

T/Stat

il Valve

O

Oil Valve Thermostat

SERVICING INSTRUCTIONS

IMPORTANT

It is essential that range cookers are serviced, and flue ways inspected and cleaned, at regular 6-monthly intervals. The frequency

ay be increased if a lower quality fuel is used. The work must be carried out by Don/Oftec trained service engineers.

m

The appliance should be turned off at least 4 hours before the arrival of the engineer, to allow it to cool.

NOTE: BEFORE STARTING WORK, MAKE SURE THAT BOTH

IL AND ELECTRICAL SUPPLIES HAVE BEEN ISOLATED.

O

22. DISMANTLING

Lift the Oil Control Box Cover and remove the 3 control knobs by

oosening the grubscrews.

l

Remove the fixing screws, then lift out the Oil Control Box Casing

nd the Inner Assembly.

a

SWITCHED OUT

40V

2

50Hz

MAINS IN

Connect the secondary leads from the 12 Volt Transformer to the

Tempomat (oil valve thermostat activator). See wiring diagram

above.

Plug the 12 Volt Transformer into the Fused Spur provided and

turn on the electricity.

If the optional Timer Control is fitted, please follow the

instructions supplied with the Timer for setting procedures.

Turn the Thermostat to its maximum position and allow 15

minutes for the oil to enter the Burrner Base.

15

lug In

P

Transformer

ess than 900mm

L

2 3 4

12VAC

1

Leave the Oil Control Knob at ‘High +’, and turn the Thermostat

to its mid position. Shut the Burner Door, and leave for 20

minutes until the burner is hot, then reset the Thermostat to its

maximum ‘Hot +’ position.

The Burner will gradually increase its oil flow rate and raise the

temperature of the oven, taking about two and a half hours to

reach 200˚C (400˚F). Turn the Thermostat to the mid position,

and the oven will maintain its temperature. When cooking is not

required, the Thermostat can be turned to its minimum

‘Warm –‘ setting.

When the appliance is first fired, it may give off a slight odour for

a short time. This is normal, and no cause for concern.

Remove the Boiling and Simmering Hotplates. First release the 3

screws on each hotplate, and wind the plate out to expose

approximately 30mm. Attach the spider tool provided by locating

it under the 3 countersunk screw heads, then rotate the plate

anti-clockwise and lift it clear of the cooker. The Boiling Plate is

much heavier, so take care as you remove it.

16

(Illustration i)

Outer burner door

Oil control

box cover

Securing screws

(Illustration ii)

Remove control box outer

cover and inner assembly

17

Remove the screw on top of the Tempomat to expose the

electrical connections.

18

Lighting port

cover

Lighting port

Insert a lit taper through the lighting port

Lift the hinged cover of the Lighting Port on the front of the

burner, and light the wick.

Replace the Lighting Port Cover, then the Burner Cover. The

hotplate covers must also be closed, to conserve heat.

21. TESTING BURNER

SMOKE

Using the Sampling Hole in the front of the Flue Hood Assembly,

sample the flue products with a Baccarach Smoke Pump and

check the flue draught. Adjust the draught divertor to give the

required flue draught. See Technical Specification on page 2.

All readings should give a Smoke Number of 0-1 at both low rate

and high rate.

NOTE: NOW COMPLETE THE COMMISSIONING CHECKLIST

ON THE FOLLOWING PAGE – AND MAKE SURE THE USER IS

FAMILIAR WITH BOTH THE OPERATION OF THE APPLIANCE,

AND THE SAFETY MEASURES.

It is a requirement under OFTEC regulations that the

comissioning is recorded on a CD

11 form, available from

Oftec. Once completed, a copy is to be given to the end user

and one copy sent to Gazco Ltd. Failure to do so may invalidate

the guarantee.

9

(Illustration iii)

Inner assembly removed

Remove the fixing screws from the Tempomat, and move it clear

of the assembly without disconnecting the wiring.

10

Loading...

Loading...