Rozna ulica 20, 6230 Postojna, Slovenia

e-mail: info@rec-bms.com; www.rec-bms.com

1

VICTRON CCGX-SUPPORTED ACTIVE BATTERY

MANAGEMENT SYSTEM REC ACTIVE BMS

Features:

- robust and small design

- 4 cells

- single cell voltage measurement (0.1 – 5.0 V, resolution 1 mV)

- single cell - under/over voltage protection

- single cell internal resistance measurement

- SOC and SOH calculation

- over temperature protection

- under temperature charging protection

- active cell balancing up to 2.5 A DC per cell

- shunt current measurement (resolution 19.5 mA @ ± 500 A)

- galvanically isolated user defined multi-purpose digital output

- programmable relay (normally open or normally closed)

- galvanically isolated RS-485 communication protocol

- CAN communication (Victron compatible)

- error LED + buzzer indicator

- 12 ERROR log on the device FIFO

- PC user interface for changing the settings and data-logging (optional accessory)

- hibernate switch

- one IP65 protected connector for all connections

- one-year warranty

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

2 www.rec-bms.com

General Description of the BMS Unit:

The Battery management system (BMS) monitors and controls each cell in the battery pack by measuring its

parameters. The capacity of the battery pack differs from one cell to another and this increases with number of

charging/discharging cycles. The Li-poly batteries are fully charged at typical cell voltage 4.16 - 4.20 V or 3.5 – 3.7 V

for LiFePO4. Due to the different capacity this voltage is not reached at the same time for all cells in the pack. The

lower the cell’s capacity the sooner this voltage is reached. When charging series connected cells with a single

charger, voltage on some cells might be higher than the maximum allowed voltage. Overcharging the cell

additionally lowers its capacity and number of charging cycles. The BMS equalizes cells’ voltage by diverting some

of the charging current from higher voltage cells to the whole pack or from the whole pack to a lower voltage cells

– active balancing. The device’s temperature is measured to protect the circuit from over-heating due to

unexpected failure. Battery pack’s temperature is monitored by Dallas DS18B20 digital temperature sensor/s.

Current is measured by a low-side shunt resistor. Battery pack current, temperature and cell’s voltage determine

state of charge (SOC). State of health (SOH) is determined by comparing cell’s current parameters with the

parameters of a new battery pack. The BMS default parameters are listed in Table 1.

Hardware parameters:

Table 1: ABMS hardware parameters.

Parameter

Value

Unit

BMS maximum pack voltage

16.8

V

BMS maximum cell voltage

5.0

V

Shunt common mode input voltage interval (Shunt+, Shunt -) to

the Cell 1 negative

-0.3 to 3.0

V

Shunt sensor differential input voltage interval (Shunt+ to Shunt -)

-0.25 to 0.25

V

max DC current relay @ 60 V DC

0.7

A

max AC current relay @ 230 V AC

2

A

max DC current @ optocoupler

15

mA

max DC voltage@ optocoupler

62.5

V

BMS unit disable power supply

< 1

mW

BMS unit stand-by power supply

< 60

mW

BMS unit cell balance fuse rating (SMD)

3

A

internal relay fuse

2 slow

A

dimensions (w × l × h)

105 x 135 x 44

mm

IP protection

IP65

Default Software Parameters:

Table 2: Default BMS parameter settings.

Parameter

Value

Unit

chemistry

3 (LiFePO4)

n.a.

capacity

720

Ah

balance start voltage

3.45

V

balance end voltage

3.58

V

maximum diverted current per cell

up to 2.5 (5 pp)

A

cell over-voltage switch-off

3.85

V

over-voltage switch-off hysteresis per cell

0.25

V

cell end of charge voltage

3.58

V

End of chrge hysteresis per cell

0.25

V

SOC end of charge hysteresis

5

%

cell-under voltage protection switch-off

2.8

V

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

3 www.rec-bms.com

under voltage protection switch-off hysteresis per cell

0.1

V

cell under voltage discharge protection

2.9

V

pack under voltage protection switch-off timer

4

s

cells max difference

0.25

V

BMS over-temperature switch-off

55

°C

BMS over-temperature switch-off hysteresis

5

°C

cell over temperature switch-off

55

°C

under temperature charging disable

-15

°C

voltage to current coefficient

0.01953125

A/bit

current measurement zero offset

0.0

A

maximum charging/discharging current per inverter device

50/120

A

Number of inverter devices

1

n.a.

Charge coefficient

0.6

n.a.

Discharge coefficient

1.5

n.a.

relay 1 voltage level

3.58

V

relay 1 voltage level hysteresis

-0.2

V

optocoupler 2 voltage level

2.9

V

optocoupler 2 voltage level hysteresis

0.2

V

CAN communication frequency

250

kbit/sec

System Overview:

Figure 1: System overview.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

4 www.rec-bms.com

BMS Unit Connections:

Figure 2: BMS unit front panel function overview.

Table 3: BMS unit male socket connections.

Connection

Designator

Description

1

relay 1 – user defined

Normally closed

2

relay 1 – user defined

Fused input 3 Main relay

Normally closed

4

Main relay

Normally open

5

Main relay

Fused input

6

Hibernate switch signal

- 7 Hibernate switch ground

-

8

Cell 4 positive +

Analog signal

9

Cell 3 positive +

Analog signal

10

Cell 2 positive +

Analog signal

11

Cell 1 positive +

Analog signal

12

Cell 1 negative -

Analog signal

13

relay 1 – user defined

Normally open

14

Charge Optocoupler collector

-

15

Charge Optocoupler emitter (darlington + reverse

protection diode + polyfuse)

-

16

Optocoupler 2 – user defined collector

-

17

Optocoupler 2 – user defined discharge emitter

(darlington + reverse protection diode + polyfuse)

-

18

CAN Vcc

4.6 V output, max 10 mA

19

CANL

-

20

RS485 Vcc

-

21

RS485 A

-

22

RS485 ground

-

23

RS485 B

-

24

Shunt-

-

25

Shunt+

-

26

Shunt shield

-

27

Dallas 18B20 temp. sensor

GND + shield

28

Dallas 18B20 temp. sensor

+ 5 V

29

Dallas 18B20 temp. sensor

1-wire digital signal

30

CANH

-

31

CAN ground

GND potential of the battery pack

32

-

-

33

Address pin 3

Normally 0, connect to pin 35 to

change to 1

34

Address pin 2

Normally 0, connect to pin 35 to

change to 1

35

Address pin ground

Fused ground for Address pins

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

5 www.rec-bms.com

Setting the RS-485 Address:

Address of the BMS unit is selected via the Address pins. Factory address is 2. Formula for changing the address is:

! If multiple BMS units are used distinguished addresses should be set to avoid data collision on the RS-485

communication bus!

BMS Unit Connector:

Before starting the assembly please go to website:

http://www.te.com/catalog/pn/en/776164-1?RQPN=776164-1

…and read the connector assembly datasheet:

AMPSEAL Automotive Plug Connector and Header Assembly in Application Specification and

AMPSEAL Automotive Plug Assemblies 776268… in Instruction Sheet (U. S.).

BMS Unit Connector, Cells part:

Connect each cell to the BMS unit cell connector plug. Use silicon wires with cross section of 0.5 – 1.4 mm2 (20-16

AWG). ! Before inserting the connector check the voltage and polarity of each connection!

Figure 3: Battery pack connection plug – front side.

BMS Unit Power Supply:

BMS unit is always supplied from the 4-th cell connection.

BMS Unit Connection Instructions:

Connect all necessary connections to the BMS connector first, check the polarities and then plug the female

connector into the BMS. When the system components are plugged in, the enable switch can be turned ON and

the unit starts the test procedure. Connection instruction video link: http://www.rec-bms.com/ABMS.html

When disconnecting the unit from the battery pack, the procedure should be followed in reverse order.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

6 www.rec-bms.com

RS-485 Communication Protocol:

Figure 4: RS-485 DB9 connector front view.

Table 4: RS-485 DB9 connector pin designator.

pin

designator

1

-

2

AGND

3 B 4

A

5 - 6

+5V to AGND

7

-

8

-

9

-

Galvanically isolated RS-485 (EN 61558-1, EN 61558-2) serves for logging and changing BMS parameters. Dedicated

PC BMS Control Software or another RS-485 device may be used for the communication. Default RS-485 address is

2.

Unlock password: Serial without the first minus e.g. 1A-XXXX.

Messages are comprised as follows:

STX, DA, SA, N, INSTRUCTION- 4 bytes, 16-bit CRC, ETX

STX start transmission <0x55> (always)

DA - destination address <0x01> to <0x10> (set as 6)

SA - sender address <0x00> (always 0)

N – number of sent bytes

INSTRUCTION 4 bytes for example.: 'L','C','D','1','?', - (combined from 4 ASCII characters, followed by ‘?’, if

we would like to receive the current parameter value or ‘ ’,’xx.xx’ value in case we want to set a new value

16-bit CRC - big endian, for the whole message except STX in ETX -

https://www.lammertbies.nl/comm/info/crc-calculation.html

ETX - end transmission <0xAA> (always)

Dataflow:

Bit rate: 56k

Data bits: 8

Stop bits: 1

Parity: None

Mode: Asynchronous

Little endian format when an array is sent

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

7 www.rec-bms.com

Table 5: RS-485 instruction set.

INSTRUCTION

DESCRIPTION

BMS ANSWER

SETTING INTERVAL

*IDN?

Identification

Answer “REC - BATTERY

MANAGEMENT SYSTEM”

Read only

ARRAYS INSTRUCTIONS

LCD1?

Main data

First answer is 28 – how many byte

data will be sent and then data

message follows as 7 float values:

LCD1 [0] = min cell voltage,

LCD1 [1] = max cell voltage,

LCD1 [2] = current,

LCD1 [3] = max temperature,

LCD1 [4] = pack voltage,

LCD1 [5] = SOC (state of charge)

interval 0-1-> 1=100% and

LCD1 [6] = SOH (state of health)

interval 0-1-> 1=100%

Read only

LCD3?

Main data

First answer is 8 – how many byte

data will be sent and then data

message follows as 8 byte values:

LCD3 [0] = min cell BMS address,

LCD3 [1] = min cell number,

LCD3 [2] = max cell BMS address,

LCD3 [3] = max cell number,

LCD3 [4] = max temp. sens. BMS

address,

LCD3 [5] = max temp. sens. number,

LCD3 [6] = Ah MSB,

LCD3 [7] = Ah LSB

Read only

CELL?

Cell voltages

BMS first responds with how many

BMS units are connected, then it

sends the values of the cells in float

format

Read only

PTEM?

Cell temperatures

BMS first responds with how many

BMS units are connected then it

sends the values of the temperature

sensors in float format

Read only

RINT?

Cells internal DC resistance

BMS first responds with how many

BMS units are connected then it

sends the values in float format

Read only

BTEM?

BMS temperature

BMS first responds with value 1, then

it sends the values of the BMS

temperature sensor in float format

Read only

ERRO?

Error number description

array

First answer is 4 – how many byte

data will be sent and then data

message follows as 4 byte values:

ERRO [0] = 0 – no error, 1 – error

ERRO [1] = BMS unit

ERRO [2] = error number (1-14) and

ERRO [3] = number of the cell, temp.

sensor where the error occurred

Read only

CELL SETTINGS INSTRUCTIONS

BVOL? or

BVOL x.xx

Balance end voltage

Returns float voltage [V]

2.5 to 4.30 V

BMIN? or

BMIN x.xxx

Balancing start voltage

Returns float voltage [V]

2.5 to 4.30 V

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

8 www.rec-bms.com

CMAX? or

CMAX x.xx

Cell over-voltage switch-off

Returns float voltage [V]

2.0 to 4.30 V

MAXH? or

MAXH x.xx

Over- voltage switch-off

hysteresis per cell

Returns float voltage [V]

0.005 to 2.0 V

CMIN? or

CMIN x.xxx

Cell-under voltage protection

switch-off

Returns float voltage [V]

1.8 to 4.00 V

MINH? or

MIN x.xxx

Over- voltage switch-off

hysteresis per cell

Returns float voltage [V]

0.005 to 2.0 V

CHAR? Or

CHAR x.xxx

Cell End of charging voltage

Returns float voltage [V]

2.0 to 4.30 V

CHIS? Or

CHIS x.xxx

End of charging voltage

hysteresis per cell

Returns float voltage [V]

0.005 to 2.0 V

RAZL? or

RAZL x.xx

Cells max difference

Returns float voltage [V]

0.005 to 1.0 V

TEMPERATURE SETTINGS INSTRUCTIONS

TMAX? or

TMAX x.xxx

cell over temperature switchoff

Returns float temperature [°C]

-20 to 65 °C

TMIN? or

TMIN x.xxx

Under-temperature charging

disable

Returns float temperature [°C]

-30 to 65 °C

TBAL? or

TBAL x.xxx

BMS over-temperature

switch-off

Returns float temperature [°C]

-20 to 65 °C

BMTH? or

BMTH x.xxx

BMS over temperature

switch-off hysteresis

Returns float temperature [°C]

1 to 30 °C

CURRENT SETTINGS INSTRUCTIONS

IOFF? or

IOFF x.xxx

Current measurement zero

offset

Returns float current [A]

-2.0 to 2.0 A

IOJA? Or

IOJA x.xxx

Voltage to current coefficient

Returns float value

0.0005 to 0.5

BATTARY PACK SETTINGS INSTRUCTIONS

CYCL? or

CYCL xx

Number of full battery pack

cycles

Returns integer value

0 to 8000

CAPA? or

CAPA x.xxx

Battery pack capacity

Returns float capacity [Ah]

1.0 to 3000.0 Ah

CHEM? or

CHEM xx

Li-ion chemistry

Returns unsigned char value

1 to 5

SOC SETTINGS INSTRUCTIONS

SOCH? or

SOCH x.xxx

SOC end of charge hysteresis

Returns float value 0 – 1.0

0.005 to 0.99

SOCS? or

SOCS x.xx

SOC manual re-set

Returns float value 0 – 1.0

0.01 to 1.00

VICTRON COMMUNICATION SETTINGS INSTRUCTIONS

CHAC? or

CHAC x.xxx

Charge coefficient (0-3C)

Returns float value 0-3.0 (default 0.6)

0.01 to 10.0

DCHC? or

DCHC x.xxx

Discharge coefficient (0-3C)

Returns float value 0-3.0 (default 1.5)

0.01 to 10.0

STRN? or

STRN xx

Number of inverter devices

on the bus

Returns unsigned char value (default

1)

1 to 6

MAXC? or

MAXC x.xxx

Maximum charge current per

inverter device

Returns float current [A]

5.0 to 280 A

MAXD? or

MAXD x.xxx

Maximum discharge current

per inverter device

Returns float current [A]

5.0 to 280 A

CLOW? or

CLOW x.xxx

cell under-voltage discharge

protection

Returns float voltage [V]

1.8 to 4.20 V

CANF? or

CANF xx

CAN Frequency

Returns unsigned integer value

100, 125, 200, 250, 500 or 1000

100, 125, 200, 250, 500

or 1000 kbit/s

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

9 www.rec-bms.com

ERROR LOG INSTRUCTIONS

ERRL?

Returns error log data (FIFO

register of the last 12 errors).

By sending the same

instruction the data pointer

shifts from the last error entry

to the first error entry, then it

starts all over again

Returns “xx,zz;

hh:mm:ss;dd.mm.yyyy”

xx-error number

zz-number of the cell/temp sensor

Read only

ERLD? or

ERLD 1

Error log delete

Returns unsigned char value. To

reset Error log set ERLD to 1 and

restart the ABMS.

0, 1

VMAX? or

VMAX xx

Number of exceeded value of

CMAX

Returns integer value

0 to 8000

VMIN? or

VMIN xx

Number of exceeded value of

CMIN

Returns integer value

0 to 8000

OUTPUTS SETTINGS INSTRUCTIONS

RE1L? or

RE1L x.xxx

Relay 1 voltage level

Returns float voltage [V]

1.8 to 4.30 V

RE1H? or

RE1H x.xxx

Relay 1 voltage level

hysteresis

Returns float voltage [V]

-2.0 to 2.0 V

OP2L? or

OP2L x.xxx

Optocoupler 2 voltage level

Returns float voltage [V]

1.8 to 4.30 V

OP2H? or

OP2H x.xxx

Optocoupler 2 voltage level

hysteresis

Returns float voltage [V]

-2.0 to 2.0 V

ABMS SETTINGS INSTRUCTIONS

CAL1? or

CAL1 x.xxx

Cell 1 calibration offset

Returns float voltage [V]

-0.025 to 0.025 V

CAL2? or

CAL2 x.xxx

Cell 2 calibration offset

Returns float voltage [V]

-0.025 to 0.025 V

CAL3? or

CAL3 x.xxx

Cell 3 calibration offset

Returns float voltage [V]

-0.025 to 0.025 V

CAL4? or

CAL4 x.xxx

Cell 4 calibration offset

Returns float voltage [V]

-0.025 to 0.025 V

SERI? or

SERI xx

ABMS Serial number

Returns unsigned integer 0 - 9999

1-9999

SWVR?

ABMS software version

Returns string v.v-dd.mm.yyyy

Read only

TIME? or

TIME xx:xx:xx

ABMS RTC Time

Returns/accepts “hh:mm:ss” format*

-

DATE? or

DATE xx.xx.xxxx

ABMS RTC DATE

Returns/accepts “dd.mm.yyy”

format*

-

WCIB?

Which cell is being balanced

Returns cell number

Read only

*BMS->Time/Date pop-up window can be used to set both values at once.

Parameter accepted and changed value is responded with 'SET' answer.

Example: proper byte message for 'LCD1?' instruction for BMS address 2 is:

<0x55><0x02><0x00><0x05><0x4C><0x43><0x44><0x31><0x3F><0x53><0x90><0xAA>

RS-485 message are executed when the microprocessor is not in interrupt routine so a timeout of 350 ms should

be set for the answer to arrive. If the timeout occurs the message should be sent again. If an array of data is sent

little endian is used for float or integer values. In case of single data is sent ASCII characters are used e.g. -1.2351e2

Custom made instructions can be added to the list to log or set the parameters that control the BMS algorithm or

its outputs.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

10 www.rec-bms.com

CAN Communication:

Figure 5: CAN female DB9 connector front view.

Table 6: CAN DB9 connector pin designator.

pin

designator

1 2

CANL + TERMINATION

3

GND

4

5

-

6

+ 5V

7

CANH + TERMINATION

8

-

9

Table 7: CAN RJ45 connector pin designator.

Pin

Designator

1 - 2 - 3

GND

4

-

5 - 6 - 7

CANH + TERMINATION*

8

CANL + TERMINATION*

* Termination plug with 120 R

No termination is used inside ABMS connector. Terminate pins 2 and 7 with 120 Ohm resistor to prevent ABMS to

reset. Additional RJ45 connector with 120 Ohms across CANL and CANH should be used for the end device on the

CAN bus for end termination.

11-bit TX identifiers: 0x351, 0x355, 0x356, 0x35A, 0x35B, 0x35E, 0x370

11-bit RX heart-beat 0x305 message from CCGX is neglected.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

11 www.rec-bms.com

BMS Unit Start Procedure:

When the BMS unit is turned ON it jumps into a boot-loader and checks if the user tries to upload a new firmware.

Then it commences the test procedure by checking the balancing fuses and temperature sensors. After the test

procedure red error LED turns off and the BMS unit starts working in normal mode.

BMS Unit LED Indication:

Power LED (green) is turned on in 2 s intervals, if the BMS is powered. When the battery pack is fully charged and

SOC/enod of charge hysteresis are set POWER LED is turne 100% on. Error LED (red) is turned on in case of system

error and blinks number of error with 50 % duty cycle. Between error number 1 s timeout is introduced.

Cell Voltage Measurement:

Cell voltages are measured every second. The cell measurement performs 4 ms cell measurement by Sigma Delta

ADC. Each cell voltage is measured after the balancing fuse, in case the fuse blows, BMS signals error 10 to notify

the user.

BMS Cell Balancing:

Cells are balanced actively with very high efficiency in opposite to passive balancing, where all energy is lost in heat.

Another benefit of active balancing is charging of dangerously low cell, if other cells are above dangerous level,

consequently longer pack usage is possible.

Balancing START Voltage:

If errors 2, 4, 5, 8, 10, 12 are not present and the highest cell voltage rises above Balance START voltage and current

is > 0.2 A (charging stage) the BMS initiates balancing algorithm. A weighted cell voltage average is determined

including cells DC internal resistance. Balancing algorithm calculates the voltage above which the cells are balanced.

The lowest cell voltage is taken into account determining balancing voltage.

Balancing END Voltage:

If errors 2, 4, 5, 8, 10, 12 are not present any cell is above balance END voltage are balanced regardless the battery

pack current.

Cell Internal DC Resistance Measurement:

Cell internal DC resistance is measured as a ratio of a voltage change and current change in two sequential

measurement cycles. If the absolute current change is above 20 A, cells internal resistance is calculated. Moving

average is used to filter out voltage spikes errors.

Battery Pack Temperature Measurement:

Battery pack temperatures are measured by Dallas DS18B20 digital temperature sensor/s. Up to two sensors can

be used in parallel. BMS should be turned off and main connector disconnected before adding sensors. If the

temperature sensors wiring is placed near the power lines shielded cables should be used.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

12 www.rec-bms.com

BMS Current Measurement:

Low-side only precision shunt resistor for current measurement is used. A 4-wire Kelvin connection is used to

measure voltage drop on the resistor. As short as possible shielded cable should be used to connect the power

shunt and BMS. The battery pack current is measured every second. A high precision Sigma-Delta ADC is used to

filter out the current spikes. The first current measurement is timed at the beginning of the cell measurement

procedure for a proper internal DC resistance calculation. Two more 300 ms measurements are performed through

the whole ABMS measurement interval Shunt connection is shown in Fig. 6.

Figure 6: Shunt resistor connection.

Voltage-to-current Coefficient:

Different size and resistance shunts can be used, since the voltage-to-current coefficient can be changed in the BMS

Control software as IOJA x.xxxx Current is calculated by the voltage drop at the shunt resistor. 1 LSB of the 18 bit

ADC represents different current values according to the shunt resistance. The LSB coefficient can be calculated as:

V

A

currentx

dropx

where the V

dropx

represents the voltage drop on shunt resistor at current I

currentx

.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

13 www.rec-bms.com

Battery Pack SOC Determination:

SOC is determined by integrating the charge in or out of the battery pack. Different Li-ion chemistries may be

selected:

Table 8: Li-ion chemistry designators.

Number

Type

1

Li-Po Kokam High power

2

Li-Po Kokam High capacity

3

Winston/Thunder-Sky/GWL LiFePO4

4

A123

5

Li-ion NMC/ LiMn2O4

Temperature and power correction coefficient are taken into consideration at the SOC calculation. Li-Po chemistry

algorithms have an additional voltage to SOC regulation loop inside the algorithm. Actual cell capacity is

recalculated by the number of the charging cycles as pointed out in the manufacturer’s datasheet.

When BMS is connected to the battery pack for the first time, SOC is set to 50 %. SOC is reset to 100 % at the end

of charging. Charging cycle is added if the coulomb counter had reached the battery pack’s capacity.

Battery Pack’s Charging Algorithm:

The communication between the REC BMS and the Victron CCGX is established through the CAN bus. All the

parameters that control the charging/discharging behavior are calculated by the ABMS and transmitted to the CCGX

unit in every measurement cycle.

The charging current is controlled by the Maximum charging current parameter. It’s calculated as Charge Coefficient

CHAC x Battery capacity. The parameter has an upper limit which is defined as Maximum Charging current per

device MAXC x number of inverter devices STRN.

When the highest cell reaches the voltage interval between Balance start voltage and Balance end Voltage, the

charging current starts to ramp down to 1.1 A x Number of Devices until the last cell rises to the End of Charge

Voltage. At that point the Maximum charging voltage allowed is set to Number of cells x (End of Charge Voltage per

cell - end of charge hysteresis per cell). End of Charge SOC hysteresis and End of charge cell voltage hysteresis are

set to prevent unwanted switching. SOC is calibrated to 100 % and Power LED lights ON 100 % Charge optocoupler

is turned off. Charging is stopped in case of systems errors (See System Errors indication chapter).

SOC is calibrated to 96 % when the maximum open circuit cell voltage rises above the 0.502 x (Balance start voltage

+ balance end voltage), minimum open circuit voltage above balance start voltage and system is in charge regime.

Battery Pack’s Discharging Algorithm:

Calculated maximum discharging current is sent to the Color Control GX by CAN communication in every

measurement cycle. When the BMS starts/recovers from the error or from Discharging SOC hysteresis, maximum

allowed discharging current is set. It is calculated as discharge coefficient DCHC x Battery capacity. If this value is

higher than maximum discharging current per device MAXD x number of inverter devices STRN, maximum

discharging current is decreased to this value. When the lowest cell voltage is discharged bellow the set threshold

CLOW maximum discharging current starts to decrease down to 0.05 C (5 % of Capacity in A). After decreasing

down, maximum allowed discharging current is set to 0 A. SOC is reset to 3 % and Discharging SOC hysteresis is set

to 5 %. If the cell discharges bellow Minimum Cell voltage CMIN, ABMS signals Error 2 and SOC is reset to 0 %. If

the Charger/inverter is connected to the grid maximum allowed discharge current is drawn from the grid. Otherwise

100 % load current is drawn from the battery until maximum allowed discharging current is set to 0 A.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

14 www.rec-bms.com

Victron System Configuration:

Inverter/charger configuration

Download and install VE Configuration tools from: https://www.victronenergy.com/support-anddownloads/software. Connect your computer to a VE.Bus product. MK3-USB interface and RJ45 UTP cable are

required. Computer with internet connection will automatically download correct driver.

Update all components to latest firmware, follow instructions on:

https://www.victronenergy.com/live/updating_firmware:updating_ve.bus_products

https://www.victronenergy.com/live/ccgx:firmware_updating

Color Control settings:

Update CCGX to 2.11 or higher.

Connect Color Control GX (CCGX) with other devices (MPPT, Multis). Open Settings menu and select System setup.

Change:

- Battery monitor to REC BMS in CAN-bus.

In Settings menu select Services, CAN-bus profile and click on VE.Can & CAN-bus BMS (250 kbit/s).

CCGX settings are automatically saved when you change it. Grid set point is not fixed value and can be modified for

user needs.

ABMS Outputs setting:

Non-Victron devices can be controlled by digital outputs Charge optocoupler and optocoupler 2 and relay 1. Charge

optocoupler is already pre-programmed as charge sources control, while optocoupler 2 and relay 1 can be user

programmed. Relay 1 hysteresis RE1H and oprocoupler 2 hysteresis OP2H play the role of top disconnect or bottom

disconnect. If the hysteresis is set positive the output will bottom disconnect, while if negative it will top disconnect.

Errors 4, 5, 8, 10, 11, 12 and 13 disconnect relay 1 and optocoupler 2.

EXAMPLE 1:

We want to use relay 1 as non-Victron charge control. Relay 1 should switch off if the highest cell reaches 3.65 V

with 0.15 V hysteresis. In communicate window we set:

RE1L 3.65

REL1H -0.15

EXAMPLE 2:

We want to useoptocoupler 2 as non-Victron charge control. Optocoupler 2 should switch off if the lowest cell

drops under 2.70 V with 0.25 V hysteresis. In communicate window we set:

OP2L 2.70

OP2H 0.25

Video instruction link for settings change: https://www.youtube.com/watch?v=sRr_5vBKupw

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

15 www.rec-bms.com

Digital Outputs:

Digital outputs are implemented with galvanic isolation. Optocouplers with diode reverse protection are used.

When closed, a 0.7 V voltage drop over the digital output should be taken into account. Optocoupler outputs can

drive a small signal relay or LED diodes. Fig. 7 shows two different connection schematics. Both outputs can be used

to drive LED diodes for charge/discharge relay indication.

Figure 7: BMS digital outputs schematics.

Current limit resistor R can be calculated as:

V

FVLED

represents LED forward voltage drop (typ. 1.9 – 2.3 V) while I

LED

represents LED current (2-5 mA).

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

16 www.rec-bms.com

Pre-charge Connection:

Battery pack main contactor is driven by ABMS internal main relay. In case of system with high input capacity (>

2,000 µF) a pre-charge system should be used to avoid high in-rush current spikes when the main contactor is

turned on. High currents like this degrade the contactor, cells and input capacitors in the electronic devices. Fig. 8

shows contactor connection with the pre-charge unit.

Figure 8: Contactor connection schematics.

Parallel Cells Connection:

Capacity can be increased by connecting multiple cells in parallel and then connect these sub-packs in series. Fig. 9

shows 2P4S connection with 2 cells in parallel and 4 pack like this in series. For proper current distribution 2

connection bars should be used between each 2P to 2P sub-pack.

Figure 9: 2P4S battery pack connection.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

17 www.rec-bms.com

System Error Indication:

System errors are indicated with red error LED by the number of ON blinks, followed by a longer OFF state.

Table 7: BMS error states.

Number of

ON blinks

ERROR

BMS

OWNER

1

Single or multiple cell

voltage is too high

(cell over voltage

switch-off).

BMS will try to balance down the

problematic cell/cells to safe voltage

level (5 s error hysteresis + single cell

voltage hysteresis is applied).

Charging is disabled, discharging is

enabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are enabled.

Wait until the BMS does its job.

2

Single or multiple cell

voltage is too low

(cell under voltage

protection switchoff).

BMS will try to charge the battery

(5 s error hysteresis + single cell voltage

hysteresis is applied).

Charging is enabled, discharging is

disabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are enabled.

Plug in the charging sources.

3

Cell voltages differs

more than set.

BMS will try to balance the cells if

balancing is enabled (5 s error hysteresis

+ 20 mV voltage difference hysteresis).

Charging is enabled, discharging is

enabled. Main relay is connected. Relay

1 and optocoupler 2 are enabled.

Wait until the BMS does its job. If

the BMS is not able to balance

the difference in a few hours,

contact the service.

4

Cell temperature is

too high (over

temperature switchoff).

Cells temperature or cell interconnecting cable temperature in the

battery pack is/are too high. (5 s error

hysteresis 2°C hysteresis).

Charging is disabled, discharging is

disabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are disabled.

Wait until the pack cools down.

5

BMS temperature is

too high –internal

error (BMS over

temperature switchoff).

Due to extensive cell

balancing/hardware error the BMS

temperature rose over the upper limit (5

s error hysteresis + 5 °C temperature

hysteresis).

Charging is disabled, discharging is

disabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are disabled.

Wait until the BMS cools down.

6

Number of cells,

address is not set

properly.

Charging is disabled, discharging is

disabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are disabled.

Set proper ABMS address

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

18 www.rec-bms.com

7

The temperature is

too low for charging

(under temperature

charging disable).

If cells are charged at temperatures

lower than operating temperature range,

cells are aging much faster than they

normally would, so charging is disabled

(2 °C temperature hysteresis).

Charging is disabled, discharging is

enabled. Main relay is connected. Relay

1 and optocoupler 2 are enabled.

Wait until the battery’s

temperature rises to usable

range.

8

Temperature sensor

error.

Temperature sensor is un-plugged or not

working properly (5 s error hysteresis).

Charging is disabled, discharging is

disabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are disabled.

Turn-off BMS unit and try to re-

plug the temp. sensor. If the BMS

still signals error 8, contact the

service. The temperature sensors

should be replaced.

9

Communication

error.

RS-485 Master-Slave communication

only.

10

Cell in short circuit or

BMS measurement

error.

Single or multiple cell voltage is close to

zero or out of range, indicating a blown

fuse, short circuit or measuring failure

(15 s error hysteresis + 10 mV voltage

difference hysteresis).

Charging is disabled, discharging is

disabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are disabled.

Turn-off the BMS and check the

cells connection to the BMS and

fuses. Restart the BMS.

If the same error starts to signal

again contact the service.

11

Main relay is in short

circuit.

If the main relay should be opened and

current is not zero or positive, the BMS

signals error 11.

Charging is disabled, discharging is

disabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are disabled.

Restart the BMS unit. If the same

error starts to signal again

contact the service.

12

Error measuring

current.

Current sensor is disconnected or not

working properly.

Charging is disabled, discharging is

disabled. Main relay is disconnected.

Relay 1 and optocoupler 2 are disabled.

Turn-off the BMS and check the

sensor connections, re-plug the

current sensor connector. Turn

BMS back ON. If the BMS still

signals error 12, contact the

service.

13

Wrong cell chemistry

selected.

In some application the chemistry preset is compulsory (5 s error hysteresis).

Charging is disabled, discharging is

disabled. Relay 1 and optocoupler 2 are

disabled.

Use PC Control Software to set

proper cell chemistry.

BATTERY MANAGEMENT SYSTEM ABMS FOR VICTRON COLOR CONTROL GX

19 www.rec-bms.com

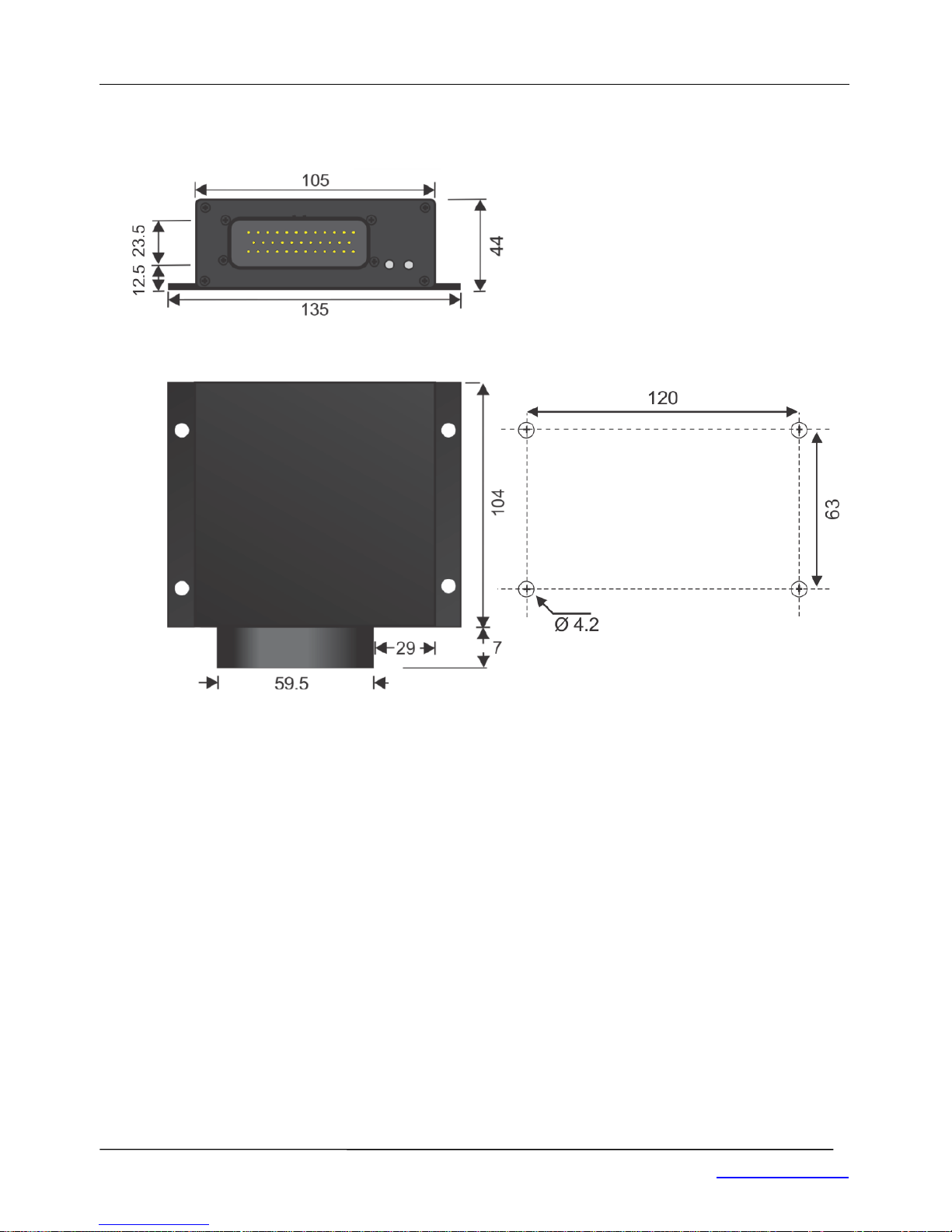

BMS Unit Dimensions:

Figure 10: BMS dimensions.

M4 bolts are preferred to use for mounting. BMS unit can be also supplied without the enclosure, if an application

is weight or space limited. The dimensions of the BMS (including connector) without the enclosure are 109 mm x

100 mm x 38 mm. The PCB has four 3.2 mm mounting holes.

Loading...

Loading...