Redflow ZBM GEN 2.8 User Manual

ZBM – Gen 2.8

Version: 1.0

Installation and Operation Manual

Model: Gen 2.8 Zinc-Bromide flowing electrolyte battery (ZBM)

Rating: 3 kW / 8 kWh

RedFlow Limited

© 2014. RedFlow Limited. All Rights Reserved.

Thank you for purchasing the RedFlow ZBM.

RedFlow’s ZBM represents the state-of-the-art in zinc-bromide flow battery technology.

It is designed as a modular battery to be integrated into electricity storage systems.

For Sales and Technical Support, RedFlow can be contacted at:

ABN 49 130 227 271

AUSTRALIA

27 Counihan Road

Seventeen Mile Rocks

Brisbane

QLD 4073

W: www.redflow.com

T: +61 7 3376 0008

F: +61 7 3376 3751

E: tech.support@redflow.com

Office hours: 8:30am to 5:00pm, Brisbane, Australia

Monday - Friday

USA

Albuquerque, NM 87108

E: tech.support@redflow.com

sales@redflow.com

sales@redflow.com

Any reproduction, modification, or electronic transmission of this publication requires the

prior written authorisation of RedFlow Limited.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 2 of 85

Table of Contents

Table of Figures ......................................................................................... 5

Table of Tables .......................................................................................... 5

1. Introduction ..................................................................................... 6

1.1. About the ZBM ................................................................................... 6

2. Safety and Handling .......................................................................... 8

2.1. Electrolyte Characteristics.................................................................... 8

2.1.1. Bromine and Bromine Complex................................................. 9

2.1.2. Gas Emissions ...................................................................... 10

2.1.3. Electrolyte Leaks .................................................................. 11

2.1.4. Personal Protective Equipment (PPE) ....................................... 11

2.2. ZBM Handling, Storage and Transport ................................................. 12

2.2.1. Handling Dry ZBMs (without electrolyte inside) ......................... 12

2.2.2. Handling Wet ZBMs (full of electrolyte) .................................... 13

2.2.3. Storing Dry ZBMs (without electrolyte inside) ........................... 13

2.2.4. Storing electrolyte not contained in a ZBM. .............................. 13

2.2.5. Storing Wet ZBMs (full of electrolyte) ...................................... 14

2.2.6. Transporting Dry ZBMs (without electrolyte inside) ................... 14

2.2.7. Transporting electrolyte not contained in a ZBM ....................... 14

2.2.8. Transporting Wet ZBMs (full of electrolyte) .............................. 14

2.3. ZBM Battery Voltage Hazard .............................................................. 15

2.4. ZBM Fire Safety Characteristics .......................................................... 15

3. ZBM Components ............................................................................. 16

3.1. Gen 2.5 ZBM Flow Battery ................................................................. 16

3.2. Mk Box ............................................................................................ 17

3.3. Sensor Analog Loom ......................................................................... 19

3.4. DC Looms ........................................................................................ 19

4. ZBM Installation and Connection ........................................................ 20

5. ZBM Operation ................................................................................. 24

5.1. Operating “From Empty” ................................................................... 24

5.2. ZBM Operating Modes ....................................................................... 24

5.3. Standard ZBM Cycle.......................................................................... 25

5.4. Shutdown Procedure ......................................................................... 26

6. ZBM Control and Communications ...................................................... 27

6.1. ZBM Status Registers (0x9001 – 0x900F) ............................................ 27

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 3 of 85

6.2. Read (Data) Registers (0x9010 to 0x90FF) .......................................... 28

6.3. Write Registers (0x9100 to 0x91FF) .................................................... 29

6.4. Operating the ZBM ........................................................................... 29

6.5. Logging Mandatory Registers ............................................................. 29

7. ZBM Wear and Failure Processes ........................................................ 30

7.1.1. Leaks .................................................................................. 30

7.1.2. Stack degradation ................................................................. 30

7.1.3. Incorrect Operation ............................................................... 30

7.1.4. Electrolyte Contamination ...................................................... 30

7.1.5. Pump Failures ...................................................................... 30

7.1.6. Electronics and Electrical Failures ............................................ 31

7.1.7. Over Temperature ................................................................ 31

8. ZBM Maintenance ............................................................................. 32

8.1. Condition Monitoring Maintenance ...................................................... 32

8.2. Periodic Maintenance ........................................................................ 32

8.2.1. Periodic Remote Monitoring .................................................... 32

8.2.2. Periodic On-Site Maintenance ................................................. 33

Appendix A Abbreviations and Definitions .................................................. 34

Appendix B RedFlow Warranty for the ZBM ................................................ 35

Appendix C Addressing ZBM Electrolyte Spills/Leaks ................................... 36

Appendix D ZBM Register Information ....................................................... 39

ZBM Status Registers (0x9001 – 0x900F) ...................................................... 39

Read (Data) Registers (0x9010 to 0x90FF) .................................................... 42

Write Registers (0x9100 to 0x91FF).............................................................. 43

Appendix E Minor Maintenance Checklist ................................................... 44

Appendix F RedFlow Battery Electrolyte Safety Datasheet ........................... 45

Appendix G RedFlow Battery Electrolyte Safety Datasheet (Uncharged)......... 58

Appendix H RedFlow Battery Electrolyte Safety Datasheet (Waste) ............... 71

Document Revision History ......................................................................... 84

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 4 of 85

Table of Figures

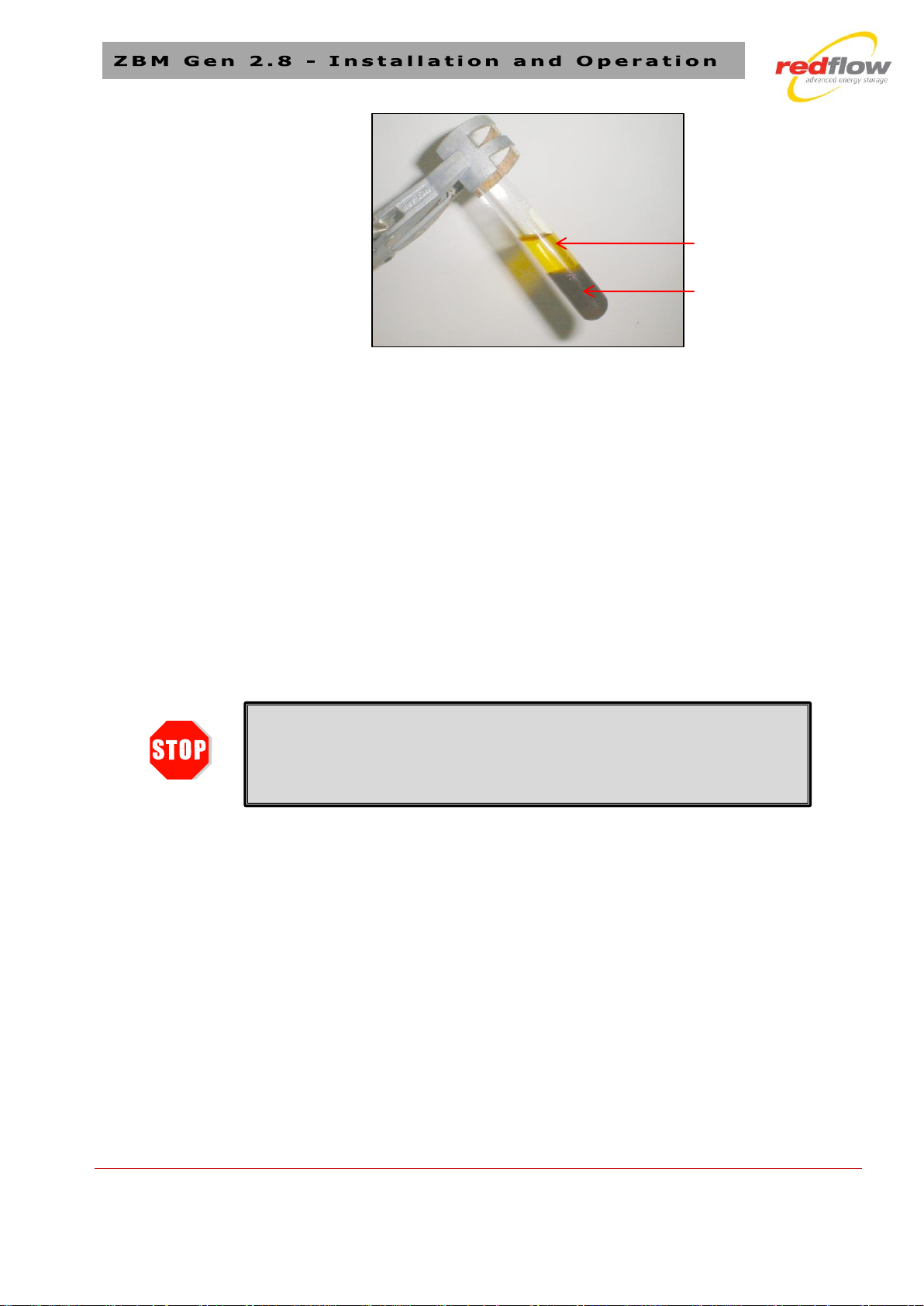

FIGURE 2.1: YELLOW ELECTROLYTE PHASE AND DENSER DARK RED BROMINE COMPLEX PHASE. ....................... 9

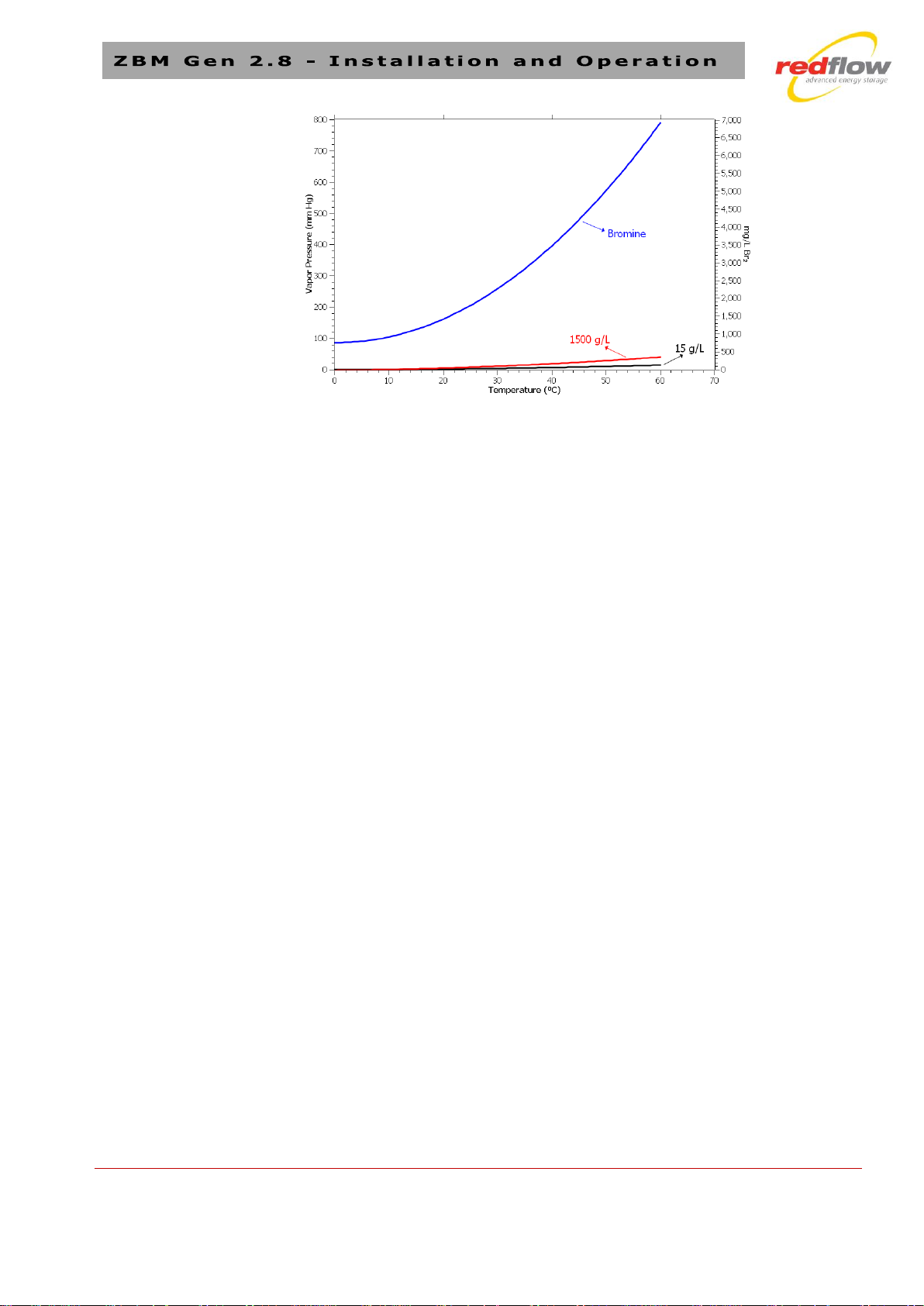

FIGURE 2.2: VAPOUR PRESSURE FOR 100% CHARGED BROMINE COMPLEX (1500G/L), BATTERY ELECTROLYTE

(15G/L) AND PURE BROMINE. ...................................................................................................................... 10

FIGURE 2.3: A FORKLIFT USING THE LISTING STRAPS TO LIFT 2 ZBMS ................................................................. 13

FIGURE 3.1: GEN 2.5 ZBM ZINC BROMINE BATTERY MODULE ............................................................................. 16

FIGURE 3.2: ZBM TERMINAL PLATES AND PUMPS ............................................................................................... 17

FIGURE 3.3: MK BOX SIDE CONNECTIONS ............................................................................................................ 18

FIGURE 3.4: MK BOX BOTTOM CONNECTIONS ..................................................................................................... 18

FIGURE 3.5 : SENSOR ANALOG LOOM .................................................................................................................. 19

FIGURE 5.1: AN EXAMPLE OF THE REDFLOW ZBM’S STANDARD CYCLE ............................................................... 26

Table of Tables

TABLE 1.1: ZBM ELECTRICAL OPERATING ENVELOPE ............................................................................................. 6

TABLE 1.2: ZBM PHYSICAL AND COMMUNICATIONS CHARACTERISTICS ............................................................... 7

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 5 of 85

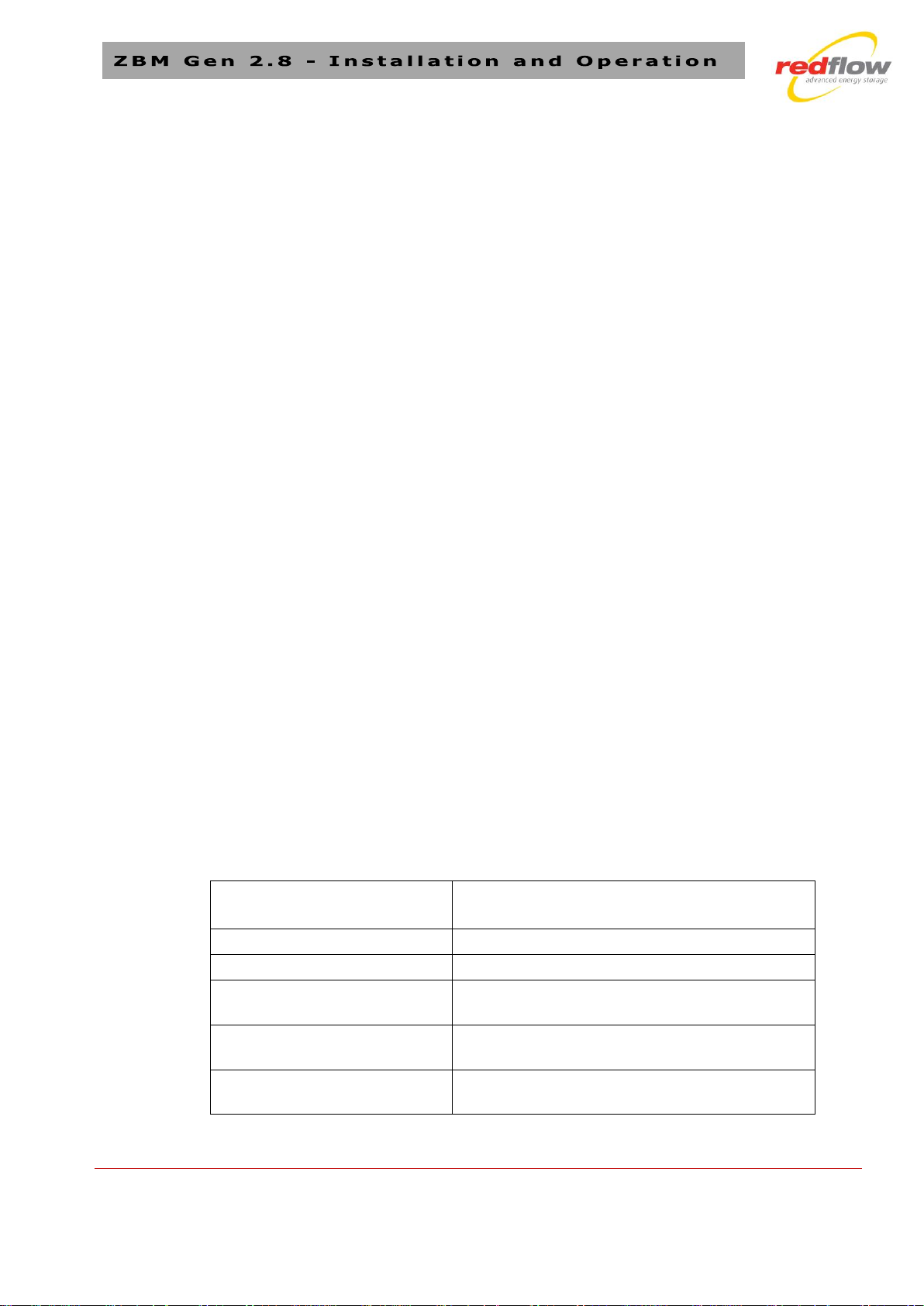

Power Range

0kW to 2.5kW during charge

0kW to 3kW during discharge

Net Energy Range

0kWh (0% SOC) to 8kWh (100% SOC)

DC Voltage Operating Range

40 to 57V

Auxiliary Power

Requirements

N/A

Operating Battery

Temperature Range

5 to 50 °C (41 to 122 °F)

Maintenance Cycle

Frequency

At least once every 120 hours of zinc pump

operation.

1. Introduction

This manual is for RedFlow’s DC flowing electrolyte battery

product, the Gen 2.8 Zinc-Bromine Module (ZBM).

It provides information on this battery’s installation, operation

and maintenance.

1.1. About the ZBM

RedFlow’s Gen 2.8 ZBM is a modular flow battery rated at 3kW &

8kWh. With appropriate ancillary circuitry, multiple ZBMs can be

connected together in parallel and series arrays.

The ZBM is ideally suited to deep cycling and long cycle life

energy storage applications requiring multiple hours of discharge

on a daily basis. It can operate to 100%, or partial depths of

discharge without a reduction in operating life.

The ZBM battery consists of:

Gen 2.8 ZBM flow battery (including electrolyte )

Mk Box

Sensor Analog Loom

DC Looms

Battery operation is controlled and managed by the internals of

the Mk Box. Operation of ZBMs must be kept within the

boundaries of the operating envelope set out in Table 1.1 to

ensure correct operation and also comply with the warranty

conditions set out in Appendix B. It should be noted that in

applications where one ZBM would not be able to remain within

the operating envelope, adding another ZBM will often bring the

performance demands on each ZBM back inside the envelope.

Table 1.1: ZBM Electrical Operating Envelope

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 6 of 85

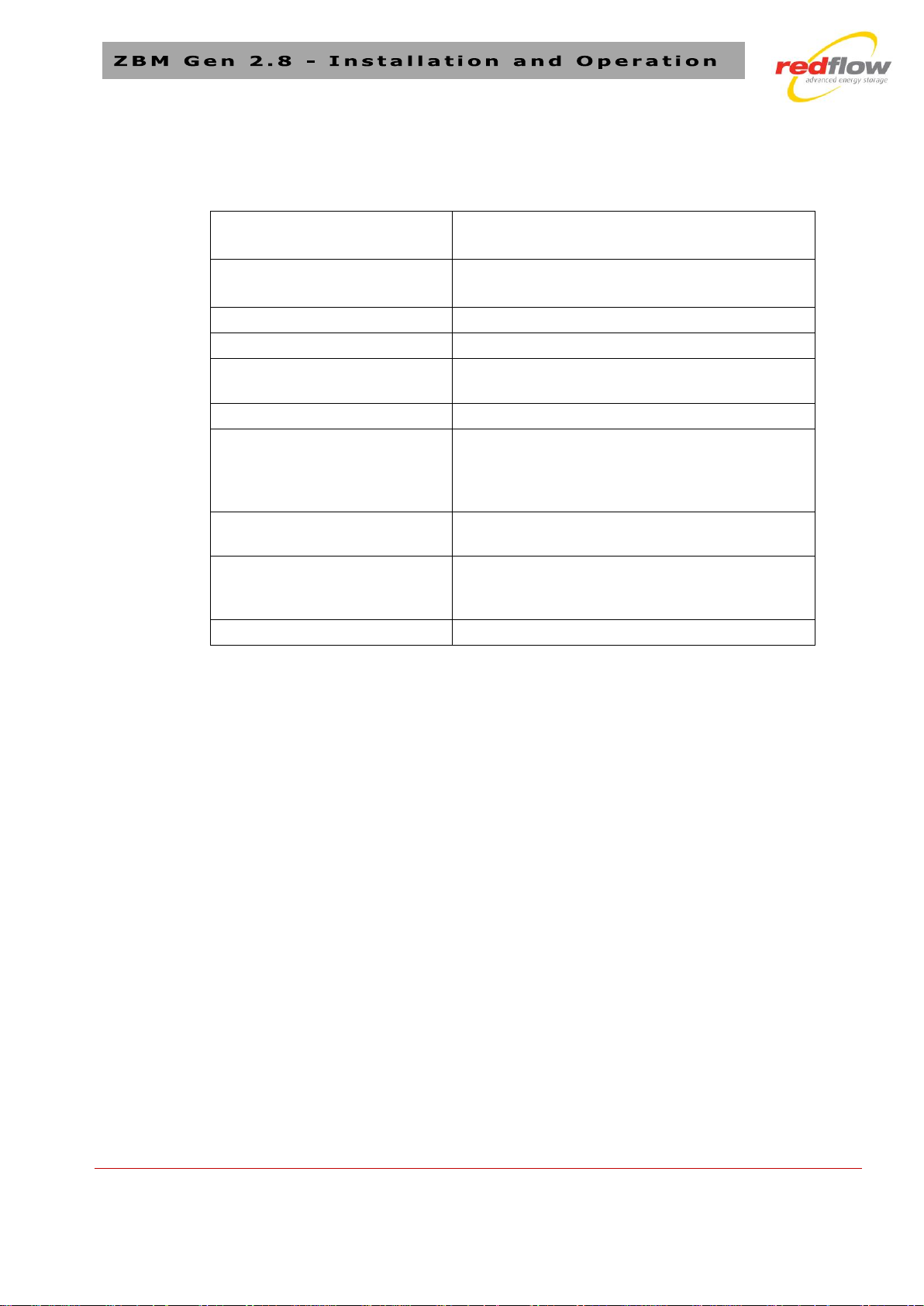

Dimensions

830 L x 823 H x 400 W (mm)

32.7 L x 32.4 H x 15.7 W (in)

Weight

239 kg (526 lb) with electrolyte

88 kg (194 lb) without electrolyte

Electrolyte Volume

100 L (26 Gal)

Module Geometry

Two parallel stacks of 33 cells

Dangerous Goods Class

DG Class 8 for electrolyte or ZBMs

containing any trace of electrolyte

Shelf Life

Indefinite

Orientation

The ZBM must be kept in an upright

position (orientation shown in Figure 3.1)

at all times of operation, storage, handling

and transportation

Operating Conditions

Stationery applications on flat, level

surfaces only

Ventilation

The ZBM must be adequately ventilated

with minimum airflow of 150L/s (540 m3/h)

per ZBM

Communications

MODBUS RTU

The physical and communications characteristics of the ZBM

can be found in Table 1.2.

Table 1.2: ZBM Physical and Communications Characteristics

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 7 of 85

All low voltage (LV) wiring must be performed by

standards are complied with.

2. Safety and Handling

licensed electrical personnel who are responsible for

ensuring that all local and government regulations and

The following general safety rules apply for any operation of the

ZBM batteries.

Use tools with insulated handles to make connections.

Do not smoke.

Check that cable connections between the ZBM and the

rest of the Energy Storage System are tightened to the

recommended torque values (see Section 0).

Even when disconnected, a ZBM battery can remain

charged and have voltage on the battery terminals.

There are also four main areas of safety specifically relevant to

the ZBM battery.

Electrolyte characteristics

ZBM handling, storage and transport

ZBM battery voltage

ZBM fire safety characteristics

These are explained in detail in the sections below.

2.1. Electrolyte Characteristics

The RedFlow ZBM is a flowing electrolyte battery containing

approximately 100L (26gal) of water-based zinc-bromide

electrolyte.

The ZBM electrolyte is an aqueous (water-based) solution of zinc

bromide salt usually including additional supporting salts and

complexing agents.

The electrochemical process of charging a ZBM battery alters the

electrolyte. Zinc ions are plated out as metallic zinc, and bromide

ions become linked with the complexing agents in the electrolyte

to form a separate dense Bromine Complex phase.

Electrolyte is yellow to orange in colour, while the Bromine

Complex phase is dark red (see Figure 2.1). This complex phase

has a higher density and readily separates (sinks) from the

aqueous electrolyte phase and can be described as “oil-like”.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 8 of 85

Personnel responsible for handling the ZBM’s

Datasheets and the following safety information.

Dark red Complex

Yellow electrolyte

Figure 2.1: Yellow electrolyte phase and denser dark red

bromine complex phase.

The following Safety Datasheets (SDS) are included in this

manual:

Appendix F: RedFlow Battery Electrolyte SDS

Appendix G: RedFlow Battery Electrolyte SDS (Uncharged)

Appendix H: RedFlow Battery Electrolyte SDS (Waste)

For ZBM electrolyte that has never been charged, refer to the

RedFlow Battery Electrolyte SDS (Uncharged).

The RedFlow Battery Electrolyte SDS in Appendix F should be

used for electrolyte that contains Bromine Complex.

electrolyte, including when cleaning up an electrolyte

spill, must be aware of the content of these Safety

2.1.1. Bromine and Bromine Complex

ZBM electrolyte contains Bromine ions, which are complexed with

a quaternary ammonium salt (N-ethyl-Nmethylpyrrolidiniumbromide, or MEP) to form the separate dense

bromine complex phase, as the battery is charged.

MEP maintains the concentration of elemental Bromine in the

aqueous electrolyte at very low levels, of approximately 0.04

mol/L. MEP also reduces the vapour pressure of Bromine above

the liquid to levels well below that of pure bromine.

Figure 2.2 shows the significantly lower vapour pressures of

bromine complex (with 1500g/l of Bromine) and charged aqueous

electrolyte (with 15g/l of Bromine), compared to pure Bromine.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 9 of 85

Figure 2.2: Vapour pressure for 100% charged Bromine complex

(1500g/l), battery electrolyte (15g/L) and pure Bromine.

Studies of both small and large leaks of Bromine complex have

shown that the concentration of Bromine evaporation in the air is

well below the safe long-term working level of 0.1 ppm (as

specified by the Occupational Safety and Health Administration

and National Institute of Occupational Safety and Health in the

United States). In this complexed form, Bromine is:

Easy to detect early via its chlorine-like smell

Easy to neutralize (e.g. with sodium bicarbonate or

ammonia)

Poses no fire risk (Bromine is actually used in many fire

retardants)

Despite the fact that there is a very low risk of being exposed to

unsafe Bromine gas levels, all personnel involved in opening a

ZBM to fill it with electrolyte, clean up an electrolyte spill, or

empty electrolyte from a ZBM, must wear the appropriate

Personal Protective Equipment (PPE) (refer to Section 2.1.3).

Bromine has a chlorine-like smell and if this is detected,

operation of the ZBM should be ceased and the user should

investigate whether there are any electrolyte leaks.

2.1.2. Gas Emissions

No gas is emitted during normal operation of the ZBM. However,

there may be small amounts of potentially hazardous hydrogen

and/or bromine gases emitted via the ZBM’s pressure relief

valve, as a result of an operational issue. This gas is

automatically diverted to the ZBM’s Catch Can, which traps gases

before they reach areas external to the ZBM, reducing the

concentration of any emissions. Regardless, energy storage

systems containing ZBMs should be located in areas designed to

ensure adequate ventilation, as stated in Section Error!

Reference source not found..

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 10 of 85

Spills and leaks of ZBM electrolyte should be cleaned up

not readily evaporate.

2.1.3. Electrolyte Leaks

The presence of liquid electrolyte in the ZBM means that there is

potential for a spill to occur.

Any electrolyte leak or spill should be cleaned up in accordance

with Appendix C.

immediately and not left as the ZBM electrolyte does

Electrolyte can be contained in readily available polyethylenelined containers or bunding. This is the same material that the

electrolyte tanks are made of.

2.1.4. Personal Protective Equipment (PPE)

The following, or equivalent, personal protection equipment must

be worn when handling electrolyte or cleaning up an electrolyte

leak.

Respirator: Moldex half-face pre-assembled respirator with

multi-gas/vapour cartridges (available from

Protector Alsafe (www.protectoralsafe.com.au),

product code 8602A, part number 0109 0268)

Goggles: Bollé Blast Duo goggles (available from Protector

Alsafe, product code 1669209, part number 0708

2887)

Gloves: Prosafe Premium 806 Blue PVC Gauntlets (available

from Protector Alsafe, part number 07841563)

Spill kits should be kept on hand at all times. 62 litre Hazchem

spill kits can be sourced from Global Spill Control at:

http://www.globalspill.com.au/?gclid=CMTvvobp64CFYJLpgodSBzjwQ

It should be noted that there is approximately 100L of electrolyte

in each ZBM, and while any leak would be unlikely to result in

more than a few milliliters of electrolyte escaping, there is

potential for a leak of up to 100L to occur.

RedFlow’s technical support can also provide additional details on

how to clean up an electrolyte leak. Contact details are provided

inside the front cover of this manual.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 11 of 85

The ZBM should always be operated, handled, stored

and transported in the upright position.

A ZBM filled with electrolyte, as well as a ZBM that once

considerations during handling.

The ZBM should never be lifted or manhandled via the

the bottom tank.

2.2. ZBM Handling, Storage and Transport

The ZBM can be delivered in one of two states:

1. Dry ZBM with electrolyte delivered in separate transport

containers. This then requires the ZBM to be filled with

electrolyte prior to use. Please contact RedFlow for an

additional guide for this procedure. A dry ZBM without

electrolyte weighs 88 kg (194 lb).

2. Wet ZBM with electrolyte pre-filled. A wet ZBM with

electrolyte weighs 239 kg (526 lb).

contained electrolyte, must be handled, stored and

transported as an item with a Dangerous Goods

Classification of 8.

ZBMs that have never contained electrolyte do not

require a Dangerous Goods rating or similar

2.2.1. Handling Dry ZBMs (without electrolyte inside)

Dry ZBMs are relatively light (88 kg, 194 lb) because they do not

contain any electrolyte. Despite this, any handling should involve

the use of the lifting straps supplied with the ZBM and a forklift

or similar lifting mechanism (Figure 2.3) with two personnel on

hand.

battery stack. Always lift and manhandle the ZBM from

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 12 of 85

Figure 2.3: A forklift using the listing straps to lift 2 ZBMs

2.2.2. Handling Wet ZBMs (full of electrolyte)

Wet ZBMs are significantly heavier than dry ZBMs (at 239 kg,

526 lb). As such, any handling must involve the use of the ZBM’s

lifting straps with a forklift or similar lifting mechanism with two

personnel on hand.

2.2.3. Storing Dry ZBMs (without electrolyte inside)

ZBMs can be stored indefinitely in their dry state. In all cases,

ZBMs should be stored on a flat, stable surface in an upright

position. The storage area should be dry and ventilated, that is, a

closed cycle air-conditioned space is not considered suitable.

ZBMs should be stored in areas that do not receive direct

sunlight, as ultraviolet rays can breakdown the ZBM’s

polyethylene components.

The ambient temperature should remain between 5 and 45 °C (41

to 113 °F).

2.2.4. Storing electrolyte not contained in a ZBM.

Discharged electrolyte that is not contained in a ZBM must be

stored in accordance with Section 7 of the RedFlow Battery

Electrolyte Safety Datasheet which is found in Appendix F. In

general, appropriately labeled, robust HDPE (High Density

Polyethylene) containers should be used – the ZBM’s electrolyte

tanks are considered to meet this requirement as are commercial

HDPE (High Density Polyethylene) UN-certified Intermediate Bulk

Containers (IBCs) conforming to the BK2 standard as specified by

the Australian Code for the Transport of Dangerous Goods by

Road & Rail [1].

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 13 of 85

2.2.5. Storing Wet ZBMs (full of electrolyte)

ZBMs can be stored indefinitely in their wet state, but must

always be fully discharged. Wet ZBMs are classified as

Dangerous Goods Class 8.

In all cases, ZBMs should be stored on a flat, stable surface in an

upright position. The storage area should be dry and ventilated to

the atmosphere, that is, a closed cycle air-conditioned space is

not suitable. ZBMs should also be stored in areas that do not

receive direct sunlight, as ultraviolet rays can breakdown the

ZBM’s polyethylene components.

The ambient temperature should remain between 5 and 45 °C (41

and 113 °F).

If ZBMs are stored in their wet state, it is recommended that

secondary containment is provided in the event of an accidental

leak or spill.

2.2.6. Transporting Dry ZBMs (without electrolyte inside)

Care should be taken to transport the ZBMs in an upright

position. If packaging is required a sturdy cardboard box can be

used to manage the Dry ZBM weight of 88 kg (194 lb).

Any ZBM that has previously contained electrolyte will still

contain traces of electrolyte, and should thus be transported as

per Section 2.2.8.

2.2.7. Transporting electrolyte not contained in a ZBM

The RedFlow Battery Electrolyte Safety Datasheet in Appendix F

identifies the transport categories for the separately shipped ZBM

electrolyte. However, it is important to note that all transport of

ZBM electrolyte must also conform to local and/or international

regulations. In general, robust HDPE (High Density Polyethylene)

UN-certified Intermediate Bulk Containers (IBCs) conforming to

the BK2 standard as specified by the Australian Code for the

Transport of Dangerous Goods by Road & Rail [1] should be

used.

2.2.8. Transporting Wet ZBMs (full of electrolyte)

Care should be taken to transport the ZBMs in an upright position

to avoid possible electrolyte leaks.

If packaging is required, suitable materials should be used to

manage the Wet ZBM weight of 239 kg (526 lb).

Any ZBM that contains electrolyte, or traces of electrolyte should

be transported in accordance with the RedFlow Battery

Electrolyte Safety Datasheet in Appendix F. However, it is

important to note that all transport of wet ZBMs must also

conform to local and/or international regulations. Where

possible, transport wet ZBMs in an area that has secondary

containment, for example, a catchment tray or bunding.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 14 of 85

Depending on the application, several ZBMs may be

voltage training for key personnel.

2.3. ZBM Battery Voltage Hazard

A single ZBM can have between 0V and 57V DC on the battery

terminals during operation. The voltage across the battery

terminals will be 0V when it is fully discharged and it is not

connected to any other power source. See Figure 3.2 to identify

the battery terminals. While the ZBM should be fully discharged

(terminal voltage at 0V) during transportation or storage, care

should be taken in case the terminals are live.

connected together in series generating higher and

more dangerous DC voltages. Therefore, only qualified

personnel should operate the ZBM with appropriate

safety measures in place to avoid harm to others and

themselves. This should include clear signage of

unsafe voltages, and the presence of high-voltage

safety and resuscitation equipment, as well as low-

2.4. ZBM Fire Safety Characteristics

The ZBM is an inherently low fire risk battery as its electrolyte is

non-flammable and has many characteristics of a fire retardant

(see Section 5 in the SDS in Appendix F, Appendix G and

Appendix H).

As a failsafe measure, the ZBM automatically shuts its electrolyte

pumps off if it detects a leak. This prevents further electrolyte

from being introduced into the battery’s stack. This means that

the battery cannot self-sustain an energy discharge. While there

will be a slight increase in temperature, these measures prevent

a thermal-runaway situation from occurring. When safe, the ZBM

automatically discharges any remaining energy in the stack and

will remain in a discharged state until manual intervention

occurs.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 15 of 85

239 kg (526lb) with

electrolyte

141V DC

bromine pumps)

Zinc and bromine

approx. 100L / 26gal)

2 x electrode

stacks

823 mm

(32.4 in)

830 mm (32.7 in)

Serial Number

Gas

Units

Mk Box

Cooling

3. ZBM Components

The ZBM battery consists of four main components, explained in

detail in each of the sections below:

Gen 2.5 ZBM Flow Battery

Mk Box

Sensor Analog Loom

DC Looms

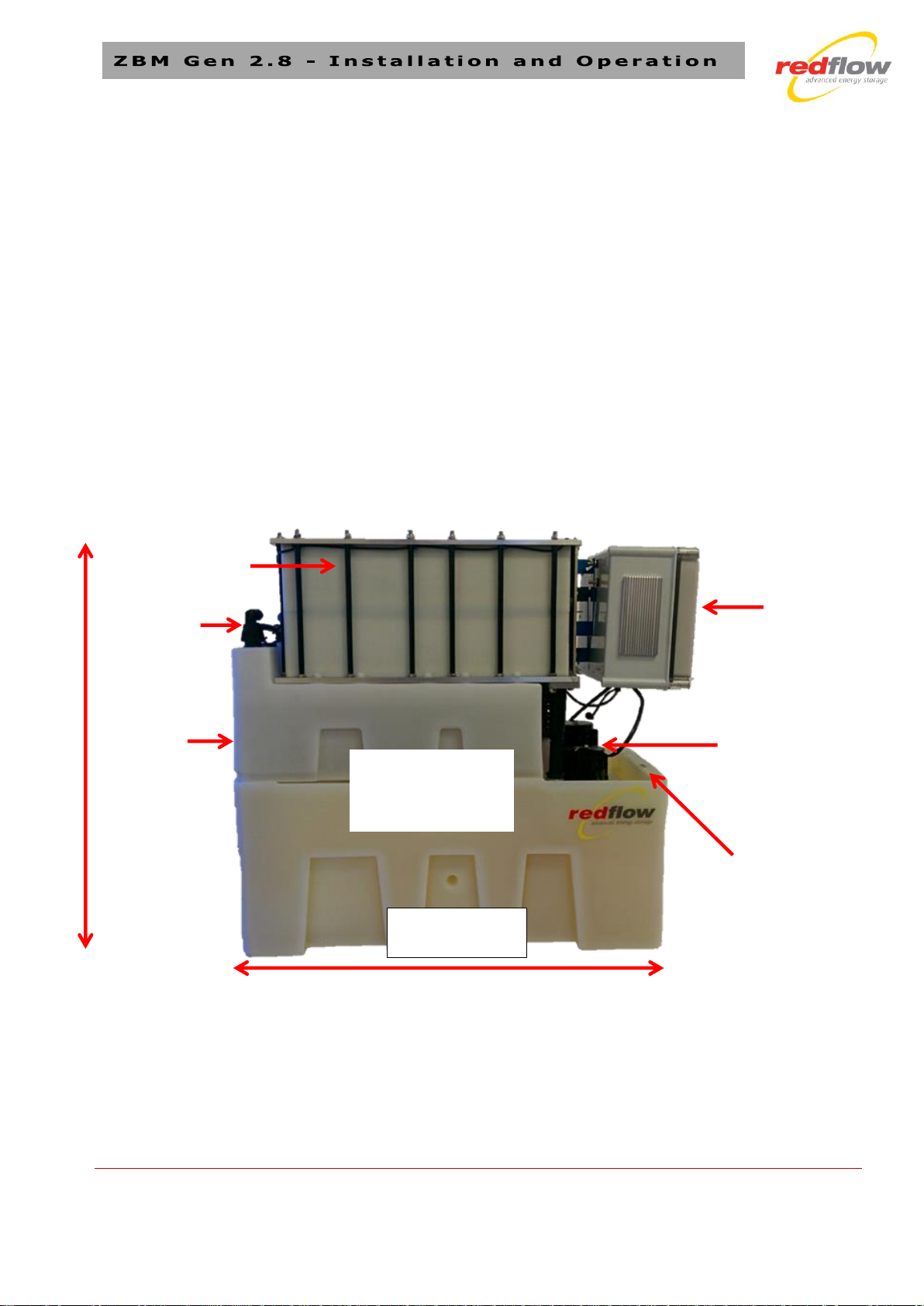

3.1. Gen 2.5 ZBM Flow Battery

RedFlow’s ZBM is a zinc-bromide flowing electrolyte battery. The

standard Gen 2.8 ZBM (see Figure 3.1) is rated at 3kW

continuous discharge power and has a rated capacity of 8kWh of

energy.

Handling

Fan

electrolyte

circulation

pumps (zinc and

electrolyte tanks

(electrolyte volume is

Figure 3.1: Gen 2.5 ZBM Zinc Bromine Battery Module

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 16 of 85

NOTE: Mk Box and Catch

be shown.

Patio Leak

Sensor Slot

Zinc

Pump

Negative

Terminals

Positive

Terminals

Bromine

Battery

Sensor Slot

Can are not shown here to

allow other components to

Electrolyte

Temperature

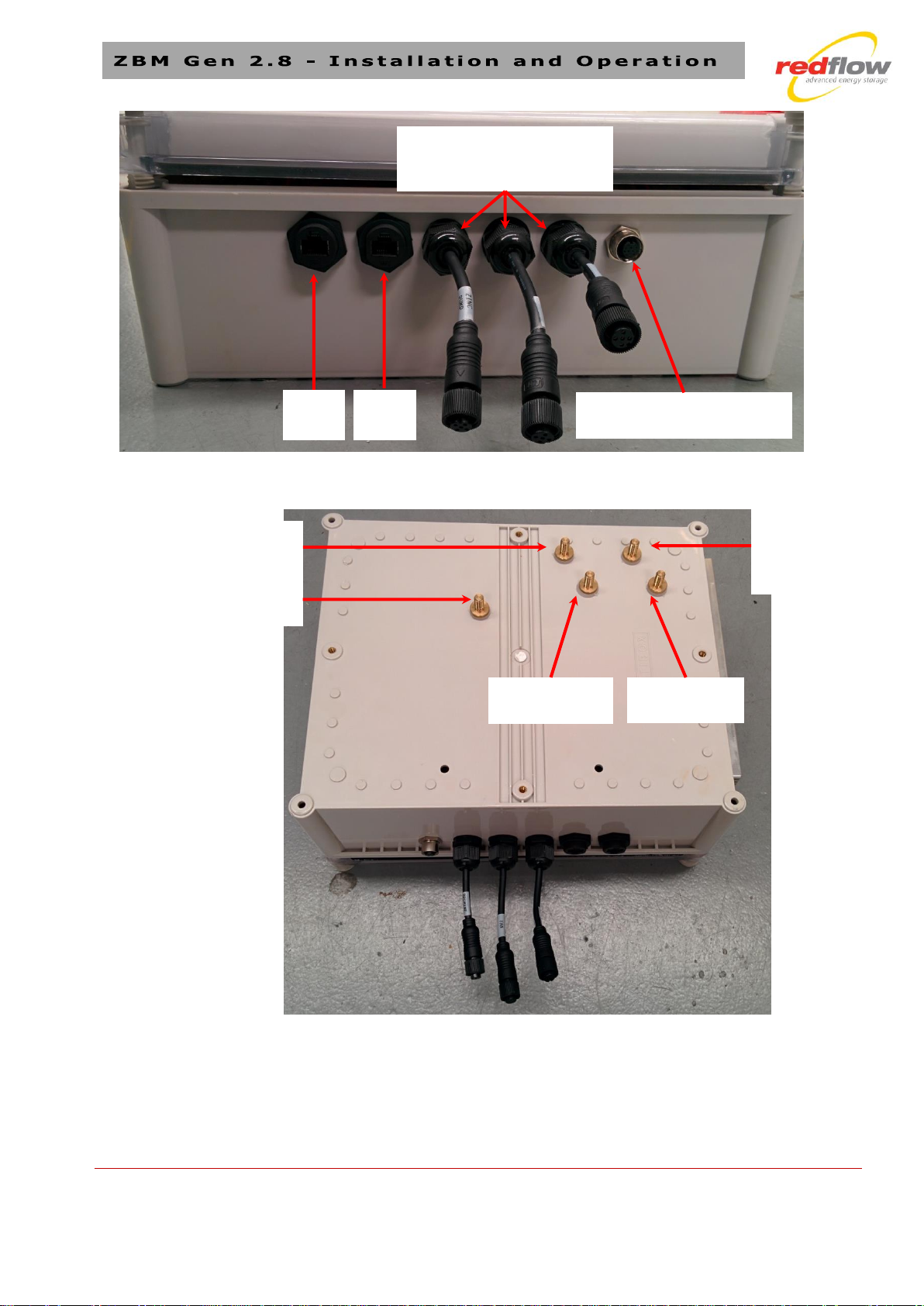

3.2. Mk Box

The ZBM is a “smart” battery that comes with in-built intelligence

to protect the ZBM battery and allowing the user to gain more

information about operation and any issues that arise. Default

communication is via MODBUS, which allows the user to read and

write data points needed to control and monitor the state of the

ZBM. Further information about these points is given in Section

6.

The Mk Box is mounted on to the ZBM battery’s terminals and is

also where connections are made to the ZBM from any external

system or communications device. The required connections are

shown below in Figure 3.3 and Figure 3.4.

Electrolyte

Pump

Figure 3.2: ZBM Terminal Plates and Pumps

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 17 of 85

COMS

Port 1

COMS

Port 2

Zinc Pump, Cooling Fan and

(internal ZBM connections)

Analog Loom COMS

(internal ZBM connection)

Positive (+)

Bus Terminal

Positive (+) ZBM Terminal

(Internal ZBM connection)

Regular

Connection)

Negative (-) ZBM Terminal

(Internal ZBM connection)

Negative (-)

Bus Terminal

Bromine Pump Power

Figure 3.3: Mk Box Side Connections

Maintenance

Terminal

(Internal ZBM

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 18 of 85

Figure 3.4: Mk Box Bottom Connections

Patio Leak Sensor

Floor Leak Sensor

Temperature

Sensors

UT Connector

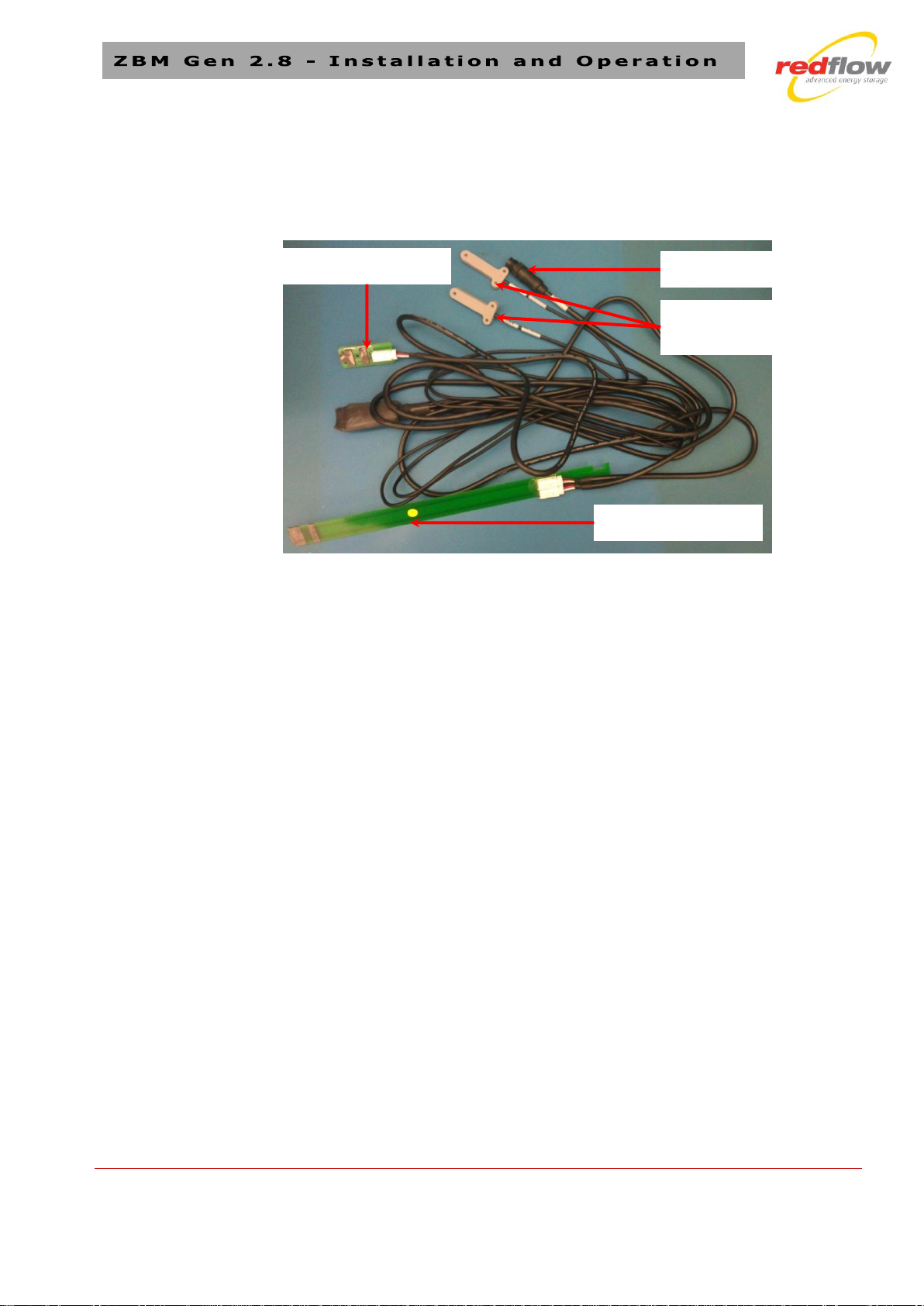

3.3. Sensor Analog Loom

An IP67-rated waterproof Sensor Analogue Loom (see Figure 3.5)

with 12-pin UT connector connects to the Mk Box and includes

two temperature sensors and two leak sensors.

All sensors provide information to the ZBM’s internal intelligence

to aid in optimal operation of the ZBM. The locations of the

sensors and instructions on connecting the Sensor Analog Loom

are described in Section 4.

3.4. DC Looms

The ZBM includes three DC looms with waterproof UT connectors

that provide DC power to the ZBM’s pumps and cooling fan from

the Mk Box. These are:

Directions detailing how to connect DC looms are given in Section

4.

Figure 3.5 : Sensor Analog Loom

Cooling Fan (3-pin UT connector with no heat shrink)

Zinc Pump (5-pin UT connector with white heat shrink)

Bromine Pump (5-pin UT connector with red heat shrink)

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 19 of 85

All DC wiring must conform to local standards and

regulations for a maximum current of 150A.

Completely

Masking Tape

4. ZBM Installation and Connection

This section lists the steps to perform in installing and connecting

a wet ZBM, such as into an energy storage system or into a

laboratory test environment.

Step 1 Check for any electrolyte leaks both visually and by

the presence of a chlorine-like smell. If a leak is

present, do not operate the ZBM and contact

RedFlow. Contact details are provided inside the

front cover of this manual. Leaks should be cleaned

up in accordance with Appendix C. Appendix F

contains the SDS for electrolyte.

Step 2 Check all hoses are securely fitted with hose clamps

and have not disconnected during transport.

Step 3 Using a multimeter, check that the ZBM is fully

discharged by ensuring the voltage across the

terminals (as shown in Figure 3.2) is 0V when

disconnected from any bus.

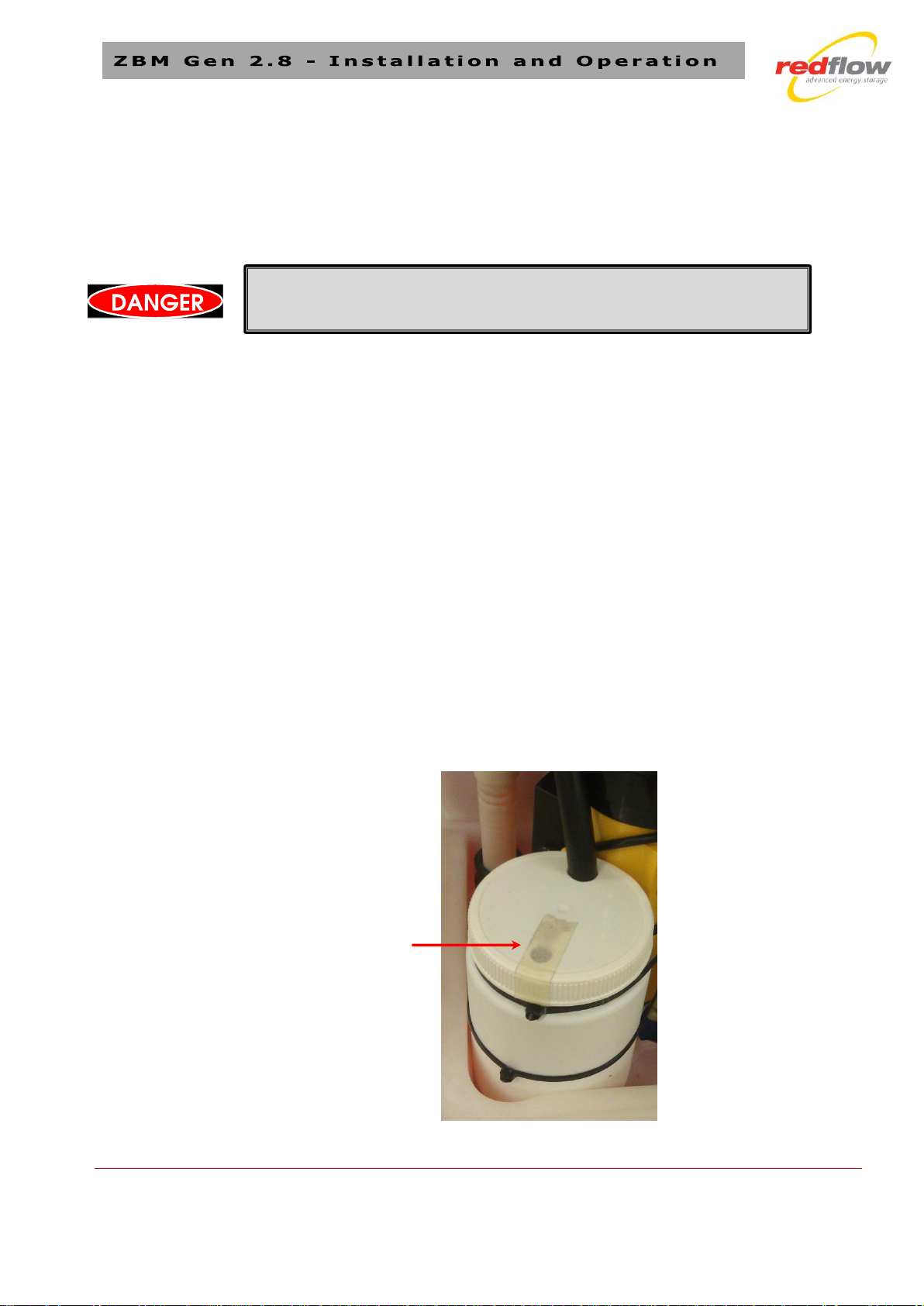

Step 4 Remove the masking tape from the Catch Can’s vent

hole. The Catch Can is designed to trap gas that is

automatically diverted to it, before these gases

reach areas external to the ZBM.

Remove

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 20 of 85

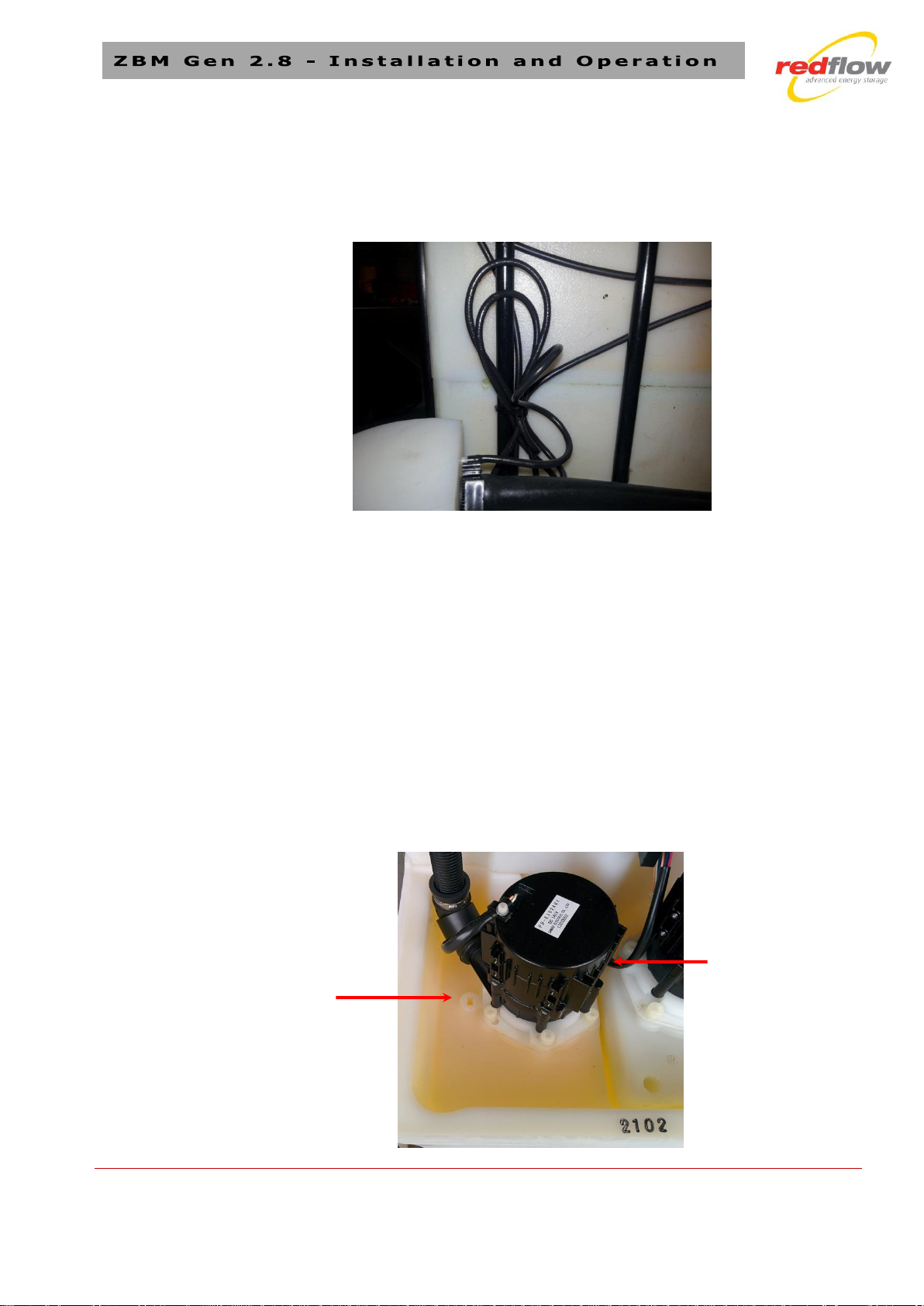

Battery

(under catch can)

Zinc

Pump

Step 5 Inspect to make sure that the ZBM Viton capillary

tubes have not been damaged during transportation

or installation. Also check to make sure each end of

the tubes are securely connected and are not

hanging free.

Step 6 Using a forklift, crane or lifting device (as shown in

Step 7 Ensure all elements of the Sensor Analog Loom are

Temperature

Sensor Slot

Section 2.2), place the ZBM into the prepared

location. Ensure care is taken to avoid damage to

the battery. It is recommended that Steps 1-5 be

repeated once the ZBM is in its required location.

located in the correct positions. The short ambient

leak sensor should be on the floor or tray at the

base of the ZBM. The patio leak sensor (see Figure

3.2) and the temperature sensors should already be

installed in their correct locations as shown below.

Ensure the Sensor Analog Loom is connected to the

Mk Box via the UT connector.

Electrolyte

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 21 of 85

Ambient

Sensor

Cooling Fan

in colour)

Temperature

(may be black

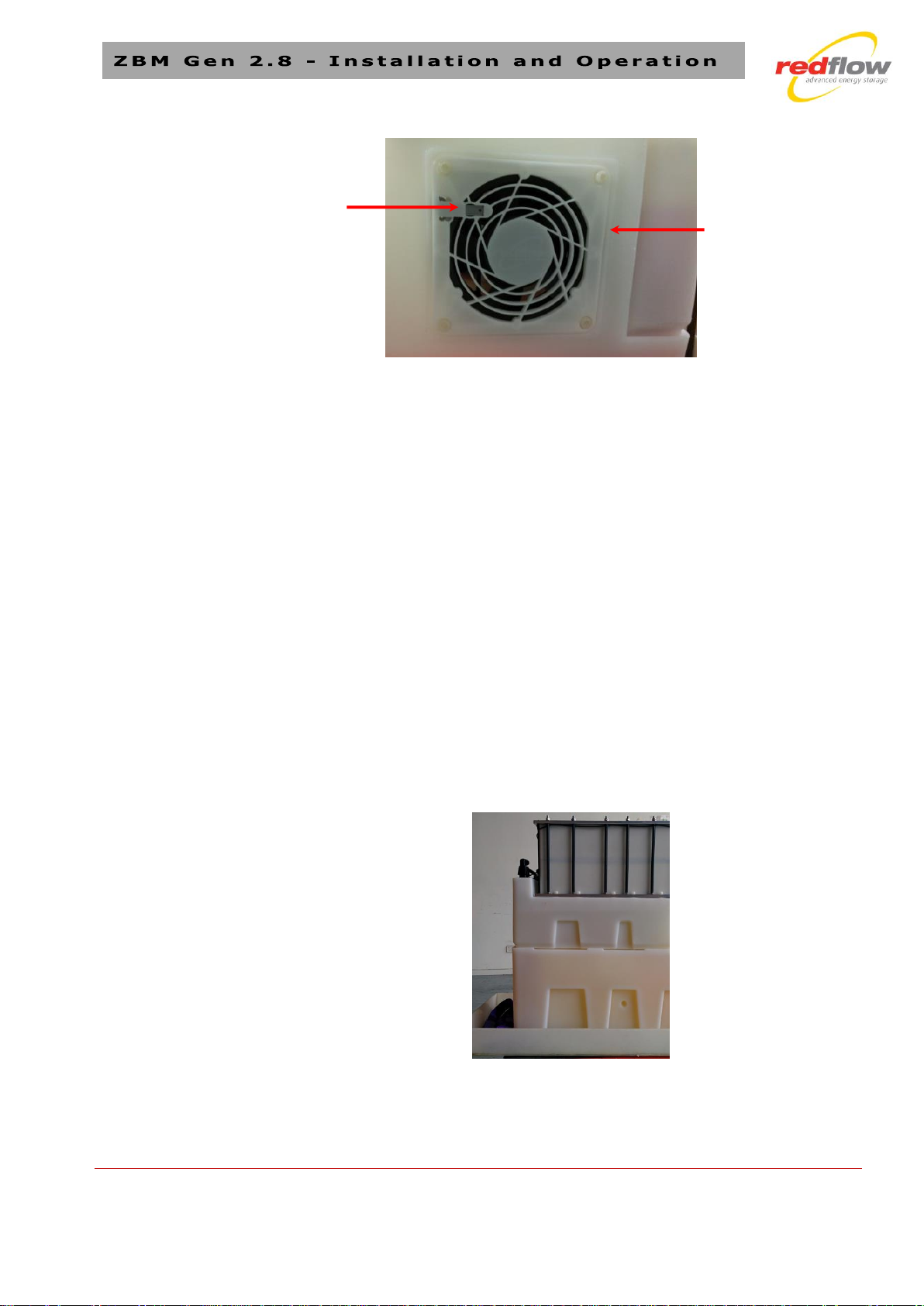

Step 8 Connect the respective the DC Looms to their

matching Mk Box connections via the colour-coded

UT connectors:

The 5-pin UT connector with white heat shrink

is for the zinc pump.

The 5-pin UT connector with red heat shrink is

for the bromine pump.

The 3-pin UT connector with no heat shrink

(black connector only) is for the cooling fan.

Step 9 Connect any external systems or controllers

requiring communication with the ZBM via the

Ethernet COMS ports on the Mk Box (see Figure

3.3).

Step 10 Connect the positive and negative bus terminals on

the Mk Box to the bus.

Step 11 Tidy the ZBM’s lifting straps away neatly. They

remain on the ZBM.

Step 12 Ensure the ZBM terminal connections to the Mk Box

are correctly torqued to 12Nm (8.85 lb-ft) (see

Figure 3.2).

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 22 of 85

Correctly torqueing the battery terminal connections is

covered by warranty (see Appendix B).

critical. If they are not sufficiently tight then heat can

be generated during high current operation leading to

ZBM failure.

It is recommended that a thermal imaging camera be

used to monitor ZBM performance to ensure there are

no such heat spots. ZBM failure arising from

incorrectly torqued battery terminal connections is not

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 23 of 85

5. ZBM Operation

This section provides some background information about the

operation of the ZBM. At all times, the ZBM must remain intact,

with all fittings and components connected as new.

5.1. Operating “From Empty”

The ZBM’s default state of charge is fully discharged, and it can

remain in this state indefinitely. ZBMs are charged from 0% state

of charge up to the desired capacity at or below 100%, and then

discharged from there. Typically, constant power charge and

discharge modes are used, but the variable supply from a PV

array on a cloudy day is equally effective.

5.2. ZBM Operating Modes

Operation of the ZBM involves charging, discharging, floating,

regular maintenance and dumping.

Charging

In the Charge state the ZBM is charged until the charging source

is removed, or the ZBM has become fully charged and the Mk Box

disconnects it from the charging source to protect the ZBM.

Charge rate is determined by the charge source.

Discharging

The ZBM discharges to a connected load or to the connected grid

when it is in the Discharge state. Discharge rate is determined by

the load or externally through a control system. Again, the Mk

Box protects against excessive current draw. The ZBM will reach

its end of discharge state when the discharge load/grid is no

longer present, or the ZBM has become fully discharged.

Floating

At any state of charge, the mode can be changed to Float, where

the battery neither charges nor discharges via the contactor.

However, the ZBM will self-discharge over this time, generating

heat.

Therefore, during Float, the electrolyte is cycled through the ZBM

for short periods of time at regular intervals to maintain

electrolyte chemistry and encourage cooling. By default, the

electrolyte is cycled for 2 minutes, followed by 28 minutes of no

cycling.

Regular Maintenance

The ZBM can be set to go through a short maintenance cycle to

remove any excess zinc from the electrodes. This maintenance

cycle will automatically occur once every 120 hours of zinc pump

operation, or when the ZBM is set to do so.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 24 of 85

A regular maintenance cycle is an optional part of the

warranty requirements (see Appendix B).

full ZBM cycle, but must be performed after the ZBM

has fully discharged and at least every 120 zinc pump

run time hours (or more frequently) to comply with

Dump

In the event of some faults, the ZBM will automatically be put

into Dump mode, where the ZBM is completely discharged into

any connected load/grid (the ZBM will attempt this regardless of

its current state of charge) and then switched off.

5.3. Standard ZBM Cycle

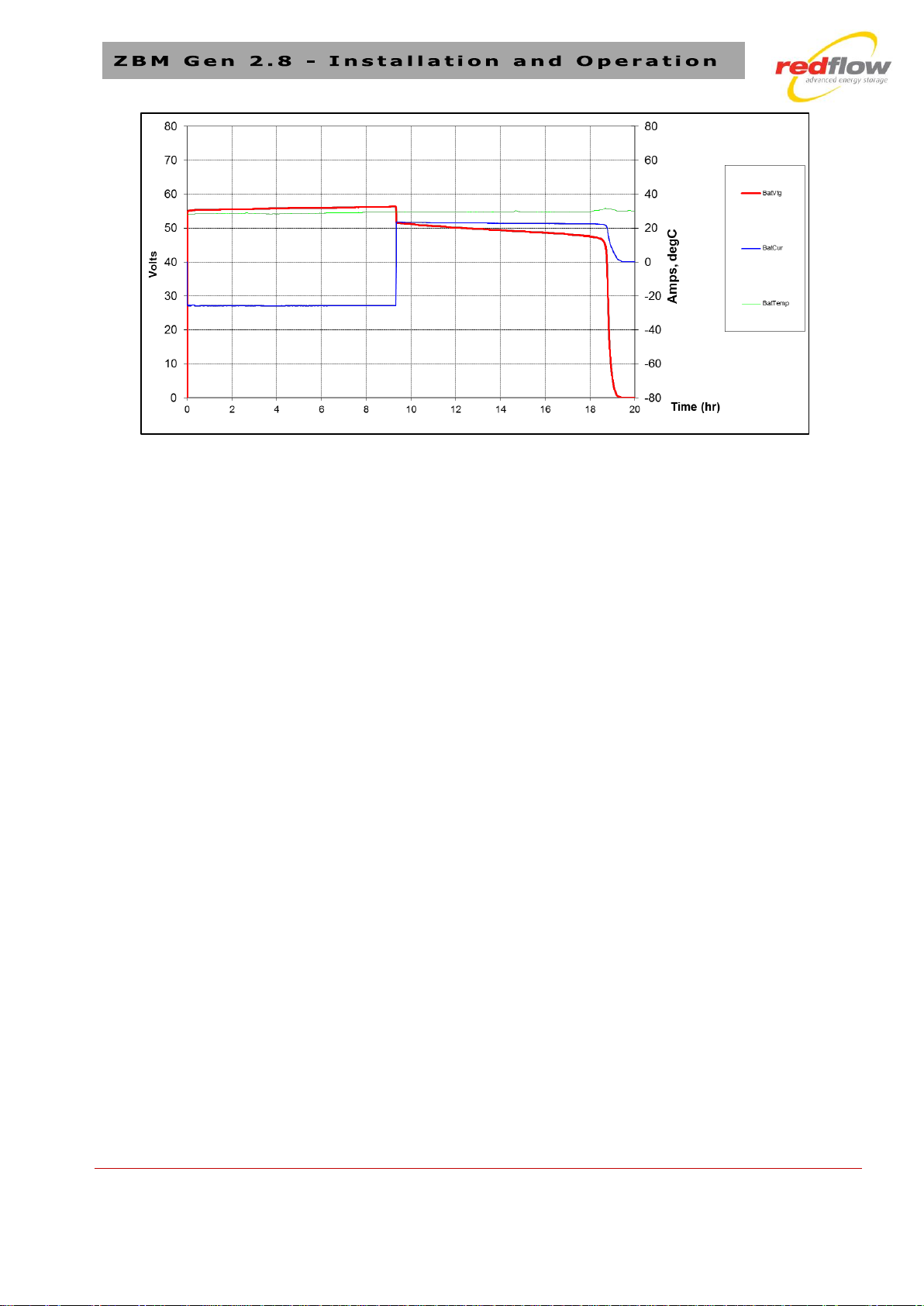

Figure 5.1 shows RedFlow’s Standard ZBM. This same standard

cycle is run in case of a warranty (see Appendix B) claim or to

determine the state of health of a ZBM in the field. The standard

cycle is always run starting with a completely discharged ZBM

(i.e. regular maintenance cycle run immediately before the

standard cycle is run).

There are three operating modes that the ZBM goes through

during this standard cycle:

1. Charging (9.2 hour period from 0 to 9.2 hours):

Current (blue trace, using right axis) at -25A DC

(negative = charging) for 9.5 hours.

2. Discharging (10 hour period from 9.2 to 19.2 hours):

Current ranges from 25A DC to 0A DC as the voltage

(red trace, using left axis) falls from 52V DC to 0V DC.

The ZBM continues to discharge until the battery

current is very close to 0A, and the ZBM is empty.

3. Regular Maintenance (0.5 hour period from 19.2 to 19.7

hours):

After discharge is completed, excess zinc is stripped

from the ZBM. Half an hour is a suitable period to allow

full regular maintenance to be performed on a healthy

ZBM.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 25 of 85

Figure 5.1: An example of the RedFlow ZBM’s Standard Cycle

5.4. Shutdown Procedure

The complete shutdown procedure below should be used when

shutting down the system for storage, shipping, de-energised

maintenance or ZBM replacement.

Step 1 Fully discharge the ZBM and perform a regular

maintenance cycle.

Step 2 With the ZBM still in Run Mode, check Register

0x9013 to ensure the ZBM’s terminal voltage is 0V.

Step 3 Enter the ZBM into Offline Mode by writing to

Register 0x9103.

Step 4 Turn off any connected loads.

Step 5 Disconnect all other connections with the ZBM.

Step 6 Using a multimeter, measure the voltage across the

battery terminals to confirm that the ZBM’s terminal

voltage is 0V.

RedFlow ZBM – Gen 2.8 Installation and Operation Manual

Document ID: IMRFS26. Version 1.0

© 2014. RedFlow Limited. All Rights Reserved. P a g e | 26 of 85

Loading...

Loading...