Instructions for

Real Good Toys’

The

Special Edition Alison, Jr.

Special Edition Kit #SE-JM907

©04/17

Congratulations on your choice of a Real Good Toys product. Your kit has been precision made with meticulous

care by our craftspeople using carefully selected materials. This Dollhouse will last for years, even generations,

if heirloom care and attention is given during assembly. Take your time and read the instructions completely. If

you have questions, ask the experts at your local Dollhouse store or at info@realgoodtoys.com

Before you begin - You have already opened the box and see all the parts organized in boxes and bundles. For

the moment, keep them that way. There are important things to do before you open your glue bottle.

Preview the Overview (page 2) to plan and organize your

build; this helps you proceed with confi dence.

Measure and identify the parts: The kit is

packed in groupings that protect the parts, and that

is how the Parts List is organized. As you measure

and identify the parts, label them with sticky notes

using the names from the parts list, and check

them off the parts list so you know you have everything. Taking the time now to identify and

organize the parts also makes them familiar

so you will understand what the instructions

intend as you read ahead.

• Plan ahead so you know where you are going

• Read ahead so you know how to get there

• Paint ahead so the parts will be ready when

you need them

Prepare your space: This dollhouse will spread

out over a large area while it is being built.

You will need a large fl at tabletop for the house,

several boxes to keep parts organized until they

are needed, and several trays lined with waxed

paper for holding small parts like windows and

railings.

A snap-lid box will keep your tools and sup-

plies handy between building sessions.

Supplies:

Paint: Interior semi-gloss latex paint... Almost everything gets at least one coat before assembly - get the paint now.

Paintbrushes 1” or 2” foam brushes for each color, 3” foam roller for interior painting

Sandpaper: 320 grit, 3-5 sheets

Glue: Aleene’s Tacky Glue for the dollhouse, Solvent-Based panel cement for shingles

Masking tape: ¾” or 1”

Wiring: it’s easiest to install some parts during assembly… order wiring supplies now.

Wallpaper paste: Roman’s “Border” Paste

Real Good Toys 122 Gallison Hill Rd Montpelier VT 05602 802 262-6018 www.realgoodtoys.com

Not suitable for children under 13 years of age

California 93120 compliant for formaldehyde phase 2

www.realgoodtoys.help

Instructions for Special Edition Kit #JM-907 Alison Jr

6803 Banister

& Landing Set

Wallpaper

P2000

HH444

#4017 Stair

and Landing Set

Split Octagonal Shingles

Dye1: Reddish Brown

Dye3: Dark Grey

Turntables, Platform

Turntables, and Turntables with wiring feed

are available

Assembly Notes /Getting Started (A) page 2

Options for building the Alison Jr. Dollhouse

See your local dollhouse shop or www.realgoodtoys.com

Exterior:

Exterior Paint Color:

see www.realgoodtoys.help for suggestions

Accessories:

Gingerbread

Flower Boxes

Foundation Stucco Grit

Octagonal Shingles

Fancy Windows and Doors

Turnposts and Spindles

Interior:

Wiring

Wallpaper

Interior paint color:

Ceilings

Painted walls

Interior trim

Flooring:

Applied wood, tile, or carpet

Banister & Landing Rails

Window and Door trim

Baseboard and Crown

A Doghouse for

your Dollhouse

Split Octagonal Shingles

#6002

Note: I often enlarge an interior door opening to fi t the #6022

Exterior

#6018

Shingle Dye

Doors:

Interior

#6022

Windows: fi t: full-size; working or non-working

#1015

Wallpaper

P2000

HH444

Turntables, Platform

Turntables, and Turntables with wiring feed

are available

Trim and Stripwood

Flute24

Dye1: Reddish Brown

Dye3: Dark Grey

#5042

Real Good Toys’ Best1

Dollhouse Wiring Set

#5041

JM33

See page 20

SW16

RGT8

#4017 Stair

and Landing Set

6803 Banister

& Landing Set

Instructions for Special Edition Kit #JM-907 Alison Jr

Assembly Notes /Getting Started (A) page 3

Overview of the Build:

Details of each step will be expanded along the way, but lots of

folks like to see how it all fi ts together before they start

Identify and label all of the parts

Paint everything one coat

Finish the fl oors

Sand painted surfaces until the paint is smooth, transparent,

and some of the wood is showing through

Optional: Add an Electrifi cation Slot to the Base Floor*

Build the housebody until the Top Floor

Optional: Start the wiring

Mark, paint, and attach theTop Floor

Build and attach the Foundation

Pre-cut wallpaper for the inside of the Roofs

Attach the Roofs (Optional: E-slot the Top Floor)

Optional: Attic wiring

Install the Dividers (but not the Blind Dividers)

Optional: Finish the wiring

Assemble and fi nish painting

Finish the outside

Finish the inside

Wiring? www.realgoodtoys.help

Click the buttons “JM907” and “Wiring” for wiring information specifi c to this house.

(see www.realgoodtoys.help/JM907/painting)

Slideshows, demos, useful links, details, and photos are all at:

www.realgoodtoys.help

Glue the shingles on

it! If the glue says ”water clean-up”, it will curl the wooden shingles. Look carefully at the glue you intend to use to be sure it is

solvent-based, or use hot-melt glue (and watch out for the burns).

I use a “Sub-Floor Adhesive” glue which comes in a caulking-gun

tube at the hardware or building supply store. It says “Caution:

Flammible” on the front, and that’s how I am sure it is solvent

based. Check ingredients and warnings!

If you Wallpaper

collage) or pre-mixed Roman’s “Border” paste.

Brush paste on the wallpaper, then the wall, and fi nally smooth

the wallpaper into position.

Taking things apart: Heat softens glue. If you have to take things

apart, warm the part in the oven at 170

the heat get into the joint where the glue is. Don’t let it get hotter

than you can touch or the paint may scorch. Don’t heat window

panes.

When glue is drying, skip ahead to up-coming assembly steps

and prepare the parts that will be used

Before you begin, read the “Finish the Inside” section on the

last page.

with glue that doesn’t have any water in

, use Yes® craft paste (for bookbinding or

o

for up to a half hour to let

Assembly Tips:

A large, clutter-free, well-lighted work area is helpful

during assembly, but a fl at work surface is essential.

Read the instructions

illustrations. !With the parts in your hands!, think the

assembly through before you proceed.

Test fi t

then you’ll know you have it right.

If more tape or a helper is needed, it’s good to know that

before the parts have glue on them.

each time you are ready to glue a piece in place...

carefully; look at each of the

Don’t be stingy with glue or tape; use generous amounts.

Always wipe off excess glue immediately.

Keep one damp rag and one dry rag handy all the time.

Have weights available

for holding things tight as glue

joints dry (stacks of books, gallons of pure Vermont Maple

Syrup - anything heavy)

Glue the body of your dollhouse together

white, water clean-up glue that dries clear. Do not use

instant-bond (super glue), fast-tack, rubber cement, silicone, or hot melt glues. They are all used in some wood

applications, but they all have some characteristic that

makes them un-desirable for the body of your dollhouse.

Carpenter Glue works well, but glue-smear dries yellow

or tan; many of the things you glue onto the house are prepainted – extra glue will show.

I use Aleene’s Tacky Glue® for housebody assembly.

Make sure everything is straight and fl at as glue dries...

That’s the shape that will be permanent.

with

Q: Can I wallpaper before I assemble the doll house?

A: Yes you can (it’s your house!) Many experienced builders are

advocates of papering before construction - I am not.

My biggest objection to papering fi rst is that you are always too

skimpy with glue so none will squeeze out and get on the paper.

I try to use the amount of glue that fi lls the joint, so some will

squeeze out in every joint and be wiped up. But wiping glue off

of wallpaper leaves a streak, so the temptation is to go skimpy,

and the joints aren’t as strong.

Second, I can always tell a house that was pre-papered because

the corners show a void instead of being continuous (see the

slideshows about how to crowd the papers together in the corner... you can’t do that with pre-papered walls).

Third, I have had to replace paper too often that has gotten

damaged by glue or tape during construction... that wastes time

and paper ($) and can make it so you are left deciding whether

to replace a damaged paper or letting it slide because you don’t

have any more of that pattern and you’ll have to order it and that

takes too much time (running out but then needing another piece

is a distressing moment).

Finally, I don’t fi nd pre-papering to be faster. By the time I have

done all of the extra planning that getting the papers in the right

place requires, I have used up any potential advantage. I have

great big blacksmith’s hands, and papering in a fi nished house is

easy for me.

All that having been said, I do pre-cut the papers used in the

attic before attaching the Roofs and I paper in front of the Blind

Dividers (2

1

/2”) before I glue them in place.

Instructions for Special Edition Kit #JM-907

(1) UE 6411 Base Floor: (

1

/

4

w/ fl ooring) 22 x 11

7

/

8

(1) UE 6412 Middle Floor: (

3

/

8

w/ fl ooring) 22 x 11

7

/

8

, Stair hole

(1) UE 6413 Top Floor: (

3

/

8

w/ fl ooring) 23

7

/

8

x 15

7

/

8

, Stair hole

(1) E 6414 Porch Base Floor: (

1

/

4

) 14 x 3

7

/

8

(1) E 6415 Porch Mid Floor: (

3

/

8

) 14 x 3

7

/

8

(2) E 6416 Side: (

3

/

8

Milled) 18

5

/

8

x 11

3

/

4

, Grooved

(1) E 6417 Right Front: (

3

/

8

Milled) 18

5

/

8

x 14, Cutouts, Grooved

(2) E 6418 Tower Side: (

3

/

8

Milled) 18

5

/

8

x 3

7

/

8

,

Grooved

(1) E 6419 Tower Front: (

3

/

8

Milled) 28 x 7, Windows, Grooved

(1) E 6420 Left Front: (

3

/

8

Milled) 18

5

/

8

x 1

1

/

2

,

Grooved

(1) E 6423 Attic Divider: (

3

/

8

) 9 x 15

5

/

8

, Door

(2) E 3615 Divider: (

3

/

8

) 9 x 11

3

/

4

, Door

(4) E 6424 Blind Divider: (

3

/

8

) 9 x 1

3

/

8

(1) E 6425 Rooftop: (

1

/

4

) 20

5

/

16

x 14

1

/

8

(1) E 6426 R. Front Roof: (

1

/

4

) 14

11

/

16

Base x 9

7

/

32

, Dormer Cutouts

(1) E 6430 Tower Rooftop: (

1

/

4

)

4

1

/

2

x 4

3

/

4

(1) E 6431 Rooftop Extension: (

1

/

4

)

7

7

/

8

x 2

5

/

8

(1) UE 6432 Tower Base Floor: (

1

/

4

w/ fl ooring) 6

1

/

2

x 4

(1) UE 6433 Tower Floor: (

3

/

8

w/ fl ooring) 6

1

/

2

x 4

(1) E 6436 Foundation: (

1

/

2

) 20

5

/

8

x 1

1

/

4

(4) E 6437 Foundation: (

1

/

2

) 14

7

/

8

x 1

1

/

4

(1) E 6438 Foundation: (

1

/

2

) 11

7

/

16

x 1

1

/

4

(1) E 6441 Foundation: (

1

/

2

) 22

5

/

32

x 1

1

/

4

(2) E 9803 Stringer: (

1

/

8)

13

/

16

x

±

10

7

/

8

,

Mitered

(2) E 9801 Bottom Stair Block: 2

1

/

4

(2) E 9802 Top Stair Block: 2

1

/

4

Top Stair Block

Bottom Stair Block

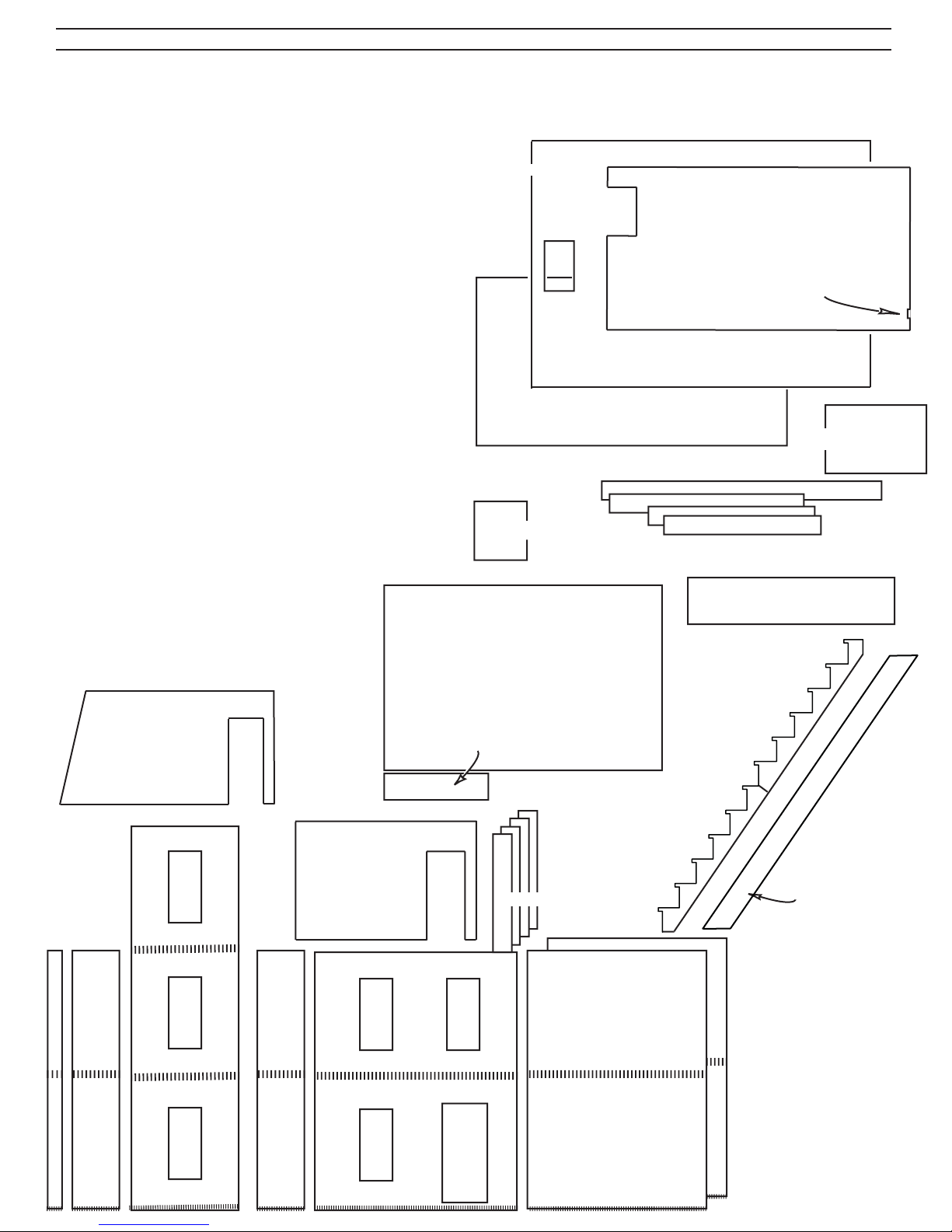

Parts List page 4

Identify the parts: Open one bundle at-a-time.

Measure each part and fi nd it on the parts list.

Label the parts and, as you preview the instruc-

tions, group them as they will be used

Parts List:

(1) UE 6411 Base Floor: (

(1) UE 6412 Middle Floor: (

(1) UE 6413 Top Floor: (

(1) E 6414 Porch Base Floor: (

(1) E 6415 Porch Mid Floor: (

(2) E 6416 Side: (

(1) E 6417 Right Front: (

(2) E 6418 Tower Side: (

(1) E 6419 Tower Front: (

(1) E 6420 Left Front: (

(1) E 6423 Attic Divider: (

(2) E 3615 Divider: (

(4) E 6424 Blind Divider: (

(1) E 6425 Rooftop: (

(1) E 6426 R. Front Roof: (

(1) E 6430 Tower Rooftop: (

(1) E 6431 Rooftop Extension: (

(1) UE 6432 Tower Base Floor: (

(1) UE 6433 Tower Floor: (

(1) E 6436 Foundation: (

(4) E 6437 Foundation: (

(1) E 6438 Foundation: (

(1) E 6441 Foundation: (

(2) E 9803 Stringer: (

(2) E 9801 Bottom Stair Block: 2

(2) E 9802 Top Stair Block: 2

Measurements are approximate and are for identifi cation purposes only

1

/

4

w/ fl ooring) 22 x 11

3

/

8

w/ fl ooring) 22 x 11

3

/

8

Milled) 18

3

/

8

1

/

1

/

3

/

8

w/ fl ooring) 23

1

/

4

) 14 x 3

3

/

8

) 14 x 3

5

/

8

x 11

3

/

8

3

/

8

3

/

3

/

8

3

) 9 x 11

3

4

) 20

1

/

2

1

/

2

1

/

2

1

/

2

13

8)

Milled) 18

Milled) 18

8

Milled) 28 x 7, Windows, Grooved

Milled) 18

/

8

) 9 x 15

3

/

4

, Door

3

/

8

5

1

/

3

) 20

) 14

) 11

) 22

/

16

) 9 x 1

/

16

x 14

11

4

) 14

1

1

/

4

)

4

/

2

1

/

4

)

1

/

4

/

8

w/ fl ooring) 6

5

/

8

x 1

7

/

8

x 1

7

/

16

x 1

5

/

32

x 1

±

7

x

10

1

/

4

1

/

4

7

/

8

7

/

8

7

/

8

3

/

4

, Grooved

5

/

8

x 14, Cutouts, Grooved

5

7

/

8

x 3

5

1

/

8

x 1

/

5

/

8

1

/

16

x 4

7

7

w/ fl ooring) 6

/

8

/

8

, Door

/

8

Base x 9

3

/

4

5

/

8

x 2

/

1

1

/

4

1

/

4

1

/

4

1

/

4

,

Mitered

7

/

8

7

/

8

, Stair hole

7

x 15

/

8

/

2

8

/

, Stair hole

8

,

Grooved

,

Grooved

7

/

32

, Dormer Cutouts

1

/

2

x 4

2

x 4

Rooftop

The Woodgrain Flooring, Assembled Door, Sawn Shingles, and other

extras make this a “Special Edition” Kit. In any correspondence

include the words “Special Edition” so we can help you properly.

Mid Floor

Electrifi cation Slot - makes running

tapewire from fl oor-to-fl oor easier... if

you do not intend to wire your dollhouse, ignore the Electrifi cation Slot

Top Floor

Base Floor

Tower Rooftop

Long Foundations

Tower Floors

Porch Floors

Left Front

Attic Divider

Tower Side

Tower Front

Tower Side

Divider

Right Front

Rooftop Extension

Blind Dividers

Sides

Top Stair Block

Bottom Stair Block

Stringer

Instructions for Special Edition Kit #JM-907

Parts List page 5

Bevel

Bevel faces out

Left Side Roof

Left Front Roof

7

(10) E 6448

/16 Trimstrip: 3/32 x 185/8 (Exterior)

(2) E 6449 1/2 Ledge Trim: (1/8) x 157/8

(1) E 6450 1/2 Ledge Trim: (1/8) x 14 13/16

(1) E 6451 1/2 Ledge Trim: (1/8) 21/4

Inner Box:

(1) E 6453 Bag of Shingles (850)

(22) E 6443 Bracket:

1

/4

(11) E 6515 3/8 Beads

(11) E 6444 Trimpost: (1/2 Flutepost) 7/8

(1) E 6456 Hanging Front Gingerbread: 11/8

(28) T1020 Window Vertical Frame: 5

5

/16, Mitered

(4) E6455 Dormer Interior Vert. Trim: 5, Miters

(28) T1021 Window Horizontal Frame: 213/16, Mitered

(4) E6454

Dormer Interior Horiz. Trim: 2

1

/2, Miters

(24) E3633 Shutter Panel: (5/64) 3/4 x 17/8

(4) E 6447 Fillstrip: (1/8) 3/8 x 9 (Interior)

(2) E 6452 9/16 Trim: 3/32 x 9

(1) E 3623 Groove Fill: (

1

/8) 3/8 x 4

(4) E 3619 Porch Post: (1/2 Flutepost) 9

(2) T0558 Door Interior Side Trim: 711/16, Miter

(12) E3632 Shutter Core: (

1

/8) 1 x 45/8

(3) E 6445 Assembled Railing: 63/8

(2) E 6446 Assembled Railing: 31/4

(1) 6042 Assembled Door

(8) T1022 Window Pane: 5 x 21/2

(4) E 6459 Porch Front Gingerbread: 63/8

(1) T0559 Door Interior Top Trim: 3

3

/8, Miters

(1) E 6462 Roof Top Cresting, Left: 75/8

(1) E 6463 Roof Top Cresting, Front: 113/16

(1) E 6464 Roof Top Cresting, Right: 123/4

(1) E 6457 Hanging Side Gingerbread: 31/4

(2) E 6458 Porch Side Gingerbread: 3

1

/4

(2) E 6460 Tower Top Cresting: 31/8

(2) E 6461 Tower Top Cresting: 31/4

1

(3) E 6429 Tower Roof: (

(1) E 6427 Left Front Roof: (

/4) 77/8 Tall x 73/8 Base

1

/4) 21/8 Base x 97/32 Tall

(1) E 6421 Left Top Tower Side: (3/8 Milled) 9 Tall x 21/8 T op

(1) E 6422 Right Top Tower Side: (

(1) E 6428R Right Side Roof: (

(1) E 6428L Left Side Roof: (

3

/8 Milled) 9 Tall x 21/8 T op

1

/4) 155/8 Base x 97/32

1

/4) 155/8 Base x 97/32

(4) E 6434 Dormer Side: (1/4) 57/16 Tall x 13/16 Top

(2) E 6435A Dormer Ceiling: (

1

/4) 29/16 x 13/16 Top, Bevel

(2) E 6435B Dormer Roof: (3/4) 15/8 x 31/2, Bevels

(3) E 3626 Flower Box: (1/2) 3/4 x 33/4, Mitered

(2) E 6439 Foundation: (5/8) 11/32 x 11/4

(3) E 6440 Foundation: (

5

/8) 5/8 x 11/4

(1) E 6442 Step: (3/4) 6 x 11/2

Right Front Roof

Interior Door Trim

Shutter Panel

Shutter Core

Dormer Ceiling

Dormer Side

Bevel

Right Side Roof

Tower Roofs

Top Tower Sides

Tower T op Cresting

Dormer Roof

Instructions for the Special Edition #SE-JM907 The Alison, Jr. Assembly notes, A: Getting Started Page 6

Coarse Double-Cut File

Batch Dye Shingles

Utility Knife

A: Getting Started:

Do these things before the house assembly

Square the corners of the window, door, and stair holes with a utility knife - each

cutout has a rounded corner left over from the tool that made it.

each corner from the outside (one from each direction), then cut from each direction on the inside to cut away the rounding in the corner so the window, door, or

stairs will fi t.

A Double-Cut Coarse File is

easier for many people to use

when squaring the corners.

Make several strokes from each

direction in each corner and test

the Window or Door to see how

it fi ts.

Coarse Double-Cut File

Make two cuts in

Stain the Shingles: Our pro uses Real Good Toys’ Shingle Dye

(available through your Real Good Toys miniature dealer) when dying

the shingles for this house. If you stain the shingles, you must use

penetrating oil based stain, not “rubbing”, “Gel” or latex-based. Batch

dye or stain the shingles several days ahead of time so they will be dry

when the time comes to use them (instructions are with the shingle dye).

Utility Knife

Batch Dye Shingles

Foundation

Step 1

7

11

/16”

11/32”

Foundation

Step 3

7

/8”

14

11/32”

7

14

/8”

Pre-Assembly: Assemble the Foundation

Foundation

Step 2

Foundation

Step 4

/8”

7

14

/8”

7

14

5

22

/32” (longest)

5

/8

63/16” spacing

205/8”

63/16” spacing

5

/8

Without glue, line up a fl oor with the edges of the Foun-

dation to hold the Foundation square as the glue dries.

5

/8

Instructions for the Special Edition #SE-JM907 The Alison, Jr. Painting Page 7

nish.

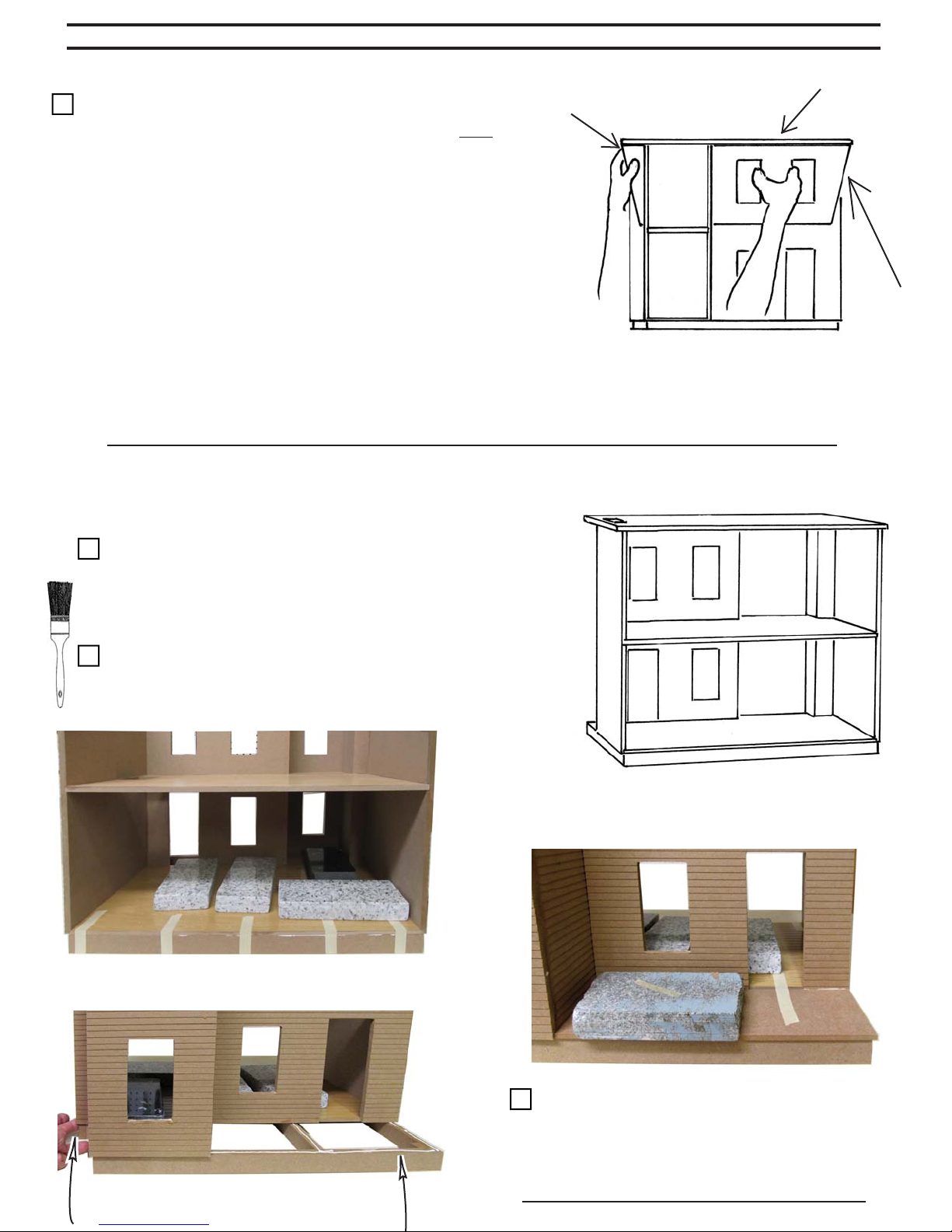

Painting: www.realgoodtoys.help has painting and sanding videos

Paint (fi rst-coat) everything. Don’t try to sand , fi ll, primp, or do much of anything to the wood before the fi rst coat.

The fi rst coat fi lls and reinforces the wood so sanding clips off the fi bers rather than pushing them around. The fi rst-

coat is all about what penetrates and fi lls the wood. There is no expectation that more than a hint of paint will be on the

surface. Don’t ‘double paint’ or try to give it an extra thick fi rst coat as you watch the paint soak in... that is expected and

preferred.

The fi rst benefi t of painting before assembly (one-coat) is that it is the easiest time to do a really thorough job of sand-

ing after painting. The difference between a heirloom-grade fi nish on a dollhouse and a “I-was-in-a-hurry” fi nish is most

often the quality of the sanding, and it’s hard to sand into the little hidden corners of an assembled dollhouse, but it’s easy

to sand the fl at panels layed out on a workbench.

So sand everything now - sand until the paint is smooth and transparent with no scratchiness to it, and with lots of wood

showing through the paint. For the clapboard walls, sand “one clapboard course at-a-time”: fold the sandpaper and hold

it on your fi nger-tips, then sand back-and-forth across one clapboard’s suface 2 or 3 times, then move up to the next clap-

board. “One at a time” is what makes it smooth and “Heirloom-Great”.

Second coat everything after building the housebody up to the top of the Walls (before attaching the Top Floor). The

second coat goes on smooth and creamy, and except for touchup, it may be enough.

First-coat

Sanding one course at a time

Q: How can I prevent glue from seeping onto the fl oor after I clamp (tape) the Sides together?

A: Do not skimp on the glue... a little squeezing out tells you that there’s enough glue in the joint. Clean up the

squeezings with a damp rag followed by a dry rag, and the little bit that remains down in the grooves will shrink back

as it dries, and will not be visible.

This issue is one of the reasons it is important to pre-fi nish the fl oors before assembly. I know, the fi nish tries to bead

up when you fi rst put it on and it is ‘paint-can-runny’, but just keep rubbing it out as it loses it’s excess moisture and

starts to get tacky, and that fi rst coat will eventually behave itself and lay down properly. I like to do the fi rst-coat-

rub-out with a crumple of brown paper bag so I can rub vigorously and ‘de-shine’ the print fl ooring, but other builders

report success with just brushing and brushing until the moisture level gets right. After the fi nish is dry, do a very light

de-shine with a non-woven abrasive pad (like ‘Scotch Brite”, the green pad you use in the kitchen for stainless steel

pots... a used one is just right), and then apply a second coat of fi nish.

fi

Finish the Floors: The fl oors need fi nishing to protect

them from damage by tape being removed, by paint or

glue, or by normal wear-and-tear during assembly. Wipe

off the fi rst coat and, when it is dry, de-shine the surface

with a non-woven pad (also called “synthetic steel wool”)

or a crumple of brown paper bag; then apply more coats.

Can I do it differently? Yes you can - it’s your house!

The information on these pages is offered as “best practices” advice, and it is what we do when we build this house.

If you are customizing or have something else in mind, test-ahead to make sure your planning includes everything!

Instructions for the Special Edition #SE-JM907 The Alison, Jr. B: HouseBody Page 8

Illustration #3

Spread glue in the grooves

Illustration #4

Install the groove fi ll

The Floor overhangs the front

of the Side panels by

1

/

8

”

Scrape the Floor

Scrape the Groove

Assemble the Housebody:

1. Select the Middle Floor. Without glue, test the Floor panel

along with the Sides to check the fi t - scrape the edges of the

grooves and the under-side of the fl oors where they fi t into the

grooves if necessary.

Scrape the Floor

Look at Illustration #2. The top edge of the Side is the edge without a groove. The top surface of the Middle Floor has the “fl oor-

ing” fi nish, the stair hole is toward the front edge, and the fl oor

sticks out

1

/8” at the front edge.

Complete steps 2 - 9 without stopping

2. Spread glue in the grooves of both Side panels (Illustration

#3). Use plenty of glue and spread it lightly with your fi nger to

keep it from dripping

Now is a great time for an extra pair of hands.

3. Stand the Middle Floor on end (check the orientation

again) in the middle groove of the Side.

Illustration #2

Check the fi t of the Middle

Floor and Side Panels

Scrape the Groove

4. Adjust and check all the parts. The Floor must be fl ush at

the back edge of the Side panel (“fl ush” means ‘forming a con-

tinuous, unbroken surface’). The Floor overhangs the front of

the Side panels by

1

/8”

5. The Base fl oor fi ts into the base fl oor groove. Notice that

the fl oorboards are wider on one edge, and narrower on the other

edge. Set up the Base Floor with the fl oorboard profi le matching

the fl oorboard profi le of the Middle Floor. Set the Base Floor into

the base fl oor groove lined up on the back edge.

6. Set the other Side onto the ends of the fl oors, fl ush at the

back edge. Tape the fl oors to the Sides. Use lots of tape and

stretch it tight for a good glue joint.

7. Install the Groove Fill; tap with a hammer and wood block

for a snug fi t (If the fi t is too tight sand the edges of the Groove

fi ll). The Groove Fill fi lls the fl oor’s groove inside the stair hole,

leaving a smooth wall (Illustration #4).

The Floor overhangs the front

of the Side panels by

Illustration #3

Spread glue in the grooves

Illustration #4

Install the groove fi ll

Base

Floor

1

/

8

”

Top Edge

The Floors stick

out 1/8” in front

If I can’t continue to step 9 for any reason, I still temporarily set the Right

Front on the housebody as in stpe 9, and straighten the house to match the

edges of the Right Front. If the glue dries without straightening the house,

Step 9 is more diffi cult.

Groove Fill

Instructions for the Special Edition #SE-JM907 The Alison, Jr. B: Housebody Page 9

8. Lay the housebody down on its BACK.

Without glue test the Right Front in place on the

house, fl ush with the Right Side at the top, bottom,

and right edge. Remove the fl oor’s tape that gets in

the way.

9. Spread glue in the grooves of the Right Front

panel and on the front edge of the Right Side panel.

Set the Right Front into position on the housebody

(Illustration #5).

Carefully tape in many places along the bottom

edge, making sure the Base Floor is tight to the top

edge of the groove.

Exactly line up the edge of the Front with the face

of the Side, all the way from the bottom to the top

(this is the operation that straightens the house).

Tape the Front securely to the Right Side to hold

everything tight as the glue dries

(Illustration #6).

Review: Make sure all parts are in place and all the

joints are tight.

• Check the position of the stair hole, closer to the

front edge.

• The Base Floor is tight to the groove-top.

• The house is exactly lined up on the right edge.

Illustration #5

Illustration #6

Flush

Right Front

Panel

Base Floor

Side Panel

Flush

Preview: In this section, you will attach the Tower

Sides, Tower Floors, Fillstrips, and Left Front.

10. Glue a Tower Side to the Right Front panel

touching the front edge of the fl oors (Illustration #7).

Glue a Fillstrip to the back edge of the Tower Side

between each fl oor.

Tape the Tower Side and Fillstrip to the Right Front.

Steps 10 and 12

view from the top

Left Front

Fillstrip

Right Front

Illustration #7

Fillstrip

Tower Side

Tower Side

Instructions for the Special Edition #SE-JM907 The Alison, Jr. B: Housebody Page 10

11. Hold the Tower Floors against the House

Floors and check out the fl ooring pattern. When

it is right, the pattern will be a continuous board

width from the back of the house to the front.

Glue and tape the Tower Floors in place, into the

grooves of the Tower Right Side, and against the

housebody’s fl oors (Illustration #8). Make sure

the top surface of the joint is lined up smoothly.

Illustration #8

12. Glue and tape the Tower Left Side and

Fillstrips to the Tower Floors.

13. Glue and tape the housebody’s Left Front

in place (Illustration #9).

14. Lay the housebody down on its back.

Without glue, test the fi t of the Top Floor

on the housebody, centered side-to-side. The Top

Floor overhangs the Tower Sides

1

/8” in the front

and overhangs the house 11/16” on each side.

Lightly trace the perimeter of the house-

body on the bottom of the Top Floor (Illustration

#10). Check to make sure the housebody’s sides

are parallel with the sides of the Top Floor. The

space outside the edges must be

11

/16” on each

side.

Remove the Top Floor and paint the outside

of the tracing now. Make sure your housebody

painting is done as well. Let the paint dry.

You can skip ahead to the section for assembling the Windows, and come back here when

the paint is dry.

Wiring? Now is the best time to prepare for wiring.

See www.realgoodtoys.help

Illustration #10

Trace the Housebody on the

bottom of the Top Floor

Illustration #9

Left Front Panel

1

/8” overhang

Top Floor

11

/16” overhang

11

/16” overhang

Instructions for the Special Edition #SE-JM907 The Alison, Jr. C: Foundation Page 11

15. Glue and tape the Top Floor to the housebody, fl ush at

the back and spaced evenly along the sides. The Top Floor must

overhang the housebody evenly (11/16”) on each side.

Review: all parts are in place and all joints are tight.

• Check the position of the stair hole - on the right when looking

at the house from the front.

• The house is straight - the Sides are straight up-and-down in

back

11

• The Top Floor overhangs the sides by

/16”

• The Top Floor lines up with the Side inside the stair hole

• The Top Floor lines up with the Sides in back

Add weights all around; let the glue dry

Attach the Foundation:

Wiring? The easiest time to prepare for wiring into the

Foundation space for an E247 Jack is now (

www.realgoodtoys.help).

Left Front Roof

Pro Tip: Do a second check for centering the

Top Floor by holding the Front Roofs upsidedown against the bottom of the Top Floor.

Each Roof should reach all the way from the

Tower Side to the end of the Floor.

Illustration #14

Top Floor

Right

Front

Roof

16 - 17. If your Foundation hasn’t been assembled yet, go back to

page 6 and do it now.

Pro Tip: Our Assembly Pro paints the foundation before attaching it to

the house.

18. Glue, tape, and weight the housebody to the foundation set,

lined up at the back edge and spaced evenly side-to-side. Make sure the

Foundation is spaced evenly from back-to-front along each side.

Centered side-to-side, lined up with the fl oor

Foundation lines up with the

rear edge of the Base Floor

Centered side-to-side along the Side walls

19. Glue, tape, and weight the Porch base Floor

(1/4” thick) to the housebody and Foundation

Let the glue dry

Instructions for the Special Edition #SE-JM907 The Alison, Jr. C: Foundation, D: Porch Page 12

Back to the Housebody...

Illustration #15

20. Glue and tape the Tower Front in place fl ush

along the edges (Illustration #15).

Tower Front

Flush

21. Glue and tape the Top Tower Sides to the Tower

Front, lined up at the top (Illustration #16).

Flush

Illustration #16

Tower

Top

Side

9

/16” Trim - 9”

Flush

Illustration #17

Porch Assembly:

The parts used in this section should be painted

ahead of time. If they have not been painted, do so now.

Preview: In this section, you will assemble the Porch.

Lay the housebody on its back. Place two Dividers on

the Right Front Panel, one touching the porch base, and

one touching the bottom of the Top Floor.

22. Glue the Porch Mid Floor to the Front Panel and

the Right Tower Side in the space between the Dividers.

Use Blind Dividers to stabilize the Porch Mid Floor in

position! (Illustration #17).

[the Porch Mid Floor is

23. Glue (2)

Tower, lined up in Front.

3

/8” thick]

9

/16” Trim - 9” to the right side of the

Divider

Temporary use of Dividers and Blind Dividers to

hold the Porch Floors while the glue sets. Remove

the Dividers before installing the Porch Gingerbread

Divider

Porch Mid Floor

Blind Divider

Instructions for the Special Edition #SE-JM907 The Alison, Jr. D: Porch Page 13

Illustration #19

1

/4” Porch Side Gingerbread

3

24. Set up the Rails, Posts and Gingerbread as shown in Illustrations 19 & 20. Use

pairs of shingles if you wish to elevate the

Railing sets above the Porch Floor.

Glue the porch parts in place.

Porch Post

Housebody

1

3

/4” Rail

Porch Floor

Instructions for the Special Edition #SE-JM907 The Alison, Jr. D: Porch Page 14

Illustration #20

3

/8” Porch Front Gingerbread

6

Porch Post

3

6

/8” Rail

Porch Post

Porch Floor

Instructions for the Special Edition #SE-JM907 The Alison, Jr. E: Roof Page 15

One

Shingle

Length

Attic Divider

Side Roof

Side Roof

Step 25

Illustration #21

Shingle Guidelines

Pro Tip: it is far easier to pre-cut wallpaper to fi t the roofs before attaching the roofs to the house.

Wiring? Visit www.realgoodtoys.helo/JM907/wiring for steps to do right now.

Housebody Roof:

Preview: In this section you will draw Shingle guidelines,

and attach the Roof Panels and Roof Tops.

1”

25. Glue and tape the Ledge Trim to the exposed edges

of the Top Floor, fl ush along the bottom edge (the Ledge

Trim sticks up above the Floor).

26. On the outside of the Front and Side Roof Panels

draw guidelines for locating Shingles. The fi rst guideline

should be drawn one Shingle length (

11/4) from the bottom

edge. Draw the rest of the guidelines spaced 1” apart (Illustration #21 and the Guideline Measure at right).

27. Without glue, Test the Roof panels on the house

to see how they fi t. Take the Roofs off, then glue and tape

them to each other, to the Top Floor, and to the Tower Top

Sides (Illustration #22).

Check to make sure the Roofs are fl ush with the edges

of the Tower Top Sides on the inside.

28. Set the Attic Divider inside the attic against the

Front Roof. Make absolutely sure that the Front Roof is

fl ush with the top edge of the Attic Divider and the Tower

Top Sides (Illustration #22). Let the glue dry.

Right

Front Roof

Step 25

Ledge Trim - lined up on the bottom

Left Front

Roof

1”

1”

1”

1”

1”

Side Roof

Attic Divider

Side Roof

Illustration #22

1”

One

Shingle

Length

Instructions for the Special Edition #SE-JM907 The Alison, Jr. F: Roof Top Page 16

29. Without glue, test the Roof Top on the tops of the Roofs and

T ower Walls, fl ush with the back edge of the Roofs, and with an even

overhang all around.

• Make sure the overhang is parallel all along the Side Roofs, make

sure the Roof Top is lined up with the back edges of the Side Roofs.

• Test the Rooftop Extension on top of the Tower, lined up with the

Roof Top on the Left edge.

Trace the outline of the house on the bottom of the Rooftop and

Rooftop Extension.

Remove the Roof Top and Rooftop Extension. Paint the outside

of the tracing. Finish painting the Tower Top Sides. Let the paint

dry.

Glue and tape the Roof Top in place.

Check to make sure the overhang is parallel all along the Side

Roofs, make sure the Roof Top is lined up with the back edges of the

Side Roof; then tape the Roof Top to the back edge of the Side Roofs

(Illustration #23). Add weights as the glue dries for a tight fi t.

30. Glue and tape the Rooftop Extension in position (Illustration

#24).

Roof T op

Tape

Illustration #23

Roof T op Extension

Roof T op

Extension

Roof T op

Review: Check the fi t of all the parts and make sure all the joints are

tight. Make sure the Floors and Roof Top are straight, fl at, and evenly

spaced around the edges. Use tape and weights as necessary to get all

the joints tight as the glue dries.

Let the glue dry

Exterior Painting:

Finish all of the Exterior painting now!

Skip ahead to the proper assembly sections to decide how

you would like each part fi nished:

• Brackets (pg.13)

• Trimstrips (pg.13)

• Windows and Door (pg.14)

• Shutters (pg.14)

• Dormers (pg.15)

• Cresting (pg.16)

• Fluteposts/Beads (pg. 16)

• Flower Boxes (pg.16)

7

/16” Trimstrips:

31. Glue Trimstrips to cover the side edges of the fronts

(Left, Right, Tower). See Illustration #25.

Illustration #25

3

/8”

Fillstrips

Illustration #24

Trimstrips

Cut and carve Trimstrip material to fi t the tower edges

above the ledge (Trimstrip material can be cut with a razor

saw, utility knife with a new, sharp blade, or with scissors)

Cut Trim 9” for the inside corner of the porch.

Carve the Trim for a perfect fi t

Instructions for the Special Edition #SE-JM907 The Alison, Jr. F: Trim, Tower Roof Page 17

Brackets:

32. Paint the Brackets before attaching them.

Turn the house upside-down.

Lay out the Brackets as follows:

• Three pairs across the Tower Front

(Illustration #26)

• Four pairs on each Side of the house (Illutrtation .#27)

The outside pairs touch the Trimstrips. Space the Brack-

1

ets in each pair about

is right (about 3

9

/16” apart. When the Bracket spacing

/16” on the sides and 33/16” on the tower),

remove the Brackets one at a time, and glue that bracket on..

etc. until all the brackets are glued on. Check that all the

spacing is still the way you like it. Let the glue dry.

Tower Roof:

33. A. On the outside of the Tower Roofs, draw guidelines for locating Shingles. The fi rst guideline should be

drawn one Shingle length from the bottom edge. Draw the

rest of the guidelines spaced 1” apart

(Guideline Measure on page 15).

Illustration #26

Illustration #27

Tower Front

3

3

/16”

Space approx. 31/16”

on center

31/16

Brackets

B. Glue and tape the Tower Roofs together with the

Tower Front Roof overlapping the Tower Side Roofs.

Glue the Tower Roof Top in place on the Tower

Roofs, spaced evenly all around. Tape and weight as necessary for a good fi t. Paint the Tower Roof Top.

C. Glue the Tower Roofs to the house Roof Top,

spaced evenly on the front and sides.

Tower Side

Roof

Tower

Front

Roof

Step 33 B

Tower Roof Top

Step 33 A

Tower

shingle

guidelines

step 33 C

Spaced

evenly

Instructions for the Special Edition #SE-JM907 The Alison, Jr. G: Windows & Door Page 18

Illustration #31

Window Assembly:

The parts used in this section should be

painted ahead of time. If they have not been

painted, do so now.

Snips of tape can hold the

corners while putting on a

rubber band - take off the

tape while the glue dries

34. Test assemble (no glue) a window set

Practice holding the frame pieces face-down

on the work surface and putting on the rubber

band (Illustration #31: a scrap of tape at each

corner helps). In the illustrations, the hands are

holding the frame parts down, not squeezing

together. When you can get the rubber band on

every time without pieces fl ying, then you are

ready for glue

35. Glue and rubber band together the

window frames. Glue, tape, and rubberband

together two Dormer Interior Trim frames

(Illustration #32). Make sure the frames are

square as the glue dries (Illustration #33).

36. Check the fi t of the windows in the

openings. Make sure the windows can sit level

with the house. Trim the corners of the openings square if necessary for a good fi t.

37. Paint the Shutter parts on both faces.

Without glue, adjust the spacing of the Shutter

Panels on the Shutter Cores (Illustration #34).

Remove the Shutter Panel, put a scant line of

glue on each edge of the back surface, then

replace the Shutter Panel. Too much glue will

make the panel curl.

38. Glue the windows, the Door, and the

Shuttters in place only after everything (including the Housebody) is painted.

Window Frame is shown face down

Illustration #31

Dormer Window

Illustration #32

Standard Wndow

Interior Window Frame

The hands are holding the frame parts

Down, not squeezing them together

Dormer Exterior Frame

Dormer Interior Frame

Window Plexi

Attach the exterior window frames as part of

the exterior fi nishing. After the interior fi nish-

ing is done (wallpaper, paint, etc.), set the window plexi into the window cutout without glue

and glue the interior window frame in place.

Illustration #33

Exterior Window Frame

Illustration #34

Instructions for the Special Edition #SE-JM907 The Alison, Jr. H: Dormers, Shingles Page 19

The Dormers:

Preview: In this section you will build and

install the Dormers.

Dormer

Side

39. Glue and tape the Dormer Sides to the

Dormer Ceiling, fl ush at the top edges.

(Illustration #35)

Pro Tip: Our Assembly Pro paints and installs the Dormer Sides/Ceiling before shingling, and pre-paints and installs the Dormer

Roofs after the shingling is complete.

40. Glue and tape a Window Frame into the Dormer

body. Glue the Dormers to the Front Roof lined up with

the Dormer holes (Illustration #36). Check to make sure

the Dormers are straight up-and-down. Tape the Dormers to the Roof from the inside.

41. Glue the Dormer Roofs to the tops of the Dormer

bodies centered side-to-side (Illustration #37).

Dormer

Ceiling

Window

Frame

Dormer

Roof

Dormer

Side

Illustration #35

Flush

Illustration #36

Illustration #37

Shingle The Roof:

Glue: Use a thick panel adhesive such as Liquid

Macco

Nails

supply stores. Trim just a little of the end of the tube for

a tiny hole, to give a thin bead of glue. Always use good

ventilation with solvent based adhesives.

42. Apply a thin line of adhesive

lowest guideline all the way across one Side Roof. Press

the top edge of a Shingle into the line of glue, squeezing

out the excess. Hold the fi rst Shingle steady and press

another shingle into the adhesive, tight to the fi rst. Hold

the next Shingle and press in another... etc. all the way

across the roof, cutting the last shingle to fi t. Cut angled

Shingles for the corners before attaching them. The fi rst

row of Shingles is tight to the bottom, the rest line up

with the guidelines. Finish each row (the sides fi rst, then

the front) before starting the next row.

available in a caulking gun tube at building

1

/8” below the

43. Continue up the roof one row at a time around

all the roofs. Start every other row with a half Shingle

so that the seam between Shingles is staggered back and

forth as you go up the roof. Cut the Shingles for the top

row so that each row will have the same reveal.

Where two roofs meet, shingle the side roofs fi rst,

then the front roof.

1” Reveal

1” Reveal

Bead of adhesive

Illustration #38

Overlap covers

the squeezings

Flush

One shingle length

Illustration #39

1” between guidlines

Guideline

1”

1”

1”

www.realgoodtoys.help has shingling demos

1” Reveal

1” Reveal

Bead of adhesive

One shingle length

Instructions for the Special Edition #SE-JM907 The Alison, Jr. I: Gingerbread Page 20

Finish the Outside

Illustration #40

3

/8” Beads

7

/8” Flutepost

Roof Top Cresting:

44. Lay out the Roof Top Cresting set.

Note from the Pro: Paint the Cresting, the

Flutepost, and the Balls before assembly.

45. Assemble the Flutepost/Bead sets

(Illustration #40).

46. Without glue, set up the Cresting set with

Posts at the corners. When the position is the way

you like it, remove one piece at a time, and glue that

piece on..etc.

31/4”

77/8”

31/8”

31/8”

31/4”

123/4”

113/16”

47. Glue the Flower Boxes in place centered

side-to-side below the Tower Windows

(Illustration #41).

48. Install the Left Gingerbread (31/4” Side and

1

1

/8” Front) with a 7/8” Trimpost and Bead (Illustra-

tion #42).

49. Glue the Front Step in place (Photo on pg. 1).

Illustration #42

Left Gingerbread

31/4” Side

Gingerbread

Illustration #41

11/8” Front Gingerbread

7

/8” Trimpost and Bead

Flower Box

Centered

side-to-side

Instructions for the Special Edition #SE-JM907 The Alison, Jr. J: Interior Page 21

Stairs and Stringer:

Line up the Stringer with the pattern, and

mark the cut. Cut the Stringer with a fi ne toothed saw

Glue the Bottom and Top Stair Blocks together (Illustration #43).

Without glue, test the Stair assembly in the stair hole. The stairs

are tight to the wall and the top tread is fl ush with the fl oor.

Wait to permanently install the stairs until fl ooring and wallpa-

pering are done.

Glue the stair assembly in place. Let dry.

Glue the Stringer to the side of the Stair assembly for support.

Dividers

are important supports for the fl oors and roof, but their

position is fl exible. Test your interior furnishings and install Di-

viders where they best serve your interior plan. Blind Dividers are

optional separators front-to-back for the Tower Rooms.

To install a Divider, spread glue on the edges, tip the Divider and

put it almost all the way into the house, set the base and stand the

Divider upright, slide it the rest of the way into position.

Finish the Inside...Plan Ahead!

Interior fi nishing involves so many choices! Will this house be a

play-house or a display for miniatures? What accessories will be

used and where will they go? Wiring? Wallpaper? Tile or carpeting? Every choice makes a difference in the order of fi nishing.

Real Good Toys has provided materials for some basic interior

work, but you may choose to do it differently.

Make your choices

Get your materials

Test your layout

With the pieces in your hands, imagine the steps to get to where

you want to be.

Now you’re ready for your order of interior fi nishing.

Here’s the order that our assembly pro follows for tackling

most custom interior fi nishing:

• Dividers

• Electrical wiring (using “tape” style wiring)

• Ceilings

• Flooring

• Wallpaper

• Interior Window T rim

• Stairs

• Baseboard and crown moldings

Top Stair Block

Illustration #43

Bottom

Stair Block

Stringer

Pattern

Dividers

position is fl exible. Test your interior furnishings and install Di-

viders where they best serve your interior plan. Blind Dividers are

optional separators front-to-back for the Tower Rooms.

To install a Divider, spread glue on the edges, tip the Divider and

put it almost all the way into the house, set the base and stand the

Divider upright, slide it the rest of the way into position.

Stairs and Stringer:

mark the cut. Cut the Stringer with a fi ne toothed saw..

Glue the Bottom and Top Stair Blocks together (Illustration #43).

Without glue, test the Stair assembly in the stair hole. The stairs

are tight to the wall and the top tread is fl ush with the fl oor.

Wait to permanently install the stairs until fl ooring and wallpa-

pering are done.

Glue the stair assembly in place. Let dry.

Glue the Stringer to the side of the Stair assembly for support.

are important supports for the fl oors and roof, but their

Line up the Stringer with the pattern, and

Attic

Divider

Blind

Divider

Cut Off

Divider

Adjust the fi t of all the parts. Everything must be in place as the glue dries

You have fi nished the Dollhouse Assembly part of your project…

ENJOY THE REST

Instructions for the Special Edition #SE-JM907 The Alison, Jr. Options Page 22

The JM907 Alison Jr.

is shown above with the JM33 Addition

added to the left side

(can also be added to the right side).

Options:

A wide variety of materials and accessories are available to help

you achieve your dream house.

The following is a partial list of accessories available through your

dealer from Real Good Toys.

J-FK Interior Finishing kit

JM33 Victorian Style Junior Addition

JM66 Junior Conservatory Addition

Dye-1 Brown Shingle Dye

Dye-3 Grey Shingle Dye

SC Sheet Copper

EL-66 EZ Punch and Electrifi cation Helper Set

(The EZ Punch piercing tool punches holes making nailing, screwing and setting electrical parts easier.)

Visit www.realgoodtoys.com for more information and wiring products.

The JM907 Alison Jr.

is shown above with the JM66 Addition

Loading...

Loading...