Page 1

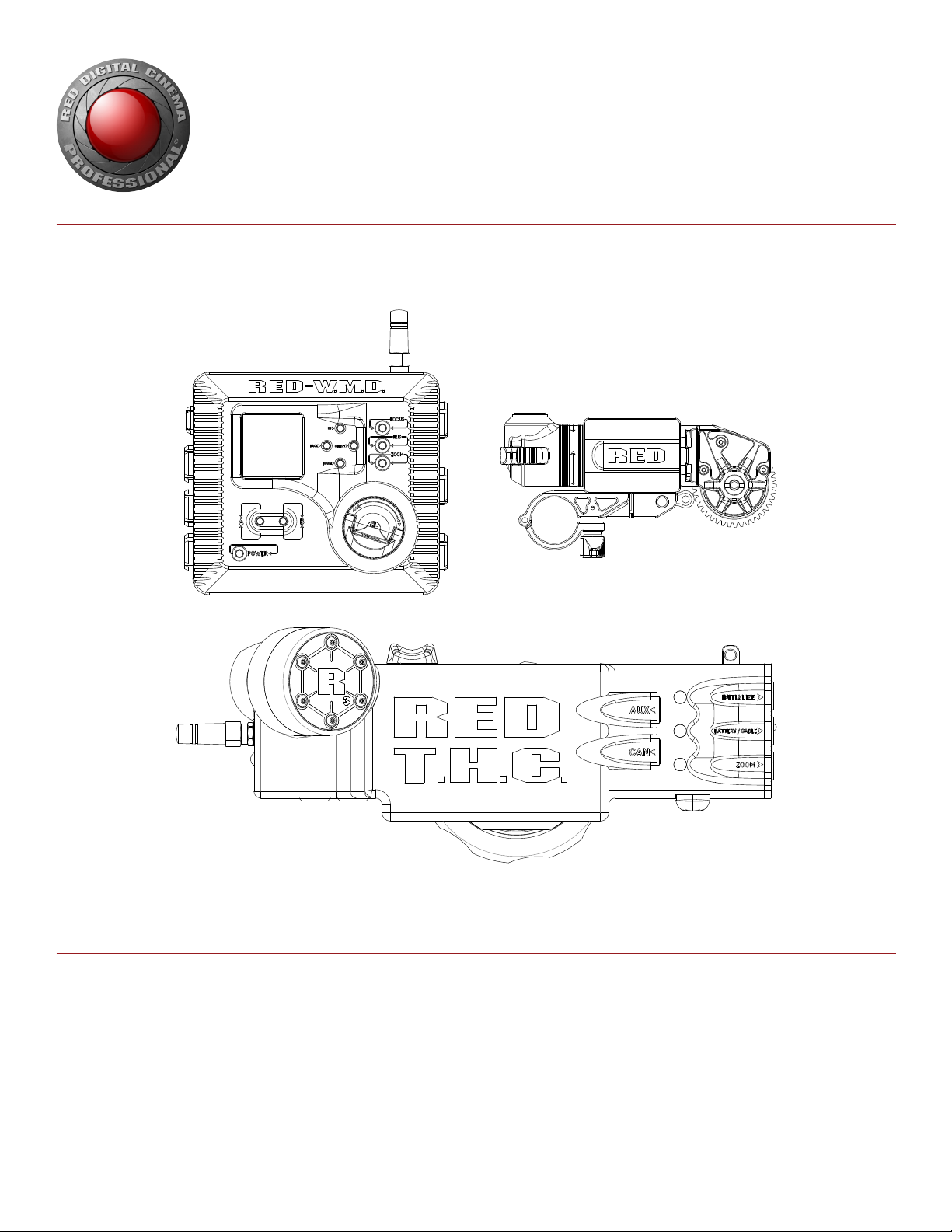

RED 3-AXIS LENS CONTROL SYSTEM

OPERATION GUIDE

W.M.D. | T.H.C. | Lens ConTroL MoTor

RED.COM

Page 2

RED 3-AXIS SYSTEM OPERATION GUIDE

TABLE OF CONTENTS

Disclaimer 3

Copyright Notice 3

Trademark Disclaimer 3

Compliance Statements 3

Safety Instructions 5

Battery Storage and Handling 6

Shipping Disclaimer 6

Chapter 1: 3-Axis System Overview 7

Introduction 7

3-Axis System Components 8

Additional Resources 9

Chapter 2: 3-Axis System Launch Sequence 10

Recommended Equipment 10

Prepare the Camera 11

Install the 3-Axis System 11

Connect the 3-Axis System 13

Configure the 3-Axis System 14

Configure Lens Control Motors 15

Metadata and Lens Profiles 15

Lens Limits and Lens Locks 15

Chapter 3: Wireless Motor Driver (W.M.D.) 16

W.M.D. Overview 16

W.M.D. Controls 17

W.M.D. LEDs 18

W.M.D. Connectors 19

Mount the W.M.D. 21

Power the W.M.D. 23

Connect Motors 23

Initialize with the W.M.D. 23

W.M.D. Main Menu 24

Configure Focus, Iris, and Zoom Motors 24

Configure Wireless Settings 26

View Motor Status 26

Configure Start/Stop, Genlock, TimeCode, Tally 27

W.M.D. Lens Profiles 28

Select a Lens Profile 29

Clear the Active Lens Profiles 29

Modify a Lens Profile 29

Save a Lens Profile 30

View Lens Metadata 30

Export Lens Profiles 30

Import Lens Profiles 30

Manage Lens Profiles 31

Access W.M.D. Diagnostic Data 31

Erase Settings on the W.M.D. 31

Chapter 4: Tactical Hand Controller (T.H.C.) 32

T.H.C. Overview 32

T.H.C. Controls 33

T.H.C. LEDs 34

T.H.C. Connectors 36

Wired Operation 37

Pair the T.H.C. 37

Change the Wireless Channel 38

Wireless Settings 38

Connect Two (2) T.H.C. Units 38

Initialize with the T.H.C. 38

Set a Lens Limit 39

Remove a Lens Limit 39

Set a Lens Lock 40

Remove a Lens Lock 40

Record Start/Stop with the T.H.C. 40

Chapter 5: Lens Control Motor 41

Lens Control Motor Overview 41

Lens Control Motor Mounting Bracket 42

19mm-to-15mm Rod Reducers 42

Lens Drive Gears 43

Install the Lens Control Motor 43

Connect the Lens Control Motor 44

Install a Lens Drive Gear 44

Remove a Lens Drive Gear 44

Chapter 6: System Maintenance 45

Clean 3-Axis System Components 45

Store the 3-Axis System 45

Chapter 7: Upgrade Firmware 46

MicroSD Card Preparation 46

Verify Current W.M.D. Firmware 46

Upgrade W.M.D. 46

Verify Current T.H.C. Firmware 47

Upgrade T.H.C. 47

Chapter 8: Troubleshoot the System 48

General Topics 48

Troubleshoot the W.M.D. 49

Troubleshoot Lens Control Motors 49

Troubleshoot Wireless Operations 50

Troubleshoot Firmware Upgrade 51

Appendix A: Technical Specifications 52

Tactical Hand Controller (T.H.C.) 52

Wireless Motor Driver (W.M.D.) 52

Lens Control Motor 53

RED Li Battery 7.2V 53

Appendix B: 3-Axis System Compatibility 54

Compatible Motors 54

Compatible Motor Drivers 54

Compatible Lenses 54

Appendix C: Connector and Cable Pinouts 55

W.M.D. Connectors 55

T.H.C. Connectors 60

Lens Control Motor Connectors 62

3-Axis System Cables 63

Appendix D: W.M.D. Main Menu Map 70

CoPYrIGHT © 2014 reD.CoM, InC

955-0044, reV-D | 2

Page 3

RED 3-AXIS SYSTEM OPERATION GUIDE

DISCLAIMER

RED has made every effort to provide clear and accurate information

in these installation instructions, which are provided solely for the

user’s information. While thought to be accurate, the information in

this document is provided strictly “as is” and RED will not be held

responsible for issues arising from typographical errors or user’s

interpretation of the language used herein that is different from that

intended by RED. All safety and general information is subject to

change as a result of changes in local, federal or other applicable

laws.

RED reserves the right to revise this document and make changes

from time to time in the content hereof without obligation to notify

any person of such revisions or changes. In no event shall RED, its

employees or authorized agents be liable to you for any damages

or losses, direct or indirect, arising from the use of any technical or

operational information contained in this document.

For comments or questions about content in this Operation Guide,

please send a detailed e-mail to OpsGuides@red.com.

COMPLIANCE STATEMENTS

INDUSTRIAL CANADA EMISSION COMPLIANCE STATEMENTS

This device complies with Industry Canada license-exempt RSS

standards RSS 139 and RSS 210. Operation is subject to the following two conditions: (1) this device may not cause interference, and

(2) this device must accept any interference, including interference

that may cause undesired operation of the device.

This Class B digital apparatus complies with Canadian ICES-003.

Le présent appareil est conforme aux CNR d’Industrie Canada ap-

plicables aux appareils radio exempts de licence. L’exploitation est

autorisée aux deux conditions suivantes : (1) l’appareil ne doit pas

produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter

tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

FEDERAL COMMUNICATIONS COMMISSION (FCC) STATEMENTS

This equipment has been tested and found to

comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment

generates, uses and can radiate radio fre-

quency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more

of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for

help.

In order to maintain compliance with FCC regulations, shielded

cables must be used with this equipment. Operation with non-approved equipment or unshielded cables is likely to result in interference to radio and TV reception. The user is cautioned that changes

and modifications made to the equipment without approval of manufacturer could void the users authority to operate this equipment.

COPYRIGHT NOTICE

COPYRIGHT© 2014 RED.COM, INC.

All trademarks, trade names, logos, icons, images, written material,

code, and product names used in association with the accompanying product are the copyrights, trademarks or other intellectual

property owned and controlled exclusively by RED.COM, INC.

TRADEMARK DISCLAIMER

All other company, brand, and product names are trademarks or

registered trademarks of their respective holders. RED has no affiliation to, is not associated or sponsored with, and has no express

rights in third-party trademarks. SD and microSD are registered

trademark of SD-3C, LLC in the United States, other countries or

both.

NOTE: This device complies with Part 15 of the FCC Rules.

Operation is subjected to the following two conditions (1) this device

may not cause harmful interference, and (2) this device must accept

any interference received, including that may cause undesirable interference.

CAUTION: Exposure to Radio Frequency Radiation.

The device shall be used in such a manner that the potential for human contact is minimized

This equipment complies with FCC radiation exposure limits set

forth for an uncontrolled environment. This equipment should be

installed and operated with a minimum distance of 20 cm between

the radiator and your body.

CAUTION: Regulations of the FCC and FAA

prohibit airborne operation of radio-frequency

wireless devices because their signals could

interfere with critical aircraft instruments.

CAUTION: If the device is changed or modified

without permission from RED, the user may

void his or her authority to operate the equipment.

AUSTRALIA AND NEW ZEALAND STATEMENTS

RED declares that the radio equipment described in this document

comply with the following international standards.

IEC 60065 - Product Safety

ETSI EN 300 328 - Technical requirement for radio equipment

RED declares digital devices described in this document comply

with the following Australian and New Zealand standards.

AS/NZS CISPR 22 – Electromagnetic Interference

AS/NZS 61000.3.2 – Power Line Harmonics

AS/NZS 61000.3.3 – Power Line Flicker

CoPYrIGHT © 2014 reD.CoM, InC 955-0044, reV-D | 3

Page 4

RED 3-AXIS SYSTEM OPERATION GUIDE

JAPAN STATEMENTS

This is a Class B product based on the

standard of the Voluntary Control Council

for Interference (VCCI) for information technology equipment. If this equipment is used

near a radio or television receiver in a domestic environment, it may cause radio interference. Install and use the equipment

according to the instruction manual.

EUROPEAN UNION COMPLIANCE STATEMENTS

RED declares that the radio

equipment described in this

document complies with the

R&TTE Directive (1999/5/

EC) issued by the Commission of the European Community.

Compliance with this directive implies conformity to the following

European Norms (in brackets are the equivalent international standards).

EN 60065 (IEC 60065) – Product Safety

ETSI EN 300 328 Technical requirement for radio equipment

ETSI EN 301 489 General EMC requirements for radio equip-

ment.

INFORMATION

Products with the CE marking comply with the EMC Directive

(2004/108/EC) and the Low Voltage Directive (2006/95/EC) issued

by the Commission of the European Community. Compliance with

these directives implies conformity to the following European Product Family Standards.

EN 55022 (CISPR 22) – Electromagnetic Interference

EN 55024-1 (CISPR 24) – Electromagnetic Immunity

EN 61000-3-2 (IEC610000-3-2) – Power Line Harmonics

EN 61000-3-3 (IEC610000) – Power Line Flicker

EN 60065 (IEC60065) – Product Safety

your nearest designated collection point. Penalties may be applicable for incorrect disposal of this waste, in accordance with you

national legislation.

For business users in the European Union, if you wish to discard

electrical and electronic equipment, please contact your dealer or

supplier for further information.

USAGE RESTRICTIONS FOR PRODUCTS THAT INCORPORATE

REDLINK

Products that fall into this category are denoted

by inclusion of the Class 2 identifier symbol (exclamation mark in a circle) accompanying the CE

Mark on the products regulatory label, example to

the left.

FRANCE

Usage Restrictions - Geographic Area Where Restriction Applies :

France

For mainland France

2.400 - 2.4835 GHz (Channels 1-16) authorized for indoor use

2.400 - 2.454 GHz (Channels 1-10) authorized for outdoor use

Restrictions d’utilisation - Zone géographique où les restrictions

s’appliquent : France

Pour la France métropolitaine

2.400 - 2.4835 GHz (Canaux 1 à 16) autorisé en usage intérieur

2.400 - 2.454 GHz (canaux 1 à 10) autorisé en usage extérieur

NORWAY

This subsection does not apply for the geographical area within a

radius of 20 km from the centre of Ny-Ålesund

Dette gjelder ikke for det geografiske området innenfor en radius av

20 km fra sentrum av Ny-Ålesund

RESPONSIBLE PARTY:

RED Digital Cinema

34 Parker

Irvine, CA 92618

USA

WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE)

The Waste Electrical and Electronic Equip-

ment (WEEE) mark applies only to countries

within the European Union (EU) and Norway.

This symbol on the product and accompanying documents means that used electrical

and electronic products should not be mixed

with general household waste. For proper

treatment, recovery and recycling, please

take this product to designated collection

points where it will be accepted free of

charge. Alternatively, in some countries you

may be able to return your products to your

local retailer upon purchase of an equivalent

new product.

Disposing of this product correctly will help save valuable resources

and prevent any potential negative effects on human health and the

environment, which could otherwise arise from inappropriate waste

handling. Please contact your local authority for further details of

CoPYrIGHT © 2014 reD.CoM, InC

955-0044, reV-D | 4

Page 5

RED 3-AXIS SYSTEM OPERATION GUIDE

SAFETY INSTRUCTIONS

DO NOT use the system or accessories near water. Avoid ex-

posing your system to moisture. The system is not waterproof,

so contact with water could cause permanent damage to the

system as well as electric shock and serious injury to the user.

DO NOT use the system in the rain or under other conditions

with high moisture without appropriate protection, and immediately remove power source if system or accessories are exposed to moisture.

WARNING: To reduce the risk of fire or electric shock, do not expose the camera or

system to rain or moisture.

DO NOT expose your system to excessive vibration or impact

(shock). Be careful not to drop your camera or system. Internal

mechanisms may be damaged by severe shock. Mechanical

alignment of optical elements may be affected by excessive

vibration.

ELECTROMAGNETIC INTERFERENCE: The use of devices us-

ing radio or other communication waves may result in the malfunction or interference with the unit and/or with audio and

video signals.

Clean only using a dry cloth. When cleaning your system, re-

member that it is not waterproof and moisture can damage

electronic circuitry. DO NOT rinse or immerse any element of

the camera, lens or other accessory, keep them dry at all times.

DO NOT use soaps, detergents, ammonia, alkaline cleaners,

and abrasive cleaning compounds or solvents. These substances may damage lens coatings and electronic circuitry.

Maintain sufficient ventilation - DO NOT block any ventilation

openings or obstruct cooling fan airflow.

CAUTION: Proper camera ventilation requires a minimum 1/2" (1.25 cm) clearance between the camera ventilation

openings and external surfaces. Verify

that objects that can block the fan intake

and exhaust ports do not impede airflow.

Failure to permit adequate airflow may result in overheating of the camera, degraded operation and in extreme situations,

damage to the camera.

en over by a vehicle. Replace any power cords suspected of

sustaining damage due to crushing or other forms of damage.

Lithium Ion batteries may be subject to special handling re-

quirements pursuant to federal and local laws. Please refer to

specific shipping instructions included with your battery regarding proper transport of your battery. Do not handle your

battery if it is damaged or leaking. Disposal of batteries must

be in accordance with local environmental regulations. For example, California law requires that all rechargeable batteries

must be recycled by an authorized recycle center. Storing batteries that are fully charged, fully discharged, in high temperatures, or otherwise outside the recommended storage conditions may permanently reduce the life of the battery. Available

battery capacity may also be temporarily lessened after storage in low temperature conditions.

WARNING: DO NOT expose batteries to excessive heat.

WARNING: Danger of explosion if an incorrect battery is charged with a RED Li

Battery Charger 7.2V or is used to power

the T.H.C. Replace only with the same or

equivalent type battery.

CAUTION: Refer all service and repair to

qualified RED service personnel. To reduce

the risk of electric shock, and damage to

the camera or accessories, DO NOT attempt to perform any servicing other than

any procedures that are recommended in

the operating instructions.

DO NOT operate or store near any heat sources such as radia-

tors, heat registers, stoves, or any other apparatus that produce heat. Store in a protected, level and ventilated place.

Avoid exposure to temperature extremes, damp, severe vibration, strong magnetic fields, direct sunlight or local heat sources during storage. Remove any batteries from the T.H.C. before

storage. Recommended storage and usage temperatures for

your system are:

‒ Operating range: 0°C to 40°C (32°F to 104°F)

‒ Storage range: -20°C to 50°C (-4°F to 122°F)

If there are any performance issues with your system when

operating within this temperature range, please file a support

ticket on support.red.com.

The W.M.D. is NOT HOT SWAPPABLE – meaning you cannot

remove or install while the camera is powered on. Before installing or removing, you MUST power down the camera. Failure to do so may result in damage to the accessory and / or

camera brain that will not be covered under warranty.

Protect all power cords from being pinched, walked on or driv-

CoPYrIGHT © 2014 reD.CoM, InC 955-0044, reV-D | 5

Page 6

RED 3-AXIS SYSTEM OPERATION GUIDE

BATTERY STORAGE AND HANDLING

WARNING: Failure to read, understand, and

follow these instructions may result in overheating, chemical leakage, smoke emission,

fire, or other potentially harmful results.

Always follow proper battery handling and storage practices. Improper handling and/or failure to abide by proper storage instructions may cause permanent damage to batteries, or degrade charge

capacity. Improper handling practices or failure to comply with instructions may also put you at risk.

LONG TERM STORAGE AND HANDLING

Lithium-Ion batteries, like the RED Li Battery 7.2V, REDVOLT®, REDVOLT XL, and RED BRICK®, self-discharge over time. When storing

for long periods of time, store batteries separately from the camera

or charger and remember to charge batteries to a capacity level of

50% to 80%. If batteries will be stored for long periods of time, RED

recommends that you check the charge level at least once every

six (6) months, and recharge batteries to a capacity level of 50%

to 80%.

When not in use, remove the battery from the camera or charger

and store the battery in a cool, dry place. Avoid non-insulated storage areas with fluctuating temperatures, extreme hot temperatures

(such as inside a hot car), corrosive gas, and direct sunlight. The

optimal storage temperature for batteries is between -20°C to 20°C

(-4°F to 68°F).

BATTERY CAUTIONS AND WARNINGS

WARNING: Batteries stored for a prolonged

period of time at less than 50% charge level

may permanently lose the ability to hold a

charge.

permanent damage.

DO NOT connect the positive (+) and negative (-) terminals to

a metal object such as a wire.

DO NOT allow batteries to get wet.

DO NOT transport or store batteries together with metal ob-

jects such as jewelry, hairpins, etc. as they may generate heat

if they come into contact with the battery.

DO NOT pierce batteries with pointed or other sharp objects.

DO NOT step on, throw, or strike batteries with a hammer.

DO NOT use batteries that appear to be deformed or damaged.

DO NOT put batteries into pressurized containers or micro-

wave ovens.

DO NOT use or subject batteries to intense sunlight or hot

temperatures such as a vehicle on a hot day.

Battery incorporates built-in safety devices. DO NOT use it in a

location where static electricity may be present.

DO NOT exceed the recharging temperature range of 0˚C to

40˚C (32˚F to 104˚F).

Only use RED chargers to recharge RED batteries.

If a battery leaks or gives off a bad odor, discontinue use im-

mediately.

If a battery gives off an odor, generates heat, becomes discol-

ored or deformed, or in any way appears abnormal during use,

recharging or storage, immediately remove it from the equip-

ment or battery charger and discontinue use.

If electrolyte from batteries comes into contact with skin or

clothing, immediately wash the area with running water. Failure

to do this may result in skin inflammation.

If electrolyte reaches the eyes, DO NOT rub them. Instead,

rinse the eyes with clean running water and immediately seek

medical attention. Failure to do this may result in eye injury.

If you find discoloration, a bad odor due to leakage, overheat-

ing and/or other irregularities when using a battery for the first

time, contact your Bomb Squad representative immediately.

WARNING: DO NOT use the battery for pur-

poses other than those specified.

WARNING: If recharging operation fails to

complete even after the specified recharging

time has elapsed, immediately stop further recharging.

Store batteries out of the reach of children.

DO NOT store batteries in a fully charged or discharged state

for extended periods of time.

DO NOT store batteries in a camera, camera module, or char-

ger for extended periods of time.

DO NOT store batteries in extreme hot or cold temperatures.

DO NOT expose batteries to fire or excessive heat.

DO NOT store batteries in direct sunlight.

DO NOT store, use, or recharge batteries near a heat source

such as a fire or a heater.

DO NOT use third-party chargers with your RED batteries.

DO NOT disassemble or modify batteries.

DO NOT overcharge batteries. Overcharging may increase in-

ternal temperature beyond the recommended limits and cause

CoPYrIGHT © 2014 reD.CoM, InC

NOTE: For more information regarding RED

battery charging and instructions for care,

please refer to our Terms and Conditions.

SHIPPING DISCLAIMER

Unless you have been certified to ship dangerous goods, you must

work with a Dangerous Goods, Class 9-certified shipper to assist

you with a shipment that includes a RED BRICK (or other regulated

lithium ion batteries). Please note that applicable laws prohibit the

shipping of batteries that are physically damaged. We urge you to

look into the formal rules and regulations of shipping Class 9 Dangerous Goods prior to preparing your shipment. For more information on these regulations, please visit www.iata.org and www.dot.

gov.

955-0044, reV-D | 6

Page 7

RED 3-AXIS SYSTEM OPERATION GUIDE

3-AXIS SYSTEM

01

01

INTRODUCTION

The RED 3-Axis Lens Control System is a versatile and highly accurate wireless lens control system. Use the

RED® Lens Control Motor, RED® Tactical Hand Controller (T.H.C.), RED® Wireless Motor Driver (W.M.D.), and

related RED accessories to configure a low-profile lens control system for your camera rig. This guide provides

setup and operation instructions for the RED Lens Control Motor, T.H.C., W.M.D., and related accessories.

The Tactical Hand Controller is also compatible with the REDLINK™ Bridge for wireless control of supported

Canon® and Nikon® motorized lenses. For more information, see the REDLINK Bridge Operation Guide, available

at www.red.com/downloads.

WARNING: ALWAYS use the RED motor cable with the appropriate internal identification resistor when using

RED LENS CONTROL MOTORs with third-party motor drivers. Any damage caused to motors or motor drivers

resulting from the use of third-party cables will not be covered under warranty.

NOTE: The DSMC does not require a minimum firmware version for operation with the W.M.D., T.H.C.,

Lens Control Motor, and other components of the RED 3-Axis Lens Control System.

OVERVIEW

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 7

Page 8

RED 3-AXIS SYSTEM OPERATION GUIDE

3-AXIS SYSTEM COMPONENTS

RED offers the following RED 3-Axis Lens Control System components individually, enabling you to customize

your lens control setup. For more information, visit the RED Store at www.red.com/store.

ITEM PART NUMBER

RED® 3-Axis Lens Control System 760-0147

RED® W.M.D. (Wireless Motor Driver) 790-0414

RED® T.H.C. (Tactical Hand Controller) 790-0413

RED® Lens Control Motor 760-0146

RED® Lens Drive Gear M 0.8 760-0139

RED® Lens Drive Gear M 0.6 760-0140

RED® Lens Drive Gear M 0.5 760-0141

RED® Lens Drive Gear M 0.4 760-0142

19mm-to-15mm Rod Reducer Kit 760-0151

RED® Lens Control Motor Mounting Bracket (Standard) 760-0137

RED® W.M.D. Motor Cable 7-Pin Straight to 7-Pin Right (12") 790-0434

RED® W.M.D. Motor Cable 7-Pin Straight to 7-Pin Right (18") 790-0406

RED® W.M.D. Motor Cable 7-Pin Straight to 7-Pin Right (24") 790-0412

RED® Lens Motor Cable (3.3KΩ version) 18" 790-0439

RED® Lens Motor Cable (3.3KΩ version) 24" 790-0438

RED® W.M.D. Power Cable 2-Pin 1B to 2-Pin 0B (18") 790-0410

RED® W.M.D. Power Cable 2-Pin 1B to 4-Pin XLR (8') 790-0411

RED® CAN Command Cable (5') 790-0407

RED® CAN Command Cable (50') 790-0408

RED® CAN Command Cable (100') 790-0409

REDLINK™-to-T.H.C. Connector Cable (3') 790-0444

RED® Start/Stop Cable (1B to Sync, Ctrl, BNC) 790-0415

RED® Start/Stop Cable (1B to BNC) 790-0416

RED® Start/Stop Cable (1B to 00B Sync) 790-0428

3BNC-to-00 Lemo Sync Cable 790-0154

Accessory Mount (V-Lock) 790-0370

RED® T.H.C./W.M.D. Antenna 790-0420

T.H.C. Focus Marking Ring 790-0430

Lanyard, RED Digital Cinema 010-0119

RED® Li Battery 7.2V 740-0032

RED® Li Battery Charger 7.2V 740-0033

3-Axis Systems Storage Case 790-0421

BNC-TO-BNC Adaptor 790-0435

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 8

Page 9

RED 3-AXIS SYSTEM OPERATION GUIDE

ADDITIONAL RESOURCES

The following resources offer additional information about RED, the DSMC® system, and the RED community:

RED.com: Check the official RED website for latest information about RED products.

RED Learn Articles: RED offers in-depth technical articles about RED cameras, post-production, and digital

cinematography.

RED.com/downloads: Go to the RED Downloads page to download the latest firmware, operation guides,

and post-production software.

Support.red.com: Check the RED SUPPORT site for FAQs, or to file a support ticket.

REDUser.net: Discuss all things RED on the REDUSER third-party forum.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 9

Page 10

RED 3-AXIS SYSTEM OPERATION GUIDE

3-AXIS SYSTEM

02

This section offers condensed installation and operating instructions to help you get started using the

RED 3-Axis Lens Control System. For more detailed information on specific components, please refer to the

respective chapter in this guide.

WARNING: The DSMC® BRAIN® must be powered off during any installation process.

LAUNCH SEQUENCE

RECOMMENDED EQUIPMENT

The following RED products are suggestions for use, or are used to depict operations within this section:

12 - 18 V DC power source

‒ AC Power Adaptor (DSMC) with REDVOLT® XL Module

‒ RED Quickplate (Short) Module with attached RED BRICK

‒ Backpack Quickplate (Short) with attached RED BRICK

Mounting platform

‒ DSMC Tactical Cage

‒ DSMC Tactical Right Plate

Mounting system

‒ DSMC Modular Assault Plate Pack

‒ Quick Release Platform or Quick Release Platform (Mini)

15mm or 19mm support rods

‒ RED CARBON-X Rod (Carbon Fiber)

‒ Black Rod (Aluminum)

‒ Steel Rod (Steel)

NOTE: For more information and other compatible products, visit the RED Store at www.red.com/store.

®

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 10

Page 11

RED 3-AXIS SYSTEM OPERATION GUIDE

PREPARE THE CAMERA

1. Install a mounting platform for the W.M.D. (Example: DSMC Tactical Cage or Tactical Right Plate)

2. Install a support rod system. (Example: DSMC Modular Assault Plate or Quick Release Platform)

3. Install 15mm or 19mm support rods.

INSTALL THE 3-AXIS SYSTEM

These instructions provide installation steps using a tactical cage or other cheeseplate. For more information

and other installation methods, go to “Mount the W.M.D.” on page 21.

1. Mount the W.M.D.

A. Remove the guide pin from the recessed storage location on the bottom of the unit.

B. Insert the guide pin into the bottom right mounting hole on the back of the W.M.D. for 18 mm mounting

configurations. Use the left mounting hole for 25 mm configurations.

Install the W.M.D. Guide

Pin

C. Position the W.M.D. at the desired location on the mounting platform, using the guide pin for alignment.

NOTE: Ensure you leave enough clearance on the sides to connect cables.

D. Push in and turn the 1/4-20 captive thumbscrew to initiate threading.

Mount the W.M.D.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 11

Page 12

RED 3-AXIS SYSTEM OPERATION GUIDE

E. Tighten the thumbscrew until hand tight.

WARNING: DO NOT OVERTIGHTEN.

2. Install the RED Lens Control Motor Mounting Bracket.

A. Push the lock button on the Lens Control Motor Mounting Bracket to disengage the locking mechanism.

B. Slide the dove-tail rail on the Lens Control Motor Mounting Bracket into the dove-tail slot on the

Lens Control Motor.

C. Release the lock button.

D. Tighten the M4 thumbscrew on the side of the Lens Control Motor Mounting Bracket to lock the bracket

in place.

3. Mount the Lens Control Motors to the support rods.

A. If you are using 15mm support rods, install the 19mm-to-15mm Reducer Bushings into the clamp.

B. Position the Lens Control Motors at the desired position on the support rods.

C. Use the thumbscrew to tighten the clamp on the Lens Control Motor Mounting Bracket.

NOTE: For more information, go to “Lens Control Motor” on page 41.

Mount

Lens Control Motors

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 12

Page 13

RED 3-AXIS SYSTEM OPERATION GUIDE

CONNECT THE 3-AXIS SYSTEM

1. Connect the RED Lens Control Motors.

A. Connect the RED W.M.D. Motor Cable to the pivoting connector on each Lens Control Motor.

B. Connect the opposite end of the LENS CONTROL MOTOR CABLE to the desired lens function.

C. Repeat steps A and B for additional motors.

2. Connect the desired RED Start/Stop cable.

A. Connect the desired RED Start/Stop Cables to the W.M.D. EXP port.

B. Connect the desired RED Start/Stop Cables to the appropriate SYNC and CTRL ports on the BRAIN.

WARNING: DO NOT connect Start/Stop Cables to the CTRL port only. This may result in undesired consequences or cause the camera to crash.

NOTE: For more information, go to “Configure Start/Stop, Genlock, TimeCode, Tally” on page 27.

Connect RED

Start/Stop Cable

3. Connect power to the W.M.D.

A. Connect the desired W.M.D. Power Cable to the W.M.D. PWR port.

B. Connect the opposite end of the W.M.D. Power Cable to a 12 V DC power supply with sufficient am-

perage.

NOTE: It is recommended that you connect the W.M.D. to a dedicated power source, such as shore

power, when operating power intensive configurations or stiff lenses that require high torque settings.

NOTE: For more information, go to “Wireless Motor Driver (W.M.D.)” on page 16.

4. Connect the T.H.C.

A. Connect the 4-pin RED CAN Command Cable to the CAN connector port on the W.M.D.

B. Connect the opposite end of the RED CAN Command Cable to the T.H.C. (CAN) port.

C. Toggle the T.H.C. power switch to Cable mode.

NOTE: The W.M.D. communicates wireless settings information via the RED CAN Command Cable. For

more information, go to “Tactical Hand Controller (T.H.C.)” on page 32.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 13

Page 14

RED 3-AXIS SYSTEM OPERATION GUIDE

CONFIGURE THE 3-AXIS SYSTEM

1. Pair the T.H.C.

A. Ensure the RED CAN Command Cable is connected to the W.M.D. and T.H.C.

B. Toggle the T.H.C. power switch to Cable mode.

Once paired, the T.H.C. retains wireless information for that W.M.D.

C. Insert a charged RED Li Battery 7.2V.

D. Toggle the T.H.C. power switch to Battery mode.

Wait a few seconds for the T.H.C. wireless LED to turn solid blue, signalling a wireless connection.

E. Remove the RED CAN Command Cable.

The T.H.C. is now successfully paired.

NOTE: For more information, go to “Pair the T.H.C.” on page 37.

2. Set motor type.

A. In the W.M.D. main menu, navigate to Focus/Iris/Zoom > Model.

B. Select your motor type. (Example: RED DLM1)

NOTE: For more information, go to “Select Motor Type/Model” on page 25.

3. Configure wireless settings.

A. In the W.M.D. main menu, select Wireless.

If you are operating the T.H.C. in close proximity (Up to 25 feet), select Low.

If you are operating the T.H.C. from greater distances, select High.

If operating multiple systems in the same vicinity, select a unique wireless channel.

NOTE: For more information, go to “Configure Wireless Settings” on page 26.

4. Initialize motors.

A. Press and hold the Initialize button on the T.H.C., or the B button on the W.M.D. for two (2) seconds.

NOTE: Fore more information, go to “Initialize the System” on page 14.

The RED 3-Axis Lens Control System is now successfully setup and ready for wireless operation. The remainder of this section offers further guidance on initialization, motor configuration, lens profiles, metadata, and

T.H.C. controls.

INITIALIZE THE SYSTEM

Initialization detects the range of motion for each motor and stores the data in the W.M.D. Lens data remains in

W.M.D. for approximately 14 hours even if system reboots are performed. W.M.D. LEDs display motor initialization status. Red LEDs indicate motors that are not initialized, solid green indicates motors that are initialized,

and flashing green LEDs indicate an initialization process is in progress.

To initialize the system, perform one of the following actions:

Press and hold the Initialize button on the T.H.C. for two (2) seconds to initialize all connected motors.

Press and hold the B button on the W.M.D. for two (2) seconds to initialize all connected motors.

Press and release the Initialize or B button to initialize only motors that need it.

A single motor can be initialized by disconnecting and reconnecting the motor cable.

IMPORTANT: Initialize motors any time a modification is made.

NOTE: The W.M.D. must be unlocked for the B button to be active. Press and hold the A button for two (2) sec-

onds to unlock the unit and access the menu.

The RED 3-Axis Lens Control System is now successfully setup and ready for wireless operation. The remain-

der of this section offers guidance on non-essential features.

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 14

Page 15

RED 3-AXIS SYSTEM OPERATION GUIDE

CONFIGURE LENS CONTROL MOTORS

The W.M.D. features a number of adjustments in the Focus, Iris, and Zoom menu topics to fine-tune specific

motor/lens combinations. After initializing the system, you may need to adjust the following settings:

Torque

Direction

Type/Model

Backlash

Endstop

NOTE: For more information, go to “Configure Focus, Iris, and Zoom Motors” on page 24.

METADATA AND LENS PROFILES

The microSD slot on the W.M.D. is used to update firmware, as well as save and share modified lens profiles

that allow you to view real-time metadata on the W.M.D. This guide offers information on the following topics:

Select a Lens Profile

Modify a Lens Profile

Clear the Active Lens Profile

View Lens Metadata

Export Lens Profiles

Import Lens Profiles

NOTE: For more information, go to “W.M.D. Lens Profiles” on page 28.

LENS LIMITS AND LENS LOCKS

The T.H.C. features several convenient and easy-to-use features for precision wireless control. This guide offers

information on the following topics:

Set a Lens Limit

Remove a Lens Limit

Set a Lens Lock

Remove a Lens Lock

NOTE: For more information, go to the chapter “Tactical Hand Controller (T.H.C.)” on page 32.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 15

Page 16

RED 3-AXIS SYSTEM OPERATION GUIDE

WIRELESS MOTOR

03

DRIVER (W.M.D.)

W.M.D. OVERVIEW

The RED® Wireless Motor Driver (W.M.D.) is the brain of the RED 3-Axis Lens Control System. The W.M.D.

receives control signals from the RED Tactical Hand Controller (T.H.C.) to drive up to three (3) RED

Lens Control MotorS. With the W.M.D., you can adjust the following settings for each motor:

Torque

Direction

Type/Model

Backlash

Endstop

R3D metadata integration is a standard on the W.M.D., allowing your recorded lens control information to carry

over into post-production. Expansion ports, tool-free installation, and start/stop connectivity make the W.M.D.

versatile and easy-to-use.

NOTE: DO NOT USE the Pro I/O Module to power the RED W.M.D. The Pro I/O Module does not provide enough

power and is not designed to support the W.M.D.

NOTE: For more information on compatibility, go to “3-Axis System Compatibility” on page 54.

NOTE: Go to the RED Downloads page at www.red.com/downloads for the latest firmware version, operation

guide, and other support resources.

COPYRIGHT © 2014 RED.COM, INC

RED W.M.D.

955-0044, REV-D | 16

Page 17

RED 3-AXIS SYSTEM OPERATION GUIDE

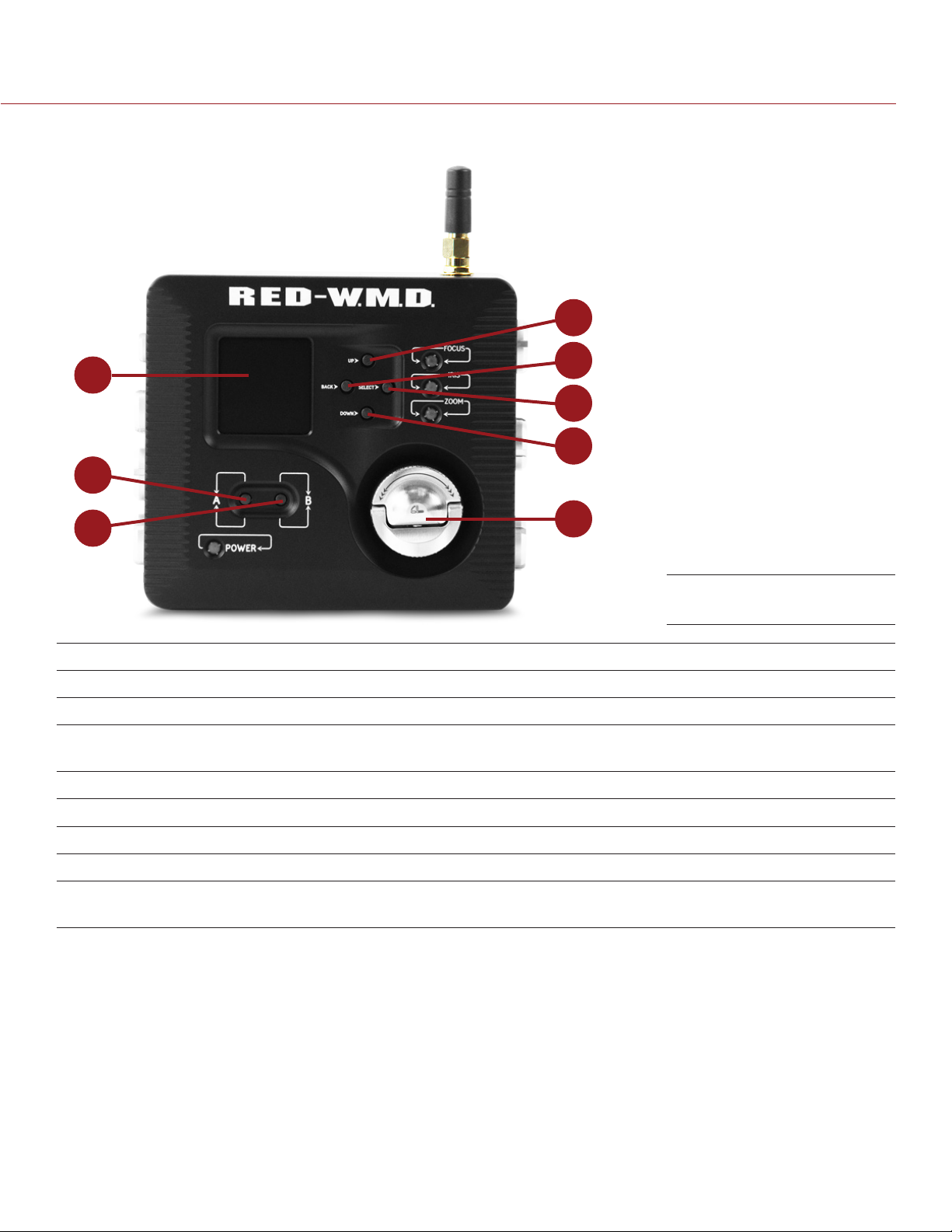

W.M.D. CONTROLS

4

1

5

6

7

2

3

# CONTROL DESCRIPTION

1 LCD display View the W.M.D. menus

2 A button Return to home screen; Toggles lock/unlock buttons

3 B button Short press initializes motors that are in an error state; long press initializes

all motors

4 Up button Navigate up through the W.M.D. main menus

8

W.M.D. Controls

5 Back button Return to the previous menu

6 Select button Enter or adjust the selected (highlighted) menu or item

7 Down button Navigate down through the W.M.D. main menus

8 Mounting

thumbscrew

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 17

Press and turn to install (CW) or uninstall (CCW) the W.M.D. to a mounting

plate (Example: DSMC TACTICAL RIGHT PLATE)

Page 18

RED 3-AXIS SYSTEM OPERATION GUIDE

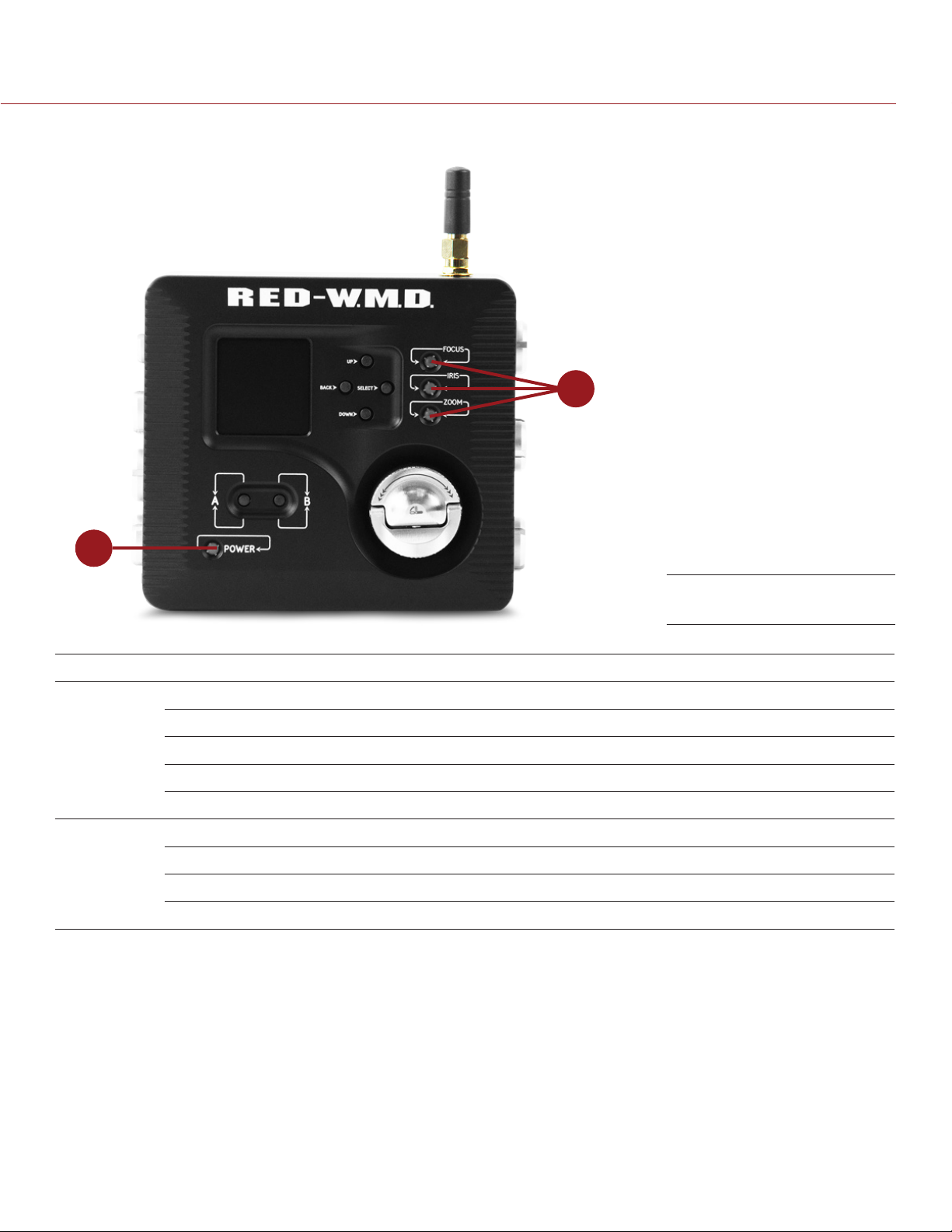

W.M.D. LEDS

2

1

# LED COLOR/FLASHING DESCRIPTION

1 Power Off No power connected

Green flashing Firmware upgrading

Green Power on; Firmware upgraded

Red Power error

Amber flashing System boot indicator or initialization in progress

2 Focus,

Iris,

Zoom

Off No motor connected

Green flashing Initialization in progress

Green Initialized and ready for operation

Red Motor error or failed initialization

W.M.D. LEDs

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 18

Page 19

RED 3-AXIS SYSTEM OPERATION GUIDE

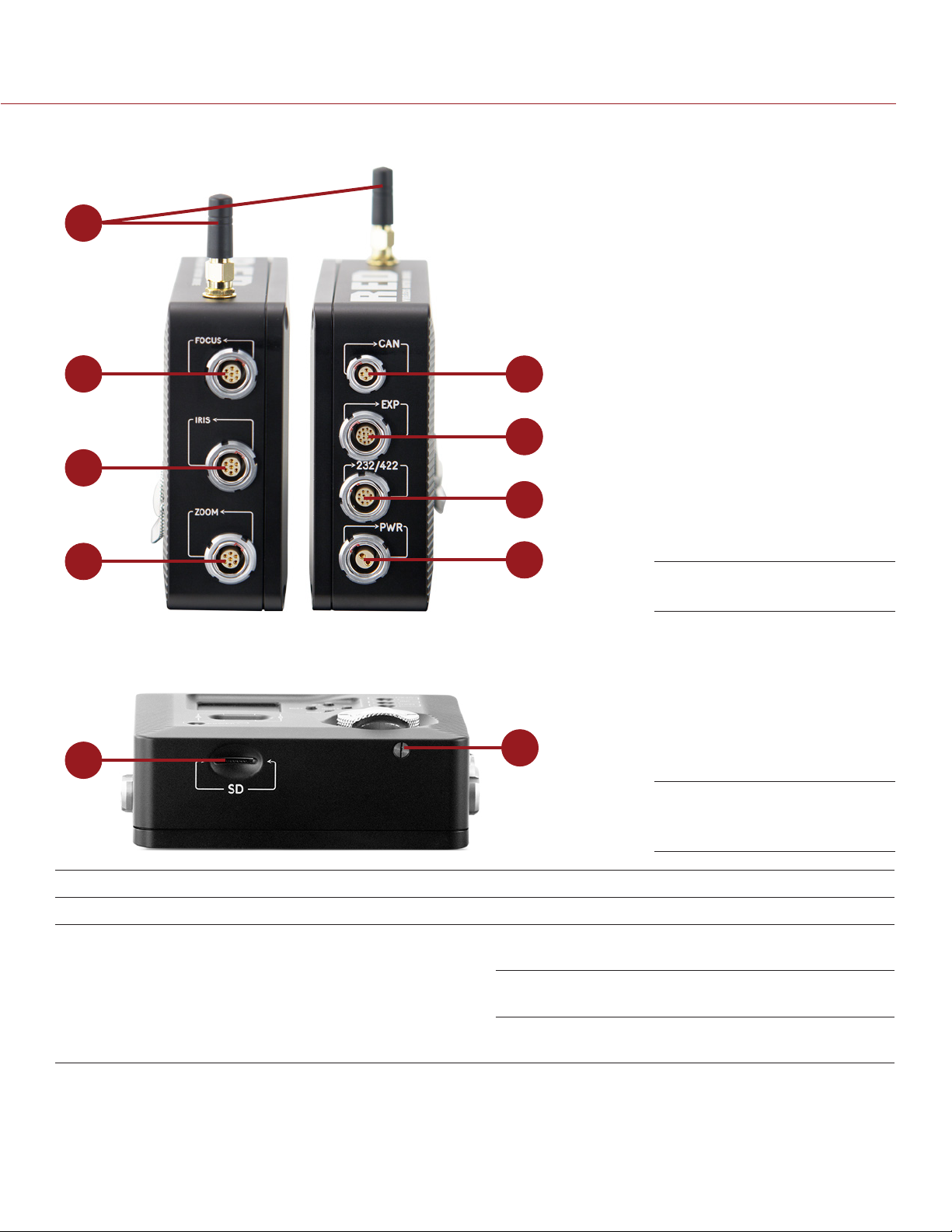

W.M.D. CONNECTORS

1

2

5

6

3

7

4

9

8

W.M.D. Connectors (Side)

10

W.M.D. Connectors

(Bottom)

# CONNECTOR DESCRIPTION COMPATIBLE PARTS PART NUMBERS

1 Wireless antenna Removeable antenna RED T.H.C./W.M.D. Antenna 790-0420

2 Focus connector

(7-pin 1B LEMO)

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 19

Connect the W.M.D. to the

Focus Lens Control Motor

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (12”)

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (18”)

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (24”)

790-0434

790-0406

790-0412

Page 20

RED 3-AXIS SYSTEM OPERATION GUIDE

# CONNECTOR DESCRIPTION COMPATIBLE PARTS PART NUMBERS

3 Iris connector

(7-pin 1B LEMO)

4 Zoom connector

(7-pin 1B LEMO)

5 CAN connector

(4-pin 0B LEMO)

6 Expansion port

(14-pin 1B LEMO)

Connect the W.M.D. to the

Iris Lens Control Motor

Connect the W.M.D. to the

Zoom Lens Control Motor

CAN port for T.H.C. wired

communication

Expansion port to connect to

DSMC via the SYNC port and

control Start/Stop functions

on the DSMC

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (12”)

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (18”)

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (24”)

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (12”)

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (18”)

RED W.M.D. Motor Cable 7-Pin

Straight to 7-Pin Right (24”)

RED CAN Command Cable (5') 790-0407

RED CAN Command Cable (50') 790-0408

RED CAN Command Cable (100') 790-0409

RED Start/Stop Cable (1B to Sync,

Ctrl, BNC)

RED Start/Stop Cable (1B to BNC) 790-0416

790-0434

790-0406

790-0412

790-0434

790-0406

790-0412

790-0415

7 232/422 port

(10-pin LEMO)

8 PWR connector

(2-pin 1B LEMO)

9 MicroSD card slot MicroSD card slot for upgrad-

10 Guide pin 1/4" guide pin to install the V-

Serial port to communicate

with third-party devices

Power in RED W.M.D. Power Cable 2-Pin 1B

ing W.M.D. firmware

LOCK to a DSMC TACTICAL

RIGHT PLATE

RED Start/Stop Cable (1B to 00B

Sync)

3BNC-to-00 LEMO Sync Cable 790-0154

BNC-TO-BNC Adaptor 790-0435

N/A N/A

to 2-Pin 0B (18”)

RED W.M.D. Power Cable 2-Pin 1B

to 4-Pin XLR (8’)

MicroSD card N/A

1/4" guide pin N/A

790-0428

790-0410

790-0411

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 20

Page 21

RED 3-AXIS SYSTEM OPERATION GUIDE

MOUNT THE W.M.D.

The W.M.D. is designed to support various mounting requirements, enabling you to customize your setup for

your own camera configuration.

ATTACH THE W.M.D. TO THE DSMC TACTICAL RIGHT PLATE

When the V-LOCK is removed from the back of the W.M.D., it can be attached to a DSMC® Tactical Right Plate

using the built-in thumbscrew and guide pin.

The W.M.D. can be attached to a DSMC Tactical Right Plate or other mounting plate with 1/4-20 screw holes.

The built-in thumbscrew and 1/4" guide pin provide convenient, tool-free attachment for the W.M.D.

1. Ensure that the V-LOCK is removed from the back of the W.M.D. For more information about how to remove

the V-LOCK, go to “Mount the W.M.D. to a V-Mount Receiver” on page 22.

2. Use a slotted screwdriver to remove the guide pin from the bottom of the W.M.D.

Remove Guide Pin

3. Use a slotted screwdriver to install the guide pin in the appropriate mounting hole on the back of the W.M.D.

Select the mounting hole based on your mounting configuration:

‒ DSMC Tactical Right Plate: Use the screw hole closest to the 1/4-20 screw for 18 mm spacing.

‒ Third-party cheeseplate: Use the screw hole farthest from the 1/4-20 screw for 25 mm spacing.

Install Guide Pin

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 21

Page 22

RED 3-AXIS SYSTEM OPERATION GUIDE

4. Place the W.M.D. against the Tactical Plate so that the guide pin and 1/4-20 screw each align with a 1/420 screw hole.

5. Push and turn the W.M.D. 1/4-20 thumbscrew until it is hand-tight. DO NOT OVERTIGHTEN.

Push and Turn

Thumbscrew

MOUNT THE W.M.D. TO A V-MOUNT RECEIVER

The W.M.D. ships with a V-LOCK to mount the W.M.D. to most industry-standard female v-mount receivers.

1. Align the V-LOCK in the desired position on the back of the W.M.D.

2. Use a Phillips #1 screwdriver to install three (3) M3x0.5 x 8 mm flathead screws that attach the V-LOCK to

the W.M.D. Fully tighten. DO NOT OVERTIGHTEN.

Use a Phillips #1 screwdriver to remove the three (3) M3x0.5 x 8 mm flathead screws, when finished.

COPYRIGHT © 2014 RED.COM, INC

W.M.D. Rear

(V-LOCK Installed)

955-0044, REV-D | 22

Page 23

RED 3-AXIS SYSTEM OPERATION GUIDE

POWER THE W.M.D.

1. Connect the 2-pin 1B LEMO connector of a RED W.M.D. Power Cable to the PWR port on the W.M.D.

2. Connect the opposite end to a 12 V DC power source with sufficient amperage.

NOTE: The W.M.D. is powered on when the power cable is connected to a live power source. Disconnect

the power cable to turn off the W.M.D.

CONNECT MOTORS

1. Connect a RED W.M.D. Motor Cable to the 7-pin LEMO connector on the motor.

2. Connect the opposite end of the RED W.M.D. Motor Cable to the corresponding lens function (Focus, Iris,

Zoom) 7-pin LEMO connector on the W.M.D.

3. After connecting all motors to the W.M.D., configure the settings for that motor. For more information about

configuring motor settings, go to “Configure Focus, Iris, and Zoom Motors” on page 24.

INITIALIZE WITH THE W.M.D.

Motor initialization detects each motor’s range of motion for the attached lens and stores the encoder positions and lens parameters within the W.M.D. lens data gathered by the initialization process remains in W.M.D.

memory for approximately 14 hours, even if system reboots are performed. This 14 hour period begins when

the W.M.D. is powered off for the first time.

To initialize ALL motors:

Press and hold the B button on the W.M.D. for two (2) seconds.

To initialize ONLY motors with unrecognized positions:

Press and release the B button.

A single motor can be initialized by disconnecting and reconnecting the motor cable.

WARNING: It is important to initialize every time a change is made to a lens or a motor. Failing to initialize may

damage lenses or motors.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 23

Page 24

RED 3-AXIS SYSTEM OPERATION GUIDE

W.M.D. MAIN MENU

The W.M.D. home screen displays the following system information for convenient user access:

Lock status icon

Wireless power setting icon

‒ H: Wireless power set to High

‒ L: Wireless power set to Low

Currently selected lens profile

‒ White: Designates a default profile

‒ Yellow: Designates a modified AND saved User profile

‒ Red: Designates a modified profile that has not been saved

When changes are made to these W.M.D. main menu settings, they automatically update on the home screen.

AUTO-LOCK FEATURE

The W.M.D. features a menu lock function to prevent inadvertent changes to system settings. When locked, the

lock status indicator is displayed in the upper left corner of the W.M.D. home screen.

The W.M.D. automatically locks after 60 seconds of non-use. Press the A button from any W.M.D. menu to lock

the W.M.D. and return to the home screen.

UNLOCK THE W.M.D.

When the W.M.D. is locked, only the A button remains active. Unlock the W.M.D. to return to the main menu.

Press and hold the A button for two (2) seconds to unlock W.M.D.

W.M.D. BUTTON LOCK

In the W.M.D. Options menu, the Button Lock feature provides the user with the ability to disable the auto-lock

feature when a menu time-out occurs. When the lock is disabled, the user no longer has to hold the A button

for two (2) seconds to unlock the unit. Regardless of the setting, pressing the A button will lock the W.M.D.

Disable the auto-lock in the W.M.D. menu, under Options > Button Lock.

CONFIGURE FOCUS, IRIS, AND ZOOM MOTORS

After initializing the W.M.D. with a Lens Control Motor, you may need to adjust the following settings:

Torque

Direction

Type/Model

Backlash

Endstop

ADJUST TORQUE

Keep the torque setting as low as possible to avoid damaging the lens and lens motors. Increase the torque

setting if the motor does not successfully initialize or an error message is displayed.

1. In the W.M.D. main menu, select the desired motor. (Example: Focus, Iris, Zoom)

2. Select Torque.

3. Press Select to cycle through to the desired torque setting. (Example: Low, Medium, High)

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 24

Page 25

RED 3-AXIS SYSTEM OPERATION GUIDE

CHANGE MOTOR DIRECTION

The last direction of the motor persists between reboots.

1. In the W.M.D. main menu, select the desired motor. (Example: Focus, Iris, Zoom)

2. Select Direction.

3. Press Select to toggle to motor direction. (Example: CW, CCW)

SELECT MOTOR TYPE/MODEL

1. In the W.M.D. main menu, select the lens function for the specific motor. (Example: Focus, Iris, or Zoom)

2. Select Model.

3. Navigate to the desired motor model.

4. Press Select.

NOTE: For a list of default motor profiles, go to “3-Axis System Compatibility” on page 54 or the “W.M.D.

Main Menu Map” on page 70.

ADJUST BACKLASH

The RED Lens Control Motor offers next to zero backlash when properly installed. However, you may experience backlash with third-party motors, or certain lens and motor combinations.

The W.M.D. allows you to compensate for any backlash. Select an anti-backlash setting in the range of 0–3,000

encoder counts.

1. In the W.M.D. main menu, select the lens function for the specific motor. (Example: Focus, Iris, or Zoom)

2. Select Backlash.

3. Use the Select and Back buttons to navigate between digit values.

‒ Press Select to move the cursor to the right one (1) digit.

‒ Press Back to move the cursor to the left one (1) digit.

‒ Press Up to increase the value or press Down to decrease the value.

4. Adjust the setting until backlash is removed.

5. Deselect the digits and return to the menu.

ADJUST ENDSTOP

The W.M.D. provides a buffer for the endstops. However, different lenses have varying requirements for this

buffer. Some lenses require the motor to drive the lens right up to the endstop. Other lenses do not require this

and allow a large buffer to prevent high speed moves from overshooting into the end stop.

The W.M.D. allows you to compensate for the endstop buffer range. Select an endstop setting in the range of

0-3,000 encoder counts.

1. In the W.M.D. main menu, select the lens function for the specific motor. (Example: Focus, Iris, or Zoom)

2. Select Endstop.

3. Use the Select and Back buttons to navigate between digit values.

‒ Press Select to move the cursor to the right one (1) digit.

‒ Press Back to move the cursor to the left one (1) digit.

‒ Press Up to increase the value or press Down to decrease the value.

4. Adjust the setting as needed.

5. Deselect the digits and return to the menu.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 25

Page 26

RED 3-AXIS SYSTEM OPERATION GUIDE

CONFIGURE WIRELESS SETTINGS

In order for the T.H.C. to control the W.M.D., the RED 3-Axis Lens Control System uses a Frequency-Hopping

Spread Spectrum (FHSS) wireless link and offers 42 channels.

1. In the W.M.D. main menu, select Wireless.

2. Select a Channel. The range is 1–42.

3. Select a power setting for the strength of the wireless signal.

‒ Low: The low power setting balances range and low power and is appropriate in most cases.

‒ High: For maximum range, the high power setting can be used.

NOTE: Be sure to set W.M.D. wireless settings appropriately. If the W.M.D. wireless setting is set to High,

the T.H.C. may not perform as desired or may lose connection if operating in close proximity to the W.M.D.

When using wireless on high, the T.H.C. should be at least one meter from the W.M.D. for proper operation.

VIEW MOTOR STATUS

This section describes each motor status and provides tips on how to resolve issues if an error occurs.

In the W.M.D. main menu, select Status to view the state of each motor.

MOTOR STATUS DESCRIPTION/POSSIBLE CAUSES TROUBLESHOOTING OPTIONS

— Motor not detected Disconnect and reconnect the motor to

the W.M.D.

Ensure that the LEMO connectors on

both ends of the cable are fully seated

and locked

Bad PWM W.M.D. cannot detect that the motor is

moving

Torque setting is too high for the lens

Bad cable or malfunctioning motor

Homing W.M.D. cannot find the endstops after mov-

ing the motor for 40 seconds

OK Motor functioning correctly N/A

Over Drive Incorrect parameters are being used for mo-

tor acceleration

Over Torque Motor was disengaged and reengaged

without re-initializing the motor, which al-

lowed the motor to drive into a hard stop

Lens is obstructed and cannot move

Torque setting is too low for the lens

Decrease torque until the status changes

to “OK”

Ensure that the correct motor model is

selected in the W.M.D. main menu

Try a different RED W.M.D. Motor Cable

Try a different motor

Ensure that the teeth on the motor drive

gear fully mesh with the teeth on the lens

gear

Ensure that the pin on the motor drive

gear properly engages the slot on the

motor hub

Ensure that all motor parameters are

properly selected in the W.M.D.

Initialize the motor

Ensure that lens movement is not ob-

structed

Increase torque and initialize

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 26

Page 27

RED 3-AXIS SYSTEM OPERATION GUIDE

CONFIGURE START/STOP, GENLOCK, TIMECODE, TALLY

This section explains how to set up start/stop, genlock, and timecode with the W.M.D. and a DSMC.

For more information about cables and configurations, go to “3-Axis System Cables” on page 63.

1. Configure Start/Stop in the DSMC menu.

A. Go to Menu > Settings > Setup > GPIO/Sync > Brain GPIO.

B. Select General Purpose In from the Camera In drop-down menu.

2. Connect the appropriate RED Start/Stop Cables for your desired configuration.

FUNCTIONS CABLE PART NUMBERS HOW TO CONNECT

Start/Stop,

Genlock,

Timecode,

and Tally

Start/Stop,

Genlock,

and Timecode

Start/Stop RED Start/Stop Cable

RED Start/Stop Cable

(1B to Sync, Ctrl, BNC)

3BNC-to-00 LEMO Sync

Cable

RED Start/Stop Cable

(1B to BNC)

3BNC-to-00 LEMO Sync

Cable

(1B to 00B Sync)

790-0415 1. Connect the 14-pin 1B LEMO to the EXP

port on the W.M.D.

2. Connect the 4-pin LEMO start/stop con-

nector to the CTRL port on the DSMC

BRAIN

3. Connect the BNC connector to the

White BNC connector of the 3BNCto-00 LEMO Sync Cable using a BNCTO-BNC Adaptor (included with the

RED 3-Axis Lens Control System)

790-0154 4. Connect the 4-pin 00 LEMO connector to

the SYNC port on the DSMC BRAIN

790-0416 1. Connect the 14-pin 1B LEMO to the EXP

port on the W.M.D.

2. Connect the BNC connector to the

White BNC connector of the 3BNCto-00 LEMO Sync Cable using a BNCTO-BNC Adaptor (included with the

RED 3-Axis Lens Control System)

790-0154 3. Connect the 4-pin 00 LEMO connector to

the SYNC port on the DSMC BRAIN

790-0428 1. Connect the 14-pin 1B LEMO to the EXP

port on the W.M.D.

2. Connect the 4-pin 00 LEMO connector to

the SYNC port on the DSMC BRAIN

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 27

Page 28

RED 3-AXIS SYSTEM OPERATION GUIDE

3. Configure Start/Stop in the W.M.D. main menu.

A. Select Start/Stop.

B. Select a start/stop option based on the intended functionality and cables used.

FUNCTIONS START/STOP CABLE PART NUMBER TYPE

Disable Start/Stop N/A N/A Off

Start/Stop, Genlock, Time-

code, and Tally with DSMC

Start/Stop, Genlock, and

Timecode with DSMC

Start/Stop with DSMC RED Start/Stop Cable (1B to 00B Sync) 790-0428 EPIC

Start/Stop

with RED ONE

C. Press Select.

RED Start/Stop Cable (1B to Sync, Ctrl,

BNC)

RED Start/Stop Cable (1B to BNC) 790-0416 EPIC

RED currently does not provide start/

stop cables to connect the W.M.D. to the

RED ONE

790-0415 EPIC+Tally

N/A RED ONE

W.M.D. LENS PROFILES

The W.M.D. includes default lens profiles, as well as the capability to modify default profiles for fine tuning. Lens

profiles are separated into three (3) menu categories, Prime (default), Zoom (default), and User (modified). If a

modification is made to a lens profile, the modified version can be saved under the User category.

NOTE: If a particular lens does not have a default profile, the W.M.D. will not support metadata. It may still be

compatible with the system. For more information, go to “3-Axis System Compatibility” on page 54.

The following lenses are supported with default profiles in the W.M.D. firmware:

PRIME LENSES

ARRI Ultra Prime: 14mm, 16mm, 20mm, 24mm, 28mm, 32mm, 50mm, 65mm, 85mm, 100mm, 135mm

ARRI Master Prime: 14mm, 16mm, 18mm, 21mm, 25mm, 27mm, 50mm, 65mm, 75mm, 150mm

Cooke S5: 25mm, 32mm, 50mm, 75mm

Cooke S4: 14mm, 18mm, 21mm, 25mm, 27mm, 32mm, 35mm, 50mm, 65mm, 75mm, 100mm, 300mm

Elite Digital: 18mm, 24mm, 35mm, 50mm, 75mm, 100mm, 135mm

Leica Summilux-C: 21mm, 25mm, 40mm, 50mm, 75mm, 100mm

RED PRO PRIME: 18mm, 25mm, 35mm, 50mm, 85mm, 100mm, 300mm

ZOOM LENSES

Angénieux Optimo: 15-40mm, 17-80mm, 30-80mm

ARRI/Fujinon Alura: 18-80mm T2.6

Fujinon Cine: 14.5-45mm T2, 19-90mm

RED ZOOM: 17-50mm, 18-85mm, 18-50mm T3, 50-150mm T3

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 28

Page 29

RED 3-AXIS SYSTEM OPERATION GUIDE

SELECT A LENS PROFILE

Default lens profiles are located Prime or Zoom menus. Modified lens profiles are saved in the User menu.

1. In the W.M.D. main menu, select Profiles.

2. Select the desired lens profile type. (Example: Prime, Zoom, or User)

3. Select the manufacturer.

4. Select the model.

5. Select the focal length.

6. Press Select to choose the lens profile for the specific lens.

Select a Lens Profile

CLEAR THE ACTIVE LENS PROFILES

The clear function deselects the current lens profiles. This will clear the active profile. Reselect a lens profile if

you wish to view metadata.

1. In the W.M.D. main menu, select Profiles.

2. Select Clear.

3. Press Back to exit to the Profiles menu.

Or press A to lock the W.M.D. and return to the home screen.

MODIFY A LENS PROFILE

The W.M.D. allows you to modify the encoder position related to a specific data point to fine-tune the active

lens profile.

1. In the W.M.D. main menu, select Profiles.

2. Select Modify.

NOTE: The 60 second auto-lock feature is disabled while the Modify menu is open.

3. Select the desired lens function. (Example: Focus, Iris, or Zoom)

4. Perform fine-tuning adjustments to calibrate the selected lens.

A. Adjust the gear so that the physical marking on the lens matches the “Mrk” value on the W.M.D. screen.

B. Press Select to update. The updated encoder position “At” value, should now match the “Mrk” value.

C. Repeat for each focal position on the lens as needed.

5. Press Down to save the profile and exit to the Profiles menu.

Or press Back to exit to the Profiles menu without saving lens profile changes.

Or press A to lock the W.M.D. and return to the home screen. This does not save lens profile changes.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 29

Page 30

RED 3-AXIS SYSTEM OPERATION GUIDE

SAVE A LENS PROFILE

If you have made lens profile modifications but did not save changes at the time, follow these steps to save

your changes.

1. In the W.M.D. main menu, select Profiles.

2. Select Save.

VIEW LENS METADATA

Metadata format is dependent on your lens profile setting:

Lens profile is selected (Select > Profiles): Focus, Iris, and Zoom data extrapolated from the motor encoder

positions displays for each lens function (Focus, Iris, Zoom).

Lens profile NOT selected: Hexadecimal motor position data displays for each lens function (Focus, Iris,

Zoom).

Once a lens profile is selected, you can view lens metadata on the W.M.D. screen.

1. In the W.M.D. main menu, select Metadata.

NOTE: If a lens does not support a particular lens function (Example: prime lenses do not have zoom) or a motor

is not connected, the resulting value is displayed as a hexadecimal value.

EXPORT LENS PROFILES

Use the export function to save modified profiles to the microSD card for repeat use and sharing.

1. In the W.M.D. main menu, select Profiles > Save.

2. Select Export.

3. Choose one of the following options:

‒ Overwrite: Exports all profiles, overwriting any differences on the microSD. Saves existing profiles.

‒ Keep: Adds W.M.D. profile library to existing microSD contents.

‒ Only: Clears the microSD and replaces contents with the existing W.M.D. profile library.

The W.M.D. displays “success” when the export is complete.

4. Press Back to exit, or press A to lock the W.M.D. and return to the home screen.

5. Remove the microSD card.

IMPORT LENS PROFILES

Use the import function to load modified profiles onto the W.M.D. from the microSD card.

1. Ensure that the desired profile “.pfl” files are loaded on the microSD card.

2. Insert the microSD card into the W.M.D.

3. In the W.M.D. main menu, select Profiles > Import.

4. Choose one of the following options:

‒ Overwrite: Imports all profiles, overwriting any differences on the W.M.D. Saves existing profiles.

‒ Keep: Adds microSD contents to existing W.M.D. profile library.

‒ Only: Clears the W.M.D. and rebuilds profile library with microSD contents.

The W.M.D. displays “success” when the import is complete.

5. Press Back to exit, or press A to lock the W.M.D. and return to the home screen.

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 30

Page 31

RED 3-AXIS SYSTEM OPERATION GUIDE

MANAGE LENS PROFILES

The W.M.D. automatically reads lens information and renames the profile on import. This effectively removes

any custom profile names. (Example: A renamed RED PRO PRIME 50mm lens profile is automatically renamed

to RED-PRIME-50mm.pfl when imported to the W.M.D.) For this reason, we recommend saving .pfl files in custom named folders, rather than changing the lens profile name.

Once you have exported lens profiles from the W.M.D. save them to your computer.

1. Insert the microSD card into your computer. Use a microSD to SD adapter, if necessary.

2. Save the .pfl files to a safe location on your computer.

A. Create a new folder on your desktop and label it appropriately. (Example: “WMD_Jun8”)

B. Place .pfl files into the new folder.

ACCESS W.M.D. DIAGNOSTIC DATA

Hardware status data for each W.M.D. component is found in the “About” menu. If you contact RED for support,

a RED representative may ask you for the hardware status of the W.M.D.

1. In the W.M.D. main menu, select About.

ERASE SETTINGS ON THE W.M.D.

If you are experiencing problems with the W.M.D. or for other reasons want to reset the unit to factory default

settings, perform the following steps:

1. In the W.M.D. main menu, select Options.

2. Select Erase Settings.

NOTE: Erasing settings will delete all existing User profiles and other adjustments that have been made on

the W.M.D. It is recommended that you export User profiles and save them to your computer before performing this operation.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 31

Page 32

RED 3-AXIS SYSTEM OPERATION GUIDE

TACTICAL HAND

04

CONTROLLER (T.H.C.)

T.H.C. OVERVIEW

The RED Tactical Hand Controller (T.H.C.) works with the RED Wireless Motor Driver (W.M.D.) and RED

Lens Control Motor to provide wireless operation of lens adjustments (Focus, Iris, Zoom). The T.H.C. delivers

on-the-fly precision tuning with independent Focus, Iris, and Zoom adjustment controls.

Up to two (2) T.H.C. units can be paired with a W.M.D. for individual operator control during shoots. The T.H.C.

uses a 2.4GHz Frequency-Hopping Spread Spectrum (FHSS) wireless link with multiple channel support. The

T.H.C. also features a field replaceable marking ring for convenient lens adjustments. A lanyard loop provides

a secure place to attach the T.H.C. to a lanyard or wristband.

The Tactical Hand Controller is also compatible with the REDLINK™ Bridge for wireless Iris and Focus control

of supported Canon® and Nikon® motorized lenses. For more information, see the REDLINK™ Bridge Operation

Guide, available at www.red.com/downloads.

NOTE: Go to the RED Downloads page at www.red.com/downloads for the latest firmware version, operation

guide, and other support resources.

COPYRIGHT © 2014 RED.COM, INC

RED T.H.C. Kit

955-0044, REV-D | 32

Page 33

RED 3-AXIS SYSTEM OPERATION GUIDE

T.H.C. CONTROLS

1

2

4

3

5

6

T.H.C. Controls

7

8

9

10

T.H.C. Controls

# CONTROL DESCRIPTION

1 Run button Record button for mobile Start/Stop

2 Iris slider

3 Zoom wheel

4 Initialize button Press and hold for two (2) seconds to initialize the system;

5 Power switch Toggles power source from cabled to battery mode

1

1

Adjusts motor connected to Iris port

Adjusts motor connected to Zoom port

OR press and release to initialize only motors unknown positions

(Must be paired or connected via CAN cable)

6 Zoom Limit button Hold down to set the “zoom” lens limit or lens lock

7 Focus wheel

8 Iris Limit button Hold down to set the “iris” lens limit or lens lock

9 Focus Limit button Hold down to set the “focus” lens limit or lens lock

10 Eject battery release Press to release the rechargeable battery from the T.H.C.

1. Focus, Iris, and Zoom controls can be used interchangeably by connecting the Lens Control Motor to the desired lens function connec-

tor on the W.M.D.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 33

1

Adjusts motor connected Focus port

Page 34

RED 3-AXIS SYSTEM OPERATION GUIDE

T.H.C. LEDS

1

2

3

4

T.H.C. LEDs

5

6

7

# LED COLOR/FLASHING DESCRIPTION

1 Focus Limit Off Function active; no limits set

Green flashing (slow) Actively setting limit (User is holding the limit button down)

Green flashing (fast) Function locked: no position updates are sent to the W.M.D.

Green Limit is enabled

2 Iris Limit Off Function active; no limits set

Green flashing (slow) Actively setting limit (User is holding the limit button down)

Green flashing (fast) Function locked: no position updates are sent to the W.M.D.

Green Limit is enabled

3 Wireless Off Off/wired connection; not attempting to connect

Blue flashing Attempting to connect to W.M.D.

T.H.C. LEDs

Blue Connected to W.M.D.

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 34

Page 35

RED 3-AXIS SYSTEM OPERATION GUIDE

# LED COLOR/FLASHING DESCRIPTION

4 Battery/Tally1Green Charged battery

Amber Low battery

Red Very low battery (replace immediately to avoid power loss)

Flashing Tally on; camera is recording

Solid Tally off; camera is not recording

5 Initialize Off One or motor motors must be initialized; no motors detected

Green flashing Initialization in process

Green All detected motors are initialized

6 Power Off Power off

Green Power on

7 Zoom Limit Off Function active; no limits set

Green flashing (slow) Actively setting limit (User is holding the limit button down)

Green flashing (fast) Function locked: no position updates are sent to the W.M.D.

Green Limit is enabled

1. The tally feature is only supported with specific cabling configurations. Refer to “Configure Start/Stop, Genlock, TimeCode, Tally” on

page 27.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 35

Page 36

RED 3-AXIS SYSTEM OPERATION GUIDE

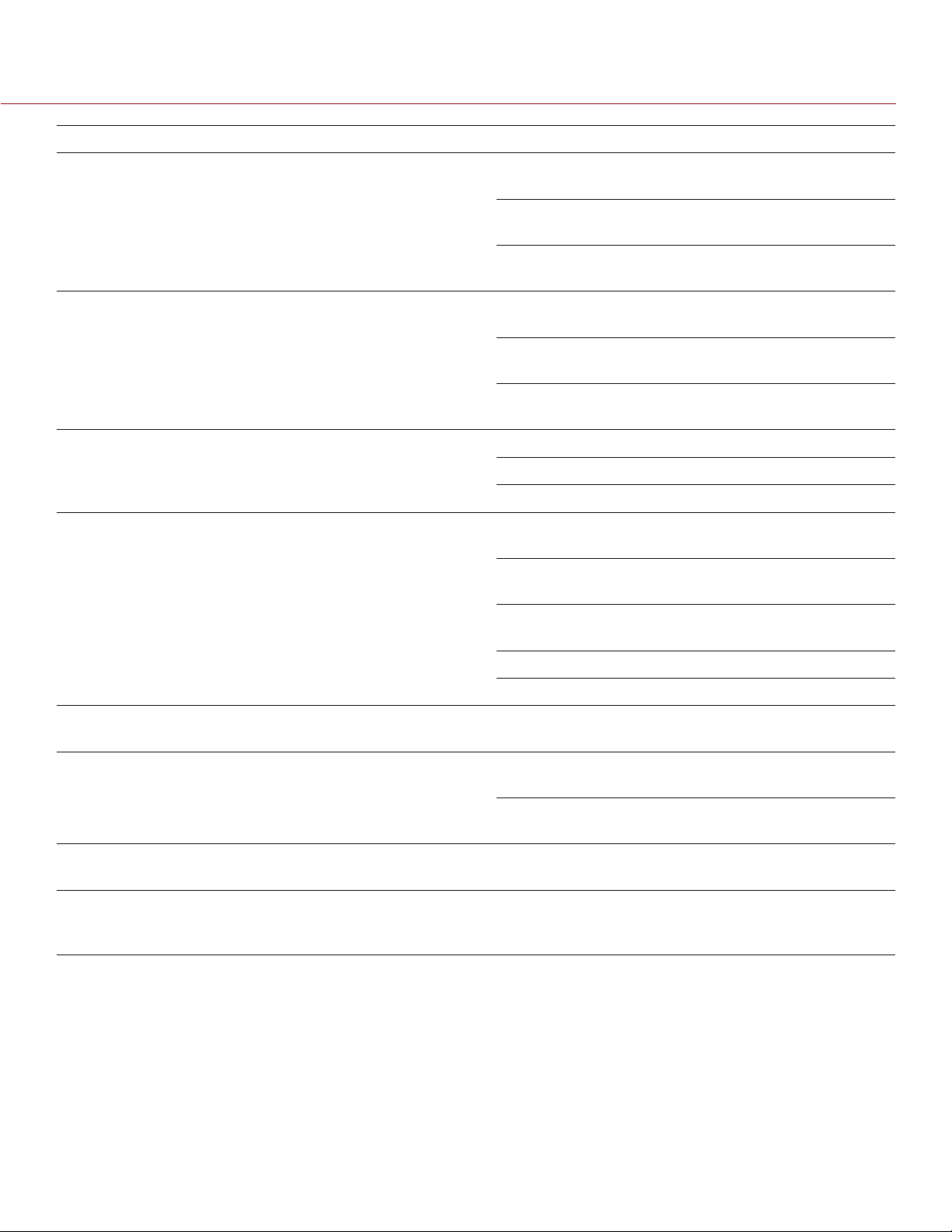

T.H.C. CONNECTORS

1

2

T.H.C. Wired Connections

5

3

4

T.H.C. Battery, microSD, and

Antenna

# CONNECTOR DESCRIPTION COMPATIBLE PARTS PART NUMBERS

1 AUX port Auxiliary power and communica-

tion for accessories (RS-232 at

38.4 K)

2 CAN port CAN communication and power RED CAN Command Cable (5') 790-0407

3 Battery compart-

ment

4 MicroSD slot

(under battery)

5 Wireless antenna Removeable antenna RED T.H.C./W.M.D. Antenna 790-0420

Holds the RED LI BATTERY 7.2V RED Li Battery 7.2V 740-0032

Standard microSD slot used to

upgrade T.H.C. firmware

RS232-to-RS232 Cable 790-0150

REDLINK-to-T.H.C. Connector

Cable (3')

RED CAN Command Cable (50') 790-0408

RED CAN Command Cable (100') 790-0409

Standard microSD N/A

790-0444

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 36

Page 37

RED 3-AXIS SYSTEM OPERATION GUIDE

WIRED OPERATION

1. Connect the T.H.C. to the W.M.D. using the RED CAN Command Cable (provided).

2. Toggle the power switch to Cable mode.

The T.H.C. is now connected and ready for wired operation.

T.H.C. Wired Connection

PAIR THE T.H.C.

Connect and pair the T.H.C. with your W.M.D. to operate in wireless mode. Once paired, the T.H.C. stores

wireless information for that W.M.D. and automatically reconnects when in range. The T.H.C. retains the MAC

address information for a single W.M.D.

1. Ensure the W.M.D. is receiving power.

2. Connect the T.H.C. to the W.M.D. using a RED CAN Command Cable.

3. Toggle the power switch to Cable mode.

The T.H.C. automatically pairs when the W.M.D. is on.

4. Install a RED LI BATTERY 7.2V.

5. Toggle the T.H.C. power switch to Battery mode.

6. Remove the RED CAN Command Cable.

The T.H.C. searches for the wireless connection. The wireless LED stops flashing and remains solid blue

when connected.

NOTE: The RED CAN Command Cable also provides power to the T.H.C. up to approximately 500 ft. When using

a cable longer than 500 ft, insert a battery and toggle the power switch to Battery to provide sufficient power.

The CAN cable will continue to support serial communication over a much longer distance.

NOTE: For more information, go to “Configure Wireless Settings” on page 26.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 37

Page 38

RED 3-AXIS SYSTEM OPERATION GUIDE

CHANGE THE WIRELESS CHANNEL

1. Power off the T.H.C. by toggling the power switch to Cable mode.

2. Press and hold the Focus Limit button, and toggle the power switch to Battery mode.

3. After a few seconds, release Focus Limit. Iris Limit and Focus Limit LEDs flash corresponding to the current

channel setting:

‒ Iris Limit: Flashes to represent the tens.

‒ Focus Limit: Flashes to represent the ones.

For example, if the Iris LED flashes twice and the Focus LED flashes once, the current channel is 21.

4. After LEDs stop flashing, press the Iris Limit and Focus Limit buttons to set the new channel:

‒ Iris Limit: Press to set the tens.

‒ Focus Limit: Press to set the ones.

For example, to set the channel to 14, press the Iris button once, and press the Focus button four (4) times.

5. Wait a few seconds for the Iris Limit and Focus Limit LEDs to flash indicating the new channel.

NOTE: For more information, go to “Configure Wireless Settings” on page 26.

WIRELESS SETTINGS

The wireless settings for the T.H.C. are managed in the W.M.D. menu. If wireless settings are changed in the

W.M.D., the T.H.C. must be connected via a wired connection to obtain the new wireless information.

NOTE: For more information, go to “Configure Wireless Settings” on page 26.

CONNECT TWO (2) T.H.C. UNITS

The W.M.D. supports up to two (2) T.H.C. units. Both units have full control over all adjustment functions. Use

the lens lock function to prevent both controllers from sending conflicting commands while both units are in

operation.

Connect a second T.H.C. using the same method described in “Pair the T.H.C.” on page 37.

INITIALIZE WITH THE T.H.C.

The motor initialization process detects each motor’s range of motion for the equipped lens and stores the encoder position and effective range information within the W.M.D. Once stored, the settings remain in the W.M.D.

for approximately 14 hours.

To initialize ALL motors:

Press and hold the Initialize button on the T.H.C. for two (2) seconds.

To initialize ONLY motors with unrecognized positions:

Press and release the Initialize button.

A single motor can be initialized by disconnecting and reconnecting the motor cable.

WARNING: It is important to initialize the system every time a modification is made to a lens or a motor. Failing

to perform the initialization sequence may cause severe damage to your lens, motor, or camera.

COPYRIGHT © 2014 RED.COM, INC

955-0044, REV-D | 38

Page 39

RED 3-AXIS SYSTEM OPERATION GUIDE

SET A LENS LIMIT

The T.H.C. enables precision on-the-fly adjustments for lens functions.

1. Adjust the desired lens function knob/slider (Focus, Iris, or Zoom) to the min/max position.

(Example: zoomed out to capture full setting)

2. Press and hold the corresponding Limit button (Focus, Iris, or Zoom) on the T.H.C.

Hold Limit Button and Adjust

3. Adjust the corresponding lens function knob/slider (Focus, Iris, or Zoom) to the max/min position.

(Example: zoomed in on target)

4. Release the Limit button.

Press and release the corresponding Limit button to reinstate a previously set limit.

NOTE: The T.H.C. is a persistent state device, meaning that the lens limit will be maintained even if the unit is

powered down.

NOTE: When a lens limit button is held for three (3) seconds without a change made to the adjustment knob/

slider, the lens function limit will lock. For more information, go to “Set a Lens Lock” on page 40.

REMOVE A LENS LIMIT

1. Press and release the corresponding Limit button.

The lens limit is now deactivated. The LED turns off to indicate that the lens limit is not set.

Press and release the Limit button again to reset the limit.

NOTE: Holding down the limit button for three (3) seconds without any change to any input locks the respec-

tive lens adjustment function on that T.H.C. unit. For more information, go to “Set a Lens Lock” on page

40.

COPYRIGHT © 2014 RED.COM, INC 955-0044, REV-D | 39

Page 40

RED 3-AXIS SYSTEM OPERATION GUIDE

SET A LENS LOCK

The W.M.D. can support wireless communication with up to two (2) T.H.C. units at any given time. Use the lens

function lock feature on the T.H.C. to prevent accidental/unwanted manipulation of that lens function on your

T.H.C. unit.

1. Press and hold the Limit button for the desired lens function for three (3) seconds. DO NOT make adjust-

ments to the knob/slider during this time.

Hold Limit Button for 3 sec

2. Release the Limit button when the corresponding LED flashes green slowly.

The lens function is now locked for that T.H.C. unit. The lens function LED will flash green to signal an active lens lock.

REMOVE A LENS LOCK

1. Press and hold the Limit button for the desired lens function for three (3) seconds.