SETUP

This setup manual contains a short instruction required

for installing, wiring, commissioning and operating the

inverters. For further instructions on installing or

operating, please refer to the detailed user manual,

which you can access via www.rct-power.com.

RCT Power GmbH reserves the right to make changes

to specifications or documents without prior notice.

RCT Power GmbH shall not be responsible for any

damages resulting from use of this document.

This document does not replace any applicable laws,

regulations, standards or codes.

Warranty conditions come enclosed with the device.

No warranties can be derived from this document.

Intended Product Usage

To prevent personal injury or property

damage, the inverter must only be installed,

wired, connected, commissioned, maintained

and serviced by qualified personnel:

•

Trained in installing electrical devices.

•

Familiar with all applicable laws, regulations,

standards and codes for electrical devices.

•

Familiar with safety requirements and safety-related

guidelines for electrical devices.

•

Familiar with work protection laws and regulations.

•

Using the appropriate personal protective equipment.

Power Storage 4.0, 5.0 and 6.0 are stationary 3-phase

string inverters with integrated battery charger. They

convert direct current (DC) supplied by the PV array and

the battery into alternating current (AC), which can be fed

into the electricity grid.

They are not designed for any other application or

connection to other devices.

Any use that differs from or goes beyond the intended

usage is considered misuse. RCT Power GmbH shall not

be liable for any damage resulting from misuse.

Any misuse will terminate warranty, guarantee and

general liability of the manufacturer.

EN

Symbols

Level of risk

Explanation

high

medium

low

Immediate

danger of death

or serious injury

Immediate

danger of minor

or moderate

injury

Danger of

equipment or

property damage

Installation

Power Storage 4.0 / 5.0 / 6.0

In 9 Steps to the installed system

Assembly and mounting.

(Section 2, p.3).

Electrical connection of the devices.

(PV, grid, battery section 3, p.4-5 / Communication section 4, p.7 /

Power Switch, Power Sensor section 5&6&6.1, p.8-10).

Inverter switch on (switch on fuses).

(Section 7.1, p.11).

Access to the inverter via APP.

(Steps 1 to 5 in the setup section 7.2, p.11-12).

Configure the inverter, select the land and norm.

(Steps 6 to 9 in the setup section 7.3, p13).

Power Sensor configuration (PV power must be >250W, so the sensor is correctly

detected and tuned, flash).

(Step 10 in the setup section 7.3, p.13).

Configure the Power Switch, if available.

(See Manual, Power Switch).

Configure the battery.

(Steps 11 to 14 in the setup section 7.3, p.13-14).

The configuration of the battery is now complete.

After the inverter has checked the specifications, it starts charging the battery.

2

[1] Scope of Delivery

Fig.1

Look over

user manual.

Wait 10 minutes after

disconnection before

touching inner parts.

Hot surface

Electrical device:

grounding necessary

[2] Inverter Mounting

Item

Description

A

Setup manual

B

PV input- and battery connectors

(Weidmüller PV-Stick)

C

Wall bracket for mounting inverter

D

Inverter

a

LCD display for information on inverter operation

b

DC switch for emergency shutdown of inverter

c

DC PV plugs

d

Cable entries for communication ports

e

Cable entry for AC cable

f

Screw hole for additional protective grounding

g

Name plate with technical data, serial number,

symbols:

h

DC battery plugs

i

Cable entries for RJ45 connectors, Battery,

Power Sensors and Power Switch

Item

Description

A

Select non-flammable, firm wall. Room may not

contain highly flammable goods, liquids or gas.

B

Protect from snow, rain, direct sunlight and dust.

Observe allowed ambient temperature (-25 … 60°C).

Maximum degree of pollution PD2.

C

Mount in upright position. Ensure enough space for

easy access. Make sure wall supports inverter

weight.

D

Minimum clearance: half of inverter width at both

sides and half of height at top and bottom.

E

Do not place inverter in closed cabinet.

Step

Description

1

Attach wall bracket firmly to wall with 3 to

6 screws (ø 6 to 8 mm), matching wall

plugs and washers (outer ø min. 18 mm).

Material not included in delivery.

2

Take out locking screw of inverter

housing. Hook inverter onto wall bracket

and fix locking screw back.

3

[3] Electrical Connection

[3.1] Overview Connection Parts

Fig. 2

[3.2] AC Connection

Risk of death or injury due to electric shock!

While the inverter is connected to grid (AC

voltage source), to PV array which is exposed to

sunlight (DC voltage source) or to the battery

(DC voltage source), high voltage is present in

cables and inner parts of inverter.

•

Important: All voltage sources (DC / PV-generator,

DC / battery and AC / utility grid) must be disabled

before any electrical work.

To disable PV-generator DC voltage connection turn DC

switch to 0-position and wait 10 minutes before

continuing.

To disable AC voltage connection turn off AC switch,

main breaker or fuse. Make sure, other persons don’t

switch back.

Do not enable voltage connections until work is finished.

•

To disable DC battery voltage connection both voltage

sources (DC / PV-generator and AC / utility grid)

must be disabled.

•

During AC connection: Do not exchange L, N and PE

wires!

•

Make sure other persons keep away during electrical

work.

Risk of death or injury due to electric

arc!

Disconnecting DC plugs under load can

cause electric arcs.

Risk of damage due to improper

installation and operation or misuse.

•

Contact local utility company or grid operator

before connecting inverter to grid.

•

Provide for an AC disconnection device

(typical miniature circuit breaker 3 pole 6kA,

B-characteristic 16A).

•

If required in country or installation, install a

residual-current device (RCD), or residualcurrent circuit breaker (RCCB).

•

Inverter contains no owner serviceable parts.

Contact local authorized personnel for service.

•

Do not remove name plate.

•

Only RCT Power certified batteries complying

with the demands of the certain region are

allowed to be used.

Item

Description

A

AC terminal block for L1, L2, L3, N and PE

phases.

B

Clamps for parallel DC mode.

C

Communication board.

D

RJ45 Connectors for Battery communication

via CAN, Power Sensor and Power Switch.

Step

Description

1

Remove cover of inverter. Locate AC

terminal block (Fig. 2, A).

2

Feed cable through AC entry (Fig. 1, e).

Push down clamps to insert L1, L2, L3, N

and PE.

3

Tighten swivel nut of cable entry.

4

[3.3] DC Connection

[3.4] DC Parallel Mode

Material not included in delivery.

This section applies only, if several Strings with an

equal amount of modules are to be connected in

parallel and the maximum input current per input

therefore exceeds 12A.

Step

Description

1

Remove cover of inverter. Locate clamps

for parallel DC mode (Fig. 2, C).

2

Connect clamps X101 and X104.

To prevent personal injury or property

damage, make sure that there is no PVDC connector plugged and DC-switch is

“0” in during this installation.

[3.5] DC Battery Connection

Make sure DC switch is “0”, the battery ON/OFF switch set to “0” and AC switch, main breaker or fuse is “OFF”.

Plug corresponding plus and minus poles into battery plugs of inverter.

(The connection cable from the inverter to the battery is not included).

Step

Description

1

Do not turn plug parts before inserting the

cable.

Select correct plugs for polarity of PV and

battery strings.

2

Push cable into plugs straight until the spring

clamp locks.

3

Turn lower part of plug shut.

4

Make sure DC switch is “0”. Plug

corresponding plus and minus poles into

adjacent PV plugs of inverter (Fig. 1, c).

DC cable -

DC cable +

5

[3.6] Second Protective Inverter Grounding

Material not included in delivery.

If required in the country of installation, attach a second protective earth connection to the Power Storage Inverter

housing.

6

[4] I/O-Board Communication Connection

Fig.3

Communication Ports

[4.1] Connection of Communication Ports

[4.2] Wiring of Communication Ports

Item

Description

1

X102: serial RS485 interface.

2

X100: Multifunctional Relay, max. 24 V, 1

A.

3

X101, Power management: 4 digital inputs

for potential free relay contacts.

4

X103: Digital in/out, max. Input 24 V,

max. output 5 V, 10 mA.

Step Description

1

Open cable entry (Fig. 1, d) and feed cables.

2

Select correct port (see next section), press down spring clamp, insert cables and release.

7

[5] RJ45 Connectors for Power Battery, Power Sensor and Power Switch communication

The inverter communicates with the battery via the CAN-Bus. If inverter is delivered with optional Power Sensor

and Power Switch please refer to user manual of these items for further detailed commissioning information.

Fig. 4

RJ45 – Communication Ports

[5.1] Connection of RJ45 – Communication Ports

[5.2] Wiring of RJ45 – Communication Ports

Standard communication with Power Battery

Additional Power Switch communication

Additional Power Sensor communication

Additional Power Switch and Power Sensor

communication

Item

Description

A

X403: Battery communication connector.

B

X403: Not used.

C

X403: Power Sensor communication

connector.

D

X403: Power Switch communication

connector.

Step Description

1

Open cable entry (Fig. 1, i) and feed cables.

2

Select correct port (see Fig. 4 and next section), insert cables in RJ45 connectors.

8

[6] Connection - Power Switch

Step

Description

1

Switch off the system (see section 8).

2

Place the Power Switch in the service entrance box or near.

3

Connect the Power Sensor and the Power Switch via patch cable at the

Power Storage on the communication connector X403.

4

For further configurations please refer to user manual.

This section applies only when using the RCT Power Switch in combination with a battery

system.

9

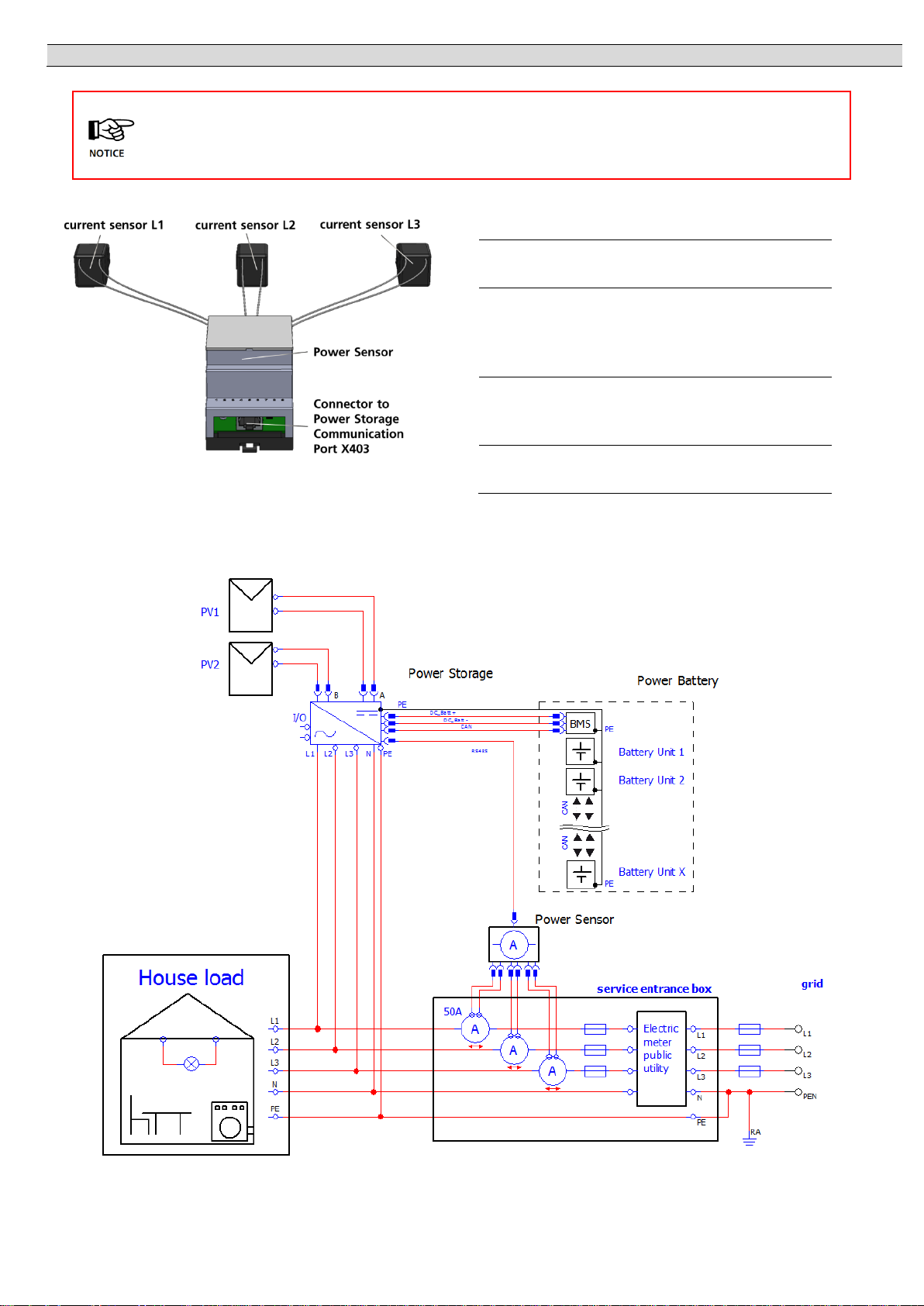

[6.1] Connection - Power Sensor

Step

Description

1

Place the Power Sensor in the service

entrance box.

2

Click the three current sensors around the

L1, L2 and L3 wires in the service entrance

box. (The order and direction of installation

is not important).

3

Connect the Power Sensor to the Current

Sensor communication connector X403 CS

at the Power Storage via patch cable.

4

For further configurations please refer to

user manual.

The Power Storage system functionality depends on energy consumption measurement.

This section applies only to Power Storage Inverters, which are delivered with Power

Sensor.

10

[7] Commissioning

Ensure proper mechanical an electrical installation before commissioning the solar inverter.

Check the cables to ensure, that they are in sound condition.

Always disconnect the mains connection first by switching off the corresponding mains fuse and

before disconnecting the solar generator side by opening the DC load break switch.

The DC-connectors on the solar generator side must not be disconnected under load. First turn the DC

load break switch to position 0.

[7.1] Inverter switch on

Step

Description

1

Establish grid connection via the external circuit breaker.

2

Switch on the solar generator voltage by closing the DC load break switch

(position 1). The solar inverter starts operating, when the input voltage

level and power is adequate.

Display will switch on and show norm „Factory defaults“.

[7.2] Access to the inverter

The Solar Inverter is equipped with an internal Wi-Fi unit. To set up Solar inverter you need to

access via Wi-Fi due to the suitable Android APP.

The Android APP is the central user interface for commissioning.

It ensures easy data collection and troubleshooting.

Obtaining Android App: Go to Google Play Store, search for “RCT Power App”, and install.

Step

Description

1

Activate Wi-Fi on your smartphone (or tablet

computer).

2

Connect with SSID identical with the name of the

Power Inverter on inverter display via Wi-Fi.

(e.g. PS 6.0 8HNE).

If the Inverter is already in a network via

Wi-Fi, connect to the network.

11

2a

If you connect the first time with a device to the

inverter you need a password.

The password corresponds to the serial number of

your device (see display or name plate).

3

Start “RCT Power APP”.

4

Switch to tab “Network” and press “Scan”.

4a

Activate “10.10.100.254“ (or if you have renamed

the device choose this) by choosing radio button.

5

If the connection is made with an inverter, the

name is displayed on the head and the icon is

edged.

Only an example!

12

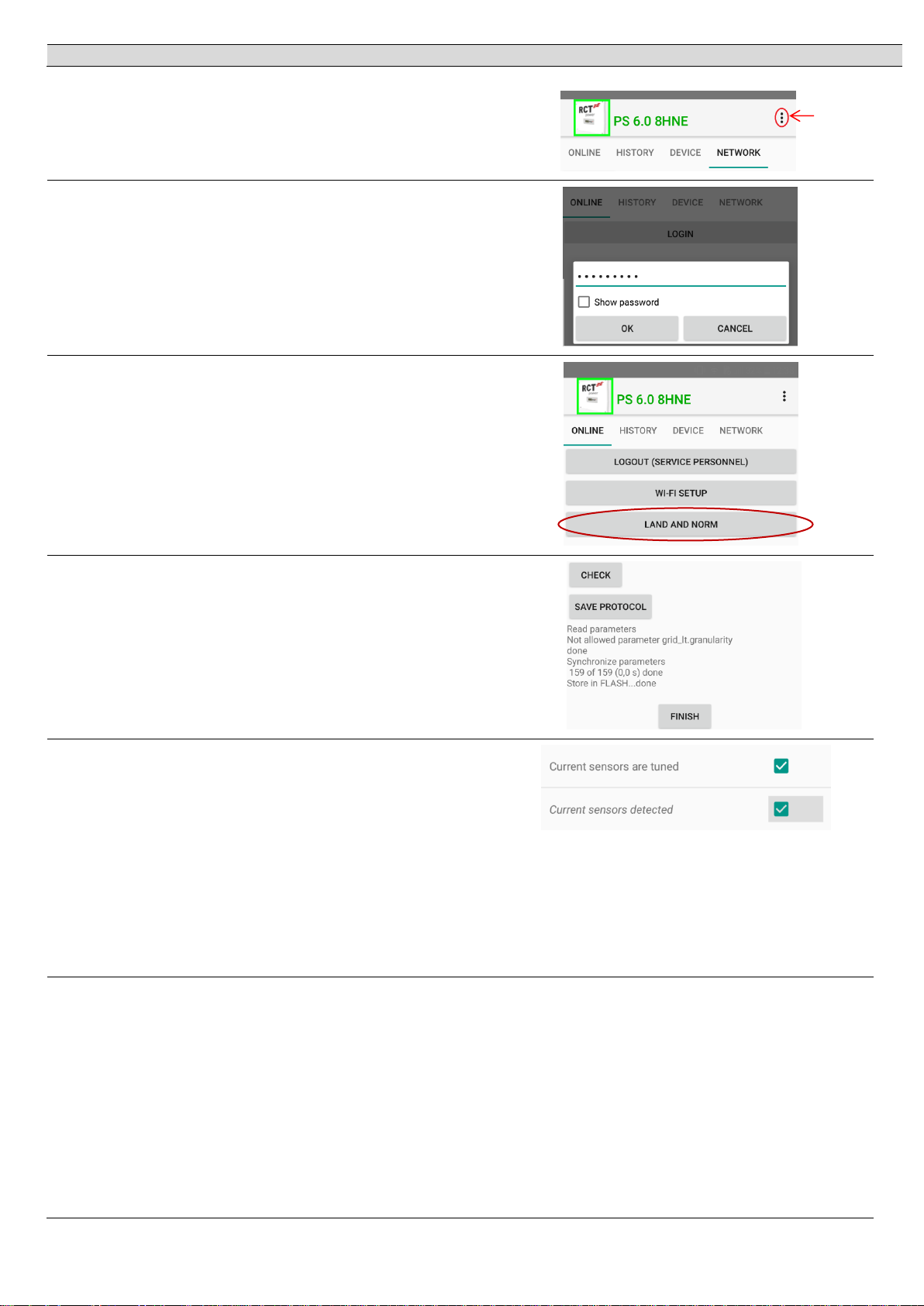

[7.3] Battery and inverter configure

6

Press “menu” and choose “Setup”.

7

Enter setup procedure by “Login”

(password: “installer”).

8

Choose “Land and Norm”, select appropriate

norm and “apply”.

9

Wait during parameters are synchronizing and

stored. When finished press “Finish”.

After the inverter has checked the specifications,

it begins to feed into the grid.

10

The Power Sensor will be detected and tuned,

automatically by an Inverter power of 200 W.

Continue with Device Settings Device

settings (scroll down) Power Sensor tuning

(scroll down)

If current sensors are tuned and detected press

“FLASH” to store settings permanent, finish!

For further configurations please refer to user

manual.

11

Go to “Device” and click “Settings” press “Battery”

and choose “Battery type”.

menu

13

12

Choose “Li-Ion RCT Power” or your appropriate

battery type.

13

Press “Flash” to finish the battery setup and

press “return“ to get on start page.

14

Switch the battery on by setting the battery

ON/OFF switch to “1”.

15

After the inverter has checked the specifications,

it starts calibrating the battery.

The battery is charged to 100%, which can take

several hours.

(When calibrating, power may be used out from

the grid to speed up the process if the power is

insufficient)

When calibration is complete, the system

automatically switches to compensation mode.

[8] How to switch off the system

Step

Description

1

Locate DC switch (Fig. 1, b) and turn to “0” position and switch off the battery with the ON/OFF switch to “0”.

2

Locate and switch off circuit breaker, main breaker or fuse for disconnecting inverter from utility grid.

3

Wait 10 minutes until capacitors have discharged.

4

Locate DC / PV connectors (Fig. 1, c) and DC / battery connectors (Fig. 1, h). Press latches of male plug

together to unlock and pull off DC plugs.

Note: For further information on installation and operation, please refer to the detailed user manual, which

can be obtained from our website www.rct-power.com .

14

[9] Technical Data

Power Storage 4.0 5.0 6.0

Order Number IHP040N1AE0 IHP050N1AE0 IHP060N1AE0

DC-INPUT

Max. recommended DC power 5000 W 6250 W 7500 W

Rated DC power 4200 W 5250 W 6300 W

MPPT 2 (paralleling possible)

Input per MPPT 1

Maximum DC current per MPPT 12 A ( 24 A in parallel mode)

Rated DC voltage 700 V

DC start up voltage / power 150 V / 25 W

DC voltage range 140 V ... 1000 V

MPP voltage range 200 V ... 800 V 220 V ... 800 V 265 V ... 800 V

Maximum voltage DC 1000 V

Connector type

Weidmüller PV-Stick (MC4 compatible)

BATTERY-INPUT

DC voltage range 150 V … 600 V

Maximum charge / discharge current 20 A / 20 A

Maximum charge / discharge power 6000 W / 4000 W 6000 W / 5000 W 6000 W / 6000 W

Connector type Weidmüller PV-Stick (MC4 compatible)

AC-OUTPUT

Rated AC output power 4000 W 5000 W 6000 W

Maximum active power 4000 W 5000 W 6000 W

Maximum apparent power 6300 VA 6300 VA 6300 VA

Nominal AC current per phase 5,8 A 7,3 A 8,7 A

Maximum AC current per phase 9,1 A 9.1 A 9.1 A

Rated frequency 50 Hz / 60 Hz

Frequency range 45 Hz ... 65 Hz

Max. switch-on current 13 A, 0,1ms

Max. fault current (RMS) 285 mA

Rated AC voltage 230V / 400 V (L1, L2, L3, N, PE)

AC voltage range 180V ... 270V

Total harmonic distortion (THD) < 2% at rated power

Reactive power factor (cos phi) 1 (adjustable range 0,8 cap….0,8 ind )

Anti-islanding operation Yes

Earth fault protection RCD

DC-current injection < 0,5% In

Required phases, grid connections 3 (L1, L2, L3, N, PE)

Number of feed-in phases 3

Grid voltage monitoring 3-phase

Type of AC connection Spring clamps

PERFORMANCE

Stand-by consumption < 4.0 W

Maximum efficiency (PV – Grid) 98,16%

European efficiency (PV – Grid) 97,6% 97,7% 97,9%

Maximum efficiency (PV – Battery – Grid) 95,9%

Topology Transformerless

15

OTHER

RCT Power GmbH

Line Eid Str. 1

78467 Konstanz, Deutschland

Tel.: +49 (0)7531 996 77-0

Mail: info[at]rct-power.com

Internet: www.rct-power.com

05/2017

PV – DC-switch Integrated

DC overvoltage protection Category II

AC overvoltage protection Category III

Data interface WIFI, optional: RS485, Multifunctional dry contact, 4 x digital in, 2 x digital in/out

Display LCD dot matrix 128 x 64 with backlight

Cooling Convection

IP degree of protection IP 42

Max. operating altitude 2000 m

Max. relative humidity 5 - 95% (non condensing)

Typical noise

Operating temperature range -25°C … 60°C (40° at full load)

Type of installation Wall mounting

Dimensions (height x width x depth) 570 x 585 x 200 mm

Weight 26 kg

SAFETY / STANDARDS

Protection class 1

Overload behavior Working point adjustment

Certificates CE, VDE-AR-N 4105:2011-08, EN 50438

Further certificates

EMC EN61000-6-2, EN61000-6-3, EN61000-3-2, EN61000-3-3

Safety EN/IEC62109-1, EN/IEC62109-2

www.rct-power.com

:

BLOCK DIAGRAM

16

Loading...

Loading...