Ready Access BO 10 Service Manual

Pass

-

Thru Window

Model BO 10

BUMP OUT 10

Self Closing & Electric Operation

TABLE OF CONTENT

Topic Page

Disclaimer 3

Serial Number Identification 3

Contact Sheet 3

Introduction 4

Product Information

Description 4

Specifications 6

Dimensions 6

Safety Information 6

Installation Procedures

Tools needed 7

Materials Needed 7

Physical Installation 8

Electrical Installation 13

Initial Operations and Testing 15

Adjustments and Calibrations 16

Operational Procedures

Modes of Operation 19

Operations 19

Control Identification, Explanation and Function 20

Maintenance

Maintenance Schedule 21

Daily 21

Monthly 21

Yearly 21

Service

Troubleshooting Guide (Cause and Effect) 22

Parts Lists

Common Replacement Parts (Description/Part Number) 25

Complete Parts List (Description/Part Number) 26

Drawings - Exploded Views / Schematics 29

Appendix A – Adjusting or Re-Hanging the Doors 37

2

DISCLAIMER

READY ACCESS DISCLAIMS ANY LIABILITY FOR ANY DAMAGE OR HARM

CAUSED TO THE BO-10 DRIVE-THRU WINDOW, IT’S OPERATOR OR ANY OTHER

EQUIPMENT HOWEVER CAUSED IF THE BO-10 DRIVE-THRU WINDOW IS

REPAIRED OR SERVICED BY ANYONE OTHER THAN AN AUTHORIZED SERVICE

ENGINEER OR CONTRARY TO THE MANUFACTURERS WRITTEN INSTRUCTION

CONTAINED HEREIN.

THIS MANUAL IS INTENDED FOR USE BY THE IN-HOUSE OR AUTHORIZED FIELD

SERVICE ENGINEERS AND SALES REPRESENTATIVES

The manufacturer maintains the right to update, add or issue a new service manual at any time without

notice, thereby rendering all previous issues obsolete.

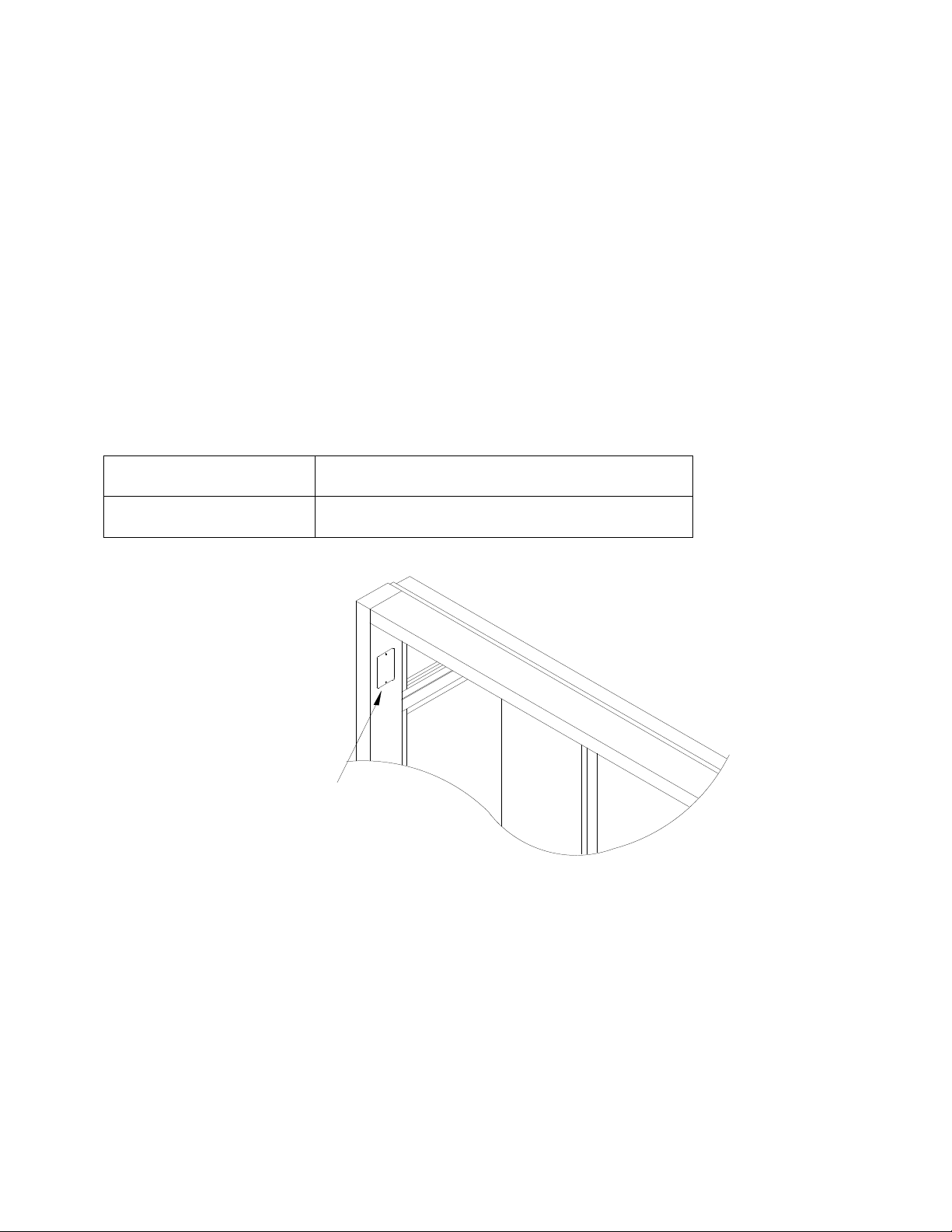

Please write the Serial Number and Installation Date for your drive-thru window in the spaces provided.

Serial Number

Date of Installation

The serial number

nameplate is located

on the post

CONTACT INFORMATION

FOR SALES AND SERVICE CONTACT

Ready Access Tel: 630-876-7766

1815 Arthur Drive Tel: 800-621-5045

West Chicago, Illinois 60185 Fax: 630-876-7767

Email: ready@ready-access.com Website: www.ready-access.com

3

INTRODUCTION

The Ready Access window is quality designed to give you years of reliable, trouble-free service.

Each window is shipped pre-assembled, fully glazed and ready for installation. All Ready

Access windows are thoroughly tested prior to shipping.

The BO-10 Bi-Parting Window is the perfect enhancement to the drive-thru concept, offering

unobstructed views of customer and crew.

The BO-10 comes in two versions, manual/Self Closing and electric. The electric version is fully

automatic with a manual override in case of a power outage. The doors will open and close by

stepping into an out of the light beam sensor. Both models meet health department

requirements for self-closing units.

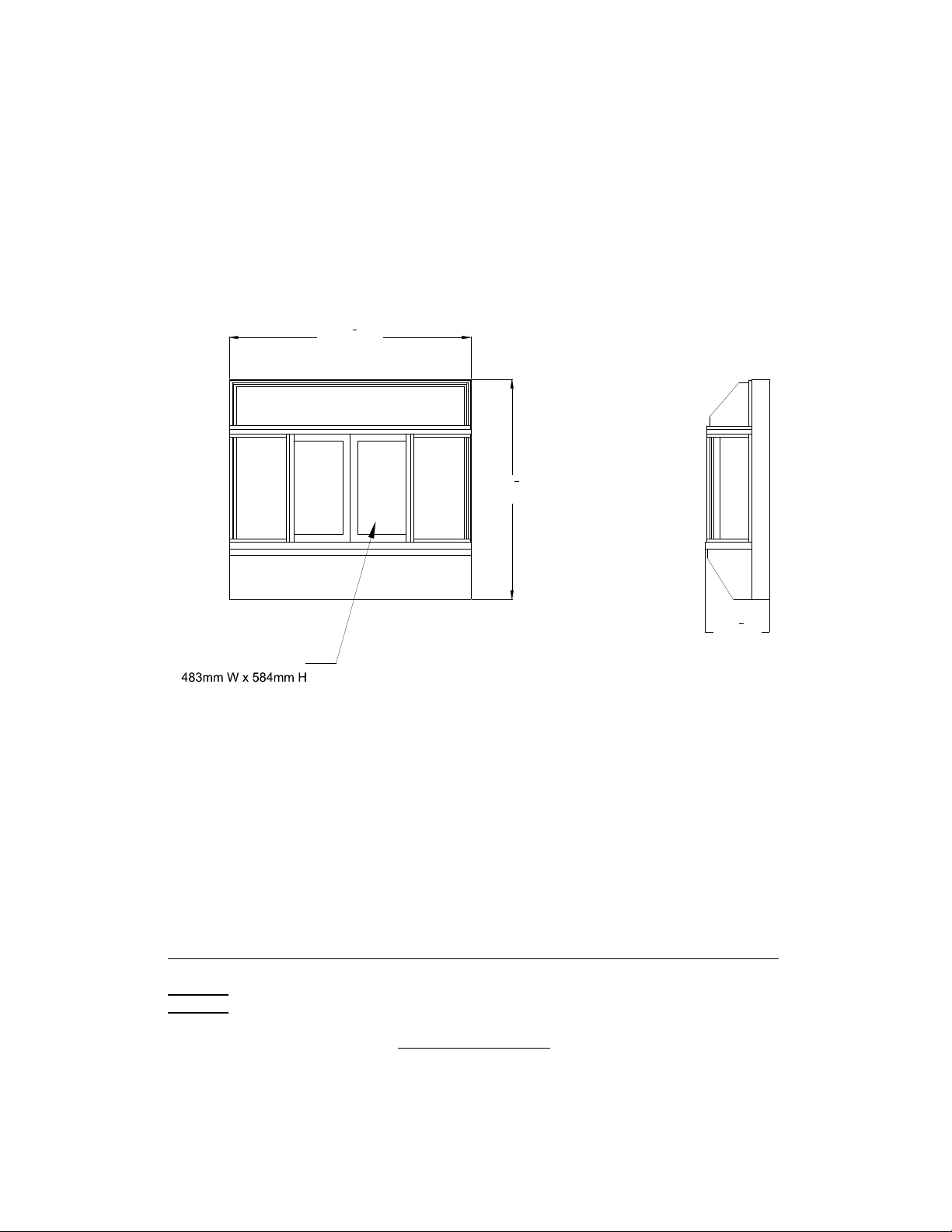

This classic bump out design offers a panoramic view of cars and outside activity. Convenience

is key with over four feet of inside usable counter space and a large 18"W x 23"H (483mm W x

584mm H) service opening. Available in manual or electric operations, the Bump Out 10 is a

practical choice for any business.

PRODUCT INFORMATION

•

Large 18"W x 23"H (483mm W x 584mm H) Service Opening

Perfect for virtually any size order, the Bump-Out 10 features a bi-parting door opening

for operating convenience.

•

Panoramic View

This original bump-out design offers the operator a 3-sided view of cars and outside

activity.

•

Counter Space

The Bump-out 10 has over 4 feet of usable inside counter space for condiments and

other necessities.

•

Quality Construction

Anodized aluminum extrusions, stainless steel and 1/4" tempered glass combine to give

you an attractive window that not only enhances building exteriors, but will not rust, pit or

weather. Track free bottom sill provides for a contaminant free surface.

•

Double Security Locks

Bump-Out 10 Windows automatically lock each time the doors close, providing security

when the window is unattended. When the drive-thru is closed, manual security locks

help to prevent outside entry. An optional security bar set is available for high risk areas.

•

Fully Assembled, Ready to Install

Ready Access windows are shipped completely preassembled, and fully glazed for lower

installation costs. Normal installation takes less than two hours.

4

•

Three to Five Day Shipping

Ready Access will ship any standard window order in 3 to 5 days from receipt of order.

•

Warranty and Service Support

Your Bump-Out 10 comes with a one year limited warranty on parts and labor. In

addition, each unit is backed by a world-wide service organization.

MANUAL/SELF CLOSING OR FULLY-AUTOMATIC SERVICE OPENINGS

•

Manual/Self Closing

In a Manual/Self Closing operation, simply release the self latching handle and pull open

the door. Both doors part from the center and easily slide open. To close the window

simply let go and gravity will close the window.

•

Fully-Automatic

The operator simply steps into an electronic light beam which opens the door panels

automatically. The door panels automatically close when the operator steps away from

the electronic light beam. By the push of a button, operators can easily adjust the

window opening size to either 12"W or 18"W.

AVAILABLE OPTIONS

•

The Bump-out 10 is available in statuary bronze or clear anodized aluminum.

•

Tinted glass is available upon request.

•

Powder coat painting is available in a wide range of custom colors.

5

Model

Number

USA International

BO-10 - E 110/120 VAC

60Hz

Dimensions

SPECIFICATIONS AND PERFORMANCE

Unit

Voltage

220/240 VAC

53

[1358.9mm]

50/60Hz

1

"

2

Actual

Unit

Amps

15 A (US)

8 A (Int’l)

3

48

"

4

[1238.3mm]

Dimensions

In Inches

W X H x D

53½” x 48¾” x 14¼”

Weight

In Shipping

Carton

180 lbs

1

14

"

4

SERVICE OPENING

18"W x 23"H

[362mm]

Figure 1

Safety Information

WARNING: To avoid the risk of fire, Electric Shock or injury to persons, observe the following:

1. Before servicing or cleaning the unit, switch the power off at the mechanical switch near the unit

(Installed by an Electrician) or the electrical entry service panel/circuit breaker. (Load Center)

• OSHA LOCK OUT – TAG OUT procedures are to be observed to prevent power from being

switched on accidentally.

2. Any Installation and / or Electrical work must be done by QUALIFIED persons in accordance with

all applicable codes / standards and manufacturers recommendations and specifications.

3. DO NOT insert fingers and / or foreign objects into the Drive-Thru Window.

DO NOT block or tamper with the unit in any manner while it is in operation.

4. This product must not be used in Potentially Dangerous locations such as Flammable, Explosive

or Chemical – laden environment.

6

Installation Procedures

Tools required to perform the installation

• Electric Drill

• Metal Drill bits –

⅛” (3mm)

¼” (6mm)

½” (13mm)

1” (25mm)

• Screwdrivers – Slotted and Phillips

• Hacksaw

• Jack / Utility Knife

• Flat File – Coarse

• Caulking gun

• ¼” Nut Driver

Materials required for installation

• Window framing, architect specified and installed in building.

(Ready Access recommended material is ⅛“ (3mm) x 1 ¾” (44.5mm) x 4” (102mm) hollow

aluminum tubing or glazing channel)

• Electrical Tape

• Wire Nuts

• Caulking – silicone (Color specific to the color of window)

• Connectors for conduit as required

• Shingle type shims – as required to level and plum the window

• Extension Cord

• Masonry drill bit –

• Masonry Hole Saw – 1” (25mm)

• Channel Lock Pliers

• Tape Measurer

• Wire Cutter

• Step Ladder

• Level

¼” (6mm)

1” (25mm)

1

½” (38mm)

7

Physical Installation

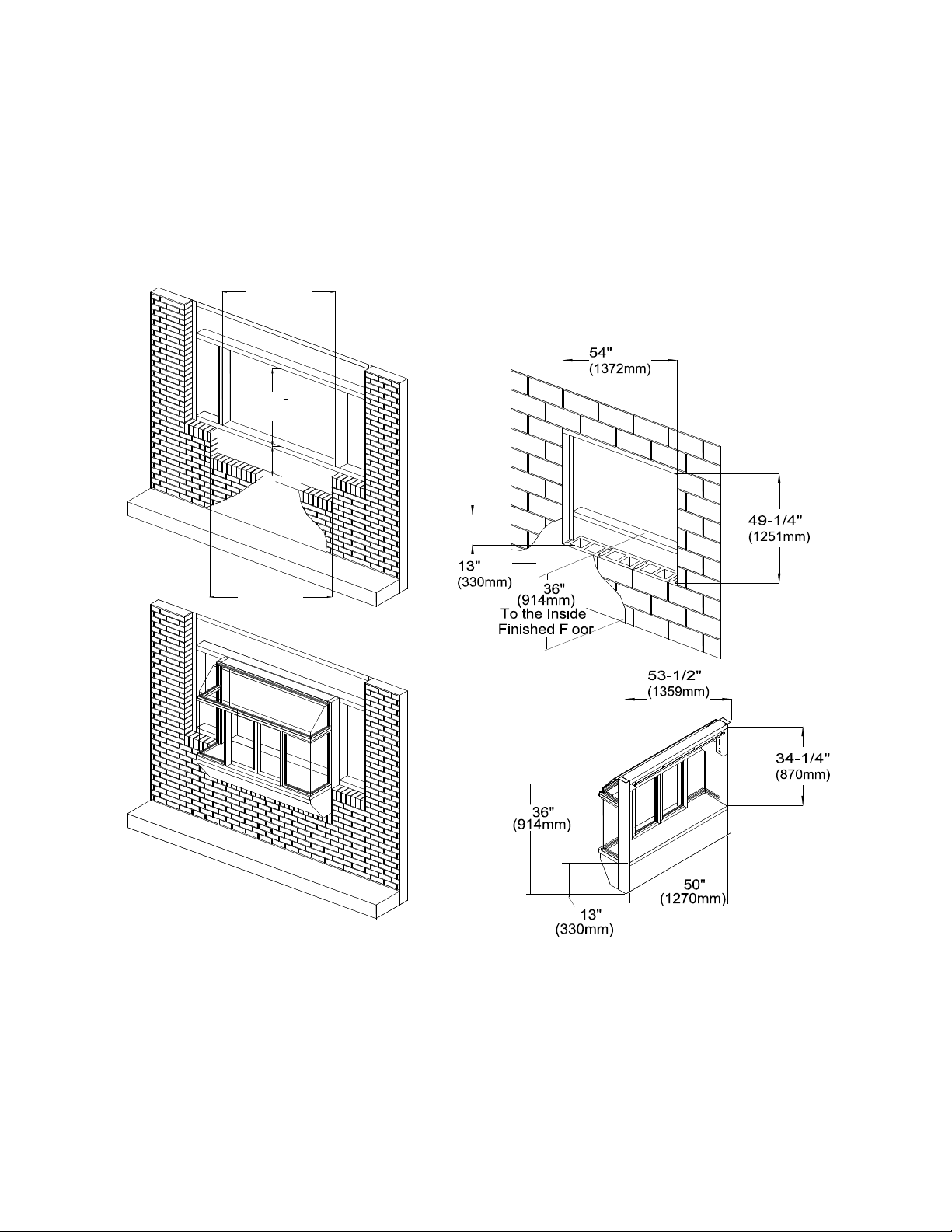

Before you begin installing your Ready Access Drive-Thru Window, you must determine what type of installation

will be required. Wood Frame, Masonry Framing, etc.

Please refer to the details below and on the next page to pick which one bests fits your application.

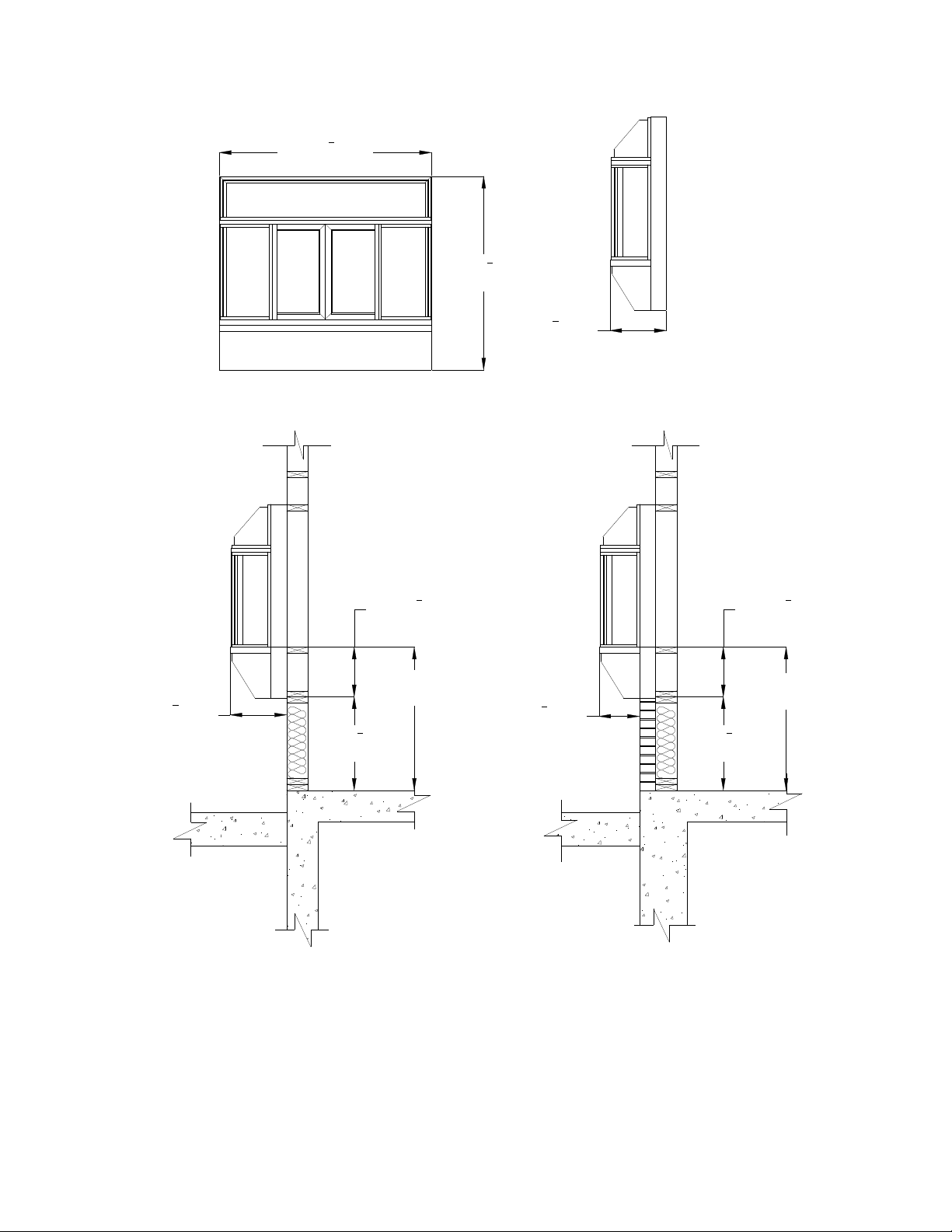

50"

[1270.5mm]

1

34

"

4

[870.3mm]

13"

[330.3mm]

54"

[1372.0mm]

FIGURE 2A

8

1

53

"

2

[1359.44mm]

3

48

"

4

[1238.74mm]

[362.09mm]

14

1

"

4

1

14

"

4

[362.09mm]

[317.63mm]

[914.76mm]

1

23

"

2

[597.14mm]

12

36"

1

"

2

FIGURE 2B

1

10

"

4

[260.45mm]

[317.63mm]

[914.76mm]

1

23

"

2

[597.14mm]

12

1

2

36"

"

9

WARNING:

TWO PEOPLE ARE REQUIRED FOR THE LIFTING AND

INSTALLATION OF THE WINDOW.

1. Confirm that the customer-supplied frame is made to accommodate the dimensions as illustrated on

page 9.

2. Confirm that AC power has been run and is ready for connection to the window.

3. Check shipping carton for any shipping damage and remove window from the carton.

4. Check window for any shipping damage.

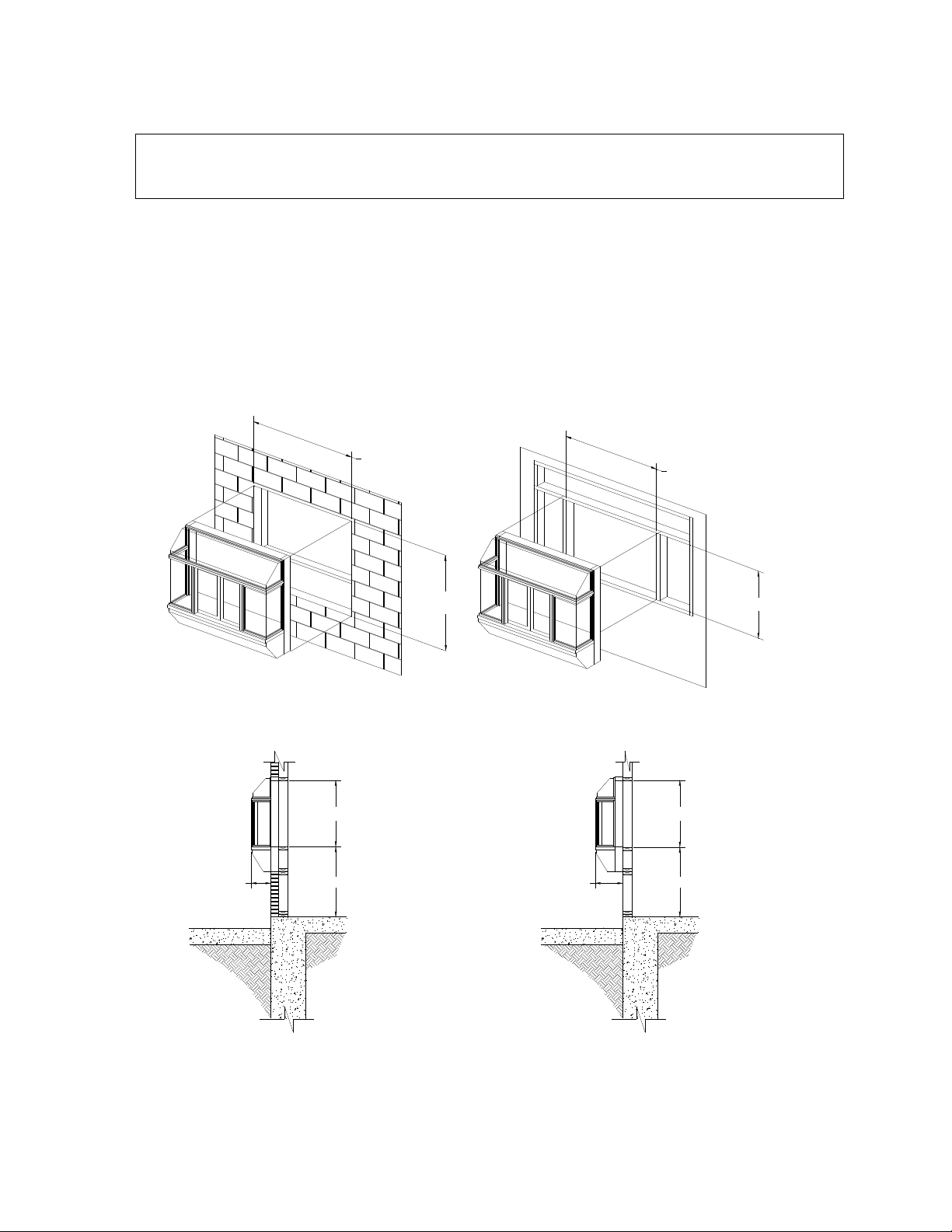

NOTE: There are two wall-mounting applications. The mounting space can be

surrounded either by sidelights (windows) or masonry. The illustrations will show

both configurations. (Figure 3)

MASONRY WALL

ROUGH OPENING

10 1/4" (260mm)

54" (1372mm)

34 1/4" (870mm)

*36" (914mm)

49 1/4"

(1251mm)

Glass Store Front

Daylight Opening

14 1/4 (362mm)

50" (1270mm)

ID

34 1/4"

(870mm) ID

34 1/4" (870mm)

*36" (914mm)

*MIN. DISTANCE FROM TOP

OF COUNTER TO FLOOR

SECTION THRU

MASONRY WALL

SECTION THRU

GLASS STORE FRONT

Figure 3

10

5. Once the application has been determined, check the daylight opening of the frame being used.

The opening dimensions should be 50” wide x 34-1/2” high.

6. For a Fully-Automatic installation, check for the electrical hook-up. The AC electric should be

installed from the breaker box (Load Center) to the window opening before the installation of the

window.

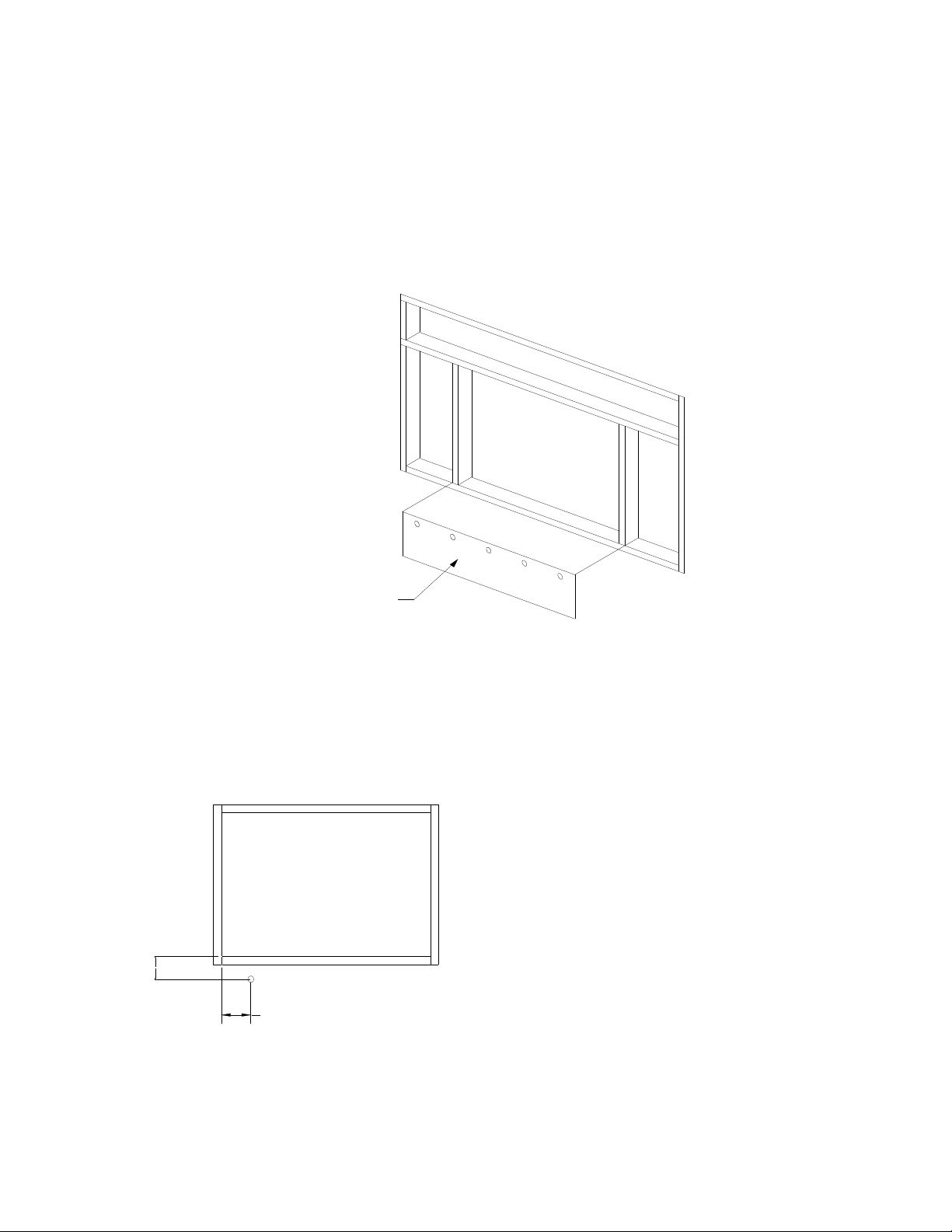

7. Using the paper mounting template, drill a quantity of 5, ¼” diameter pilot holes for mounting. (See

Figure 5) OUTSIDE ONLY – DO NOT DRILL THROUGH THE FRAME.

Paper

Mounting

Template

Figure 5

8. Remove the template and drill 5, ½” holes using the ¼” pilot holes.

OUTSIDE ONLY – DO NOT DRILL THROUGH THE FRAME.

9. For Fully-Automatic installations, Drill a 1½” hole through the wall as illustrated in Figure 6.

(The dimensions shown are from the inside of the building.)

Rough Opening Shown from

the Inside looking Out.

Dimensions are taken from the

inside daylight opening of the

frame.

5.50

7" (178mm)

Figure 6

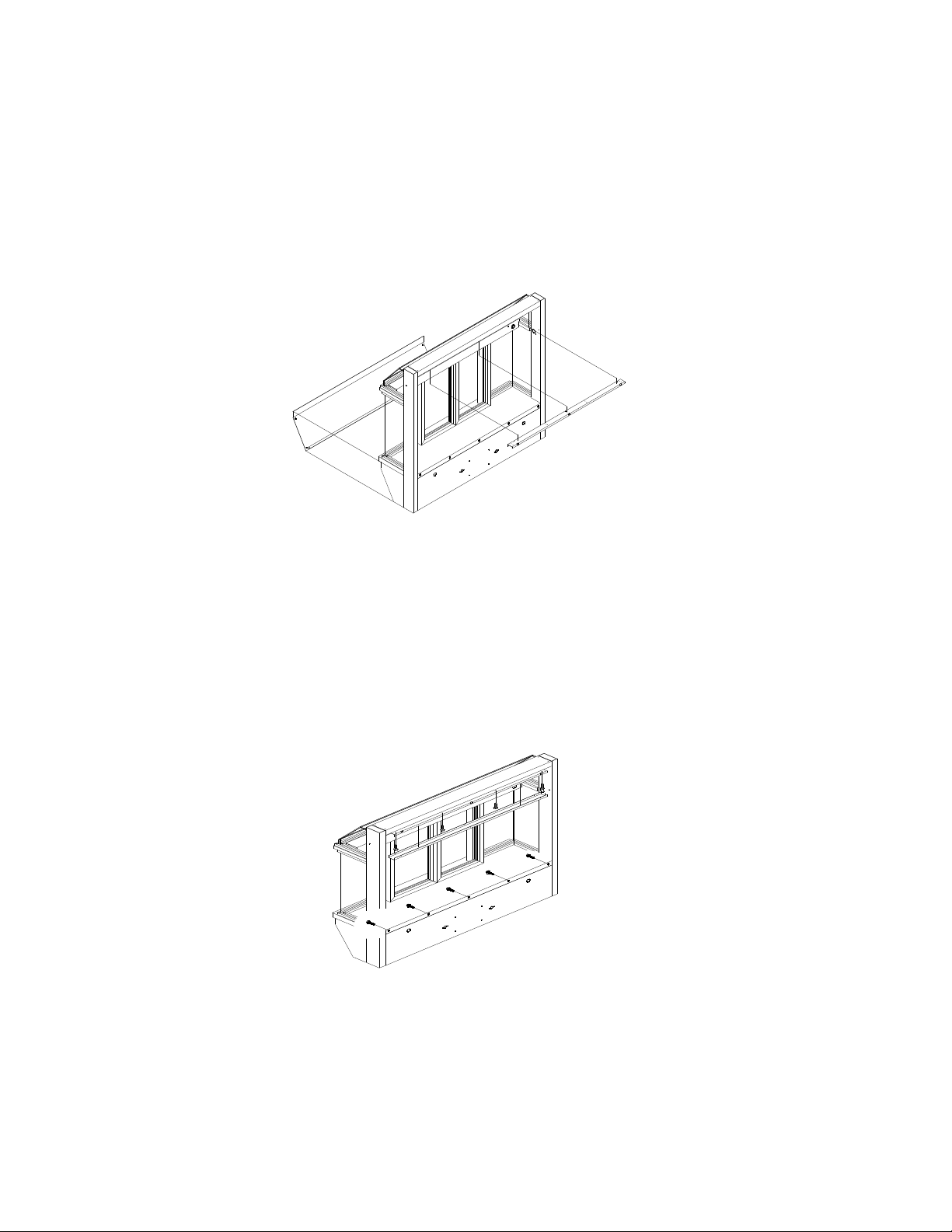

10. Requiring 2 people, remove Ready Access Window from carton and place on top of carton lid to

prevent scratching.

11

11. Person number 1 should remove the bottom cover from the window and organize the mounting

hardware.

Person number 2 should apply a bead of caulk to the outside surface of the building window frame.

(Reference 1/2" drilled holes for mounting window.)

12. Mount the mullion mounting strip provided to the underneath side of the header frame of the window.

Pilot holes are provided in the header frame of the window unit.

Figure 7

13. Requiring 2 people, stand window upright. With one person on each side of the window, lift the

window into position, aligning the counter top with the building frame sill and the mullion mounting

strip going underneath the rough opening header.

With one person holding the front of the window from falling forward, the other person from the

inside will start inserting mounting screws through the mullion strip that has been mounted to the

window in step 12.

From the outside, insert the 5 well nuts and fasten with the bolts and washers provided, through the

bottom, underneath the counter, into the building frame.

(Mounting into wood, use lag bolts. Mounting into masonry, use mason anchors.)

Figure 8

14. DO NOT TIGHTEN - Shim unit to be square and plum. Once this has been done, tighten mounting

hardware and snap on mullion mounting strip cover.

15. When the window is fully secured, seal the outside of the window to the frame or building using

silicone caulk.

.

12

Loading...

Loading...