www.reac.se

USER MANUAL ACTUATOR

RE7000

www.reac.se

About REAC

REAC is passionate about helping people in their daily lives, and by providing a wide range of advanced

power solutions suitable for many different applications, we hope to make people's lives a little bit easier.

Our aim is to offer our clients an excellent service, backed up by experience and know-how in the

application of advanced motion systems.

REAC's power solutions contain compact and strong electrical actuators, lift and tilt systems, control

boxes and hand controls. We know that our customers have different needs and therefore our products

are designed to be customized according to their application’s specific requirements.

We are confident to say that we can solve a wide range of motion problems, so please challenge us!

Contact information:

REAC AB

Forsbrogatan 4

662 34 Åmål

Sweden

Phone: +46 (0)532 78 50 00

Email: info@reac.se

Web: www.reac.se

www.reac.se

Table of Content

1 INTRODUCTION ..................................................................................................................................... 1

1.1 ABOUT THIS MANUAL .................................................................................................................... 1

1.2 SYMBOLS .................................................................................................................................... 1

1.3 PRODUCT OVERVIEW .................................................................................................................... 1

2 TECHNICAL DATA ................................................................................................................................. 2

2.1 SYSTEM AND COMPATIBILITY ......................................................................................................... 2

2.2 BASIC CHARACTERISTICS .............................................................................................................. 3

2.3 ENVIRONMENTAL CONDITIONS....................................................................................................... 3

2.4 FUNCTIONAL FEATURES ................................................................................................................ 4

2.5 MOUNTING INSTRUCTION .............................................................................................................. 4

2.6 OPERATING INSTRUCTIONS ........................................................................................................... 5

2.7 CONNECTORS .............................................................................................................................. 5

3 SAFETY .................................................................................................................................................. 6

3.1 MANUAL LOWERING ...................................................................................................................... 6

3.2 PULL FORCE PROTECTION ............................................................................................................ 6

3.3 OVER LOAD ................................................................................................................................. 7

3.4 SIDE FORCE ................................................................................................................................. 7

4 MAINTENANCE ...................................................................................................................................... 8

4.1 SERVICE INTERVALS ..................................................................................................................... 8

4.2 CLEANING AND DISINFECTION ....................................................................................................... 9

4.3 WASTE DISPOSAL ......................................................................................................................... 9

4.4 WARRANTY ................................................................................................................................ 10

4.5 REPAIRS .................................................................................................................................... 10

4.6 TROUBLESHOOTING ................................................................................................................... 11

5 LABELING ............................................................................................................................................ 12

6 COMPLYING STANDARDS ................................................................................................................. 15

Failure to comply with these instructions may result in accidents involving personal injury.

Failing to follow these instructions can result in the product being damaged or destroyed.

Useful tips, recommendations and information for efficient, trouble-free use.

1 Introduction

1.1 About this manual

The aim with this user manual is to describe the REAC actuator RE7000 with focus on:

Working principle descriptions

Safety

Maintenance

Troubleshooting

Service

Next to this manual the following documentation is available:

RE7000 data sheet

1.2 Symbols

The following symbols will be used in this document:

1.3 Product overview

RE7000 is a very efficient, high speed 12 000 N actuator developed to meet

the requirements in patient lift systems. It is equipped with a manual lowering

function, which allows lowering the lift by hand if the electrical power is not

available. It also has a “pull force protection” to prevent injuries.

In combination with REAC control systems for patient lifts (RCB15, RCB20

and RCB25), RE7000 regenerates energy back to the batteries when

lowering the lift, giving increased battery life time between charging.

1

RE7000 must be combined with a control system that can handle regenerative energy.

Using RE7000 with a not approved control system may lead to malfunction or personal

injury.

RHC15

RE7000

RCB20

RCB15

Figure 1. System and compatibility

2 Technical data

2.1 System and compatibility

Since RE7000 is so efficient and regenerates energy it must be combined with a control system which

can handle this generative energy, the following REAC control systems can all handle this. If another

control system is to be used this must be verified and approved by REAC.

2

2.2 Basic characteristics

Basic characteristics

Operating voltage

24V DC

Current consumption (Max load)

8,5 A

Current consumption (No load)

1,0 A

Max load

12000 N

Min built in length

290 mm + stroke

Stroke

100 - 300 mm

IP-class

IP26

Efficiency

>40%

Duty cycle

10%

Weight

5,6 kg

Flammability rating

UL94 V-0

Color

RAL 9016

Expected service life

8 years1

Using the the products outside theire specified limits may lead to malfunction or personal

injury.

1

Environmental conditions

Operating

Storage

Ambient temperature

-15 °C to +50 °C

-25 °C to +70 °C

Relative humidity

15% to 90%

15% to 90%

Atmospheric pressure

700 to 1060 hPa

700 to 1060 hPa

2.3 Environmental conditions

Provided that service schedule described in the user manuals are followed

3

Functional features

Manual lowering

Built in limit switch

Safety nut

Energy regeneration

Pull force protection

2.4 Functional features

2.5 Mounting instruction

RE7000 is easily mounted by using a pin with minimum Ø12mm together with a bushing. Without bushing

a pin up to Ø14mm can be used. RE7000 is as standard equipped with a stereo jack plug for easy

connection to REAC control systems.

Figure 2 Mounting of RE7000

Loads should act along the axis of the actuator. Off centre loads may cause binding and lead to

premature unit failure.

4

The actuator must not be subject to off centre loading, as this can damage the actuator

The mounting brackets must be capable of handling at least 30 Nm (22 ft-lb) torque

generated by the Re7000 between top and bottom mount. Failing to do so may lead to

subsequent malfunction or personal injury.

Figure 3 Load position

2.6 Operating instructions

The normal way to interact with the actuator is via the hand control (RHC15) and one of REACs control

systems. RHC15 has as default two speed operations, which makes it possible to run the RE7000 with

different speeds.

RE7000 has built-in end limit switches, which will immediately stop actuator movement when activated.

For smoother stops (patient friendlier) it is recommended that the actuator is stopped by releasing the

hand control button slightly before the mechanical end is reach to ensure the stop ramp to elapse.

2.7 Connectors

The RE7000 is equipped with a RCB-connector, which will serve as an identifier when used together with

a REAC control box. For futher information please refer to the user manual for the applicabel control box.

5

Do not use the actuator without inspection of authorized service personnel after the

manual lowering mechanism has been used2.

Using the actuator after the manual lowering was forced to be used may lead to

subsequent malfunction or personal injury.

2

3

3 Safety

3.1 Manual lowering

The RE7000 is equipped with a manual lowering function (patent pending), intended to be used in case of

an emergency when the normal lowering function is not working.

To lower the actuator manually, turn the top of the actuator clockwise and the lift will move downwards.

Figure 4 Manual lowering principle

3.2 Pull force protection

ISO 105353 specifies that if the spreader bar or lifting arm of the patient lift comes in contact with the lifted

person, the lifting machinery must not increase the load imposed to lifted person by more than 50 N.

RE7000 has a patented solution for detection of actuator pull force, which will immediately stop downward

movement when detected. Many patient lifts has a gearing of 1:5 and with that assumed it takes

approximately a force of 8,5 N at the end of the lifting bar for the actuator to stop, i.e. RE7000 will only

add a load of 8,5 N before the downward movement is stopped.

If not obvious that nothing is wrong with the actuator, for example battery to low

Hoists for the transfer of disabled persons – Requirements and test methods (ISO 10535:2006)

6

The actuator must not be subject to overload (> 12 000 N), as this can reduce the life

length of the actuator or subsequent malfunction and personal injury

The actuator must not be subject to a side load above 1 000 N, as this can cause

bending, which can lead to subsequent malfunction and personal injury.

4

5

3.3 Over load

The RE7000 is designed for loads up to 12 000 N and should not be used above this limit as it will reduce

the life length of the actuator and it can also lead to subsequent malfunction and personal injury.

An RE7000 used in combination with a REAC control system4 will be supervised for over load and if

detected by the control system the movement will be aborted and a warning alarm5 will be initiated.

3.4 Side force

RE7000 is designed primarily for a patient lift system in line with ISO

10535. When used in a patient lift, it should be marked with a label to

make sure that the user is aware of that the actuator should not be used

as a handle and it is not allowed to move the lift by holding on the

actuator tube or otherwise expose the actuator to side forces.

RCB15. RCB20 or RCB25

Indicated by warning LED on the hand control or a sound warning. Must be configured pre-delivery.

7

Initially

Every

3:rd

month

At

planned

service

Actuator

Ensure actuator is firmly fixed

Pull force protection

Run actuator downwards and put some stop object below, actuator

should stop

Bolts and brackets

Bolts and brackets are to be inspected and must be replaced if

there are signs of wear

Cables

Ensure cable that connects actuator with control box is firmly

fixated.

Cover

The plastic housing must be checked for mechanical damage

(cracks).

Sealing

The sealing rings of the actuator plug must be checked for damage

and exchanged if necessary.

Limit switch

Check the power cut-off (via limit switches) while running the

actuator to both end positions. When reaching the end position, the

actuator must stop without the button on the control device being

released.

6

4 Maintenance

4.1 Service intervals

To ensure proper and safe operation, regular service is required. When used together with REAC control

systems6 a service interval based on number of actuator cycles and/or calendar time can be configured

and a LED will be lit when service time is due. Note: there can be national norms for the applications in

which the actuator is used, that specify a certain service interval. This can easily be handled with this

configuration.

Between this service points regular maintenance and minor inspection must also be performed. Below

follows a suggested maintenance schedule.

RCB15, RCB20 or RCB25

8

4.2 Cleaning and disinfection

Product

Cleaning instructions

RE7000

Clean with a damp cloth or with a brush and water (water can be under

pressure)

The systems must not be washed directly with a high pressure cleaner.

Cleaning with a steam cleaner is not permitted.

For disinfection it is recommended to use soap or equal and clean with a damp cloth.

Cleaners and disinfectants must not:

Be highly alkaline or acidic

Contain caustic agents

Be able to change the structure of the surface or adhesion of the plastic

Break down grease

All REAC products are marked with this symbol, which according to Waste Electrical and

Electronic Equipment (WEEE) Directive 2002/96/CE means that products marked with this

sign must be taken to a proper disposal site and cannot be disposed in in normal household

waste.

Cables

Electronics

Metal

Plastic

RE7000

Internal harness

Connector cable

Limit switch PCB

PCB

Inner tube

Outer tube

Motor plates

Screws

Nuts

etc

Cover

End sleeve

Manual lowering handle

4.3 Waste disposal

A RE7000 consist of several parts with different material, which means that they cannot be disposed as

one single item. It is recommended (at disposal) to disassemble and divide the product as much as

possible into feasible waste groups to be able to recycle the product in the most environmental friendly

way.

The following waste groups have been identified for the RCBs:

Some of these main groups can be divided into sub-groups, for example metal can be divided into iron,

stainless steel and aluminum and alloy steel. Plastic can e.g. be divided into ABS, PA, PE and POM.

All our plastic units are provided with an interior code for plastic types and fibre contents.

9

If any of the REAC products are opened, there will be a risk of subsequent malfunction.

4.4 Warranty

The warranty covers manufacturing defects in the product, starting from the date of manufacture.

Standard warranty is 12 months. The warranty is limited to the value of the product.

REACs warranty is only valid if the product has been used and maintained correctly and has not been

manipulated with.

This warranty does not apply to damage or failure of the product which is caused by improper or

unprofessional use. The products must not be exposed to violent treatment. In the event of this, the

warranty will be invalid.

4.5 Repairs

In order to avoid the risk of malfunction, all repairs must only be carried out by authorised REAC

workshops or by a REAC appointed representative. Products under warranty must also be returned to an

authorised REAC workshop.

10

4.6 Troubleshooting

Problem

Probable cause

Description

Solution

No

actuator7

movement

(or actuator

switches off

during

operation)

Over current

If the actuator run in to a

mechanical stop the current will

increase fast. Current peaks

above the current limit are

allowed for 250ms, when this is

exceeded the actuator will be

turned off.

Run in opposite direction.

Over load

Alert indication LED will be lit

and/or sound alarm will be

activated.

Reduce load. Use manual

lowering8 to lower the system.

Short circuit

Alert indication LED will be lit.

Service needed.

Duty cycle protection

Duty cycle protection is a function

to protect the actuator motor from

overheating.

Alert indication LED will be lit,

during attempt to run the

actuator.

Wait until actuator “rest time” has

elapsed.

Hand control out of order

Nothing happens

Try to control the actuator via

control box panel.

The emergency stop

button has been

pressed.

The emergency stop is a normally

closed switch, which at activation

beaks all circuits (charger and

battery) and immediately stops all

movements.

Unlock the emergency stop

button by turning it clock wise.

Actuator not correctly

connected to control box

Nothing happens

Make sure actuator is properly

plugged into control box.

Actuator mix up

Wrong actuator will move.

If actuators are equipped with

RCB-connectors9, mix up will be

detected, movement will not be

allowed and alert indication LED

will lit

Make sure actuator/actuators are

connected properly.

Internal error

Alert indication LED will be lit.

If error remains after 10 s, service

is needed.

Actuator cable faulty

Check the cable and replace the

actuator if necessary

Charging ongoing

Operation is not allowed (and is

prevented by the system) during

charging, the yellow LED will

blink if any operation is

requested.

Disconnect charging cable.

7

8

9

Combination with REAC control system assumed

Further information on manual lowering, see chapter 3.1

See chapter 2.7 for further details.

11

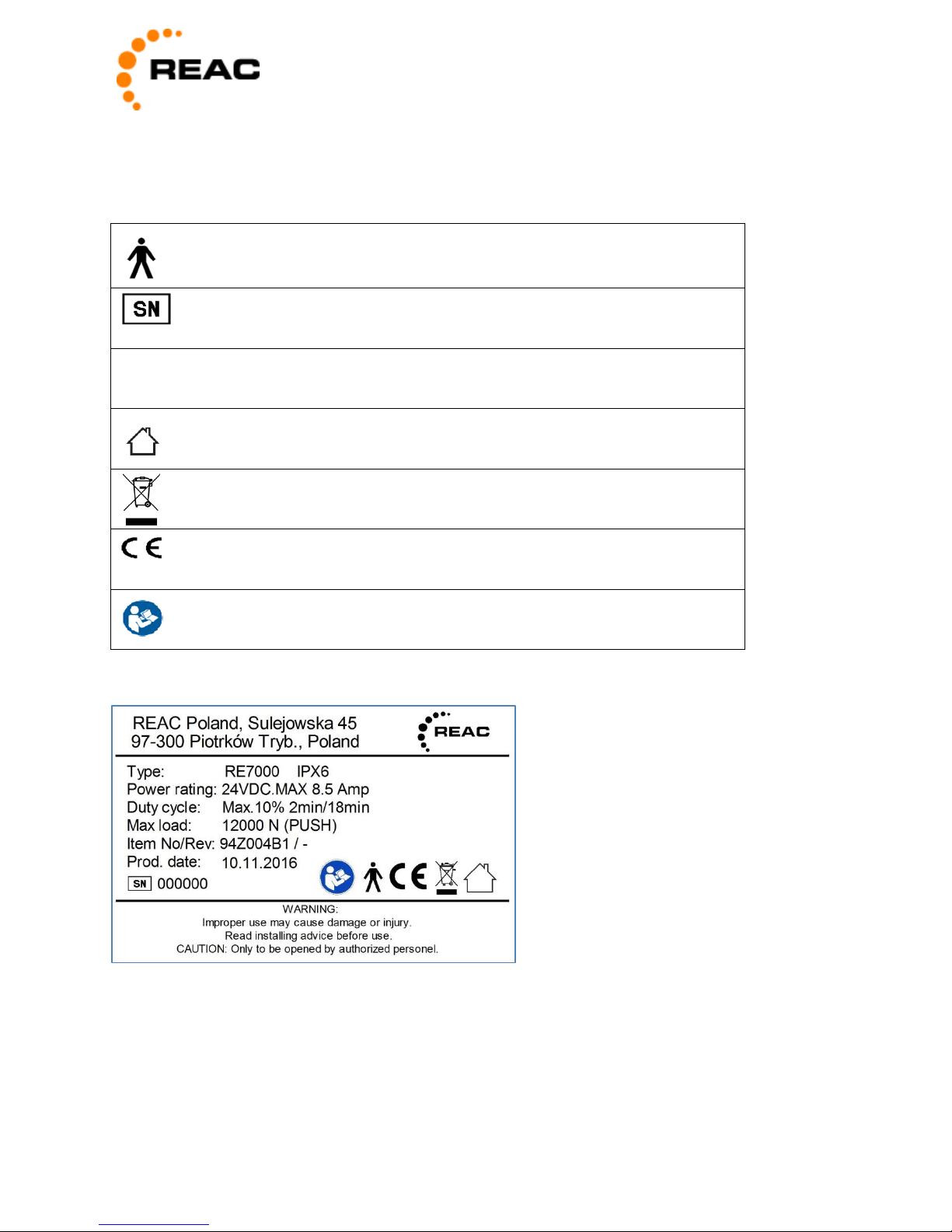

IEC 60417-5840: Patient part of type B

Serial number./LOT number

IPXX

Ingress of particles (first character) and water (second

character) as per EN60529.

IEC 60417-5957: For indoor use only

WEEE compliant

CE-label attached based on Low Voltage Directive and EMC

Directive.

ISO 7010-M002: Risk(s) mitigated in accompanying

documents

5 Labeling

The following symbols are used on the label of RE7000.

Example of label:

12

Manufacturer

Do not use if package is damaged.

Fragile, handle with care

Keep dry

Temperature limits

Relative humidity limits

Atmospheric pressure limits

Consult instructions for use (Can be ordered via REAC

homepage)

The following symbols are used on the packaging of RE7000.

13

Example of packaging information:

14

6 Complying Standards

Complying Standards

Description

Hoist Specific

ISO 10535:2006

Hoists for the transfer of disabled persons –Requirements

and test methods

Applicable parts

Electrical Safety

IEC 60601-1:2006 and

amendment 1:2012

Medical electrical equipment – Part 1: General requirements

for basic safety and essential performance.

IEC 60601-1-11:2015

Medical electrical equipment – Part 1-11: General

requirements for basic safety and essential performance –

Collateral Standard: Requirements for medical electrical

equipment and medical electrical systems used in the home

healthcare environment.

IEC 60601-1-2:2014

Medical electrical equipment – Part 1-2: General

requirements for basic safety and essential performance –

Collateral Standard: Electromagnetic disturbances –

Requirements and tests.

Electromagnetic

Emission

CISPR 11 Class B (2009)

Radiated and conducted emission

IEC 61000-3-2 (2014)

Harmonic current emission

IEC 61000-3-3 (2013)

Voltage fluctuations and flicker

Electromagnetic

Immunity

IEC 61000-4-2 (2008)

Immunity to electrostatic discharge

Test levels:

±8 kV contact discharge ±2, ±4, ±8 and ±15 kV air discharge

IEC 61000-4-3 (2006 + A1 +

A2)

Immunity to radiated electromagnetic fields in the frequency

range 80 – 1000 MHz and 1,0 – 2, 7GHz

Test levels:

80 – 1000 MHz 10 V/m with 80 % AM @ 2 Hz

1,0 – 2,7 GHz 10 V/m with 80 % AM @ 2 Hz.

IEC 60601-1-2:2014

Table 9 (up to 28 V/m pulse modulation at frequencies in ISM

bands)

IEC 61000-4-4 (2012)

Immunity to fast transients/burst

Test levels on AC Power input port: AC input/output power

input port ± 2,0 kV ncies in ISM bands)

Cont. next page

15

Electromagnetic

Immunity cont.

IEC 61000-4-5 (2006)

Surge immunity test

Test levels on AC Power input port: AC Power input port,

±0,5 kV and ±1,0 kV differential mode.

IEC 61000-4-6 (2014)

Immunity to conducted disturbances in the frequency range

0,15 – 80 MHz

Test levels on AC Power input port: 6 Vrms with 80 % AM @

2 Hz.

IEC 61000-4-8 (2009)

Immunity to power frequency magnetic fields

Test level: 30 A/m, 50 Hz and 60 Hz

IEC 61000-4-11 (2004)

Voltage Dips and Interruptions

Test levels on AC Power input port:

Test frequency: 50 Hz. Test

voltages: 100 and 230 V.

100 % for ½ cycle positive and negative half period.

60 % for 10 cycles.

30 % for 25 cycles.

100 % for 250 s.

16

© REAC, November 2016, Issue 2.0

REAC AB

REAC Poland Sp. z o.o

www.reac.se

REAC is continuously developing our products and can make changes without prior notice. Therefore we can’t guarantee that the

information stated on our webpage or in our written material always is up to date, nor can we take responsibility for any

misinterpretation of our written context. Technical specification might change due to load and external circumstances. REAC products

shall be tested in its intended application before use.

Forsbrogatan 4

662 34 Åmål, Sweden

Ul. Sulejowska 45

97-300 Piotrków Trybunalski, Poland

E-mail: info@reac.se

Phone: +46 532 78 50 00

Loading...

Loading...