Page 1

USE AND INSTALLATION

MANUAL

EN

COD.8901113900

Page 2

Contents Technical dept. - All rights reserved - Reproduction prohibited

1. GENERAL INFORMATION ..................................................................................................... 3

1.1. Symbols used in this manual ................................................................................................... 3

1.2. Proper appliance use............................................................................................................... 3

2. GUARANTEE TERMS .............................................................................................................. 5

2.1. Warnings ............................................................................................................................... 5

The guarantee applies, provided that: .................................................................................................. 5

2.2. Exclusions .............................................................................................................................. 5

2.3. Additional clauses ................................................................................................................... 6

2.4. Liability .................................................................................................................................. 6

2.5. Court with jurisdiction ............................................................................................................. 6

2.6. Liability exclusion.................................................................................................................... 6

2.7. Service call ............................................................................................................................. 7

2.8. Installation standards .............................................................................................................. 7

3. TECHNICAL SPECIFICATIONS AND DIMENSIONS ............................................................... 8

3.1. General information on hot water boilers .................................................................................. 8

3.2. TECNIKA 28-35 boiler description ............................................................................................. 8

3.3. Technical data ........................................................................................................................ 9

3.4. Boiler fuel supply .................................................................................................................. 11

3.5. Main components ................................................................................................................. 12

4. INSTALLING A "TECNIKA" HOT WATER BOILER ................................................................ 16

4.1. Packaging ............................................................................................................................ 16

4.2. Boiler room .......................................................................................................................... 16

4.3. Connection to the flue pipe .................................................................................................... 17

4.3.1 Roof outlet along an external steel flue pipe ........................................................................ 19

5.3.1 Roof outlet along a traditional flue pipe ............................................................................... 20

4.4. System connection ................................................................................................................ 21

4.5. Filling the system.................................................................................................................. 21

4.6. Basic requirements for installing “Tecnika” hot water gasification boiler to allow simple

maintenance and servicing: ............................................................................................................... 22

5. OPERATION ........................................................................................................................ 29

5.1. “Tecnika” hot water wood gasification boiler interface control panel .......................................... 29

6. START-UP PROCEDURES .................................................................................................... 31

6.1. Basic requirements ............................................................................................................... 31

6.2. Electrical connections ............................................................................................................ 32

6.3.1 Wiring diagram ................................................................................................................. 33

6.3. Boiler start-up preparation procedure ..................................................................................... 34

6.4. Igniting the fuel and heating the boiler ................................................................................... 34

6.5. Adjusting the air flow control thermal valve ............................................................................ 36

6.6. Nominal operating mode of the boiler ..................................................................................... 37

6.7. Fuel hopper loading .............................................................................................................. 38

6.8. Adjusting boiler operating parameters .................................................................................... 40

6.9. Boiler operation in stand-by mode .......................................................................................... 43

6.10. Boiler shutdown ................................................................................................................... 43

7. TROUBLESHOOTING ........................................................................................................... 45

8. CLEANING AND MAINTENANCE ......................................................................................... 47

8.1. Instructions for inspection and maintenance ........................................................................... 47

8.2. Training and end user demonstration of maintenance and adjustment procedures of the boiler ... 53

Page 3

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

1

page 3

General information Technical dept. - All rights reserved - Reproduction prohibited

General information

The user is NOT permitted to service this boiler.

The manufacturer cannot be held liable for personal injury, harm to animals or property damage resulting

from failure to observe the instructions contained in the manuals supplied with the boiler.

1. GENERAL INFORMATION

1.1. Symbols used in this manual

When reading this manual, pay particular attention to the parts marked with symbols. These symbols are

used to give the following warnings:

1.2. Proper appliance use

The instruction manual is an integral and essential part of the product and must be kept by the user or

system manager.

Read the warnings contained in the manual carefully, since they provide important information about safe

installation, use and maintenance.

Keep the manual in a safe place for future reference.

Installation and maintenance must be performed in compliance with the applicable regulations according to

the manufacturer's instructions and by qualified personnel trained pursuant to the law.

Incorrect installation or improper maintenance could cause personal injuries, harm to animals or property

damage, for which the manufacturer will not be held liable.

Before carrying out any cleaning or maintenance operations, disconnect the appliance from the mains power

supply using the system switch and/or the relevant cut-off components and close all cocks.

If the appliance has a fault and/or is not operating correctly, switch the appliance off and do not make any

attempt to repair it or service it directly. Contact authorised personnel only. Any repairs to products must be

carried out using only original spare parts. Failure to observe the above recommendations may compromise

the safety of the appliance.

If the appliance is sold or transferred to a new owner or the owner moves, leaving the appliance in situ,

always ensure that the manual is kept with the appliance so that it can be consulted by the new owner

and/or installer.

For all appliances with optional equipmement or kits (including electrical kits) use only original accessories.

This appliance must be used only for the use expressly intended. Any other use is to be considered incorrect

and therefore dangerous.

DANGER!

Serious risk to safety

and to life

CAUTION!

Potentially hazardous

situation for the product and

the environment

NOTE!

Recommendations for

users

Page 4

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

1

page 4

General information Technical dept. - All rights reserved - Reproduction prohibited

The TECNIKA appliance has been built according to the latest technologies and in

accordance with the applicable technical safety regulations.

Nonetheless, the incorrect use of the appliance may result in hazards and also endanger the

user or others, or even damage the appliance or other objects.

The appliance is intended for the operation of hot water heating systems.

Appliance use in accordance with the envisaged purposes includes scrupulous observance of

the instructions provided in this manual.

RED reserves the ri

g

ht to make any changes to the design and factory settings of the burner and hot water

boiler without having to inform the end users of such changes.

Page 5

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

2

page 5

Guarantee term Technical dept. - All rights reserved - Reproduction prohibited

2. GUARANTEE TERMS

The Manufacturer guarantees the product, with the exception of parts subject to normal wear specified

below, for two years from the date of purchase, provided that proof of purchase is supplied in a document

specifying the name of the retailer and the date the sale was made and that the completed guarantee

certificate was sent within 8 days of said purchase. The product must also be installed and tested by a

specialised installer and in accordance with the detailed instructions provided in the instruction manual that

accompanies the product.

The guarantee covers the replacement or free repair of parts recognised as being faulty at source due to

manufacturing defects.

2.1. Warnings

Installation, electrical connection, functional check and maintenance of this appliance must only be

performed by qualified or authorised personnel.

This appliance must not be used by anyone (including children) with reduced physical, sensory or

mental skills and with little experience and knowledge, unless they are supervised or have been

instructed to use the appliance by the person in charge of its safety.

The guarantee applies, provided that:

1. The boiler is installed, in accordance with the applicable standards in force and the instructions

provided in the product use, maintenance and installation manual, by legally qualified personnel

(Italian Ministerial Decree no. 37 of 22

nd

January 2008);

2. The customer holds the documentation certifying its suitability in all parts:

a. INSTALLATION REPORT - filled in by the installer

b. TEST REPORT and GUARANTEE APPLICATION - filled in by an authorised serviceman

c. The guarantee applies from the date of first start-up of the boiler, which must be

indicated on the boiler manual or from the invoice date. This documentation must be

presented to the authorised service centre in the event of servicing.

2.2. Exclusions

The guarantee does not cover any parts found to be faulty due to negligence or inappropriate use, incorrect

maintenance, or installation not performed in compliance with the manufacturer's instructions. The

manufacturer will not be held liable for any damage which may - either directly or indirectly - be caused to

persons, animals or property resulting from failure to observe all the instructions provided in this manual

and, specifically, concerning the warnings regarding installation, use and maintenance of the appliance.

The guarantee is not valid if:

1. The terms for the guarantee application were not observed.

2. Installation was not performed in observance of the applicable standards in force and the

instructions provided in the use, maintenance and installation manual.

Page 6

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

2

page 6

Guarantee term Technical dept. - All rights reserved - Reproduction prohibited

The guarantee does not cover:

1. Damage made by atmospheric agents, chemicals, electrochemical elements, incorrect product use,

natural disasters, electrical discharges, fires, faults in the electrical system, modifications to or

tampering with the product, and/or other causes not ensuing from the product manufacturing

2. Damage caused by normal corrosion

3. Damage relating to the combustion chamber

4. Damage to seals, claddings, painted/chromed parts, handles and electrical wires

5. Damage to masonry work

6. Damage to parts of the system for the production of DHW not supplied by RED

7. Damage to the heat exchanger if a suitable condensation-proof circuit is not set up to guarantee a

minimum boiler return temperature of at least 55 °C.

8. Servicing for calibration or product adjustments

9. Incorrect or negligent use.

10. All damage caused by transport; we consequently advise you to check the goods carefully upon

receipt, notifying your retailer immediately of any damage, making a note on the delivery note and

on the copy that travels with the carrier.

Please contact your retailer and/ or local importer in the event of product failure.

RED will not be held liable for any damage which may - either directly or indirectly - be caused to property,

or personal injury or harm to animals ensuing from failure to observe all the instructions provided herein and

the applicable regulations regarding installation, use and maintenance of the appliance.

The parts replaced will be guaranteed for the remaining guarantee cover period starting from the original

date of purchase of the product.

2.3. Additional clauses

If faulty or malfunctioning parts are detected during normal product use, these will be replaced free of

charge ex retailer who made the sale or ex our local technical service centre.

For products sold abroad, the same circumstances will again result in free replacement, ex our retailer, with

the exception of specific conditions agreed upon at the time of negotiations with the foreign distributor.

In the case of replaced parts, the guarantee will not be extended.

No damages are awarded for the product downtime period.

This is the only applicable guarantee and no-one is authorised to provide any other guarantees in the name

of or on behalf of RED.

2.4. Liability

RED will not pay any compensation for direct or indirect damage caused by or dependent upon the product.

2.5. Court with jurisdiction

In the event of any controversy, the court with jurisdiction is the Court of Pordenone (Italy).

2.6. Liability exclusion

The manufacturer is not able to supervise the observance of the instructions provided in this manual. Nor is

it able to monitor the conditions and methods of installation, operation, use and maintenance of the product.

Incorrect installation could cause damage and endanger persons. Consequently, we cannot be held in any

Page 7

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

2

page 7

Guarantee term Technical dept. - All rights reserved - Reproduction prohibited

way liable for losses, damage or costs ensuing from incorrect installation, improper functioning and incorrect

use and maintenance or in any way connected to the latter. Similarly, we will not be held in any way liable

for any violations of patents or third party rights ascribable to the use of this product.

The manufacturer reserves the right to make any changes to the product, technical specifications or to the

manual without notice.

If hazard-free operation is no longer possible (for instance, due to visible damage), turn off the appliance

immediately.

2.7. Service call

Service calls must be made to the retailer, who will forward the call to the technical support department.

The manufacturer cannot be held liable if the product and any of its accessories are used incorrectly or

modified without authorisation.

Only original spare parts must be used for replacements.

2.8. Installation standards

Tecnika 28-35 is wood-fired boiler.

It must be installed according to the provisions of the following standards:

Italian Law Decree no. 93 of 25

th

February 2000

Implementation of Directive 97/23/EC (P.E.D.) on the subject of pressure equipment.

SCOPE OF APPLICATION: liquid fuel (naphtha, gas oil, fuel oil) and solid fuel operated appliances.

ITALIAN LAW no. 46 of 5

th

March 1990 and related applicative regulations Italian Ministerial Decree no.

447 of 6

th

December 1991 (and subsequent amendments)

System safety standards

SCOPE OF APPLICATION: without limits to heat potential.

Standard UNI 10847 of 03/2000

Single flue systems for liquid and solid fuel generators. Maintenance and control. Guidelines and procedures.

SCOPE OF APPLICATION: liquid and solid fuel operated systems.

ITALIAN LAW of 9

th

January 1991 No. 10 and related applicative regulations Italian Ministerial Decree

no. 412 of 26

th

August 1993 (and subsequent amendments), Italian Ministerial Decree no. 551 of 21

st

December 1999.

Regulations specifying amendments to Italian Presidential Decree 412 on the subject of planning, installing,

running and servicing heating systems in buildings for the purposes of limiting energy consumption.

SCOPE OF APPLICATION: without limits to heat potential.

ITALIAN LAW NO. 186 of 01.03.1968

Installation standard CEI 64-8 / II ed.

Electrical utility systems at a nominal voltage of no more than 1000 V in alternating current and 1500 V in

direct current.

Installation standard CEI 64-8 / I ed.

Electrical utility systems in buildings intended for residential and similar purposes.

Page 8

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

3

page 8

Technical specifications and dimensions Technical dept. - All rights reserved - Reproduction prohibited

3. TECHNICAL SPECIFICATIONS AND DIMENSIONS

3.1. General information on hot water boilers

"TECNIKA" hot water wood gasification boilers are have a steel structure and use solid biomass, in the form

of wood logs, as fuel. The boiler is designed for connection to hot water heating systems.

Tecnika boilers comply with P.E.D. 97/23/EC.

TECNIKA series hot water wood gasification boilers consist of the following components:

"TECNIKA" hot water boiler - 1 (one)

ceramic ducting element in combustion chamber - 1 (one)

thermal valve for controlling air flow rate - 1 (one)

steel brush for cleaning ashes - 1 (one)

ash scraper – 1 (one)

"TECNIKA" series hot water boiler use and instruction manual - 1 (one).

3.2. TECNIKA 28-35 boiler description

The "TECNIKA" hot water boiler heat exchanger complies with the operating requirements of this type of

appliance, as set out in the operation standard:

EN 303-5/2000.

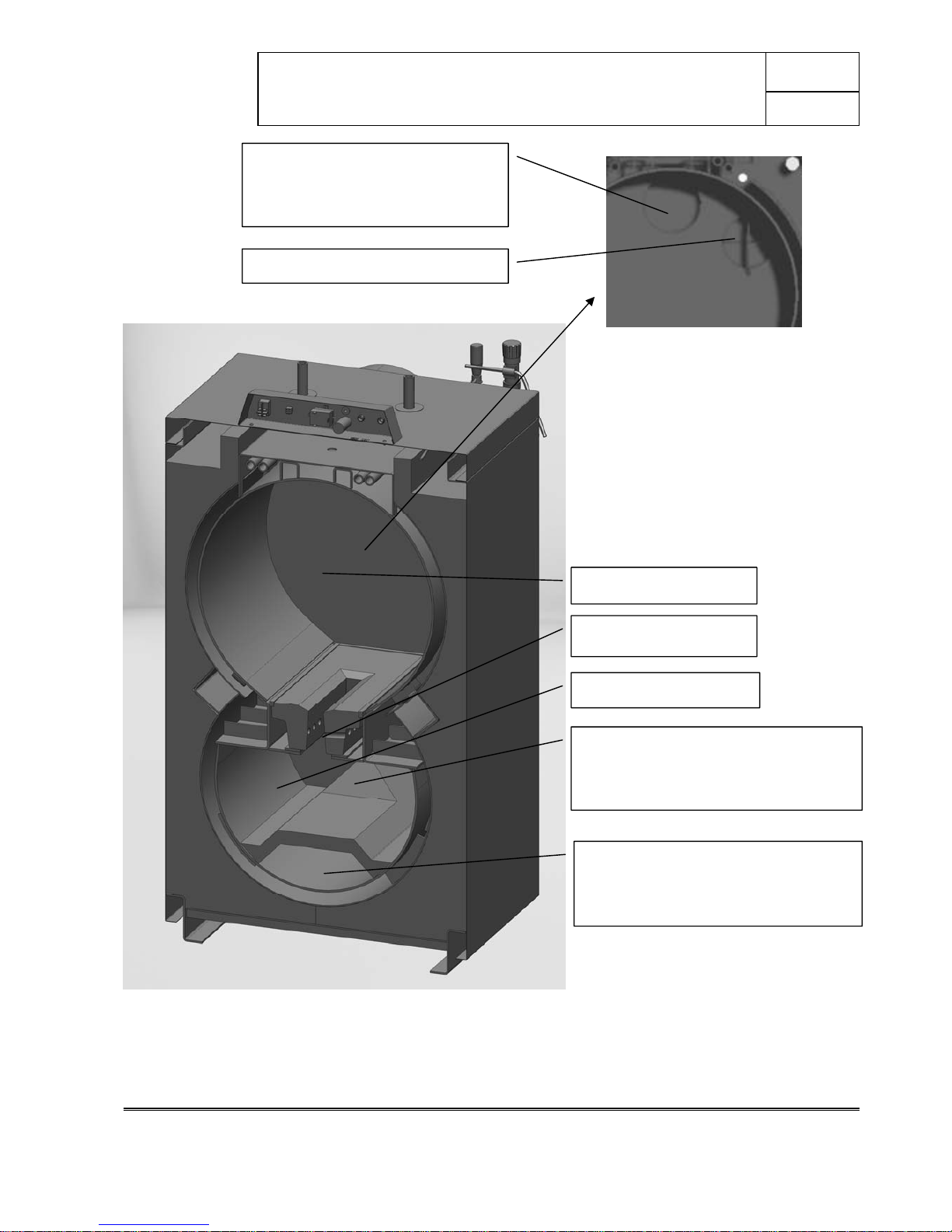

The hot water boiler consists of the following components/modules:

heat exchanger, consisting of a welded steel plate structure. The upper part of the boiler

accommodates the fuel hopper which is manually filled with wood logs. The fuel chamber is the ideal

environment for the fuel pyrolysis process and volatile gases are conveyed towards the lower section

of the boiler, where they are oxidised in the combustion chamber. The combustion chamber contains

a ceramic coating, a nozzle and a combustion gas ducting element to ensure combustion process

efficiency;

comb ustion nozzle, made of ceramic material, positioned in the lower section of the fuel hopper

to ensure optimal conditions for combustion process efficiency;

ceramic ducting element, positioned in the boiler combustion chamber allows high temperature

levels and guarantees optimal fuel oxidation;

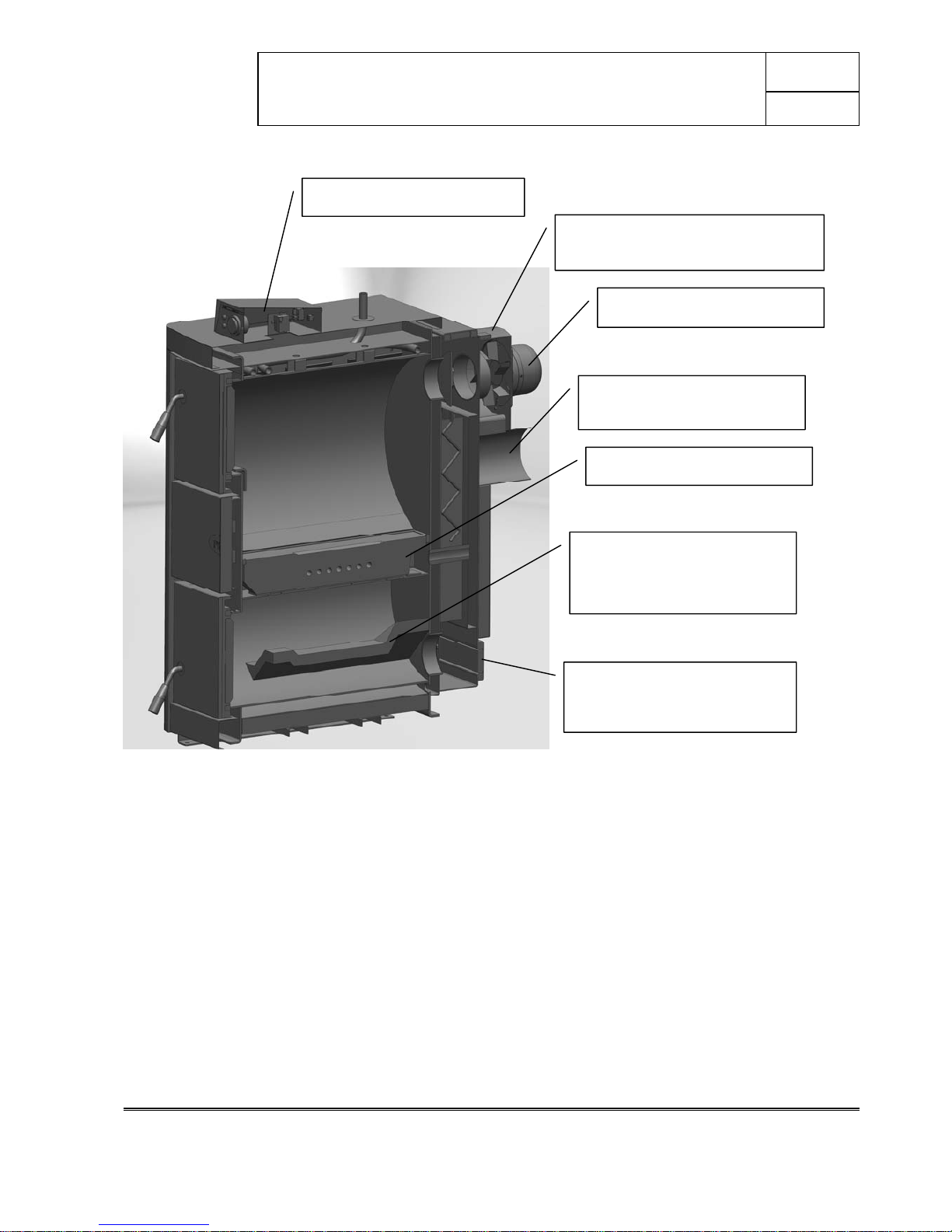

combustion gas fan fitted on the back of the boiler conveys combustion gases outside the boiler

and controls its operation;

air distrib ution box, provided with primary air control valve. This box doubles as heat exchanger

and pre-heats the ambient air before it is used in the combustion chamber of the boiler. The inlet of

this box is provided with an inlet control fin actuated by a thermostat valve and controls the air

taking into the boiler;

Page 9

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

3

page 9

Technical specifications and dimensions Technical dept. - All rights reserved - Reproduction prohibited

hydraulic connections, have female threading (see table for dimensions) and are positioned in

the lower rear left part of the heat exchanger along the return line and in the upper rear left part of

the boiler along the flow line;

exhaust connection has female threading (see table for dimensions) and must be connected to

the exhaust valve;

emergency cooling coil is used for emergency cooling of the water circulating the heat exchanger

of the boiler when the water is very hot. The coil has a G½” male union threading;

comb ustion gas outlet duct (external diameter shown in Table 2.2) is located in the upper rear

part of the boiler;

the heat exchanger is thermally insulated with mineral wool to minimise thermal dispersion;

doors of the fuel hopper and the combustion chamber are made of cast iron to ensure high thermal

resistance and sealing of the boiler;

external casing of the boiler is made with sheet steel.

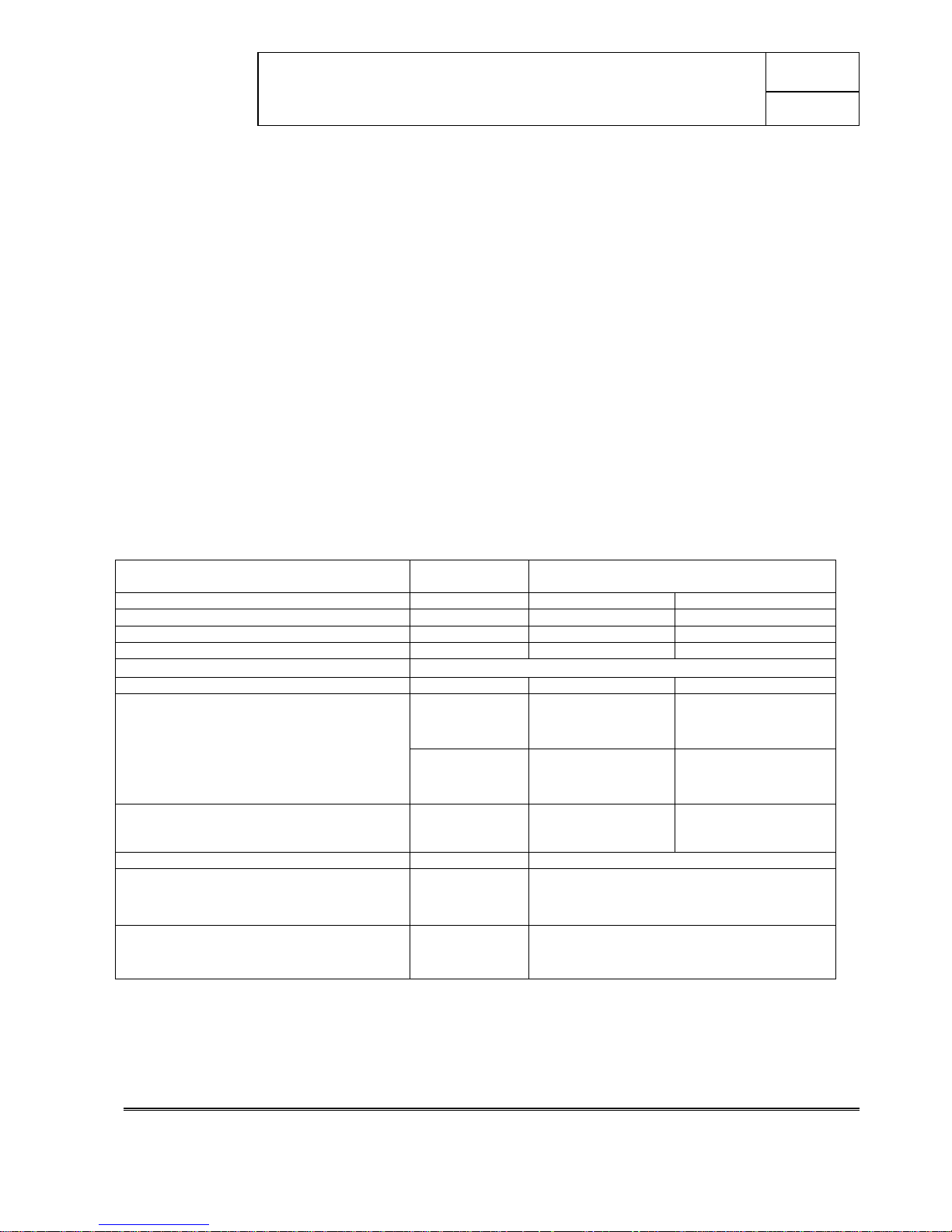

3.3. Technical data

Thermal and technical data of “TECNIKA” hot water wood gasification boilers:

PARAMETERS UNIT OF

MEASURE

VALUES

MODEL 28 35

HEAT OUTPUT AT COMBUSTION CHAMBER kW 28 35

NOMINAL HEAT OUTPUT kW 25 30

OPERATING RANGE (min-max) kW 13-25 15-30

SOLID FUEL USED

Wood logs for heating, max. water content 20%

WOOD LOG CONSUMPTION RATE (min-max) kg/h 3,7-6,9 5,1-9,7

FRESH AIR RATE REQUIRED FOR EFFICIENT

COMBUSTION PROCESS AND BOILER

OPERATION

kg/h 80-95 110-130

m3/h 55-70 100-110

AVERAGE WOOD LOG CONSUMPTION RATE

(the boiler operates in a normal heating

system)

kg/h 4.7 6.7

HEATING EFFICIENCY (min-max) % 85

TEMPERATURE OF COMBUSTION GASES AT

NOMINAL HEAT OUTPUT

°C 180-230

SOLID FUEL RESIDUE ASH

The quantity depends on the ash contents of

the raw fuel, as well as on the operating

conditions

Page 10

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

3

page 10

Technical specifications and dimensions Technical dept. - All rights reserved - Reproduction prohibited

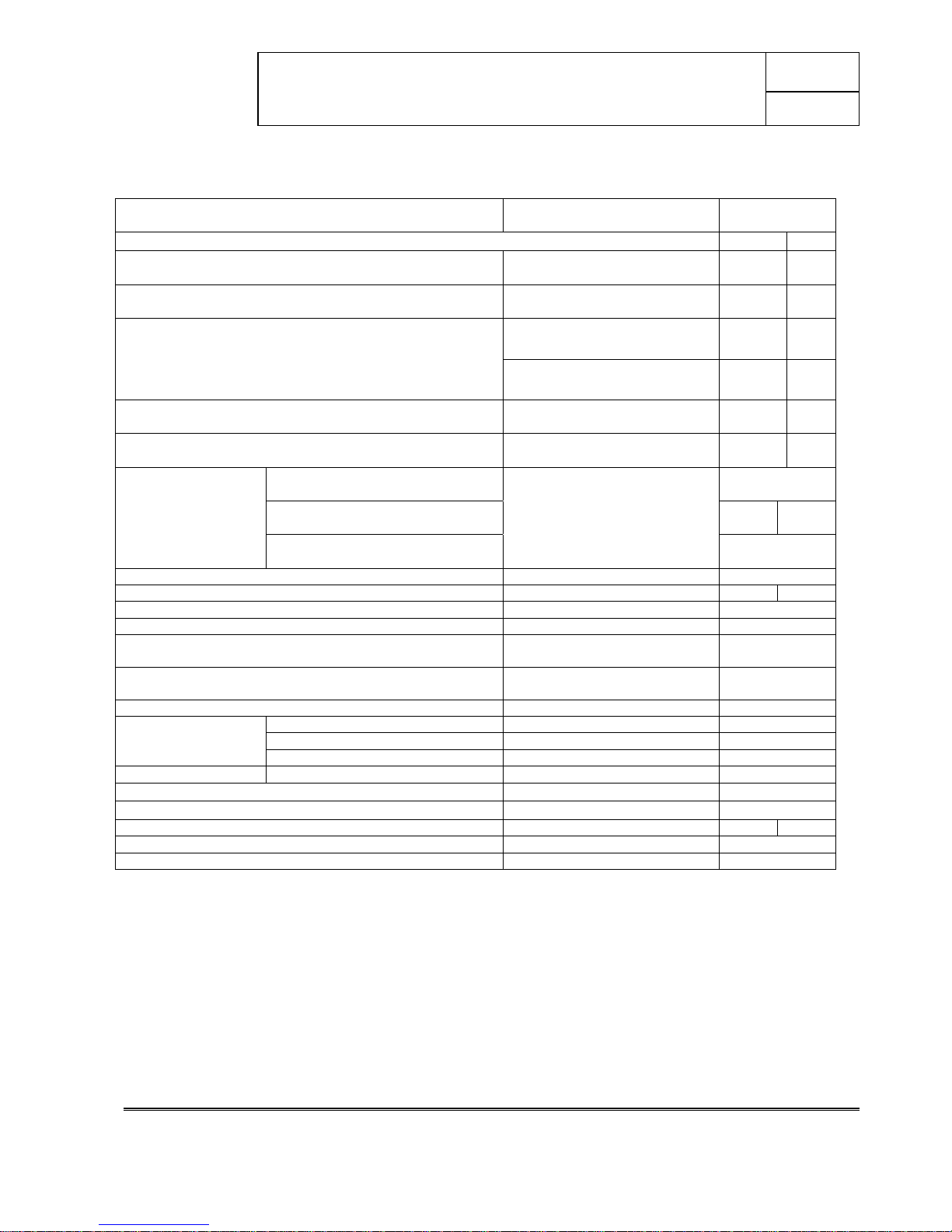

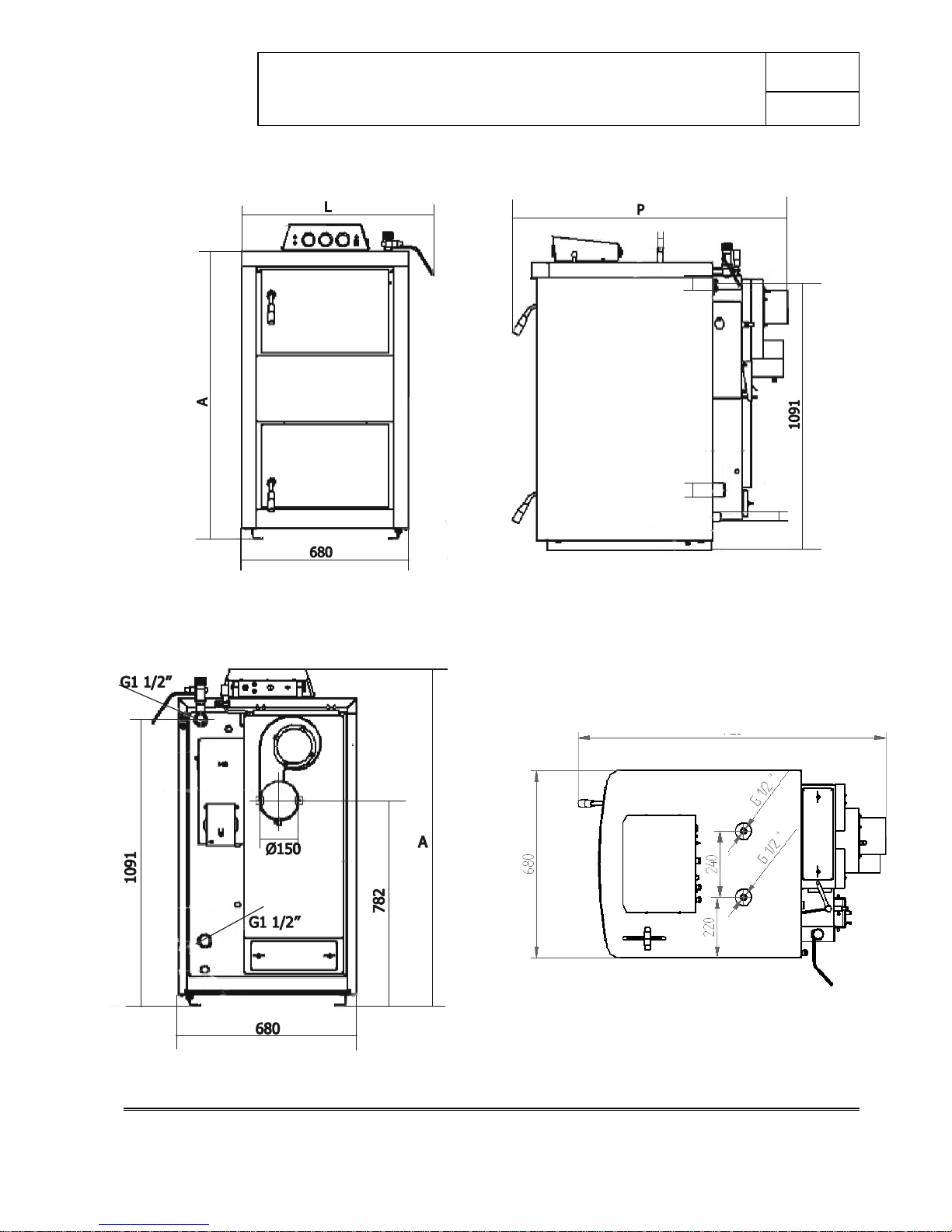

Dimensions and technical data of “TECNIKA” hot water wood gasification boilers:

PARAMETERS UNIT OF MEASURE

V

ALUES

MODEL 28 35

WEIGHT kg

290 370

WATER SLEEVE CAPACITY dm3

70 90

FUEL CHAMBER CAPACITY

dm

3

100 130

kg

16-20 20-24

NOMINAL HEAT OUTPUT TIME INTERVAL AFTER LOADING

FUEL CHAMBER

Hours

2-3 2-3

MAXIMUM WOOD LOG LENGTH mm

330 500

DIMENSIONS

L=WIDTH

mm

780

P=DEPTH

975 1123

A=HEIGHT

1282

OPERATING PRESSURE OF CIRCULATING WATER bar 2

HYDRAULIC PRESSURE LOSS AT NOMINAL HEAT OUTPUT Pa 20 21

TYPE OF EXPANSION VESSEL FOR THE HEATING SYSTEM - Open or closed

PRESSURE TESTED IN THE FACTORY bar 4

RECOMMENDED TEMPERATURE FOR THE WATER

CIRCULATING IN THE BOILER

°C 80-85

RECOMMENDED TEMPERATURE FOR RETURN WATER IN THE

BOILER

°C 60

DRAUGHT hPa 0.18-0.24

CONNECTIONS

FLOW/RETURN G 1 ½”

EXHAUST G ¾”

EMERGENCY COOLING COIL G ½”

COMBUSTION GAS DUCT mm 150

POWER SUPPLY -

230 V; 50 Hz

POWER SUPPLY CABLE -

3 x 1.5 mm2

ELECTRICAL CAPACITY VA 37 65

ELECTRICAL PROTECTION - IP20

BOILER CLASS (ACCORDING TO EN 303-5) - 3

Page 11

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

3

page 11

Technical specifications and dimensions Technical dept. - All rights reserved - Reproduction prohibited

3.4. Boiler fuel supply

The boiler must be supplied with the following fuel:

wood logs, preferably cut, with the following features:

o pure wood, use of contaminated wood is not allowed (i.e. painted wood, subjected to

chemical treatment or other mineral or organic substances)

o the length of the wood logs must correspond to the depth of the combustion chamber of the

boiler

(see boiler technical specifications)

o the crosswise section (diameter) of the wood logs must be: D ≤ 200 mm

o the raw material humidity content must be less than 20% (W

r

≤ 20%)

o wood-based fuel such as sawdust, wood chips and other small combustible particles may be

used in addition to wood logs, but their total amount must be less than 20% of the fuel

loaded into the boiler chamber.

Approximate recommended fuel parameters - cut, pre-dried wood logs

PARAMETERS UNIT OF MEASURE VALUES

TYPE OF FUEL WOOD LOGS

WOOD LOG LENGTH mm See previous table

HUMIDITY CONTENT % ≤20%

CALORIFIC POWER OF FUEL

USED IN OUR CALCULATIONS

MJ/kg >13.9

kWh/kg >3.9

EXPLANATION: the maximum percentage of humidity in wood must be 20%. It is advisable to use wood

dried for at least 1 year.

Page 12

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

3

page 12

Technical specifications and dimensions Technical dept. - All rights reserved - Reproduction prohibited

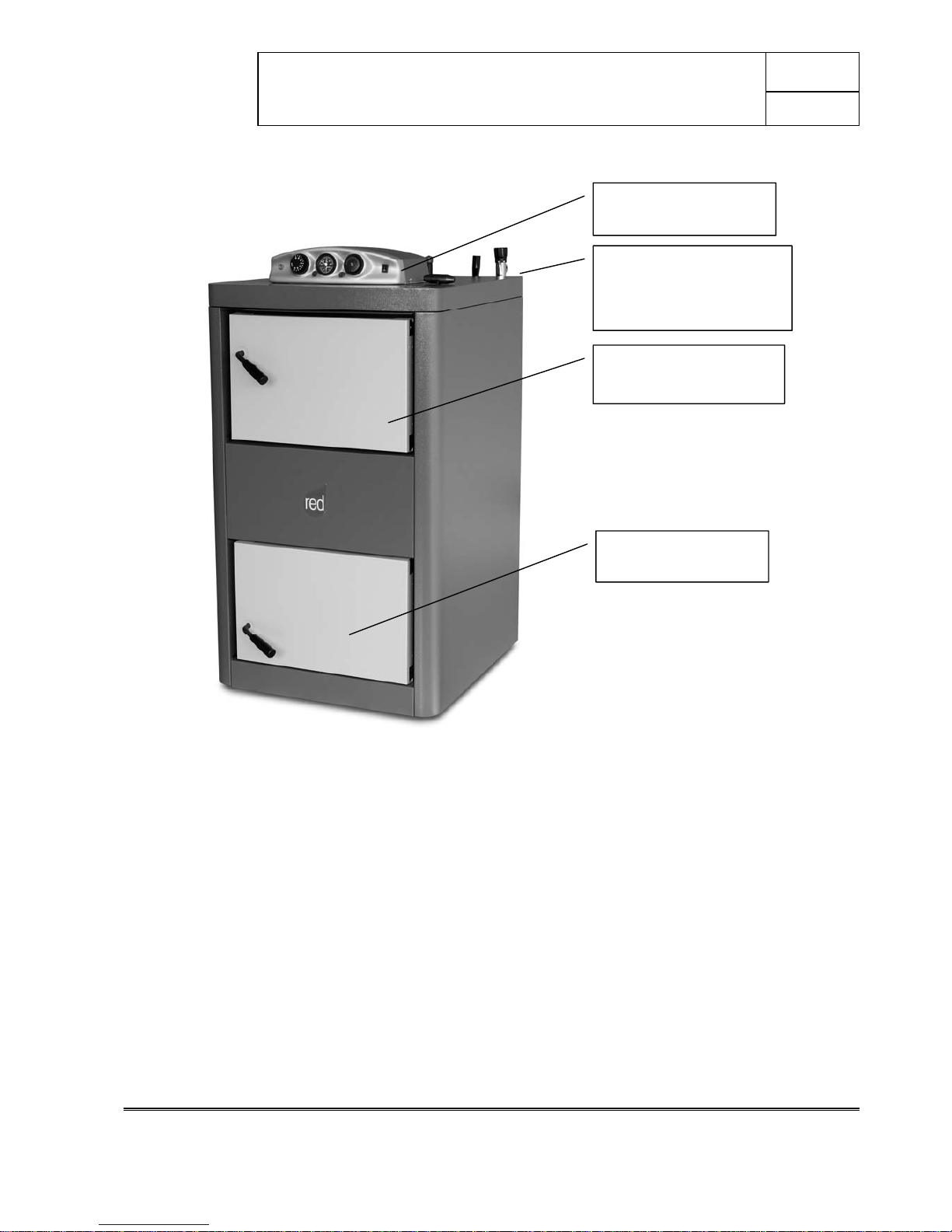

3.5. Main components

Fig. 3.5.1 View of the “TECNIKA” hot water wood gasification boiler - Description of main

components of the boiler

COMBUSTION

CHAMBERDOOR

FUELHOPPERDOOR

BOILERCONTROLPANEL

AIRFLOWCONTROL

THERMALVALVE

Page 13

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

3

page 13

Technical specifications and dimensions Technical dept. - All rights reserved - Reproduction prohibited

G 1 ½”

G 1 ½”

G ½”

G

¾

”

EXPLANATION: the values of the dimensions indicated by letters: L, A and P are shown in Table page 12.

Fig.3.5.3 Side view of the “TECNIKA” hot water

wood gasification boiler

Fig.3.5.2 Front view of the “TECNIKA” hot water

wood gasification boiler

Fig.3.5.4 Rear view of the “TECNIKA” hot water wood

gasification boiler

Fig.3.5.5 Top view of the “TECNIKA” hot water

wood gasification boiler

P

Page 14

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

3

page 14

Technical specifications and dimensions Technical dept. - All rights reserved - Reproduction prohibited

Combustion gas outlet (conveyed to

convective ducting of the boiler)

Ceramic combustion gas ducting element

in combustion chamber

Combustion chamber

Combustion nozzle

Fuel hopper

Opening for extracting gas from

combustion chamber for start-up

Primary air inlet opening

Fig.3.5.6 Section view of the “TECNIKA” hot water wood gasification boiler

Page 15

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

3

page 15

Technical specifications and dimensions Technical dept. - All rights reserved - Reproduction prohibited

The manufacturer reserves the right to make any changes to design and construction of the

boiler without having to inform end users of such changes.

Boiler control box

Upper lid of boiler convective ducting

Combustion gas fan

Combustion gas outlet ducting

Combustion nozzle

Ceramic coated combustion

gas ducting element

Lower lid of boiler convective

ducting

Fig.3.5.7 Longitudinal view of the “TECNIKA” hot water wood gasification boiler

Page 16

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 16

Installing Technical dept. - All rights reserved - Reproduction prohibited

4. Installing a "TECNIKA" hot water boiler

CAUTION: be careful not to damage or crack the ceramic element fitted inside the combustion chamber of

the boiler when transporting the boiler (secure the element appropriately or transport it separately from the

boiler):

installing the hot water boiler in rooms not fit for occupancy, including corridors, is not allowed

the "TECNIKA" wood gasification boiler may be connected to a heating system equipped with open

or closed expansion vessel designed according to the water capacity of the entire heating system

both the heating system and the hot water boiler must be filled with circulating fluid (water) and air

must be bled from the system before starting up the boiler.

4.1. Packaging

The boiler is delivered complete with assembled electrical and mechanical parts after having been tested at

the factory.

The boiler is delivered on one pallet. The boiler must always be handled vertically, using manual or

mechanical cranes, which can lift the pallet on which it is packaged or the boiler itself directly.

Take special care not to damage electrical or mechanical parts, with shocks or water sprays once the

protective packaging has been removed.

After removing the packaging, make sure the boiler is complete and undamaged

If in doubt, contact the retailer

The document envelope contains:

System manual

An instruction manual for installation, use and maintenance

Appendix G - Technical inspection report for heating system with an output of less than 35 kW

Guarantee

4.2. Boiler room

Make sure the room complies with the requirements and characteristics set out in the applicable regulations

in force. It is also necessary for the room to provide at least as much air as is required for regular

combustion. It is therefore necessary to make holes in the walls of the room, which comply with the

following requirements:

Have a free cross-section of at least 6 cm

2

for every 1 kW (859.64 kcal/h). Nevertheless, the

minimum cross-section of the opening must never be less than 100 cm

2.

The cross-section can also

be calculated using the following ratios:

S = K * Q ≥ 100 cm

2

Where “S” is expressed in cm2, “Q” in kW, “K” = 6 cm2/kW

The opening must be situated at the bottom of an external wall, preferably opposite the one where

the combustion gases are vented.

Page 17

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 17

Installing Technical dept. - All rights reserved - Reproduction prohibited

4.3. Connection to the flue pipe

For the connection of the flue outlet pipe, local and national regulations must be observed (see Standards

UNI 7129 and UNI 10683).

A flue pipe must comply with the following requirements:

It must be made of waterproof material resistant to the temperature of the smoke and related

condensation.

It must ensure sufficient mechanical resistance and weak heat conductivity.

It must be perfectly sealed, to avoid the cooling of the flue pipe itself.

It must be arranged as vertically as possible.

Chimneys both old and new, built without observing the above specifications, may be conveniently

recovered by "intubating" the chimney itself. This means a metal flue shall be inserted inside the

existing chimney and the space between the metal flue and the chimney shall be filled with suitable

insulation.

In order to prevent the wind from creating pressure areas around the chimney that prevail over the

rising force of the combustion gases, the outlet aperture must be positioned at least 0.4 metres

above any structure adjacent to the chimney itself (including the ridge of the roof) at least 8 metres

away.

The flue pipe must have a diameter of no less than the boiler union; for flue pipes with a square or

rectangular cross-section, the internal cross-section must be increased by 10% compared to the

boiler union.

The useful cross-section of the flue pipe can be calculated using the following formula:

S = K x P/√H

S ensuing section in cm

2

K reduction coefficient:0.045 for wood

P boiler output in kcal/h

H height of the chimney in metres, measured from the flame axis to the outlet of the chimney into

the atmosphere. When sizing the flue pipe, please take into account the actual height of the

chimney in metres, measured from the flame axis t the top, decreased by:

0.50 m for every change in direction of the union duct between the boiler and the flue pipe

1.00 m for every metre of horizontal development of the union itself.

We recommend the sole use of outlet ducts which are suitable for the

type of fuel used. The supplier will not be held in any contractual and

non-contractual way liable for damage caused by installation and

usage errors and in any case due to failure to observe the instructions

provided by the manufacturer of the appliance.

The products of combustion of the boiler cannot be discharged in

collective flue ducts.

The correct installation of the flue duct is necessary to encourage the

normal flow of smoke from the combustion chamber to the outside in

the event of an electrical power failure.

Remember that a draught of 20 Pa must be guaranteed.

Page 18

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 18

Installing Technical dept. - All rights reserved - Reproduction prohibited

Below are the main characteristic traits of the flue duct according to the provisions of

standards UNI 7129 and UNI 10683:

The smoke outlet must be equipped with inspection valves;

The minimum height of the pipe directly connected to the smoke outlet of the boiler must be

between 2-3 m;

If the presence of a horizontal section is necessary, we recommend that the same is of a maximum

length of 1.5 m and with a slope gradient of 3-5% to encourage the smoke to flow away;

Use of a wind-proof and rain-proof terminal to avoid changing the slight overpressure inside

the flue pipe (we recommend you end the flue pipe with a horizontal section);

The outlet ducting must be made with suitable materials which can withstand the products of

combustion and any condensation of the same (the inspection valve can allow any condensation

that has formed to be vented);

The ducts must be built to ensure maximum seal against smoke (UNI 10683);

We recommend you insulate the duct, especially on the outside part exposed to the weather.

Avoid installing completely horizontal sections.

The room where the heat generator is to be installed must not contain any existing or

envisaged smoke suction hoods in order to avoid depressurising the setting.

The air intakes must not be closed.

Make sure the flue pipe is kept clean, cleaning it at least once a year.

In the event of a fire in the flue pipe or duct, switch the boiler off

immediately and disconnect it from the domestic electricity mains

Page 19

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 19

Installing Technical dept. - All rights reserved - Reproduction prohibited

4.3.1 Roof outlet along an external steel flue pipe

One of the installation solutions which could be used is to position the boiler near a perimeter wall of the

home (see figure below) so that the smoke is discharged along an external flue pipe. Here are some of the

provisions of standard UNI 7129 for this particular system configuration:

- Always make sure there is an inspection valve to allow periodic and efficient cleaning, as well as the

venting of any condensation that may have formed;

- The chimney must under all circumstances be wind-proof and rain-proof;

- Make sure the smoke outlet duct is suitably insulated in the section that crosses the wall.

It is advisable for the smoke outlet duct, if it is completely outside, to be made of double-wall stainless steel

to guarantee both greater resistance to the atmospheric agents as well as the appropriate temperature of

the smoke outlet.

Chimney

Insulatethe

fluepipe

Soottray

Page 20

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 20

Installing Technical dept. - All rights reserved - Reproduction prohibited

5.3.1 Roof outlet along a traditional flue pipe

The flue smoke can also be discharged using an existing traditional flue pipe provided it is compliant to

standards (see UNI 10683).

Here is a brief list of the main characteristics highlighted in the standard that distinguish a good chimney:

- Suitable insulation and lagging especially in the external section exposed to the atmosphere;

- Constant internal cross-section (there must not be any narrower sections);

- Made with material resistant to high temperatures, to the action of the products of combustion and to the

corrosive action of any condensation that may form;

- Prevalently vertical arrangement with deviations from the axis of no more than 45°;

It is compulsory to plan a chamber for the collection of solid material and/or any condensation, which can be

inspected through an airtight door.

It is compulsory for you to observe the provisions of standards UNI 9615 and 9731 for the sizing of the

chimney cross-section and in any case that you avoid installing ducts with a cross-section of less than

150 mm.

In the case of larger cross-sections, it may be necessary to insert a steel duct inside the masonry one.

Direct wall discharge is not permitted.

The steel pipe must be suitably insulated with material which is resistant

to high temperatures and sealed off from the external chimney.

Soot tray accessible for

inspection with possible

condensation discharge

Page 21

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 21

Installing Technical dept. - All rights reserved - Reproduction prohibited

4.4. System connection

It is advisable for the connections to be easy to disconnect by means of swivel pipe unions. It is always

advisable to fit suitable cut-off gate valves on the heating system piping.

Caution: a safety valve must under all circumstances be fitted on the system.

To prevent hazardous corrosion of the heating system and the formation of scaling and deposits, it is of the

utmost importance to wash the system before installing the appliance, in accordance with standard UNI-CTI

8065, using appropriate products such as Sentinel X300 (new systems), X400 and X800 (old systems) or

Fernox Cleaner F3.

Full instructions are provided with the product. However, for further details contact the manufacturer

directly: SENTINEL PERFORMANCE SOLUTIONS LTD or FERNOX COOKSON ELECTRONICS.

After washing the system, you are advised to use inhibitors such as Sentinel X100 or Fernox Protector F1 to

protect the system from corrosion and deposits.

It is important to check the concentration of the inhibitor after each modification to the system and each

maintenance check, according to the specifications provided by the manufacturers (relevant tests are

available from retailers).

The outlet from the safety valve must be connected to a collection funnel to channel any discharge if

servicing is carried out. If the heating system is at a higher level than the boiler, you must install cut-off

cocks on the system flow/return pipes. These cocks are provided in the optional kits.

Caution: failure to wash the heating system and to add a suitable inhibitor shall invalidate the

appliance guarantee.

4.5. Filling the system

Before making the boiler connections, it is good practice to allow water to flow through the piping to

eliminate any foreign bodies that could compromise the correct functioning of the appliance.

The appliance should be filled slowly to allow any air bubbles to be released through the appropriate vents

within the heating system. In closed circuit heating systems, the cold filling pressure of the system must

correspond to the expansion vessel pre-inflation pressure.

In heating systems with an open vessel, the circulating liquid may come into contact with the air.

During colder months when the heating system is in use, the end user must check the level of water

circulating in the expansion vessel regularly. The water content of the recirculation system must

remain constant. Practical experience shows that a regular check of the water level must be carried

out every fortnight to keep the water content almost constant. If more water is required, perform

the filling process, when the hot water boiler has cooled down to room temperature. These

precautions are designed to prevent the occurrence of heat stress on the steel body of the boiler.

The water used to fill the heating system must be purified and not contain any air.

Caution!

Do not mix the heating water with anti-freeze or anti-corrosion products

in the wrong concentrations! This could damage the seals and cause noisy

operation.

RED will not be held liable for any damage to persons, animals or property

caused by failure to observe the above instructions.

Page 22

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 22

Installing Technical dept. - All rights reserved - Reproduction prohibited

Once all the hydraulic connections have been made, check the seals under pressure by filling

the boiler.

This should be done carefully, in the following sequence:

open the air relief valves on the radiators, boiler and system;

gradually open the system filler cock, making sure any automatic air relief valves fitted on the

system are working properly;

close the air relief valves on the radiators as soon as water starts to trickle out;

check on the system pressure gauge that the pressure reaches a value of approximately 1 bar (this

only applies for systems with a closed vessel - consult any local regulations or standards that allow

it); for systems featuring an open vessel, the reintegration is automatic through the vessel itself;

close the system filler cock and then vent any air again through the radiator air relief valves;

check the seal on all connections;

after starting the boiler up for the first time and the system is at the right temperature, stop the

pump operation and repeat the air venting operations;

allow the system to cool down and, if necessary, return the water pressure to 1 bar (this only

applies for systems with a closed vessel - consult any local regulations or standards that allow it);

for systems featuring an open vessel, the reintegration is automatic through the vessel itself.

NOTE

In systems with a closed vessel, where permitted, the water pressure in the heating

system - when the system is cold - should not drop below 1 bar; if it does, open the

system filler cock. This should be done with the system cold.

The pressure gauge in the system allows you to read the pressure in the circuit.

4.6. Basic requirements for installing “Tecnika” hot water gasification boiler

to allow simple maintenance and servicing:

o the boiler must be installed on a thermally safe, fireproof support 50 mm high;

o the minimum clearance in front of the boiler to allow it to be cleaned, serviced, etc. must be

1000 mm;

o the minimum clearance permitted between the rear of the boiler and a wall must be 400 mm;

o the minimum clearance between side of the boiler and a wall must be 500 mm in order to allow

simple maintenance and servicing of the convective heat exchanger and the back of the

appliance;

o the minimum clearance between upper side of the boiler and the ceiling must be 600 mm to

guarantee easy access to the appliance control panel, for connecting the emergency coil and for

heat exchanger cleaning and maintenance;

o the ceramic combustion gas ducting element must be positioned in the boiler combustion

chamber.

Page 23

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 23

Installing Technical dept. - All rights reserved - Reproduction prohibited

CAUTION: the utmost care is needed when fitting and installing the ceramic element. Take all the

preventive measures needed to avoid damaging the element. After having installed the element in the

combustion chamber, push it back until it touches the vertical rear plate of the heat exchanger.

Fig.4.6.1 Ceramic combustion gas ducting element positioned in boiler

combustion chamber.

Page 24

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 24

Installing Technical dept. - All rights reserved - Reproduction prohibited

o Fit the thermostatic valve for controlling the air flow.

EXPLANATION: the chain length and inlet air fin opening must be adjusted with the boiler running and

once the thermal opening parameters have been reached. The air fin must be open to allow the flow of air

into the boiler in order to start the boiler:

Fig. 4.6.2 Thermostatic valve for controlling the

combustion process air flow is installed and the stem

is connected to the air fin (

by means of the chain

).

Page 25

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 25

Installing Technical dept. - All rights reserved - Reproduction prohibited

fit an automatically opening overtemperature valve which opens at high temperatures (not included in

the supply of the boiler). The valve opens and sends water from the cock to the emergency cooling coil

of the boiler thus decreasing the circulating water temperature. Check the valve instruction manual for

more details.

EXPLANATION: the detecting section of the thermostatic valve must be screwed into an opening situated

in the upper rear part of the heat exchanger (see photo). The water flow control module of this thermostat

valve must be fitted on one of the ends of the emergency coil (either the inlet or outlet end). The water flow

control module of this thermostat valve must be connected to the water from the cock at DHW network

pressure. The emergency cooling coil must be connected to the exhaust system. Be careful: the water may

be very hot.

Openingforinstallingtheemergencycoilthermostatic

valvesensorsection

Fig. 4.6.3 View of the opening of the hot water boiler where to fasten the thermostatic valve sensor

module for the emergency cooling coil to be connected to the water flow from the cock

Page 26

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 26

Installing Technical dept. - All rights reserved - Reproduction prohibited

Hotwaterboiler

emergencycoolingcoil

inlet/outlet

Fig. 4.6.4 View from back of boiler - with indication of ends of the emergency cooling coil

Page 27

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 27

Installing Technical dept. - All rights reserved - Reproduction prohibited

o Connect the hot water boiler inlet and outlet to the heating system using suitable fittings, etc.

according to the installation diagram.

Flowline(toheatingsystem)

Returnline(fromheating

system)

Combustiongasoutlet(toflue)

Exhaustopening

Combustionaircontrolfin

Fig. 4.6.5 Rear view of "Tecnika" hot water boiler -

with indication of connection points

Page 28

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

4

page 28

Installing Technical dept. - All rights reserved - Reproduction prohibited

Fig. 4.6.6 General hydraulic circuit recommended for connecting the "Tecnika" hot water boiler to

the heating system provided with three-way valve and heat accumulator

Solar control

unit

Solar

p

ane

l

Safety

valv

e

Pressure

switch

Water flow

meter

Tank in Tank

c

y

linde

r

Thermostatic

mixer

Safety

valv

e

H

i

g

h temperature

direct circuit

Solar

pump

station

Page 29

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

5

page 29

Operation Technical dept. - All rights reserved - Reproduction prohibited

5. OPERATION

5.1. “Tecnika” hot water wood gasification boiler interface control panel

The following control devices are arranged on the front part of the boiler interface control panel:

Figure 5.1.1 Interface control panel provided with "Tecnika" hot water boiler control and operation devices

-

front view

Switch

"START"

START

Combustion

gas

thermostat

Thermometer

Operation

thermostat

Alarm2Alarm1

Page 30

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

5

page 30

Operation Technical dept. - All rights reserved - Reproduction prohibited

Operation thermostat - Assigns the set point of the water circulating the boiler. The

combustion gas fan of the boiler will run until this set point is reached and supplies thermal

energy to the heating system. The boiler will switch to stand-by mode.

Combustion gas thermostat - Assigns the combustion gas temperature set point. The

boiler combustion gas fan does not work at temperatures lower than the set point of this

thermometer and combustion gases will not be extracted by the fan. Consequently, the

remaining combustion residues will not be consumed if they remain in the fuel hopper of the

boiler only.

Temperature pressure gauge - This indicates the operating temperature of the water

circulating in the heat exchanger sleeve of the boiler in addition to water overpressure.

"START" switch - This sends the "START/STOP" signal to the boiler combustion gas fan

which will run at nominal heat output (ON) or switch to stand-by mode (OFF).

"START" warning light - This indicates the "START/STOP" state signal to the boiler

combustion gas fan.

"Alarm 1" warning light - Overheat emergency - This indicates an overheating

emergency of the boiler caused by activation of the emergency thermostat. In case of

activation, cool the appliance, check and repair the cause of the emergency situation.

Finally, reset the emergency thermostat.

“Alarm 2" warning light - (optional) - This indicates the heat exchanger state - If the

combustion gas temperature is higher than given levels the warning light will come on and

ashes must be cleaned.

The following control devices are arranged on the rear part of the boiler interface control panel:

Figure 5.1.2 Interface control panel provided with "Tecnika" hot water boiler control and operation devices

-

rear view

Main "POWER" switch - Turns main power supply of the boiler ON and OFF.

Emergency thermostat - Protects the boiler from exceeding emergency temperature

levels and overheating. This thermostat is calibrated at the factory to cut off the power

supply of the appliance at a water temperature higher than 95

o

C.

POWERswitch

Emergency

thermostat

Wireduct

elements

Page 31

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 31

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

6. START-UP PROCEDURES

CAUTION: The boiler must be installed, adjusted and controlled ONLY by trained,

authorised personnel.

6.1. Basic requirements

It is strictly forbidden for the fuel to be kept near the boiler; the minimum safety clearance between the

fuel and the appliance is 500 mm.

It is advisable for the fuel to be kept in a room close to the one where the boiler is installed.

The fire prevention regulations must be taken into consideration during the appliance installation

procedure and during the fuel storage. It is also recommended that a fire extinguisher be fitted in a

safe and easily accessible place.

All maintenance procedures must be carried out as shown in this manual.

The "Tecnika" hot water boiler must be loaded with fuel by personnel who have read this entire

instruction manual.

CAUTION: presence of children in the operating area of the boiler is not allowed.

The boiler must be regularly inspected by maintenance personnel or other trained personnel.

The end user must not carry out interventions or repairs etc. on the appliance. In case of faults or

warning messages, refer to the troubleshooting table (at the end of this manual) and contact the

service centre if the situation is not described in the table.

Setting or increasing the heat output to values higher than the nominal heat output of the boiler is not

allowed.

Ash deposited in the combustion chamber of the boiler must be collected in fireproof containers and

cooled at ambient temperature. Cooled ash can be disposed of in specific rubbish containers.

At the end of the each heating season, the boiler, flue duct and other modules of the system must be

cleaned completely to remove deposited ash, tar, etc.

Fuel is fed manually into "Tecnika" series hot water wood gasification boilers. The heat output of the

boiler essentially depends on fuel properties and mainly on the humidity content, but also on the operating

mode of the boiler. Practical experience has proven that efficient pyrolysis process in hot water boilers of

this type is reached with circulating water temperatures higher than 60

o

C.

Page 32

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 32

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

6.2. Electrical connections

Generalwarnings

Electrical safety is only ensured if the system is correctly connected to an efficient earthing system, built in

accordance with the provisions of the applicable safety standards.

Remember that an easily-accessed bipolar switch with a minimum contact opening

of 3 mm must be installed on the electrical power supply line to the boiler, in order

to facilitate and speed up any maintenance operations.

The power supply cable must only be replaced by authorised technical personnel. Failure to observe the

above recommendations may compromise the safety of the appliance.

Page 33

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 33

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

10A

FS1

1

2

L1

Alarmthermostat

–95

0

C

Operating

thermostat

C

C

N

Fluegas

thermostat

C

Fluegasfan

Ì1

~1

SB1

STh

BTh

FTh1

STARTindicator

55

4

N

L

N

PE

220V~

1

2

3

1

2

2

1

2

Fluegas

FTh2

HL1HL2

C

12

Alarm‐ cleaning

OPTION

SB2

START

7

8

Roomth ermostat

N

Overheating

HL3

6.3.1 Wiring diagram

The wiring diagram of the "Tecnika” hot water wood gasification boiler is shown in Figure 6.2.1

Preliminary checks

The first start-up must be performed by professionally qualified personnel.

RED will not be held liable for any damage to persons, animals or property

caused by failure to observe the above instructions.

A

mbient thermostat

Combustion

gas

thermostat

Operation

thermostat

Combustion

gas

Page 34

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 34

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

6.3. Boiler start-up preparation procedure

The "Tecnika" hot water boiler is turned on by setting the POWER switch to the ON position.

Check operation of the various elements/modules of the boiler crucial for reliability, efficiency and operation

of the heating system before manually igniting the fuel in the upper chamber:

combustion gas fan

start-up fin

position and state of ceramic element in the boiler combustion chamber

thermostat valve controlling air flow and distribution

function of control and measuring elements (thermostats, thermometer-pressure gauge)

flap seal bead.

Load a small amount of starter particles in the fuel hopper chamber (e.g. dry sticks, branches, etc.). Arrange

the particles to form a heap located over the nozzle of the burner arranged in the lower section of the

combustion chamber of the boiler. It is advisable to use no more than 5 kg of starter materials to start a

stable combustion process. The opening of the burner must never be obstructed by particles to prevent

volatile gases from passing through the nozzle and entering into the combustion chamber.

6.4. Igniting the fuel and heating the boiler

The boiler operating thermostat must be set to a temperature higher than 60

o

C.

Turn the combustion gas thermostat set point to minimum.

Turn the combustion gas fan off (set START switch to the OFF position).

Open the start-up fin - the start-up fin control lever is positioned on the right of the boiler upper

section, simply by pulling it.

Figure 6.4.1 The start-up fin lever of the boiler is pushed back and the fin is closed.

Open the fuel hopper door of the boiler, arrange the starter material forming a small heap over the

burner opening so that the combustion gases can easily pass through the burner nozzle. Make sure

that the heap does not obstruct the opening of the nozzle and allows the easy passage of

combustion gases and fresh air. Start initial combustion, preferably using newspaper. Make sure that

this material does not release toxic or harmful gases.

Start-up fin control lever

NOTE: the figure shows

the closing position of

the start-up fin

.

Page 35

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 35

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

CAUTION - Use of flammable liquids is not allowed. The figure shows how to arrange starter

material in the fuel hopper chamber of the boiler.

Figure 6.4.2 Arrangement of starter material needed to start the boiler combustion process.

After initial combustion, close the door to prevent combustion gases from being released from the

chamber. Combustion gases produced by the combustion process pass through the open start-up fin

and are aspirated by the chimney.

NOTE:

Starting speed may vary according to local conditions (chimney and atmospheric conditions). This

process must be observed close to acquire the practical experience needed to start the fire.

After starting the fire, turn the combustion gas fan on (turn the START switch to the ON position),

close the fuel hopper door and close the start-up fin by pushing the lever backwards. This will make

the combustion gas change direction and flow through the burner nozzle, the combustion chamber

and the convective ducting section of the boiler instead of being conveyed directly to the chimney.

Turn the combustion gas thermostat to set the operating position. The position must be determined

on a trial and error basis (you are advised to mark the position for the sake of convenience) by

observing the start-up process in the boiler.

Adjust the thermostatic valve for controlling the air flow. After start-up, the fin must be open to

ensure available air for the combustion process. After turning on the boiler and reaching operating

parameters, set the thermostatic valve as needed (

see description below

).

Page 36

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 36

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

NOTE:

A large amount of steam may condense on the inner surfaces of the boiler causing leakage of

water from the boiler combustion chamber door and from the combustion gas duct fin positioned

on the rear lower part of the boiler when the boiler is started for the first time. This event does

not influence operation and function of the boiler.

It is not recommended to open the boiler loading chamber door unless the combustion gas fan is

running and the start-up fin is closed, because volatile gases could be released from the chamber

and introduced into the surrounding atmosphere thus contaminating the boiler room.

6.5. Adjusting the air flow control thermal valve

The thermostatic valve which controls the air flow is needed for an efficient combustion process which

must be adjusted so as to allow optimal operation of the boiler.

EXPLANATIONS: the fin actuated by the thermostatic valve must be open to guarantee a sufficient flow

of air for the start-up process until the nominal heat output is reached.

The thermostatic valve controls the air flow needed to obtain an efficient combustion process. This valve

closes the air control fin if the temperature of the circulating water has reached high levels consequently

preventing the boiler from overheating. This valve detects the temperature of the circulating water and

actuates the lever which controls the position of the air control fin - At low circulating water

temperatures, the lever opens the air control fin and conversely at high circulating water temperatures

the valve closes the air control find and consequently reduces the air flow for the combustion process,

thus reducing the heat output of the boiler. This thermostatic valve operates without any power supply

source. The position of the air control fin must be observed and manually adjusted by using the applied

chain.

CAUTION: the thermostatic valve must be regulated to close the air control fin when the circulating

water temperature reaches 90

o

C.

Adjust the thermostatic valve as follows:

The boiler is heated to reach a circulating water temperature of 80

o

C (measured by means of

thermometer-pressure gauge).

Adjust the position of the thermostatic valve knob - The notch of the thermostatic valve must

correspond to the temperature of the water circulating in the boiler (operating temperature of 80

°C).

Adjust the chain (which connects the lever of the thermostatic valve and the air control fin) thus

modifying the position of the hook. The air control fin must be in the closed position. The chain must

be taut.

If needed, adjust the minimum position of the air control fin using the adjustment screw.

EXPLANATION: the air control fin must not seal the air opening otherwise it will "suffocate" the

combustion process and cause a large amount of tar to be deposited on the inner surfaces of the

boiler. The fin must be opened to 3-8 mm according to local conditions (chimney draught, heat

output of the boiler, fuel properties, etc.).

Page 37

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 37

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

EXPLANATION: refer to the respective instruction manual for how to adjust the thermostatic valve.

6.6. Nominal operating mode of the boiler

After starting the boiler (i.e. after igniting the fuel, the additional fuel, after reaching high boiler temperature

levels, with a stable combustion process and water circulating in the heating system) the system must be

adjusted and only then can be considered working in constant manner.

If the heating system is provided with a recirculation pump, the operation of this pump must comply with

the requirements above, i.e. must work with circulating water temperature higher than 65

o

C. If the boiler

works at lower temperature levels, operation will cause a considerable deposit of tar and a decrease of heat

transfer, in addition to chemical corrosion which decreases efficiency and reliability of the appliance.

Figure 6.5.1 Air flow control thermostatic valve

for the combustion process.

Air flow control thermostatic valve

Air flow control fin

Chain connecting thermostatic

valve lever to air control fin

Minimum air flow screw

Page 38

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 38

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

6.7. Fuel hopper loading

o Open the start-up fin (by pulling the start-up fin lever - see figure below): the combustion gases in

the fuel hopper are released into the chimney by this fin.

Figure 6.7.1 Position the lever which controls the start-up fin position - The fin is open as shown in the

figure above.

o Wait for 5-10 seconds, open the door of the fuel hopper chamber. The door must be opened in

steps - ambient air initially penetrates into the chamber with door half open but does not allow

combustion gases to be released from the chamber into the atmosphere.

o Open the door of the fuel hopper chamber and load the hopper with wood logs. It is advisable to

keep wood logs handy to facilitate the fuel loading process.

CAUTION: apply all the preventive measures to avoid burns and suffocation caused by combustion

gases released from the combustion chamber by wearing protective clothing etc. The fuel must be

loaded so as to be arranged in the chamber and optimise the volume available in the chamber for

this purpose. Position the wood logs lengthwise. It is advisable to mix combustion residues when

opening the burner before loading new fuel into the chamber to facilitate convection of volatile

gases through the nozzle using the specific tool contained in the boiler maintenance kit.

o Close the fuel hopper door and the start-up fin (pushing the lever).

EXPLANATION: the loaded fuel must be heated. For this reason, the temperature of the circulating water

decreases initially after this fuel is loaded. Practical experience shows that the heat output of the hot water

wood gasification boiler starts increasing after approximately 30 minutes from loading the fuel hopper and

rapidly reaches nominal heat output, and the nominal operating parameters as a consequence.

Page 39

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 39

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

Figure 6.7.2 View of the fuel hopper chamber and fuel state approximately 30 minutes after loading.

The figure above shows that the wood logs have already dried out and partial carbonation is

apparent - wood logs appear darkened and a great deal of volatile gas (smoke) is being released. If a

combustion process is visible, this is due to penetration of fresh air in the chamber from the open door (in

nominal opening conditions there is no flame but only release of plenty of volatile gases in the chamber).

NOTE:

Be careful not to block the door in order to close it easily when arranging wood logs.

If different material is loaded into the fuel hopper chamber, the particles with a higher humidity

content and/or larger particles must be arranged in the centre of the chamber, while partially

dried or smaller particles must be arranged by the side of the chamber. This allows to avoid

accumulation of fuel directly over the burner nozzle and consequently obstructing the nozzle

itself, which would greatly decrease the heat output of the boiler.

EXPLANATIONS:

The combustion gas fan is turned off when the circulating water set point is reached and the boiler

switches to stand-by mode. In this mode, the fuel consumption rate decreases, as does the heat

output of the boiler. Practical experience indicates that the typical heat output of a boiler in stand-by

mode is approximately 10% of the nominal heat output of the boiler. In this mode, a small amount

of air enters into the boiler and starts combustion residue oxidation to keep the boiler in so-called

"ready for operation" mode.

Page 40

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 40

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

6.8. Adjusting boiler operating parameters

The combustion process must be adjusted at the nominal operating conditions for optimal, efficient fuel use.

You are keenly recommended to adjust the combustion process by measuring combustion gases using a gas

analyser. The adjustment must be carried out by a specialised technician.

The combustion process is adjusted by adjusting the air flow and distribution. The air consumed during the

combustion process is aspirated into the fuel hopper chamber by the burner nozzle by means of the

combustion gas fan. Air is distributed by the air box, where it is pre-heated and conveyed towards the fuel

hopper chamber ("primary air") and towards the burner nozzle ("secondary air"). Air distribution is adjusted

by the position of the primary air control fin (positioned over the air inlet). The primary air aspirated into the

fuel hopper chamber is used to feed the wood gasification process (called "pyrolisis"). The secondary air is

used to oxidise volatile gases which pass through the burner nozzle. These gases are mixed with pre-heated

secondary air, mixed and oxidised in the combustion chamber of the boiler. This process allows effective fuel

use with low running costs of the heating system. The process could be explained as gas combustion

because most of the fuel is gasified and burnt in the oxidisation chamber of the boiler. The structure of the

boiler allows optimal combustion process conditions and high heat efficiency in addition to simple heat

output and boiler operating mode control. Adjusting the position of the primary air flow control fin requires

knowledge of the boiler operating function, of the combustion process and of the fuel properties in addition

to the services of a technician in order to obtain optimal results. Practical experience demonstrates that

varying the position of the primary air control fin affects operating conditions of the boiler with a delay of

approximately 15-30 minutes. Consequently, in this case wait for at least 15 minutes (preferably 30 minutes)

to obtain constant operating mode of the boiler for the fin position to have a significant effect on the

combustion process.

Air is appropriately distributed by the primary air control fin and by adjusting the fin itself, by means

of the chain, hooked to the thermostatic valve lever. The following figures show details related to air control

adjustment.

NOTE: an inspection opening is provided for checking the position of the primary air control fin.

Page 41

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 41

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

Figure 6.8.1 View of primary air control fin axis fastening screw

It must be possible to easily change the position of the fin by loosening the fastening screw, by manually

pushing or pulling the fin axes (i.e. changing its position). You are keenly recommended to change the

position of the fin by minor adjustments, approximately 1 or 2 mm at a time, and then fix the primary air

control fin using the specific screw.

EXPLANATION: minor movements of the primary air control fin axes have considerable effects on the

combustion process operating conditions and on the general performance of the boiler. For this reason, any

change to the boiler air distribution setting must be followed by an adequate time before the expected result

is obtained. Practical experience shows that using wood logs compliant with the requirements above the

primary air control fin should be closed (pushed back and inwards). However, if the fuel contains more

humidity than required, the primary air control fin should be open so as to assist fuel pyrolisis in the hopper

chamber. In order to do this, adjust the position of the primary air control fin in small steps to obtain

gasification of the raw fuel.

Primaryaircontrolfinaxes

Primaryaircontrolfinaxis

fasteningscrew

Airdistributionbox

Page 42

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 42

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

Figure 6.8.2 View of primary air control fin and air distribution box.

EXPLANATION: the mobile lid is provided to allow to visually inspect the primary air control fin. The lid must

close the opening in nominal operating conditions.

Adjusting the combustion process

The operating parameters defining the hot water boiler heat output must be adjusted by authorised

technicians to guarantee an efficient combustion process and optimal operation of the appliance. It is

advisable to adjust the combustion process by means of measurements made with a combustion gas

analyser.

The flame released from the burner opening is sent downwards thus reaching the ceramic combustion

gas ducting element positioned in the boiler combustion chamber. The flame colour in nominal

operating conditions with an optimal combustion process (i.e. when the process occurs with low CO

content in combustion gases and low excess air ratio) will be bright yellow with blue edges.

Mobilelidoftheinspection

openingforobservingthe

positionoftheprimaryair

controlfin

Primary air controlfin

Primaryaircontrolfinopening

direction(toincreaseprimary

airflow)

Primaryaircontrolfinclosingdirection(todecreaseprimaryairflow)

Page 43

red

TECNIKA 28-35

USE AND INSTALLATION MANUAL

Chapter

6

page 43

Start-up procedures Technical dept. - All rights reserved - Reproduction prohibited

Other flame features:

a bright red flame indicates lack of secondary air and consequently the need to increase the

secondary air flow by opening the total air flow control fin (operated by the thermostatic valve);

a light yellow or short flame indicates excess of secondary air and the secondary air flow