Page 1

Page 2

Forge/CTRL User Manual

P/N R-400015

Version 2.0

Welcome

You’re READY to unleash the power of industrial automation! The Forge/CTRL system is the future of easy-toprogram manufacturing automation. With this system, your business has the tools to enter a world of more

efficient and more precise manufacturing processes. This user manual, along with the included “Quick Reference

Guide” and “Risk Assessment Procedure,” will get you on the path to setting up your Forge/CTRL as soon as

possible.

Safety and risk assessment

The Forge/CTRL system is partly completed machinery and as such a risk assessment is required for each

installation of the system. It is particularly important that all relevant safety standards be observed. The system

itself is considered party completed machinery as the safety of the Forge/CTRL installation depends on how the

system is integrated (e.g. tool, obstacles, and other machines). A comprehensive risk assessment is often required

to comply with local and national safety standards and is always recommended. It is also recommended you follow

the guidelines in ISO 12100 and ISO 10218-2 to conduct the risk assessment.

Industrial robots can cause severe and fatal injuries to workers during interventions such as maintenance,

unjamming, adjustments, and setup.

The information contained herein is the property of READY Robotics Corporation and shall not be reproduced in

whole or in part without prior written approval of READY Robotics Corporation. The information herein is subject

to change without notice and should not be construed as commitment by READY Robotics. This manual is

periodically reviewed and revised.

Any information given in this manual regarding safety must not be construed as a warranty by READY Robotics that

the Forge/CTRL system will not cause injury or damage even if all safety instructions are complied with.

READY Robotics assumes no responsibility for any errors or omissions in this document.

Page 3

Forge/CTRL User Manual

P/N R-400015

Version 2.0

Safety and Precautions

4

Overview

General safety

Robot safety

Electrical safety

Pneumatic safety

Introduction to the Forge/CTRL

8

Overview

Choosing the right task

Overview of your system

TeachMate

Primary axes

Hardware Set Up

14

Overview

Connecting power and air

Starting the Forge/CTRL system

Attaching an end effector to the robot arm

Attaching devices to the air and PLC modules

Connect to a camera

103

Overview

Before you Begin

Setup the Camera

Setup the Camera in Forge/OS

Use the camera in a task

Troubleshooting and Technical Support

111

Technical Specifications

107

System technical specifications

Force sensor threshold values

Table of Contents

Page 4

Forge/CTRL User Manual

Safety and Precautions

Version 2.0

!

Be sure to follow all the safety rules and regulations of your workplace while using the Forge/CTRL

safety.

Safety and Precautions

Overview

The Forge/CTRL system connects to a variety of robotic arms and devices. Although some robot arms are

collaborative and designed to be used in proximity to people, there are still safety considerations that come with

working with any system that uses electric and air power for high-speed handling of parts.

General safety

system. None of the safety features built in to the Forge/CTRL overrule your workplace’s standards for

• Always wear all recommended personal protective equipment in accordance with your workplace’s safety

standards, including:

o Safety glasses

o Hearing protection

o Hard hats

o Steel-toe boots

o Chemical protective material

• Always use proper safety precautions when working with tools that contain sharp edges, pinching

surfaces, or generate heat.

• Always lift heavy objects with your legs, not your back. If you cannot lift an object alone, ask for help or

find another method to move it.

• Always store sharp objects, including robot tools and peripherals, in a safe location with sharp edges

covered.

• Always inspect all electrical and pneumatic cables to ensure that they are in good condition.

• Never allow minors to operate the Forge/CTRL system.

• Never enter the workspace of the robot while it is in motion or executing a task.

• Never use defective, dull, or broken tools.

• Never use the Forge/CTRL in an environment over 122º F (50º C).

• Never open the enclosure of the Forge/CTRL or attempt maintenance on the system’s internal

components.

Page 5

Forge/CTRL User Manual

Safety and Precautions

Version 2.0

Although safety devices and collaborative robot arms increase the safety of the work environment, it

A risk assessment must be performed for all collaborative applications.

Robot safety

does not mean that all devices used with the Forge/CTRL system or functions the system performs are

inherently safe as well.

!

• Always use caution around fast-moving objects, heavy objects, and sharp edges.

•

The Forge/CTRL system is designed to connect to a variety of robot arms. Some robot arms are human-safe and

designed to enter a protective stop when they contact any object, including a person. Whether the arm is

collaborative or not, there are some guidelines that should be considered when working with a robot arm.

• Know the motion limitations of your system and be sure to remove any objects that could be easily

damaged or destroyed from the reach of the arm. See your robot arm’s manual for specific details.

• The safest way to stop the robot arm is with either of the emergency stop buttons located on either the

monitor or the teach pendant.

• The main power switch is not an emergency stop switch. Do not use the main power switch for

emergency situations.

• Do not wear loose fitting clothing that could get stuck in a moving robot joint, end effector, or devices.

For safety information specific to the Universal Robots arm, see the included manual for the robot arm.

Collaborative robot arms

Forge/CTRL systems that include a human-safe, collaborative robot arm are designed to enter a protective stop

when they contact any object in their path, including a person. The force threshold for each robot arm varies,

consult your robot arm’s manual for specific information. When the force threshold is met the robot arm enters a

protective stop. Although this meets the threshold for a “human-safe” system, the robot arm can still cause injury

if carrying a sharp object or moving above shoulder height.

Safety modes

Depending on your set up, there are different safety modes you may experience during operation. The most

common safety mode is an emergency stop. If you are using a collaborative arm, the robot arm may enter a

protective stop. Reduced mode and safeguard stop are safety modes triggered by attached safety devices.

Page 6

Forge/CTRL User Manual

Safety and Precautions

Version 2.0

Safety modes - continued

Emergency stop

The robot arm enters an emergency stop when either an emergency stop button is pressed or when a high-speed

collision occurs. When in an emergency stop:

• The robot arm applies internal brakes to ensure rigidity.

• Attached end effectors and devices release grip and turn off.

• The TeachMate LEDs turn red.

• Forge/OS notifies you the robot is in an emergency stop and the margins are red and display “Robot

Error.”

If an emergency stop occurs because of an emergency stop button, Forge/OS instructs you to turn the emergency

stop button clockwise, releasing the stop. Once the stop is released, the robot arm enters idle mode.

If an emergency stop occurs because of a high-speed collision, Forge/OS instructs you to clear the system through

the teach pendant, connected to the controller of the robot arm. Follow all on-screen instructions to restart the

robot arm from the teach pendant. Once the stop is released, the robot arm enters idle mode.

Protective stop

The robot arm enters a protective stop when it encounters an obstacle that triggers the human-safe force sensors

inside the robot arm. When in a protective stop:

• The robot arm applies internal brakes to ensure rigidity.

• Attached end effectors and devices release grip and turn off.

• The TeachMate LEDs turn yellow.

• Forge/OS notifies you the robot is in a protective stop and the margins are yellow and display “Robot

Warning.”

To clear the protective stop and turn on the robot arm, tap Turn Robot On from the Robot Mode panel, see

section the “Robot Mode” section of the “Control Suite” chapter for more information.

Reduced mode

The robot arm enters reduced mode when a connected safety device detects a condition that causes the robot

arm to slow movement to maintain a safe work environment. Reduced mode can be triggered by a person or

object entering the work area or coming within a defined distance of the system.

• The robot arm continues to execute the task at a reduced speed.

• The TeachMate’s LEDs blink green.

• Forge/OS notifies you the robot arm is in reduced mode by displaying “Reduced Mode” in the margins.

To return the system to Active mode, clear the condition that triggered the safety devices.

Page 7

Forge/CTRL User Manual

Safety and Precautions

Version 2.0

Step

Action

1

Enter the work area, stop the task in Forge/OS, and enter the override key into the key switch.

Result: Forge/OS mutes the safety device and puts the system into Active mode.

2

Perform the necessary actions to the task or system.

3

Remove the override key, start the task in Forge/OS, and exit the work area.

Result: Forge/OS resumes executing the task.

Safety modes – continued

Safeguard stop

The robot arm enters a safeguard stop when a connected safety device detects a condition that that causes the

robot arm to stop to prevent harm or injury and maintain a safe work environment. Safeguard stops can be

triggered by a person or object entering the work area or coming within a defined distance of the system.

• The robot arm applies internal brakes to ensure rigidity.

• Attached end effectors and devices maintain their state.

• The TeachMate LEDs blink green.

• Forge/OS notifies you the robot is in a safeguard stop and the margins are yellow and display “Safeguard

Stop.”

To return the system to Active mode, clear the condition that triggered the safety device.

The safeguard stop can be overridden to perform things like maintenance, task programming, or error recovery.

Follow these steps to override the safeguard stop.

Page 8

Forge/CTRL User Manual

Safety and Precautions

Version 2.0

Electrical safety

The Forge/CTRL system uses a standard 120V cable for power.

• Do not open the Forge system’s enclosure to attempt maintenance on any electrical system within.

• Only use cables provided by READY Robotics that are in good condition and do not show signs of wear.

• Unplug the Forge/CTRL system in these situations:

o During electrical storms or power outages.

o When turning on circuit breakers to which the system is connected.

• Regularly inspect the cable harness running from the Forge/CTRL to the TeachMate. If electrical cables

appear frayed or worn, unplug the system and contact READY Robotics.

• Ensure that any electrical device that is attached to the system operates within the parameters of the

Forge/CTRL electric tool add-on.

Pneumatic safety

The Forge/CTRL system uses 90 psi to actuate end effectors and attached devices.

• Never have your hand or face near any end effector or device when it is actuating. Pneumatic end

effectors and devices can exert hundreds of pounds of force.

• Do not attach a device rated for less than 90 psi to the system without an air regulator.

• Do not open the Forge/CTRL enclosure to attempt maintenance on any pneumatic system within.

• Regularly inspect the cable harness running from the Forge/CTRL to the TeachMate. If pneumatic cables

appear frayed or worn, unplug the system and contact READY Robotics.

• Ensure that any pneumatic devices attached to the system operate within the parameters of the

Forge/CTRL air device specifications.

Page 9

Forge/CTRL User Manual

Introduction to the Forge/CTRL

Version 2.0

Questions to consider

Example answers where the system is best suited

How complex is the task for the machine

This task involves minimal dexterity or complex part interaction.

How repetitive is the task?

This task involves the same motions or processes, repeated many

How is the part introduced to the machine?

The part is placed in a rigid jig in the machine.

How is the part packaged?

The part is placed in a rigid box or package after processing.

How much time does the operator spend

This task involves downtime during which the operator is waiting

How much does the operator interact with

The machine does most of the work in this task and the operator

What decision points or feedback

This task is a very straightforward process and doesn’t require

Introduction to the Forge/CTRL

Overview

The Forge/CTRL system is designed to be flexible, efficient, and easy-to-use. Understanding the role that a robotic

system can fulfill in your business will help you employ the system to its fullest capability. In general, robotic

systems are best suited for repetitive or non-value-added tasks.

Choosing the right task

The best way to learn the capabilities of your Forge/CTRL system is to work with it yourself! Try various tasks at

different machines and with different end effectors, parts, and devices. If there’s a task you believe your system

can handle but you don’t have the tools for it, reach out to READY Robotics to discuss expanding the capability of

your system.

Here are some questions to consider when choosing a task that is right for your system. Answers to each question

are provided as an example of where your system is suited for the task.

operator to perform?

times in succession.

waiting for the machine to process the

part?

the part compared to the machine?

determine how the operator will proceed

in this task?

Example of tasks where the system is best employed.

• Machine tending

• Product packaging

• Material loading and unloading

• Holding parts for processing

for the machine.

simply loads or unloads the part.

the operator to make complex decisions.

Page 10

Forge/CTRL User Manual

Introduction to the Forge/CTRL

Version 2.0

Piece

Description

Forge/CTRL

The system that connects Forge/OS and you to the robot arm. Forge/CTRL also acts as

the hub to provide power and air to the TeachMate and attached devices.

Forge/OS

The READY Robotics software through which you interact with and program the robot

you can track the performance of the system throughout the execution of tasks.

TeachMate

The LED module at the end of the robot wrist that provides power and air to the

information.

Overview of your system

Your system is comprised of three major pieces of the Forge/CTRL system. Each piece plays an important role in

helping you create a task for your system to complete.

arm. Forge/OS enables you to create, save, load, and execute tasks. Through Forge/OS

attached end effector. When moving the robot arm by hand, the TeachMate is the

recommended gripping point, see the “TeachMate” section of this chapter for more

Page 11

Forge/CTRL User Manual

Introduction to the Forge/CTRL

Version 2.0

Overview of your system – continued

Forge/CTRL left side

The following labels the main interaction points of the left side of the Forge/CTRL system.

Forge/CTRL right side

The following labels the main interaction points of the left side of the Forge/CTRL system.

Page 12

Forge/CTRL User Manual

Introduction to the Forge/CTRL

Version 2.0

Color

Mode

Description

White

Idle

The robot arm is rigid, and tasks cannot be executed. The margins in Forge/OS are

Green

Active

The robot arm is rigid and waiting for instruction. Tasks are executable when in this

Before executing a task, executing a block on the Canvas, or toggling the

Always confirm the robot workspace is clear of obstacles or persons.

The TeachMate

The TeachMate is the LED module at the end of the robot wrist. The

TeachMate provides power and air to the attached end effector. When

moving the robot arm by hand, the TeachMate is the recommended

gripping point.

With the TeachMate you can:

• Identify the current mode of the Forge/CTRL

• Switch the Forge/CTRL between active mode and teach mode

• Toggle the state of the attached tool

• Invoke the rapid teach feature

See the “TeachMate button control” section of this chapter for more

information on the TeachMate’s button functionality.

TeachMate mode indicator

The TeachMate LEDs indicate the current operating mode of the Forge/CTRL system. Use this table for information

on the status:

white and display “Robot Idle”.

To exit idle mode, switch to Active mode or Teach mode from the TeachMate or

Robot Controls, see the “Robot Controls” section of the “Control Suite” chapter for

more information.

mode. The margins in Forge/OS are green and display “Active Mode”.

state of a end effector,

!

• Always warn anyone in the robot workspace.

•

Page 13

Forge/CTRL User Manual

Introduction to the Forge/CTRL

Version 2.0

Color

Mode

Description

Blue

Teach

The robot arm is compliant and can be moved by hand. Tasks cannot be executed

Because the arm is easily moved by hand, the robot arm can fall suddenly

of the “Hardware Set Up” for more information.

Blinking

Executing task

The robot arm is moving and executing a task. The margins in Forge/OS are green

Reduced mode

The robot arm is moving and executing a task at a reduced speed. The margins in

Safeguard stop

The robot arm is rigid, and tasks cannot be executed. The margins in Forge/OS are

TeachMate mode indicator - continued

when in this mode. The margins in Forge/OS are blue and display “Teach Mode”.

Use this mode to teach the set waypoints. See the “Robot Moves” section of the

“Blocks” chapter for more information on waypoints.

and unexpectedly if the weight of the end effector is not properly

!

configured, see the “Attaching an end effector to the robot arm” section

green

and display “Active Mode”.

Forge/OS are green and display “Reduced Mode”.

Reduced mode happens when attached safety devices detect conditions that cause

the robot arm to slow movement to maintain a safe work environment.

Reduced mode can be triggered by a person or object entering the work area or

coming within a defined distance of the system. When the system enters

Reduced mode, clear the condition to return the system to active mode.

yellow and display “Safeguard Stop”.

A safeguard stop happens when the safety devices detect conditions that cause the

robot arm to stop to prevent harm or injury and maintain a safe work environment.

Safeguard stop can be triggered by a person or object entering the work area or

coming within a defined distance of the system. When the system encounters a

safeguard stop, clear the condition to return the system to active mode.

Page 14

Forge/CTRL User Manual

Introduction to the Forge/CTRL

Version 2.0

Color

Mode

Description

Yellow

Warning

The robot arm is rigid, and tasks cannot be executed. The margins in Forge/OS are

Red

Error

The robot arm is rigid, and tasks cannot be executed. The margins in Forge/OS are

TeachMate mode indicator - continued

yellow and display “Robot Warning”.

A warning happens when the robot arm encounters a condition that causes an

error that is corrected through Forge/OS. Warnings include recovery after an

emergency stop has been released or when a protective stop occurs; see the

“Robot Safety” section of the “Safety and Precautions” chapter for more

information on protective and emergency stops.

When a warning happens, follow the instructions in Forge/OS to resolve the

condition and return the Forge/CTRL system to active mode.

white and display “Robot Error”.

An error happens when the robot arm encounters a condition that causes an error

that is only corrected externally. Errors include robot faults or violations,

emergency stops, and loss of connection between Forge/OS and the robot arm.

When an error occurs, follow the instructions in Forge/OS to resolve the condition

and return the Forge/CTRL system to active mode.

Page 15

Forge/CTRL User Manual

Introduction to the Forge/CTRL

Version 2.0

Function

Action

Description

Mode control

Simultaneously

Switch between Active mode and Teach mode. When the robot arm is

Rapid teach

Short/long press 02

Record waypoints and end effector state as blocks on the Canvas. See

Toggle end

Double press 03

Toggle the end effector state. On the first press, the TeachMate LED

TeachMate button control

The TeachMate buttons are the primary user interface for mode control, end effector control, and the rapid teach

feature. The buttons on the TeachMate are labeled 01, 02, 03, and 04. Buttons 01 and 04 are on opposing sides of

the TeachMate; buttons 02 and 03 are on the face of the TeachMate.

The following functionalities are available through the TeachMate’s buttons:

press 01 and 04

effector

in idle mode, the mode control puts the robot arm into teach mode.

the “Rapid Teach” section of this chapter for more information.

will blink yellow; on the second press, the end effector state changes.

Press any other button after the first press to cancel the gripper state

change.

Page 16

Forge/CTRL User Manual

Introduction to the Forge/CTRL

Version 2.0

Action

Result on Canvas

Result in Blend settings or Pattern settings

Short press

Open a Blend and save the current position

Save the current positions as a waypoint in

Long press

Place a Tool block for the current state of the

Accept the settings and place the Blend or

Rapid teach

Rapid teach allows you to interact with the robot arm and record actions from the TeachMate. For rapid teach to

work, you must be on the Canvas. When rapid teach is invoked the TeachMate provides feedback so that you know

if the input was accepted or not.

When using rapid teach, the TeachMate flashes

• White once if the input was accepted.

• Four times if the input was rejected.

If your input is rejected, it could be because a window is open on the Canvas or an end effector is not properly

setup.

Rapid teach is invoked by pressing the 02 button on the TeachMate. Rapid teach works in either Active mode or

Teach mode. The 02 button responds to two inputs:

• Short press (less than a second)

• Long press (hold until the LED turns white, then release).

On the Canvas, short press 02 to open the settings of a Blend and save the current position of the robot arm as a

waypoint. With the Blend settings open, short press 02 to add the current position of the robot arm as a waypoint

to the Blend. This can be done in either Active mode or Teach mode.

The following are the available actions when using rapid teach.

as a waypoint.

end effector. For example, if a Schunk twofinger gripper is configured and the fingers

are in the open position, an Open Gripper

block is placed.

For more information on Blend, Pattern, waypoints, and Tool blocks, see sections “Robot Moves” and “Tools” of

the “Blocks” chapter for more information.

the current Blend or Pattern.

Pattern on the Canvas.

Page 17

Forge/CTRL User Manual

Hardware Set Up

Version 2.0

!

Hardware Set Up

Overview

The Forge/CTRL system is designed with flexibility and ease-of-use in mind. To that end, setting up the hardware is

easy. Connect the system to power and air, turn it on, and connect an end effector. After that, you are ready to

start programming your task.

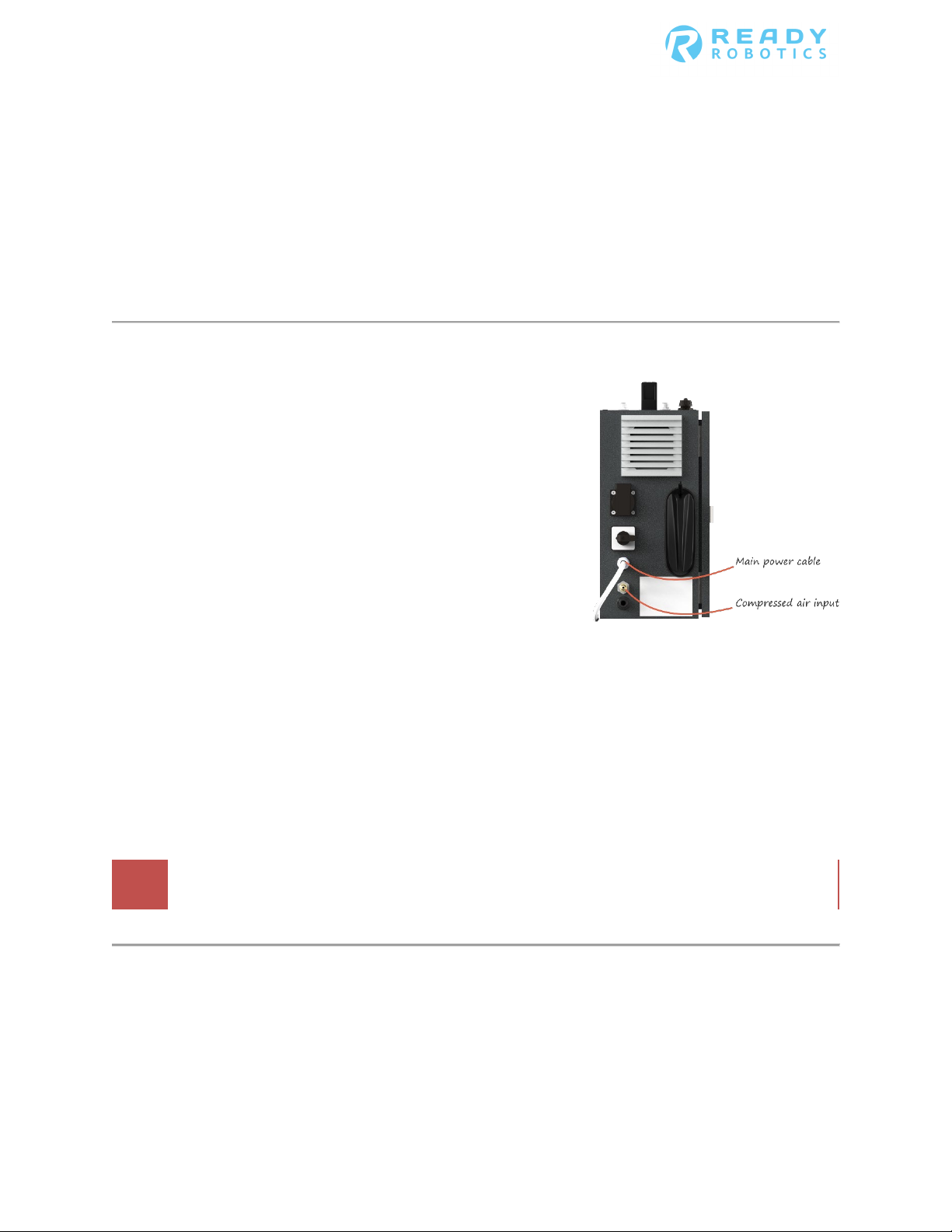

Connecting power and compressed air

The Forge/CTRL system requires 120V power and 90 psi of

compressed air to operate.

• Removing power from the system without safely shutting

down the system may damage the robot arm.

• Removing air from the system may prevent certain

peripherals and end effectors from working properly.

The power and compressed air inlets are located on the left side of

the system.

Power

The main power cable for the Forge/CTRL system must be attached to AC power for the system to turn on and

operate.

Compressed air

The compressed air connection takes a standard 1/4-inch industrial quick coupler. READY Robotics recommends

that air provided to the Forge/CTRL system be between 80 - 110 psi. Providing compressed air above or below this

range could cause the system to operate in an unexpected manner. Note: Your system’s set-up may differ.

Do not attach compressed air greater than 110 psi to the system.

Page 18

Forge/CTRL User Manual

Hardware Set Up

Version 2.0

Starting the system

Power on the Forge/CTRL

The Power Disconnect switch, on the left side of the Forge/CTRL provides the system with power. It does not start

up the system. Once the Power Disconnect is on and power is available, pressing the Power button starts up the

system.

Before turning the main power switch to the on position, ensure that AC power and compressed air are both

attached to the system.

Startup procedure

When the Power button is pressed, the system goes through its startup procedure. The monitor and TeachMate

LEDs turn on. While starting up, the robot arm may move slightly and make a clicking sound, and the monitor

displays a loading status. Allow the system to fully startup before attempting to use the system. When the system

is ready for use, the monitor displays the End User License Agreement in Forge/OS.

Page 19

Forge/CTRL User Manual

Hardware Set Up

Version 2.0

Step

Action

1

Rotate the Power Disconnect switch a quarter turn clockwise to the On position.

2

Press the Power button

3

Read through the End User License Agreement (EULA) and tap Accept.

Startup the system

Follow these steps to turn on and startup the Forge/CTRL system.

Result: Power is supplied to the system. The Forge/CTRL can be turned on.

Result: The green LED lights up and the startup procedure begins. When ready, Forge/OS displays the

End User License Agreement.

Result: The System Loadout screen appears.

Note: Declining the EULA or closing the EULA window causes the system to shutdown.

Attaching an end effector to the robot arm

End effectors attach to the robot arm by securing the end effector’s tool flange to the wrist flange. The wrist flange

at the end of the robot arm is designed to interface with a variety of end effectors provided by READY Robotics.

The tool flange connects to the wrist flange with the end effector in only one position. If an adjustment to the end

effector’s position needs to be made, to allow for clearance beneath the TeachMate for example, the tool flange

can be removed, adjusted, and reattached to the end effector.

Note: Extra and replacement tool flanges can be provided by READY Robotics for damaged flanges or custom end

effectors.

Page 20

Forge/CTRL User Manual

Hardware Set Up

Version 2.0

Step

Action

1

Release the locking bolt.

2

Line up the alignment pin on the wrist flange with the alignment slot on the tool flange. Push the two

3

Lock the locking bolt by pushing the locking lever all the way closed.

4

Configure the end effector in System Loadout, see the “System Loadout” chapter for more

• Define the center of mass (COM) of the tool.

Attach an end effector to the arm

Follow these steps to attach an end effector to the end of the robot arm.

a. Pulling button out on the end of the locking lever.

b. Pull the locking lever all the way open.

flanges together.

Result: The face of the tool flange is touching the face of the wrist flange.

information.

In System Loadout, you

• Receive instructions on how to attach the end effector’s air hoses or power cables to the

TeachMate.

• Provide the measurements for the tool center point (TCP).

Page 21

Forge/CTRL User Manual

Hardware Set Up

Version 2.0

When adding devices to the air or PLC modules, remember to select both the device and the correct

Forge/OS is not able to actuate the device in the task.

Step

Action

1

Determine the type of power needed for the device.

If the device is ...

Then ...

Powered by air

Connect the air hose to one of the air outlets on the stand.

A PLC

Connect the cable to the PLC module on the stand.

2

In Forge/OS, configure the device in System Loadout; see the “System Loadout” chapter for more

Attaching devices to the air and PLC modules

The air and programmable logic controller (PLC) modules are located on the right side of the Forge/CTRL system.

Your Forge/CTRL system comes preconfigured with modules depending on your task needs. The air modules take a

standard 1/4-inch industrial quick coupler.

module in System Loadout. If you do not select the device in System Loadout, Forge/OS does not

!

provide options to actuate the device in your task. If you select the incorrect module for the device,

Attach a device to the stand modules

Follow these steps to attach a device to the Forge/CTRL stand.

information.

Page 22

Forge/CTRL User Manual

Connect to a camera

Version 2.0

Connect to a Camera

Overview

Integrating a camera into your task can increase the flexibility of your system. The camera acts as the eyes of the

robot arm. Without the camera, you program the location of each workpiece the robot arm interacts with. The

result is manually programming several blocks and waypoints. This is fine in situations where the workpieces can

be presented in a consistent manner and Grid and Pattern blocks can be used. But what about times where

workpieces can’t be consistently presented?

A camera takes a picture of the work area, identifies the workpiece’s location, and saves the location. The robot

arm can then be programmed to move to the location and pick up the piece. Each time the camera takes a picture

of the work area, it updates the location of the workpiece it finds. So only one Robot Moves block needs

programmed.

Before you begin

Prior to setting up the camera’s software or setting up the camera in Forge/OS:

1. Ensure the camera is physically secured to the work area and has a clear view of the work surface.

2. Connect the camera to the Forge/OS device via the ethernet port.

Setup the camera’s software

Compatibility requirements

For a camera to be compatible with Forge/OS, the camera’s software must be set to send data over TCP/IP.

Forge/OS uses this information sent by the camera to identify the workpiece and its location.

Page 23

Forge/CTRL User Manual

Connect to a camera

Version 2.0

Network Setting

Value

Communication

TCP/IP

DHCP

Disabled

Static IP

172.16.255.254

Server Host

172.16.255.250

Port

8890

Terminator

String CR + LF

i Example of the guidelines applied to a Cognex

camera

Network settings

Use these network settings when setting up the camera. These settings will allow the camera to send information

to Forge/OS. In the camera’s software settings:

For information specific to setting up your camera with these settings, consult the Camera’s set up guide or your

camera integrator.

Information formatting

For Forge/OS to read the information sent by the camera, the

following formatting guidelines need to be applied:

• Left curly bracket, {, as the leading character

• Right curly bracket, }, as the trailing character

• Comma delimited text

• Labels in a ‘keyword’: format

Example: ‘angle’:

Page 24

Forge/CTRL User Manual

Connect to a camera

Version 2.0

Step

Action

1

Access System Loadout in Forge/OS.

2

Select Devices => Camera.

3

If your camera requires a calibration grid, place the calibration grid on the work surface.

3

Follow the on-screen wizard to:

3. Define the boundaries of the frame.

Setup the camera in Forge/OS

Follow these steps to begin the camera setup process in Forge/OS.

1. Test the connection.

2. Calibrate the tool center point (TCP).

Test the connection

To test the connection, place a workpiece on the camera’s training grid and press Test Camera Connection.

When you test the connection, Forge/OS validate the information it’s receiving from the camera. If the connection

is successful and the part is detected, you continue setting up the camera in Forge/OS. If the connection is

unsuccessful, to continue setup, check the camera’s software settings, update them as needed, and try again.

Calibrate the tool center point

Calculating the tool center point (TCP) of the probe helps Forge/OS gather information about the robot arm and

end effector’s orientation. This makes it easier for Forge/OS to create an accurate frame for the camera.

To calibrate the TCP, follow the on-screen guide to capture the probe in three different poses:

1. Pointing straight down.

2. Rotated at a 45º relative to the +X axis.

3. Rotated at a 45º relative to the -X axis.

Note: Refer to the images in the setup wizard for help with positioning the robot arm and probe.

Page 25

Forge/CTRL User Manual

Connect to a camera

Version 2.0

Step

Action

1

From the Blocks menu, select Checks > Camera.

Result: The settings for the Camera block appears.

2

Provide a name for the landmark that is created for the workpieces location and tap Accept.

Note: The landmark is used for pick and place tasks.

3

Select the new Camera block and, from the Execute menu, select Step.

Result: The landmark created by the Camera block can be referenced in Robot Moves blocks.

4

If using the camera for a pick and place task, assign the camera’s landmark to the waypoint of the

move block that brings the end effector on or above the workpiece.

Define the frame

To define the frame, establish two axes from three points, the origin point and two points extending out from the

origin point.

Things to consider while defining the frame:

• Begin the process by snapping the end effector to the Z axis of the stand frame.

1. Open the Robot Controls and set the Jog Mode to Jump.

2. Select Stand as the Frame.

3. Tap Snap Z Axis and Execute Jump.

• When jogging the arm along the axis indicated in the wizard:

• The direction of the jog controls may be different than what is indicated in Robot Controls.

• Two inches is the minimum distance required to define frame. Jogging the arm more than two

inches increases the accuracy of the frame.

Use the camera in a task

When executed, the Camera block takes a picture of the work area, identifies the workpiece, and creates a

landmark out of the information. Each time the Camera block executes, the landmark is updated based on the

workpiece’s location.

After placing a Camera block, step the block to establish its settings in Forge/OS.

The Camera block is available in the Checks section of the Blocks menu. Follow these steps to place a Camera block

in your task

Page 26

Forge/CTRL User Manual

Troubleshooting and Technical Support

Version 2.0

Issue

Cause

Solution

Power not attached

Verify that the power cable is attached to an active power source

Teach pendant is

Verify that the teach pendant is on and does not say "Robot

Teach pendant is

See below, "The Teach Pendant is showing an error."

Power not attached

Verify that the power cable is attached to an active power source

Monitor cables

Verify that the cables in the back of the monitor are firmly and fully

Monitor is not

Use the power button the right side of the monitor to turn on the

Robot Position

The robot arm was moved while the system was powered off. On

Robot Emergency

Clear the Emergency Stop by rotating the red button the Teach

System Emergency

The PLC is in error, turn the system off and unplug the Forge

Safety Violation or

Clear the Emergency Stop by rotating the red button the teach

Troubleshooting and Technical Support

Troubleshooting

Nobody’s perfect, and the Forge system is no exception. If you’re having issues getting the system to work as

expected, this section should provide some guidance on troubleshooting. If there isn’t a fix for your issue in the

manual, please contact READY Robotics via email or phone.

The Forge system

will not turn on

The Forge

system’s monitor

will not turn on

to Forge system

not on

showing an error

to Forge system

loose or unplugged

turned on

Verification (teach

pendant)

in your facility.

Alignment Error" or "Protective Stop Enabled". Verify that the

Teach Pendant emergency stop button is not pressed. If necessary,

turn on the teach pendant with the silver power button.

in your facility.

inserted.

monitor. Confirm that all power cables are attached before turning

on the monitor.

the Teach Pendant, clear the error by checking the box to confirm

the pictured orientation is the same as the arm orientation. Then

press "Robot Position Verified". When the error is cleared, turn the

robot on from the Robot Control Panel.

Stuck on Begin

screen/the Teach

Pendant is

showing an error

Stop

Stop (teach

pendant)

Safety System Fault

(teach pendant)

Pendant clockwise until it pops out. When the button is cleared,

turn the robot on from the Robot Control Panel.

system from power. Wait 5 seconds, the plug the system in and

turn it back on.

pendant clockwise until it pops out. When the button is cleared,

Restart the robot from the teach pendant. If the teach pendant

returns "low voltage", clear the error and Restart the robot from

the teach pendant again. If the system still does not restart, shut

down the Forge system with the main power switch.

Page 27

Forge/CTRL User Manual

Troubleshooting and Technical Support

Version 2.0

Issue

Cause

Solution

Air not attached to

Check that the air hose is attached to the stand and that air is

Gripper is not

Confirm that the air hoses or power cable are in the correct

Gripper is not

Select Open Robot Config from the Robot Control Panel and select

Air not attached to

Check that the air hose is attached to the stand and that air is

Peripheral is not

Confirm that the air hoses or power cable are in the correct

Peripheral is not

Select Open Robot Config from the Robot Control Panel and select

Teach pendant is not

Verify that the teach pendant is on and does not say "Robot

Emergency Stop

Rotate all Emergency Stop buttons clockwise so that the button

The incorrect end

If the incorrect gripper is configured, the arm will compensate for

Forge/OS or the

Software and/or

Restart the Forge system using the main power switch. After the

Troubleshooting - continued

End effector is not

working as

expected

Device is not

working as

expected

Forge system

attached to the

Forge system

properly

selected on robot

configuration panel

Forge system

attached to the

Forge system

properly

selected on robot

configuration panel

flowing. Verify that the lockout valve is pulled up and air is not

leaving through the valve. The taskbar Fan icon should be green.

numbered input and that they are firmly and fully inserted. The

Robot Config screen shows which ports take which air hoses.

the gripper is that attached to the Forge system arm. Be sure to

attach the peripheral to the chosen end effector slots.

flowing. Verify that the lockout valve is pulled up and air is not

leaving through the valve. The taskbar Fan icon should be green.

numbered input and that they are firmly and fully inserted. The

Robot Config screen shows which ports take which air hoses.

the peripheral is that attached to the robot arm. Be sure to attach

the peripheral to the chosen air module.

Robot arm is not

responding to

Forge/OS

commands

Robot arm is

unable to support

its own weight

robot arm are very

slow to respond

on

button is activated

effector is

configured

driver issues

Alignment Error" or "Protective Stop Enabled". If necessary, turn

on the teach pendant with the silver power button.

pops out. Use the Robot Control Panel to turn the robot on.

the wrong weight. From the Robot Config screen, select the

gripper that is on the end of the robot. Or select "No Gripper" and

remove the end effector from the robot arm.

system has shut down, wait ten seconds, then turn it back on

again.

Page 28

Forge/CTRL User Manual

Troubleshooting and Technical Support

Version 2.0

Issue

Cause

Solution

Force sensor is not

Verify that the force sensor is firmly and fully attached to the

Force threshold is

Raise the force threshold in the force blocks. A low threshold (<10)

Software and/or

Restart the Forge system using the main power switch. After the

Stabilization legs are

Lower the stabilization legs so that they are making full contact

Object is not secure

If multiple waypoints are off by the same amount, the object the

Gripper is in

Verify the gripper is mounted in the same orientation as when the

Landmarks were not

Manage the landmarks for the task by opening a waypoint block

Troubleshooting - continued

Force blocks are

not working as

expected

Robot arm is not

accurately hitting

waypoints

plugged in

too low

driver issues

not in place

incorrect orientation

TeachMate. If needed, use pliers or a small wrench to tighten the

wire cap against the TeachMate.

may fail unexpectedly on high speed motions or in a facility with

ambient vibrations

system has shut down, wait ten seconds, then turn it back on

again.

with the floor and the stand can no longer roll on its wheels.

Tighten the locking nuts (underneath the Robot) against the

bottom of the Robot with a wrench so that they cannot be

loosened by hand.

robot arm is moving to may have moved. If the object is on the

stand, firmly secure it into place with multiple screws. If the object

is mounted to another object, firmly secure it to the object with as

many connection points as possible.

waypoints were programmed. There are up to four rotations that

each gripper can attach to the wrist at. If the gripper articulates

and has changed positions since the waypoints were initially

programmed, you may either need to reprogram the waypoints or

realign the gripper joints.

updated after

moving Forge

system

and hitting Manage Landmarks. Use the R-Align Probe to update

the landmark to the R-Align Socket. Save the new landmark and

verify that the waypoints are now correct.

Page 29

Forge/CTRL User Manual

Troubleshooting and Technical Support

Version 2.0

Issue

Cause

Solution

A waypoint is

Check that a waypoint is not repeated consecutively, either by

The blend is a

A blend move is not the most reliable block for a rotation-only

Vector block is not

The vector is a

A vector move is not the most reliable block for a rotation-only

Jog block is not

Driver issues

Restart the Forge system with the main power switch.

Email not configured

Verify that the email address is entered properly and spelled

Network not

Verify that the network settings are correct in the Setup Network

Troubleshooting - continued

Blend block is not

working as

expected

working as

expected

working as

expected

Email Notifications

are not working

repeated

consecutively in the

blend

rotation-only motion

rotation-only motion

or configured

incorrectly

properly configured

name or position, in the blend. Select each waypoint in order and

press "Move To" to confirm that each waypoint is different.

motion. Use a rotational jog instead.

motion. Use a rotational jog instead.

correctly. Select the desired email address from the dropdown list

in the Task Info screen or in the Breakpoint block.

screen. Choose the correct network for your facility and verify that

the password, if needed, is entered correctly. Contact your

network administrator for help if you are unfamiliar with these

settings.

Technical Support

If the troubleshooting information doesn’t address your Forge system’s bug, reach out to us with the Report Issue

feature via the READY menu in the lower left corner. READY Robotics recommends using the Report Issue feature

before contacting technical support, as the issue report will help us pinpoint the problem in your system and

significantly reduce the time to troubleshoot.

• Email READY Robotics: support@ready-robotics.com

• Call READY Robotics: 410-914-8230

Page 30

Forge/CTRL User Manual

Technical Specifications for the Forge/CTRL

Version 2.0

Power Requirements

Power Consumption without peripherals

Voltage

Main Power Input: 120V VAC

PLC Inputs:

(See Siemans S7-1200 Functional Safety Manual for more information)

Type

Sinking PNP

Rated voltage

24 V DC at 4 mA, nominal

Continuous permissible voltage

30 V DC, max.

Logic 1 signal (min.)

15 V DC at 2.5 mA

Logic 0 signal (max.)

5 V DC at 1 mA

Cable length (meters)

500 m shielded, 300 m unshielded

PLC Outputs:

(See Siemans S7-1200 Functional Safety Manual for more information)

Type

Solid state - MOSFET (sourcing)

Current (max.)

0.5 A

Logic 1 signal at max. current

20 V DC min

Logic 0 signal with 10 KΩ load

0.1 V DC max

Surge current

8 A for 100 ms max.

L+ -48 V DC, 1 W dissipation. External Supression must be used for most

Cable length (meters)

500 m shielded, 150 m unshielded

Air Requirements

Main Air Input:

80-100 psi

4mm Push to Connect Fittings

1/4 Industrial Quick Disconnect Fittings

Category 3, Performance Level (PL) d in accordance with EN ISO

Mechanical:

Weatherproofing

IP54

Max Operating Temperature

50 degrees C (does not include end effector peripherals)

Min Operating Temperature

0 degrees C (does not include end effector peripherals)

Payload

Teachmate + Force Sensor:

1.54 lbs (0.7 kg)

Force Sensor:

0.66 lbs (0.3 kg)

Teachmate:

0.88 lbs (0.4 kg)

Arm Speed typical tool:

1 m/Sec. / 39.4 in/Sec. for all

Technical Specifications for the Forge/CTRL

System technical specifications

The follow section includes any technical specifications that may help setup your Forge system. If you have

questions that aren’t answered by the information in this section, please reach out to us right away.

Inductive clamp voltage

Air Output (TeachMate)

Air Output (Air Modules)

Safety Rated Air Ouputs

inductive coils

Same psi as input

Same psi as input

13849:2008

Page 31

Forge/CTRL User Manual

Technical Specifications for the Forge/CTRL

Version 2.0

Force sensor threshold values

If the troubleshooting information doesn’t address your Forge system’s bug, reach out to us with the Report An

Issue feature. The below values are the amount of force applied in pounds when the force sensor is triggered for a

motion in +Z in a jog block with an end effector that is calibrated from the Setup Tool screen.

Solid line values are tested, dotted line are extrapolated.

Applied Force in +Z (lbs) by Threshold

20

18

16

14

12

10

8

6

Force to Trigger (lbs)

4

2

0

10 20 30 40 50 60 70 80 90 100

y = 1.4344x + 2.8864

Force Threshold

Loading...

Loading...