© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 1 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

REA ScanCheck 3n

Bar Code Verification Unit

Operating Manual

Document Version 1.1.0 -20100530SC3-GUI-Version from 1.0.10.7

TD-GPT-Printer version 1.20

Verifier-Version 1.0.10.14

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 2 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Table of Contents / Page 1

1.

Introduction................................................................................................................. 6

1.1

Documentation Conventions ....................................................................................... 7

1.2

Safety Instructions ...................................................................................................... 7

1.3

Determination of Serial Numbers on the REA Product ................................................ 8

2.

The Delivery Components of the REA ScanCheck 3n................................................. 9

3.

Startup of the REA ScanCheck 3n............................................................................ 11

3.1

Activation and Deactivation of the REA ScanCheck 3n............................................. 12

3.1.1

Reactivation of the REA ScanCheck 3n after Power Supply Failure ......................... 13

3.2

Changing Presets on the REA ScanCheck 3n .......................................................... 14

3.2.1

Standard Parameters of Factory Settings ................................................................. 14

3.2.2

Change Menu Language Selection........................................................................... 15

3.2.3

Change Data Output Parameters.............................................................................. 16

3.3

Operating REA ScanCheck 3n with Report Printer.................................................... 17

3.4

REA ScanCheck 3n with PC Evaluation Software..................................................... 18

3.4.1

Connection of the REA ScanCheck 3n to Power Supply ........................................... 19

3.4.2

Network Installation................................................................................................... 19

3.4.2.1

Firewall ..................................................................................................................... 20

3.4.2.2

MAC Addresses........................................................................................................ 20

3.4.2.3

Technical Functionality Test of a Network Connection.............................................. 21

3.5

Use of Extension Plates on the ScanCheck 3 ........................................................... 22

3.6

Charging the Batteries .............................................................................................. 23

3.7

Storage and Transport .............................................................................................. 24

3.8

Updating Operating Software in REA ScanCheck 3.................................................. 25

3.8.1

Updating Using a USB Memory Stick........................................................................ 25

3.8.2

Updating with the "Update Program" from the REA CD-ROM ................................... 27

3.9

Calibrating the REA ScanCheck 3n .......................................................................... 29

3.9.1

Calibrating the REA ScanCheck 3n for 6, 8 and 10 mil Apertures ............................. 30

3.9.2

Calibrating the REA ScanCheck 3n for 20 mil Aperture............................................. 31

3.9.3

Verification Tool Monitoring....................................................................................... 32

3.9.3.1

Allowable Unit Tolerances......................................................................................... 32

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 3 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Table of Contents / Page 2

4.

Operation of the REA ScanCheck 3n........................................................................ 34

4.1

Handling of the REA ScanCheck 3 ........................................................................... 34

4.1.1

Instructions for Correct Execution of Code Evaluations............................................. 35

4.2

First Measurement of Bar Codes .............................................................................. 36

4.2.1

Depiction of a Code Evaluation on the REA ScanCheck 3........................................ 37

4.2.1.1

Quick Display with LED and Acoustic Signaling........................................................ 37

4.2.1.2

Evaluation of an ISO/IEC 15416 Verification - 1st Screen ......................................... 37

4.2.1.3

Evaluation of an ISO/IEC 15416 Verification - 5th Screen Optional Parameters ....... 38

4.2.1.3.1 Evaluations of an ISO/IEC 15416 - 6th Screen, Error List ......................................... 38

4.3

Adjustments / Selection of the Correct Aperture........................................................ 39

4.3.1

6, 8 and 10 mil Apertures.......................................................................................... 39

4.3.2

20 mil Aperture (Option)............................................................................................ 39

4.4

Settings / Button Functions / Setup Menu ................................................................. 42

4.4.1

General Button Assignments and Operating Functions............................................. 42

4.4.2

Buttons with Special Functions ................................................................................. 44

4.5

Setup Menu Structure ............................................................................................... 46

4.6

Setup Main Menu "Configuration" with 6 Sub-Menus................................................ 46

4.6.1

Setup Sub-Menu 1 - Measurement Archive............................................................... 46

4.6.2

Setup Sub-Menu 2 Calibration .................................................................................. 47

4.6.3

Setup Sub-Menu 3 Settings with 9 Additional Sub-Menus......................................... 47

4.6.3.1

Setup Sub-Menu 3 Settings - Sub-Menu 1 Code Type Selection - Code Type Tables47

4.6.3.1.1 Code Selection ......................................................................................................... 49

4.6.3.2

Setup Sub-Menu 3 Settings - 1 Code Type Selection - Additional Verification Criteria50

4.6.3.2.1 The EAN / UPC Code Family.................................................................................... 50

4.6.3.2.2 EAN-13 - Additional Verification Criteria.................................................................... 50

4.6.3.2.3 UPC-A Code - Additional Verification Criteria............................................................ 52

4.6.3.2.4 EAN-8 Code - Additional Verification Criteria ............................................................ 53

4.6.3.2.5 UPC-E Code - Additional Verification Criteria............................................................ 53

4.6.3.3

The Code 128 Family................................................................................................ 54

4.6.3.3.1 GS1-128 - Additional Verification Criteria.................................................................. 54

4.6.3.3.2 The GS1 DataBar Code Family................................................................................. 56

4.6.3.3.3 RSS / GS1 DataBar Code - Additional Verification Criteria ....................................... 56

4.6.3.3.4 The Code 39 Family.................................................................................................. 56

4.6.3.3.5 Code 39 - Additional Verification Criteria................................................................... 56

4.6.3.3.6 Code 39 – Full ASCII - Additional Verification Criteria............................................... 57

4.6.3.3.7 PZN Codes - Additional Verification Criteria.............................................................. 58

4.6.3.3.8 Codabar - Additional Verification Criteria (Optional).................................................. 58

4.6.3.3.9 ITF-14 Code - Additional Verification Criteria ............................................................ 59

4.6.3.3.10 2/5i Code - Additional Verification Criteria................................................................. 59

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 4 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Table of Contents / Page 3

4.6.3.3.11 Plessey Code - Additional Verification Criteria (

Not Yet Available in the Current Version

)60

4.6.3.3.12 MSI Code - Additional Verification Criteria ................................................................ 60

4.6.3.3.13 Pharma and Mini Pharma Code - Additional Verification Criteria............................... 61

4.6.3.3.14 Setup Menu 3 Settings - 2 Aperture.......................................................................... 61

4.6.3.3.15 Setup Menu 3 Settings - 3 Evaluation ....................................................................... 61

4.6.3.3.16 Setup Menu 3 Settings - 3 Evaluation - First Sub-Menu Page................................... 62

4.6.3.3.17 Setup Menu 3 Settings - 3 Evaluation - Second Sub-Menu Page.............................. 62

4.6.3.3.18 Setup Menu 3 Settings - 3 Evaluation - Third Sub-Menu Page.................................. 63

4.6.3.3.19 Setup Menu 3 Settings - 3 Evaluation - Fourth Sub-Menu Page ............................... 64

4.6.3.4

Setup Menu 3 Settings - 4 Unit Configuration with 8 Sub-Menus .............................. 65

4.6.3.4.1 Setup Menu 3 Settings - 4 Unit Configuration - 1 Operating Modes .......................... 65

4.6.3.4.2 Setup Menu 3 Settings - 4 Unit Configuration - 2 Output Parameters........................ 67

4.6.3.4.3 Setup Menu 3 Settings - 4 Unit Configuration - 3 Options......................................... 69

4.6.3.4.4 Setup Menu 3 Settings - 4 Unit Configuration - 4 Date and Time .............................. 69

4.6.3.4.5 Setup Menu 3 Settings - 4 Unit Configuration - 5 Network Parameters ..................... 70

4.6.3.4.6 Setup Menu 3 Settings - 4 Unit Configuration - 6 Password...................................... 70

4.6.3.4.7 Setup Menu 3 Settings - 4 Unit Configuration - 7 Company/User Information ........... 71

4.6.3.4.8 Setup Menu 3 Settings - 4 Unit Configuration - 8 Printing Parameters ...................... 71

4.6.3.5

Setup Menu 3 Settings - 5 Code Comparator (Option Only)...................................... 72

4.6.3.6

Setup Menu 3 Settings - 6 Article Search (Option Only)............................................ 73

4.6.4

Setup Menu 5 Article Trigger (Option for Article Database)....................................... 73

4.6.4.1

Setup Menu 3 Settings - 7 RESET to Factory Settings ............................................. 73

4.6.4.2

Setup Menu 3 Settings - 8 USB Update.................................................................... 74

4.6.4.3

Setup Menu 3 Settings - 9 Language........................................................................ 74

4.6.5

Setup Menu 4 Document Editing (from Version 1.0.8.12).......................................... 74

4.6.5.1

Setup Menu 4 Document Editing "Order Number"..................................................... 75

4.6.5.2

Setup Menu 4 Document Editing "User Comment" ................................................... 75

4.6.5.3

Setup Menu 5 System Information............................................................................ 76

5.

Appendix Standards and Literature on Bar Code Verification Units........................... 77

6.

Appendix Glossary of Technical Code Verification Terms ........................................ 79

7.

Appendix Technical Data - REA ScanCheck 3n........................................................ 82

7.1

Appendix Technical Data - PoE Power Supply / Charger for REA ScanCheck 3n.... 84

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 5 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Table of Contents / Page 4

8.

Intellectual Property Provision................................................................................... 85

9.

Environmental Protection.......................................................................................... 85

10.

Appendix - Warranty Terms ...................................................................................... 86

11.

Appendix - CE Conformity Statement for REA ScanCheck 3 .................................... 87

12.

Appendix ISO/IEC Conformity Certificate for REA ScanCheck 3............................... 88

13.

Appendix - Conformity Confirmation for Verifier Calibration Card.............................. 89

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 6 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

1. Introduction

The REA ScanCheck 3n is a mobile bar code verification unit for zero-contact inspection of the quality

of printed linear and stacked bar codes. It can be used in a portable manner on site for quick

evaluation. The verification result "good" or "error" is represented both by acoustic signals and visually

by means of multi-colored LED displays. The detailed measurement results can be stored in the

internal memory and shown on the color display. The evaluations can also be printed out with an

optionally available record printer. With the optional expansion, the ScanCheck3 can also be

connected to a PC with the REA TransWin32 software for remote control and evaluation via network

cable.

The important details of the evaluations can be read on the color display.

The arrow buttons can be used to page forward and back to additional menu fields or screen pages.

The additional detailed information can be provided via the printing of records. The unit is consequently

well suited for use in printing process control and quality control of codes on products in goods

receiving.

For evaluating film masters, applicability is limited to the reading and decoding of codes and

comparison of their content with a template.

All bar code evaluation units from REA Elektronik GmbH offer code evaluation according to the

ISO/IEC 15416 standard. The measurement and evaluation of additional, optional parameters is

additionally available. With these evaluation parameters (previously called traditional measurement

values), more detailed requirements can be evaluated, particularly for optimization of the printing

process.

Evaluations according to ISO/IEC 15416 are also known as CEN or ANSI evaluations and are also

described as ISO evaluations. In North America, the standard methods ANSI X3 182-1990 and

ANSI/UCC5 apply. The European standard EN 1635 has meanwhile been retracted (CEN evaluation).

The measurements, formerly called "traditional evaluation," are replaced by the optional parameters.

Optional parameters are based on the respective symbology standards. For EAN/UPC codes, for

example, this is the standard ISO/IEC 15420. The evaluation of optional parameters can be

categorized in classes, as in ISO/IEC 15416. This enables one to obtain a clear evaluation result,

based on previously specified, individual quality requirements.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 7 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

1.1 Documentation Conventions

In order to be able to clearly represent complicated subject matter, a special depiction was selected for

each of specific processes.

• If a specific button is to be pressed or a selection made from a list, this is described in angle

brackets: <Tab>

• Buttons to be pressed in sequence are placed adjacent to one another in the textual depiction:

<Menu> <8> <OK>

• Program names and window titles are printed in bold

• Text inputs are shown in square brackets: [File Name]

• Upon calling up programs, the program names (bold) are not set in square brackets. Any text inputs

(parameter/path/file name...) related to the program call, however, are in square brackets for

identification: BCT_SEND [File Name]

• The calling of executable files (file extension: EXE and BAT) is normally completed with the <OK

Enter> button. In order to increase comprehensibility of the depiction, "…process is

started/confirmed with <Enter>" is omitted on the depiction and explanation in most cases

• Cross-references to other chapters are set in " " and printed in italics: (See Chpt. "xxx" page xx)

Warning notices indicate operations that must be observed in order to protect the operator, the

unit and the data from damage. They are specially highlighted in a frame.

Good to know

Information that is important for better understanding and correct handling are supplied with

this symbol and shown in a frame.

1.2 Safety Instructions

This REA product was correspondingly developed, manufactured and inspected before delivery in

consideration of the current safety requirements of the corresponding standards for electrical safety. As

with any electrical device, it is important to know the possible risks and to operate it correctly. The

safety instructions were created in order to effectively protect the operator and other people nearby

from possible damage.

Before starting and operating the REA product, be sure to read and observe the operating instructions

and especially the safety instructions very carefully.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 8 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

1.3 Determination of Serial Numbers on the REA Product

For contact with the manufacturer or a system partner, it is important to

indicate the precise type and the serial number of the affected REA

product. This information can be found on the company label on the

hardware together with the article number.

Please notate this information on your delivery documents and always

use it when corresponding with REA Elektronik or an authorized system

or service partner.

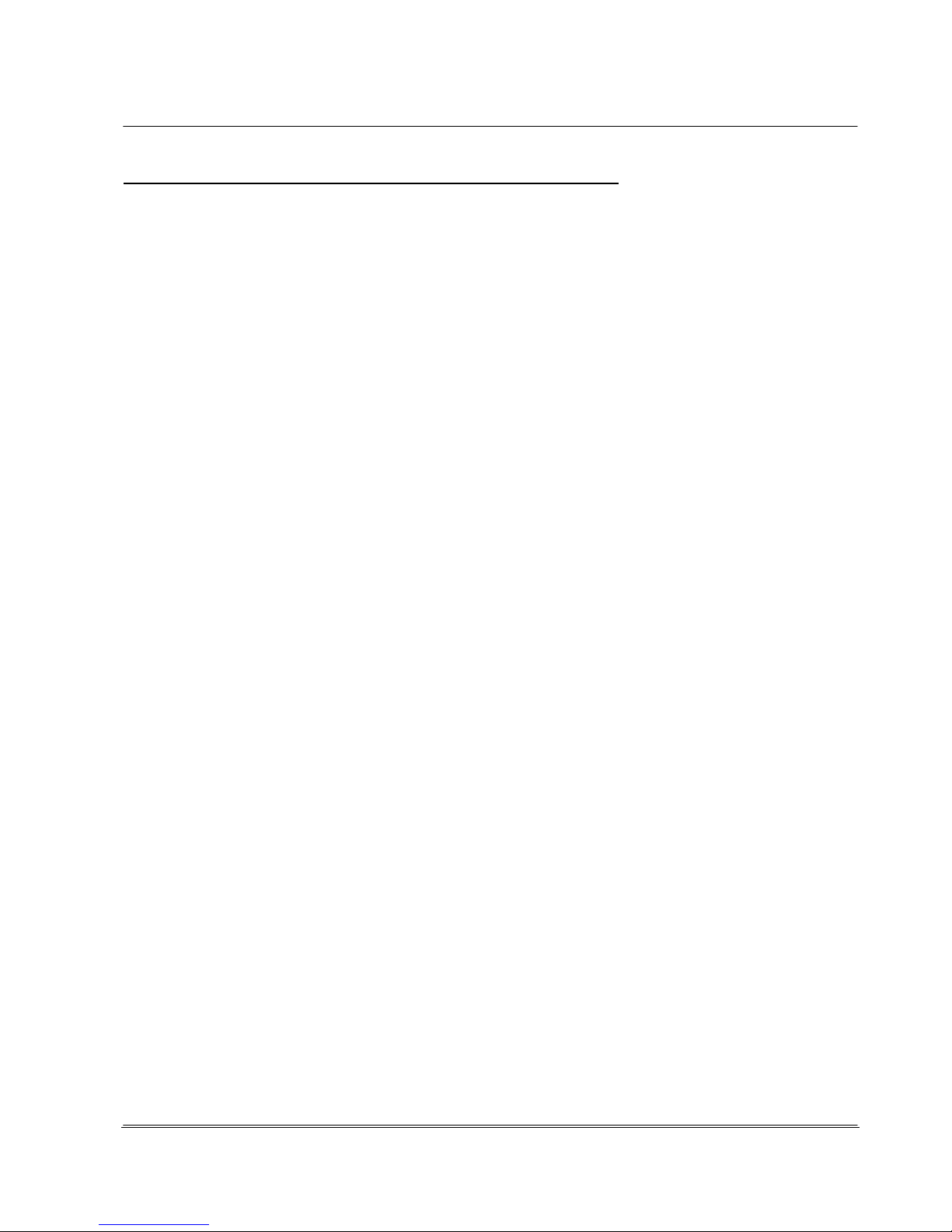

If the unit is already in operation, the system information can be called

up from the Setup menu via the menu item "5 System Info."

Button sequence: <Setup> <5 Systeminfo>

Version of operating program (GUI software)

Version of core operating software

Version of verifier evaluation software

Serial number of the unit. 0030.207.106-0XXXX-X

This should be identical to the serial number on the ID plate.

The unit name: Standard: SC3_Master

User name: Standard: SC3 User

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 9 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

2. The Delivery Components of the REA ScanCheck 3n

In the standard version, the REA ScanCheck 3n is supplied in the following configuration and always in

a specialized transport box with form insert.

A REA ScanCheck 3n consists of the following components

(Network PoE version from May 2009):

• Bar code verification unit REA ScanCheck 3n

• Calibration card for white balance and code size calibration incl. protocol of a reference

measurement for verification tool monitoring

• Operating manual (this document)

• Transport box with special fitted foam, optional transport case

• Four rechargeable Mignon NiMH AA batteries (already installed in the REA ScanCheck 3's

battery compartment)

• 1 PoE power supply (100 - 240 volts~; 0.4A; 50-60Hz~) with cold unit socket according to

IEC-60320 C5 / C6

• Power connection cable with cold unit plug and power plug for the standard ordered (Euro, UK,

USA)

• 2 network cables, highly flexible, RJ45 CAT5, approx. 2 m long

• 1 cross-over adapter for using a network cable with rotated connections

• 1 CD-ROM with all REA Verifier documents and program files

A REA ScanCheck 3 consists of the following components (USB version up to May 2009):

• Bar code verification unit REA ScanCheck 3

• Calibration card for white balance and code size calibration incl. protocol of a reference

measurement for verification tool monitoring

• Operating manual (this document)

• Transport box with special fitted foam, alternatively transport case

• Four rechargeable Mignon NiMH AA batteries (already installed in the REA ScanCheck 3's

battery compartment)

• Universal plug power supply (100 - 240V), secondary 9V, with connection cable with low

voltage hollow plug socket

• Primary plug adapter (EURO, UK or US according to delivery country, already installed)

• Connection cable for data interface and charge unit (cable with CompShield plug, hollow plug

and USB plug, type A)

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 10 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Options / Alternatives (only present if ordered, see delivery note)

Hardware:

• Extension plate made of Plexiglas with 82.5 mm cut-out

• Extension plate made of Plexiglas with 175 mm cut-out

• 20 mil adapter for using the 20 mil aperture function

• Portable protocol printer, type TD-GPT-U with 2 rolls of thermal paper

• Connection cable for protocol printer

• Power supply for protocol printer

• Unit case in place of cardboard packaging, black, plastic

Software:

• REA TransWin32 PC program with operating manual for capturing, evaluation and saving

measurement protocols on a PC with MS-WINDOWS operating system;

this program is most often used as an alternative to the protocol printer (internal software option

usable via activation code)

• Article database software with operating manual (internal software option usable via activation

code)

• Code comparator function (internal software option usable via activation code)

• Optional code types (internal software option usable via activation code)

All software options can be freely activated and operated exclusively with the serial number of a REA

ScanCheck 3n. A REA ScanCheck 3n will not work with TransWin32 software or another software

option without the corresponding activation code if the activation key is not correct.

The license key is inseparably linked to the respective REA ScanCheck 3n.

Software options that are provided with a new unit are made available before delivery and require no

additional license key for activation.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 11 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3. Startup of the REA ScanCheck 3n

Special installation on the REA ScanCheck 3n is no longer required. It is delivered ready to operate.

The unit is configured for a standard presetting and can inspect and evaluate most code types

according to the GS1 standard requirements immediately after activation.

The four NiMH batteries provided have an especially low discharge rate.

They are already installed in the battery compartment before delivery.

It is also possible to use 4 Mignon primary batteries instead of the 4 batteries.

In the case of heavily discharged batteries and no power supply

connection, the REA ScanCheck 3n can be activated briefly after

startup. The activation process is interrupted and the unit shows no

further response. In this case, the batteries are probably empty or

even incorrectly installed.

There is continuous monitoring of battery voltage during operation

with rechargeable (or non-rechargeable) batteries.

When the voltage reaches a critical threshold, an electronically

monitored charging process is started or completed.

If the operating voltage value sinks below a critical threshold, the unit

outputs a corresponding warning message and ends the operating

program, saving the settings.

Attention:

If the REA ScanCheck 3n is operated by non-rechargeable batteries instead of rechargeable

batteries, the power supply must never be connected. Connection of the power supply will lead

to destruction of the batteries and, with a high degree of probability, to the destruction of the

unit as well.

Any manufacturer's warranty is thereby voided.

When the PoE power charger is correctly connected, the recharging of the rechargeable batteries

takes place automatically and is monitored electronically (see also Chapter 3.4.1). Over-charging or

over-heating is monitored and prevented by corresponding protection circuits.

If the unit is operated during the charging process, the complete charging of the rechargeable batteries

will take correspondingly longer than it would with the unit deactivated.

The unit also operates properly if no rechargeable batteries are installed, only one cell is missing but

the power supply is correctly connected and connected to the mains voltage.

Upon removal of the connection cable, however, all programs will immediately end without saving data

or settings and without pre-warning.

If the rechargeable batteries are heavily discharged, there is risk that the rechargeable batteries will not

be recognized by the charging circuit (charging LED remains off). In this case, the rechargeable

batteries must be replaced. In some cases, the rechargeable batteries can be reactivated by an

external charger with single-cell charging.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 12 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.1 Activation and Deactivation of the REA ScanCheck 3n

The device is activated by pressing the red <ON> button.

Upon initial activation, the green "On LED" lights up. It takes 30-50

seconds until all programs are initialized. Only then does the main screen

appear as shown at right.

Once the REA ScanCheck 3 has been activated, it can be deactivated by

pressing the <ON> button again.The display then opens the menu window

for various modes.

The colored focus can be moved to the desired command with the arrow

keys and then confirmed with the <OK Enter> button.

The digit in front of the menu item can also be activated by pressing the

corresponding number button <1...6> and thereby immediately initiating the

desired function.

1. Sleep Mode

Sets the unit to a power-saving sleep mode in which the display

and other drivers are deactivated and the processor continues to

operate at the lowest power consumption.

It can be immediately reactivated from this mode by pressing the

<ON> button. The sleep mode should be activated automatically

via the unit settings after a pre-specified time in order to save

power in rechargeable battery mode.

2. Shut down device

Completely deactivates the unit and closes all programs. You

should select this function when the unit will not be used for an

extended period, such as at the end of measurements or work day.

A minor amount of energy is also required from the rechargeable

batteries or power supply in this operating mode.

3. Reboot device

A restart of the complete system can be carried out with this menu

item. Executing this command can be helpful if the unit no longer

responds as expected.

4. Terminate GUI (Graphical User Interface)

This can be used to close the program for the graphical user

interface. Execution of this command is only useful for service

purposes.

The REA ScanCheck 3n display becomes black/white.

The operating system only displays the text line editor. This then

responds only to corresponding text commands.

The cursor blinks at the first position of the entry field after

indication of the operating system version number

(0.9 in this case)

#_

Entering the following command sequence can restart the GUI:

<1>, <OK Enter>.

The restart takes several seconds.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 13 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

The REA ScanCheck 3n can also be completely deactivated from this menu with the key

sequence <ON>, <OK Enter>.

If a software update is carried out with a USB memory stick in this operating mode, this can be

started with the command sequence <6>, <OK Enter>.

5. Reboot Verifier

With this menu item, the verifier program for the code evaluation can also be restarted. A

restart can be useful if, for example, data communication with the PC program no longer

responds normally.

3.1.1 Reactivation of the REA ScanCheck 3n after Power Supply Failure

If the unit is suddenly disconnected from power, such as by removal of one of the batteries, by deep

discharging or by separation of the mains supply in an operating mode without installed

batteries/rechargeable batteries and without proper closing of programs, the unit cannot be restarted

immediately upon first pressing the red <ON> button.

Upon initial activation after a crash of this kind, all improperly closed programs must first be reinitialized

and properly closed. The screen then remains dark, the green "On LED" goes out and the unit remains

deactivated.

The unit is not properly started until pressing the red <ON> button again.

The green "ON LED" lights up and after the activation delay, the unit operates properly again.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 14 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

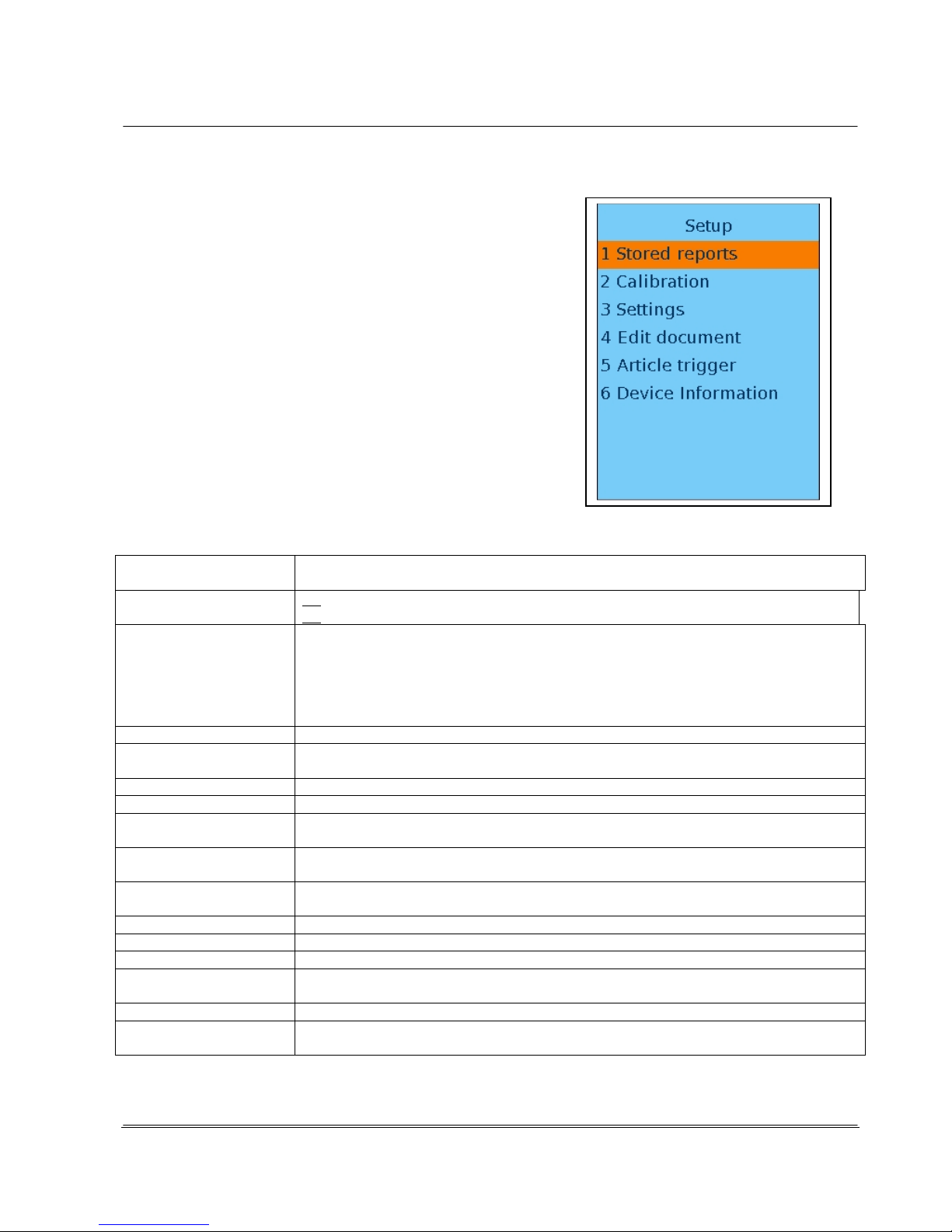

3.2 Changing Presets on the REA ScanCheck 3n

The REA ScanCheck 3 is configured to a standard

configuration, the "factory settings," ex factory or after a

RESET, with which most user bar code verifications can be

carried out immediately and without additional settings.

In order to be able to make basic and other individual presets

for operation on the unit, <3 Settings> can be selected in the

menu that appears after pressing <Setup> and confirmed with

<OK>.

Any sub-menu window can be closed without accepting

changes to the settings by pressing the <ESC> button. The

top-level menu window is then displayed again.

3.2.1 Standard Parameters of Factory Settings

Operating Mode

Unit switches to power saving mode after 10 min.

Unit shuts down completely after 60 min.

Output Parameters:

No automatic print output after a measurement

No automatic saving of measurements

Code Type Selection:

According to standard code list. Searching all possible code types; the respective

structure verification is not active.

In the case of GS1 codes, EAN structures and module sizes are verified and

evaluated.

The size verification takes place for the respective general tolerance range.

The verification of AI file contents is deactivated.

Aperture:

6 mil

Evaluation:

According to ISO/IEC standard 15416 incl. verification and evaluation according to

respective code standard for all optional parameters

Optional Parameters:

All parameters are switched active for display and for evaluation

Selected Class:

Only parameters with grade / class 3 and better result in total result "Good"

Number of

Measurements:

3 measurements are preset when selecting multiple measurement. Non-decoded

individual measurements are not considered in the total evaluation

Metric Deviations:

Indicators for bars - gaps - E-value - P-value are indicated as relative values in [%]

rounded up or down to "5"

Optional Software

Expansions:

Activated as previously, e.g.: Code comparator, article database function, etc.

Language:

English

Day and Time:

Unchanged

Network Settings:

Unchanged

Company/User

Information:

Unit name, user name, company information are overwritten with the REA factory

specifications

Password:

Overwritten with spaces

Format of Report PrintOut:

Long version complete, prints all elements that can be selected

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 15 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.2.2 Change Menu Language Selection

The unit is preset to the national language of the delivery country

before shipment. It can happen that the operator desires a

different menu language than the one that is preset.

The language selection can be changed via the keyboard

commands <Setup>, <3 Settings> <9 Language>.

The desired language can be selected from the list in the submenu by moving the orange-colored focus to the desired

language field with the arrow buttons and then confirming by

pressing the <OK Enter> button. The field in front of the

language changes correspondingly and is activated.

With the <Store> button or the cursor on <OK> and confirming

with <OK Enter>, the new language setting is accepted.

From that point on, all menu dialogues and the texts of the

reports will be output in the newly selected language (English, in

this case).

The provision of additional languages is also scheduled for

future software versions.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 16 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.2.3 Change Data Output Parameters

Back to the sub-menu for the settings.

The sub-menu for the possible settings follows.

With <4 Unit Configuration>, another sub-menu appears in which the

basic settings can be made.

Under the sub-menu "1 Operating Mode Settings," it can be set:

• whether and at what interval the unit switches to sleep mode or

deactivates completely after the last operation

• whether the installed signal tone encoder is activated or deactivated.

Under the sub-menu "2 Output Parameters," it can be selected in another

sub-menu:

• whether the measurement reports are to be automatically or manually

printed on the connected report printer

• whether the output of the measurement reports should take place via

the connected report printer.

If the TD-GPT-USB printer is to be used to create measurement

reports on site, this menu item must be activated.

The corresponding measurement reports are then always printed when

the button <Print L> or <Print S> is pressed on the REA ScanCheck

3n.

• If the unit is connected via the connection cable to the PC on which the

evaluation software REA TransWin32 is installed and operated and if

the activation code for operating with this software has been entered on

the unit and activated, the evaluations of the measurements can

additionally be executed via the PC program REA TransWin32.

• Whether the measurement reports should always automatically be

saved in the memory of the REA ScanCheck 3n

• or saving should only take place upon command

• or only when explicitly commanded with the <Store> button

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 17 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.3 Operating REA ScanCheck 3n with Report Printer

The REA ScanCheck 3n verification unit can also be operated together with the portable report printer

type REA TD-GPT-U.

The printer is first connected with the supplied connection cable via the Mini USB plug and then with

the Type A USB plug to the USB socket to the lower face of the REA ScanCheck 3.

The printer has its own power supply via an installed battery.

This must be completely charged before use with the supplied printer power supply.

(see also operating manual for the portable printer REA TD-GPT-U).

A compact plug charger for charging the internal battery with 6 volts of output voltage is supplied with

the printer. Interchanging the plug power supply for the REA ScanCheck 3n is not possible. The

specifications in the REA TD-GPT-U operating manual must be observed for all other operating

instructions for the report printer.

Operation with other printers is not possible and not intended.

The predecessor model REA ScanCheck 3, which could be connected to a PC via USB, was supplied with a 9V

power supply. The printer power supply and the ScanCheck 3 power supply could be interchanged in this

configuration.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 18 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.4 REA ScanCheck 3n with PC Evaluation Software

The REA ScanCheck 3n can be operated independently, connected to the portable REA TD-GPT-U

printer as well as on a PC with optional PC software programs REA TransWin32 or REA Article

Database 32.

The unit has 2 different plug sockets on the lower face for

the corresponding connections. The REA ScanCheck 3n

can be connected with the report printer with the right

USB host port, type A, via the supplied USB connection

cable and verification reports can thereby be printed out.

Via the left-hand RJ45 type network port, the

REA ScanCheck 3n can be connected to the supplied

PoE power supply via the supplied network cable and

operated. The network cable provides the external power

supply as well as data communication via TCP-IP protocol. The connection options are described

below.

The software REA TransWin32 is not included in the standard scope of delivery of a REA ScanCheck 3n. If

REA TransWin 32 was ordered, the necessary license key is already stored in the verification unit ex

factory. If not equipped until later, a license key supplied with the delivery note must be entered on the unit

(see Chapter 4.6.3.4.3).

The PC used for the program REA TransWin32 should have the following hardware configuration at

minimum:

- CPU processor with 1.5 GHz and at least 1 GB RAM

- Hard drive with at least 500 MB of free storage space

- Color graphics card with minimum resolution of the monitor

- 1 CD-ROM or DVD drive

- 1 free USB 1.1 interface (for connecting REA ScanCheck 3, REA PC-Scan)

- 1 serial interface (for connecting REA PC-Scan, REA ScanCheck and REA ScanCheck II as well as

REA Check 3)

- 1 color monitor with at least 1280 x 1024 pixel resolution or more

The software configuration should be at least the following:

- Microsoft Windows 2000 with SP4, Windows XP with SP2 or Windows Vista

- .NET Framework from vers. 2.0

- Microsoft Internet Explorer IE from version 6.0

- Microsoft Windows Installer from version 3.1

The software was successfully tested with operating software versions Microsoft Windows 2000 with

Service Pack 4, Windows XP Professional with Service Pack 2, Windows 7 and Windows Installer 3.1.

Additional details on unit connection to the PC network can be found both in the manual for

REA TransWin32 and in the separate document on network installation of REA Verifiers on the REA Verifier

CD-ROM.

Administrator rights are required for installation of the software and configuration on the PC. If the user

account does not have administrator rights, the installation aborts with a corresponding error message.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 19 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.4.1 Connection of the REA ScanCheck 3n to Power Supply

The REA ScanCheck 3n can only be operated for a limited

time via the supplied and installed rechargeable batteries

independent of the power supply.

No later than when the unit outputs the warning message

"Batteries empty," the REA ScanCheck 3n must be connected

to the power network via the PoE power supply included in the

scope of supply and with the supplied network cable. The plug

types are specified in the standard IEC 60320. The socket on

the power supply has type C6 and the plug on the connection

cable has type C5.

The "Data In" socket must be connected to the existing network

installation.

The "Data Out" socket must be connected to the REA

ScanCheck 3n with the help of one of the supplied network

cables. The "Data Out" socket supplies the power supply for the

REA ScanCheck 3n and, simultaneously, the interface for the

network data communication.

3.4.2 Network Installation

No driver installation is required for the REA ScanCheck 3n. No network configuration must be made,

either, as this normally takes place automatically (basic setting ex factory).

The REA ScanCheck 3n is connected to the PC via the network. The cabling can be implemented as

follows:

• The PC and the REA ScanCheck 3n are each connected to one network connection socket in

the room (DHCP mode)

• The PC and the REA ScanCheck 3n are connected directly (ZeroConfig or fixed IP address)

• The PC and the REA ScanCheck 3n are connected via an Ethernet switch (ZeroConfig or fixed

IP address)

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 20 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

• The PC and the REA ScanCheck 3n are connected via an Ethernet switch and the Ethernet

switch is connected to the network (DHCP mode).

DHCP Mode: The PC and the REA ScanCheck 3n are in the company network and obtain the network

configuration via the DHCP server. This mode is active in the factory settings.

ZeroConfig Mode: The PC and the REA ScanCheck 3n are connected directly.

Because no server can be reached (due to the direct point-to-point connection), the

setting falls back to the no-configuration network setting (called ZeroConfig). This

mode is active in the factory settings. The PC network adapter reports the status

"Limited or no connectivity."

ZeroConfig mode is reached after a wait time of about 1 - 2 minutes. During the waiting period, the PC

displays a network icon with a moving yellow dot in the status bar. No connection is possible in this

status.

When the automatic configuration is complete, the network icon is displayed with the

yellow exclamation mark. Communication is now possible and active.

Fixed IP Address Mode: Fixed addresses are issued by IT administration. This mode must be

manually adjusted.

The settings on the REA ScanCheck 3n must be set to DHCP "ON" and ZeroConfig "ON" (factory

settings). The setting only has to be changed if manually fixed IP addresses are to be issued.

3.4.2.1 Firewall

A so-called firewall is always activated on correctly configured PCs. The firewall may not block the

network communication between the PC and the REA ScanCheck 3n.

3.4.2.2 MAC Addresses

Every network-capable device receives a hardware address or a hardware serial number,

which is unique worldwide. This number is called a MAC address. If only known devices are integrated

into the user network for security reasons, this MAC address must be entered in the system (see

Display Network Configuration in Chapter 3.4.2).

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 21 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.4.2.3 Technical Functionality Test of a Network Connection

The TCP/IP connection can be inspected with

Windows help programs.

Select the following with the left mouse button:

<Start>, <All Programs>, <Accessories> and

then click on <Command Prompt> with the left

mouse button.

A new window with the command prompt

opens.

Computer commands oriented by text lines (as

in a DOS program) can be entered here.

Enter the command <ping 192.168.222.22> in the command prompt and confirm with ENTER. The IP

address must be the respective IP address of the connected REA ScanCheck 3n.

Attention: other IP addresses are used in this image as examples.

After a few seconds, new text lines appear with specifications on the response times of the pinged IP

address or error messages.

With this test, it can be determined whether the TCP/IP connection between the IP address of the REA

verification unit and the IP address of the PC network interface is generally functioning.

If there is no reply shown like in the image above or there is an error / timeout message, the installation

must be checked and corrected.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 22 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.5 Use of Extension Plates on the ScanCheck 3

Transparent extension plates with various cut-out widths can be used as accessories for the REA

ScanCheck 3n. To do so, the standard-installed trapezoidal transparent base plate is removed and

replaced by one of the extension plates.

Extension plate with 82.5 mm cut-out Extension plate with 175 mm cut-out

The use of extension plates is always recommended when labels or films must be pressed flat on the

underlay because otherwise the label material can wrinkle up.

They are indispensable if codes must be measured on round surfaces (e.g. barrels, cans, etc.). They

are also required if bar codes must be measured at positions or on articles with too small of a surface

for positioning the unit.

Attention:

Extension plates must always be removed for calibration.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 23 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.6 Charging the Batteries

4 NiMH Mignon batteries (size AA) are included in the battery compartment of the unit upon delivery.

These have been inspected, charged and installed in the battery compartment before delivery. With

new and completely charged batteries, the REA ScanCheck 3n can be operated without interruption for

about 2 to 3 hours. If the energy-saving function is used for automatic deactivation of the unit, the

operating time can be significantly extended.

To charge the batteries, they do not normally have to be removed. The PoE power supply is simply

connected with the network cable and connected to a socket with its mains plug. The green LED on the

power supply lights up for verification.

In addition, a supplied network connection cable is connected to the "OUT" socket on the power supply

and the RJ45 socket on the REA ScanCheck 3n (see also Chapter 3 and 3.4).

The charge time equals at least approximately 4 hours with empty batteries. During charging, the righthand green LED underneath the display with the label "charge" lights up on the REA ScanCheck 3n.

It goes out once the charge is complete and no further charging is carried out or if the power supply is

emitting no voltage. In cases of emergency, operation with Mignon batteries (non-rechargeable primary

cells) is permitted.

Attention:

REA Elektronik does not recommend using non-rechargeable primary cells (Mignon batteries)

in the REA ScanCheck 3n. These may never be charged. If the charger is connected by

accident, there is risk of damaging or destroying the batteries and the unit with the charge

current.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 24 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.7 Storage and Transport

The REA ScanCheck 3n is a valuable verification unit with highly precise optical and electronic

assemblies. It should always be stored and transported protected in the custom-fit foam forms in the

supplied original box or in the optionally available transport case. Both the unit parts and additional

accessories are optimally protected against dust collection and shock and damage.

If the unit is not stored in the original packaging, it should always be stored with a covering,

protected from dust and humidity and at room temperature and only in enclosed spaces.

The unit with all accessories should be operated on a dust-free verification station intended for

this purpose, only under observation of the indicated operating instructions.

In order to obtain knowledge for optimal use of all operating and evaluation options for optimal

code production, participation in one of the corresponding basic and user trainings by the

manufacturer REA or its agencies is highly recommended for the user.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 25 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.8 Updating Operating Software in REA ScanCheck 3

The REA ScanCheck 3n operates with its own embedded computer system and software programs

installed upon it. This software is always up to date upon delivery.

REA will work on improvements and updates in the future and provide these to customers in order to

update their units. REA places the latest versions on the Internet in the Support area for download.

The address is:

http://support.rea-verifier.de

The data required for access are:

Username: REA_Verifier, Password: REA-C36754

An update can be made in various ways:

• By USB memory stick

• By using the update program that is located on the supplied CD-ROM. The PC program thereby

communicates with the REA ScanCheck 3n via the network interface on the PC and the

supplied connection cable (see Chapter 3.4).

To use the update program, the PC requires the Microsoft ".Net Framework" program, in

version 2.0 or newer.

Attention:

The charger should always be connected during the update.

If the ScanCheck is deactivated during an update due to empty batteries, it must be shipped to

the manufacturer for repair.

3.8.1 Updating Using a USB Memory Stick

This update requires a conventional USB memory stick with at least 10 MB of memory free and the

common FAT formatting. The software required for updating is available from REA as a compressed

(zipped) file.

This file must first be copied to a directory on the local PC and extracted there.

The software consists of at least 2 files:

• a Linux program "run"

without file extension and

• an update file with the name 'updatesc3.tgz'

Both files must then be copied from the PC to the

root directory (not a sub-directory) of a USB memory

stick.

Once the copy process is successful, the memory

stick can be removed from the PC.

Then insert the memory stick into the left-hand USB

port on the REA ScanCheck 3n.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 26 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Fig.: REA ScanCheck 3n with connected USB memory stick

In order to start the update program on the REA ScanCheck 3n, activate the REA ScanCheck 3n with

the <ON> button and wait until the start screen is displayed.

Then select and press the following keys in sequence:

<Setup>, <3> or "Settings", <8>, or "USB Update"

Older versions (GUI below 1.06):

The operating program window must be closed for an update. To do so, press the <ON> button, then press the button <5>.

The program confirms with the message: “Terminate GUI”. After 10 to 15 seconds, the screen turns black and a command line appears. The update

can be started by pressing the button <6> (the 6 appears in the command line). Confirm with the <OK ENTER> button.

The "USB Update" menu page shows a selection of possible update files.

- The field "Application Update" must be selected to update the main program.

- To update the dialogue language files, the "Language Update" field must be selected.

- To update an article database, the "Article Database Update" field must be activated. (This function is

only optional and active after acquiring the corresponding license).

After a short time, the REA ScanCheck 3n starts with the update program.

The graphical interface is closed. The screen turns black and there are no other displays on the screen

for some time. Attention: the update requires approx. 3 to 5 minutes.

The unit then automatically carries out a RESET/restart and then displays the start screen again. The

updated version number should now appear in the version display.

Start screen

Setup

Settings

USB-Update

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 27 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Attention:

No button may be activated on the unit during the update process. Pressing a button can disrupt the

updating program or even cancel it. The existing operating software may then be defective. The unit no

longer responds. The batteries/rechargeable batteries must be removed from the battery compartment

for a RESET or the unit must be sent back to the manufacturer for repair.

If the update should fail for other reasons, the update program is

interrupted and a corresponding error message is displayed on the

screen.

This must be read and confirmed by pressing the <OK> button.

The unit then goes back to the setup menu screen. An update has

not been carried out, however. If you cannot resolve the error

yourself, the details of the error message should be notated and

the manufacturer contacted.

Return to the main menu with <ESC>.

3.8.2 Updating with the "Update Program" from the

REA CD-ROM

To carry out an update, the PC program must be loaded onto a PC and started. The program required

for this is called UpdateServer.Exe.

It can be downloaded separately from the enclosed CD-ROM to a PC with the Windows operating

system or started from the program REA TransWin32 from the menu bar (see operating instructions of

REA TransWin32 for installation instructions).

To use this software, network communication must be established between REA ScanCheck 3n and

the network interface on the PC. The supplied network cable and the PoE power supply are required

for the connection (see Chapter 2).

Once the program has started, the following screen

appears on the desktop:

The new update file must first be found with the

browse function on the PC and highlighted.

Press the <...> button after the "Update File" field.

The PC file explorer opens. Find the corresponding

directory and select the desired update file

"updatesc3.tgz" by clicking on the right mouse

button.

Confirm by pressing the <Open> button.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 28 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

The connected REA ScanCheck 3n must now be

selected from the list of possible REA verification

units by selecting it with a click on the left mouse

button.

The REA ScanCheck 3n appears in the list e.g.

with the name "SC3n_PoE-Master." If more than

one unit is listed with the same name, the

individual units can be differentiated by the

different information in the Description column

based on the different serial numbers. Ensure

that you have selected the correct unit and click

the <OK> button for confirmation.

The REA ScanCheck 3n must be activated and

the sleep mode must be deactivated.

Activate the window with the Update Server

program. The selected unit in the unit list is

accepted by pressing the <ADD> button.

The "Update Server" program now looks as

shown at left. By clicking with the left mouse

button on the <Start Update>, the transfer

program can begin transferring the data to the

verification unit.

A progress display shows the progress in percent, from 0-100%. The transfer takes approx.

approx. 20 seconds, during which nothing appears to happen.

Only the label on the <Start Update> button changes to <Stop Update>.

When the data transfer is complete, the progress bar shows "complete" and a message appears that

the update files have been completely transferred. The update program can then be closed by pressing

the "Cancel" button.

After a short time, the REA ScanCheck 3n then

starts with the update program. The light diodes

underneath the display then illuminate in

alternation. The screen then turns black and there

are no additional displays on the screen except for

a command line.

The update requires approx. 3 to 5 minutes.

The unit then automatically restarts and then

displays the start screen again. The updated

version number should now appear in the version

display.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 29 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Attention:

No button may be activated on the unit during the update process.

Pressing a button can disrupt the updating program and even cancel it. The existing operating

software may then be defective. If the unit no longer responds, it may need to be sent to the

manufacturer for repair.

Good to know

The unit has the standard factory settings again after an update.

All individual user settings must be made again.

3.9 Calibrating the REA ScanCheck 3n

Attention:

The REA ScanCheck 3n - like any other verification unit - should be recalibrated at regular

intervals of about 4 weeks. If the light conditions change severely, a recalibration must then

also be carried out immediately.

Calibration and measurement under the influence of direct sunlight leads to incorrect

measurement results.

In order to ensure that the unit operates properly and within its specifications, every 4 weeks:

1. carry out a white balance calibration with the white field of the calibration card and

2. measure the reference code (EAN Code 100 %) from the calibration card.

The individual results of the measurements must always lie within the specifications that are specified

in the conformity statement in the appendix of this documentation (see Chapter 3.9.3.1).

A stamped verification report of a measurement of the reference code with calibration card in new

condition is enclosed as a reference measurement. This measurement was created with a REA

reference verification unit: REA reference verification units are in turn regularly calibrated with external

reference standards for the contrast and metric values (by Applied Image, USA).

The calibration card should always be stored protected, may not be contaminated and should not be

touched on its surface. It should be replaced every 1 to 2 years by a new, original REA calibration card.

If the card was previously damaged or dirtied, immediate replacement is required.

Do not calibrate with a photocopy of the original calibration card because the metric and reflective

properties change due to the copying. For the same reason, the calibration card may also not be

laminated. Both would lead to false calibration and faulty measurement results.

Good to know

No extension plate may be installed on the REA ScanCheck 3n during calibration because these

restrict the reading field of the laser beam and falsify the reflection.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 30 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.9.1 Calibrating the REA ScanCheck 3n for 6, 8 and 10 mil Apertures

The calibration process can be selected from the Setup Menu. The key sequence <Setup>,

<Calibration> with the arrow buttons and <OK Enter> or the buttons <Setup> and <2> opens the

Calibration input window.

1. The value printed at lower right on the calibration card used

must be entered in the orange-colored field "reflection factor."

By pressing the <Store> button

or moving the active orangecolored input field with the arrow

buttons to the field OK and then

pressing the <OK ENTER> button, the entered reflection factor

for the white value of the calibration card is accepted into the

unit settings.

2. The REA ScanCheck 3n must be positioned on the marked

unit silhouette on the calibration card as shown in the figure

below so that the illuminated laser beam can pass over the

unprinted white field of the calibration card unhindered.

Pressing <Store> activates the laser beam. Please check

whether the laser beam fully lands in the white field.

3. Pressing the <OK ENTER> button starts the actual calibration

process for the white reflection value.

The laser beam then deactivates when the calibration is

complete. The completed calibration is effective immediately

for the 6, 8 and 10 mil apertures.

Fig.: REA ScanCheck 3n with white value calibration on the calibration

card

Good to know

A special calibration must be made for the use of the 20 mil aperture

(with the additional adapter foot).

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 31 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

4. After the adjustment, the unit reports: Calibration OK.

The calibration process is then complete. By pressing the

<Store> button, the program goes back to

the main screen.

5. The unit can be positioned for measurement in front of the

corresponding EAN -13 sample code for verification tool

monitoring (see Chapter 3.9.3).

3.9.2 Calibrating the REA ScanCheck 3n for 20 mil Aperture

For white value calibration for the measurements with the

20 mil aperture, the 20 mil adapter foot must first be

installed and the operating part moved to the front position

up to the stop.

The unit must then be positioned with its enlarged foot on

the center position in front of the white field of the

calibration card (dashed silhouette) such that the laser

beam illuminates the white surface unhindered.

The calibration steps 1 through 3 according to Chapter

3.9.1 must then be correspondingly repeated.

Figure: REA ScanCheck 3n with 20 mil adapter

A white value calibration is always required if the ambient light conditions have changed.

In order to verify whether white value calibration is required again at other locations, a calibration and

verification tool monitoring is first carried out at the normal unit location.

The verification tool monitoring is then repeated without renewed white value calibration on all other

desired measurement locations. If all measured values for all measurements remain within the desired

tolerances, no recalibration of the white value is required in the future when switching to the other

locations.

A dimensions calibration with the sample code on the calibration card is no longer required with REA

ScanCheck 3n. The unit was already calibrated in the factory to the corresponding size parameters

and adjusted by means of a factory calibration.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 32 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

3.9.3 Verification Tool Monitoring

Regular monitoring of the verification tool is indispensable in order to ensure that the comparability of

all measurement results. Through regular measurements and comparison of the evaluation results of

measurements of the same reference code sample with the calibrated REA ScanCheck 3n, you can

inspect whether the verification unit is still operating within the specifications indicated by the

manufacturer.

For this purpose, there are two test codes on the REA ScanCheck 3 calibration card that were printed

there with high precision.

The left-hand EAN-13 code, with a nominal size of 100%, should always be used for the verification

tool monitoring. This EAN code must always be calibrated in the same manner with the aperture of

6 mil and under consideration of the handling instructions (see Chapter 4.1). The REA calibration cards

have a serial number on the rear side and are always supplied together with the related REA reference

measurement report that bears the same serial number. The measurement results of the

REA ScanCheck 3n on site must be regularly compared with the measurements of this reference

report. As long as the deviations found in the comparison lie within the specified tolerances, the

following measurements are also comparable within the indicated specifications.

3.9.3.1 Allowable Unit Tolerances

The individual values of the control measurement must each be

compared to one another.

ISO/IEC evaluation, summary

(1st screen of evaluation)

Symbol Good 4/06/670

Code Type EAN13

Code content

4008654123454

ISO/IEC 15416 Parameters (1st screen of the evaluation)

(The values in the diagram are examples; use the reference report)

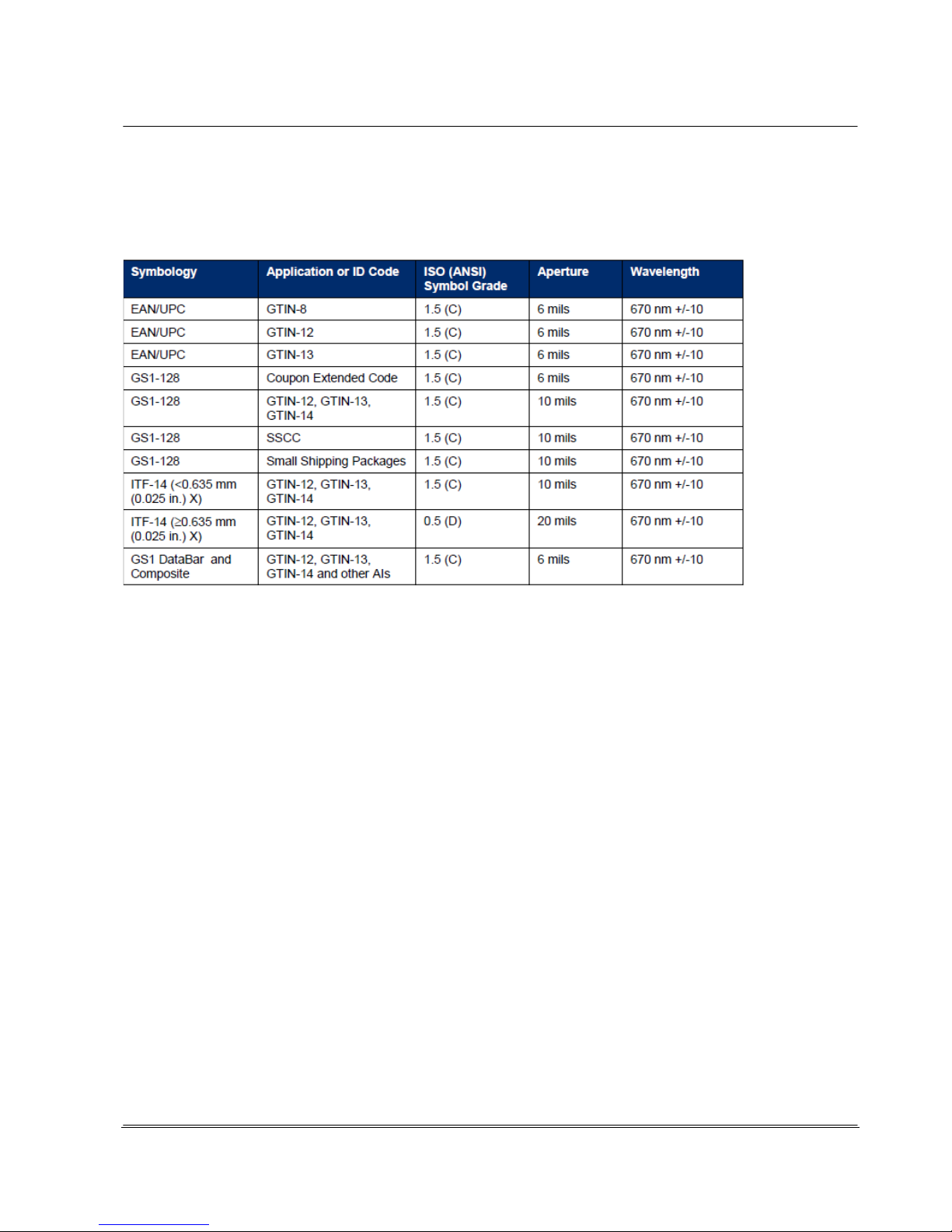

Parameter % Grade Allowable Tolerance

Decoding 4 Always Grade 4

Symbol contrast 80% 4 +/-8 %

Edge contrast 62% 4 +/-8 %

Modulation 79% 4 +/-8%

Rmin/Rmax 1% 4 +/-8%

Defect: 5% 4 +/-8%

Decodability 87% 4 +/-8%

Optional Parameters (2nd Screen of Evaluation)

Bar Width Deviation Allowable Tolerance Grade

Average Bar Width Deviation: +/- 5% (absolute +/-5 µm) 4

Maximum Bar Width Deviation: +/- 10% (absolute +/-10µm)

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 33 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

Optional Parameters (3rd Screen of Evaluation)

E-value deviation Grade

E-value deviation: +/-20 % (absolute +-10µm), Grade 4

Optional Parameters (4th Screen of Evaluation)

P-value deviation

P-value deviation: +/-20 % (absolute +-10µm), Grade 4

Optional Parameters (5th Screen of Evaluation)

Brightness value Rmax +/-5 %

Dark value Rmin: +/-3 %

Size: 100 % +/- 1 %

(corresponding. Z-Module 330 µm +/- 3.3µm)

In addition, a second measurement of the 200% EAN Code from the

right-hand side of the calibration card can be measured:

Size: 200 % +/- 1 %

(correspond. Z-Module 660 µm +/- 6.6µm).

A size error is only displayed if the measured value is greater than 201%.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 34 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

4. Operation of the REA ScanCheck 3n

The following chapters describe the operation and correct handling of the REA ScanCheck 3n. It must

always be noted that bar codes are measured and verified with the REA ScanCheck 3n. The

measurement results should therefore be comparable and repeatable. To this end, it is necessary that

all measurements also be carried out under uniform conditions and with a calibrated verification unit.

The reading and lighting angle and distances of the unit to the measured code must primarily always

remain the same.

In bar code reading systems or scanners, this requirement does not apply and can also rarely be

complied with. This is explained by the wholly different purpose of scanners: Scanners should be able

to register bar codes quickly and correctly under the most favorable conditions and provide the

decoded data to the logistic processes.

4.1 Handling of the REA ScanCheck 3

Attention:

Please never hold the unit as shown in the image at lower left. The index finger is touching the

output window of the laser beam.

A) The finger covers the emitting laser beam and

B) The filter pane is dirtied with fingerprints.

Both cause disruptions of the measured light beam which can falsify measurements or even

make them impossible.

Attention: Never put fingers on red light pane Suggestion for correct handling

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 35 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

4.1.1 Instructions for Correct Execution of Code Evaluations

The following procedures must generally be observed when evaluating bar codes so that comparable

and repeatable measurement results are obtained:

1. The laser beam must cross the bar code bars at an angle of 90°.

If this is not the case, the unit indicates bar code sizes incorrectly.

2. The bar code sample must lie flat and even in front of the verification unit. If this is not the

case, the contrast results change. Metallic and glossy materials are particularly critical.

3. The distance to the bar code sample must always remain the same. The ideal distance is

when the REA ScanCheck 3 is in front of the calibration code, exactly as on the calibration card.

4. There should be a free region of about 30 cm in front of the REA ScanCheck.

If there is a bright/dark wall in this region, for example, the contrast results will change.

5. If the ambient light changes, a recalibration must be carried out.

Light changes from light with high ratios of red light/infrared light to light types with low ratios of

red/infrared (e.g. changing from daylight to neon light) are critical.

6. Measurements in direct sunlight are to be avoided because the measurements are falsified.

7. The bar code to be verified should be located centered in front of the REA ScanCheck 3, in

order to obtain the best measurement accuracy (see the positioning help on the calibration card).

8. If there is more than one code in the scanning beam region, then the first code is registered

and measured from the left side by default. It can thus be necessary to cover other codes in

order to be able to center the code to be verified in front of the REA ScanCheck 3.

9. The REA ScanCheck 3n may never be calibrated with extension plates installed, because the

calibration is falsified by the cut-outs in the plates.

© REA Elektronik GmbH REA ScanCheck 3 - August 2010

Page 36 of 89

D-64367 Mühltal-Waschenbach

+49 (0) 6154-638 0 www.rea-verifier.de

REA

Elektronik

GmbH

Streamlining • Development • Automation

Electronic Devices and Systems

4.2 First Measurement of Bar Codes

To measure bar codes, the REA Scan Check 3n must be

calibrated (see Chapter 3.9).

After activation of the REA ScanCheck 3n, the system

requires approx. 15 seconds for initialization of the programs.

Only thereafter does the main screen appear with the

following information:

Name of verification unit: (default: PoE-Master)

Version of operating program (GUI): here 1.0.810.172

Preadjusted aperture: here 8 6 mil

For evaluation of enabled code types:

here automatically searching

Evaluation standard here ISO/IEC 15416

Selected grade according to ISO or ANSI: here 3 (2.5)

Type or address of network connection here DHCP

The left-hand icon in the footer bar indicates green a sufficiently charged battery. If it is colored red,

the charger should be connected immediately. The left-hand number field is only for internal reporting