Page 1

"EPSILON"

®

FUEL LEVEL SENSOR

"ESx - H" model

User Manual

EH.000 UM

_v. 171228_

Page 2

2

CONTENTS pages

INTRODUCTION………………………………………………………………3

1 SPECIFICATION AND PRINCIPLE OF OPERATION ...................... 3

1.1 Specification and operation of device ................................................................ 3

1.2 Specification and operation of device components .......................................... 10

2 INTENDED USAGE ............................................................................. 11

2.1 Operating restrictions ....................................................................................... 11

2.3 Device preparation for use ............................................................................... 11

2.4 Use of device .................................................................................................... 11

3 TECHNICAL SUPPORT ...................................................................... 12

3.1 Technical support of device ................................................................................... 12

4 TECHNICAL MAINTENANCE .......................................................... 13

4.1 Malfunctions diagnosis of device and troubleshooting actions ....................... 13

5 TRANSPORTATION AND STORAGE .............................................. 17

The present installation manual is intended to provide information necessary for

users during operation and maintenance of “Epsilon” fuel level sensor “ESx-H model”

(hereinafter – sensor, FLS or product).

Personnel familiar with the present manual is allowed to install the sensor.

Page 3

3

1 SPECIFICATION AND PRINCIPLE OF OPERATION

1.1 Specification and operation of device

1.1.1 Intended use

Sensor is purposed for fuel level measurement in fuel tanks of vehicles and

stationary fuel tanks. Sensor can be used to measure level of other nonconductive

liquids.

ES2-H, ES4-H sensor can be used with equipment that supports unified

communication protocol Epsilon Data Exchange. (hereinafter - EDE).

ESA-H model sensors can be used with analogue interface devices.

Sensor has electronic galvanic isolation through interface and power circuits.

Sensor is compatible with different GPS tracking devices, such as:

- "Автограф";

- "Скаут";

- "Locarus";

- "Intellitrac";

- "Patriot";

- "Teletrack";

- "Teltonika";

- "M2M – Cyber GLX";

- "Ruptela FM";

- "BCE FM blue» and others.

Additional features

Model ES2-H sensors provide frequency interface (signal outputting from 500

to 1500 Hz frequency with linear frequency dependence vary with measured level of

fuel). Also, model ES2-H sensors can provide analogue interface (signal outputting

from 0 to 10 V voltage with linear voltage dependence vary with measured level of

fuel), when using FV-10 frequency-to-voltage converter.

Page 4

4

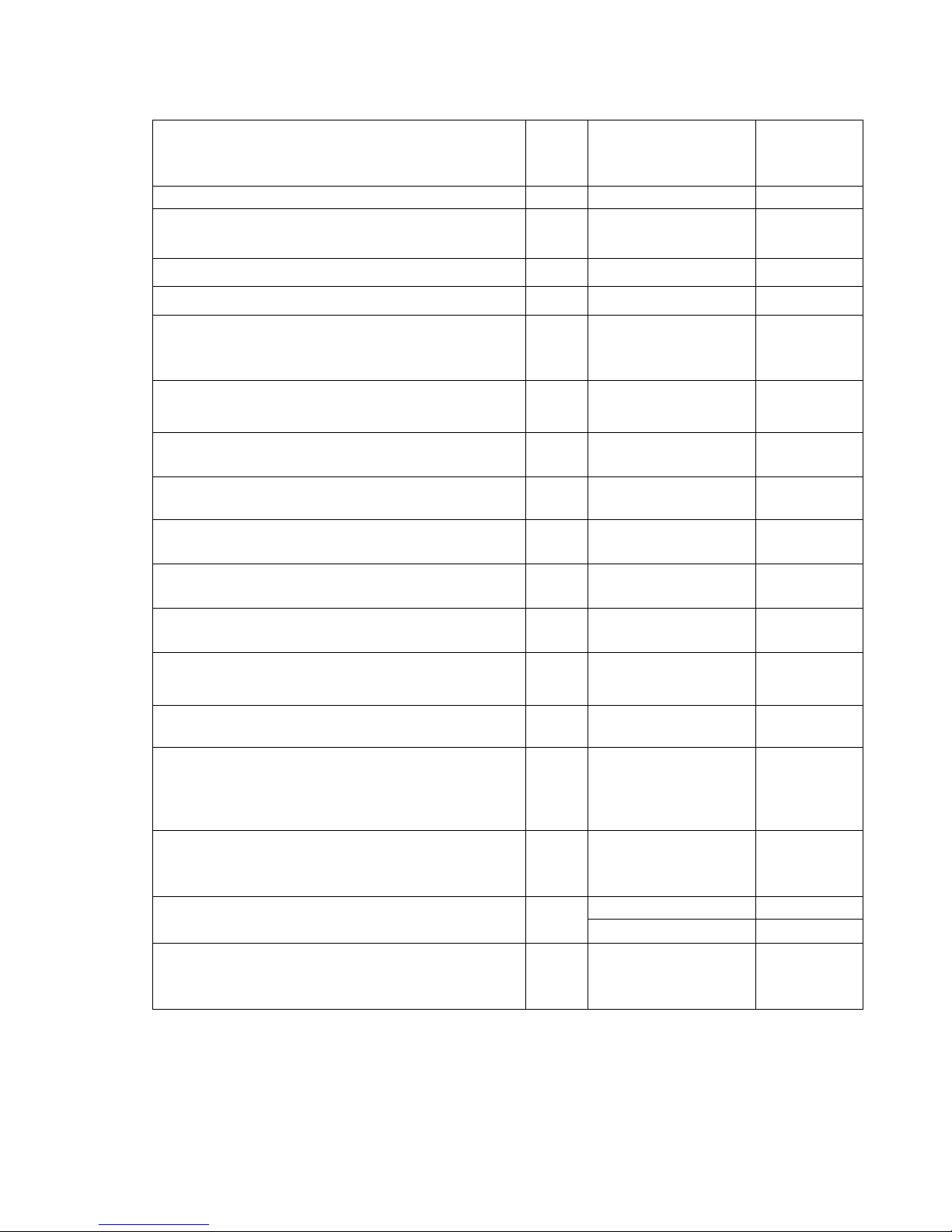

1.1.2 Technical specification

Table 1.1

Parameter or characteristic name

Unit

Value

Note

(Note

number)

1

2 3 4

Operational temperature range

°

С

– 40 … + 75

Ingress protection rating

IP67

Mode of operation

Continuous

Upper variation range of level measurement

mm

from 150 to 2000

(1)

Ranges of permissible reduced error of level

measurement

%

±1,0

(2)

Variation range of relative dielectric

permittivity in controlled fuel (ε)

-

1,5…5,0

The period of measurement results averaging

Sec.

0…128

Code length of presentation of measurement

results

bit

10;12;14;16

(3)

Temperature measurement range of

measuring head

°

С

- 40…+ 85

Code length presentation of measuring head

temperature

bit

8

Power supply voltage, operational range

V

+9.5…+36

Nominal

value

Current consumption, max

mA

25

Acceptable exposure of impulse voltage

through power circuits

V

+120, long-term

+ 180 V, 1 sec.

-1000 V, long-term

(4)

Acceptable short-term exposure of potentials

difference between signal ground and body of

measuring head

V

±1500 V, 1 sec.

Digital interface

RS-485

ES4-H

RS-232

ES2-H

Exchange rate through the serial port

bps

2400, 4800, 9600,

19200, 38400,

57600, 115200

programm

ed

Page 5

5

Table end 1.1

1

2 3 4

Frequency interface (when using ES.700

compatible device)

Hz

500…1500

ES2-H

Analogue interface

V

0…10

ESA-H

model

Analogue interface (when using frequency to

voltage converter FV-10)

V

0…10

ES2-H

Flange version

4 holes, 4,2 mm

Height of a measuring head over a tank top,

including flange and gasket, max

mm

26

Notes for table 1:

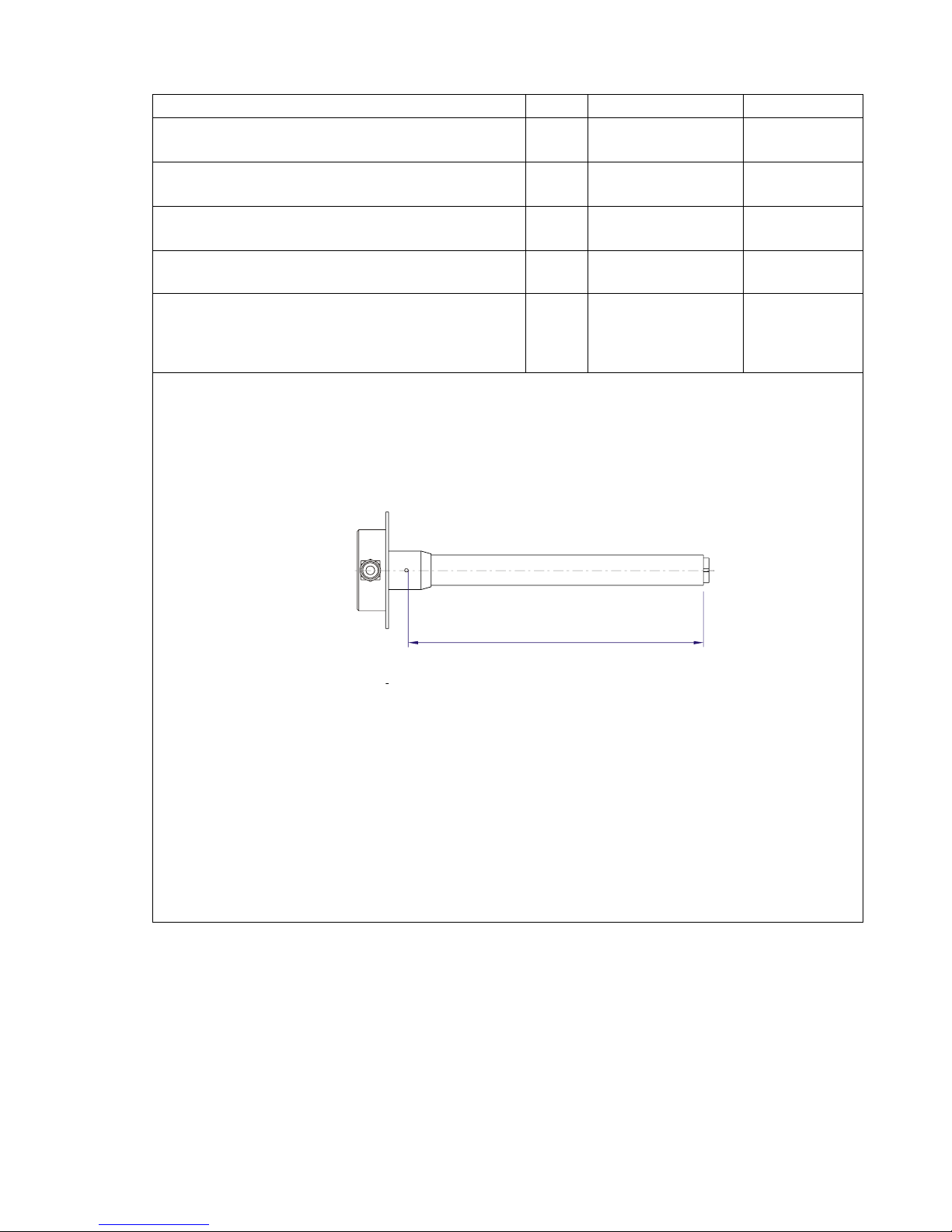

1 Level measurement range – Ly distance from the lower cut of metal tube (lower threshold

of measurement) to the lower edge of drain orifice (highest threshold of measurement),

according to Figure 1.1:

Figure 1.1 - Level measurement range

2 When testing fuel with the same dielectric permittivity as the fuel which was used during

calibration process. To ensure precise monitoring with other fuel grades (according to

dielectric permittivity of fuel grade) adjustment of calibration table must be used.

3 Data output has two layouts: 16 bit and 10/12/14/16 bit. Capacity 10/12/14/16 bit is

switched according to the program. 10 bit value is set by default.

4 Pulse parameters according to GOST (ГОСТ) 28751 (severity degree 3 for 24V on-board

power use).

Ly

Page 6

6

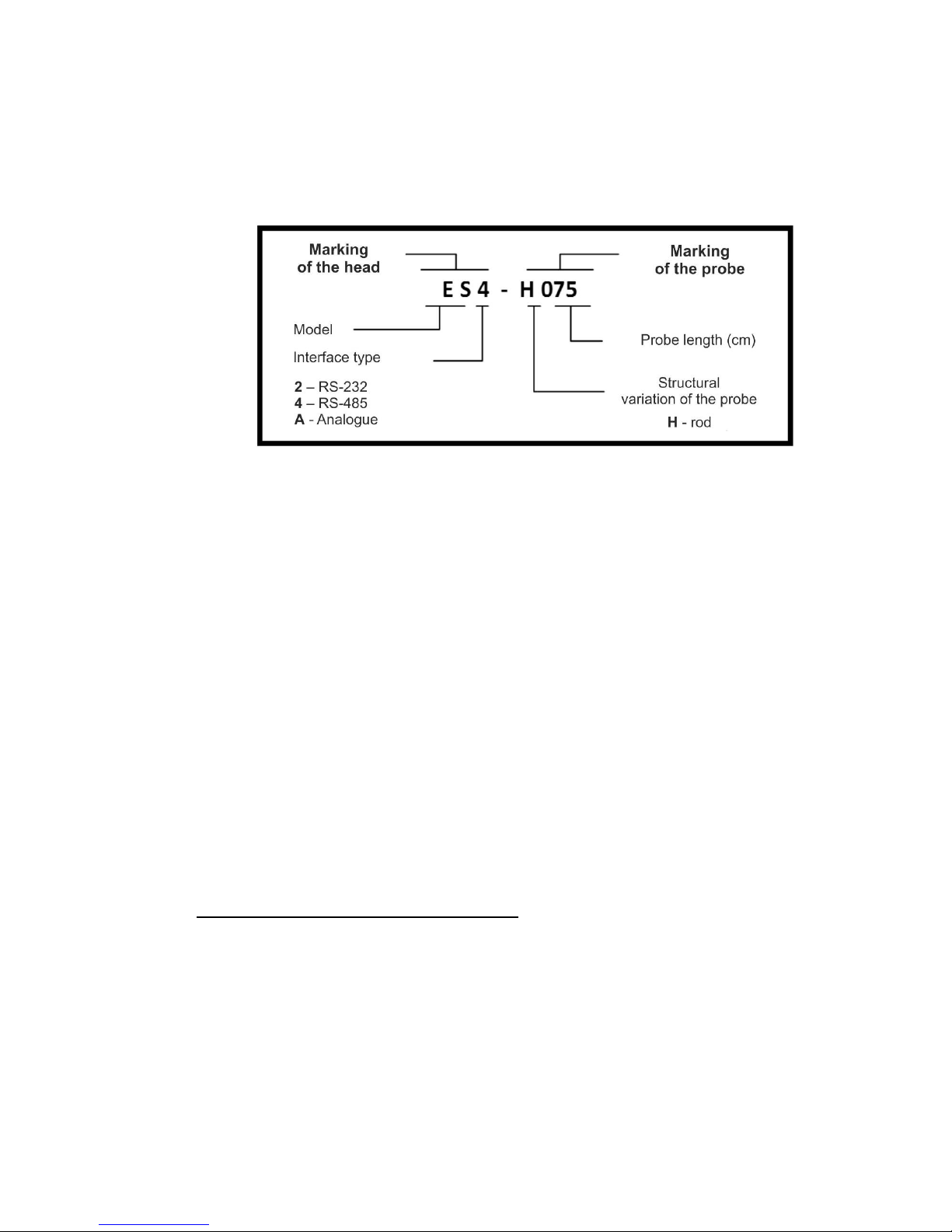

1.1.3 Marking of device

Sensor has different marking, depending on the interface type and fuel probe

length (figure 1.2):

Figure 1.2 – Sensor legend

"Epsilon ES2-H" – exchanges data through RS-232 interface.

"Epsilon ES4-H" – exchanges data through RS-485 interface.

"Epsilon ESA-H" – exchanges data through analogue interface.

1.1.4 Device ordering

1.1.4.1 When ordering sensors marking includes:

- title name;

- sensor name - "Epsilon “

- model marking;

- interface type;

- fuel probe length in centimeters;

1.1.4.2 Example of “Epsilon” sensor marking for registration when ordering as

well as in specification of other products it can be used with:

Fuel level sensor "Epsilon" ES4-H-075

where "Fuel level sensor" is a title name;

"Epsilon" – sensor name;

"ES-H" – model;

"4" – interface RS-485;

"-" – spacer;

"075" – fuel probe length 75 cm;

Page 7

7

1.1.4.3 Evaluation of fuel probe length when ordering (See figure 1.4)

Figure 1.4 - Evaluation of fuel probe length when ordering

To evaluate the proper fuel probe length it is necessary to measure fuel tank

depth in place of intended sensor installation and to calculate length of fuel probe

according to the formula:

Lm = L- ∆,

where Lm – approximate length of fuel probe as per order;

L– tank depth in place of intended sensor installation;

∆ - distance between measuring part and tank bottom.

Recommended values for distance ∆:

- ∆ = 15…20 mm – for rigid metal tanks (the deeper the tank the bigger

the distance);

- ∆ = 30 mm – for tanks without enough rigidity (such as plastic tanks of

considerable height).

During installation process, the necessity of reducing fuel probe length may arise

(on-site).

You can find the procedure of reducing fuel probe length in “EH.000-EN IM_

Installation Manual”.

L

D

Page 8

8

1.1.5 Delivery set

1.1.5.1 Basic delivery set

Table 1.2

Name

q.

Note

Assembled sensor

1

Assembled with ~ 40 cm cable

Interface cable

1

~ 7 m long

Self-drilling screw

1

With hole for safety seal

Self-drilling screw

3

∅4,2 х 19 mm

Gasket

1

Tamper-evident seal

1

With wire for safety seal

Fuse SI 0,1 A

1

Zip tie

15

200 х 3.6 mm

Passport

1

1.1.5.2 Additional accessories and documentation

(delivered by additional order)

Table 1.3

Name

Ref.

Note

EA2 sensor connection cable to PC

IEC EA С.100

For EA2-H models

EA4 sensor connection cable to PC

IEC EA С.100-01

For EA4-H, ESA-H

models

Interface adapter

USC234-A

For ESA-H models

Matching device

ES.700

For EA2-H models

Frequency-to-voltage

converter

FV-10

For EA2-H models

CD with software

EA.000 CD3

For ES2-H, ES4-H

models

CD with software

EH.000 CD3

For ESA-H models

Installation manual

EH.000-EN IM

User manual

EH.000-EN SM

Page 9

9

1.1.6 Design and operating principle

A measuring head together with a sensor probe submerged in fuel provides fuel

level measurement.

Sensor probe acts as a condenser, which capacity linearly depends on a fuel level

in a tank.

Measuring head of the sensor performs linear conversion of sensor probe volume

into fuel level digital code, processes acquired digital information with averaged

results, measures sensor head temperature and outputs data in unified EDE protocol

through RS-232 or RS-485 interfaces (for ES2-H and ES4-H models) or through

analogue output (for ESA-H model). Fuel level data outputs in 16-bits (additionally,

data output can be selected in 10-, 12-, 14- or 16-bits), temperature data outputs in 8bits.

To measure the volume of monitored fuel calibration of fuel tank must be

performed. This procedure determines volume-level code dependence of fuel.

Calibration procedure and installation of data exchange parameters (by using

“EP30_Install” software) described in appendix A of “EH.000 IM. Installation

Manual”.

Data exchange protocol EDE can be found in appendix B of aforementioned

document.

The process of firmware updating and methods of saving and restoring

configuration data described in appendix B of aforementioned document.

1.1.7 Marking and sealing

1.1.7.1 Marking

1.1.7.1.1 Measuring head marking:

- title name and manufacturer brand mark;

- "epsilon® fuel level sensor” caption;

- marking of model;

- serial number according to the manufacturer.

1.1.7.1.2 Sensor package marking:

- title name and manufacturer brand mark;

- “EPSILON® fuel level sensor” caption;

- marking of model;

- fuel probe length (mm);

- manufacture date;

1.1.7.2 Sealing

To protect the sensor from tampering, two seals must be

fixed after sensor installation. The first seal protects the measuring head from

Page 10

10

unscrewing, and the second is installed on the detachable connection of the interface

cable. Sealing procedure is described in Section 4 of “EH.000-EN IM. Installation

Manual”.

1.1.8 Packaging

Sensor is packed in a polyethylene “sleeve”; components from basic delivery set

(see table 1.2) are packed in several polyethylene packs.

1.2 Specification and operation of device components

1.2.1 General information

A measuring head together with the sensor probe provides fuel level

measurement.

1.2.2 Measuring head

Measuring head contains (see figure 1.2):

- capacitymeter;

- digital circuit for data processing;

- data exchange device;

- power supply regulator and circuit for protection of incoming and outcoming

electric circuits.

Sensor is connected to the external devices by the interface cable. Capacity meter

performs conversion of current probe volume into digital code. Conversion is a linear

function with variable parameters.

Digital circuit for data processing manages the capacity meter performance

(limits of measurement, offset nulling, etc.), temperature compensation and received

data scaling.

Data exchange device performs data exchange with GPS trackers, save/load of

sensor calibration and configuration data and remote updating of embedded software.

Sensor is mounted onto tank with self-drilling screws. Gasket ensures tightness

between tank and flange.

1.2.3 Fuel probe

Fuel probe is a coaxial capacitor formed by an aluminum alloy tube (outer

electrode) and an isolated aluminum rod (inner electrode). Required centering of the

rod is achieved by placing a plug on the edge of the fuel probe and by isolated inner

position-spacers.

Page 11

11

2 INTENDED USAGE

2.1 Operating restrictions

2.1.1 During sensor operation, it is forbidden:

– to use sensor not on purpose;

– connect to the interface of devices, which do not meet requirements of the

operational documentation;

– expose to influence of aggressive environments;

– apply a power with voltage exceeding the limit value of 120 V;

– allow pulse voltage exposure through power-supply circuits with values

exceeding the limits in table 1.1.

2.1.2 It is not forbidden to use the sensor with liquids, which maintain their

physical form within the operating temperature range.

2.1.3 Dielectric permittivity of measured liquid must correspond to dielectric

permittivity of tested liquid. Error of measurement will rise if abovementioned

requirements are not met.

2.3 Device preparation for use

Device preparation for use must be carried out according to “EA.000-EN IM.

Installation Manual”.

2.4 Use of device

2.4.1 Sensor is used to send digital data about fuel level in tank to GPS tracking

device.

Sensor is operated by external device through the interface cable and do not

require additional human assistance.

2.4.2 The possible malfunctions of device and troubleshooting actions described

in table 4.1.

2.4.3 Emergency actions

In case of fire at the sensor area, it is necessary to kill power supply and perform

all standard firefighting procedures.

Page 12

12

3 TECHNICAL SUPPORT

3.1 Technical support of device

3.1.1 General information

3.1.1.1 Sensor is a maintenance-free device but if it is necessary to perform a tank

maintenance according to a vehicle servicing schedule, it’s a good practice to perform

sensor maintenance as well.

3.1.1.2 Personnel familiar with the present manual and document "ES.000-EN

IM. Installation manual" are allowed to install the sensor.

3.1.2 Safety measures

3.1.2.1 During installation of the fuel level sensor, organizational and technical

actions that ensure the safety of the work with control and measuring equipment,

ancillary equipment and consumable materials have to be carried out.

3.1.2.2 The responsibility for the implementation of security measures lies with

the technical staff involved in the installation of the fuel level sensor, as well as the

employees responsible for the equipment at the working site.

3.1.2.3 Requirements of fire safety regulations, according to ГОСТ (GOST)

12.1.004-91" Occupational safety standards system. Fire safety. General

requirements," and electrical safety, according to ГОСТ (GOST) 12.1.019-91

"Occupational safety standards system. Electrical safety. General requirements" or

other requirements in force within the consumer territory have to be observed on the

working site.

3.1.2.4 Requirements of occupational health and safety rules have to be

observed on road transport at the working sites according to ПОТ РМ (POT RM)-027-

2003 "Interindustry occupational safety and health rules on road transport" or

requirements of regulatory documents in force within the consumer territory.

Page 13

13

3.1.3 Maintenance procedure of device

3.1.3.1 Carry out dismantling of the sensor in next order (figure 3.1):

- disconnect interface cable from the sensor;

- unscrew 4 self-drilling screws and take out sensor from the tank;

- rinse the inner part of sensor probe with the fuel (in which the sensor was

operating) and blow it with a compressed air;

- check the sensor parameters (with “EP30_ Install” software for ES2-H and ES4-

H models and with “EP31_ Install” software for ESA-H model), according to

the procedure described in Annex A of “EH.000 IM. Installation Manual”);

- perform sensor installation and sealing according to requirements in 1.1.7.2

4 TECHNICAL MAINTENANCE

4.1 Malfunctions diagnosis of device and troubleshooting actions

4.1.1 General instructions

4.1.1.1 Personnel familiar with the present manual and document “EH.000 IM.

Installation Manual” are allowed to install the sensor.

4.1.1.3 Possible malfunctions during sensor operation and troubleshooting

actions are described in table 4.1.

Page 14

14

Table 4.1

Malfunctions

Probable causes

Troubleshooting actions

1

2

3

Fuel sensor shows

value "0" in

monitoring

software

Fuel sensor head is faulty

- Poll the sensor using the “EP30_Install” *

program. Replace the sensor head, if

necessary.

Sensor isn't

responding

Absence of external

power on the fuel sensor

- Check the power supply on the interface

cable connector;

- Check the integrity of fuses in the power

cable, replace them, if necessary.

Fuel sensor head is faulty

- Poll the sensor using the “EP30_Install” *

program. Replace the sensor head, if

necessary.

Sensor transmits

data showing the

maximum level in

tank, but in fact

fuel level is lower

than the maximum

Presence of water or other

liquids on the tank bottom

- Disconnect the interface cable;

- Unscrew and remove the measuring head,

then unscrew the sensor probe from the

flange;

- Remove the tank, wash and dry it;

- Install the sensor back and connect the

interface cable.

The fuel indication

vanishes and

reappears

periodically.

Loose contact on the fuel

sensor fuse

- Check the power circuits of fuel sensor,

reliability of fuse contact of fuel sensor,

replace, if needed;

There is no reliable

connection through

interface signal wires

- Check the alarm indicators of TXD" and

"RXD" interfaces, reliability of cable

connection;

Supply voltage threshold

of sensor head is

underrated

- Check the supply voltage applied for fuel

sensor, it should be ranged no lower

than 10 V;

- at undervalued level check the charge

of accumulator battery of the vehicle.

During stops fuel

level smoothly

changes its value

depending on the

time of day

Temperature deformation

of tank

The heating causes a tank to deform (usually

plastic tanks), which leads to a variation of the

fuel level in the tank.

To correct this problem, it is necessary to

eliminate the possibility of tank deformation.

Change of dielectric

constant of fuel in

dependence on its

temperature

Appearance of this dependence is associated

with an expansion coefficient of fuel. This

dependence must be considered in the overall

measurement error.

Page 15

15

Table continuation 4.1

1

2

3

The fuel sensor is

not responding to

"EP30_Install"

software

Faulty converter COMRS485 (RS232)

- In "My Computer" - "Properties" - "Task

Manager" check converter availability;

- In case of its absence drivers must be

reinstalled;

- If there is no communication with the

computer, carry out the replacement of

converter.

No power consumption

on the sensor head

- Check the supply voltage on the interface

cable connector;

- Check the fuses in the interface cable,

replace them if needed;

- Check the integrity of the power supply

wires.

Reversed connecting of

"TXD" and "RXD"

channels

- If the sensor is not responding it’s

necessary to change the wires via "TXD"

and "RXD". Correct connection of " Green

" - TXD, " Yellow "-RXD.

No driver (or incorrect

installation) for the

converter COM-RS485

(RS232)*

- Configure the COM port converter COM-

RS485 (RS232);

- Check for proper installation of the driver.

The driver is supplied with a converter set.

Offset the initial

sensor N code

during long

continuous sensor

operation

Changing the dielectric

parameters of the fuel

probe

- Disconnect the interface cable from the

sensor;

- Unscrew and remove the measuring head,

then unscrew the sensor probe from the

flange;

- Check probe for external and internal

impurities;

- Wash the interior of the fuel probe (use the

same fuel as it was used during sensor

operation) and blow it with compressed air;

- Install the sensor in the working position

and connect the interface cable;

- If necessary, perform re-calibration of the

tank, according to the Section 5 of “EA.000

IM. Installation Manual”.

During the

movement the

sensor does not

change its value in

the control

software

Probe drain hole is

clogged

- Disconnect the interface cable from the

sensor;

- Unscrew and remove the measuring head,

then unscrew the sensor probe from the

flange;

- Check and clean the drain hole of the

probe;

- Install the sensor into the working position

and connect the interface cable.

The presence of sediment

(mud) on the bottom of

the tank

- Disconnect the interface cable from the

sensor;

Page 16

16

- Unscrew and remove the measuring head,

then unscrew the sensor probe from the

flange;

- Wash the interior of the fuel probe and

clean the drain hole of the probe;

- Remove the fuel tank;

- Clean and wash the tank;

- Set the tank into working position;

- Install the sensor into the working position

and connect the interface cable.

Invalid data from

the fuel sensor

(the discrepancy

between the actual

filling and data in

the control

software)

Incorrect calibration

Perform re-calibration of the tank, according to

the Section 5 of “EA.000 IM. Installation

Manual”.

Offset of the initial sensor

code during continuous

exploitation

- Disconnect the interface cable from the

sensor;

- Unscrew and remove the measuring head,

then unscrew the sensor probe from the

flange;

- perform re-calibration of the tank,

according to the Section 5 of “EA.000 IM.

Installation Manual”.

- Install the sensor into the working position

and connect the interface cable.

Large fluctuations

in the readings of

the fuel level when

vehicle is on the

move

Nonlinear calibration

table

Perform re-calibration of the tank, according to

the Section 5 of “EA.000 IM. Installation

Manual”.

Large fuel tank and (or)

its complex structure

Consider installing two sensors in one fuel

tank.

Tilt an jolting of vehicle

on the move

Increase the averaging time

Sudden change of

the fuel readings

from the current

indication up to

the maximum

point in the control

software.

The presence of water in

the tank.

- Disconnect the interface cable from the

sensor;

- Unscrew and remove the measuring head,

then unscrew the sensor probe from the

flange;

- Remove the fuel tank;

- Clean and wash the tank;

- Install the sensor into the working position

and connect the interface cable.

* - Absence of sensor polling by “EP30_Install” software can be caused by incorrect COM port

adjustment. This malfunction can be fixed by:

Perform the interface converter (RS485, RS232) COM port adjustment.

Check if driver installed correctly.

Check the (RS485, RS232) converter availability and its adjustment in "My Computer" -

"Properties" - "Task Manager".

Choose the appropriate baud rate for sensor settings in “EP30_Install” software.

Page 17

17

4.2 Replacement procedure of device

4.2.1. Sensor is a maintenance-free device and sustains stability of parameters

during its warranty life.

In case of sensor functional loss, it must be replaced.

4.2.2. Sensor dismantling must be done as follows:

- Disconnect interface cable from the sensor;

- unscrew 5 self-drilling screws and take out sensor from the tank;

- upload configuration parameters into the new sensor (see annex B of “EH.000

IM. Installation Manual”);

- install and connect the new sensor (with the same probe length), perform the

sealing procedure according to Section 4 of “EH.000 IM. Installation Manual”

requirements.

4.2.3 In case of configuration data loss, it is necessary to perform a sensor

configuration procedures described in Annex B of “EH.000-EN IM. Installation

Manual”.

In case of successful restoration of configuration data, re-calibration of tank is

not required.

5 TRANSPORTATION AND STORAGE

Transportation of the sensor in an avenue packing of the manufacturer is allowed

by all types of covered land and sea transport (in railway cars, containers, closed-top

cars, holds, etc.). Transportation in the pressurized compartments of planes is allowed.

Transportation and storage must comply with GOST (ГОСТ) 15150-69

requirements.

Loading...

Loading...