RDF PRODUCTS

17706 NE 72nd Street

Vancouver, Washington, USA 98682

Tel: +1-360-253-2181 Fax: +1-360-635-4615

E-Mail: mail@rdfproducts.com

Web Site: www.rdfproducts.com

OPERATOR'S MANUAL

DFA-1325B2 60-1,000 MHz FIXED-SITE

DIPOLE ADCOCK DF ANTENNA

Rev A03/07-15/dfa1325b2_opm_01

Copyright © 2015 by RDF Products

Original Writing: October 2013

WARNING

Please comply with the following basic rules of safety and common sense to ensure safe installation

and operation as well as long product service life:

1. LIGHTNING PROTECTION

- Lightning strikes can cause death or serious injury to operating

personnel and destruction of equipment if appropriate precautions are not taken. It is essential

that the DFA-1325B2 be installed with the lightning protection precautions discussed in Section

V-G and Appendix C.

2. ELECTRICAL POWER LINES

- Never install the DFA-1325B2 in the immediate vicinity of

electrical power lines. If the antenna comes in contact with power lines, death or serious injury

to operating personnel is likely to result. See Section V-H.

3. INSTALLATION ISSUES - The user must provide a mast mount for the DFA-1325B2 as

discussed in Section V. In addition, the user must securely guy the unit for maximum safety.

Please study Section V carefully and take all necessary steps to ensure that the DFA-1325B2

is safely mounted. If there is any doubt regarding the safety of the installation, obtain

professional help as required as per Section V-A.

4. ELECTROSTATIC DISCHARGE (ESD) ISSUES - Although all RDF Products DF antennas and

DF processors are designed to minimize vulnerability to electrostatic discharge (ESD) induced

damage, fixed-site DF systems are especially prone to this hazard. Do not connect the DFA-

1325B2 to the DF receiver/processor before studying and complying with the necessary system

grounding and procedural precautions discussed in Section V-I.

5. EXTERIOR WEATHER-SEALING

enhance weather-sealing and prevent water intrusion. For longest product service life, do not

break the integrity of these exterior weather-seals.

Check the RDF Products website at www.rdfproducts.com for updates and bulletins.

Can we improve this manual? Contact us at mail@rdfproducts.com

- Sealants have been applied to the DFA-1325B2 exterior to

to offer suggestions.

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

TABLE OF CONTENTS

SECTION I - GENERAL DESCRIPTION .................................................................. 1

SECTION II - SPECIFICATIONS .............................................................................. 3

SECTION III - PRE-ASSEMBLY INFORMATION .................................................... 5

A. UNPACKING AND INSPECTION ...................................................................... 5

B. EQUIPMENT SUPPLIED ................................................................................... 5

C. EQUIPMENT REQUIRED BUT NOT SUPPLIED .............................................. 6

SECTION IV - ASSEMBLY ....................................................................................... 7

A. INTRODUCTION ................................................................................................ 7

B. STEP-BY-STEP ASSEMBLY INSTRUCTIONS ................................................. 8

SECTION V - INSTALLATION ................................................................................. 13

A. GENERAL .......................................................................................................... 13

B. SELECTING A DF SITE ..................................................................................... 13

C. MOUNTING THE MAST SUPPORT PIPE ......................................................... 14

D. INSTALLING THE DFA-1325B2 ON THE MAST SUPPORT PIPE ................... 14

E. ORIENTATION ISSUES ..................................................................................... 16

F. SITE CALIBRATION .......................................................................................... 17

G. LIGHTNING PROTECTION ............................................................................... 19

H. ELECTRICAL POWER LINES ........................................................................... 19

I. ELECTROSTATIC DISCHARGE (ESD) ISSUES .............................................. 19

SECTION VI - MAINTENANCE ................................................................................ 21

SECTION VII - SIMPLIFIED THEORY OF OPERATION .......................................... 23

APPENDIX A - INTERFACE CABLE MATING CONNECTOR PIN-OUT ................. 25

APPENDIX B - INTERFACE CABLE EXTENSIONS ................................................ 26

APPENDIX C - MORE ON LIGHTNING PROTECTION

........................................... 28

iii

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

LIST OF ILLUSTRATIONS

Figure 1 - DFA-1325B2 60-1,000 MHz H/Sleeve-Dipole Adcock DF Antenna .. 1

Figure 2 - DFA-1325B2 Major Components ...................................................... 6

Figure 3 - DFA-1325B2 Hardware Close-Up ..................................................... 6

Figure 4 - Inserting the Cable into the Mast ...................................................... 8

Figure 5 - Installing the Mast Flange onto the Main Chassis ............................ 8

Figure 6 - UHF Sleeve-Dipole Array Installation ................................................ 9

Figure 7 - Turnbuckle Fastener Detail ............................................................... 9

Figure 8 - Kevlar Guy Tie-Down Detail .............................................................. 9

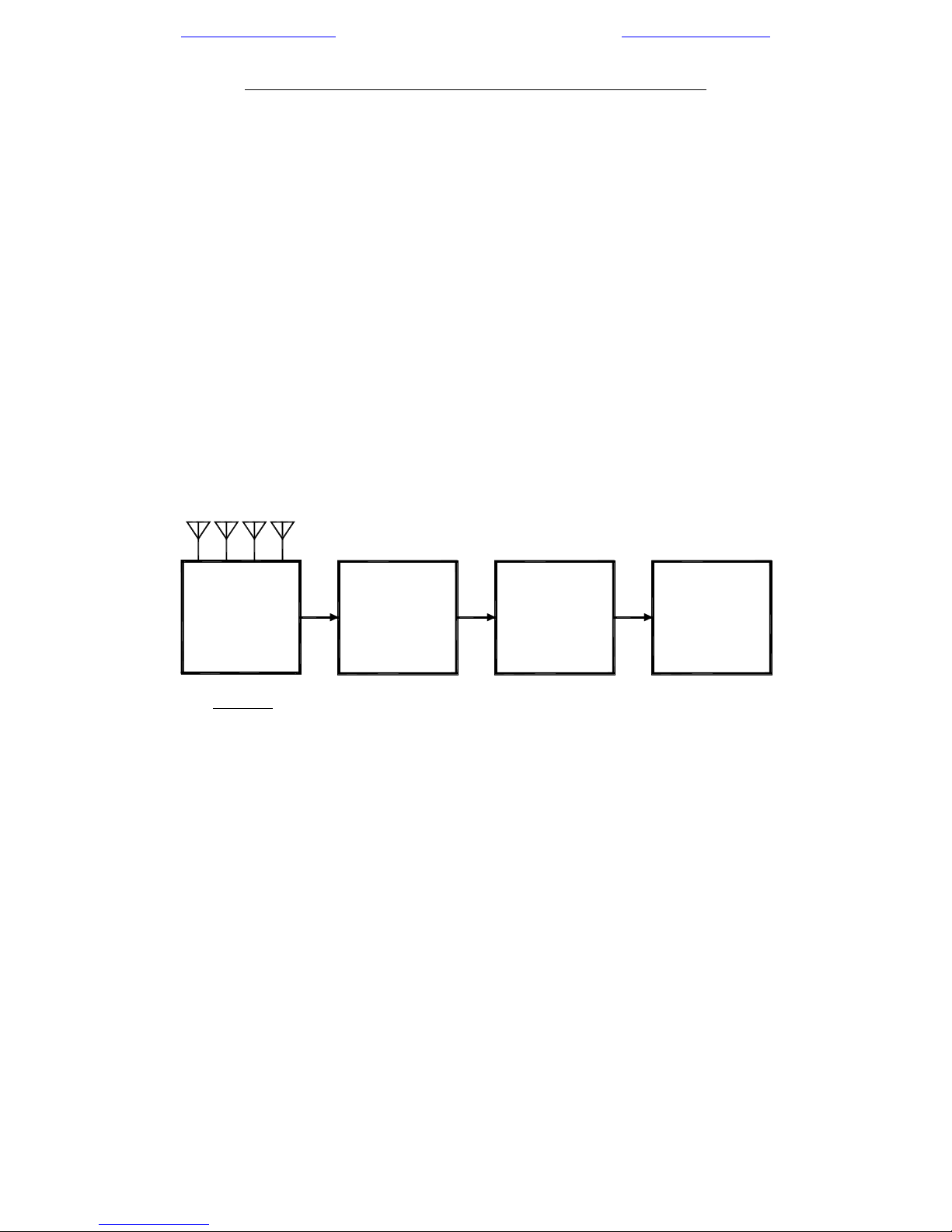

Figure 9 - Watson-Watt DF System Simplified Functional Block Diagram ........ 23

Figure 10 - Adcock DF Antenna Azimuthal Gain Patterns ................................... 24

Figure 11 - Interface Cable Mating Connector Pin-Outs ...................................... 25

iv

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

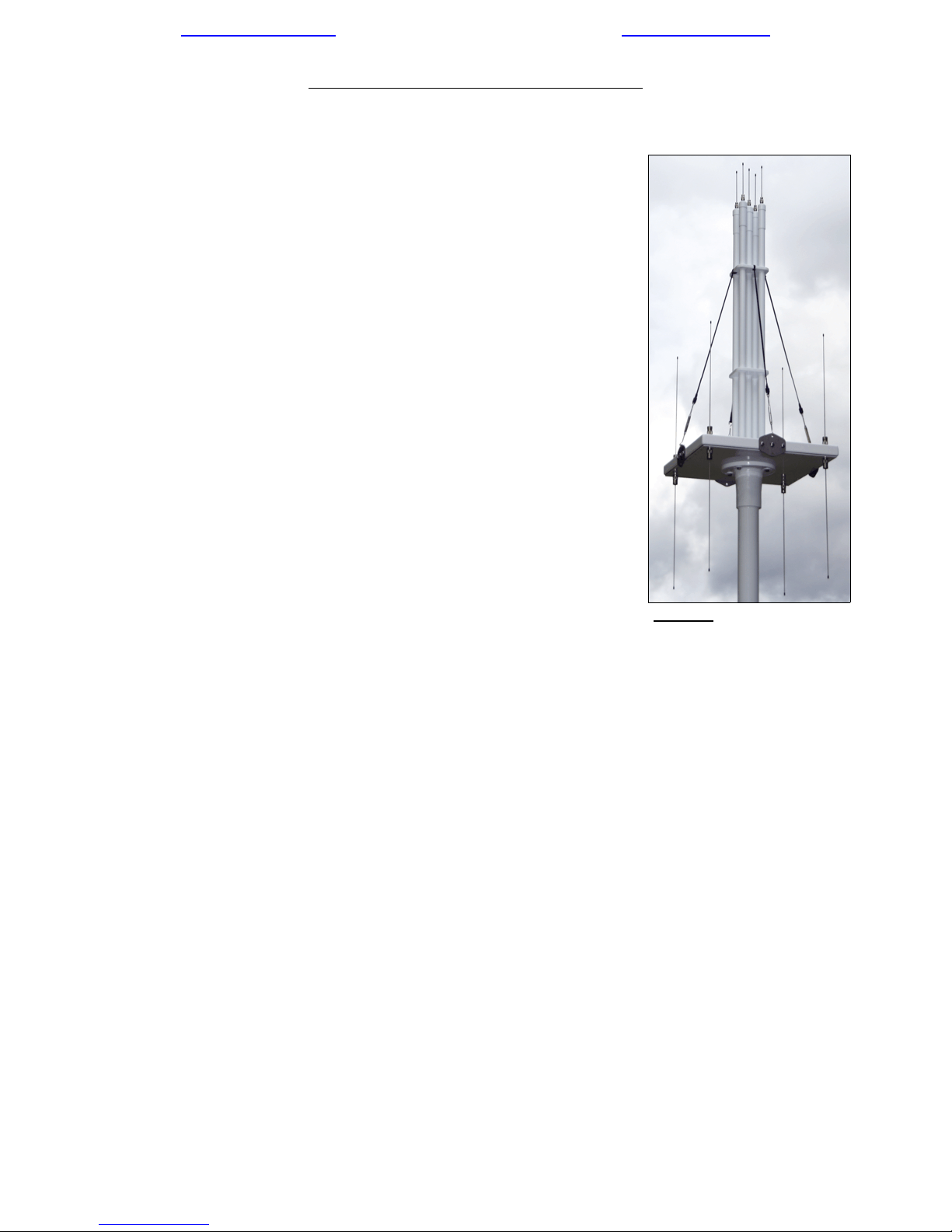

SECTION I - GENERAL DESCRIPTION

The RDF Products Model DFA-1325B2 is a dual-array VHF/UHF

H/sleeve-dipole Adcock single-channel radio direction finding

antenna covering 60-1,000 MHz in two bands. This rugged,

weather-sealed unit is specifically designed for permanent or

transportable fixed-site DF applications and is readily mast- or

tower-mounted.

Being of a true Adcock design, the DFA-1325B2 avoids the erratic

performance associated with inferior loop DF antennas and

provides sensitivity and listen-thru capability superior to that of

comparable pseudo-Doppler DF antennas. The DFA-1325B2 has

also been designed for high signal-handling capability for reliable

performance in dense signal environments. It is a particularly

good choice for tactical military, signal intelligence, and frequency

management applications where ultra-wide frequency coverage is

required.

The DFA-1325B2 has been specially designed so that its

performance is independent of its supporting mast or tower. (This

is accomplished with the supplied isolation mast.) This is in sharp

contrast to competing mast-mounted DF antenna designs where

performance is adversely and unpredictably affected not only by

the presence of the mast, but also by changes in mast height.

Figure 1 - DFA-1325B2 60-

1,000 MHz H/Sleeve-Dipole

Adcock DF Antenna

The DFA-1325B2 directly interfaces with all RDF Products DF

receivers and bearing processors via a single 8-meter interface cable set (routed through the

isolation mast). Custom interface cables with user specified lengths are also available. The

aerials are removable to facilitate storage, transport, and user testing. The isolation mast can

likewise be removed.

The DFA-1325B2 includes a digital “personality module” that reports model number and

frequency coverage information for this DF antenna. When connected to any of the RDF

Products “B”-series DF processors/receivers (e.g., the DFP-1000B, DFP-1010B, DFR-1000B,

or DFR-1200B), the DFA-1325B2 automatically reports its model number and frequency

coverage information. This information is then displayed so that the user can easily avoid outof-band operation.

1 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

NOTES

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

2 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

SECTION II - SPECIFICATIONS

DF Technique: Single-channel 2-phase Adcock (mixed sense).

Frequency Coverage: 60-200/200-1,000 MHz continuous (two bands).

Bearing Accuracy: 3.0/5.0E RMS maximum; 2.5/4.0E RMS typical (V/UHF; ideal

siting conditions).

Polarization: Vertical.

Output Impedance: 50 ohms nominal.

2nd Order Intercept: +40/+28 dBm typical (V/UHF; referred to sense input).

3rd Order Intercept: +25/+13 dBm typical (V/UHF; referred to sense input).

Required X & Y Axis 1.0 volts p-p (+/-5%), sinusoidal (100-2000 Hz)

Encoding Tone Voltages:

Personality Module: Reports antenna model and frequency coverage information as

300N81 RS-232 data string “DFA-1325B-2, 60-200, 200-1000

<CR><LF>”.

Power Requirements: 11-16 VDC @ 300 mA (negative ground).

Operating Temperature: -40 to +60 degrees C.

Storage Temperature: -40 to +70 degrees C.

Humidity: 0-100%.

Maximum Wind Velocity: 80 mph.

Dimensions: 118.75"x20.75"x20.75" (HxWxD, including 5' isolation mast, and

2' stainless-steel mast support pipe).

Weight: 63.5 lbs. (structural weight including main chassis, aerials,

isolation mast, and 8-meter interface cable; excluding 14 lbs.

stainless-steel mast support pipe and external guy lines).

3 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

NOTES

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

4 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

SECTION III - PRE-ASSEMBLY INFORMATION

A. UNPACKING AND INSPECTION

Carefully examine the shipping carton for damage before it is opened. If damage is evident,

have the carrier’s agent present, if possible, when the equipment is unpacked. If the carrier’s

agent cannot be present, retain the cartons and packing material for the carrier’s inspection

if the equipment is subsequently found to be damaged after unpacking.

Do not use knives or other sharp instruments to remove packing material from individual

items. To facilitate easy unpacking, the packing material protecting these individual items is

secured with easy-to-remove tape where possible.

To ensure that the shipment has been received complete, inventory all items against the

detailed shipping list. If a discrepancy is found, notify us immediately.

The equipment was thoroughly inspected and factory adjusted for optimum performance prior

to shipment and is ready for immediate use. If evidence of damage during shipment is found,

notify us immediately.

B. EQUIPMENT SUPPLIED

The following equipment is supplied:

1. Main chassis (P/N B325-6002; 1 ea., includes attached ferrite-loaded interface cable).

2. 200-1,000 MHz UHF sleeve-dipole array assembly (P/N S061-6103; 1 ea.).

3. Kevlar guy assemblies (P/N S061-6104; 4 ea., attached to P/N S061-6103 above).

4. DAB-053B aerials (P/N S024-0053; UHF, 5 ea.).

5. DAD-154B aerials (P/N S022-0154; VHF, 8 ea.).

6. 5' isolation mast (P/N S092-6005; 1 ea.).

7. 1.0" long 3/8" dia. 16 tpi stainless-steel anti-rotation bolts (P/N 605-009; 3 ea.).

8. 1.5" long 3/8" dia. 16 tpi stainless-steel bolts (P/N 605-022; 4 ea.).

9. DFA-1325B2 spare hardware kit (P/N B325-3002; 1 pack).

10. 2' long 3" inside-diameter schedule 40 unthreaded stainless-steel mast support pipe

(P/N S092-0002; 1 ea.).

11. Silicone sealant (P/N 701-012; 1 tube, partial).

12. DFA-1325B2 Operator’s Manual (P/N B325-9002; 1 ea.).

Note: The tube of silicone sealant is no longer. In current-production units, all sealing is done

at the factory.

All of the above components are illustrated in Figures 2 and 3 below. Refer to these photos

as required to identify these components during the assembly procedure presented in Section

IV.

5 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

Figure 2 - DFA-1325B2 Major Components

*Note: The 3 anti-rotation bolts (P/N 605-009) are pre-installed in the mast base*

C. EQUIPMENT REQUIRED BUT NOT SUPPLIED

The DFA-1325B2 must be used with an appropriate

RDF Products DF receiver/bearing processor. In

addition, a suitable user-supplied mast mount fitting may

also be required to mount the DFA-1325B2 as discussed

in Section V. The user must also supply non-conductive

guy lines and associated hardware. Finally, an

extension interface cable may be required if the

standard 8-meter interface cable is insufficiently long to

reach the DF receiver/bearing processor.

Figure 3 - DFA-1325B2 Hardware

Close-up

6 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

SECTION IV - ASSEMBLY

A. INTRODUCTION

As mentioned, the DFA-1325B2 is shipped in disassembled form so that it can be stored and

transported in a compact container. It is therefore necessary for the user to assemble the unit

prior to use. Although assembly is not difficult, it must be done carefully and in proper

sequence to avoid damaging the unit.

* CAUTION *

1. Two-Man Assembly - At least two people are required to properly

assemble and install the antenna.

2. Aerial Bending - Although the aerial rods are constructed of rugged

stainless steel, they can be bent by improper handling. Exercise

particular care during assembly not to place stress on these rods. Never

lay down the antenna in such a fashion that its weight is supported by the

aerials. Bent aerials will reduce antenna bearing accuracy. Do not install

these aerials until the DFA-1325B2 is ready to be mounted atop its

supporting structure.

3. Ferrite-Loaded Cable - The cable attached to the main housing (see

Figure 2) is loaded with large ferrite cylinders. Since these ferrites are

somewhat brittle and can shatter, exercise caution when handling this

cable so as to prevent impact against hard surfaces or objects. Also, do

not attempt to bend this cable too tightly.

4. Main Chassis Integrity - The main chassis is a pre-assembled weathersealed unit. This housing contains no user-serviceable parts and should

never be opened. Disassembling the main housing without written

factory authorization voids the warranty.

5. Exterior Weather-Sealing

- Sealants have been applied to the DFA1325B2 exterior to enhance weather-sealing and prevent water intrusion.

For longest product service life, do not break the integrity of these

exterior weather-seals.

7 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

B. STEP-BY-STEP ASSEMBLY INSTRUCTIONS

1. Locate the main chassis (B325-6002) with its attached ferrite-loaded interface cable and

place it on a long table.

** WARNING **

All the DFA-1325B2 main chassis screws and bolts have been sealed

with RTV (silicone sealant) to prevent water intrusion. Do not attempt to

tighten, loosen, remove, or replace any of this hardware. Attempting to

do so will likely break the weather-seal and cause internal corrosion.

2. Orient the mast (S092-6005)

so that its upper flange (at the

top of the mast is facing the

main chassis (B325-6002)

underside as per Figure 4.

3. Push the ferrites along the

cable in the direction of the

main chassis so that these

ferrites are located along the

cable as far away as possible

from the two cable

connectors.

4. Insert the cable end (i.e., the

cable connectors) into the

hole in the mast flange (see

Figure 4) and then push the

Figure 4 - Inserting the Cable into the Mast

cable (including the ferrites)

into the mast until the connectors exit from

the opposite mast end. If the cable binds

during this process, roll the mast as required

to free the cable. If the cable connectors will

not push through the opposite mast end,

finger-pull them through.

5. Attach the upper mast flange onto the main

chassis using four 1.5" long x 3/8" dia.

stainless-steel bolts (605-022). See Figure

5. Be sure to first wipe away any debris on

the chassis/flange mating surfaces. Also, be

sure to push the ferrites as close to the main

chassis as possible so that the flange can

reach the chassis. Confirm that these bolts

are fully tightened and that the mast flange

is completely flush with the main chassis.

Figure 5 - Installing the Mast Flange

onto the Main Chassis

8 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

Figure 8 - Kevlar Guy

Tie-Down Detail

Figure 6 - UHF Sleeve-Dipole

Array Installation

Figure 7 - Turnbuckle

Fastener Detail

6. Do not install the four VHF aerials (S022-0154) at this time. These will be installed when

the DFA-1325B2 is ready to be mounted atop is supporting structure.

7. Locate the UHF sleeve-dipole array assembly (S061-6103). In the following steps, this

assembly will be mounted on its mating connectors on the main chassis. These

connectors will then be tightened in sequence.

8. Inspect this assembly to see if one of the sleeve-dipoles is marked. If one of the dipoles

is marked, the assembly should be oriented so that so that the marked dipole is installed

on the “North” N-connector on the main chassis topside in the steps that follow. (The

“North” N-connector is the one corresponding to the position of the arrow label on the

main chassis topside.)

9. The following steps and illustrations are based on a vertical mast orientation for assembly

purposes. With this orientation, be sure that the bottom end of the mast does not crush

the exiting cables (i.e., elevate the mast bottom off the floor slightly so that the cables can

exit freely).

10. Position the UHF sleeve-dipole assembly so that its five N-connectors are directly atop

the mating N-connectors on the main chassis topside. (Since the UHF sleeve-dipole

array assembly is heavy and awkward to handle, this and the following related steps are

9 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

best accomplished with two people.) See Figure 1. Exercise caution in this and the

following related steps so as not to damage the N-connector threads.

11. Rotate all 5 sleeve-dipole connectors counter-clockwise to verify that they are fully

loosened and disengaged from the chassis connectors. Also verify that the sleeve-dipole

array is completely vertical with respect to the horizontal chassis surface.

12. Slightly finger-tighten any two opposing connectors until the threads just “catch” (once

the threads catch, do not tighten any further for the time being). Repeat this procedure

for the other two opposing connectors. Once these threads catch, repeat this procedure

for the center connector.

13. Continue to progressively finger-tighten these connectors in the above sequence, being

sure to tighten each connector no more than 1/4 turn at a time (so as to prevent thread

binding) until all connectors are fully finger-tightened. If binding occurs, grasp the UHF

sleeve-dipole assembly near the top with one and gently pressure it back and forth

horizontally while attempting to finger-tighten the offending connector with the other hand

(this will help relieve the binding).

14. To verify that all the connectors have been fully finger-tightened, again grasp the UHF

sleeve-dipole assembly near the top with one hand and gently pressure it back and forth

horizontally while attempting to continue to tighten the connectors with the other hand.

(This will help relieve any thread galling or binding that might prevent the connectors from

fully finger-tightening.)

15. When no further finger-tightening is possible, carefully inspect the assembly to verify that

the sleeve-dipole stalks are perfectly vertical with respect to the chassis. If any tilt is

visible, loosen all five connectors slightly and repeat the above steps. Do not proceed

to the next step until no tilt is visible. It is imperative that the all five connectors be fully

seated and that there is no thread galling or binding. As a final check confirm that the

distances between the 5 sleeve-dipole connector lower rims and the chassis connector

flanges are all visibly the same.

16. With the connectors fully finger-tightened and the sleeve-dipole assembly confirmed to

have no tilt with respect to the chassis, continue progressively tightening the connectors

in succession using pliers. To prevent binding, tighten each connector only 1/8 turn at

a time. Repeat this successive tightening process as many times as required until all 5

connectors are tight. Use only moderate force. Also, do not install the DAB-053B aerials

at this time. These will be installed during the installation phase. Premature installation

of these aerials will increase the likelihood of them being bent.

Do not attempt to use pliers to tighten any connectors where binding is present.

Doing so will likely cause damage to the connector threads. If there is binding

that cannot be relieved by the procedures enumerated above, loosen all 5

connectors and repeat the procedure.

17. Note that the 4 Kevlar guy lines pre-attached to the sleeve-dipole array are terminated

with hooked stainless-steel turnbuckle fasteners. Insert these hooks into the

10 of 29 - RDF Products - Vancouver Washington USA

** WARNING **

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

corresponding guy bracket support holes on the main chassis sidewalls as illustrated in

Figures 6 and 7 (use the upper holes) and then tighten the turnbuckles. Be sure to

tighten these turnbuckles in pairs (opposing sides) by simultaneously tightening

the opposing fasteners so that the sleeve-dipole array is not pulled to either side.

(Rotate the turnbuckle fasteners clockwise to tighten.) To avoid damage to

internal components, exercise caution not to allow the chassis topside to bend or

bow while tightening these turnbuckles. Tighten to the point where moderate

finger pressure on the center of the line results in approximately 1 cm of play.

18. Apply a small amount of the supplied sealant compound (701-012) to the turnbuckle

threads (8 places as per Figure 7 to prevent the turnbuckles from loosening over time.

19. Inspect all installed hardware to verify that it is fully tightened-down. If any hardware is

loose, tighten-down with a wrench or pliers as appropriate using moderate force.

20. Inspect the junction between the mast flange and the main chassis underside to verify

that there is no space in between (i.e., the flange top should be fully flush with the

chassis underside). If the surfaces are not flush, remove the four bolts, verify there is no

debris on the mating surfaces, and reinstall (being careful to ensure there is no crossthreading).

21. If it becomes necessary to remove the UHF sleeve-dipole array, loosen the connectors

in a successive and progressive manner similar to the procedure above by which they

were tightened.

22. This completes preliminary assembly of the DFA-1325B2. Do not attach the DAB-053B

and DAD-154B aerials to the aerial connectors at this time in order to reduce the risk of

bending during handling. These aerials will be installed during final installation as

discussed in the following Section.

11 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

NOTES

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

12 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

SECTION V - INSTALLATION

A. GENERAL

Once the DFA-1325B2 has been assembled as per Section IV, the remaining steps are to

select a DF site, fabricate a suitable mast mount, install the DAB-053B/DAD-154B aerials,

secure the unit to the mount, and then properly orient the DF antenna. These steps are

discussed in the paragraphs that follow.

*** DANGER ***

Installing outdoor antennas can be dangerous. An unsafe installation can result

in property damage, injury, or even death. With this in mind, the DFA-1325B2

installation should be done only by qualified personnel experienced in this field.

Since most users are not likely to have these qualifications and experience, we

strongly recommend that users have the installation done professionally by a

reputable contractor proficient in this line of work with a full knowledge of all

applicable rules, regulations, ordinances, and codes governing such

installations.

B. SELECTING A DF SITE

The importance of a good DF site cannot be overstated. Although the DFA-1325B2 yields an

instrument accuracy as per its specifications, system accuracy can be many times worse than

this if the DF antenna is installed at a poor site. Unlike mobile DF systems where poor

bearing accuracy can often be forgiven due to the tracking and homing nature of typical

mobile DF missions, mast-mounted fixed-site DF systems generally require a much higher

degree of bearing accuracy. This is especially true where the fixed-site DF system is a

component of a larger DF network used for triangulation.

The fundamental requirement for good DF antenna siting is that the DF antenna be mounted

so that it is free of obstructions. (Obstructions tend to cause re-radiation that leads to multipath reception at the DF antenna that in turn results in bearing errors.)

Although it is not strictly necessary that the DF antenna be mounted high off the ground, a

high installation is more likely to raise the antenna above the various obstructions that are

likely to be encountered (e.g., trees, buildings, utility poles, water towers, and even the DF

operating console). A high installation is also advantageous in that bearing errors induced by

non-uniform ground conductivity are likely to be reduced.

It is therefore important that a best effort be made to select a DF site that is as “clean” as

possible. Although site calibration is often a useful procedure for improving the instrument

accuracy of a DF system, it cannot compensate for bearing errors caused by poor siting. (For

a fuller discussion of this topic, see paragraph V-F below).

13 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

C. MOUNTING THE MAST SUPPORT PIPE

The bottom of the DFA-1325B2 isolation mast is designed so that it can be directly inserted

onto the supplied 2' long 3" inside-diameter schedule 40 stainless-steel mast support pipe

(S092-0002). This mast support pipe in turn must be safely mounted to a user-supplied tower

or other suitable support structure. Since the details of the mounting technique can vary

widely depending upon user preferences and requirements, it is the user’s responsibility to

employ whatever construction techniques are necessary to safely secure the mast support

pipe to the support structure. In this regard, it is also necessary that the user obtain or

fabricate any custom fittings or adaptors that may be required to successfully complete the

installation.

*** DANGER ***

The support structure must be sufficiently strong to support the DFA-1325B2

under all conditions. If the user is inexperienced in large antenna mounting or

if there is any doubt regarding the ability of the support structure to support its

own weight plus that of the DFA-1325B2 under conditions of maximum wind and

ice loading, professional help should be obtained to guarantee a safe

installation. It is solely the user’s responsibility to ensure a safe installation.

There are a number of different mounting techniques available to the user. A common

method is to weld or bolt the mast support pipe to a steel tower. Regardless of the method

chosen to secure the mast support, it should be installed very carefully to ensure that it is

nearly perfectly vertical with no measurable tilt.

** WARNING **

Do not attempt to directly side-mount the DFA-1325B2 isolation mast against

a pipe, tower, chimney, or any other structure. Doing so will defeat its purpose

and prevent the DFA-1325B2 from being isolated from its supporting structure,

resulting in diminished performance. Also, the fiberglass isolation mast is not

designed for the stresses inherent in such a mounting scheme and may become

damaged as a result. (This mounting scheme is unsafe as well.) Always

construct a suitable mast mount as discussed above.

Regardless of the mounting technique selected, be sure to leave a sufficient length of the

upper portion of the mast support pipe unobstructed so that the DFA-1325B2 mast mounting

base can be slid onto the pipe and fully seated.

D. INSTALLING THE DFA-1325B2 ON THE MAST SUPPORT PIPE

Once the mast support pipe has been successfully installed, the DFA-1325B2 must be fitted

with its DAB-053B/DAD-154B aerials, mounted, oriented, and secured. To accomplish this,

proceed as follows:

14 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

1. Locate the DAB-054B (S024-0053)and DAD-154B (S022-0154) aerials and inspect their

TNC male connectors to verify that they are clean and free of dirt and debris.

2. Similarly, inspect the corresponding TNC female mating connectors to verify that they are

likewise clean and free of dirt and debris.

3. Install the five DAB-053B UHF aerials on the mating TNC connectors atop the UHF

sleeve-dipoles. Firmly hand-tighten only - do not use a wrench.

** WARNING **

Once the aerials have been installed, handle the DFA-1325B2 very carefully so

as not to bend the aerial rods. Do not mishandle the assembled antenna, and

especially do not lay it down in such a fashion that force is applied to the rods.

4. Carefully inspect the DAB-053B top-aerials to ensure that they are all in proper alignment

with respect to each other. This is most conveniently done by sighting the aerials along

each horizontal axis in succession and verifying that the 3 visible aerial safety tips line

up straight. If they are misaligned, bend the aerials slightly as required (grasping them

by the tips). Since there will likely be interaction between the two axes, repeat this

process as many times as necessary until both axes are properly aligned and all five

aerials are straight. Do not install the eight DAD-154B VHF aerials at this time.

5. Insert the free end of the interface cable into the top hole of the mast support pipe.

6. Retrieve this cable end by bringing it out through the lower end of the mast support pipe,

pulling it all the way through.

7. Position the DFA-1325B2 mast mounting base (at the lower end of the mast) directly over

the mast support pipe and carefully lower the DFA-1325B2 onto it. To prevent

inadvertent pinching of (and possible damage to) the cable, have an assistant pull the

cable from below so as to always maintain sufficient cable tension to prevent it from

bending while the DFA-1325B2 is being lowered onto the pipe. If resistance is

encountered, do not use force - lift the DFA-1325B2 off the mast support pipe and

determine the source of the blockage before proceeding.

8. Install the eight DAD-154B VHF aerials on the mating TNC connectors on the UHF

sleeve-dipoles. Firmly hand-tighten only - do not use a wrench.

9. Carefully inspect the VHF aerials to assure that they are straight, vertical, and in proper

alignment with respect to each other. Correct any misalignment by bending the aerials

as required.

10. Rotate the DFA-1325B2 as required to establish the desired azimuthal orientation (the

arrow or other marking on the chassis underside indicates the zero degree reference).

Once the correct orientation is achieved, install and hand-tighten the three 1.0" long antirotation bolts (605-009) at the base of the isolation mast. Once done, recheck the

orientation and then firmly tighten the bolts with a wrench using moderate force. Again

recheck the orientation to confirm that it is still correct. If the DFA-1325B2 is

15 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

inadvertently rotationally misaligned during tightening, loosen the bolts and repeat this

step as required. See Section V-E below for additional information regarding orientation.

11. Secure the DFA-1325B2 with four non-conductive guy lines. Attach these guys to the

support brackets located on the main chassis sidewalls (use the lower holes). We

recommend that these guy lines be made of a stretch resistant material such as UVprotected Kevlar. When installing these guy lines, be sure that the tension on each line

is the same and that they not cause the iso-mast to bend.

12. If the DFA-1325B2 is to be permanently installed, we recommend that all mast mount

openings (including the exit opening for the interface cable) be sealed with an appropriate

weather-resistant compound. To facilitate de-installation, however, we recommend that

this compound be of a soft-cure removable variety (e.g., silicone sealant) rather than a

hard-cure permanent type (e.g., epoxy).

13. To prevent electrostatic discharge (ESD) damage, do not connect the DFA-1325B2 to

the DF receiver/processor before studying and complying with the necessary system

grounding and procedural precautions discussed in Section V-I.

E. ORIENTATION ISSUES

A DF system provides bearings that are relative to the orientation of the DF antenna. In order

for these bearings to be meaningful, it is necessary that the DF antenna be oriented in such

a fashion that these relative bearings correspond to absolute bearings of a selected format.

A car-top mounted mobile DF antenna, for example, is usually oriented so that a zero degree

bearing corresponds to the forward direction of the vehicle. Similarly, a mast-mounted

shipboard DF antenna is usually oriented so that a zero degree bearing corresponds to the

forward direction of the vessel. In contrast, a fixed-site mast-mounted DF antenna is usually

oriented so as to be compatible with a geographical coordinate system. In typical fixed-site

installations, the DF antenna is oriented so that a zero degree bearing corresponds to true,

magnetic, or grid north.

For the DFA-1325B2 a zero degree bearing occurs when its “north-south” aerial axis is in-line

with the signal source, with the “north” aerial closest to the signal source. The “north”, or zero

degree reference aerial is indicated by an arrow or other marking on the chassis underside.

We strongly recommend that the desired orientation be established based on appropriate

mechanical rotational alignment of the DFA-1325B2. That is, if a zero degree bearing is to

indicate true north, for example, the antenna should be rotated so that the two diagonallyopposed aerials on the 0-180 degree (or “north-south”) axis are physically aligned with the

true north-south axis based on careful visual siting.

This is preferable to attempting to establish orientation based on the actual bearing received

by a test transmitter or other signal source of known location. This latter technique introduces

potential errors as a consequence of possible multi-path reception and is therefore unreliable.

16 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

If for some reason it is difficult or inconvenient to rotate the DFA-1325B2 to obtain the precise

orientation desired, or if the antenna must be used in a variety of DF missions requiring

compatibility with different geographical coordinate systems, virtual orientation can be

accomplished by the simple expedient offsetting the azimuth indication of the bearing display.

In the more typical case where a computer will be used to display the bearings, this can be

accomplished in software (most computer interface programs written for DF applications have

a suitable azimuth offset feature). If an analog bearing display is used, an azimuth offset is

normally accomplished by mechanically rotating the calibration bezel.

In either case, the procedure is reasonably straightforward. First, the actual orientation of the

DF antenna (referenced to the zero degree orientation of the selected geographical coordinate

system) is established by careful visual siting as discussed above. This observed angle is

then entered into the bearing display program as an azimuth offset. As an example, suppose

that it is desired that bearings be referenced to true north, and it is established by careful

visual siting that the actual DF antenna orientation with respect to true north is +7 degrees.

Without azimuth offset compensation, this would result in displayed bearings generally being

low by 7 degrees. To correct this, an azimuth offset of +7 degrees would be entered into the

bearing display program to compensated for this error. Note that this azimuth offset is

frequency independent.

F. SITE CALIBRATION

Site calibration is a means by which bearing accuracy of a DF antenna can be improved by

carefully positioning a test transmitter at various known azimuths around the DF antenna,

recording the actual measured bearings, and then constructing a calibration “look-up” table

that can be used to correct subsequent bearing readings. For a DF system employing a

computer interface, this look-up table would normally be constructed in software and would

employ automatic interpolation to allow corrections to be applied to bearing readings between

calibration points.

Although site calibration can be a useful tool, it is subject to many limitations. Some of the

issues associated with site calibration are as follows:

1. Multi-Path Limitations

- Site calibration is totally ineffective as a means of reducing

bearing errors caused by multi-path reception (i.e., reflections). Generally speaking, a

reflection has the effect of altering the apparent angle-of-arrival of the incoming

wavefront, and the very best we can ask of a narrow-aperture DF antenna is to correctly

report this apparent angle-of-arrival. More specifically, the reason for this is that the

amount of bearing error caused by a reflection is dependent not only upon the magnitude

of the reflected ray, but also upon its phase relationship to the direct ray. Depending

upon this phase relationship, the bearing error induced by a reflection can be either

positive or negative (or even zero). Since there is no a priori knowledge of this phase

relationship in the general case, site calibration cannot offset the error. A corollary to this

point is that site calibration in general is ineffective if the DF site is poor and most of the

bearing errors are caused by multi-path. When considering site calibration then, always

keep in mind the all-important point that only DF system instrument error can be reduced,

and that it is ineffective in reducing site error.

17 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

2. Number Of Calibration Azimuths - In general, a substantial number of calibration

azimuths are necessary to construct an effective calibration look-up table, particularly if

linear interpolation is employed to estimate and correct for errors between the calibration

azimuths. Non-linear interpolation (if skillfully implemented) is somewhat more forgiving

in this regard and in general demands fewer calibration azimuths for the same corrected

bearing accuracy. Site calibrations conducted using 16 equally-spaced calibration points

(i.e., at 22.5E azimuth increments) should be adequate in most cases.

3. Frequency Dependency - A site calibration is theoretically valid only at the frequency at

which it was conducted. It is therefore necessary to repeat the calibration procedure at

a number of different frequencies throughout the antenna frequency range. Once again,

interpolation can be used to compute corrections for intermediate frequencies.

4. Elevation Angle Dependency - A site calibration is theoretically valid only at the elevation

angle at which it was conducted. In practice, however, since most signals intercepted

by fixed-site DF antennas are received at or near 0E elevation, site calibrations are

similarly performed at or near 0E elevation. Another mitigating factor is that DF antenna

bearing accuracy does not change much over a modest range of elevations centered

around 0E.

5. Distance Between DF Antenna And Test Transmitter - For best results, the test

transmitter should be located close to the DF antenna since this increases the magnitude

of the desired direct ray in relationship to any reflected rays (thus minimizing any bearing

errors due to multi-path reception). The test transmitter should not, however, be closer

than a wavelength or so at the lowest test frequency. Since the low-end band-edge

frequency for the DFA-1325B2 is 200 MHz, the test transmitter should be located about

3' away and at the same elevation as the main housing.

6. Error Contribution Of Other DF Components - Although the DF antenna is usually the

dominant DF system component with regard to bearing errors, the error contribution of

the DF receiver/bearing processor may not be negligible (especially after a wellimplemented site calibration). It is therefore good practice to first measure and record

the bearing accuracy of the DF receiver/bearing processor so that these errors can be

subtracted out from the measured composite system bearing errors to determine the

error contribution of the DF antenna alone. Using this procedure, the calibration look-up

table constructed for the DF antenna is still valid if a different DF receiver/bearing

processor is later substituted. Of course, the bearing accuracy of the new DF

receiver/bearing processor will have to be measured and the calibration look-up table

appropriately modified to accommodate these errors.

Site calibration is an involved topic and a more detailed discussion is beyond the scope of this

manual. Users having additional questions about site calibration should contact RDF

Products.

18 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

G. LIGHTNING PROTECTION

Although the DFA-1325B2 is sufficiently robust to survive the electromagnetic pulses

generated by nearby lighting strikes, it cannot survive a direct hit. With regard to lightning

protection, however, the far more overriding concern is that of operator safety.

*** DANGER ***

Lightning strikes can cause death or serious injury to operating personnel and

destruction of equipment if appropriate precautions are not taken. Proper

lightning protection requires the use of specialized equipment to subdue the

high voltages on the antenna feed-in cable that can be induced by lightning.

Never install the DFA-1325B2 without the benefit of such protection.

In general, such protection requires the use of appropriate high-voltage clamping devices

combined with suitable grounding techniques. Due to the specialized nature of this equipment

and technology, we strongly recommend that users procure the necessary protective devices

directly from the various sources who manufacture them. One such source is PolyPhaser

Corporation (P.O. Box 9000, Minden, NV, USA 89423). Polyphaser publishes a variety of

application notes relevant to this topic that we strongly recommend users read. PolyPhaser

can be reached at +1-800-325-7170, and has a website at

www.smithspower.com/brands/polyphaser/

.

H. ELECTRICAL POWER LINES

*** DANGER ***

Never install the DFA-1325B2 in the immediate vicinity of electrical power lines.

If the antenna comes in contact with power lines, death or serious injury to

operating personnel is likely to result.

In addition to the obvious safety issues, the presence of power lines and supporting utility

poles in the immediate vicinity of the DFA-1325B2 are very likely to degrade bearing accuracy.

I. ELECTROSTATIC DISCHARGE (ESD) ISSUES

Although all RDF Products DF antennas and DF receivers/processors are designed to minimize vulnerability to electrostatic discharge (ESD) induced damage, fixed-site DF systems are

especially prone to this hazard. This is particularly true in installations where a long interface

cable set is employed as would be the case where the DF antenna is mounted atop a tall

tower or mast.

With a significant distance between the DF antenna and DF receiver/processor, a significant

19 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

electrostatic charge can accumulate on the antenna relative to the receiver/processor. This

relative charge can become especially large if wind is blowing on the antenna. As a result,

connecting the antenna control cable to the DF processor under such circumstances can

result in a severe electrostatic discharge that can damage both the DF processor and antenna

if reasonable precautions are not taken.

We therefore recommend that the following steps be taken prior to connecting the DFA1325B2 to the DF receiver/processor.

1. Tower Grounding - Be sure to earth-ground the tower or supporting mast upon which the

DFA-1325B2 is mounted. This earth-ground should be low resistance. Typical earth

grounding techniques include the use of metal ground stakes and buried wires.

2. RF Cable Shield Grounding - Since the DFA-1325B2 mast is non-conductive, grounding

the tower does not ground the antenna chassis or RF cable shield. In installations where

an extension cable is used (i.e., when there is a large physical separation between the

DFA-1325B2 and the operator), this is most conveniently done at the junction point where

the DFA-1325B2 RF output cable is connected to the RF extension cable. To obtain a

good earth ground at this point, use a bulk-head cable junction connector or adaptor and

directly mount it to the metal frame of the tower for good electrical contact.

3. Operator Console Grounding - Be sure that the DF processor and receiver are also

connected to earth ground. Although the AC safety ground is usually adequate for this

purpose, do not automatically assume that the DF processor and receiver chassis are

connected to AC safety ground. Since these units will likely be run from DC power

sources that may be electrically isolated from the AC safety ground, effective earth

grounding may not exist. It is therefore necessary to verify first-hand that the DF

processor and receiver chassis are both firmly electrically bonded to AC safety ground.

If they are not, then it will be necessary to add a safety ground wire for this purpose.

Also be sure that the DF processor and receiver are firmly electrically bonded to each

other.

Once the above earth grounding requirements have been met, we also recommend that the

following procedure be followed when connecting the DFA-1325B2 to the DF processor and

receiver:

1. First connect the RF cable to the DF receiver. The BNC connector is designed so that

the ground contact is made before the inner conductor when the BNC plug is inserted

into the BNC socket. This will help equalize static charges between the DF antenna and

the DF processor/receiver.

2. Once the RF cable has been connected to the receiver (and the static charges equalized

as discussed above), the DF antenna control cable plug can then be safely inserted into

its mating socket on the DF processor.

20 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

SECTION VI - MAINTENANCE

Although the DFA-1325B2 is mostly maintenance-free and should provide many years of

trouble-free service, we recommend the follow routine maintenance:

1. Guy Lines

- The installation should be checked periodically to confirm that appropriate

tension is maintained for both sets of guy lines (the ones supporting the entire structure

and the ones supporting the UHF sleeve-dipole assembly).

2. Mast Base Bolts

- The mast base bolts should be checked periodically to verify that they

have not loosened.

3. Nesting - The installation should be inspected periodically to confirm that there is no bird

or insect nesting.

4. Fresh Water Flushing - Units installed in marine environments should be fresh water

flushed periodically to remove salt build-ups.

21 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

NOTES

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

22 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

SECTION VII - SIMPLIFIED THEORY OF OPERATION

In the most general sense, all non-rotating radio direction finding systems employ a DF

antenna having an array of spatially-displaced aerials (three or more are required for

unambiguous operation) that are illuminated by the received signal wavefront. The resulting

voltages produced by these aerials exhibit attributes (phase, amplitude, or both) that are then

measured. Since these characteristics are unique for every received azimuth in a properly

designed DF antenna, the wavefront angle-of-arrival (bearing) can be ascertained by

appropriately processing and analyzing these aerial output voltages.

The specific DF technique employed by RDF Products DF bearing processors and associated

antennas is known as the single-channel Watson-Watt DF technique. A single-channel

Watson-Watt DF system can be broken down into the following four basic functional blocks:

1. DF Antenna

2. DF Receiver

3. DF Bearing Processor

4. DF Bearing Display

DF ANTENNA DF RECEIVER

Figure 9 - Watson-Watt DF System Simplified Functional Block Diagram

DF BEARING DF BEARING

PROCESSOR DISPLAY

As per Figure 12, the DF antenna receives the incoming wavefront, appropriately processes

the signal and feeds it to the DF receiver. The DF receiver further processes the signal,

demodulates it, and feeds it to the DF bearing processor. The DF bearing processor then

provides additional signal processing and converts the signal into a format suitable for driving

the DF bearing display.

A standard Watson-Watt DF system employs either Adcock or loop DF antennas, with

Adcocks usually preferred because of their superior performance. Actually, the DF antenna

is really an array of three separate but co-located antennas. Referring to a 4-aerial Adcock

configuration, the first of these antennas is the N-S bi-directional array comprising the north

and south aerials. As illustrated in Figure 13 below, the resulting figure-of-eight az imuthal

gain pattern consists of circular lobes with maximum sensitivity to the north and south and

nulls to the east and west. This figure-of-eight gain pattern is obtained by applying the N and

S aerial voltages to a differencing network that vectorially subtracts them (N-S).

The second of these antennas is the E-W bi-directional array comprising the east and west

aerials. Again as illustrated in Figure 13, its azimuthal gain pattern is identical to that of the

N-S bi-directional array, but orthogonally oriented (as a consequence of the fact that the two

arrays are physically at right angles to each other). This pattern is again obtained by applying

23 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

the E and W aerial voltages to a differencing network that vectorially subtracts them (E-W).

The third of these antennas is the omni-directional sense antenna. In early Adcock designs,

a central sense antenna was implemented using a single aerial physically centered in the

Adcock array. Most (but not all) modern Adcock antennas employ a derived sense antenna

configuration whereby the omni-directional pattern is derived by vectorially summing the

output voltages of all four aerials. This omni-directional sense azimuthal gain pattern is

illustrated in Figure 13. The sense antenna is required to resolve a 180E bearing ambiguity

that would otherwise result. Early Watson-Watt DF systems required three separate but very

carefully matched receivers to process the three DF antenna outputs. Since this was

expensive and it was operationally difficult to maintain the precise gain and phase matching

among the three receivers necessary for good bearing accuracy, an antenna axis tone

encoding (modulation) scheme was developed so that all three DF antenna outputs could be

combined into a single composite signal that could be fed to a single receiver. Essentially, this

is done by amplitude modulating the N-S bi-directional output with one tone and the E-W bidirectional output with another. The receiver then processes this composite signal in the

standard fashion and recovers the two tones (whose respective amplitudes are now

proportional to the two bi-directional antenna outputs) from its AM demodulator. These two

tones are then fed to the DF bearing processor where they are separated and converted into

proportional DC voltages, which in turn drive the bearing display.

Analog bearing displays are typically two-phase devices such as a CRT or magnetically

controlled mechanical pointer. For a CRT display, these two DC voltages drive the CRT X

and Y deflection amplifiers, resulting in a true real-time polar bearing display. For a

mechanical pointer display, these two DC voltages drive the X and Y deflection coils.

Bearings can also be computed in software and then displayed in a variety of different

formats. This is typically accomplished by first converting the X and Y DC voltages to a digital

format using an analog-to-digital converter. The resulting digitized representation of the DC

voltages is then fed to a microprocessor, which in turn computes the bearing in software using

a 4-quadrant arc-tangent algorithm. Once the bearing has been computed, the

microprocessor can then drive one or more of several different bearing displays, including

azimuth rings, numeric displays, or even computer emulations of analog bearing displays.

For a more detailed explanation of the Watson-Watt DF

technique, see RDF Products Web Note WN-002

(“Basics Of The Watson-Watt DF Technique”). WN002 can be downloaded from the RDF Products web

site at www.rdfproducts.com

, and is also included on

the RDF Products publications CD.

Figure 10 - Adcock DF Antenna

Azimuthal Gain Patterns

24 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

APPENDIX A - INTERFACE CABLE MATING CONNECTOR PIN-OUT

Refer to Figure 14 below for the pin-out of the mating connector for the female microphone

(mobile radio) connector terminating the multi-conductor (antenna control) portion of the

antenna interface cable. This is the “Antenna Control” male chassis connector on the DF

receiver/bearing processor.

Note that while the current “B-series” equipment employs an 8-pin connector for this purpose,

earlier DF processors (e.g., the DFP-1000, DFP-1000A, DFP-1010, DFR-1000, and DFR1000A) employ a 7-pin connector. Figure 14 illustrates both connector styles along with a pinout list.

As can be seen from the illustration, the pin-outs are nearly identical, with the only difference

being how the ground connection is implemented. With the 7-pin version, the connector metal

shell (body) is relied upon to provide the ground connection. With the 8-pin version, the added

8th pin provides the ground connection. The standard microphone connector termination for

the DFA-1325B2 interface cable is the 8-pin version, although users with earlier DF

processors can purchase the RDF Products DCA-087 Cable Adaptor.

Figure 11 - Interface Cable Mating Connector Pin-Outs

The pin functions are explained below:

Pin 1 - X-axis encoding tone from DF receiver/bearing processor (1 volt p-p sinusoid).

Pin 2 - Y-axis encoding tone from DF receiver/bearing processor (1 volt p-p sinusoid).

Pin 3 - Antenna band switch line (Bit-1).

Pin 4 - Antenna band switch line (Bit-2).

Pin 5 - Antenna band switch line (Bit-4).

Pin 6 - 11-16 volt DC power from DF receiver/bearing processor.

Pin 7 - Antenna band switch line (Bit-3).

Pin 8 - Ground (8-pin version only)

Shell - Ground (7-pin version only). The connector shell must be connected to the DF

receiver/bearing processor chassis ground.

Note that setting all four band switch lines low signals the personality module to report the

model and band information. This information is sent as a 300N81 RS-232 data string in TTL

format, and is sent repeatedly as long as all four band switch lines are held low. The string

format is as follows:

DFA-1325B-2, 60-200, 200-1000<CR><LF>

25 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

APPENDIX B - INTERFACE CABLE EXTENSIONS

Although the supplied captive 8-meter interface cable set should be sufficiently long for most

applications, there may be some applications where a longer cable is necessary (e.g., if the

DFA-1333B1 is to be mounted atop a tall tower, or if the operator’s console cannot be located

close to the DF antenna). Although this can be done, there are certain issues that the user

should keep in mind.

Addressing first the 8-conductor control cable, this cable can be extended out to 100 meters.

This cable should employ #22 AWG wires with a weather-proof jacket. If the cable will be in

direct sunlight, the jacket should have an appropriate UV rating. Alpha Wire & Cable P/N

1178C works well for this purpose (available from Mouser Electronics, Inc.; P/N 602-1178C500 (the last three/four digits specify the cable length in feet, with standard lengths of

100/500/1000 feet).

Mating connectors are available to match the 8-pin mobile radio plug connected to the end of

the 8-meter antenna control cable. Keep in mind, however, that these mobile radio

connectors are not waterproof, so it will be necessary to seal the junction to prevent water

intrusion if this junction is outdoors.

Alternatively, the 8-pin mobile radio plug can be cut off and the end directly spliced onto the

extension cable. Again, this junction must be appropriately sealed against water intrusion.

For a long cable run, it is possible that there may be excessive voltage drop through the +13.8

VDC line. It is important that the user verify that the DC supply voltage presented to the DFA1333B1 be no less than 11.0 VDC under full load (i.e., with the antenna connected) to

guarantee that the internal voltage regulator will not drop out of regulation. If the voltage

presented to the DFA-1333B1 is less than 11.0 VDC, the most expedient means to correct this

is to “goose-up” the head-end DC power supply voltage (connected to the DFP-1000B/DFP1010B DF processor) slightly.

Many DC power supplies have internal adjustments allowing the output voltage to be raised

or lowered slightly. If this is the case, the output voltage can often be raised to offset the

antenna control cable wire voltage drop. Since the DFP-1000B/DFP-1010B can accept up

to +16 VDC, there is considerable latitude to raise the supply voltage as required to offset this

voltage drop. (Be certain, however, that this voltage does not exceed the host receiver input

DC voltage rating if this host receiver is powered from the same supply.)

For a fuller discussion of this DC voltage drop issue, see Section IV (“Extended Interface

Cable Lengths”) of the “DFA-Series Mobile Adcock Radio Direction Finding Antennas”

Operator’s Manual. This manual can be downloaded from the RDF Products website.

With regard to the RF output cable, an extension can be added using an appropriate coaxial

cable adaptor as required. If this junction is outdoors, it will have to be weather-sealed if the

junction is not inherently weather-proof.

The two major concerns with respect to the selection of a suitable RF extension cable are

cable loss and cable shielding. Since coaxial cables have significant loss in the 60-1000 MHz

range covered by the DFA-1325B2, a premium low-loss cable must be used for a long

26 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

extension. As a point of reference, matched cable loss per hundred feet for RG-223 (the RF

output cable supplied with the DFA-1333B1 is approximately 3.4 dB at 60 MHz and 17.6 dB

at 1000 MHz (for 50 feet these dB loss figures would be halved). Since losses of this

magnitude can noticeably degrade system sensitivity (especially at the higher frequencies),

it is better to use a premium low-loss cable such as RG-214 (with corresponding 100 foot

cable losses of 1.7 dB at 60 MHz and 8.4 dB at 1000 MHz).

If extension cable losses cannot be kept within reasonable bounds, a cable line amplifier can

be employed. Since this amplifier is likely to be exposed to a large number of strong signals

over a wide frequency spectrum, it is important that it be a premium device having very wide

dynamic range and good strong signal handling capability so as to minimize the generation

of intermodulation products that can interfere with desired signals.

Cable shielding is also very important. If inexpensive coaxial cable is used, it is likely to suffer

from signal pickup that will degrade DF antenna performance. To explain, it is very important

that nearly all signal pickup be from the DF antenna itself rather than from the coaxial feedline.

If significant feedline pickup occurs, bearing errors and reduced sensitivity are the likely result.

This shielding issue becomes more of a problem at higher frequencies and for longer cable

runs.

It is therefore very important that double-shielded coaxial cables (i.e., RG-223 and RG-214)

be used for cable extensions. Always avoid less expensive substitutes such as RG-58 and

RG-213 - these cables do not have adequate shielding.

27 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

APPENDIX C - MORE ON LIGHTNING PROTECTION

Addressing DF system lightning safety issues more fully, we advise users to prioritize these

issues in the following order:

1. First and foremost, protection of personnel must always be the highest priority.

2. The next most important issue is the protection of all equipment at the operating console

including the building housing this equipment.

3. The DF antenna and its associated cables are the final priority.

Issues #1 and #2 are best addressed using a special lightning protection interface panel for

the DF antenna cables. This panel includes lightning arresters that are intended to protect

personnel and equipment at the operator console. These panels are specialized products that

can be obtained from various sources. One of these sources is PolyPhaser

(www.smithspower.com/brands/polyphaser/). PolyPhaser also posts relevant literature on this

website that is well worth the time to read.

Unfortunately, the DF antenna itself is very hard to protect from a lightning strike. Although

one might think that a tall grounded lightning rod extending vertically through the center of the

chassis would serve this purpose, this is not the case for the following two reasons.

First, keep in mind that any conductive object in the vicinity of the DF antenna is an

unintended parasitic re-radiator. In effect then, this conductive object becomes part of the DF

antenna. In the general case, this undesired parasitic re-radiation results in pattern distortions

that can cause serious performance degradation.

For a fuller discussion of this issue, see our 1999 Application Note AN-005 (“An Introduction

to Dipole Adcock Fixed-Site DF Antennas”). In particular see the discussion in Section V-D

(“Dipole Adcock Performance Degradation Caused by the Vertical Support Mast”) beginning

on page 13. This discussion details the adverse effects of the central vertical support mast

(which in effect is what a lightning rod would be) on DF antenna gain patterns. The paper

goes on to discuss how this issue is resolved in RDF Products dipole Adcock DF antennas

by means of a special “iso-mast” (a special mast isolation technique employing ferrites).

Replacing this iso-mast with a lightning rod would reverse all of the careful and timeconsuming

engineering effort that was invested in its development and would undo one of the premier

features of RDF Products dipole Adcock DF antennas that distinguish them from less capable

competing designs.

The second issue is that even if such a lightning rod could be installed with no adverse

performance repercussions, it would almost certainly be ineffective in protecting the DF

antenna. To explain, the discharge voltage of a lightning strike on the lightning rod would

typically be in excess of 1,000,000 volts with a resulting current pulse peaking at over 10,000

amperes. In addition to likely structural damage, this massive current pulse would result in

a localized electro-magnetic pulse (EMP) that would almost certainly destroy any

semiconductors inside the DF antenna. (Unlike passive FM broadcast, TV, and shortwave

receiving antennas, DF antennas contain active electronics.)

28 of 29 - RDF Products - Vancouver Washington USA

mail@rdfproducts.com -- Copyright © 2015 by RDF Products -- www.rdfproducts.com

With these issues in mind, we believe that the best course of action is to invest whatever is

necessary to protect personnel, operating equipment, and the building housing this equipment

from a lightning strike as discussed above, but to recognize that there is no practical or

reliable way to protect an antenna containing active electronics from this same event. <>

29 of 29 - RDF Products - Vancouver Washington USA

Loading...

Loading...