Page 1

Battery Management System

BMS1230S2

THE

MANAGER

Page 2

WARNINGS & SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS - This manual contains IMPORTANT SAFETY INSTRUCTIONS for The

Manager30 battery management system.

DO NOT OPERATE THE BATTERY CHARGER UNLESS YOU HAVE READ AND UNDERSTOOD THIS MANUAL

AND THE CHARGER IS INSTALLED AS PER THESE INSTALLATION INSTRUCTIONS. REDARC RECOMMENDS

THAT THE CHARGER BE INSTALLED BY A SUITABLY QUALIFIED PERSON.

RISK OF EXPLOSIVE GASES:

WORKING IN THE VICINITY OF A LEAD-ACID BATTERY IS DANGEROUS. BATTERIES GENERATE EXPLOSIVE

GASES DURING NORMAL OPERATION. FOR THIS REASON, IT IS OF UTMOST IMPORTANCE THAT YOU

FOLLOW THE INSTRUCTIONS EACH TIME YOU USE THE CHARGER.

1. The Battery Charger should not be used by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they are supervised or have been instructed

on how to use the appliance by a person responsible for their safety. Children should be supervised to ensure

that they do not play with the Battery Charger.

2. Do NOT alter or disassemble the Battery Charger under any circumstances. All services or repairs must be

returned to REDARC for repair. Incorrect handling or reassembly may result in a risk of electric shock or fi re and

may void the unit warranty.

3. Use of an attachment not recommended or sold by REDARC may result in a risk of fi re, electric shock, or injury

to persons.

4. The AC power connection must be connected to an earthed socket outlet. Do not use the AC input if the cord is

damaged. Use of a non-genuine or damaged AC input cord may result in a risk of fi re, electric shock, or injury

to persons. (If the supply cord is damaged, it must be replaced by a special cord or assembly available from the

manufacturer or service agent).

5. Cable and fuse sizes are specifi ed by various codes and standards which depend on the type of vehicle the

Battery Charger is installed into. Selecting the wrong cable or fuse size could result in harm to the installer

or user and/or damage to the Battery Charger or other equipment installed in the system. The installer is

responsible for ensuring that the correct cable and fuse sizes are used when installing this Battery Charger.

6. When charging a battery, make sure the settings at the Battery Setup menu on the Remote Monitor are correct

for the type of battery under charge. Charging a battery with the wrong profi le may cause the Battery Charger

to indicate a fault or give misleading results and cause injury to persons, damage to the Battery Charger and/or

property. Noticeable oscillations between Boost and Absorption stages indicate the wrong choice of battery type.

Check and adjust battery type. If you are unsure of the battery type or settings to use, set to the Gel setting.

7. Only use the Battery Charger for charging Standard Automotive Lead Acid, Calcium Content, Gel, AGM, SLI,

Deep Cycle or Lithium Iron Phosphate type 12V batteries.

THE MANAGER30

The Manager30 Battery Management System is a complete charging solution for your

Lead Acid or LiFePO

4

Auxiliary or House battery. The system incorporates 12V Solar, 240V

AC and 12/24V DC inputs to provide a 12V charging output at a maximum 30A rating.

The system also includes a Remote Monitor which provides information such as current,

voltage and temperature as well as a simplifi ed battery percentage and charge rate.

1

SAL.FOR.Instruction Manual.BMS1230S2 – Version 3

Page 3

2

WARNINGS & SAFETY INSTRUCTIONS

8. When using the Battery Charger to charge a Lithium Iron Phosphate battery, only batteries that feature an inbuilt

battery management system featuring inbuilt under and over voltage protection and cell balancing are suitable.

9. NEVER smoke or allow a spark or fl ame in vicinity of battery. This may cause the battery to explode.

10. Be extra cautious so as to reduce the risk of dropping a metal tool onto a vehicle battery. Doing so might cause

the battery to spark or might short-circuit the battery or other electrical parts that may cause an explosion.

11. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a lead-acid

battery. A lead-acid battery can produce a short-circuit current high enough to weld a ring or the like to metal,

causing a severe burn.

12. A SPARK NEAR A BATTERY MAY CAUSE THE BATTERY TO EXPLODE. TO REDUCE THE RISK OF A SPARK

NEAR A BATTERY WHEN CONNECTING THE BATTERY INSTALLED IN A VEHICLE TO THE BATTERY CHARGER,

ALWAYS DO THE FOLLOWING:

Always wire the Output Connector before connecting it to the Battery Charger. During connection of the unit,

the Battery Output (positive) must be connected fi rst, followed by the Ground (chassis) terminal. The chassis

connection should be made away from the battery and fuel lines. DC Input (positive) should be connected

last. Once all connections are wired to the Output Connector, plug the connector into the Main Unit.

When disconnecting the Battery Charger, remove the AC Connector fi rst, followed by the CAN connection then

the Output Connector from the Main Unit. The DC Input should be disconnected next, followed by the Ground

(chassis) connection, then the Battery Output connection if complete removal is necessary.

13. PERSONAL SAFETY PRECAUTIONS

To assist with the safe operation and use of the Battery Charger:

a) Consider having someone close by to come to your aid when you are using the Battery Charger.

b) Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

c) Wear complete eye protection and clothing protection. Avoid touching eyes while working near a battery.

d) If battery acid contacts your skin or clothing, remove the affected clothing and wash the affected area of your

skin immediately with soap and water. If battery acid enters your eye, immediately fl ood the eye with running

cold water for at least 10 minutes and seek medical assistance immediately.

e) To improve user safety it is recommended to control the charger and monitor the charging process using the

remote away from the vicinity of the battery being charged.

1. Do NOT connect computers or IT equipment to the Charger front panel connector or remote. Damage may occur.

2. It is recommended to leave the remote connected at all times to the base unit.

3. The Main Unit must be fi xed using suitable screw mounts. Failure to adequately mount the unit, such as using

adhesives to mount the unit will result in unreliable operation of the charger.

4. When using the charger in Storage mode, make sure that all loads are disconnected from the house battery

under charge. Failure to do so may cause the house battery to be under charged, give false readings on the

State of Charge indicator and possibly cause damage to any loads connected.

5. A partially shaded panel (or low-light conditions such as dawn or dusk) will increase the target solar panel

voltage level to match the maximum power point. In this situation solar will be selected as a source however

little or no current will be fl owing into the battery.

6. Modifi cation of the ‘Advanced Settings’ menu items affect the way the Battery Charger responds to charging situations.

Modifi cation of these settings may result in the Battery Charger not functioning at 100% of its capacity. These settings

should only be modifi ed if absolutely necessary and when the effects of the changes are 100% understood.

7. Touring mode will achieve it’s best charge level if a Storage mode charge has been recently performed.

8. It is the installers responsibility to ensure their installation complies with any applicable legal and regulatory

requirements. Within Australia, installers may wish to consult AS/NZS 3001 as one potentially relevant standard.

Page 4

3

CONTENTS

Table of Contents Page

Warnings and Safety Instructions 01

Contents 03

Features and Benefi ts 04

1 Introduction 05

1. General Description 05

2. The Remote Monitor 05

3. The Kit Includes 05

4. Specifi cations 06

5. Multi-stage Charging Process 08

6. Maximum Charging Current Setting 10

7. Green Power Priority 10

2 INSTALLATION Guide 11

1. System Layout 11

2. Mounting Instructions 11

1. Mounting the Main Unit 12

2. Mounting the Remote Monitor 13

3. Mounting the Battery Sensor 16

3. DC Cable Size Requirements 16

4. The Manager30 Wiring Connections 18

1. Load Disconnect Feature 18

2. Ignition Trigger Feature 18

3. Connecting the Battery Sensor 19

4. Wiring the Main Unit 19

5. Batteries 21

6. MPPT Solar Regulator 22

3 USER Guide 23

1. Remote Monitor 23

2. Understanding the Display 23

3. Initial Setup 24

4. User Menu 25

5. Settings Menu 27

6. Fault Screens 31

7. Troubleshooting 32

8. Factory Settings 34

9. FAQs 35

4 Remote Drill Template 36

5 Two Year Warranty 38

Page 5

4

FEATURES AND BENEFITS

1. The Manager30 incorporates six products in one, it’s a DC-DC charger, a 240-volt

charger, a solar charger, a dual battery isolator, a load disconnect controller and a

remote battery monitor. The Manager30 will automatically select between charging

sources, requiring no input from the operator during its operation.

2. The Manager30 has no fan, which makes it SUPER quiet and very reliable.

3. The Manager30 is designed and manufactured in Australia, for Australian conditions,

using the latest electronic and design technologies. It is manufactured with highquality components to ISO9001 quality and ISO14001 environmental standards and

backed with REDARC’s quality service and two-year warranty.

4. The Manager30 charging algorithm uses solar whenever possible making the unit

more energy effi cient and better for the environment.

5. The Manager30’s DC-DC charging enables optimal charging of house batteries, even

if they have different chemical characteristics from the vehicle battery. The input

voltage can be above, equal to or below the output voltage.

6. State of Charge (SOC) indication means you will always know how fully charged the

battery is and how much longer it will need to achieve full charge. An easy to operate,

high-quality, user friendly graphical display module lets you know what’s going on at

all times.

7. The Manager30 is very reliable and includes reverse polarity protection (without

depending on fuses) and short circuit protection. The unit has undergone stringent

safety & electrical compliance testing.

8. The Manager30’s easily selectable charging profi les make it suitable for charging all

lead-acid battery types and suitably protected LiFePO

4

battery types commonly used

in modern caravans and motorhomes.

9. The Manager30 disconnects automatically from the vehicle battery, so there is always

power to start the car.

10. Sophisticated fault detection monitors the house battery condition during all stages

of charging, keeping you and your caravan/ camper/ RV safe.

11. The Manager30 has a separate battery sensor to monitor battery conditions and

state of charge even while The Manager30 is in standby mode. The battery sensor

monitors current, voltage and temperature of the house batteries.

12. Automatic temperature and voltage drop compensation.

Page 6

5

1 INTRODUCTION

1.1 General Description

The Manager30 is designed to offer a complete solution to battery charging and

maintenance needs for recreational automotive applications.

The Manager30 incorporates AC, DC and Solar inputs to achieve the best charge

to a house battery.

1.2 The Remote Monitor

The Manager30 comes with a Remote Monitor designed to give you house

battery information and charge status along with critical system information

while charging is in progress.

With the Remote Monitor, you can customise how your house battery is charged

and monitor where the charge is coming from, keeping you in control at all times.

The Remote Monitor can be surface mounted on a wall, or recessed (into the

dashboard of an RV for example).

1.3 The Kit Includes

Main Unit

Battery Sensor

Remote Monitor

Output Connector

T-Piece (RJ45 with RJ12 insert)

CANBus Cables (1m & 5m)

Power Cable

1

2

3

4

5

6

7

2009/19/EC adapting to Council Directive 72/245/EEC relating to radio interference

(electromagnetic Compatibility) of vehicles, clauses 6.5, 6.6, 6.8 & 6.9 only.

2004/104/EC: 14th October 2004 adapting to technical progress of Council Directive

72/245/EEC relating to radio interference (electromagnetic compatibility) of vehicles.

IEC 60335-2-29:2002 (Fourth edition) + A1:2004 in conjunction with

IEC 60335-1:2001 (Fourth edition) +A1:2004 +A2:2006

EN 60335-2-29:2004 in conjunction with

EN 60335-1:2002+A1+A2+A11+A12+A13

RoHS

Compliant

Page 7

6

1 INTRODUCTION

1.4 Specifi cations

Electrical Specifi cations

Inputs

AC Input

Input Voltage Range (nominal) 220-240VAC 50Hz

Power Rating 520W

Effi ciency 80% - 90%

Connection IEC Mains Plug

DC Input

Input Voltage Range 9 - 32V

Turn ON/OFF Threshold 12V (24V) 13.2V/12.7V (26.4V/25.4V)

Power Rating 520W

Effi ciency 94%

Connection Phoenix 1967498 Connector

Solar Input

Input Voltage Range 9 - 32V

Turn ON (Open Circuit Voltage) 17.5V

Power Rating 520W

Effi ciency 93%

Connection Phoenix 1967498 Connector

Max Volts @ Battery Terminals (25°C Nominal)

Storage Mode Touring Mode Float

Gel Setting 14.4V 14.4V 13.5V

AGM Setting 14.4V 14.4V 13.5V

Calcium Setting 16.0V 15.2V 13.5V

Standard Lead Acid Setting 15.5V 14.8V 13.5V

Lithium Setting 14.5V 14.5V 13.6V

Output Current (Nominal) 30A

Temperature Compensation

Standard Lead Acid, AGM, Gel or Calcium Battery +30mV / °C < 25°C < -30mV / °C

Lithium Setting 40°C < 0.5%/°C < 60°C

Operating Temperature* -40°C - 80°C

Over Temperature Shutdown Yes

Total Battery Capacity 40 - 800Ah

Output Battery Volts (Nominal) 12V

Output Battery Volts (Minimum) 4V

Maximum Current on Load Disconnect Wire 1A

Memory Save on Battery Disconnect Yes

Output Protection

Short Circuit Protection Yes

Surge Protection Yes

Reverse Polarity Protection Yes

Overload Protection Yes

Compliance

CE 2009/19/EC

2009/104/EC

Safety IEC60335

Environmental RoHS Compliant

General Specifi cations

Main Unit Dimensions 445x185x79mm

Remote Dimensions 186x74x29mm

Kit Weight 5.5kg

Warranty 2 years

* The Manager30 will only charge the battery when the battery temperature is between 0°C and 60°C in order

to protect the battery from damage.

Page 8

7

1 INTRODUCTION

27

74

186

21 29

185

429

445

404

82

79

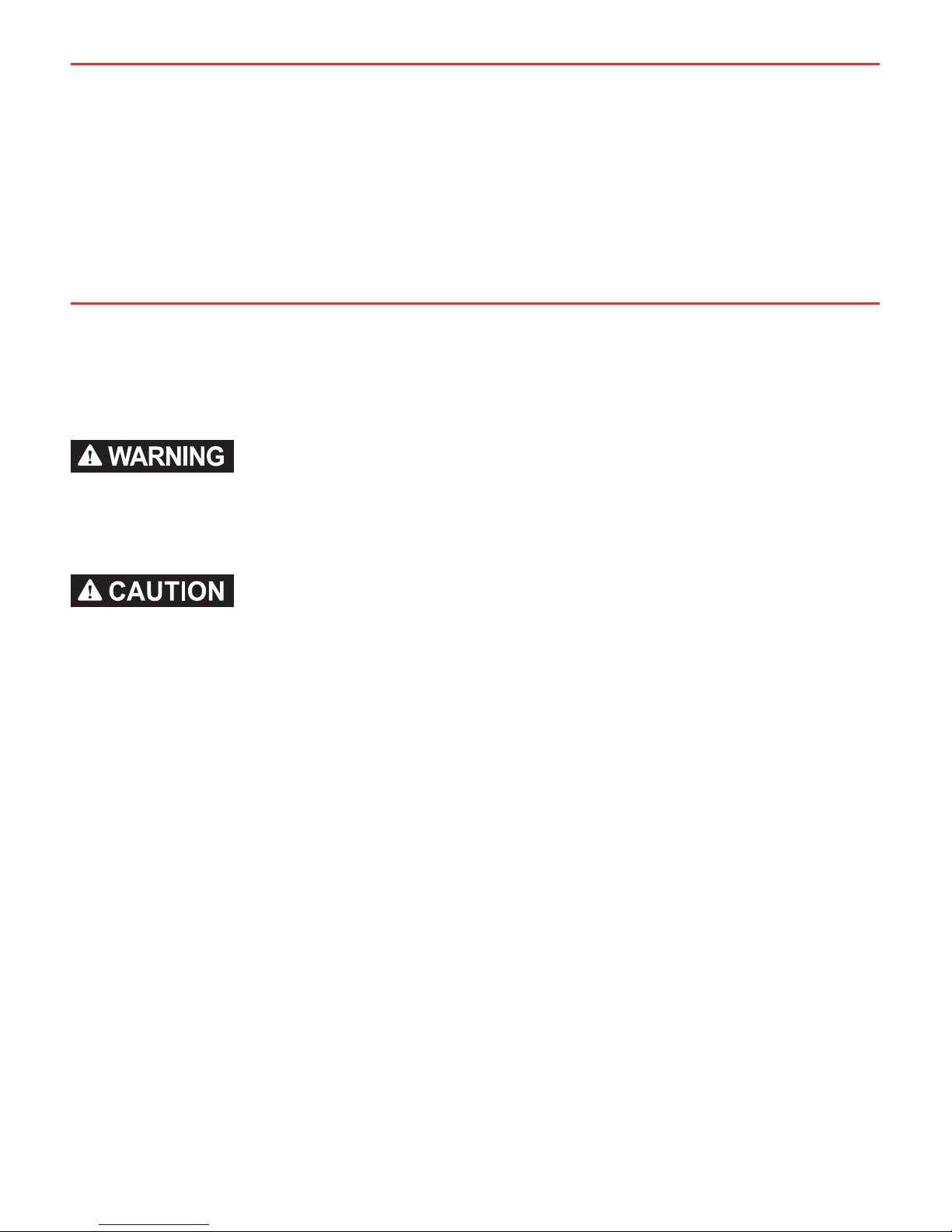

Figure 1.4.1 - Main Unit Dimensions

Figure 1.4.2 - Remote Monitor Dimensions

Page 9

8

1 INTRODUCTION

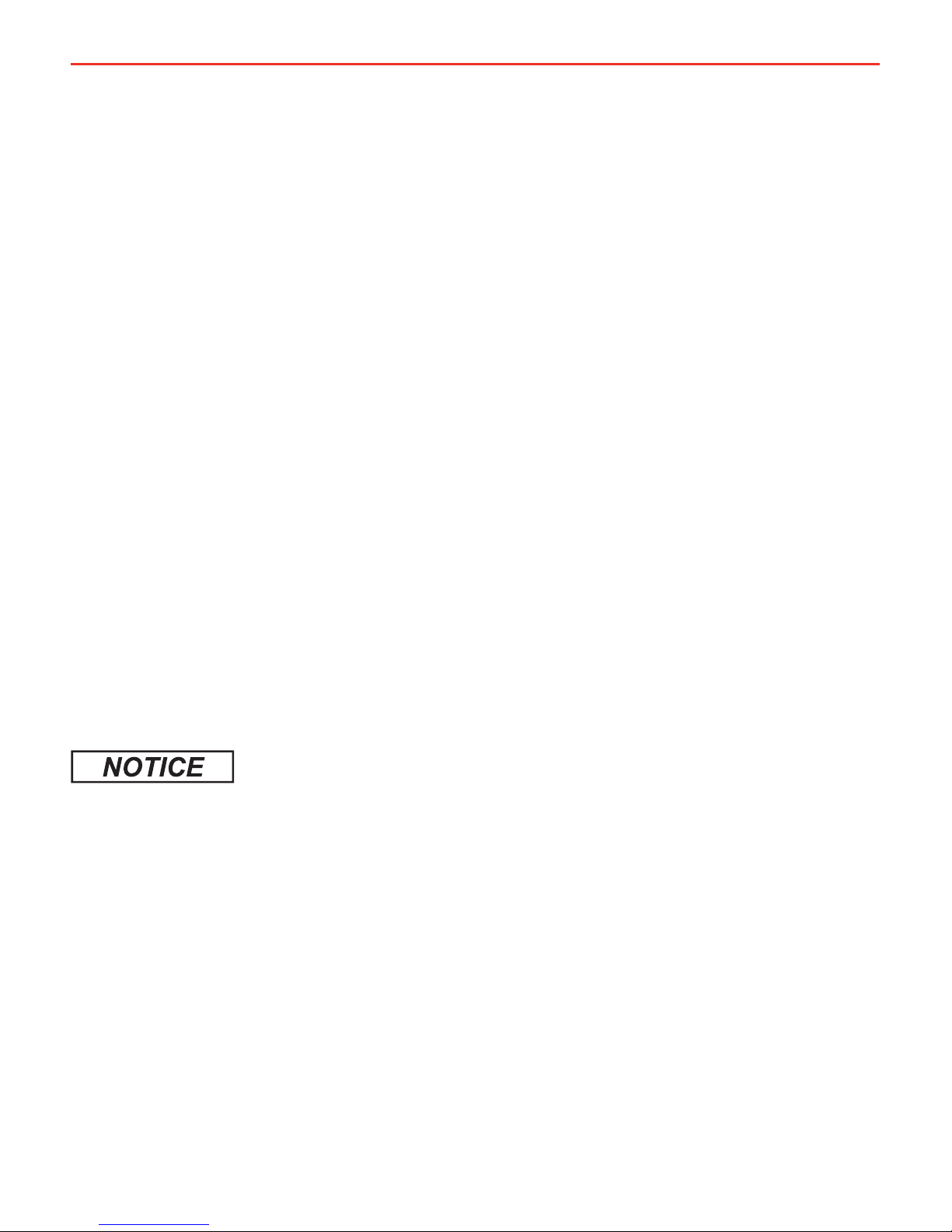

1.5 Multi-stage Charging Process

The Manager30 incorporates two different multi-stage charging profi les – Touring

(3-stage) and Storage (8-stage) – which can be selected in the Battery Mode

menu on the Remote Monitor.

Touring Mode

Touring mode is designed for use when ‘on the road’. Touring mode offers a

3-stage charging profi le consisting of Boost, Absorption and Float stages (see

Figure1.4.1). In Touring mode, the house battery is monitored to detect only a

limited number of faults such as short circuit, over current and over voltage. This

allows The Manager30 to operate correctly even when loads are connected to the

house battery. This mode will always produce an output (unless a fault condition

is detected) and will cycle through the three stages as required to maintain the

house battery as outlined in Figure 1.4.1.

Touring mode will achieve its best charge level if a Storage mode charge has been

recently performed.

BOOST

ABSORPTION

FLOAT

FloatAbsorptionBoost

Voltage

SLA & Lithium

Current

Touring Mode Charging Process

Figure 1.4.1 - Touring Mode Charging Process

Page 10

9

1 INTRODUCTION

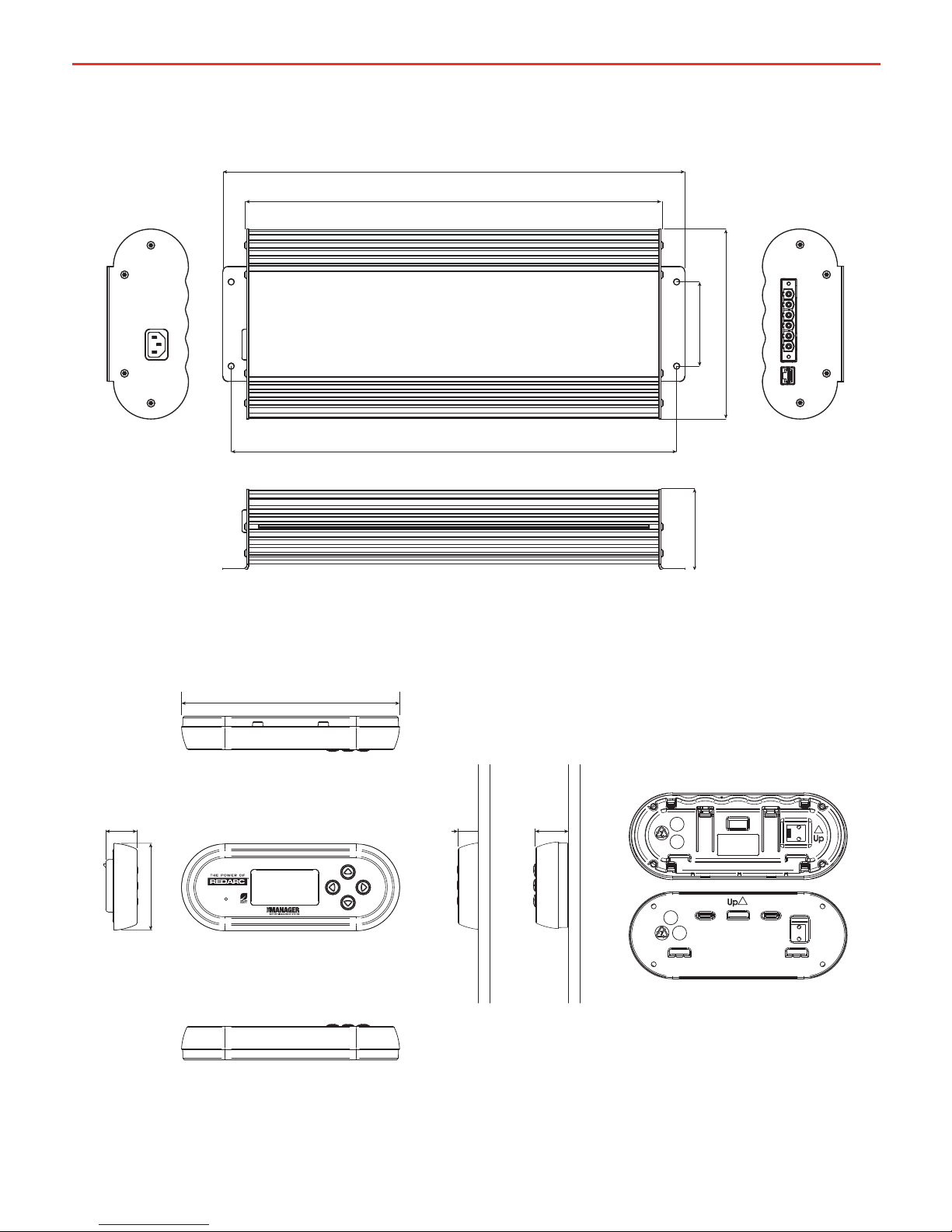

Storage Mode

Storage mode is designed to charge the house battery to its optimal level and

maintain that level while your caravan is in storage. This mode requires all loads

to be switched off or disconnected from the house battery before charging. It

uses a 8-stage* charging profi le consisting of Desulphation*, Soft Start, Boost,

Absorption, Battery Test, Equalise*, Float and Maintenance stages (see Figure1.4.2).

Storage mode is designed to detect a wide range of battery fault conditions, for

more information on these fault conditions, please refer to the Troubleshooting

section of this manual. Unlike Touring mode, Storage mode does not cycle. This

means that when the charging process is completed, The Manager30 will always

remain in either Float or Maintenance stages. Float stage will provide the house

battery with a ‘trickle’ charge whenever the house battery voltage drops below a

predetermined threshold to ensure the battery stays charged. Maintenance stage

turns The Manager30 output off, but continues to monitor the house battery and

will revert to Float stage when necessary.

NOTE: If The Manager30 is set to Storage mode and the vehicle is started

The Manager30 will automatically switch to Touring mode once it senses an

increase in input voltage from the alternator.

When using the charger in Storage mode, make sure that all loads are disconnected from

the house battery under charge. Failure to do so may cause the house battery to be under

charged, give false readings on the State of Charge indicator and possibly cause damage

to any loads connected.

*The Lithium profi le does NOT incorporate a Desulphation stage.

**The Lithium, AGM and Gel profi les do NOT incorporate an Equalise stage

BATTERY TEST

FLOAT

SOFT START

DESULPHATION

Desulphation*

Current

Storage Mode Charging Process

BOOST

ABSORPTION

MAINTENANCE

EQUALISE

MaintenanceFloatEqualise**AbsorptionBoostSoft Start Batt. Test

Voltage SLA

Voltage Lithium

Figure 1.4.2 - Storage Mode Charging Process

Page 11

10

1 INTRODUCTION

IMPORTANT

When The Manager30 is set to ‘Storage’ mode and no valid charging sources are

connected, it will enter a ‘Sleep’ mode 30 seconds after the last user interaction.

The sleep mode is designed to limit the amount of current drawn from the output

battery by the system whilst in Storage mode and does this by switching the

screen and all non-essential functions off. The Manager30 will ‘wake-up’ from

its Sleep mode if a button is pushed or if any valid input source is sensed, though

this may take 30-60 seconds to occur after the source is connected.

1.6 Maximum Charge Current Setting

The Manager30 allows the user to set the maximum charge current for their

battery, making it suitable for charging batteries as small as 40Ah in capacity.

When the charge current is set below the maximum 30Amps, the current supplied

to charge the battery is restricted to the user setting. Any excess current is used

to power loads running from the battery under charge.

If no loads are running from the battery, total current from The Manager30 will be

restricted to the level set by the user.

1.7 Green Power Priority

The Manager30 is designed to charge from multiple sources simultaneously

to charge the auxiliary/house battery. If the Solar power input is available the

maximum available solar power will be used before topping up the output

charging current from another source if available (e.g. mains). Priority is given to

Solar then to AC Mains power, then to DC Vehicle power.

Page 12

11

2 INSTALLATION GUIDE

2.1 System Layout

2.2 Mounting Instructions

This section describes how to mount the three major components of The

Manager30: the Main Unit, the Remote Monitor and the Battery Sensor.

Vehicle

Battery

(Not Supplied)

House Battery

(Not Supplied)

BMS1230

Solar Panels

(Not Supplied)

Remote

Monitor

To Loads

(Not Supplied)

Battery

Sensor

240VAC

Mains Power

DC - DC

Power Source

Figure 2.1.1 - System Layout

Figure 2.2.1 - The Manager30 System

Page 13

2 INSTALLATION GUIDE

2.2.1 Mounting the Main Unit

Do NOT expose the Main Unit to rain, snow, spray or bilge water. For optimum

operation, The Manager30 should be mounted where the temperature is nominally

below 35°C and does not exceed a maximum of 60°C.

The Main Unit must not be installed in a location with any less than 10cm

clearance at the top of the Main Unit, to allow for airfl ow across the heatsink fi ns.

The Main Unit should be installed as close as possible to the house battery. The

cable length should be less than 2m.

The Main Unit must be mounted to a fl at, solid support using M6 sized screws or

bolts, using all four mounting holes.

The Main Unit must be fi xed using suitable screw mounts. Failure to adequately mount

the unit, such as using adhesives to mount the unit will result in unreliable operation of

the charger.

REDARC recommends that the Main Unit be mounted to optimise airfl ow past the

heatsink. Mounting the unit horizontally (see Figure 2.2.1.1) is recommended and

mounting vertically (see Figure 2.2.1.2) is still acceptable. Do NOT mount the unit

as shown in Figure 2.2.1.3.

12

8

8

9

9

9

9

9

Ideal Acceptable

NOT Recommended

Figure 2.2.1.1 - Horizontal

mounting is recommended

Figure 2.2.1.2 - Vertical

mounting is acceptable

Figure 2.2.1.3 - Do NOT mount the unit upside down

Page 14

13

2 INSTALLATION GUIDE

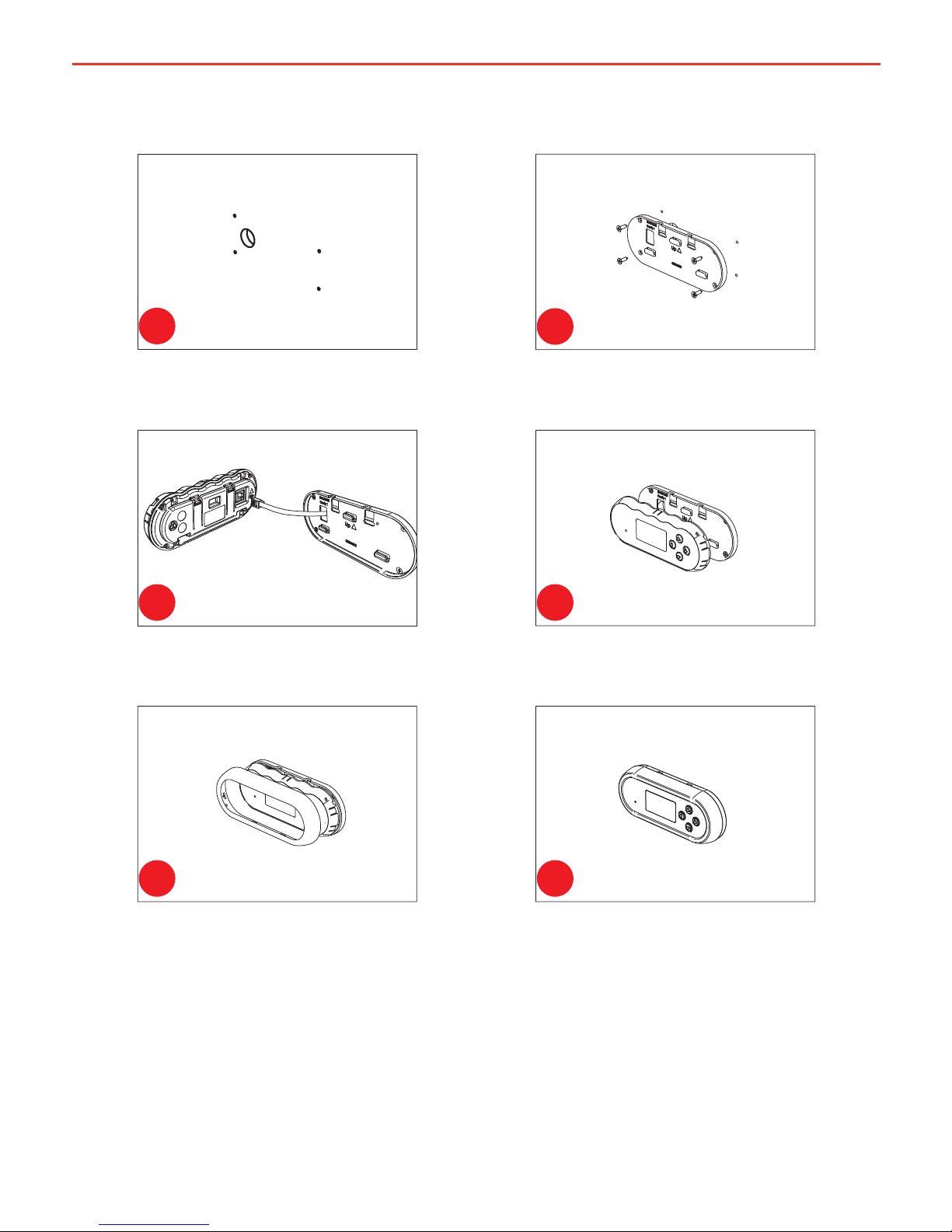

2.2.2 Mounting the Remote Monitor

The Remote Monitor should be mounted inside the caravan or RV using

the template provided inside the box. It is acceptable however to mount the

Remote Monitor in any convenient location, as long as it is protected from harsh

environments.

Figures 2.2.2.1 and 2.2.2.2 illustrate how to recess and wall mount the Remote

Monitor unit, fi gure 2.2.2.3 illustrates removal of the Remote Monitor.

Recess

Use the template provided (Page 36)

to mark the position and drill and cut

the mounting holes into the wall.

Feed the Remote Monitor cable

through the hole and connect it to

the Remote Monitor.

Mount the Inner Assembly to the

wall using 4 suitably sized screws.

Clip the Front Face to the Inner

Assembly.

Figure 2.2.2.1 - How to recess the

Remote Monitor into the wall.

1

2

3 4

5

Page 15

2 INSTALLATION GUIDE

Wall Mount

Use the template provided (Page 36)

to mark the position and drill and cut

the mounting holes into the wall.

Attach the Back Plate to the wall

using 4 suitably sized countersunk

screws.

Clip the Inner Assembly into the

Back Plate.

Clip the Front Face to the Inner

Assembly.

Feed the Remote Monitor cable

through the hole and connect it to

the Remote Monitor.

Figure 2.2.2.2 - How to wall mount the

Remote Monitor.

1

2

3 4

5 6

14

Page 16

15

2 INSTALLATION GUIDE

Removing the Remote Monitor

Figure 2.2.2.3 - How to remove the

Remote Monitor.

The locking tabs on the back of the

Inner Assembly need to be unclipped

from the Back Plate.

The locking tabs can be accessed

through holes on the top of the

backing plate when installed.

Slide fi ngers between the Front Face

and the Inner Assembly in positions

marked above and carefully pull

back towards the front of the

Remote Monitor.

Remove the Remote Monitor cable

and the Inner Assembly is removed.

Insert a fl at-head screwdriver at a

slight angle towards the front of the

Remote Monitor and push back to

depress the locking tabs.

1 2

3 4

5 6

When the screwdriver is in a vertical

position, gently push upwards on the

bottom of the Remote Assembly to

unlock tab. Repeat 3 & 4 for 2

nd

tab.

Page 17

2 INSTALLATION GUIDE

2.2.3 Mounting the Battery Sensor

The length of cables on the Battery Sensor to connect to the Main Unit and the

House Battery will dictate the allowable mounting distance from the battery

however REDARC recommend mounting the Battery Sensor as close to the Main

Unit as possible.

The Battery Sensor should be mounted to a solid surface using two suitably sized

screws for attachment.

Figure 2.2.3.1 illustrates how to mount the Battery Sensor.

2.3 DC Cable Size Requirements

Cable and fuse sizes are specifi ed by various codes and standards which depend on the

type of vehicle the Battery Charger is installed into. Selecting the wrong cable or fuse

size could result in harm to the installer or user and/or damage to The Manager30 or

other equipment installed in the system. The installer is responsible for ensuring that the

correct cable and fuse sizes are used when installing the Battery Charger.

The Manager30 is capable of drawing up to 50A from the Vehicle Battery (which

may be several metres from its installation location) and is limited to 30A output

to the House Battery. The installer needs to ensure the appropriate cable is used

to connect the positive and negative connections of The Manager30 to both the

Vehicle Battery and the House Battery. The Manager30 will operate with less

effi cient cabling however for best performance, high-quality cable connections

should be used to minimise voltage drop and effi ciency losses.

16

Figure 2.2.3.1 - Mounting the Battery Sensor

Page 18

2 INSTALLATION GUIDE

2.3.1 Input Wire Diameter Selection

REDARC recommends the installer use cabling and connections between 8B&S

and 6B&S automotive. REDARC recommends that the input wire be of the size

outlined in Table 2.3.1.

Distance from input vehicle

battery to The Manager30

Recommended Cross

Sectional Area (mm²)

Recommended

Diameter Equivalent

≤3m 8 8 B&S

>3m 10 6 B&S

2.3.2 Output Wire Diameter Selection

REDARC recommends the installer use cabling and connections between 8B&S

and 6B&S automotive. REDARC recommends that the output wire be of the size

outlined in Table 2.3.2. For longer runs using 10mm² is recommended, however

this will lower effi ciency by up to 3% (the recommended maximum length is 5m).

Distance (metres) from The

Manager30 to House battery

Recommended Cross

Sectional Area (mm²)

Recommended

Diameter Equivalent

≤1.5m 8 8 B&S

>1.5m 10 6 B&S

Figure 2.3.2 - Recommended output

cable size

17

Figure 2.3.1 - Recommended input

cable size

REDARC recommend using the SBI12-BLD

as the 12V relay for setting up the Load

Disconnect Feature for Non-Essential Loads.

Similarly, the SBI12-LLD is recommended

for use between the Auxiliary battery and the

Essential Loads in a Lithium Battery setup,

to protect the Lithium battery from excessive

discharge.

Page 19

2 INSTALLATION GUIDE

2.4 The Manager30 Wiring Connections

REDARC recommends that this unit be installed by a suitably qualifi ed person.

The AC power connection must be connected to an earthed socket outlet. Do not use

The Manager30 AC input if the cord is damaged. Use of a non-genuine or damaged AC

input cord may result in a risk of fi re, electric shock, or injury to persons. (If the supply

cord is damaged, it must be replaced by a special cord or assembly available from the

manufacturer or service agent).

Always wire the Output Connector before connecting it to the Main Unit. During

connection of the unit, the Battery Output (positive) must be connected fi rst, followed by

the Ground (chassis) terminal. The chassis connection should be made away from the

battery and fuel lines. DC Input (positive) should be connected last. Once all connections

are wired to the Output Connector, plug the connector into the Main Unit.

When disconnecting remove the Output Connector from the Main Unit fi rst. The DC Input

should be disconnected next, followed by the Ground (chassis) connection, then the

Battery Output connection.

2.4.1 Load Disconnect Feature

The Load Disconnect wire is a ground switch to activate a relay for disconnection

of any loads running from the house battery. The relay must be 12V with a

maximum coil current of 1A and resistor or diode suppresion is recommended.

The Load Disconnect feature must be activated in the User Menu as explained in

section 3.3 of this manual.

2.4.2 Ignition Trigger Feature

The Ignition Trigger wire is used to turn the DC charging source on with ignition.

In most circumstances this wire does not need to be connected. This feature is

designed to allow vehicle with Variable Voltage alternators to trigger the DC Input.

Figure 2.4.2 shows how to wire the Ignition Trigger wire.

The Ignition Trigger feature must be activated in the User Menu as explained in

section 3.3 of this manual.

18

Page 20

to Vehicle

Common

Ground

to House Battery

Positive Terminal

to House Battery

Negative Terminal

to Main

Unit

to Remote

Monitor

CAN Bus

Connection

2 INSTALLATION GUIDE

2.4.3 Connecting the Battery Sensor

Wire the Battery Sensor as shown in fi gure 2.4.1.1 ensuring that the “BNEG” stud

connects to the House Battery negative terminal and the “GND” stud connects to

the vehicle common ground point.

Connect the CANBus Connection cable, the cable with the RJ12 connector, to the

CANBus network via the T-Piece supplied (see fi gure 2.4.2). The CANBus Connection

cable should be connected to the T-Piece using the RJ12 Insert provided.

The Battery Positive Lead connects to the house battery positive terminal, this

lead measures voltage and temperature at the battery.

2.4.4 Wiring the Main Unit

Refer to Figure 2.4.1 for required connections and to Figure 2.4.2 typical setup.

NOTE: If a longer Remote Monitor cable is required, a replacement CAT5 patch

cable may be used, up to a length of 10m.

19

CANBus Interface

Ground

1

3

5

6

Solar Input

AC Mains Input

DC Input

Battery Output

4

2

Load Disconnect

Ignition Trigger

AC

MAINS

Figure 2.4.1 - Required connections.

Figure 2.4.1.1 - Battery Sensor connections

Page 21

2 INSTALLATION GUIDE

30

AMPS

MODEL

AC INPUT

VEHICLE INPUT

SOLAR INPUT

BATTERY OUTPUT

BMS1230

230V, 50-60Hz, 560W

9 - 32VDC, 520W

9 - 32VDC, 520W

12VDC Nom./ 0-30A

Please refer to owners

manual for appropriate wire

gauge and fuse ratings.

The Redarc CAN system is

designed to operate Redarc

CAN based devices only.

WARNING: Before obtaining access to terminals, all supply circuits must be disconnected

Solar

Panel

50A

Fuse

Not

supplied

Start

Battery

Essential Loads**

Remote

Monitor

BMS1230

+

+

+

Mains AC from

mains power

(rear side)

AC

MAINS

-

+

Non-essential

Loads**

House

Battery

1 2

3 4 5

6

2

Battery

Sensor

40A

Fuse

Not

supplied

Load

Fuses

Not

supplied

*

* The size of this fuse relates

to the total current draw of all

the loads connected to the

House Battery, and should be

rated slightly higher than this.

** Essential loads are loads which

must be left on at all times, until

the battery is flat. Non-essential

loads are those switched off

when the battery reaches a

particular low-charge level,

which can be set in the

‘Advanced Settings’ menu.

Ignition

Trigger

SBI12-BLD

Figure 2.4.2 - Typical setup.

20

Page 22

21

2 INSTALLATION GUIDE

2.5 Batteries

Working in the vicinity of a Lead-Acid battery is dangerous. Batteries generate explosive

gases during normal operation. For this reason, it is of utmost importance that you follow

the instructions each time you use the charger.

When charging a battery, make sure the settings at the Battery Setup menu on the Remote

Monitor are correct for the type of battery under charge. Charging a battery with the wrong

profi le may cause The Manager30 to indicate a fault or give misleading results and could

result in damage to the battery. Noticeable oscillations between Boost and Absorption stages

indicate the wrong choice of battery type. Check and adjust battery type. If you are unsure

of the battery type or settings to use, set The Manager30 to the Gel setting.

Figure 2.5.1 and 2.5.2 show standard wiring for batteries in series and parallel

respectively.

To ensure that all batteries are equally charged, loads and The Manager30 should

be connected with ground and 12V power connected diagonally opposite across

all batteries as shown in Figure 2.5.2.

The Ah rating needs to be setup when prompted on fi rst start up (Refer section

3.3), these settings can also be modifi ed in the “Advanced Settings” menu (Refer

section 3.5). To calculate Ah rating of batteries in parallel simply add the rating

of each battery in the bank together. For example, 3 batteries with an Ah rating

of 100Ah each will yield a total of 3 x 100Ah or 300Ah. Batteries connected in

series will assume the lowest Ah rating of the batteries in the bank. For example,

2 batteries in the bank, one is 50Ah the other 100Ah. When connected in series

the Ah rating is 50Ah.

12V 12V 12V

Ground

To 12V

system

Battery Sensor

Figure 2.5.1 - Batteries in Series. Figure 2.5.2 - Batteries in Parallel.

Ground

6V

To 12V

system

Battery

Sensor

6V

Page 23

22

2 INSTALLATION GUIDE

2.6 MPPT Solar Regulator

The Manager30 is designed for use with 12V solar panels. A minimum input

voltage of 17.5V is required to start charging from a solar source. Once charging

has started, the operating voltage range of the solar input can go as low as 9V

and as high as 32V; outside of this range, charging will stop.

The power output from solar panels varies depending on the amount of sunlight

and the electrical load on the solar panel output. The Manager30 utilises a

Maximum Power Point Tracking (MPPT) algorithm on the solar input, to ensure

that the greatest charge possible is transferred from the solar panels to the battery

under charge. As conditions change, the MPPT algorithm adjusts its parameters

accordingly, in order to maintain the optimum point at which the solar panels can

deliver the most power.

An array of solar panels can be connected to The Manager30 solar input, on the

condition that the open circuit output voltage of the array is at least 17.5V and

does not exceed 32V*. For this reason, 12V panels must be connected in parallel

(Refer to Figure 2.6.1). So long as the voltage requirements are met, there is no

limit to the number of panels that can be connected in a solar array; however The

Manager30 will not draw more than 520W from the solar input.

For installations with a single 12V solar panel, a blocking diode is not necessary.

For installations with an array of solar panels, please refer to the panel

manufacturer’s instructions for requirement and/or fi tment of diodes.

+

-

+

-

+

-

Figure 2.6.1 - Array of 12V Solar Panels

Page 24

23

3 USER GUIDE

3.1 Remote Monitor

The Remote Monitor is designed to give you control of how the battery is being

charged, as well as up-to-date house battery and charge information at any time

during the charging process. You can check battery charge status, estimated

charge time and State of Charge (SOC) per hour over a day and per day over a

month. It also allows you to select charging profi les specifi c to the battery type

and size. The four controls ‘Up’, ‘Down’, ‘Enter’ and ‘Home’ allow you to select

options or move in and out of menu items. The Signal Indicator LED will glow

Green when suitable AC Mains signal is present and Red in the event of a fault

occuring.

3.2 Understanding the Display

The top left corner of the screen always displays the title of the present menu.

Use the ‘Up’ and ‘Down’ buttons to move between menus and to change settings

such as battery type and contrast level. At any time during operation, the ‘Home’

button will take you back to the Home Screen, unless otherwise specifi ed. The

Home Screen can be set to any of the top level User Menu screens described in

section 3.4 by pressing and holding the ‘Home’ button for 2 seconds whilst the

desired screen is displayed. At any time during operation, the menu at the bottom

of the screen will explain the function of the ‘Enter’ and ‘Home’ buttons.

LCD Display

Signal Indicator

Home Button Up Button

Enter Button

Down Button

Screen Title

Down Key Function

Up Key Function

Home Key Function

Sound On/Mute Battery Status

Enter Key Function

Menu Location

Figure 3.1.1 - The Remote Monitor

Figure 3.2.1 - The LCD Display

Page 25

24

3 USER GUIDE

3.3 Initial Setup

When The Manager30 is fi rst switched on the unit will prompt the user to enter

a number of settings. It is important to enter these settings accurately as they

directly affect the operation and performance of The Manager30.

Set the Language:

Setup your Battery Type:

Setup the Date and Time:

When charging a battery, make sure the settings at the Battery Setup menu on the Remote Monitor are correct for the

type of battery under charge. Charging a battery with the wrong profi le may cause The Manager30 to indicate a fault or

give misleading results and could result in damage to the battery. Noticeable oscillations between Boost and Absorption

stages indicate the wrong choice of battery type. Check and adjust battery type. If you are unsure of the battery type

or settings to use, set The Manager30 to the Gel setting.

The fi nal step required for initial setup is selecting the Time and Date to be

displayed on Remote Monitor. Time and Date settings are used not only for the

clock screen but also on the Charge per Hour and Charge per Day log screens.

The Time and Date settings are not retained in memory so in the event that the

charger loses ALL power sources (Input and Output), upon reconnection the unit

will prompt the user to enter the Time and Date again.

The Clock screen is also the default Home Screen.

Set the Time & Date

N/A

Charging Status Screen

Battery Charge Screen

The second and most important step required for initial setup is Battery Type

and Size selection. Please refer to the battery manufacturers specifi cation sheet

for Size(AH) and Type specifi cations. If you are unsure of the type of your battery

please select the Gel setting. Should power to the Battery Sensor be removed at

any time, the unit will revert to the Gel setting and prompt the user to input their

Battery Type again. The Battery Size setting will be retained in memory.

The fi rst step required for initial setup is Language selection. Once entered the

Language is set in memory and retained should power be lost and reconnected.

Edit Battery Type & Size

N/A

About Screen

Remote Settings Screen

Edit Battery Type & Size

N/A

About Screen

Remote Settings Screen

Page 26

25

3 USER GUIDE

3.4 User Menu

The Manager30 features a real time clock (time and date) function which needs

to be setup when the power is fi rst connected.

Set the Time & Date

N/A

Charging Status Screen

Battery Charge Screen

The Manager30 monitors current in and out of the house battery, keeping track

of the charge remaining. This screen displays the estimated state of charge of

the house battery in percentage along with a bar graph. For the duration of the

initial charge cycle for a new battery this screen will show ‘Calculating’. This is

when The Manager30 is gathering information about the battery under charge.

State of Charge is determined by current in or out of the house battery, and uses

the fi rst charge cycle (Calculating) and the battery size input by the user at setup

to determine what the full State of Charge should be.

Once The Manager30 has calculated the full state of charge for the system this

screen will display either the Time to Full Charge or the Battery Time Remaining,

depending on whether the house battery is currently being charged or discharged.

The Manager30 uses the estimated State of Charge value to calculate, based on

the current into and out of the house battery, the time to reach 100% State of

Charge. You may use this to decide when to disconnect AC power, for example.

Similarly, The Manager30 uses the estimated State of Charge value to calculate

- based on the current power usage of the system (e.g. of loads such as fridges,

lighting) - the useful time remaining of the battery.

NOTE: Zero State of Charge occurs when The Manager30 determines that the

amount of charge removed from the house battery, in Ah, is equal to the amount

input by the user at initial setup.

View Charge Logs (per Hour)

Home Screen (Clock)

Home Screen (Clock)

Input Status Screen

The Charge per Hour screen displays the average State of Charge of the

battery under charge at the end of each hour across the course of the last

day. The most recent hour is always the right most line on the graph.

View Charge Logs (per Day)

Battery Charge Screen

Previous Hour SoC

Next Hour SoC

The Charge per Day screen displays the maximum and minimum State of

Charge of the battery under charge for each day across the course of the last

month. The most recent day is always right most line on the graph.

Clear Logs (Hold to Confi rm)

View Charge Logs (per Day)

Previous Day SoC

Next Day SoC

Page 27

26

3 USER GUIDE

When using the charger in Storage mode, make sure that all loads are disconnected from the house battery under

charge. Failure to do so may cause the house battery to be under charged, give false readings on the State of Charge

indicator and possibly cause damage to any loads connected.

The Change Mode screen allows switching between Touring and Storage

modes. Remember to disconnect all loads before setting Storage mode.

The Solar Information screen displays information on the power and voltage

output of the solar panels. From this screen you can access a log of daily

power generation measured in Watt Hours. The log will store up to 7 days of

data and will overwrite, storing only the last 7 days at any one time.

The Input Status screen displays a summary of the inputs to the system. The Solar

input is the priority, providing as much usable input power as possible. If another

source is present and the Solar input is not providing maximum (30A) input, the

other source will attempt to make up the remaining allowable input power. This

screen provides input voltage level as well as percentage (bar graph) of input power

provided. Only two sources are used at any one time. If a source is not detected a

circle with a line diagonally through it will display indicated that the source is not

present. If the Solar and AC inputs are both in use and the DC input is detected, the DC

voltage will be displayed however the bar graph will display the not available symbol.

Solar Information Screen

Home Screen (Clock)

Battery Charge Screen

Output Status Screen

Clear Logs (Hold to Confi rm)

Input Status Screen

Previous Day Solar Information

Next Day Solar Information

The Output Status screen displays a summary of the current fl ow of the system.

The screen will display current from The Manager30 unit, current in to or out of

the battery and current provided to the loads. The direction of the current fl ow is

indicated by the arrows, and a moving white dot.

N/A

Home Screen (Clock)

Input Status Screen

Charging Status Screen

The Charging Status screen displays the charging status of The Manager30,

including Charge Stage, Charge Mode and Battery Voltage and Battery Temperature.

Change Charging Mode

Home Screen (Clock)

Output Status Screen

Home Screen (Clock)

Confi rm Mode Selection

Charging Status Screen

Change Mode Selection

Change Mode Selection

Page 28

27

3 USER GUIDE

3.5 Settings Menu

When charging a battery, make sure the settings at the Battery Setup menu on the Remote Monitor are correct for the

type of battery under charge. Charging a battery with the wrong profi le may cause The Manager30 to indicate a fault or

give misleading results and could result in damage to the battery. Noticeable oscillations between Boost and Absorption

stages indicate the wrong choice of battery type. Check and adjust battery type. If you are unsure of the battery type

or settings to use, set The Manager30 to the Gel setting.

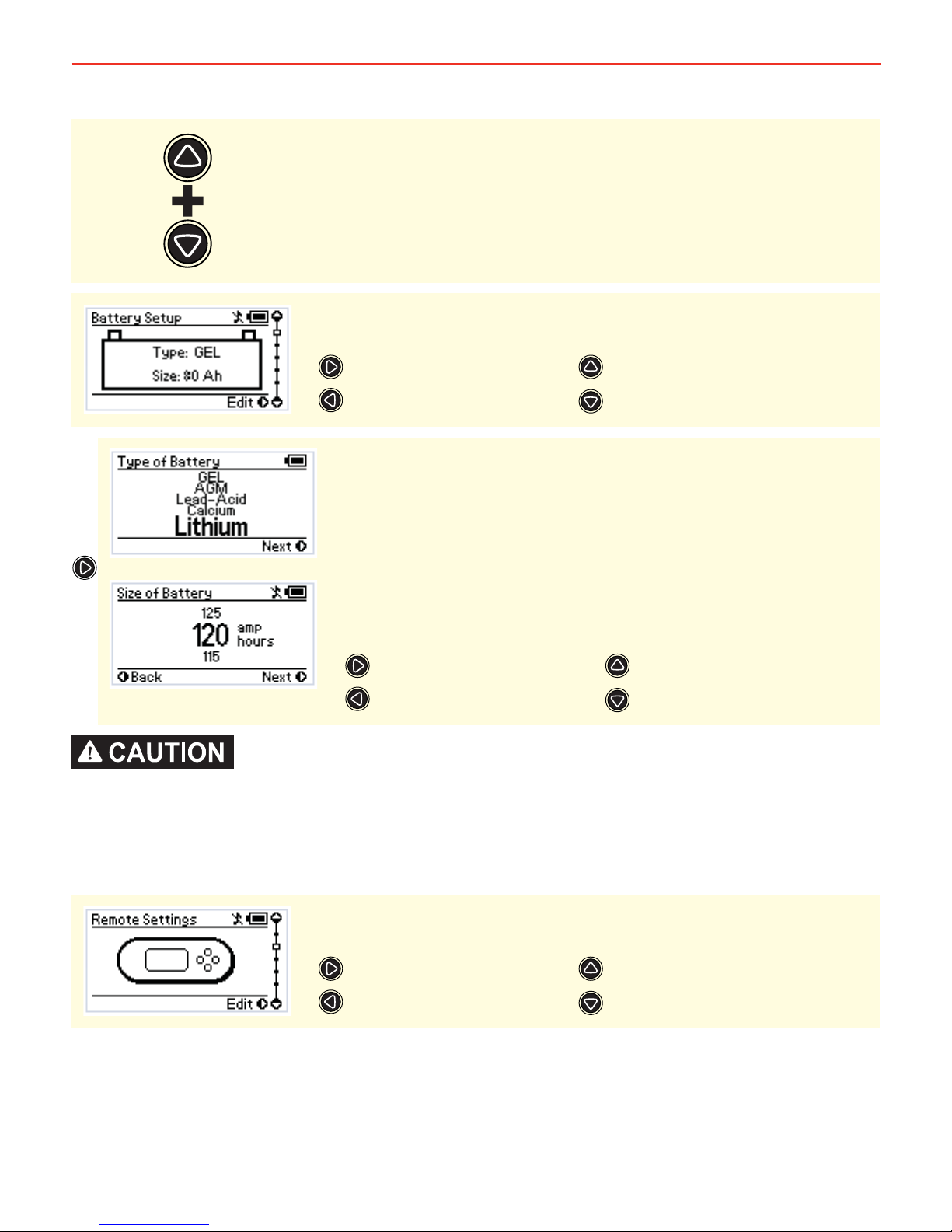

The Remote Settings Menu allows modifi cation of settings relating to the Remote

Display and its operation.

The Type of Battery screen allows the user to indicate the type of battery

being charged by The Manager30. This setting will affect the charge profi le

that The Manager30 uses to charge the battery so it is important to select the

correct battery type. Once you are happy with your selection move on to the

Size of Battery screen.

The Size of Battery screen allows the user to indicate the battery bank size.

When you have chosen this value, the menu will ask for confi rmation of the

settings while displaying them on the screen. Refer section 2.5 for battery

size calculation.

The fi rst screen in the Settings menu is the Battery Setup screen. The Battery

Setup displays the selected battery settings for the battery under charge.

To access the Settings menu both the Up and Down buttons must be held for

2 seconds. This allows you to modify your Battery Setup, Remote Settings and

some Advanced Settings, as well as providing a restore Factory Settings option

and an About screen.

Edit Battery Type & Size

N/A

About Screen

Remote Settings Screen

Next menu/Confi rm

Back/Cancel

Cycle through options

Cycle through options

Remote Settings Menu

N/A

Battery Setup Screen

Advanced Settings Screen

Page 29

28

3 USER GUIDE

Modifi cation of the ‘Advanced Settings’ menu items affect the way The Manager30 unit responds to charging situations.

Modifi cation of these settings may result in the unit not functioning at 100% of its capacity. These settings should only

be modifi ed if absolutely necessary and when the effects of the changes are 100% understood.

The Advanced Settings menu allow modifi cation of settings relating to advanced

operations of The Manager30 unit.

The Remote Settings menu allows modifi cation of the settings listed below.

Edit Selected Setting

Remote Settings Screen

Cycle through Settings

Cycle through Settings

Each setting can be adjusted using the ‘Up’ and ‘Down’ controls.

Confi rm Setting Adjustment

Cancel Setting Adjustment

Adjust Setting (Up)

Adjust Setting (Down)

MaxCharge Current Setting

N/A

Remote Settings Screen

Restore Factory Settings Screen

Page 30

29

3 USER GUIDE

It is recommended to set the SoC or Voltage Alarm level above the Load Disconnect Turn OFF level and below the Turn

ON level. This will ensure that, in the event the loads have been disconnected, when reconnection occurs the Alarm

does not sound.

The Set Alarm Voltage setting sets the Voltage at which the alarm will

sound. The Alarm Voltage can be set to OFF.

The Low Voltage Alarm setting will sound an alarm when the battery Voltage

reaches a particular setting.

The Low SOC Alarm setting will sound an alarm when the battery State-ofCharge reaches a particular setting.

The Set Alarm SOC setting sets the percentage of State-of-Charge at

which the alarm will sound. The Alarm SOC can be set to from 0 - 100%.

The MaxCharge Current setting refers to the amount of current permitted by

The Manager30 to charge the battery, up to a maximum of 30 Amps.

Set Charging Current Screen

Advanced Settings Screen

R-Bus Diagnostics Screen

Low SOC Alarm Screen

If the Charging Current setting is set lower than 30 Amps the excess current

will be used to supply the loads running from the battery under charge.

Confi rm Setting

Cancel Setting

Increase Charging Current

Decrease Charging Current

Set Alarm SOC Screen

Advanced Settings Screen

MaxCharge Current Screen

Low Voltage Alarm Screen

Confi rm Setting

Cancel Setting

Increase Alarm SOC

Decrease Alarm SOC

Set Alarm Voltage Screen

Advanced Settings Screen

Low SOC Alarm Screen

Load Disconnect Screen

Confi rm Setting

Cancel Setting

Increase Alarm Voltage

Decrease Alarm Voltage

Page 31

3 USER GUIDE

30

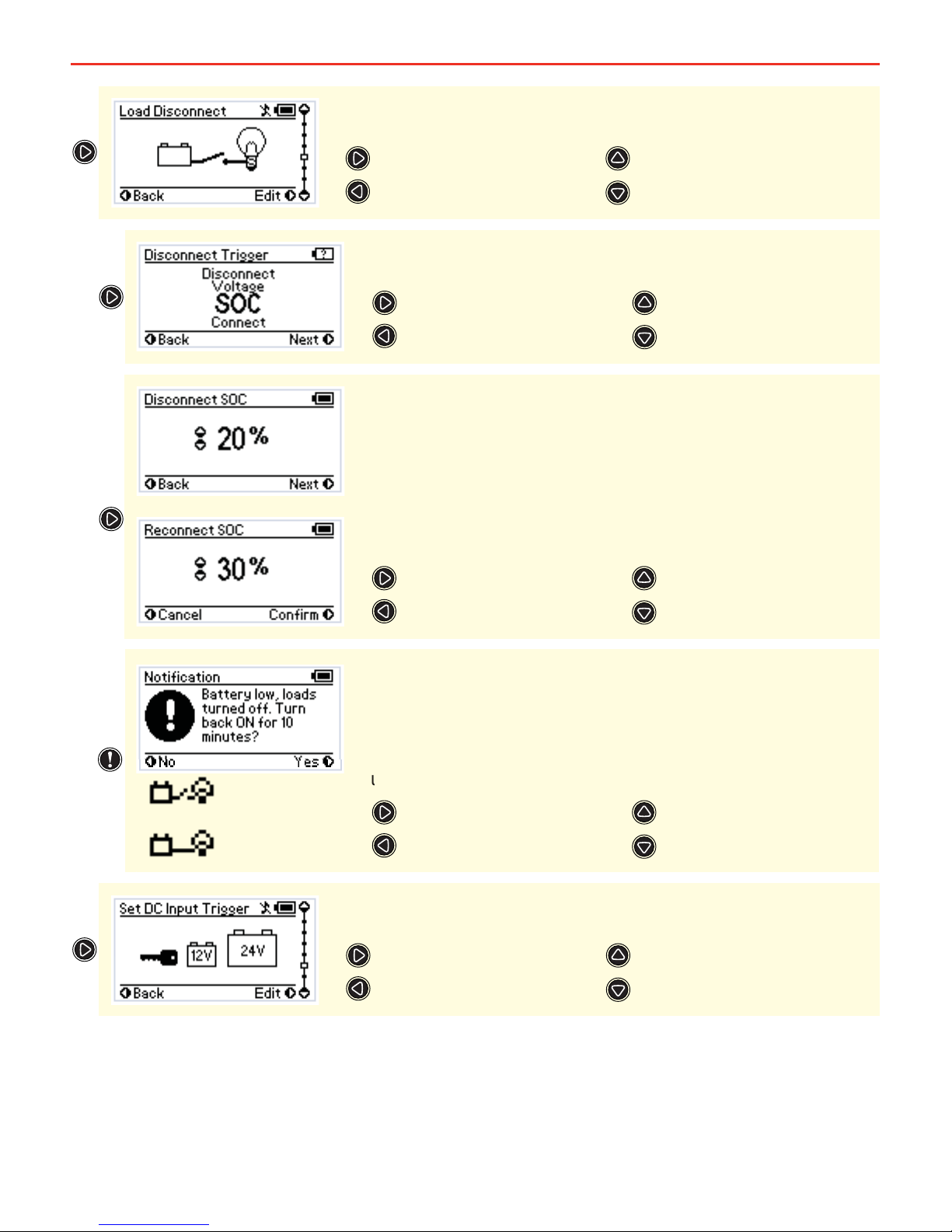

Should the Load Disconnect feature be triggered the Remote Monitor will

prompt the user to allow the Loads to be reconnected for 10 minutes.

This allows the user to temporarily use power (for loads such as lighting)

to rectify any issues and/or engage another charging source. After this

time has lapsed the load will disconnect and the prompt will reappear,

unless the battery voltage is above the Disconnect level.

Turn Loads ON for 10 mins

No

N/A

N/A

The DC Input Trigger allows you to select whether you would like your DC input to

be triggered via Ignition, automatically via The Manager30, or at a specifi c voltage.

Set DC Input Trigger Screen

Advanced Settings Screen

Load Disconnect Screen

R-Bus Diagnostics Screen

The Disconnect Trigger setting can be set to Disconnect (Loads OFF),

Connect (Loads ON) or to operate from either SOC or Voltage level triggers.

If either Voltage or SOC are selected at the Disconnect Trigger setting

screen the Disconnect trigger level will need to be selected.

Once the Disconnect trigger level is selected the Reconnect trigger

level must be selected. Note that there is a built in minimum hysteresis

constraint on this setting and a non-adjustable time delay exists to stop

repetitive switching.

Next Menu Item

Back

Change Setting

Change Setting

Next Menu Item/Confi rm

Back/Cancel

Increase Setting

Decrease Setting

The Load Disconnect setting will output a GROUND relay trigger signal based

on a user set SOC or voltage level.

Disconnect Trigger Screen

Advanced Settings Screen

Low Voltage Alarm Screen

Set DC Input Trigger Screen

t

u

Load

Disconnected

Load Temporarily

Connected

Page 32

3 USER GUIDE

3.6 Fault Screens

Ignition selects Ignition Trigger, Auto is controlled by The Manager30, and

12V or 24V lock the unit to a 12V or 24V system. ON means the unit can

trigger DC charging whenever there is a voltage betwwen 9 - 32V on the

DC Input wire. The default value is ‘Auto’.

31

This screen is used by REDARC to identify problems with a The Manager30 setup

and does not need to be accessed unless requested by REDARC Technicians.

Start Process/ More Info

Advanced Settings Screen

Set DC Input Trigger Screen

MaxCharge Current Screen

The About Screen allows you to access information about the build of The

Manager30 and the company. You may be asked to access this menu should you

ever call up for technical support with The Manager30.

About your Manager30

N/A

Factory Settings Screen

MaxCharge Current Screen

This screen gives the option of restoring the Factory Settings for The Manager30.

A list of the factory settings can be found on Page 34.

Restore Settings/ Confi rm

N/A

Advanced Settings Screen

About Screen

If The Manager30 detects a problem with the charging system that does not

prevent it from charging the battery, it will alert you via a Warning screen and

an alarm buzzer, and continue charging. The screen will give a brief description

of the problem and allow you to select either ‘Clear’ or ‘Ignore’. Both options

will clear the warning screen. After selecting ‘Clear’, however, The Manager30

will immediately check to see if the fault condition still exists. If it does, it

will display the warning screen again. Selecting ‘Ignore’ will prevent The

Manager30 from detecting the same fault for up to one minute.

NOTE: If “Ignore” is selected but the fault is not removed, when the warning reappears after one minute, it will not be accompanied by the alarm buzzer.

The troubleshooting section (3.7) of this manual contains a description of faults

detected.

Clear Warning

Ignore Warning

N/A

N/A

Confi rm Setting

Cancel Setting

Change Setting

Change Setting

Page 33

3 USER GUIDE

3.7 Troubleshooting

The Manager30 is designed to detect and advise the operator of a variety of fault

conditions and will terminate the charging cycle immediately should a critical

fault be detected. This ensures that it will not attempt to charge a faulty battery,

which protects The Manager30, house battery and most importantly the user.

The Remote Display is used to inform the user of the nature of the problem

whenever possible. These indicators should be used to diagnose, and if possible

correct any faults that may occur. When attempting to diagnose a fault, cabling

should be adequately rated and all components, including all input sources and

house battery should be connected as close as possible to The Manager30.

The listing on the following page (33) outlines the probable cause and

recommended action to take when faults occur with The Manager30 system.

If after attempting to rectify the situation, a fault still occurs, please contact

REDARC for further diagnosis.

Contact Details:

REDARC Electronics

(08) 8322 4848

power@redarc.com.au

www.redarc.com.au

32

If The Manager30 detects a problem with the charging system that prevents it

from continuing to charge the battery, it will alert you via a ‘Fault’ screen and

an alarm buzzer, and will instantly terminate the charging cycle until the fault

condition is cleared. The screen will give a brief description of the problem and

will allow you to select either ‘Clear’ or ‘Ignore’. Both options will clear the fault

screen. After selecting ‘Clear’, however, The Manager30 will immediately check

to see if the fault condition still exists. If it doesn’t, the unit will restart charging.

Selecting ‘Ignore’ will simply hide the fault screen for up to one minute. It will

not allow The Manager30 to recommence charging unless The Manager30 itself

detects the removal of the fault condition.

NOTE: If “Ignore” is selected but the fault is not removed, when the warning reappears after one minute, it will not be accompanied by the alarm buzzer.

The troubleshooting section (3.7) of this manual contains a description of faults

detected.

Clear Fault

Ignore Fault

N/A

N/A

Page 34

33

3 USER GUIDE

Faults

CHARGER FAULT MESSAGE CAUSE ACTION

Charger over current fault An internal error has caused excessive

current draw

Return to supplier

Charger over voltage fault The output voltage is too high (above

18V)

Check battery is correct type (12V, 6

cell)

Unit over temperature fault. Allow to cool The unit has over heated Allow to cool, charging will

recommence automatically

Output battery under temperature fault Output battery is below 0°C Charger will halt charging until battery

is above 5°C

Output battery over temperature fault Output battery is above 60°C Charger will halt charging until battery

is below 55°C

Dry cell detected in output battery Charger has detected a dry cell in

output battery

Replace battery

Shorted cell detected in output battery Charger has detected a shorted cell in

output battery

Replace battery

Warnings

CHARGER WARNING MESSAGE CAUSE ACTION

AC supply over voltage The internal AC converter output

voltage is too high

Contact supplier

AC supply over temperature The internal AC converter temperature

is too high

Contact supplier

DC supply over voltage The DC input voltage is too high (over

32V)

Check DC input, refer to specifi ed input

range

Solar supply over voltage The solar input voltage is too high

(above 32V)

Check solar input, refer to specifi ed

input range

No battery sensor connected The supplied battery sensor is not

connected or is faulty

Connect battery sensor, if faulty return

to supplier

Low battery State of Charge House battery is almost fl at Reduce/remove loads on house battery

Bad cable detected Too much voltage drop between

charger and battery sensor

Check cable for correct sizing

requirments

Load Disconnect output shorted Load disconnect output faulty Contact supplier

Battery voltage low! Disconnect all loads Loads exceeding charge available from

input sources

Connect additional input source or

disconnect loads

Other issues

FAULT ACTION

Low output current can occur when the unit is hot and

temperature derating is implemented to protect the Charger

Check that the unit is in a well ventilated space

The current display shows a negative current when there

are no loads on the house battery and the house battery is

charging

The current shunt connection is reversed

Noticable oscillations between Boost and Absorption stages Check and select the correct battery type

Page 35

34

3 USER GUIDE

3.8 Factory Settings

The Manager30 is shipped with a number of settings already programmed into

the unit. These settings are set to ensure that the charger will safely charge any

battery and may not refl ect the actual requirements for your battery type. It is

important to review these settings and adjust as required.

Setting Factory Value

Battery Type GEL

Capacity 40AH

Charge Mode TOURING

Temperature Scale Celsius

Key Tone Status ON

Contrast 50%

Brightness 90%

Backlight Timer 30 secs

Home Screen Timer 30 secs

Time/Date Format 12 Hour/DD/MM/YYYY

Language English

Max Charge Current 30 Amps

Low SOC Alarm 10%

Low Voltage Alarm 10.5 Volts

Load Disconnect Off

DC Input Trigger Auto

Modifi cation of the ‘Advanced Settings’ menu items affect the way The Manager30 unit responds to charging situations.

Modifi cation of these settings may result in the unit not functioning at 100% of its capacity. These settings should only

be modifi ed if absolutely necessary and when the effects of the changes are 100% understood.

Page 36

35

3 USER GUIDE

3.9 Frequently Asked Questions

Q I have damaged my Power Cable and need to replace it, do I have to buy a special kind

of cable.

A To ensure the correct operation of The Manager30, REDARC advise that if the

supply cord is damaged it must be replaced by a special cord available from the

manufacturer.

Q I am running a load from my house battery, but it does not seem to register on The

Manager30 Remote, why can I not see this current draw?

A This is generally caused by incorrect wiring of the Battery Sensor. Ensure no

equipment earths go direct to the house battery negative or to the house battery end

of the shunt. They must all go to common or chassis ground or to the ground end of

the shunt

Q My Input Status screen shows a voltage on the Solar input but the bar graph shows that

no charge is coming from the Solar input, what does this mean?

A A partially shaded panel (or low-light conditions such as dawn or dusk) will increase

the target solar panel voltage level to match the maximum power point. In this

situation solar will be selected as a source however little or no current will be

fl owing into the battery.

Q I have just fi nished wiring The Manager30 and when i turn the unit on the Remote Monitor

says ‘No Battery Sensor Detected’, is my unit faulty?

A The Battery Sensor has a timeout function in-built into the unit. If the Battery Sensor

is wired to Power and Ground for a considerable amount of time before the Main Unit

is connected this message may appear. Try disconnecting the Red Battery Positive

terminal of the Battery Sensor and reconnecting it. If the message appears again

please contact REDARC Electronics.

Page 37

4 REMOTE DRILL TEMPLATE

36

Page 38

37

THIS PAGE INTENTIONALLY LEFT BLANK

Page 39

38

5 TWO YEAR PRODUCT WARRANTY

Over the last three decades our company has established a reputation as the power conversion specialist.

Over the last three decades our company has established a reputation as the power conversion specialist.

A 100% Australian-owned company, we have met the needs of customers in transport and other industries through exciting, innovative thinking.

A 100% Australian-owned company, we have met the needs of customers in transport and other industries through exciting, innovative thinking.

We believe in total customer satisfaction and practice this by offering our customers:

We believe in total customer satisfaction and practice this by offering our customers:

• Technical advice free of jargon and free of charge

• Technical advice free of jargon and free of charge

• Prompt turnaround of orders throughout Australia and globally

• Prompt turnaround of orders throughout Australia and globally

• Friendly, personalised, professional service and product support

• Friendly, personalised, professional service and product support

In the unlikely event that a technical issue arises with a Redarc product, customers are encouraged to initially contact the Redarc Technical Support Team on (08) 8322 4848

In the unlikely event that a technical issue arises with a Redarc product, customers are encouraged to initially contact the Redarc Technical Support Team on (08) 8322 4848

or

or

power@redarc.com.au

power@redarc.com.au

for prompt and effi cient diagnosis and product support.

for prompt and effi cient diagnosis and product support.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and compensation for

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and compensation for

any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not

any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

amount to a major failure.

The benefi ts of this Warranty are in addition to other rights and remedies available at law in respect of the Products and shall not derogate from any applicable mandatory statutory

The benefi ts of this Warranty are in addition to other rights and remedies available at law in respect of the Products and shall not derogate from any applicable mandatory statutory

provisions or rights under the Australian Consumer Law.

provisions or rights under the Australian Consumer Law.

Redarc Electronics Pty Ltd atf the Redarc Trust trading as Redarc Electronics (“

Redarc Electronics Pty Ltd atf the Redarc Trust trading as Redarc Electronics (“

Redarc

Redarc

”) offers a warranty in respect of its Products where the Products are purchased from an

”) offers a warranty in respect of its Products where the Products are purchased from an

authorised distributor or reseller of Redarc by a person (“

authorised distributor or reseller of Redarc by a person (“

Purchaser

Purchaser

”), on the terms and conditions, and for the duration, outlined below in this document (“

”), on the terms and conditions, and for the duration, outlined below in this document (“

Warranty

Warranty

”).

”).

1. In this Warranty, the term Products means:

1.1 all products manufactured or supplied by Redarc (excluding its solar products

which are covered by Redarc’s Solar Product Warranty); and

1.2 any component of or accessory for any product in clause 1.1 manufactured or

supplied by Redarc.

Offer and duration of product warranties

2. Redarc warrants that its Products will be free, under normal application, installation,

use and service conditions, from defects in materials and workmanship affecting

normal use, for 2 years from the date of purchase (Warranty Period).

3. Where a Product malfunctions or becomes inoperative during the Warranty Period,

due to a defect in materials or workmanship, as determined by Redarc, then subject

to further rights conferred by the Australian Consumer Law on the Purchaser,

Redarc will, in exercise of its sole discretion, either:

3.1 repair the defective Product;

3.2 replace the defective Product; or

3.3 provide a refund to the Purchaser for the purchase price paid for the defective

Product,

without charge to the Purchaser.

4. The warranty given by Redarc in clause 3 covers the reasonable costs of delivery

and installation of any repaired or replaced Products or components of Products

to the Purchaser’s usual residential address notifi ed to Redarc, together with the

reasonable costs of removal and return of any Products determined by Redarc to be

defective.

5. If the Purchaser incurs expenses of the nature referred to in clause 4 in the

context of making a claim pursuant to this Warranty that is accepted by Redarc,

the Purchaser will be entitled to claim for reimbursement of those expenses which

Redarc determines, in exercise of its sole discretion, to be reasonably incurred,

provided that the claim is notifi ed to Redarc in writing at the postal address or email

address specifi ed in clause 21 and includes:

5.1 details of the relevant expenses incurred by the Purchaser; and

5.2 proof of the relevant expenses having been incurred by the Purchaser.

Exclusions and limitations

6. This Warranty will not apply to, or include any defect, damage, fault, failure

or malfunction of a Product, which Redarc determines, in exercise of its sole

discretion, to be due to:

6.1 normal wear and tear or exposure to weather conditions over time;

6.2 accident, misuse, abuse, negligence, vandalism, alteration or modifi cation;

6.3 non-observance of any of the instructions supplied by Redarc, including

instructions concerning installation, confi guring, connecting, commissioning,

use or application of the Product, including without limitation choice of location;

6.4 failure to ensure proper maintenance of the Product strictly in accordance with

Redarc’s instructions or failure to ensure proper maintenance of any associated

equipment or machinery;

6.5 repairs to the Product that are not strictly in accordance with Redarc’s

instructions;

6.6 installation, repairs or maintenance of the Product by, or under the supervision

of, a person who is not a qualifi ed auto electrician or technician, or if nongenuine or non-approved parts have been fi tted;

6.7 faulty power supply, power failure, electrical spikes or surges, lightning, fl ood,

storm, hail, extreme heat, fi re or other occurrence outside the control of

Redarc;

6.8 use other than for any reasonable purpose for which the Product was

manufactured;

6.9 any indirect or incidental damage of whatever nature outside the control of

Redarc.

7. Warranty claims in respect of a Product must be made in writing to Redarc at the

postal address or email address specifi ed in clause 21 within the Warranty Period.

Such claims must include the following:

7.1 details of the alleged defect or fault and the circumstances surrounding the

defect or fault;

7.2 evidence of the claim, including photographs of the Product (where the subject

of the claim is capable of being photographed);

7.3 the serial number of the Product, specifi ed on the label affi xed to the Product;

and

7.4 proof of purchase documentation for the Product from an authorised distributor

or reseller of Redarc, which clearly shows the date and place of purchase.

The return of any Products without the prior written instructions of Redarc will not

be accepted by Redarc.

8. Without limiting any other clause in this Warranty, Redarc has the right to reject any

Warranty claim made by a Purchaser pursuant to this Warranty where:

8.1 the Purchaser does not notify Redarc in writing of a Warranty claim within the

Warranty Period;

8.2 the Purchaser does not notify Redarc in writing of a Warranty claim within 1

month of becoming aware of the relevant circumstances giving rise to the

claim, so that any further problems with the Product are minimised;

8.3 the serial number of the Product has been altered, removed or made illegible

without the written authority of Redarc;

8.4 the Purchaser is unable to provide proof of purchase documentation in

accordance with clause 7.4 or evidence that the Product was properly installed

and removed (if relevant), and that proper maintenance has been performed

on the Product, by, or under the supervision of, a qualifi ed auto electrician or

technician, in accordance with the instructions of Redarc.

9. If the Product is found to be working satisfactorily on return to Redarc or upon

investigation by Redarc, the Purchaser must pay Redarc’s reasonable costs of

testing and investigating the Product in addition to shipping and transportation

charges. Where Redarc is in possession of the Product, the Product will be

returned to the Purchaser on receipt of the amount charged.

10. Any replaced Products or components of Products shall become the property of

Redarc.

11. Redarc may, in exercise of its sole discretion, deliver another type of Product or

component of a Product (different in size, colour, shape, weight, brand and/or

other specifi cations) in fulfi lling its obligations under this Warranty, in the event

that Redarc has discontinued manufacturing or supplying the relevant Product or

component at the time of the Warranty claim, or where such Product or component

is superior to that originally purchased by the Purchaser.

Other conditions of Warranty

12. If the Purchaser acquired a Product for the purpose of resupply, then this Warranty

shall not apply to that Product.

13. In particular, the sale of a Product via an online auction, online store or other

internet website by a party that is not an authorised distributor or reseller of the

Product will be deemed to be a resupply within the meaning of the Australian

Consumer Law and will render this Warranty void, as Redarc has no control over the

storage, handling, quality or safety of Products sold by such persons.

14. A Purchaser shall only be entitled to the benefi t of this Warranty after all amounts

owing in respect of the Product have been paid.

15. While Redarc warrants that the Products will be free from defects in materials and

workmanship in the circumstances set out in this Warranty, to the maximum extent

permitted by law Redarc does not warrant that the operation of the Products will be

uninterrupted or error-free.

16. To the maximum extent permitted by law, Redarc’s determination of the existence of

any defect and the cause of any defect will be conclusive.

17. Spare parts or materials for the Products are guaranteed to be available for a period

of at least 2 years after purchase of the Products.

18. The agents, offi cers and employees of any distributor or reseller of the Products and

of Redarc are not authorised to vary or extend the terms of this Warranty.

19. Redarc shall not be responsible or liable to the Customer or any third party in

connection with any non-performance or delay in performance of any terms and

conditions of this Warranty, due to acts of God, war, riots, strikes, warlike conditions,

plague or other epidemic, fi re, fl ood, blizzard, hurricane, changes of public policies,

terrorism and other events which are beyond the control of Redarc. In such

circumstances, Redarc may suspend performance of this Warranty without liability

for the period of the delay reasonably attributable to such causes.

20. If a clause or part of a clause in this Warranty can be read in a way that makes it

illegal, unenforceable or invalid, but can also be read in a way that makes it legal,

enforceable and valid, it must be read in the latter way. If any clause or part of

a clause in this Warranty is illegal, unenforceable or invalid, that clause or part is

to be treated as removed from this Warranty, but the rest of this Warranty is not

affected.

Redarc’s contact details

21. Redarc’s contact details for the sending of Warranty claims under this Warranty are:

Redarc Electronics Pty Ltd

23 Brodie Road (North), Lonsdale SA 5160

Email:

power@redarc.com.au

Telephone: +61 8 8322 4848

Page 40

Free technical assistance!

please contact

REDARC Electronics

23 Brodie Road North, Lonsdale SA

(08) 8322 4848

power@redarc.com.au

www.redarc.com.au

Copyright © 2015 REDARC Electronics Pty Ltd. All rights reserved.

www.redarc.com.au

WARBMS1230S2 - REV3

Loading...

Loading...