Page 1

RCS

Model TR60

RS485 Thermostat

Installation Manual

DCN: 140-01761-01

3/21/09

*** IMPORTANT NOTICE ***

DO NOT USE THIS PRODUCT FOR BUILDING FREEZE PROTECTION! YOU ARE ADVISED TO

INSTALL A MECHANICAL FREEZE PROTECTION DEVICE ON YOUR SYSTEM FOR THIS PURPOSE.

Page 2

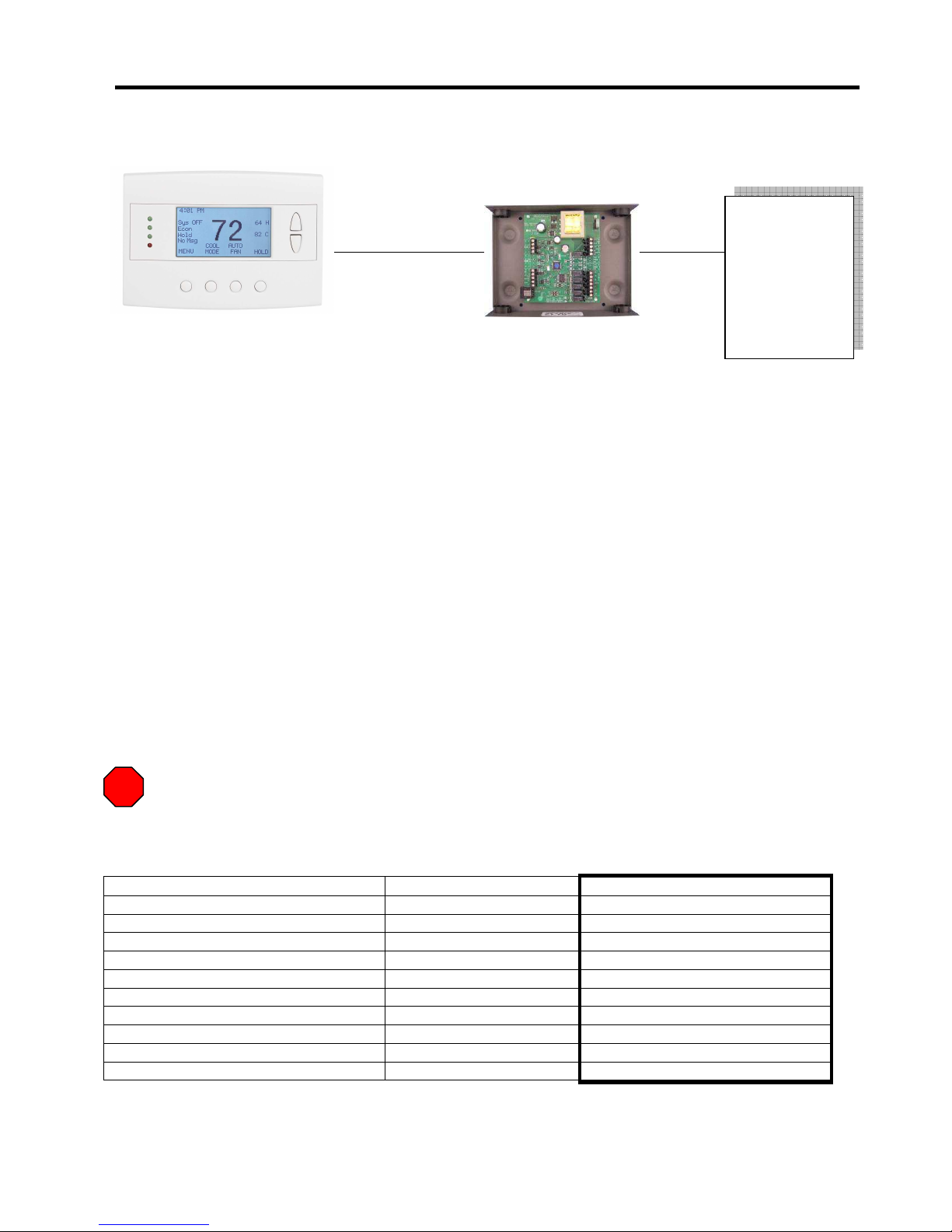

TR60 Thermostat Installation

The TR60 thermostat is a two part thermostat with a Wall Display Unit (WDU) and a HVAC Control Unit.

TR60 Wall Display Unit

Model: TS60 Model: ZCV1

4 Wire

Thermostat wire or

Cat 5 wire

Install theTR60 Wall Display Unit (WDU) on the wall in the traditional thermostat location. The HVAC

Control Unit is typically installed at the HVAC mechanical system location, but it can be installed anywhere

in the wiring between the WDU and the HVAC system.

Wiring

Retrofit installations

The Wall Display Unit replaces the traditional thermostat. The existing thermostat wiring can be used (4

wires required). Install the TR60 WDU at the thermostat end and simply cut the cable at the desired

location of the HVAC Control Unit and connect it in the line. 4 wires are required between the WDU and

HVAC Control Unit and typically 5 wires are required between the HVAC Control Unit and the HVAC

system. Heat Pump and Multistage systems may require additional wires between the HVAC Control Unit

and the HVAC System. Consult your HVAC system wiring diagram.

New Construction

For new installations, prewire the thermostat location back to the mechanical HVAC system with either

thermostat wire, 5 conductor, (18-20ga) or Cat 5 cabling. The TS60 WDU wires to the HVAC Control Unit

with this cable. The HVAC Control Unit wires to the HVAC system with thermostat wiring, typically 5 wire,

18-20Ga. Heat Pump and Multistage systems may require additional wires between the HVAC Control

Unit and the HVAC System. Consult your HVAC system wiring diagram.

STOP

BEFORE REMOVING THE OLD THEMOSTAT! Write down connections!

Be sure to write down the existing wiring connections to the old thermostat. Label the wires with the

thermostat connection. Refer to these when connecting the HVAC Control Unit to the HVAC system.

Old Thermostat Terminal Marking Typical Wire Color Your Wire Color

C or B (24V common) Blue or Black

R (or RH for split heating systems) Red from heating system

RC (for split cooling systems) Red from cooling system

G Green

W or W1 White

W2 Brown

Y or Y1 Yellow

Y2 Black or Blue

O (heat pump system only) Orange

B (heat pump system only) Brown or Blue

Caution: Thermostat wiring color codes are not standardized beyond simple 5 wire systems. Do

not rely on the color of the wire to determine function. Check it and write it down!

TR60 HVAC Control Unit HVAC System

5 Wire

minimum

Thermostat

wire

DCN 140-01761-01 3/21/09

2

Page 3

Wall Display Unit Installation

For retrofit installations, install the WDU at the existing thermostat location. You may reuse the existing

thermostat wiring (4 wires required).

For new installations, be sure to locate the WDU in a location for best temperature sensing in the area to

be controlled. Avoid these locations:

• Outside walls

• Drafty locations

• Direct sunlight exposure

• Near HVAC vents

• Corners or behind doors

Install the WDU

• Mark the location of the installation holes

• Install the screw anchors

• Run wiring through the back plate

• Install the back plate on the wall with the screws provided.

• Connect wiring to terminals. CAUTION! Double check your wiring. Mis-wiring the WDU can

result in damage to the unit.

• Write down the terminal wiring colors for connecting the WDU cable on the HVAC Control Unit

end.

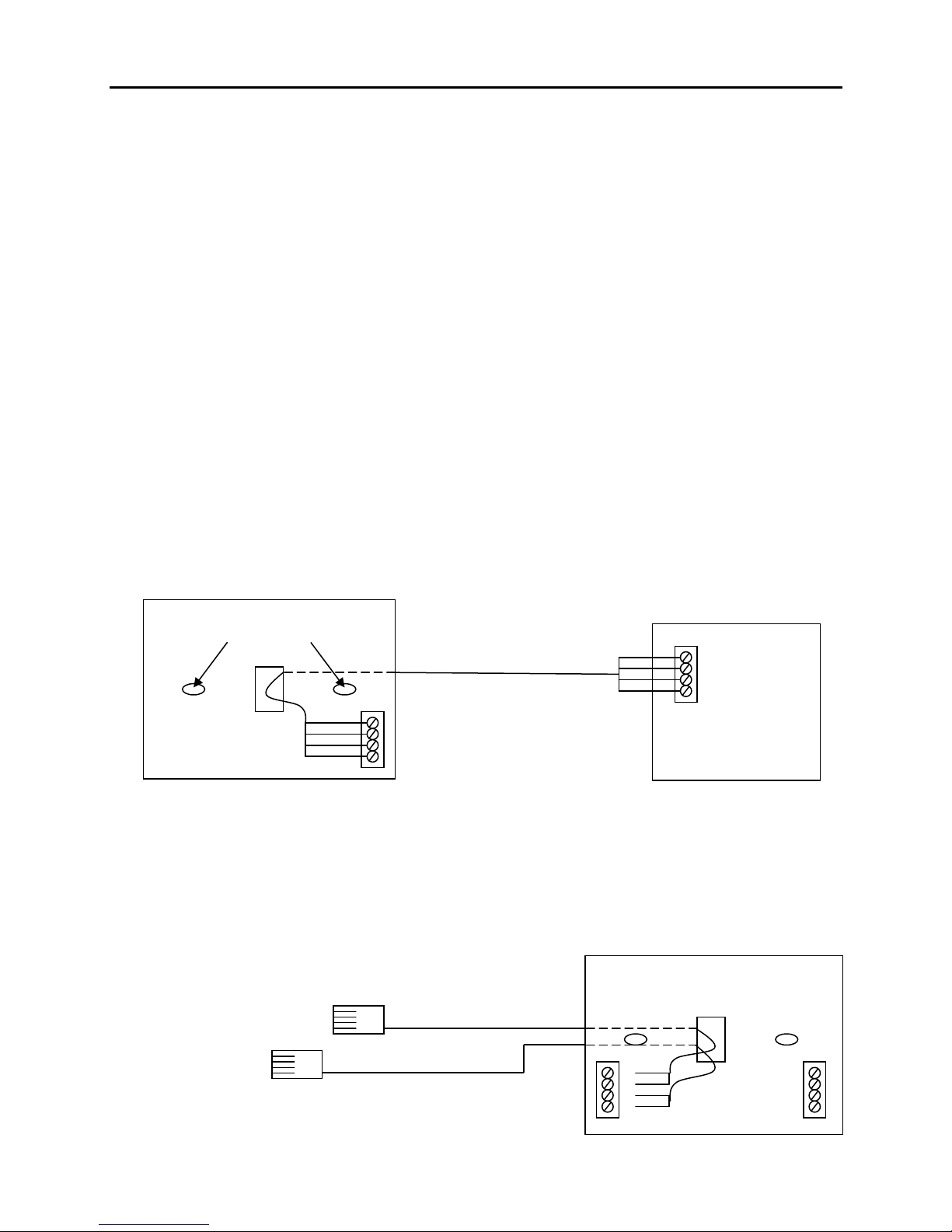

WDU Wiring to HVAC Control Unit

Wall Display Unit

Back Plate

Model: TS60

Mounting holes

Control Unit

G

+V

C

D

Remote Sensor Connection

Two remote sensors can be connected to the TR60 Wall Display Unit.

• Sensor S1 will replace the internal sensor

• Sensor S2 will be averaged with the internal sensor

or Sensor S1 if attached

• Use only RCS 10K Thermistor style sensors

Remote Temp Sensors

Model RTS3 or RTS4

S2

S1

Note the wire color connections.

4 wire connection is required back

to the HVAC Control Unit. Existing

thermostat wiring can be used.

For new construction, thermostat

wire or Cat 5 wire can be used.

Remote sensor wiring is non-polarized.

Remote Sensors

S1

S1

S2

S2

HVAC Control Unit

WDU

G

+V

C

D

Model: ZCV1

Wall Display Unit

Back Plate

DCN 140-01761-01 3/21/09

3

Page 4

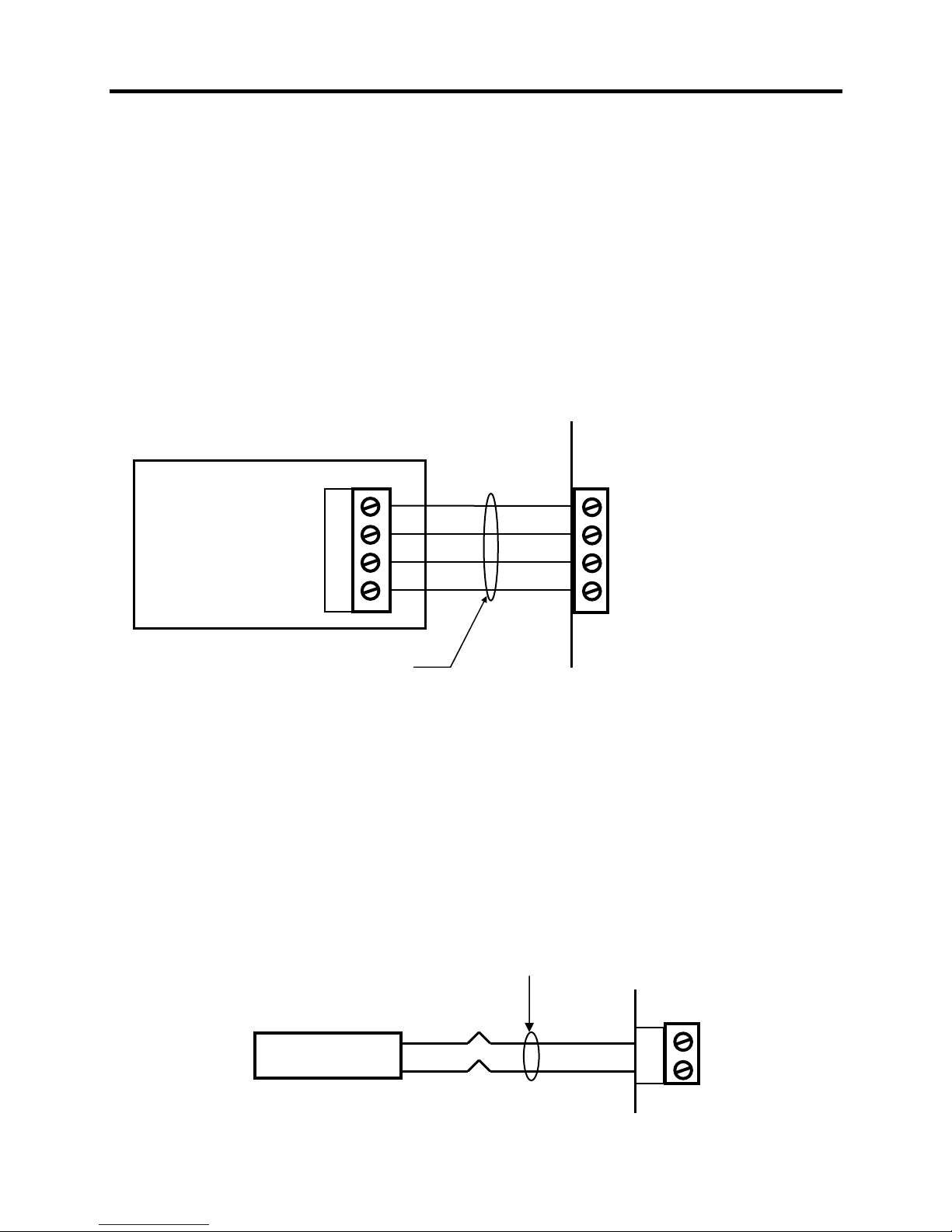

HVAC Control Unit Installation

GND G

+12VDC +V

CLOCK C

DATA D

+12V

GND

DATA

CLK

can be used.

Location and Mounting

Install the HVAC Control Unit in a protected, convenient, indoor location near the HVAC system or in a

service accessible area such as an equipment closet or garage.

Mount the HVAC Control Unit in a vertical position on a wall or sturdy structural member. The unit may be

mounted on the HVAC system but care should be taken to avoid hot burner sections or high vibration

areas.

Wall Display Unit Connection

Wire specification: 4 conductor, 18/20Ga thermostat wire or 22Ga twisted pair or Cat 5 wire (preferred)

Connect the Wall Display Unit to the HVAC Control Unit by four wires. In retrofit applications, the existing

thermostat wiring may be used, however, for best results and in new construction, a Category 5 twisted

pair cable is recommended.

TR60 WALL DISPLAY UNIT

Standard Thermostat Wire or Cat 5 cable

Standard thermostat Wire color code

Ground: Green

12VDC: Red

Clock: Yellow

Data: White

Preferred Cat 5 Wire color code

Ground: Brown pair (twisted together)

12VDC: Blue Pair

Clock: Green Pair

Data: Orange Pair

CAUTION! Do not mis-wire the Wall Display Units – damage may result. Check the wiring before

applying power to the HVAC Control Unit.

TR60 HVAC CONTROL UNIT

WDU

Zone 1

Outside Temp Sensor Connection

Wire specification: 2 conductor, 22Ga twisted pair or Cat 3/5 wire (preferred)

Model OS5

Outside Temp Sensor

DCN 140-01761-01 3/21/09

Black

Red

Sensor wiring is not polarized.

4

TR60 HVAC CONTROL UNIT

S1

OS Sensor

S1

Page 5

RS485 Network Connection

The RS485 communications port is a 2 wire (D+ and D –) plus ground, half-duplex network connection.

Wiring options are direct to a host com port or wired to a RCS RS485 hub to allow star or homerun wiring.

Host System

RS485 port

12V

Gnd

D+

D -

Always wire + to + and – to –, regardless of the D+/ D- or A/B or TX/RX labels.

Up to 4000 ft

RS485 Wiring Note

RS485 Wiring Methods

The HVAC Control Unit can be wired by three methods:

1. Direct connection to RS485 Host com ports (as above)

2. Multi-drop (daisy chained) to other thermostats/devices

3. Homerun wired to an RCS Star Wiring Hub.

Multi-drop Wiring

Host System

RS485 port

12V

Gnd

D+

D -

Cat 5 cable recommended

RS485

Gnd

D+

D -

RS485

Gnd

D+

D -

Star Wiring Hub

CommStar Model CS308 or

Model 8AH485 8 Channel Star RS485 Hub

RS485 Port

RS485 Port

RS485 Port

RS485 Port

RS485 Port

RS485 Port

RS485 Port

RS485 Port

Cat 5 cable recommended

Each TR60 HVAC Control Unit is homerun wired to the Star Wiring Hub

HVAC Control Unit

RS485 Port

HVAC Control Unit

RS485 Port

HVAC Control Unit

RS485

Gnd

D+

D -

RS485

Gnd

D+

D -

HVAC Control Unit

RS485 Port

HVAC Control Unit

RS485 Port

100 ohm line

termination resistor

recommended on

last device (>100ft)

DCN 140-01761-01 3/21/09

5

Page 6

Connecting to RS232 Communications Ports

RCS Model 485PB 5-Port RS232 to RS485 Converter with power outputs.

PC or

Control System

DB9 Serial

Com Port

5 Port

RS485

Hub

Standard PC serial cable (incl)

(DB9 to DB9)

V

G

B+

A -

12VDC Power

Transformer (incl)

B&B Electronics Model 485DB9TB RS232 to RS485 Converter - 2 wire

PC or

Control System

Model 485DB9TB

DB9 Serial

Com Port

+12 G G TD(B) TD(A)

USConverters Model RS485 RS232 to RS485 Converter – 2 wire

PC or

Control System

DB9 Serial

Com Port

Model RS485

+5V

G

DD+

Connecting to USB Ports

Several companies make USB to RS485 Converters.

B&B Electronics

Model 485USBTB-2W

USConverters

Model US485MIO

Model USB485CAB

HVAC Control Unit

RS485

Gnd

D+

D -

HVAC Control Unit

RS485

Gnd

D+

D -

HVAC Control Unit

RS485

Gnd

D+

D -

DCN 140-01761-01 3/21/09

6

Page 7

Power Connection

The TR60 HVAC Control Unit requires 24VAC power. Power is provided from the HVAC system or by an

external transformer (not supplied). Do NOT connect the HVAC system power if you are connecting an

external power transformer.

Power

24C C

24R R

[or]

Standard

C

R

W

W2

G

Y1

Y2

Alternate power input.

External Transformer

24VAC 40VA

24V Com

24V Return

HVAC System

Connect only one

power source!

Vent Damper Wiring

Wire specification:

RD Series dampers: requires 2 conductor cable

RDM Series dampers: requires 3 conductor cable

Recommended wire: 18/20GA thermostat wire

Dampers

Vent Damper output supports either two wire (normally closed, power open/spring return) or three wire

dampers (power open, power close).

The vent damper output is 24VAC, 1 A max.

RD Series 2 Wire Dampers

24V R

24C

PWR

24R

24C

Vent

NC

Damper

NO

Yellow

Yellow

Normally Closed Damper

Power Open

Spring close

RDM Series 3 Wire Dampers

24V R

24C

PWR

24R

24C

Vent

NC

Damper

NO

1 Com

2 Open

3 Close

Power Open/Close Damper

Power Open (24V on 1-2)

Power Close (24V on 1-3)

DCN 140-01761-01 3/21/09

7

Page 8

HVAC System Connection

RH 24V

W2/CO

Y1 COMP

W1 Heat

W2/CO

Y1 Comp

The TR60 HVAC Control Unit connects to the HVAC system like a standard thermostat.

Standard Gas/Electric HVAC System Wiring

HVAC Control Unit

24C

PWR

24R

HVAC System

RC 24V

W1 HEAT

G FAN

Y2 COMP

Install jumper wire for power

from HVAC System

Standard HVAC System

THERMOSTAT CONNECTION

Blue

Red

White

Orange

Green

Yellow

Brown

C 24VAC COMMON

R 24VAC RETURN

W 1 Heat Stage 1

W2 Heat Stage 2

G Fan

Y1 Compressor Stage 1

Y2 Compressor Stage 2

JP1

Heat Pump HVAC System Wiring

HVAC Control Unit

HVAC System

24C

PWR

24R

RC 24V

RH 24V

G Fan

Y2 Comp

JP1

JP1: RH and RC Jumper

This commons both RH and RC for normal single transformer HVAC systems.

Cut JP1 jumper for separate RH and RC transformer systems.

NOTE: When jumper JP1 is cut, W1 and W2 are switched to RH. G, Y1

and Y2 are switched to RC.

Install jumper wire for power

from HVAC System

Heat Pump HVAC System

THERMOSTAT CONNECTION

Blue

Red

White

Orange

Green

Yellow

Brown

JP1: RH and RC Jumper . Do not cut.

Leave RH and RC connected for Heat Pump Systems

C 24VAC COMMON

R 24VAC RETURN

W1 Aux Heat

O/B Changeover (CO) Valve

G Fan

Y1 Compressor Stage 1

Y2 Compressor Stage 2

NOTE: Set correct Changeover

value operation for O (CO w/Cool)

or B (CO w/Heat) mode on

DIPSW1 on the control board.

DCN 140-01761-01 3/21/09

8

Page 9

HVAC SYSTEM SETUP

The TR60 must be configured for the correct HVAC system type. This is done by

setting the dipswitch, SW1, on the HVAC Control Unit.

You must know what type of HVAC system you have to correctly setup the thermostat. Determine the

following before you install the TR60. Check your HVAC system manual to verify.

• HVAC System Type: Standard Gas, Electric or Heat Pump system.

• HVAC System Fan Type: Gas or Electric

• Heat Pump System Changeover valve Type: Changeover with cooling or changeover with

heating.

For retrofit installations, the original thermostat settings and wiring may be clues to the proper settings. If

you are not sure, consult the HVAC system manual or contact a qualified service technician.

Setup Dipswitch SW1

Switch S1: System Type

Off: Standard gas/electric HVAC system (default)

On: Heat Pump System

Switch S2: S2 function is dependent on the setting of S1

If S1= Standard system

Then S2 = Fan Type

Off: Gas heating system (default)

On: Electric heating system

If S1= Heat Pump system

Then S2 = Changeover valve type (CO)

Off: CO/C Change over with cooling (default)

On: CO/H Change over with heating

Any change to the SW1 settings requires the

HVAC Control Unit to be power cycled (Off/On).

You can view and confirm the system setup in the Wall Display Unit’s Main Menu “Thermostat Info”

screen.

Additional setup options and operational preferences are available in the “User Settings” and “Installer

Settings” menus accessed from the Wall Display Unit.

Refer to the “Installer Settings” document from details of these optional settings.

Off On

S1

S2

S1 S2 OFF S2 ON

STD GAS ELECT

HP CO/C CO/H

Setting SW1 correctly is

required for proper system

operation.

DCN 140-01761-01 3/21/09

9

Page 10

SYSTEM CHECKOUT

It is strongly recommended that you hook-up and run a simple bench test before installing the TR60

thermostat. Not only will this save you time in system checkout but will also familiarize you with the TR60

operation.

Quick Test

NOTE: Before power up, set the dipswitch, DIPSW1, to ALL OFF.

1. Connect the Wall Display Unit to the WDU input on the HVAC Control Unit with a 3 foot 4 wire cable.

2. Connect a 24VAC transformer to the HVAC Control Unit Power Input connector.

3. Plug the transformer into a power outlet

4. Verify Status LED is flashing.

5. Verify the WDU display comes on and shows the current temperature.

a. If no display or a “CF” display is shown on the WDU, double check your wiring.

b. Do not proceed until the current temperature is displayed on the WDU and communications

between it and the HVAC Control Unit is OK. Any problems will result in a “CF”

(Communications Failure) display on the WDU.

6. Press the WDU Fan button on the WDU. The HVAC Control Unit Fan LED and relay should turn on.

7. Press the WDU Fan button again. The Fan LED and relay should turn off.

8. Press the WDU Mode button until Heat Mode is selected.

9. Press the Setpoint Up button until the setpoint is above the current temperature. The Heat LED and

relay should come on. (after any MOT delays, check WDU system status LED label)

10. Press the Mode button until OFF mode is selected. The Heat LED and relay will turn OFF.

11. Press the Mode button until Cool mode is selected.

12. Press the Setpoint Down button until the setpoint is below the current temperature. The Y1 and G

(Fan) LEDs and relays should turn on. (after any MOT delays, check WDU system status LED label)

13. Press the mode button until OFF mode is selected.

14. All LEDs and relays should turn off.

15. When you have successfully completed these tests, you have verified that the basic thermostat

functions are working correctly.

16. BEFORE INSTALLING THE THERMOSTAT, SET THE DIPSWITCH, SW1, TO THE CORRECT

CONFIGURATION FOR YOUR HVAC SYSTEM TYPE.

Communications Test with a PC

1. With the TR60 connected as above, proceed with connecting the HVAC Control Unit’s RS485 port to

a PC serial port (COM1) using a RS232 to RS485 converter (RCS Model 485DBTB or eqv).

Note: If you are not using an RCS RS485 to RS232 converter, be sure that your converter supports

automatic Send Data Control (required).

2 Confirm the thermostat address is 1 in the Thermostat Info screen. This is the default address. If not,

change in the Installer Settings/Network Settings menu item

3. Start Hyperterm terminal emulator program in Windows/Accessories/Communications/Hyper

Terminal.

4. Set Hyperterm communications parameters for COM1 to 9600 baud, no parity, 8 data bits, 1 stop bit

and NO flow control.

5. Set CAPS lock on (Commands are case sensitive).

6. Send the Request for Status command R=1.

Type “A=1 R=1” followed by the carriage return (cr).

7. Thermostat should respond with the R=1 status response showing temp, setpoint, mode and fan.

(A=00 O=1 Z=1 T=xx(current temp) SP=70 SPH=70 SPC= 74 M=0 F=0)

8. Set Mode to Heat. Type “A=1 M=H (cr)”.

9. WDU should change to show the new mode is “Heat”.

10. Set heat setpoint to 78 degrees. Type “A=1 SPH=78 (cr)”

11. WDU should change to show a setpoint update of “Heating Setpoint 78”.

12. If the WDU responds properly to these commands, proceed with final installation.

DCN 140-01761-01 3/21/09

10

Page 11

HVAC SYSTEM QUICK TEST

In the event that you have difficulty with the TR60 controlling the HVAC system, you can perform the

following quick test to confirm that the HVAC system is working correctly.

The TR60 HVAC Control Unit connects to the HVAC system at the normal thermostat connections on

the HVAC unit. Standard thermostat control of the HVAC systems consist of contact closures in the

thermostat. You can verify that your HVAC system is working correctly by duplicating these contact

closures by shorting across the proper terminals on the HVAC systems thermostat connection. Refer to

the following HVAC system example.

HVAC SYSTEM EXAMPLE

This is a simplified diagram of a Standard HVAC

System and Thermostat. The Thermostat operates

like switches to control the HVAC Fan, Heat, and Cool

functions.

FURNACE AND BLOWER UNIT

THERMOSTAT

FAN

COMP

Thermostat

R 24VAC

G FAN

W HEAT

Y COMP

C 24VAC COMMON

For Standard HVAC systems:

Go to the HVAC system’s thermostat connection terminals

Verify FAN operation by shorting across the R to G (Fan) terminals

• HVAC system fan should come on. (Caution: Delays may be

part of normal start up cycle, check HVAC system’s manual)

• If not check HVAC system power and fuses.

• If power is OK, HVAC system is NOT working correctly.

Verify HEAT operation by shorting across R to W (Heat) terminals (A Fan call is not necessary for gas furnaces)

• Heating operation should start. (Caution: Delays may be part of normal start up cycle, check HVAC

System’s manual)

• If not, check wiring, check 24VAC power is on R terminal. (measured across R to C).

• If power is OK, HVAC system is NOT working correctly.

Verify COOL operation by shorting across R to Y (Compressor) and R to G (Fan) terminals

• Cooling operation should start. (Caution: Short Cycle Protection 5 minute delays are normal

between calls and may delay start)

• If not, check wiring, check 24VAC power is on R terminal (measured across R to C)

• If power is OK, HVAC system is NOT working correctly.

If any of these checks fail, the HVAC system is not working correctly. Call an HVAC professional.

Heat Pump Systems are similar, but have an additional output for the changeover valve.

The basic fan and heating test are the same.

HVAC SYSTEM

STANDARD GAS/AC

FAN

RELAY

GAS

VALVE

COMP

RELAY

Outdoor

Condensing

Unit

24VAC

DCN 140-01761-01 3/21/09

11

Page 12

DCN 140-01761-01 3/21/09

12

GND

12V

CLK

DATA

Outside

Sensor

Vent Damper

RDM Series

shown

24C R

NC G

NO W

HVAC

System

G

12V

C

D

Green

Red

Yellow

White

75

G

+

C

D

WDU

Red

Black

24VAC

Power

Vent

Damper

HVAC System

Standard or Heat Pump

Set DIPSW1 to

Correct System Type

24V Com

24V

W1

W2

G1

Y1

Y2

Typical Thermostat Connection

24VC

24VH

Heat 1

*Heat 2

Fan

Comp1

Comp2

Outside

Temperature

Sensor

OS5

RC

RH

W1

W2/O

G

Y1

Y2

RC/RH Jumper JP1

Cut for separate Heating and

Cooling Transformers

Zone 1

Blue

Red

White

Orange

Green

Yellow

Brown

*Note: W2 = O/B (Changeover) when

Heat Pump System Type Selected

Red

White

STD HP

DIPSW1

Fuse

Mini ATO type

2A

S1 S2 OFF S2 ON

STD GAS ELECT

HP CO/C CO/H

S2

Typical Thermostat

Wiring Color Codes

180-01006-11

ZCV2 REV K

RCS

RCSRCS

RCS

Status LED

GND

D+

D -

RJ45

JACK

RS485

Network

Ground

Data +

Data -

RS485

Com Port

Alternate RS485 Connector

(8 Wire Modular Jack)

HVAC System Setup – Dipswitch SW1

DIPSWITCH HVAC SYSTEM SETUP

S1 Sets HVAC System Type Position

STD - Standard System Set S1 OFF (default) Left

HP - HP System Set S1 ON Right

S2 If S1= Standard System – Sets Fan Type

Gas System Set S2 OFF (default) Left

Electric System Set S2 ON Right

S2 If S1 = HP System – Sets Changeover (CO) Valve Type

O Mode: CO with Cool Set S2 OFF (default) Left

B Mode: CO with Heat Set S2 ON Right

Wall Display Unit

M

odel

TS60

RS485 RJ45

Connector Pinout

1 Data+

2 Data 3 NC

4 NC

5 NC

6 NC

7 NC

8 GND

12345678

Front View

1 24V Com

2 Open

3 Close

24VAC

24C B

24R R

Alternate power input.

External Transformer

24VAC 40VA

TR60

Wiring Diagram

S1

S2

Power from HVAC system.

Do not connect if using

external power transformer.

24V Com

24V

W1

O / B

G

Y1

Y2

Standard Heat Pump

HVAC Control Unit

Model ZCV1 Rev K

Loading...

Loading...