Redball Electrical 565 User Manual

Par ts and Operator’s

Manual

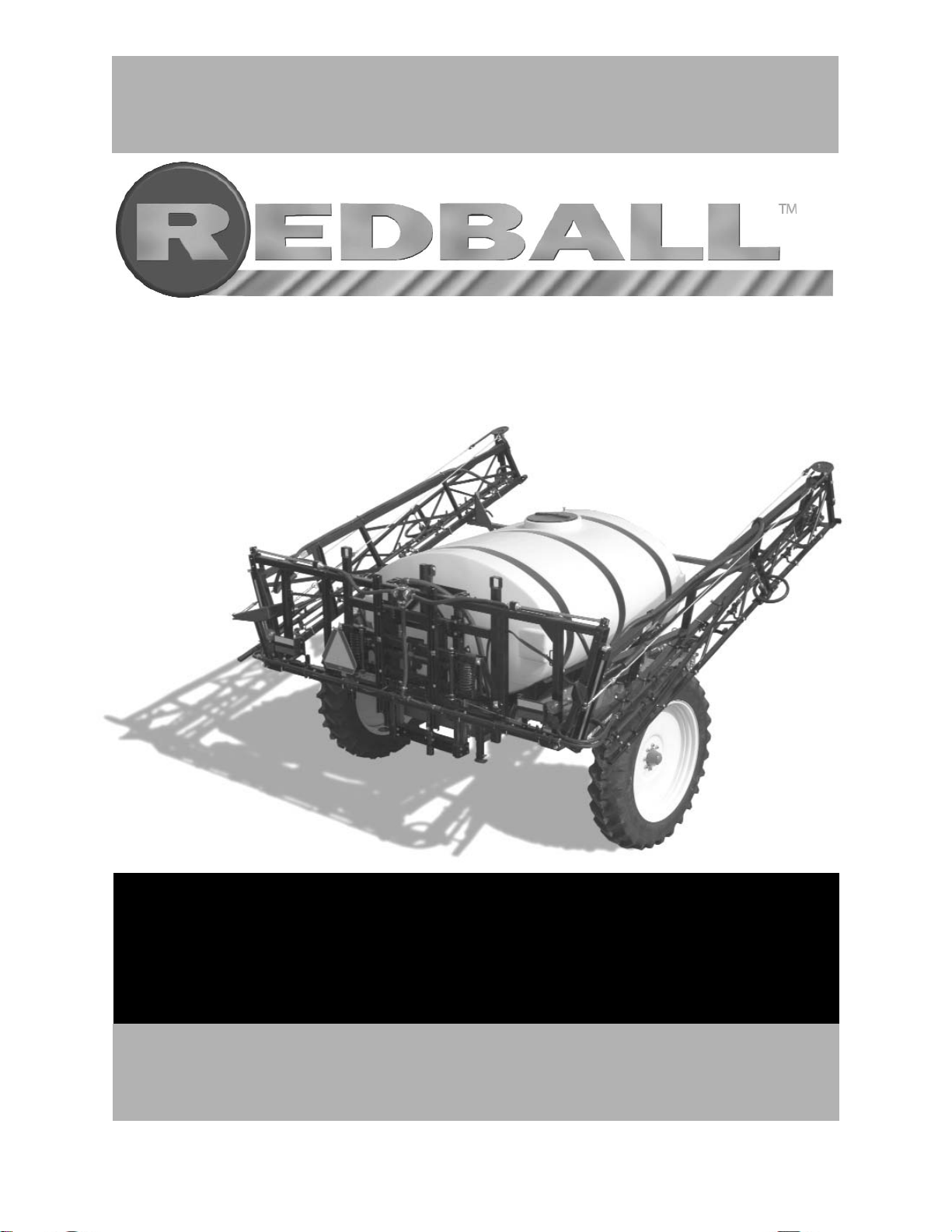

565 Trailer Sprayer

3-07

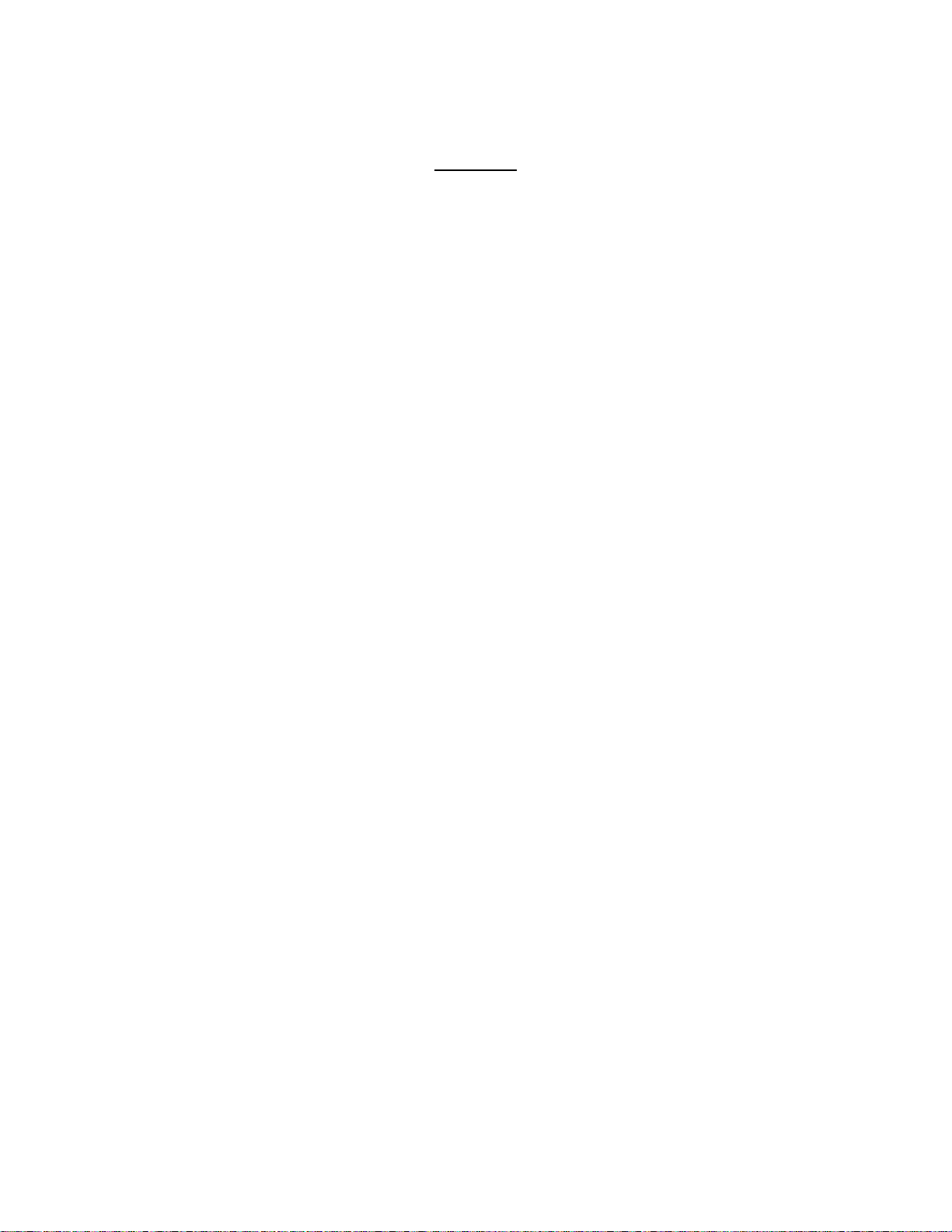

TO THE OWNER

Congratulations on your selection of a Redball

®

Model 565 Trailer Sprayer.

Redball

®

Sprayers have earned a reputation of providing a durable sprayer throughout

the U.S. and Canada.

Redball

®

Sprayers have been designed to provide many years of profitable and

dependable service. To assure maximum performance of your sprayer, it is mandatory

that you thoroughly study the operator's manual and follow its recommendations. Proper

operation and maintenance are essential for safety, to maintain performance, and to

maximize the life of the sprayer.

It is the owner's responsibility to:

• Operate and maintain this sprayer in a safe manner and in accordance with all

applicable local, state, and federal codes and/or laws; and in compliance with

labeling instructions furnished by the supplier of the chemical being used.

• Make sure each and every operator has read the operator's manual and thoroughly

understands safe and correct operating procedures.

• Make sure unauthorized people do not operate or are not in the vicinity of the sprayer

while it is in operation.

• Maintain the sprayer in accordance with the maintenance schedule in this manual.

Furthermore, as additional technology becomes available, the owner is

responsible for improving the safety and reliability of the system.

• Fulfill all warranty obligations so as not to void the warranties. Verify the unit is

warranty registered prior to making any warranty claims. The warranty section

at the back of this manual outlines the warranty policy of Redball, LLC.

Abuse or modifications to the sprayer that change the performance other than original

factory specifications void the warranty.

Redball, LLC reserves the right to make product improvements to the equipment at any

time. It shall not be obligated to make such changes to machines already in service.

* The owner, manager and/or operator is responsible for safe, accurate operation

and maintenance of the Redball

®

Sprayer.

565 Trailer Sprayer

Patent Pending

3-07

TABLE OF CONTENTS

Safety Instructions Section A

Safety First 1

Safety Instructions for Operation 2

Safety Decal Placement 5

Operation Instructions Section B

Inspect Unit 1

System Overview 1

Hitch 2

Liquid Tanks & Cradle Frame 2

Sprayboom & Nozzles 2

Liquid Pumping & Plumbing 3

Centrifugal Pump 4

Hydraulically Driven Centrifugal Pump 4

PTO Driven Centrifugal Pump 5

Fill Solution Tank 5

Fill Solution Tank,

Utilizing Eductor (Optional) 6

Fill Solution Tank, Tank Agitation 7

Rinse Solution Tank 8

Rinse Sprayboom Plumbing 9

Rinse Agitation System 9

Spraying 10

Spraying With Agitation 10

Unload 11

Hydraulic Boom Controls 11

Solution Spray Control System 12

Light and Marking System 12

Foam Marker 12

(Continued on next page)

565 Trailer Sprayer

Table of Contents

3-07

TABLE OF CONTENTS

Connection & Startup Section C

Connection 1

Hitch 1

Visual Inspection 2

Axles 2

Fixed Row Crop Width Axles 2

Tire Weight Capacities 3

Hydraulics 5

Hydraulically Driven Pumps

Centrifugal Pump 5

Hydraulic SprayBoom Control 6

Solution Spray Control System 7

Light System Seven Pin Connector 8

Foam Marker 8

Storage Section D

Storage 1

Sprayer Winterization 2

Maintenance, Service & Troubleshooting Section E

Liquid Tank, Frame and Plumbing 1

Hydraulics 2

Electrical & Control System 2

Lubrication 3

Wheel Lug Nut Torque 4

Bolt Torque Data 5

Troubleshooting 6

Parts & Schematics Section F

Warranty Section G

Serial and Model Number Location 1

Warranty 2

565 Trailer Sprayer

Table of Contents

3-07

565 Trailer Sprayer - Safety Instructions

Section A

3-07

565 Trailer Sprayer - Safety Instructions

Section A

Safety First

Accidents can be prevented by recognizing the causes

or hazards before an accident occurs..... and doing

something about them.

Regardless of the care used in the design and

construction of this equipment, there are some areas

that cannot be completely safeguarded without

interfering with the accessibility and efficiency

of operation.

In this manual and on labels used on the machine the

words “ DANGER”, “WARNING”, and “CAUTION”, are

used to indicate the following:

DANGER

: Indicates an imminently hazardous

situation that, if not avoided, will result in

death or serious injury.

W

ARNING: Indicates a potentially hazardous situation

that, if not avoided, could result in death

or serious injury.

CAUTION:

Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury.

In this manual the words “IMPORTANT” and “NOTE”

are used to indicate the following:

IMPORT

ANT: Highlights information that must

be heeded.

NOTE:

A reminder of other related information

that needs to be considered.

THIS MESSAGE ALERT SYMBOL IDENTIFIES INFORMATION THAT

MUST BE HEEDED FOR PROPER OPERATION OF EQUIPMENTAND

TO PREVENT DAMAGE OR DETERIORATION OF THE EQUIPMENT.

THIS MESSAGE ALERT SYMBOL IDENTIFIES IMPORTANT MESSAGES

IN THIS MANUAL. WHEN YOU SEE THIS SYMBOL, BE ALERT TO THE

POSSIBILITY OF PERSONAL INJURY AND CAREFULLY READ THE MESSAGE THAT FOLLOWS.

1

Section A

3-07

Safety Instructions for Operation

1. DO NOT ALLOW ANYONE TO OPERATE THIS

REDBALL SPRAYER UNTIL HE OR SHE HAS

READ THIS MANUAL AND IS COMPLETELY

FAMILIAR WITH ALL SAFETY AND OPERATION PROCEDURES.

2. If any safety devise on the sprayer itself is not

functioning properly, DO NOT use the sprayer.

Remove it from service until it has been properly

repaired by a qualified service technician.

3. Do not allow the following people to operate or

repair this equipment.

* Children

* Irresponsible persons

* People under the influence of alcohol,

medications or other drugs that can

cause drowsiness or impaired judgement.

* Persons unfamiliar with equipment or

people who are careless or unfamiliar

with safe operating procedures.

Observe the IMPORTANT SAFETY INSTRUCTIONS

listed below at all times!

THE BEST KIND OF SAFETY IS ACAREFUL OPERATOR

Always wear protective clothing, goggles, respirator and gloves

when handling chemicals.

Safety instructions furnished by the chemical manufacturer

must be followed exactly to prevent serious harm to individuals

and / or the environment.

Observe all Federal and State EPAregulations and all Local,

State and Federal codes and / or laws regarding licensing,

handling, storage, transportation, application and waste

disposal of chemicals.

W

ARNING

CAUTION

W

ARNING

DANGER

565 Trailer Sprayer - Safety Instructions

Section A

2

Section A

3-07

4. People who are allergic to any of the chemicals

used must never be allowed in or near the sprayer.

5. Always park the sprayer on a level surface, and lock

the tractor brakes,or block the tires, before making

adjustments or repairs.

6. Before operating this equipment, thoroughly inspect

the unit to insure it is in good working order.

7. Do not operate this unit if any defect or malfunction

exists. Pay particular attention to safety features

such as PTO guards and safety chains.

8. Verify that the sprayer is securely hitched to the

tractor and safety chains are in place.

9. Always position the sprayboom in cradles prior to

disconnecting the trailer hitch from the tractor.

10. S

topping distance increases as the square of

the speed. For example : It will take twice as much

distance to stop a unit traveling15 mph as one going

10 mph; and four times the distance at 20 mph!

(more than eight times the distance at 25 mph!)

Road surface will influence stopping distance.

Dry pavement is usually considerably better than

gravel road. Materials (such as ice, snow, water, oil

or mud) on the surface can greatly increase stopping

distance.

Road slope has a significant impact on stopping

distance and can greatly magnify the other factors

mentioned above. Under some downhill conditions

stopping can be very difficult or impossible.

565 Trailer Sprayer - Safety Instructions

Section A

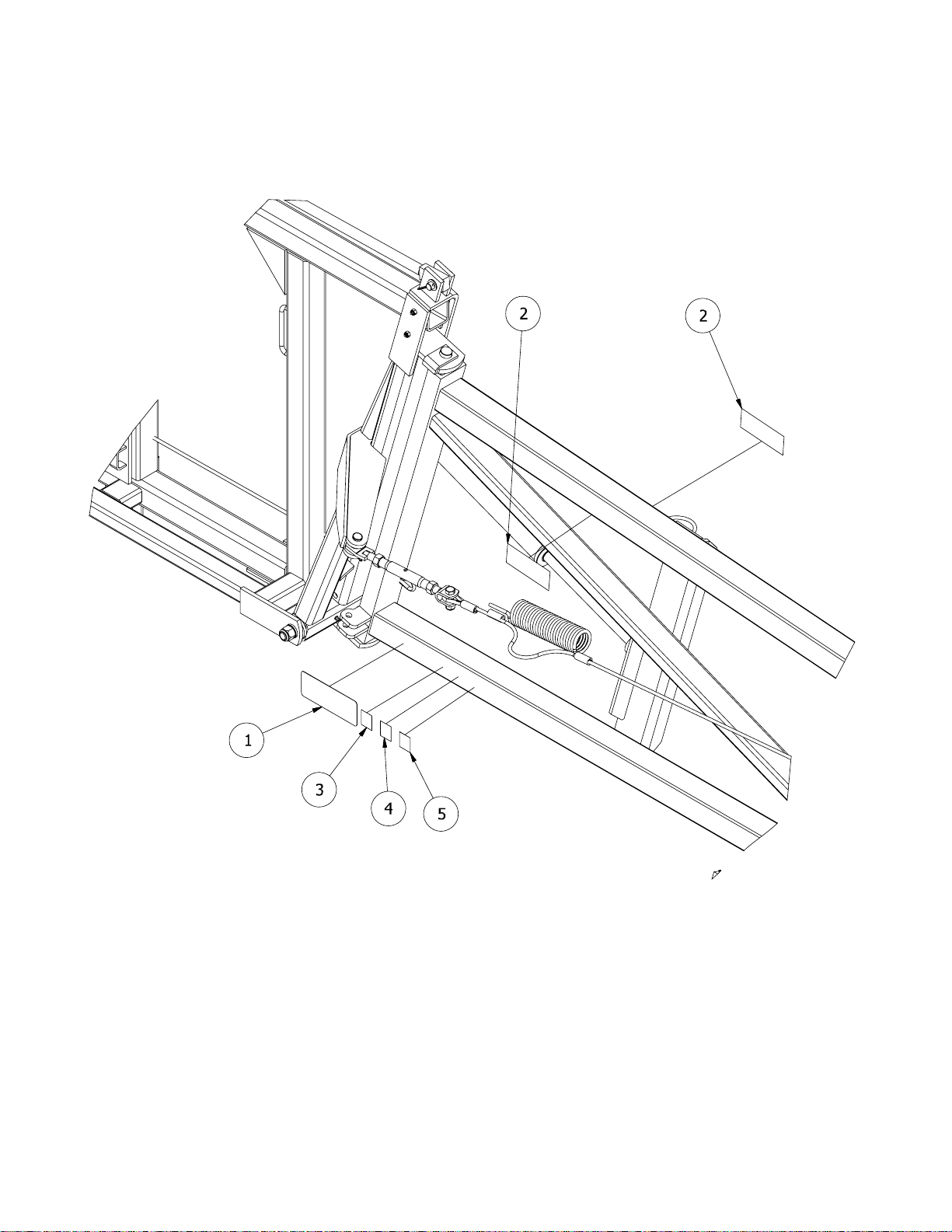

Never disconnect the sprayer from the tractor hitch while the

sprayboom wings are in the spray position. This action will

cause this sprayer to tip backwards with a high probability of

injury to the operator and damage to the unit.

WARNING

3

Section A

3-07

565 Trailer Sprayer - Safety Instructions

Section A

4

Section A

11. Do not replace components or parts with those

other than genuine Redball

®

Factory Service Parts.

To do so may reduce the effectiveness of safety

features or decrease the accuracy of the unit.

12. Read the Operator Instructions

section of this manual for further

necessary information relating to

the safe operation of the

applicator.

3-07

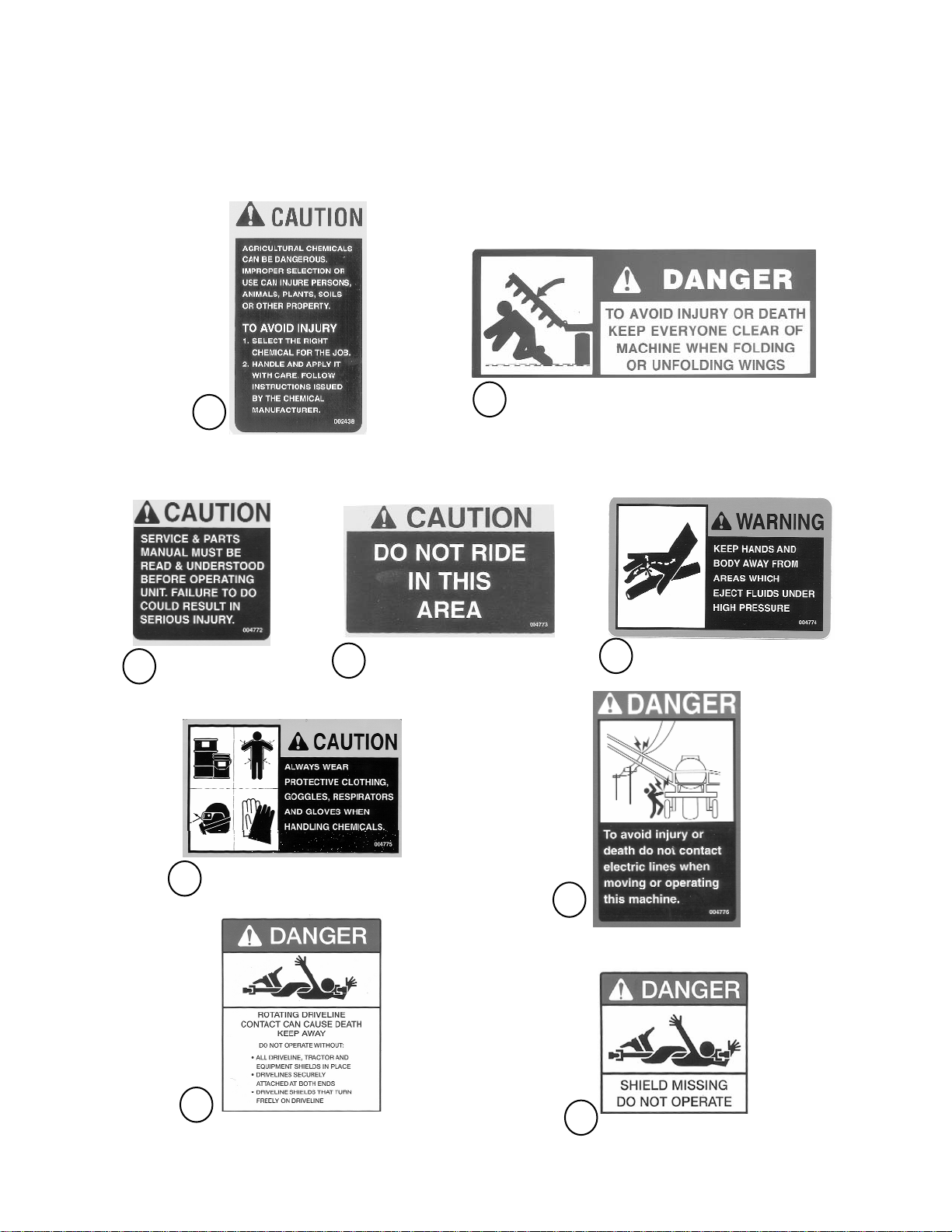

SAFETY DECALS ON A REDBALL

®

565 TRAILER SPRAYER

565 Trailer Sprayer - Safety Instructions

Section A

5

Section A

1

7

5

4

3

8

6

P/N 004773

P/N 004774

P/N 004776

P/N 004772

P/N 004775

P/N 30000000

P/N 002439

P/N 002438

2

9

P/N 30000001

3-07

565 Trailer Sprayer - Safety Instructions

Section A

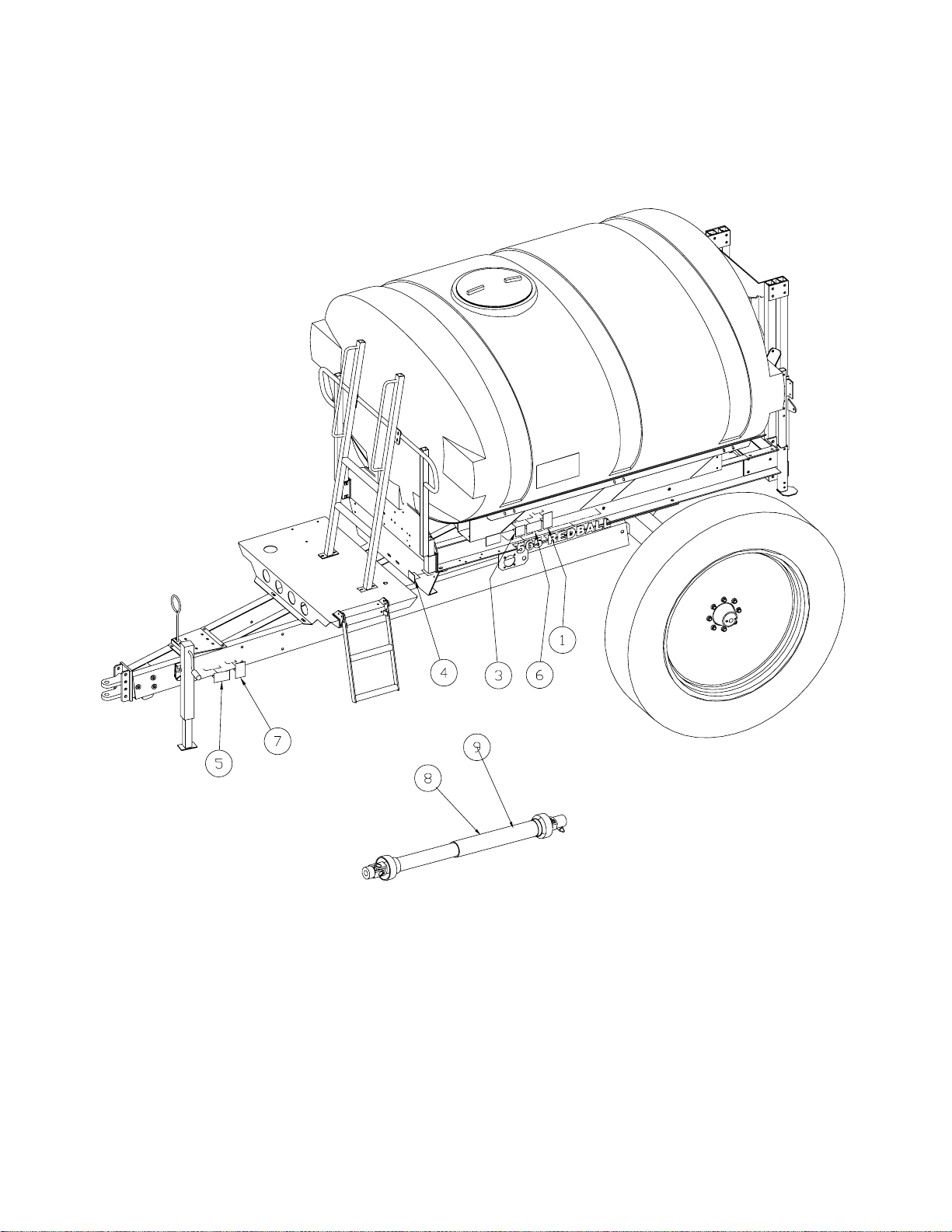

SAFETY DECAL PLACEMENT

6

Section A

Ref-016805B

3-07

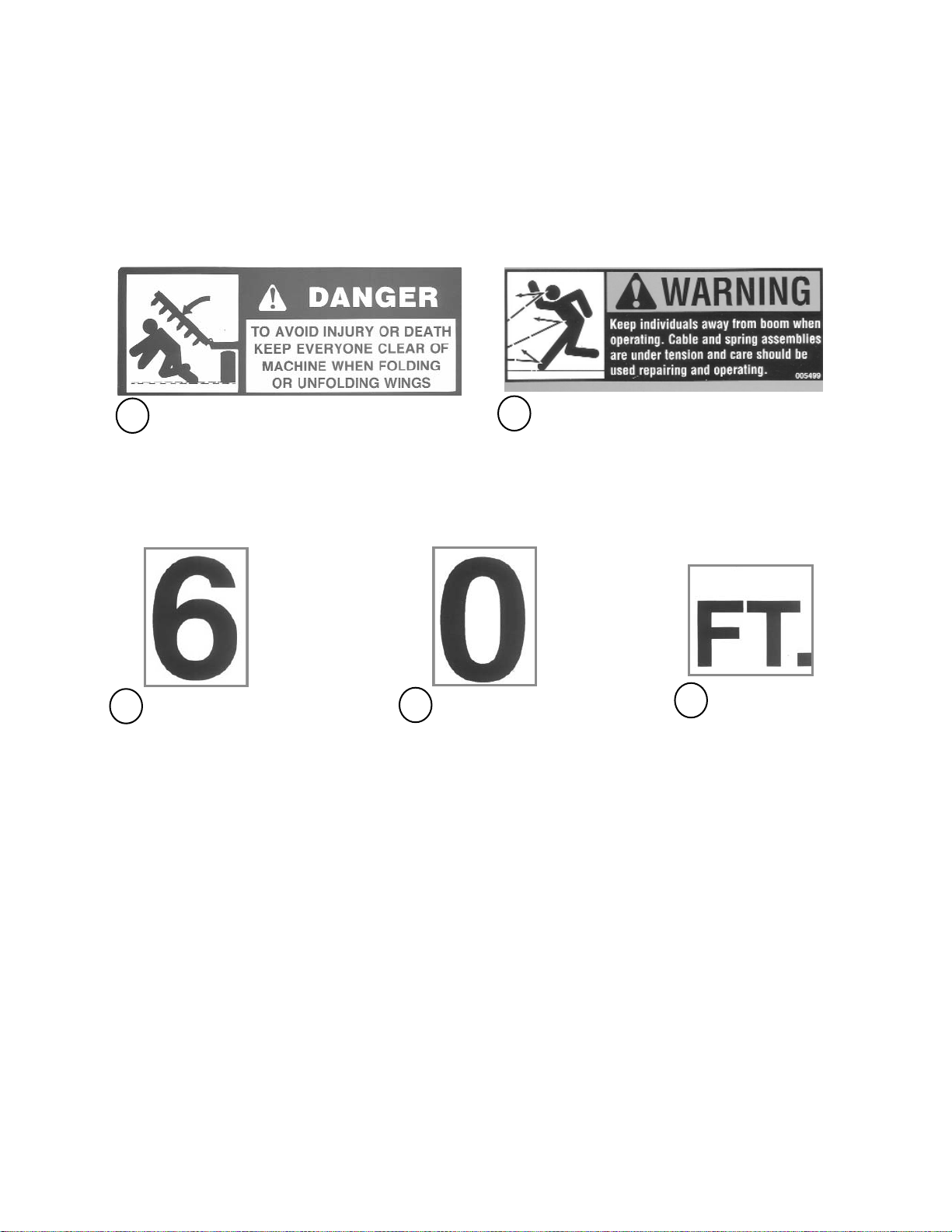

SAFETY DECALS ON A REDBALL

®

565 TRAILER SPRAYER

Boom Decals

565 Trailer Sprayer - Safety Instructions

Section A

7

Section A

1

P/N 002439

2

P/N 005499

3

4

5

3-07

565 Trailer Sprayer - Safety Instructions

Section A

SAFETY DECAL PLACEMENT

8

Section A

015890A

565 Trailer Sprayer - Safety Instructions

Section A

9

Section A

2-07

NOTES:

3-07

3-07

565 Trailer Sprayer - Operation Instructions

Section B

1

Section B

Inspect Unit

System Overview

The Redball®Model 565 Trailer Sprayer could be comprised of the following subsystems:

• Hitch

• Liquid Tanks & Saddle

• Sprayboom and Nozzles

• Liquid Pumping

• Hydraulics

• Centrifugal Pump

• Sprayboom Folding

• PTO Pump

• Solution Spray Control System

• Light and Marking System

• Foam Marker

IMPORTANT

Prior to loading with chemical, the operator needs to test the

sprayer with water only to ensure the system is intact prior to

putting chemical into the system. Test to verify application at

the desired rate and all components work correctly.

CAUTION

Check machine thoroughly for screws, bolts, fittings, etc.,

which may have come loose during transport or operation.

3-07

Hitch

Verify hitch is correctly attached to the tractor. See

Section C for connection procedures.

Main Product Liquid T

ank & Steel Saddle

A polyethylene tank is supported by a structural steel

saddle. The tank is strapped in the saddle.

S

prayboom and Nozzle(s)

The boom comes in one configuration with a boom size

of 60’. Hydraulic cylinders, powered via the tractor

hydraulics, achieve folding of the sprayboom.

Your sprayer will not come with nozzle tips. Your application may require a different size or type of tip as it

relates to the speed and application rate you desire.

Choose the proper size and type of nozzle for your application. See your nozzle supplier for correct selection and

required spacing.

565 Trailer Sprayer - Operation Instructions

Section B

Never allow the clean water safety tank to become

contaminated with chemical. Use the clean water for skin

and eye rinse in case of accidental chemical contact.

WARNING

2

Section B

1.) Towing tractor must

weigh 12,000 pounds to

ensure adequate stopping

ability. Refer to your tractor manufacturer rating

capabilities.

2.) Do not tow sprayer

over 20 MPH.

IMPORTANT

Clevis Hitch Safety Chain

3-07

565 Trailer Sprayer - Operation Instructions

Section B

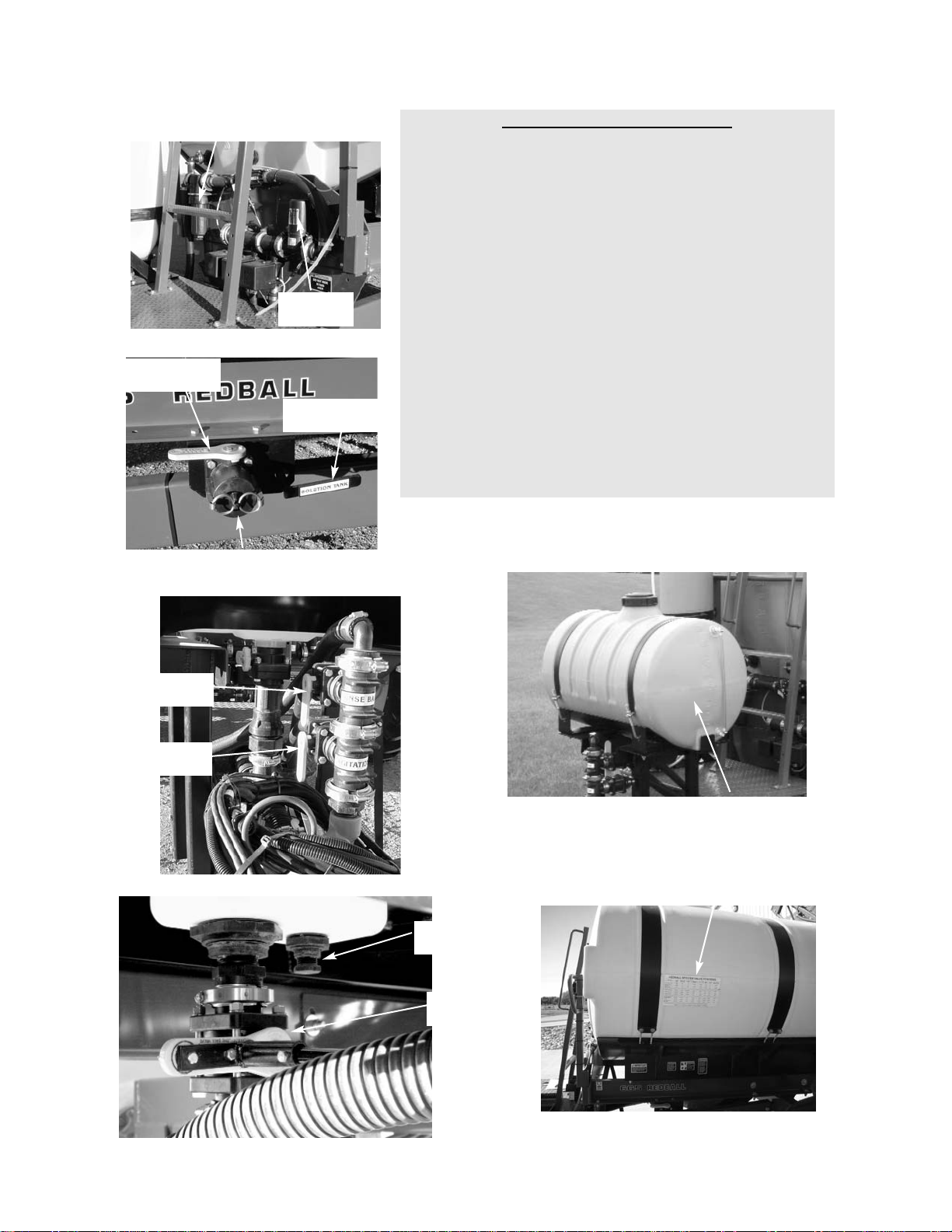

Liquid Pumping & Plumbing

The liquid system begins with a suction line supplying a

centrifugal pump. This pump is powered via tractor

hydraulics or PTO shaft and provides flow to the

sprayer. The pump and plumbing have been configured to provide for the following functions:

• Fill Solution Tank

• Fill Solution Tank, Utilizing Eductor

• Fill Solution Tank, With Tank Agitation

• Fill Clean Water Rinse Tank

• Rinse Agitation System

• Rinse Solution Tank

• Rinse Sprayboom Plumbing

• Spray

• Unload

Actual valve configuration will vary, depending on

options purchased.

3

Section B

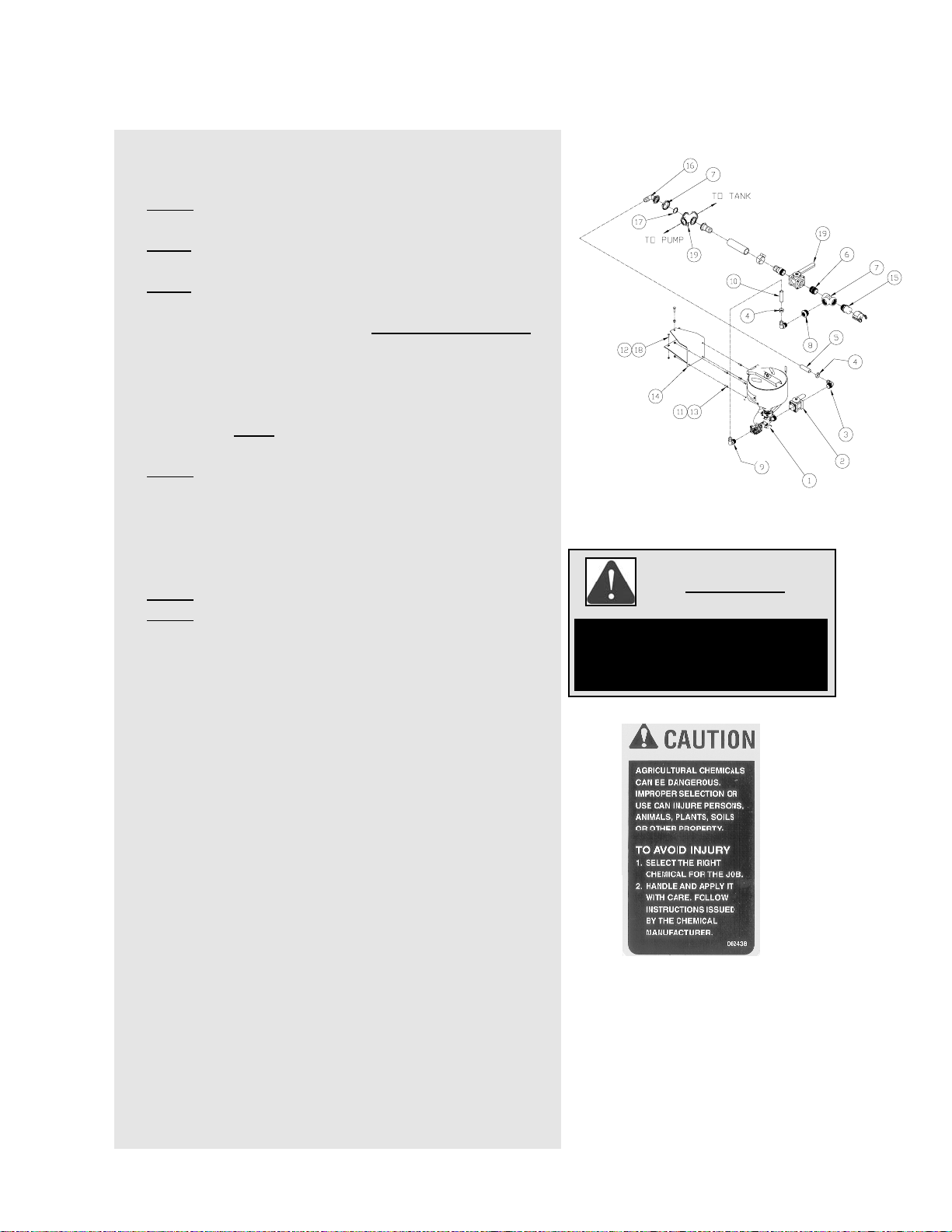

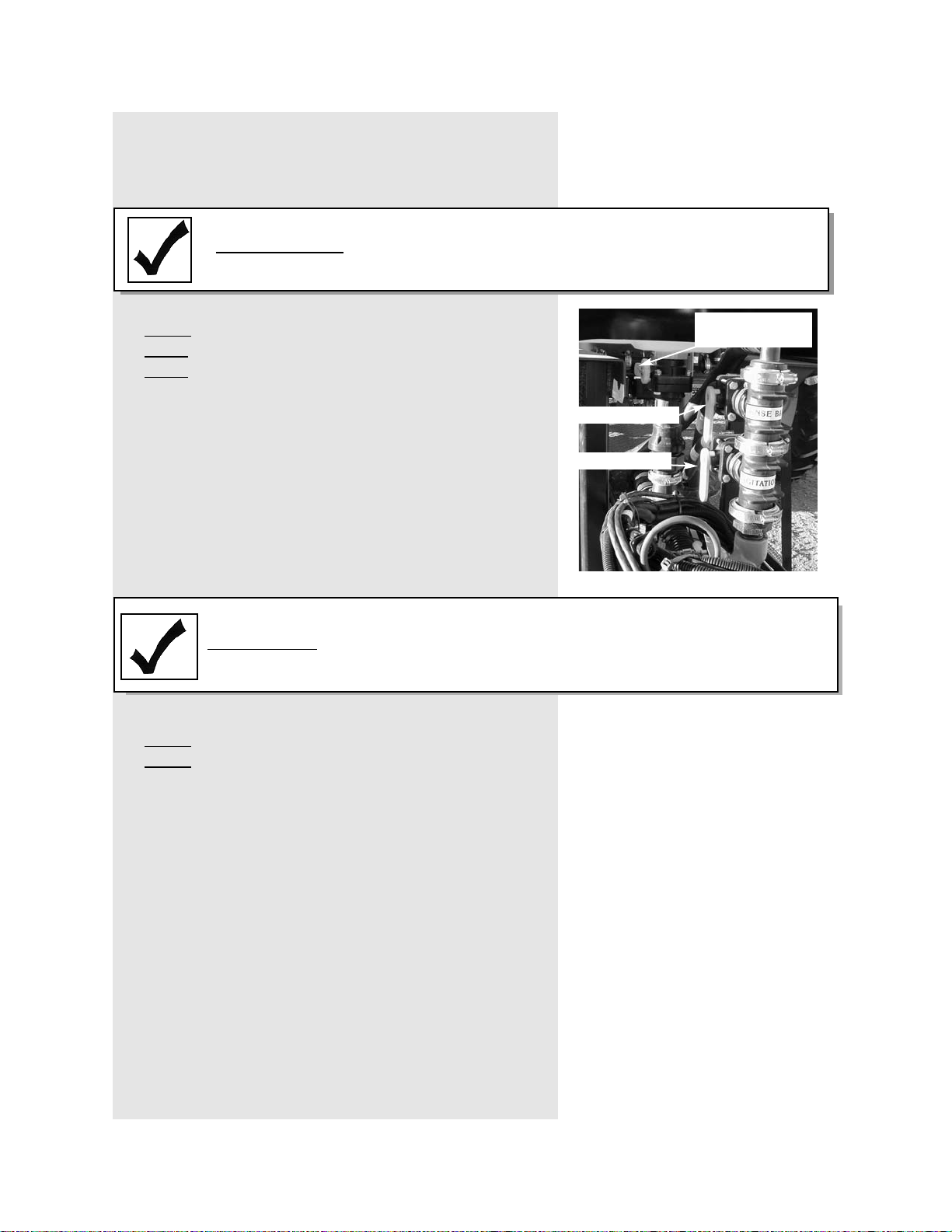

Main Line

Filter

Regulating

Valve

Quick Fill Cap

Solution Quick

Fill Valve

Solution Tank

Main Valve

Rinse Ball

Valve

Agitation

Valve

Drain

Plug

Main Product

Tank Valve

Rinse Tank

Valve Position Chart

3-07

565 Trailer Sprayer - Operation Instructions

Section B

4

Section B

Centrifugal Pump

Pump operation is very important. The following must be

followed when operating a centrifugal pump. Proper

pump operation will make your system operate with minimal maintenance and down time. Failure to follow the

manufacturer’s pump operation instructions will void

the pump warranty.

The pump must never be run in a non-flooded condition.

Operating the pump in a non-flooded condition will cause

extensive seal damage and possible pump damage. To

verify the pump is flooded, visually check pump vent line

for fluid, fluid will appear in vent line when pump is

flooded.

A “flooded” condition is when the centrifugal pump is

completely full of fluid and no pockets of air are present

in the pump. In order to get maximum pump efficiency

the mounting and plumbing must meet the guidelines

stated below.

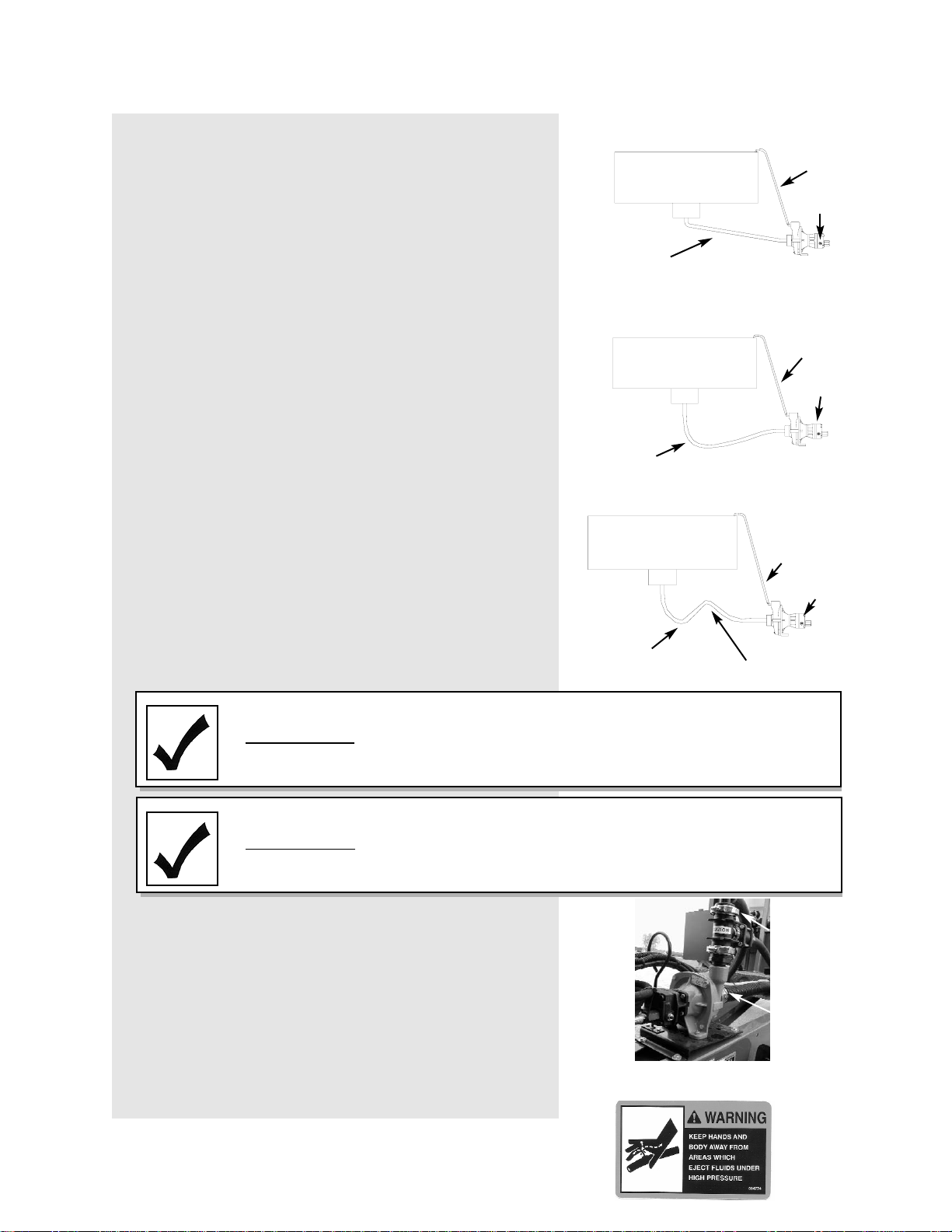

1. The pump inlet must be mounted below the product

tank(s) sump to allow gravity to naturally fill the

pump with liquid. See Figures 1 - 3.

2. The suction line must have a continual rise from the

pump inlet to the tank sump.

3. The pump must have the vent line plumbed to it.

Hydraulically Driven Centrifugal Pump: It is very

important that the proper oil flow is supplied to the

hydraulic motor which powers the pump. Excessive flow

will over-speed the motor and cause motor damage. To

regulate the correct oil flow to the pump motor see

the pump manufacturer’s manual.

IMPORT

ANT

The vent line is designed to prevent air lock by bleeding off

trapped air. This allows the pump to prime and keeps some

fresh solution circulating by the seal.

IMPORT

ANT

For proper venting, the vent line must continually rise from the

pump to the top of the tank. A small amount of solution will

move through this line back to the solution tank indicating a

primed pump.

Product Tank

Vent

Line

Suction Line

Ideal

Pump

Figure 1

Product Tank

Vent

Line

Suction Line

Acceptable

Pump

Figure 2

Product Tank

Vent

Line

Air Trap Point

Pump

Figure 3

Suction Line

Not Acceptable

Hydraulically Driven

Centrifugal Pump

Outlet

Suction

Line

3-07

565 Trailer Sprayer - Operation Instructions

Section B

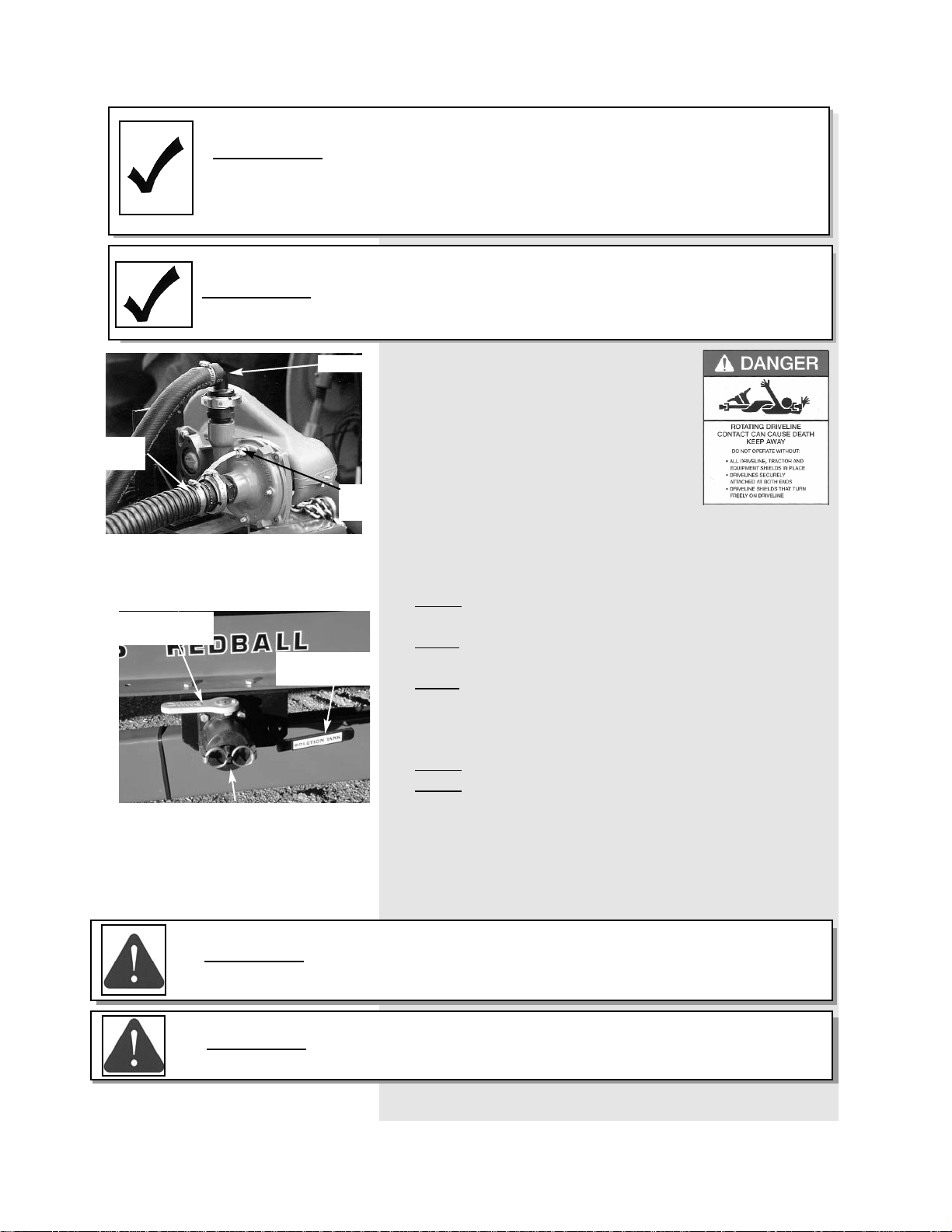

PTO Driven Centrifugal Pump: Make

sure your desired tractor speed turns the

PTO shaft at the correct speed. See the

pump manufacturer’s manual for further

operational information.

Fill Solution Tank:

Load the solution tank without using the trailer sprayer

pump via the following steps.

1. Close all valves.

2. Remove solution quick fill cap & connect load hose.

3. Open

solution quick fill valve and solution tank main

valve, located at the sump of the solution tank.

4. Open

valve on loading reservoir (i.e. nurse tank).

5. Start the remote transfer pump.

6. Run remote transfer pump until the desired amount

of solution is transferred into the trailer sprayer.

7. Close

valves on loading reservoir.

8. Close solution quick fill valve on trailer sprayer.

9. Remove load line & replace cap on trailer quick fill.

Small amounts of liquids will remain in the load hose.

Splashing of this liquid can cause a safety hazard to you and

to those in the vicinity of the trailer sprayer.

CAUTION

Overfilling will cause a failure of the tank lid causing splashing

of solution from the tank lid, which may be hazardous to you

and the environment.

CAUTION

5

Section B

IMPORTANT

Turn off a hydraulically driven centrifugal pump using the “float” position of the tractor’s hydraulic valve. This allows the motor to stop

slowly helping to protect the motor and motor seals.

IMPORTANT

There are two basic rules to follow when operating a hydraulically

driven centrifugal pump:

1. Never run the pump in a “non-flooded” condition.

2. Always have the correct oil flow to the pump motor.

Always read and follow the pump manufacturer’s operational

instructions.

PTO Driven Centrifugal Pump

Outlet

Vent

Line

Suction

Line

Quick Fill Cap

Solution Quick

Fill Valve

Solution Tank

Main Valve

3-07

Fill Solution Tank, Utilizing Optional Eductor:

Load the solution tank using the optional eductor via the

following steps:

1. Close

all valves.

2. Remove solution quick fill cap & connect load hose.

3. Open

solution quick fill valve and solution tank main

valve.

4. Open valve on loading reservoir (i.e. nurse tank)

5. Fill eductor with desired amount of chemical to be

pulled into the solution tank. CLOSE Eductor Lid

.

6. Start the remote transfer pump.

7. Once there is a steady flow rate from the nurse tank to

the solution tank, open the eductor valve and close the

solution quick fill valve. Once there is a steady flow

rate again, open

the eductor tank valve for 15-30

seconds.

8. Close the eductor tank valve and verify the chemical

has been completely removed from the eductor tank.

Repeat steps 7 and 8 if chemical remains in the

eductor tank.

9. Run remote transfer pump until the desired amount

of solution is transferred into the sprayer.

10. Close

valves on the loading reservoir.

11. Close

solution quick fill valve, solution tank main

valve and the eductor valve on the sprayer.

12. Remove load line & replace cap on sprayer quick fill.

565 Trailer Sprayer - Operation Instructions

Section B

6

Section B

CAUTION

DO NOT open the lid of the

eductor while in operation as

splashing of chemical may occur.

3-07

565 Trailer Sprayer - Operation Instructions

Section B

Fill Solution Tank, With Tank Agitation: Loading of

the solution tank, using tank agitation, is accomplished

via the following steps:

1. Close

all valves.

2. Remove solution quick fill cap & connect load hose.

3. Open

solution quick fill valve and the solution tank

main valve.

4. Open

valve on loading reservoir (i.e. nurse tank).

5. Start the remote transfer pump.

6. Open the agitation valve.

7. Engage the liquid pump of the trailer sprayer.

8. Disengage the liquid pump of the trailer sprayer

when adequate agitation is achieved.

9. Run remote transfer pump until the desired amount

of solution is transferred into the trailer sprayer.

10. Close

the agitation valve.

11. Close valves on loading reservoir.

12. Close the solution quick fill and the solution tank

main valves.

13. Remove load line and replace cap on sprayer quick

fill.

Fill Freshwater Rinse Tank

1. Close all valves.

2. Remove the freshwater rinse tank cap.

3. Fill tank to desired level.

4. Replace the freshwater rinse tank cap.

7

Section B

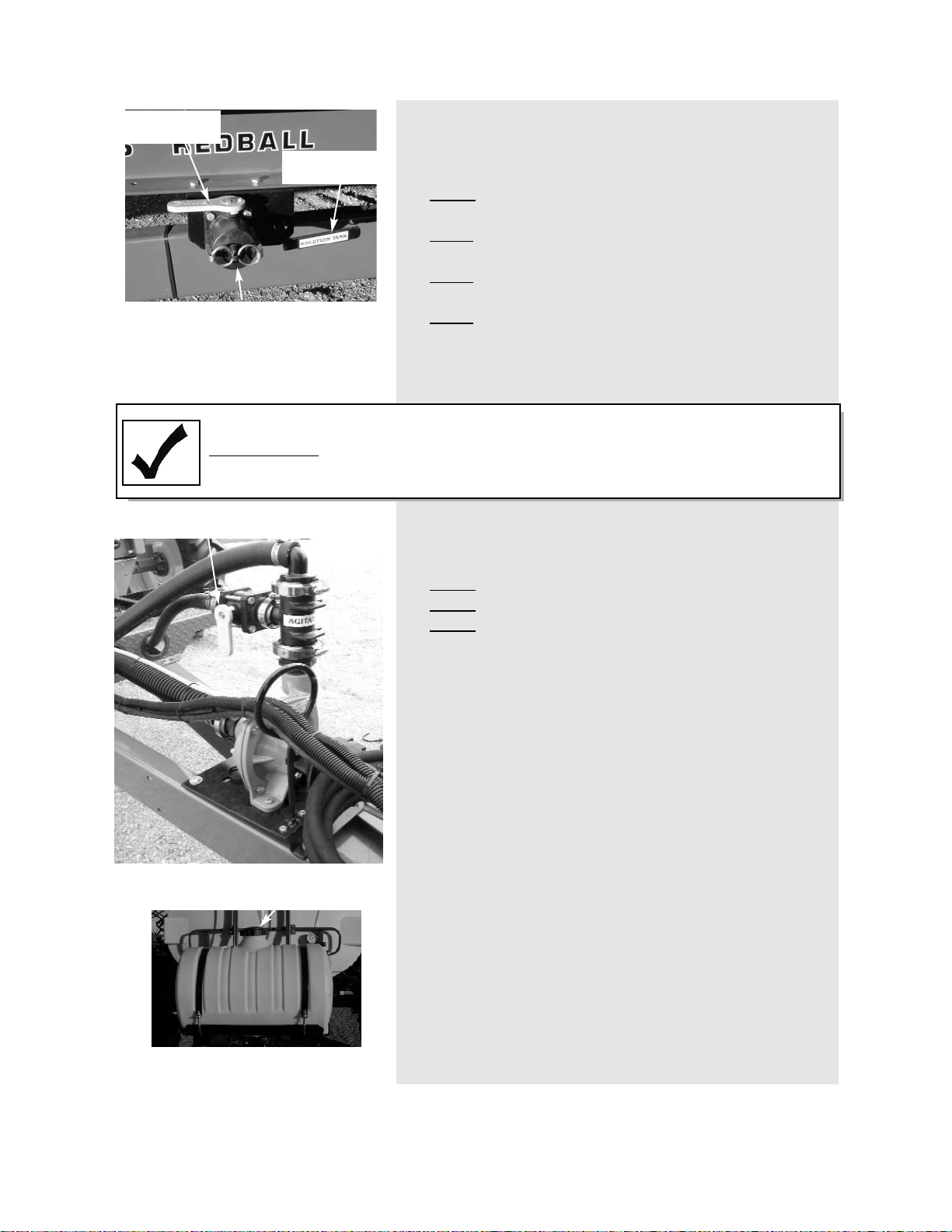

IMPORTANT

Turn off a hydraulically driven centrifugal pump using the “float” position of the tractor’s hydraulic valve. This allows the motor to stop

slowly helping to protect the motor and motor seals.

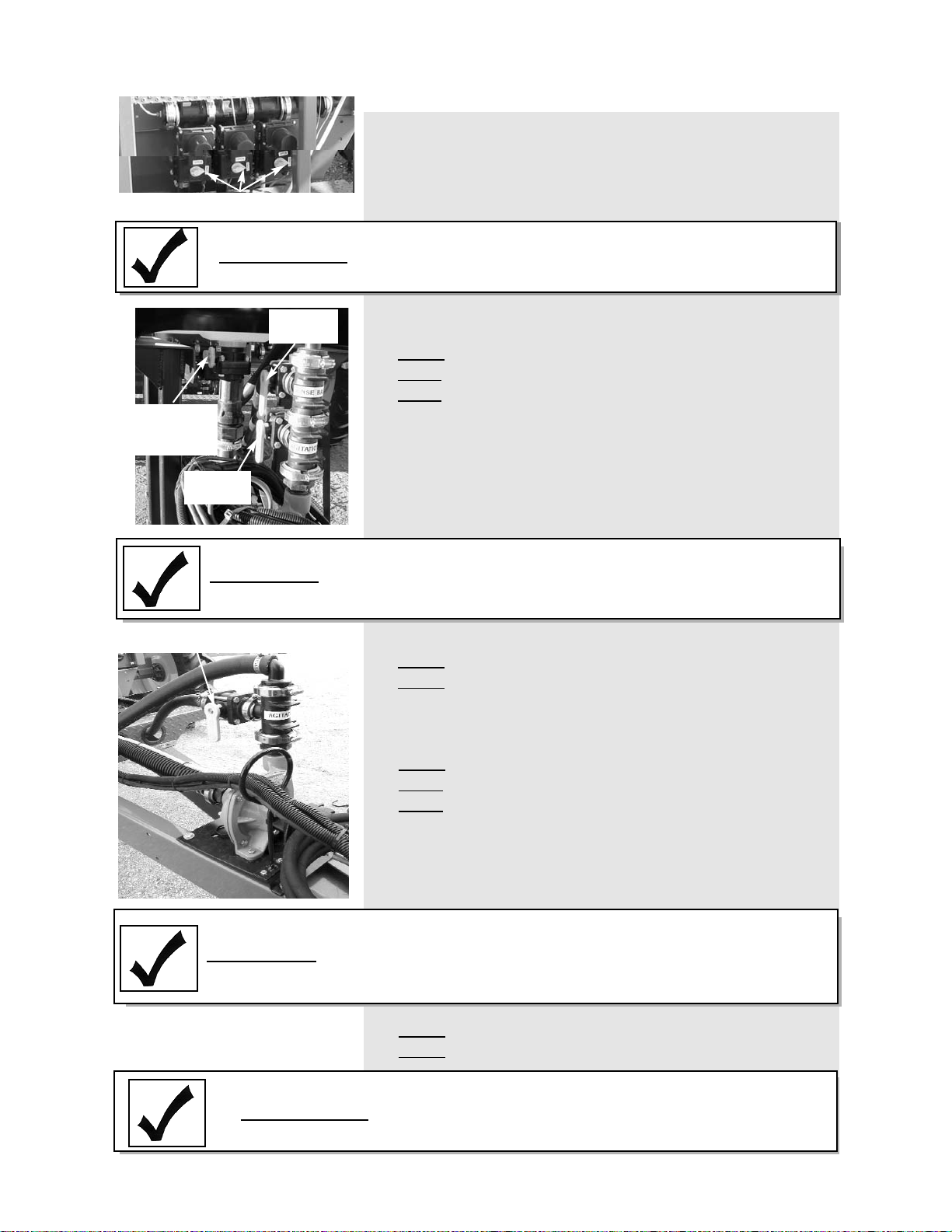

Agitation Valve

Quick Fill Cap

Solution Quick

Fill Valve

Solution Tank

Main Valve

55 Gallon Fresh Water

Rinse Tank

Freshwater

Rinse Tank Cap

3-07

565 Trailer Sprayer - Operation Instructions

Section B

8

Section B

Rinse Solution Tank

Using the clean water rinse tank system (optional on 665),

rinsing the solution tank with clean water is accomplished

via the following steps:

1. Close

all valves.

2. Open the clean water rinse tank valve.

3. Open

the rinse ball valve.

4. Power ON the liquid pump of the sprayer.

5. Run for 15-30 seconds to thoroughly rinse the

insides of the solution tank. Repeat if needed.

6. Power OFF the liquid pump of the trailer sprayer.

7. Close

the clean water rinse tank valve.

8. Close the rinse ball valve.

Only you, the operator can determine the length of time

required to completely rinse all chemical residue from

the sprayer tanks and plumbing systems.

IMPORTANT

IMPORT

ANT

Turn off a hydraulically driven centrifugal pump using the “float” position of the tractor’s hydraulic valve. This allows the motor to stop

slowly helping to protect the motor and motor seals.

Agitation Valve

Rinse Ball Valve

Clean Water

Rinse Tank Valve

3-07

565 Trailer Sprayer - Operation Instructions

Section B

9

Section B

Rinse Sprayboom Plumbing

Using the clean water rinse tank system (optional on 665),

rinse the sprayboom plumbing with clean water via the

following steps:

1. Close

all valves.

2. Open the clean water rinse tank valve.

3. Open all sprayboom section valves with the solution

spray controller.

4. Power ON the liquid pump of the trailer sprayer.

5. Run for 15-30 seconds to thoroughly rinse. Repeat if

needed.

6. Power OFF the liquid pump of the trailer sprayer.

7. Close

the clean water rinse tank valve.

8. Close all sprayboom section valves.

Rinse Agitation System

Rinse the agitation plumbing via the following steps:

1. Close

all valves.

2. Open

the clean water rinse tank valve.

3. Open the agitation valve.

4. Power ON the liquid pump of the trailer sprayer.

5. Run for 15-30 seconds to thoroughly rinse the

insides of the agitation plumbing.

6. Power OFF the liquid pump of the trailer sprayer.

7. Close

the clean water rinse tank valve.

8. Close the agitation valve.

Only you, the operator can determine the length of time

required to completely rinse all chemical residue from the

sprayer tanks and plumbing systems.

IMPORTANT

IMPORT

ANT

Turn off a hydraulically driven centrifugal pump using the “float” position of the tractor’s hydraulic valve. This allows the motor to stop

slowly helping to protect the motor and motor seals.

Only the operator can determine the length of time

required to completely rinse all chemical residue

from the sprayer tanks and plumbing systems.

IMPORTANT

IMPORTANT

Turn off a hydraulically driven centrifugal pump using the “float” position of the tractor’s hydraulic valve. This allows the motor to stop

slowly helping to protect the motor and motor seals.

Sprayboom Section Valves

Agitation

Valve

Rinse Ball

Valve

Clean Water

Rinse Tank

Valve

Agitation Valve

3-07

Spraying

Spraying is accomplished via the following steps:

1. Close

all valves.

2. Open

the the solution tank main valve.

3. Setup control system. (Setup and operation of the

control system is covered in the manual provided by

the controller manufacturer.)

4. Power ON the liquid pump of the trailer sprayer.

5. Open desired spray boom section valves.

6. Perform spraying according to the control system

provided.

7. To stop spraying, close

all sprayboom section

valves.

8. Power OFF the liquid pump of the trailer sprayer.

Spraying with Agitation: Certain chemicals require

continuous agitation. If agitation is required during

spraying, open the agitation valve provided. If severe

foaming of your chemical occurs, check the chemical

label or your supplier to determine if agitation is required

or reduce the opening of the agitation valve to limit the

flow rate back to the solution tank. Reduce agitation if

adequate spray pressure cannot be maintained.

10

Section B

565 Trailer Sprayer - Operation Instructions

Section B

IMPORT

ANT

Turn off a hydraulically driven centrifugal pump using the “float” position of the tractor’s hydraulic valve. This allows the motor to stop

slowly helping to protect the motor and motor seals.

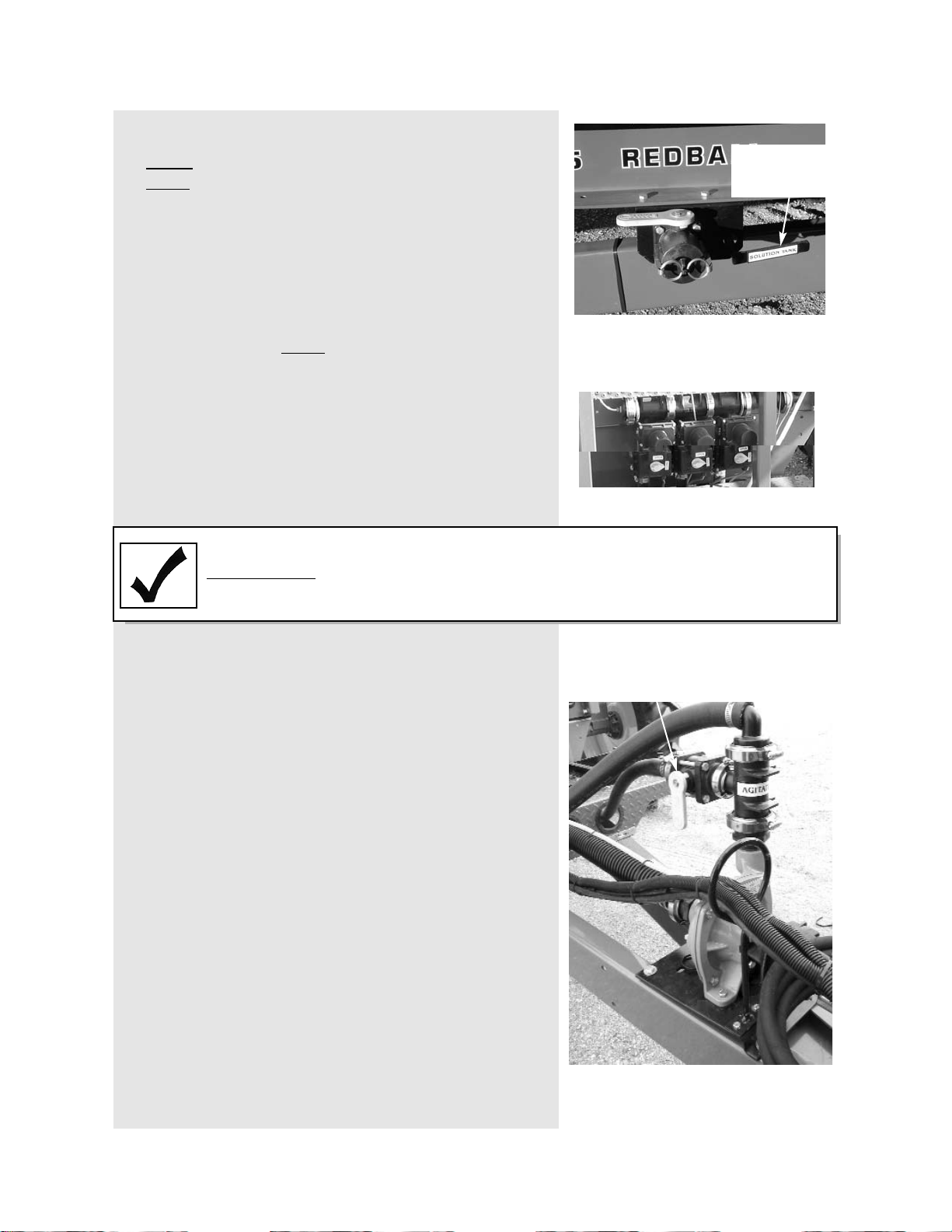

Sprayboom Section Valves

Solution Tank

Main Valve

Handle

Solution Tank Main Valve

Agitation Valve

3-07

Unload

Three processes can be utilized for unloading of liquid

remaining in the solution tank.

Option A: Spray remaining liquid out the sprayboom

plumbing.

Option B: Remove Quick Fill Cap, open the solution

quick fill valve and the solution tank valves

and let remaining liquid drain via gravity from

the solution tank.

Option C: Remove plug in main solution tank.

Hydraulics

Hydraulic power for the trailer sprayer is supplied from

the tractor hydraulic system. The hydraulically driven

centrifugal pump and the sprayboom fold operations are

powered by the tractor hydraulics. The pressure return

line for the liquid pump has red tape wrapped around the

ends, with two wraps on the pressure line and one wrap

on the return line. The pressure and return line for each

of the boom fold cylinders are wrapped with color coded

tape near the ends as well. A minimum requirement of

25 absolute micron filtration should be incorporated into

the tractor hydraulics to assure adequate filtration of the

oil supplied to the trailer sprayer components.

11

Section B

565 Trailer Sprayer - Operation Instructions

Section B

Make certain to correctly connect the pressure and return lines

between the sprayer and the tractor. See pump manufacturer’s

manual for open center and closed center hydraulic system

instructions.

IMPORTANT

Always dispose of chemical or diluted chemical according

to your local, state, and federal regulations.

IMPORTANT

Quick Fill Cap

Solution Quick

Fill Valve

Solution Tank

Main Valve

3-07

Solution Spray Control System (Optional)

See the controller manufacturer’s manual for operation

instructions.

Light and Marking System

The light system on the sprayer works with the tractor’s

light system. Amber lights flash in unison with the tractor

amber flashing lights. If a turn is not being signaled, both

amber lights flash. When the operator signals a right turn

with the tractor’s turn signal switch, the left amber light

stops flashing and remains on and the right amber flashes at the same flashing rate as the tractor’s right amber

turn light. If a left turn is signaled, the opposite takes

place.

Red taillights also follow the tractor lights in their function.

If road lights are on and the taillights of the tractor are lit,

the red taillights will be lit on the implement. In a turn, the

red, high intensity portion of the taillight will come on. As

with the amber, in a right turn the left red, high intensity

portion of the taillight will remain on and the right taillight

flashes at the same rate as the tractor’s red turn signal

light. If a left turn signal is turned on, the opposite takes

place. In a turn situation, this lighting system produces

the effect of a vehicle braking and turning in the direction

of the flashing light. The turn signal module, "The Black

Box", produces the turn signal/stop effect with the red

lights. See Section F for the location of this module.

The light and marking system also incorporates reflective

decals front and rear of proper size and location for night

travel and fluorescent decals of proper size and location

for daylight travel.

Foam Marker (Optional)

Refer to the foam marker manual for operational

instructions.

565 Trailer Sprayer - Operation Instructions

Section B

12

Section B

Lights and Rear Facing Reflective and

Florescent Decals

3-07

565 Trailer Sprayer - Operation Instructions

Section B

13

Section B

NOTES:

3-07

565 Trailer Sprayer - Connection & Startup

Section C

3-07

565 Trailer Sprayer - Connection & Startup

Section C

1

Section C

Connection

Hitch

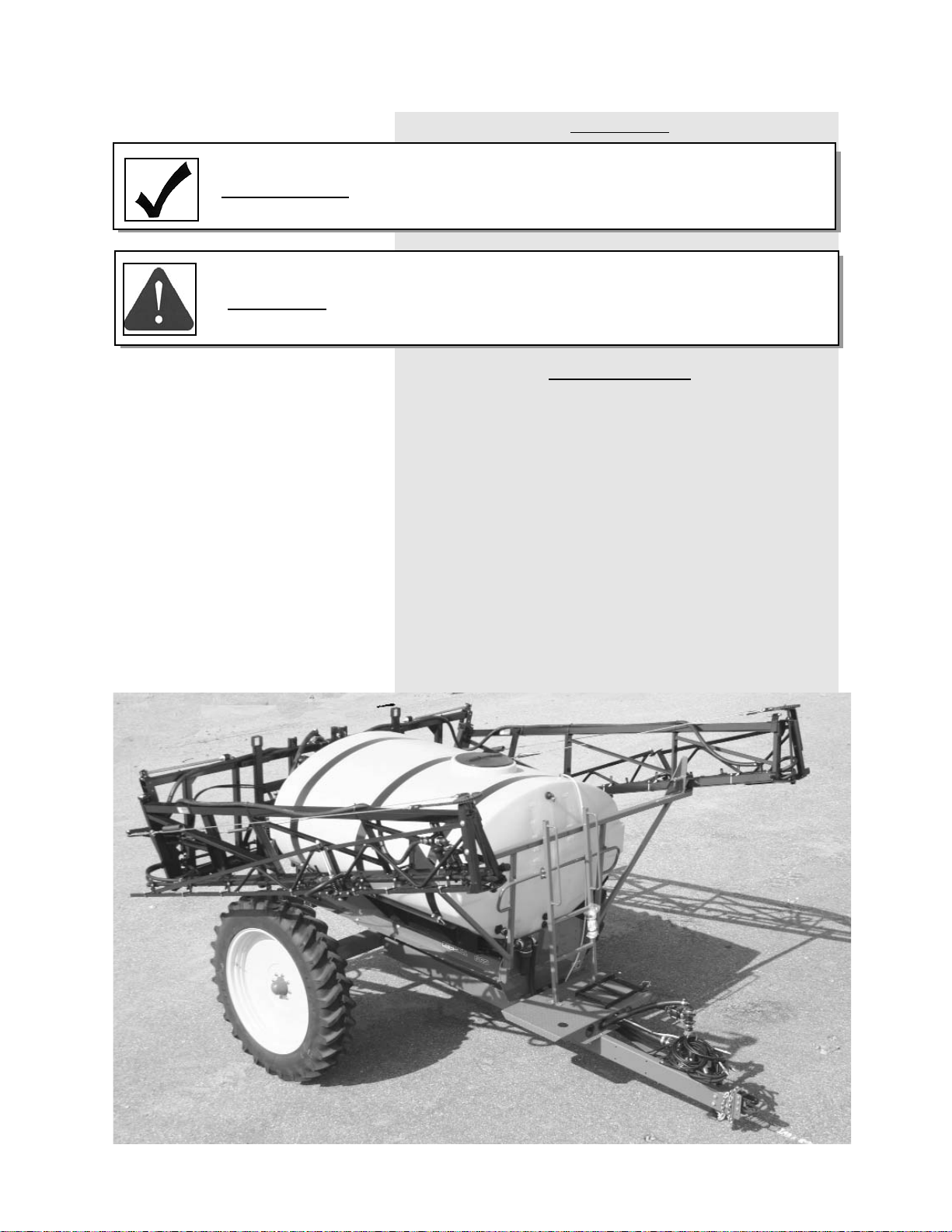

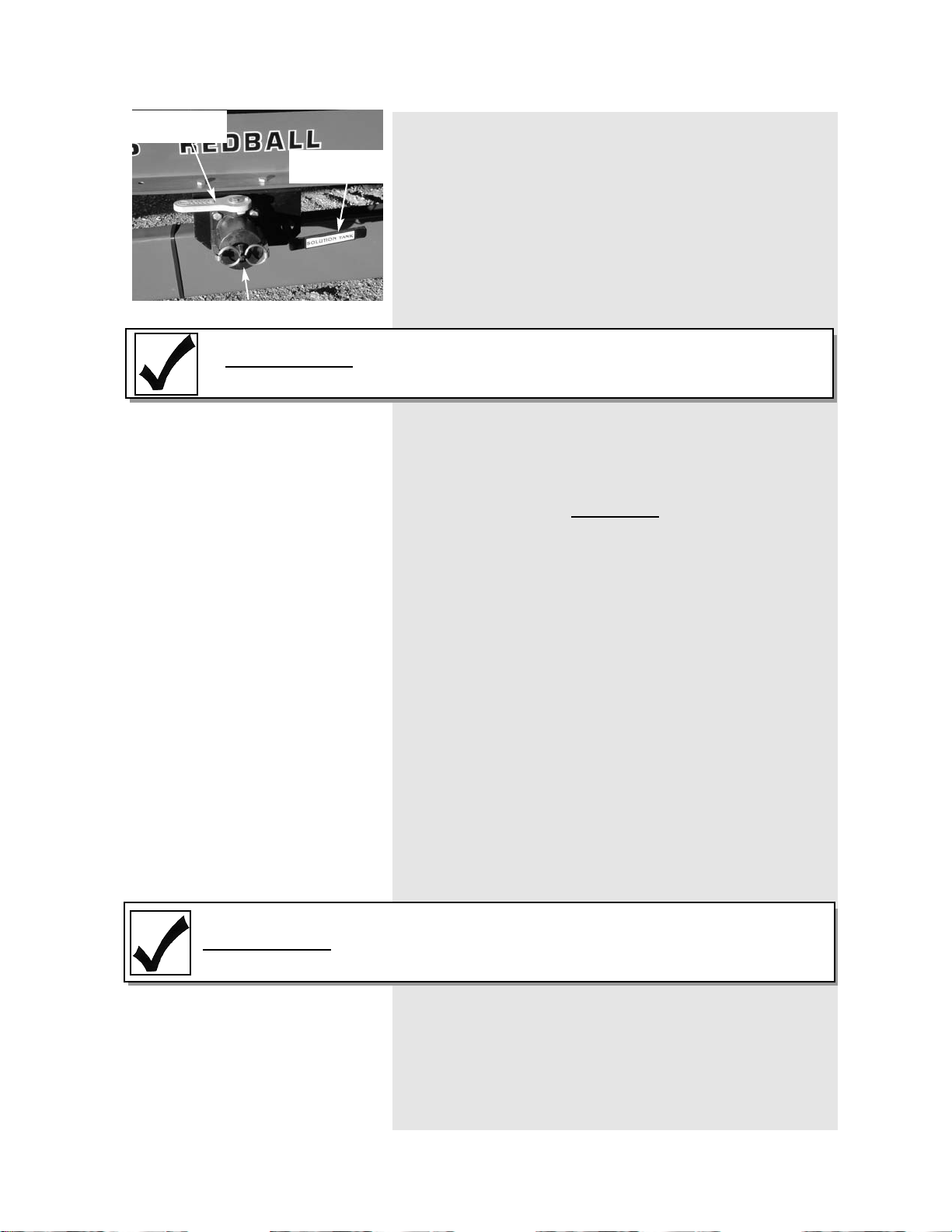

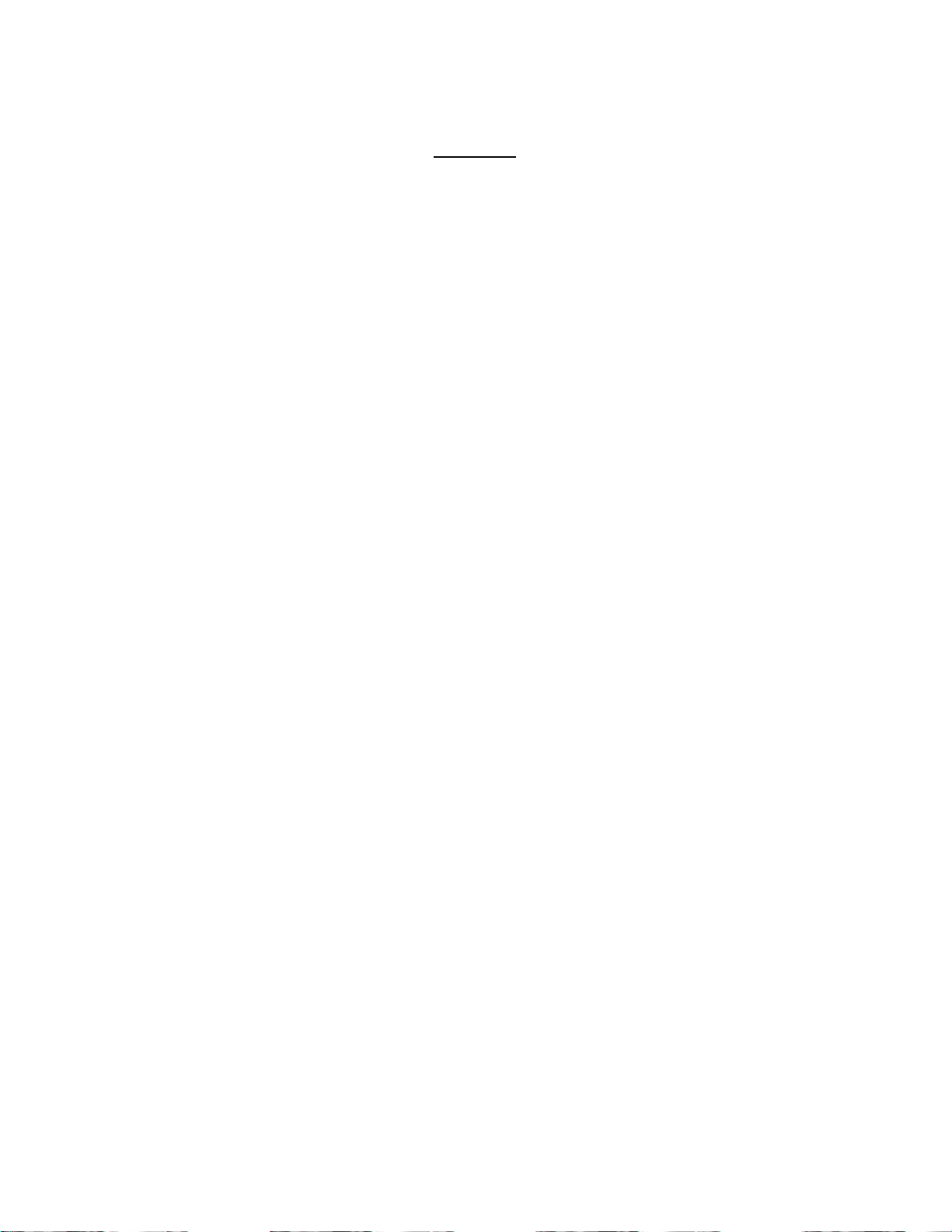

Redball®provides a clevis style hitch. Connect the sprayer

to the tractor according to the tractor manufacturer’s

instruction via the clevis.

Safety Chain

Make certain that the safety chain is securely fastened to

both the tractor and the sprayer. The tractor end must be

attached according to the tractor manufacturer’s instructions. The sprayer end is attached as shown in the picture

to the left with the chain hook hooked through the hole

prevented from falling out by the “hook latch”. Allow no

more chain slack than necessary for articulation and do

not attach either chain hook to an intermediate point not

specified for hooking to. The safety chain can be stored

by detaching it from the tractor and draping it over the

tongue of the sprayer.

Hitch Jack

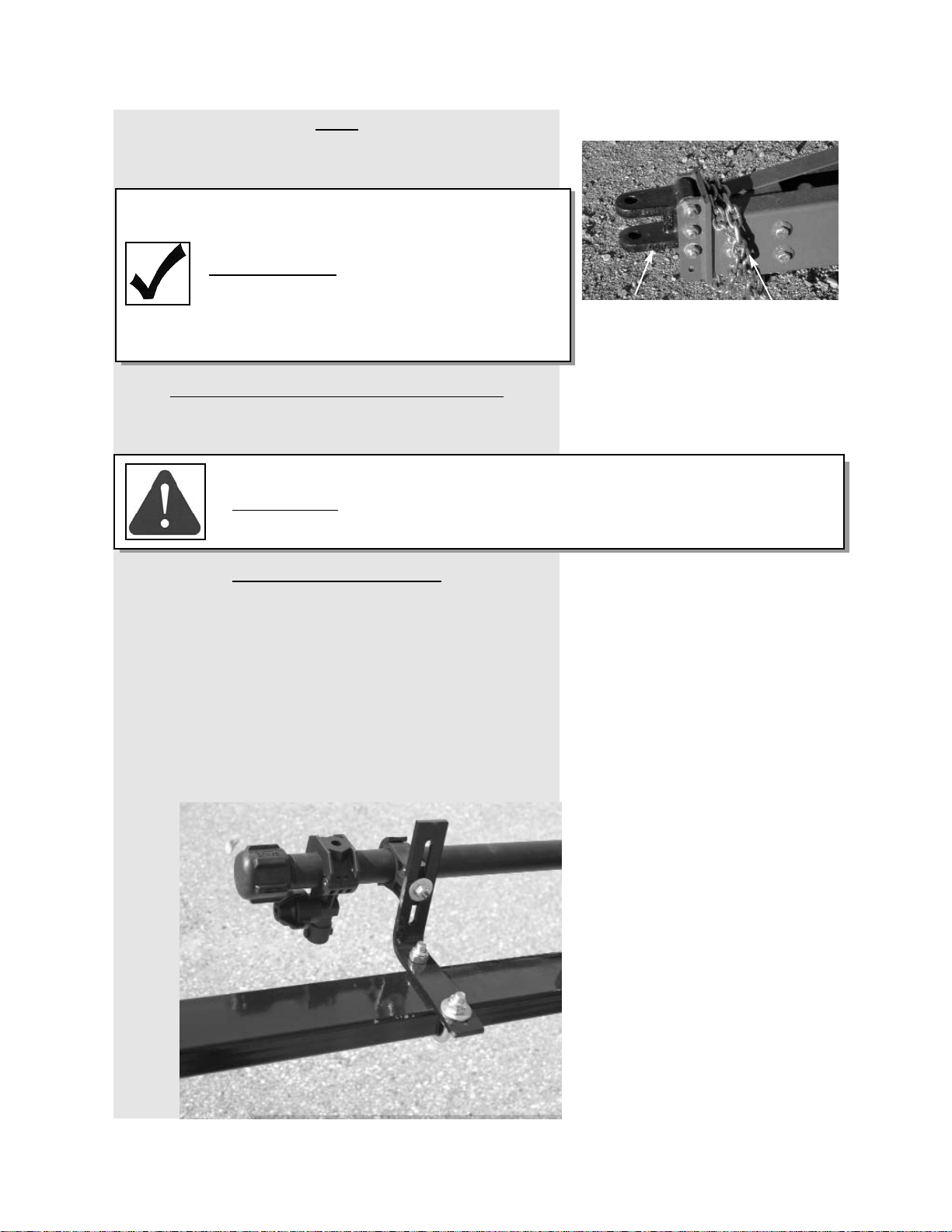

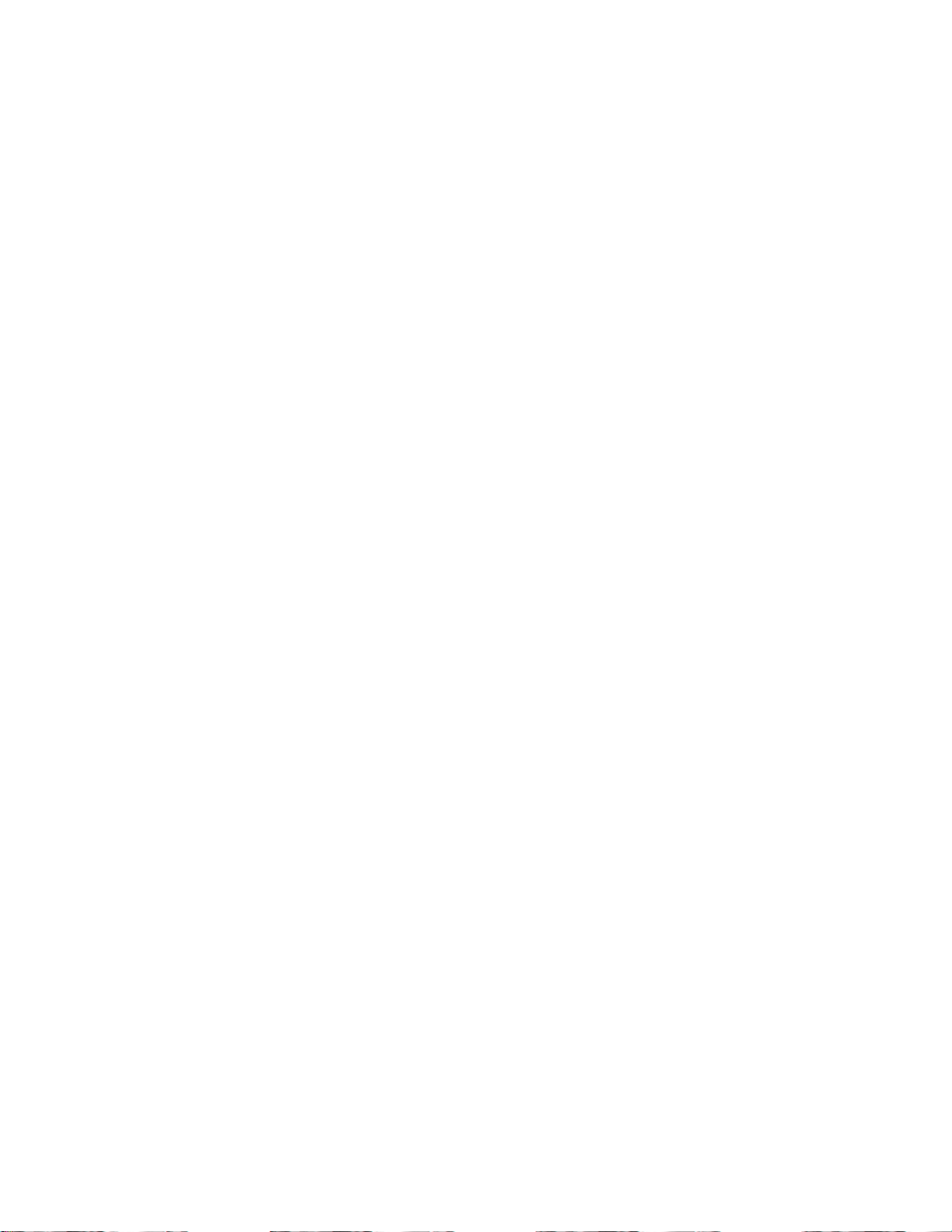

Jack position when sprayer is connected to tow vehicle Using the hand crank, retract the hitch jack enough to

allow for pivoting of the jack assembly. Pull the pin and

rotate until horizontal and the pin is re-engaged.

Jack position when sprayer is not connected to a tow

vehicle - pull the pin and rotate hitch jack verticle and the

pin is re-engaged. Using crank, extend the jack enough

to support the hitch weight on the jack.

Towing of the sprayer by any type of vehicle requires the safety

chain properly attached to both tractor and sprayer. Replace

safety chain if one or more links or end fittings are broken,

stretched, or otherwise damaged or deformed.

WARNING

Prior to loading with chemical, the operator needs to test the

sprayer with water only to ensure the system is intact prior to

putting chemical into the system. Test to verify application at the

desired rate and all components work correctly.

CAUTION

Safety

Chain

Hook

Latch

Safety

Chain Hook

Clevis Hitch

Pivot Pin

Jack

Loading...

Loading...