Rectorseal SS1 Installation Manual

INSTALLATION INSTRUCTIONS

D

R

pprop

NOTICE: FAILURE TO READ AND COMPLY WITH ALL WARININGS, RECOMMENDATIONS AN

INSTRUCTIONS PRIOR TO STARTING INSTALLATION MAY CAUSE PERSONAL INJURY AND/O

PROPERTY DAMAGE AND VOID WARRANTEE.

∆ WARNING

This device must be installed in accordance with manufacturer’s instructions and all applicable

plumbing, drainage and electrical codes to ensure proper operation.

∆ WARNING

Electric shock hazard – Disconnect power supply before installation to avoid injury and/or

equipment damage. For use in Class

2 circuits only - Do not use on circuits exceeding 24 volts.

CAUTION: This device will not detect clogs occurring upstream from installation point.

CAUTION: If not present, it is recommended that a fuse and time delay be installed to protect the 24-volt circuit

and to avoid rapid cycling of equipment prior to installing this product.

CAUTION: When installing this device in plugged configuration on auxiliary drain pan outlets, it is essential that

PVC plug is closed off and watertight.

CAUTION:

CAUTION: Refer to the a

This product is not intended for use in the presence of corrosive or flammable liquids and vapors.

riate HVAC equipment operating manual prior to installing this product.

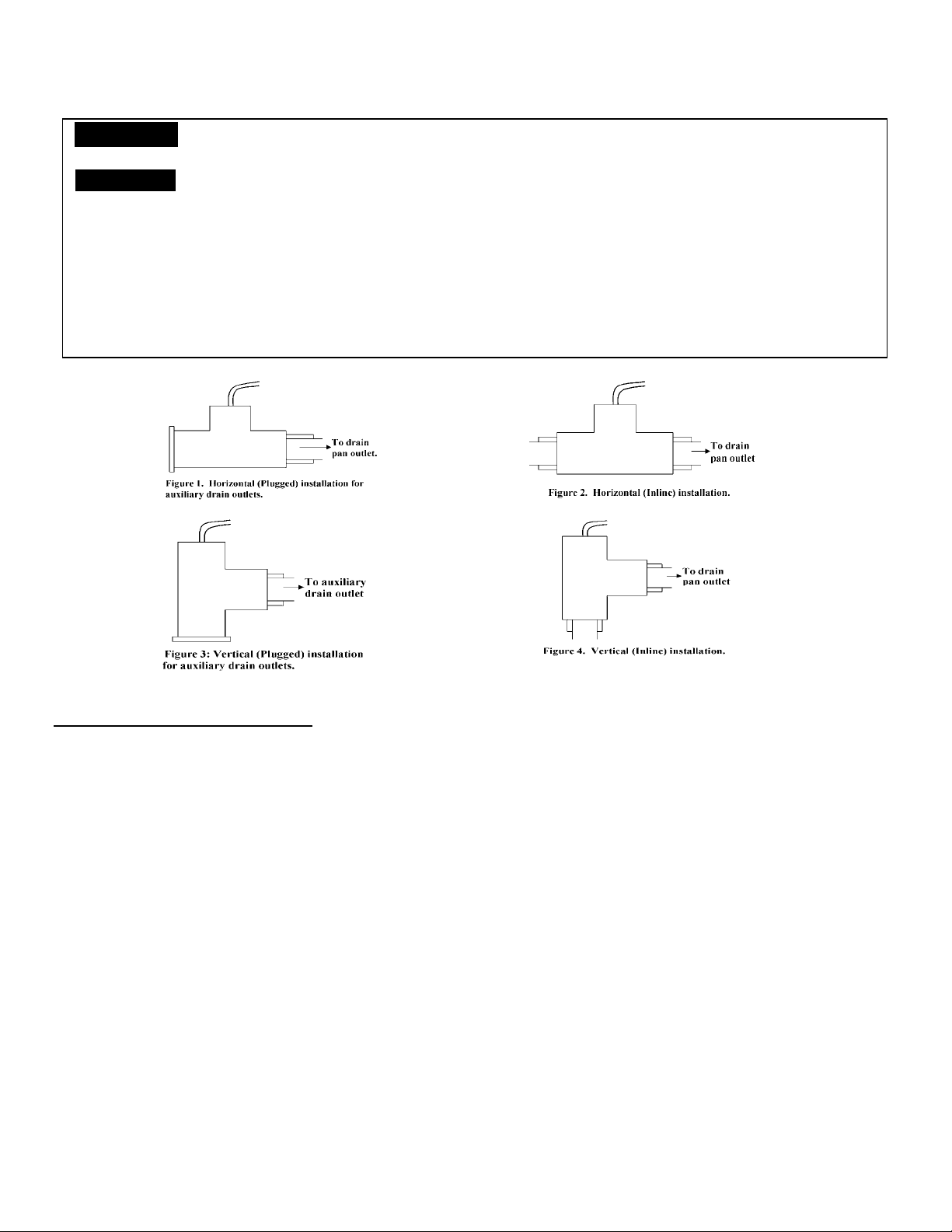

HORIZONTAL INSTALLATION: (See Figs. 1 and 2).

1. Female Pan Outlets: Glue ¾” long end of supplied threaded male X male stub into female drain pan outlet.

2. Press switch/cap assembly firmly into top 1” opening in Tee until the rim is flush against the Tee opening.

If more sensitivity is desired, switch may be threaded out of cap. DO NOT GLUE SWITCH/CAP INTO TEE.

3. Glue 1” X ¾” bushing into remaining 1” Tee inlet.

4. Thread female end of supplied adaptor tightly onto male pan outlet or supplied male stub, ensuring it is watertight.

5. Glue bushed inlet of Tee onto other end (SLIP end) of supplied adaptor. Tee may be sloped up to 45

o

from pan

outlet. If more slope is desired, see Vertical Installation, below.

6. For plugged installation on auxiliary outlets:

a) Seat plug firmly into ¾” outlet of Tee ensuring it is watertight. DO NOT GLUE. Pipe tape may be required

to ensure seal. Ensure Tee is level or sloped downward from pan outlet.

b) Adjust float switch downward out of cap by threading counterclockwise until float stem is at inside bottom

of Tee when switch/cap is inserted to the rim

7. For inline installation, glue ¾” outlet of Tee onto drain line.

8. Wire switch as per instructions under Wiring, below.

9. Test switch by lifting float while unit is on. If wired correctly, unit will stop when float is lifted.

10. Test all drain and fitting connections for plumbing leaks.

11. Test switch sensitivity: Plug drain downstream from installation point and run unit to fill pan. Float should

rise and unit should stop before pan overflows. If pan overflows, reposition float lower by either:

a) plumbing entire assembly lower OR;

b) by threading switch assembly counterclockwise 1/8-inch away from cap/plug so that it stops unit

sooner in response to rising water in drain.

12. Affix warning sticker to air handler or condenser unit.

d

VERTICAL INSTALLATION: (See Figs. 3 and 4)

1. Female Pan Outlets: Glue ¾” long end of supplied threaded male X male stub into female drain pan outlet.

2. Remove switch/cap assembly from top 1” Tee inlet and insert into remaining 1” Tee inlet so that rim is flush against

the Tee opening. Switch may be threaded out of cap if necessary if more sensitivity is desired. DO NOT GLUE.

3. Glue 1” X ¾” bushing into open 1” Tee inlet.

4. Thread female end of supplied adaptor tightly onto male pan outlet or supplied male stub, ensuring it is watertight.

5. Glue bushed inlet of Tee onto other end (SLIP end) of supplied adaptor. Tee may be sloped up to 45o in eit her direction by rotating on stub.

6. For plugged installation on auxiliary outlets:

a) Seat plug firmly into ¾” outlet of Tee ensuring it is watertight. DO NOT GLUE. Pipe tape may be required to

ensure seal. Ensure Tee is level or sloped downward from pan outlet.

b) Adjust float switch downward out of cap by threading counterclockwise until float stem is at inside bottom of Tee

when switch/cap is insert to the rim

7. For inline installation, glue ¾” outlet of Tee onto drain line.

8. Wire switch according to instructions under Wiring, below.

9. Test all drain and fitting connections for plumbing leaks.

10. Test switch sensitivity: Plug drain downstream from installation point and run unit to fill pan. Float should rise

and unit should stop before pan overflows. If pan overflows, reposition float lower by either:

a) plumbing entire assembly lower OR;

b) by threading switch assembly counterclockwise 1/8-inch away from cap/plug so that it stops unit sooner in

response to rising water in drain.

11. Affix warning sticker to air handler or condenser unit.

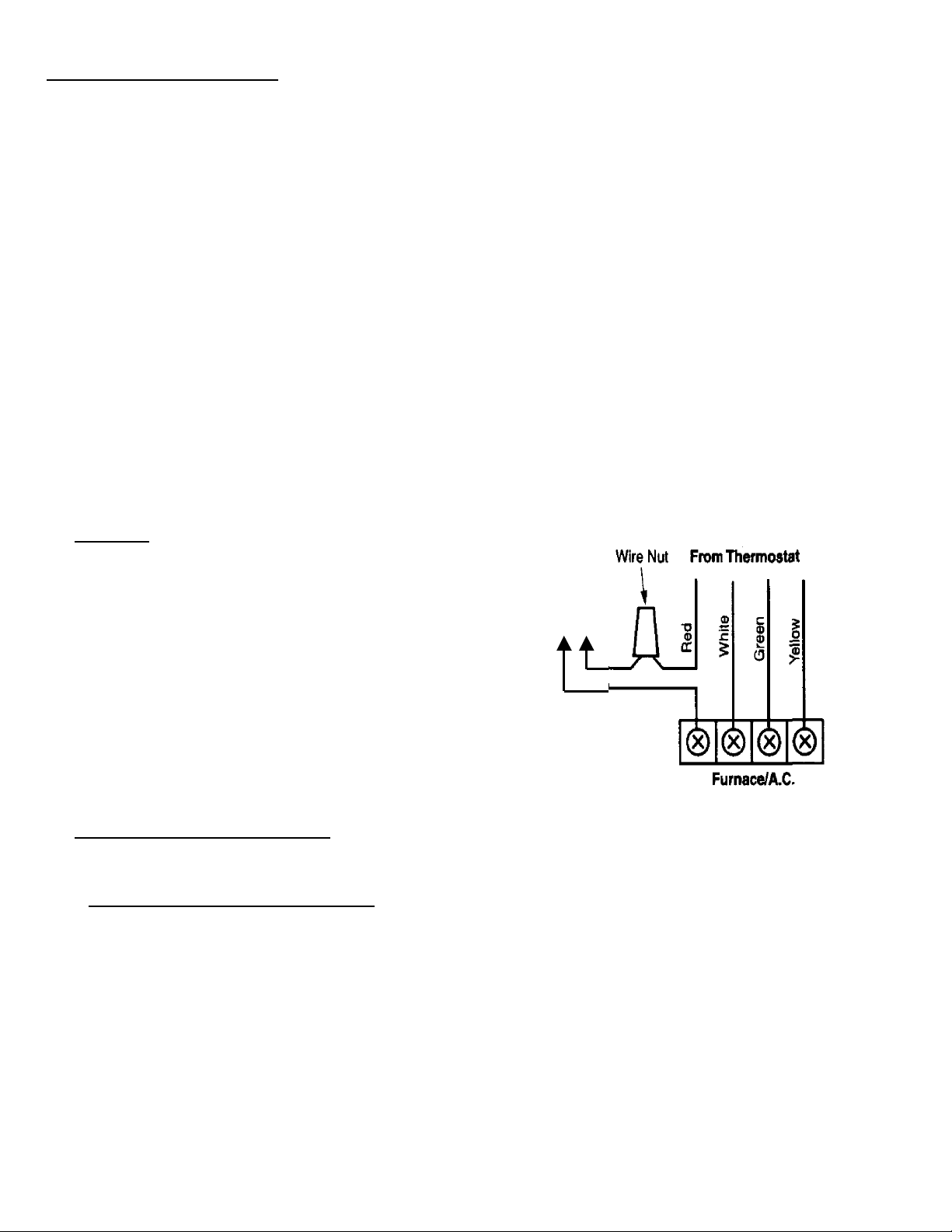

WIRING:

1. WARNING: Disconnect power to unit at main

panel prior to performing electrical work.

2. If not present, it is recommended that an inline fuse

to protect 24-volt circuit be installed.

3. Locate 24-volt thermostat cable entering air

To Switch

handler unit. Disconnect or cut red or wire and

connect to switch lead using wire nut. Connect

other switch lead to air handler terminal.

Incorporating switch in red circuit shuts entire unit,

fan continues to run if incorporated in yellow

circuit (inhibits mold during long absences).

4. Test switch by lifting float while unit is on. If wire

correctly, unit will stop when float is lifted.

Figure 4: Wiring Diagram for Unit Shutdown.

ALARM CIRCUIT (OPTIONAL):

This device designed to work with the Safe-T-Gard® condensate overflow alarm.

OPERATION AND MAINTENANCE:

It is recommended that the switch/cap assembly be removed and cleaned every three months with Nu Line®

Condensate Drain Cleaner:

1. Shut power to unit at main panel and lift switch/cap assembly out of Tee.

2. Clean switch, float, stem and inside surface of Tee.

3. Replace switch/cap assembly.

Loading...

Loading...