Page 1

Battery Master Isolation Switch

BMIS-4PN, BMIS-4PP

Page 2

THE BATTERY MASTER ISOLATION SWITCH (BMIS)

The Battery Master Isolation Switch (BMIS) allows for manual isolation of a vehicle’s (trucks) electrical

system from its battery. The BMIS will also ensure that no loads are drawn from the vehicle whilst not

in use, thereby reducing flat battery faults.

The BMIS models are intended to meet the compliance

and specification requirements found in this document and are designed for use with roll over

switches or sensors (ROS).

WARNINGS & SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS - THIS MANUAL CONTAINS IMPORTANT SAFETY INSTRUCTIONS FOR THE BMIS.

DO NOT OPERATE THE ISOLATION SWITCH UNLESS YOU HAVE READ AND UNDERSTOOD THIS MANUAL AND THE

ISOLATION SWITCH IS INSTALLED AS PER THESE INSTALLATION INSTRUCTIONS.

1. IT IS OF UTMOST IMPORTANCE THAT YOUR ISOLATION SWITCH BE INSTALLED BY A QUALIFIED INSTALLER

AND THE ISOLATION SWITCH FUNCTION BE CHECKED AT LEAST EVERY 3 MONTHS. AN IMPROPERLY

INSTALLED AND/OR FAULTY ISOLATION SWITCH CAN CAUSE ERRATIC VEHICLE BEHAVIOUR AND LOSS OF

VEHICLE CONTROL.

2. ENSURE THAT THE BMIS IS MOUNTED IN THE ORIENTATION AS DEPICTED. ALTERNATIVE ORIENTATION

MAY COMPROMISE CORRECT PRODUCT FUNCTION.

3. ENSURE THAT ALL WIRES ARE TERMINATED CORRECTLY. FAILURE TO CORRECTLY TERMINATE WIRES

COULD RESULT IN ERRATIC VEHICLE BEHAVIOUR AND LOSS OF VEHICLE CONTROL, BATTERY FIRE,

EXPLOSION OR LEAKAGE.

4. ENSURE THAT THE BMIS SWITCH IS OFF BEFORE INSTALLING THE UNIT. INSTALLING THE BMIS WHILST

THE SWITCH IS ON COULD RESULT IN FIRE AND MAY CAUSE INJURY TO PERSONS AND/OR DAMAGE TO

PROPERTY.

5. ENSURE THAT THE RED COVER IS INSTALLED, TO PROTECT THE SWITCH MECHANISM FROM ACCIDENTAL

OPERATION DUE TO IMPACT OR CORROSION. ACCIDENTAL OPERATION COULD RESULT IN UNEXPECTED

POWER ISOLATION AND LOSS OF VEHICLE CONTROL.

6. BMIS 4PP OR 4PN MODELS ARE NOT FOR OPERATION IN EXPLOSIVE ATMOSPHERES. OPERATION WHEN

EXPLOSIVE ATMOSPHERE ARE PRESENT MAY CAUSE FIRE OR EXPLOSION AND RESULT IN INJURY TO

PERSONS AND/OR DAMAGE TO PROPERTY. ALLOW EXPLOSIVE ATMOSPHERES TO DISSIPATE OR INSTALL

UNIT IN NON-EXPLOSIVE ATMOSPHERES BEFORE OPERATING.

1. Ensure that the cable used to install the BMIS is of adequate thickness to supply the required current to operate

the vehicle electrical system. Incorrect wiring can result in fire and may cause injury to persons, damage to the

BMIS and/or damage to property.

2. Do NOT alter or disassemble the BMIS under any circumstances. There are no user serviceable parts inside. The

BMIS is not serviceable and is lubricated for life. The BMIS must be returned to your supplier for Assessment.

Incorrect handling, disassembly or reassembly may result in a risk of electric shock or fire and may void the

unit warranty.

SAL.FOR.Instruction Sheet.BMIS – DOC397 – Version 8

1

Page 3

WARNINGS & SAFETY INSTRUCTIONS

1. Ensure that a correct grounding point is used. Bad grounding of the unit will result in poor or no operation.

2. Do NOT use the BMIS to shut off the engine except in an emergency or for routine testing. Use the ignition

key as per normal vehicle operation. It is recommended for an engine shutdown test, to perform this on a fully

charged battery, or allow a few minutes of engine operation beforehand to recharge the battery as much as

possible. Following these recommendations will minimise the possibility of damage or accelerated wear to

vehicle electrical systems.

3. Ensure unused holes in the connector are filled with cavity plugs as contamination ingress may damage the

BMIS or connector.

4. To prevent contamination ingress, do not insert multiple wires into a single Deutsch connector terminal.

5. For vehicles fitted with SCR / Adblue, it is recommended to restart the truck engine immediately after testing

if isolating via the BMIS. Allow 30 seconds minimum or as per the manufacturer’s recommendations between

key off and isolating the BMIS to allow the SCR system to purge. Refer to the Vehicle manufacturer’s manual

for further information.

CONTENTS

Table of Contents Page

Warnings & Safety Instructions 01

Contents 02

Specifications 03

1. Installation 04

1. Mounting the BMIS 04

2. Wiring Connections 09

3. Data Connector Wiring Diagram 10

2 User Guide 11

1. Operating the BMIS 12

2. LED Indication 12

3. Faults 12

1. LED Fault & Self-test Conditions 12

2. Flashing LED Diagnosis 12

3. Troubleshooting 13

1. Remote Switch 13

2. Troubleshooting Flow-chart 13

3. Battery Not Charging 14

4. FAQs 14

5. Tech Tips 14

6. Maintenance and Cleaning 15

7. Standards & Testing 16

8. Notes 17

9. Two Year Warranty 18

2

Page 4

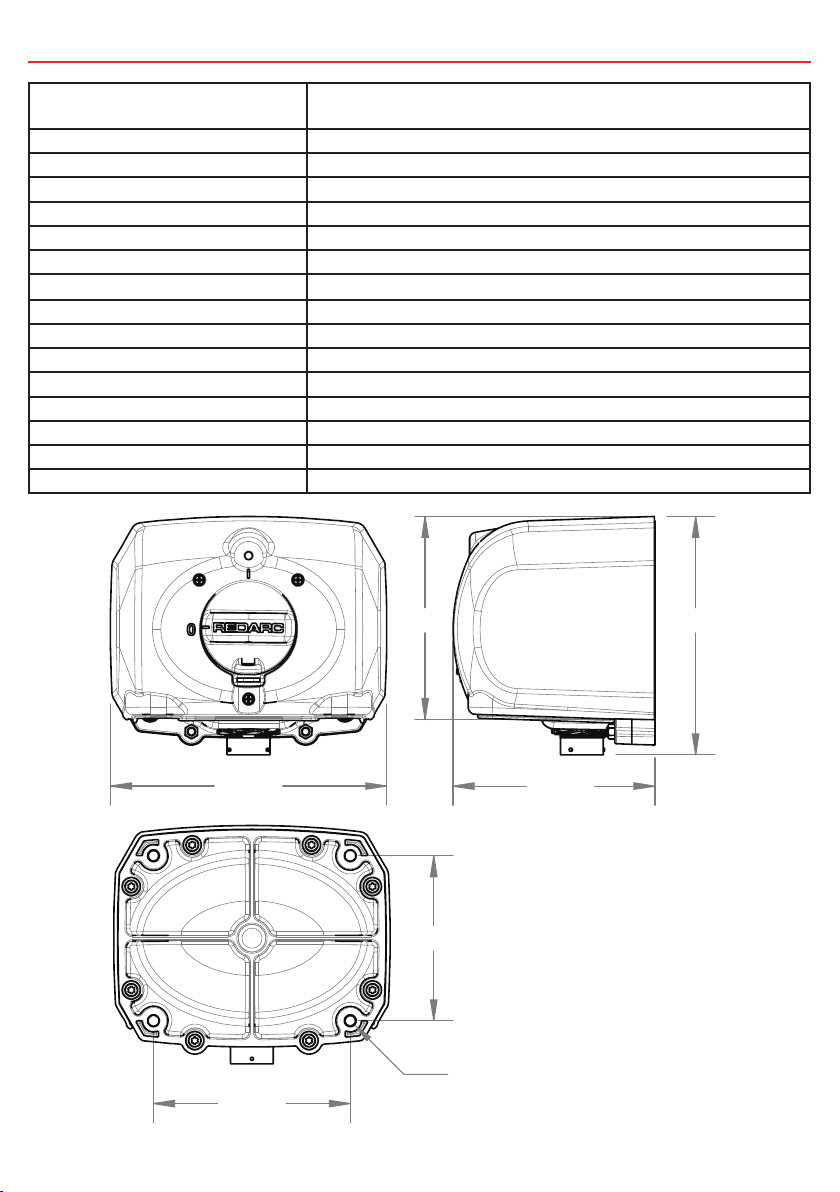

SPECIFICATIONS

Part Numbers BMIS-4PN

BMIS-4PP

Hazardous area protection Not for operation in explosive atmospheres

Housing material GF PBT

Input Voltage 9V to 32V (12V or 24V systems)

Standby Current Draw <30mA

Ambient Operating Temperature -20°C to 70°C

Ambient Operating Humidity 0% to 100%

Current Rating (continuous 20°C) 400A per pole

Current Rating (90s, 20°C) 1500A (12% Duty cycle)

Current Rating (20s, 20°C) 3500A per pole

Field Isolation Current Rating 10A Resistive, 5A (field) inductive

Environmental protection IP66, IP67 & IP69K

Ancillary (Tacho) Current Limit 10mA @ vehicle voltage

Lamp Drive 2W max

Control Inputs (Remote, ROS) 14mA current limited

Weight 3.5kg

218

155

188 160

159

130

ø9mm

3

Page 5

1 INSTALLATION

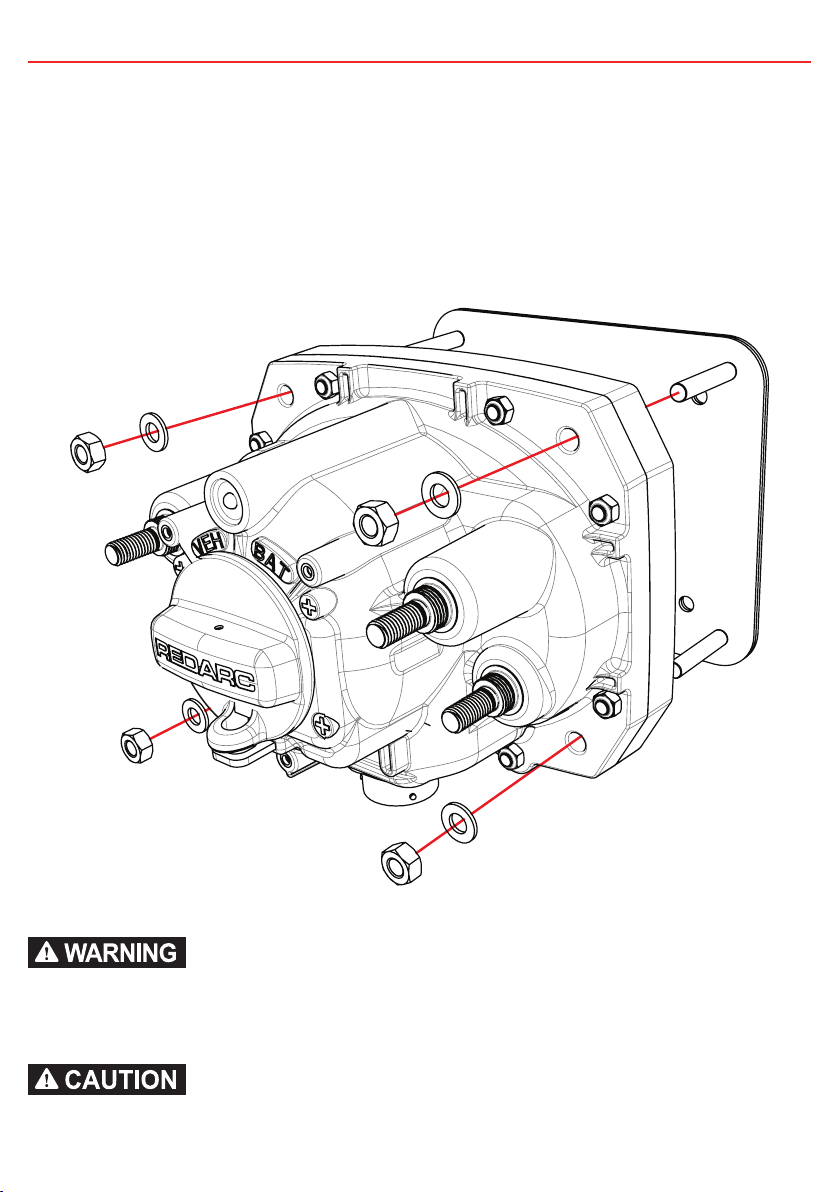

1.1 Mounting the BMIS

STEP 1.

Bolt the BMIS to a mounting plate with 4 x M8 anti-vibration fasteners and large flat

washers as shown (Grade 8.8 minimum). Recommended to use 19mm OD, 1.6mm Flat

washer as a minimum size.

TORQUE: 10Nm then 20Nm in a cross pattern (to avoid stressing the housing)

ENSURE THAT SWITCH IS OFF BEFORE INSTALLING THE BMIS UNIT (MARKED ‘0’).

ENSURE THAT THE BMIS IS MOUNTED IN THE ORIENTATION AS DEPICTED ON A FLAT PLANE OR USING THE

BMIS-AP. ALTERNATIVE ORIENTATION MAY COMPROMISE CORRECT PRODUCT FUNCTION.

DO NOT ATTEMPT TO OPEN THE UNIT BY REMOVING THE REAR COVER. THIS UNIT IS NOT SERVICEABLE.

4

Page 6

1 INSTALLATION

STEP 2.

Wire the power and ground connections in the order shown below.

TORQUE: 20Nm

4

3

2

1

Alternator

B+ Connection

ENSURE THAT ALL WIRES ARE TERMINATED CORRECTLY.

ENSURE THE SWITCH IS IN THE OFF POSITION (MARKED ‘0’) BEFORE COMMENCING THIS STEP.

THE ALTERNATOR B+ CONNECTION IS TO BE CONNECTED TO THE VEHICLE POSITIVE (TERMINAL3). NO

ADDITIONAL WASHERS TO BE USED ON THE TERMINALS. ENSURE CABLES ARE ALIGNED PROPERLY SO

THEY DO NOT INTERFERE WITH RED COVER.

5

Page 7

1 INSTALLATION

STEP 3.

Insert and secure the Data connector, ensuring that pins align correctly before insertion by

aligning the guides on the plug housing.

The wiring diagram for the data connector is on page 10.

A SEALING PLUG SHOULD BE USED IF DATA CONNECTOR IS NOT USED. IF ALTERNATOR FIELD WINDING NOT

CONNECTED, ACTIVATING THE SWITCH MAY NOT STOP THE ENGINE.

ENSURE THE SWITCH IS IN THE OFF POSITION (MARKED ‘0’) BEFORE COMMENCING THIS STEP.

6

Page 8

1 INSTALLATION

STEP 4.

Place cover on unit and secure with 3 x phillips head screws.

TORQUE: 2Nm

THE RED COVER MUST BE INSTALLED TO PROTECT AGAINST ACCIDENTAL SWITCH ACTIVATION. CONFIRM

OPERATION POST INSTALLATION.

7

Page 9

1 INSTALLATION

STEP 5.

Install Remote Switch and Roll Over Sensor / Roll Over Switch (ROS) if required. Refer to

component supplier instructions.

STEP 6.

Test the unit by switching to ‘on’ position (marked ‘1’) and checking that the indicator led is

lit. The unit should stay in the on position.

• If installed, push the remote switch. This should cause the switch to turn off (marked

‘0’). The LED will also turn off. Ensure field winding is isolated.

• If installed, Test by following Roll Over Switch (ROS) instructions.

LED INDICATOR

CLICK

REMOTE SWITCH

8

Page 10

1 INSTALLATION

1.2 Wiring Connections

1.2.1 BMIS-4PN

BMIS-4PN

Redarc supplied

Customer supplied

Vehicle -ve

Vehicle

+ve

Vehicle

Alternator

1.2.2 BMIS-4PP

Vehicle +ve

Vehicle

+ve

Roll Over

Switch

to Alternator

Field Control

BMIS-4PP

Remote

Switch

Battery

-ve

Battery -ve

Battery +ve

Example

Truck

Wiring

Battery +ve

Battery +ve

Example

Truck

Wiring

Dash

Lamp

(Optional - 2W max)

Redarc supplied

Customer supplied

Dash

Lamp

(Optional - 2W max)

Roll Over

Switch

Vehicle

Alternator

to Alternator

Field Control

Remote

Switch

9

Page 11

1 INSTALLATION

1.3 Data Connector Wiring Diagram

Pin Connections

P

E

F

A

G

H

N

D

M

C

B

J

L

K

Pin 8

Pin 5

Pin 3

Pin 6

Pin 1

REDARC ROS1224

BMIS-4PP Variant Only

M

BMIS-4PN Variant Only

M

F

A

G

H

J

DPST-NO

Remote Switch

ABB push button

recommended P/N

CP6-10R-20

DPST NO switch

D

E

Alternator

C

Field Isolation

B

Optional In-Cab

Field Isolation

ROS Warning

Lamp Output

+12v

Ignition

Ancillary Positive to Radio,

Tachograph, ECU,etc.

(10mA max)

Connection

2W

max

Dash

Warning Lamp

P

N

Roll Over Switch

J

K

Ancillary Negative to Radio,

Tachograph, ECU,etc.

L

ROS -

ROS TRIP

ROS +

(10mA max)

F

A

G

H

GND

Accessories Available

Part number Description

BMIS-CK Deutsch Male Connector Kit

BMIS-AP Big Red/Lucas bolt pattern adapter plate.

ENSURE UNUSED HOLES IN THE CONNECTOR ARE FILLED WITH CAVITY PLUGS AS CONTAMINATION INGRESS

MAY DAMAGE THE BMIS OR CONNECTOR.

DO NOT INSERT MULTIPLE WIRES INTO A SINGLE DEUTSCH CONNECTOR TERMINAL TO PREVENT

CONTAMINATION INGRESS.

10

Page 12

1 INSTALLATION

BMIS

Function Recommended

Pin

M BMIS-4PP Variant

GND or Vehicle negative

(connect to chassis)

BMIS-4PN Variant

Ancillary negative output

(10mA)

L Ancillary positive output

(10mA)

N Field Isolation Switch -

Normally open (fused 10A

max)

P Field Isolation Switch –

Common (fused 10A max)

K Warning Lamp (maximum

2W, fused 1A)

C Remote Switch Supply

negative

B Remote Switch Control Low 0.5-1.5mm

D Remote Switch Control High 0.5-1.5mm

E Remote Switch Supply

positive

J ROS-Data-Warning Lamp

Control

H ROS Control High

Trigger Enable

A ROS Control Low

Trigger

G ROS Supply Positive 0.5-1.5mm

F ROS Supply Negative 0.5-1.5mm

Wire Size

0.5-1.5mm

20-16B&S

0.5-1.5mm

20-16B&S

2

2mm

14B&S

2

2mm

14B&S

0.5-1.5mm

20-16B&S

0.5-1.5mm

20-16B&S

20-16B&S

20-16B&S

0.5-1.5mm

20-16B&S

0.5-1.5mm

20-16B&S

0.5-1.5mm

20-16B&S

0.5-1.5mm

20-16B&S

20-16B&S

20-16B&S

Vehicle iROS Liquip

2

Chassis Ancillary memory power

return from Tacho/radio/ECU if

required

2

Ancillary memory power to

Tacho/radio/ECU if required

Alternator field disconnect

Alternator field disconnect

2

Warning lamp to Ignition switch

positive (optional but recommended)

2

Connect via NO switch contact

to B

2

Connect via NO switch contact

to C

2

Connect via NO switch contact

to E

2

Connect via NO switch contact

to D

2

Black

(optional)

2

Connect

to pin G

2

2

2

Green White PIN 5

Brown Red PIN 3

Blue Green &

RS400

ROS1224

N/A PIN 1

(Optional)

REDARC

Connect

PIN 6

to pin G

PIN 8

Grey

2 USER GUIDE

2.1 Operating the BMIS

TO CONNECT TRUCK POWER:

• Turn the Yellow Handle to the ‘ON’ position (marked ‘1’).

• The LED will be lit.

TO DISCONNECT THE TRUCK POWER

• Turn the Yellow Handle to the ‘OFF’ position (marked ‘0’).

• The LED will not be lit.

11

Page 13

2 USER GUIDE

2.2 LED Indication

• The LED is ON when the truck power is Connected.

• The LED is OFF when the truck power is Disconnected.

• The LED is flashing when the BMIS is in fault or in self test mode.

2.3.1 LED Fault & Self-test Conditions

Faults are indicated by flashing of the Warning Lamp and the LED on the unit. If the LED

is on solid, the unit is working correctly.

Flashing for approximately 2 seconds after the ignition is turned ON and for up to 5

seconds after the isolation switch is turned ON is normal. This indicates the unit is

performing a self test and does not indicate a fault.

Flashing at any other time indicates a problem - see section 2.3.2

2.3.2 Flashing LED Diagnosis

If a Roll Over Switch (ROS) is connected, remove the ROS.

• If the flashing stops, there may be an issue with the ROS.

If a remote switch is fitted, disconnect the remote switch and remote switch harness.

• If the flashing stops, there may be an issue with the remote switch or its associated

harness.

If the flashing continues the BMIS may be faulty.

• Check inside ROS connectors for moisture ingress - including signs of terminal

corrosion and water (droplets).

• Check remote switch for moisture ingress - look for signs of water (droplets),

corrosion (on metallic parts and terminals) or ‘high tide marks’ in enclosures and

inside connectors.

• With ROS disconnected and harness disconnected from BMIS (data connector),

measure resistance between harness circuits for remote switch and ROS - any

2 circuits measuring less than 100kΩ must be checked for moisture ingress and

rectified.

• If LED is not lit, check that you have used the correct part (PN or PP) and that the

switch is on.

• If LED remains on after switch is turned off, check that:

• The battery is connected to the correct side of the switch.

• All circuits are connected through the BMIS.

12

Page 14

3 TROUBLESHOOTING

3.1 Remote Switch

If the remote switch does not work, check that all four wires are connected to the contacts

(DPST type) as per the data connector wiring diagram (figure 1.3). The remote switch will

not work if only two wires are connected to a single contact. Do not short wires together

when connected to the remote switch, this will render the remote switch inoperable with

the Redarc BMIS. When installing or diagnosing the remote switch circuit, Test that a

short circuit on either pole of the remote switch does not cause the BMIS to trigger.

3.2 Troubleshooting Flow-Chart

No LED

ROS does not

operate BMIS

during test

Battery voltage in

operating range?

LED Blinking more

than 30sec after

switching on or 2sec

after cranking

Battery voltage in

operating range?

BMIS turns off

unexpectedly

Remote switch does

not operate BMIS

Battery voltage in

operating range?

PP variant?

Yes

Check continuity from

BMIS Pin M to vehicle GND

Not

Connected

Repair Wiring

Connected

Battery voltage in

operating range?

No

Charge or

replace battery

Yes

Does remote switch

operate BMIS?

No

No Yes Yes

Yes No Ye s

BMIS may be faulty

No

Do shorting pins

H+G and F+A

operate the BMIS?

No Yes

ROS or wiring

may be faulty

Check remote switch

wiring for shorts

or water ingress

OK Not OK

No

Charge or

replace battery

Disconnect ROS Disconnect ROS

BMIS works

correctly

Stops

blinking

Remains

blinking

Disconnect

remote switch

Remains

blinking

Stops

blinking

Still does

not work

Disconnect

remote switch

Still does

not work

BMIS works

Remote switch or

wiring may be faulty

Repair Wiring

correctly

No

Shorts between

remote switch wires?

Yes

Check continuity from

BMIS to remote switch

Connected

Do shorting pins

B+C and D+E

operate the BMIS?

Yes

No

Not

Connected

Repair Wiring

Contact Supplier

13

Page 15

3 TROUBLESHOOTING

3.3 Battery not charging

Check alternator field connections.

• Bridge the field isolation connection at the alternator to verify correct operation.

• Bridge the BMIS harness

4 FAQS

Question: Is the unit protected against voltage spikes?

Answer: Yes, the BMIS incorporates a number of spike protection components

specifically designed to reduce the risk of damaging the unit. The BMIS is also

designed to prevent any spikes being generated by the unit and in turn affecting any

vehicle equipment.

Question: What does the LED indicate?

Answer: The LED indicates the unit is activated and power is available to the vehicle.

A flashing red LED indicates a fault except during the first 5 seconds after turning the

isolation switch on. See section 2.3.1 on page 12.

Question: Can I use the BMIS to shut off the engine?

Answer: Do NOT routinely use the BMIS to shut off the engine except in an emergency

or for routine testing. Use the ignition key as per normal vehicle operation.

It’s recommended to perform an engine shutdown test on a fully charged battery (or

allow a few minutes of engine operation beforehand to recharge the battery as much

as possible). Following these recommendations will minimise the possibility of damage

and/or accelerated wear to vehicle electrical systems.

5 TECH TIPS

When mounting - ensure torque in 2 stages, criss-cross method with torque wrench

Do NOT install star washers between cable lugs and terminals

Ensure cables are straight and do not interfere with the cover/fascia

Flashing LED - check for water or fault connection in wiring harness

Remote switch requires dual pole to operate the BMIS

Make sure the mating Deutsch connector has blanking plugs installed to prevent

potential water ingress

14

Page 16

6 MAINTENANCE & CLEANING

If the BMIS is installed or used in dirty conditions, check and clean on a regular basis.

Do not open the Unit by removing the rear cover.

Clean the unit with warm, soapy water.

• Do Not high pressure clean.

• Periodically check that the screws and nuts are tight and for correct torque on

power on battery and starter motor connections.

• Periodically check isolation switch function in accordance with warnings found on

page 1 of this manual.

DO NOT ALTER OR DISASSEMBLE THE BMIS UNDER ANY CIRCUMSTANCES. THERE ARE NO USER SERVICEABLE

PARTS INSIDE. THE BMIS IS NOT SERVICEABLE AND IS LUBRICATED FOR LIFE. THE BMIS MUST BE RETURNED

TO YOUR SUPPLIER FOR ASSESSMENT. INCORRECT HANDLING, DISASSEMBLY OR REASSEMBLY MAY RESULT IN

A RISK OF ELECTRIC SHOCK OR FIRE AND MAY VOID THE UNIT WARRANTY.

15

Page 17

7 STANDARDS & TESTING

7.1 Standards and Testing

The BMIS 4-PP and 4-PN are Tested/Certified to:

Reference Title

IEC 60529 IP66/67 Degree of protection provided by enclosures

UL94 Tests for flammability of plastic materials for parts in devices and appliances

AS/NZS CISPR 11

GROUP 1 CLASS A

ISO60068-2-74 (MOD)

ISO 8092-2

SAE J1113-11,-12

ISO 7637-2

ISO 11452-10

SAE J1113-4,-21

ISO 11452-2,-4

CISPR25 (MOD)

CLASS 3

IEC 60068-2-30

IEC 60068-2-38

ISO 60068-2-2 Accelerated temperature aging test for electrical and electronic components

ASTM D3170 Gravel bombardment test for electrical and electronic components

ASTM B117 1000Hrs Salt-fog test for electrical and electronic components

ISO 16750-3

IEC 60068-2-64

TEST VII

ISO 10605 Electrostatic discharge (ESD) immunity test requirements

IEC 60068-2-14

ISO 16750-4

IEC 60068-2-2

ISO 16750-4

IEC 60068-2-1

ISO 16750-4

Industrial, scientific and medical (ISM) RF equipment electromagnetic

disturbance characteristics.

Resistance to automotive fluids

Electrical transients for electrical and electronic devices

Electromagnetic-radiated-immunity requirements for electrical and electronic

components

Electromagnetic-radiated emissions for electrical and electronic components

Humidity testing for electrical components

Vibration requirements for electrical/electronic devices, Commercial Vehicle

6g

Temperature cycling test for electrical and electronic components

High temperature test for electrical and electronic components

Low temperature test for electrical and electronic components

16

Page 18

8 NOTES

17

Page 19

9 TWO YEAR PRODUCT WARRANTY

Over the last three decades our company has established a reputation as the power conversion specialist.

A 100% Australian-owned company, we have met the needs of customers in transport and other industries through exciting, innovative thinking.

We believe in total customer satisfaction and practice this by offering our customers:

• Technical advice free of jargon and free of charge

• Prompt turnaround of orders throughout Australia and globally

• Friendly, personalised, professional service and product support

In the unlikely event that a technical issue arises with a Redarc product, customers are encouraged to initially contact the Redarc Technical Support Team on (08) 8322 4848

or power@redarc.com.au for prompt and efficient diagnosis and product support.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and compensation for

any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

The benefits of this Warranty are in addition to other rights and remedies available at law in respect of the Products and shall not derogate from any applicable mandatory statutory

provisions or rights under the Australian Consumer Law.

Redarc Electronics Pty Ltd atf the Redarc Trust trading as Redarc Electronics (“Redarc”) offers a warranty in respect of its Products where the Products are purchased from an

authorised distributor or reseller of Redarc by a person (“Purchaser”), on the terms and conditions, and for the duration, outlined below in this document (“Warranty”).

1. In this Warranty, the term Products means:

1.1 all products manufactured or supplied by Redarc (excluding its solar products

which are covered by Redarc’s Solar Product Warranty); and

1.2 any component of or accessory for any product in clause 1.1 manufactured or

supplied by Redarc.

Offer and duration of product warranties

2. Redarc warrants that its Products will be free, under normal application, installation,

use and service conditions, from defects in materials and workmanship affecting

normal use, for 2 years from the date of purchase (Warranty Period).

3. Where a Product malfunctions or becomes inoperative during the Warranty Period,

due to a defect in materials or workmanship, as determined by Redarc, then subject

to further rights conferred by the Australian Consumer Law on the Purchaser,

Redarc will, in exercise of its sole discretion, either:

3.1 repair the defective Product;

3.2 replace the defective Product; or

3.3 provide a refund to the Purchaser for the purchase price paid for the defective

Product,

without charge to the Purchaser.

4. The warranty given by Redarc in clause 3 covers the reasonable costs of delivery

and installation of any repaired or replaced Products or components of Products

to the Purchaser’s usual residential address notified to Redarc, together with the

reasonable costs of removal and return of any Products determined by Redarc to be

defective.

5. If the Purchaser incurs expenses of the nature referred to in clause 4 in the

context of making a claim pursuant to this Warranty that is accepted by Redarc,

the Purchaser will be entitled to claim for reimbursement of those expenses which

Redarc determines, in exercise of its sole discretion, to be reasonably incurred,

provided that the claim is notified to Redarc in writing at the postal address or email

address specified in clause 21 and includes:

5.1 details of the relevant expenses incurred by the Purchaser; and

5.2 proof of the relevant expenses having been incurred by the Purchaser.

Exclusions and limitations

6. This Warranty will not apply to, or include any defect, damage, fault, failure

or malfunction of a Product, which Redarc determines, in exercise of its sole

discretion, to be due to:

6.1 normal wear and tear or exposure to weather conditions over time;

6.2 accident, misuse, abuse, negligence, vandalism, alteration or modification;

6.3 non-observance of any of the instructions supplied by Redarc, including

instructions concerning installation, configuring, connecting, commissioning,

use or application of the Product, including without limitation choice of location;

6.4 failure to ensure proper maintenance of the Product strictly in accordance with

Redarc’s instructions or failure to ensure proper maintenance of any associated

equipment or machinery;

6.5 repairs to the Product that are not strictly in accordance with Redarc’s

instructions;

6.6 installation, repairs or maintenance of the Product by, or under the supervision

of, a person who is not a qualified auto electrician or technician, or if nongenuine or non-approved parts have been fitted;

6.7 faulty power supply, power failure, electrical spikes or surges, lightning, flood,

storm, hail, extreme heat, fire or other occurrence outside the control of

Redarc;

6.8 use other than for any reasonable purpose for which the Product was

manufactured;

6.9 any indirect or incidental damage of whatever nature outside the control of

Redarc.

7. Warranty claims in respect of a Product must be made in writing to Redarc at the

postal address or email address specified in clause 21 within the Warranty Period.

Such claims must include the following:

7.1 details of the alleged defect or fault and the circumstances surrounding the

defect or fault;

7.2 evidence of the claim, including photographs of the Product (where the subject

of the claim is capable of being photographed);

7.3 the serial number of the Product, specified on the label affixed to the Product;

and

7.4 proof of purchase documentation for the Product from an authorised distributor

or reseller of Redarc, which clearly shows the date and place of purchase.

The return of any Products without the prior written instructions of Redarc will not

be accepted by Redarc.

8. Without limiting any other clause in this Warranty, Redarc has the right to reject any

Warranty claim made by a Purchaser pursuant to this Warranty where:

8.1 the Purchaser does not notify Redarc in writing of a Warranty claim within the

Warranty Period;

8.2 the Purchaser does not notify Redarc in writing of a Warranty claim within 1

month of becoming aware of the relevant circumstances giving rise to the

claim, so that any further problems with the Product are minimised;

8.3 the serial number of the Product has been altered, removed or made illegible

without the written authority of Redarc;

8.4 the Purchaser is unable to provide proof of purchase documentation in

accordance with clause 7.4 or evidence that the Product was properly installed

and removed (if relevant), and that proper maintenance has been performed

on the Product, by, or under the supervision of, a qualified auto electrician or

technician, in accordance with the instructions of Redarc.

9. If the Product is found to be working satisfactorily on return to Redarc or upon

investigation by Redarc, the Purchaser must pay Redarc’s reasonable costs of

testing and investigating the Product in addition to shipping and transportation

charges. Where Redarc is in possession of the Product, the Product will be

returned to the Purchaser on receipt of the amount charged.

10. Any replaced Products or components of Products shall become the property of

Redarc.

11. Redarc may, in exercise of its sole discretion, deliver another type of Product or

component of a Product (different in size, colour, shape, weight, brand and/or

other specifications) in fulfilling its obligations under this Warranty, in the event

that Redarc has discontinued manufacturing or supplying the relevant Product or

component at the time of the Warranty claim, or where such Product or component

is superior to that originally purchased by the Purchaser.

Other conditions of Warranty

12. If the Purchaser acquired a Product for the purpose of resupply, then this Warranty

shall not apply to that Product.

13. In particular, the sale of a Product via an online auction, online store or other

internet website by a party that is not an authorised distributor or reseller of the

Product will be deemed to be a resupply within the meaning of the Australian

Consumer Law and will render this Warranty void, as Redarc has no control over the

storage, handling, quality or safety of Products sold by such persons.

14. A Purchaser shall only be entitled to the benefit of this Warranty after all amounts

owing in respect of the Product have been paid.

15. While Redarc warrants that the Products will be free from defects in materials and

workmanship in the circumstances set out in this Warranty, to the maximum extent

permitted by law Redarc does not warrant that the operation of the Products will be

uninterrupted or error-free.

16. To the maximum extent permitted by law, Redarc’s determination of the existence of

any defect and the cause of any defect will be conclusive.

17. Spare parts or materials for the Products are guaranteed to be available for a period

of at least 2 years after purchase of the Products.

18. The agents, officers and employees of any distributor or reseller of the Products and

of Redarc are not authorised to vary or extend the terms of this Warranty.

19. Redarc shall not be responsible or liable to the Customer or any third party in

connection with any non-performance or delay in performance of any terms and

conditions of this Warranty, due to acts of God, war, riots, strikes, warlike conditions,

plague or other epidemic, fire, flood, blizzard, hurricane, changes of public policies,

terrorism and other events which are beyond the control of Redarc. In such

circumstances, Redarc may suspend performance of this Warranty without liability

for the period of the delay reasonably attributable to such causes.

20. If a clause or part of a clause in this Warranty can be read in a way that makes it

illegal, unenforceable or invalid, but can also be read in a way that makes it legal,

enforceable and valid, it must be read in the latter way. If any clause or part of

a clause in this Warranty is illegal, unenforceable or invalid, that clause or part is

to be treated as removed from this Warranty, but the rest of this Warranty is not

affected.

Redarc’s contact details

21. Redarc’s contact details for the sending of Warranty claims under this Warranty are:

REDARC Electronics Pty Ltd

23 Brodie Road (North), Lonsdale SA 5160

Email: power@redarc.com.au

Telephone: +61 8 8322 4848

18

Page 20

Free technical assistance!

please contact

REDARC Electronics

23 Brodie Road North, Lonsdale SA

+61 8 8322 4848

power@redarc.com.au

www.redarc.com.au

Copyright © 2017 REDARC Electronics Pty Ltd. All rights reserved.

WARBMIS - REV8

www.redarc.com.au

Loading...

Loading...