Page 1

Fuel Level Sensor

EPSILON

Models ES2 and ES4

Service manual

Page 2

2

Contents

1. USE ................................................................................................................................................... 5

2. EXPLOSION PROTECTION .............................................................................................................. 5

3. MAIN TECHNICAL CHARACTERISTICS ......................................................................................... 6

4. DELIVERY SET .................................................................................................................................. 8

4.1

Main delivery set

..................................................................................................................................... 8

4.2 Extra accessories ............................................................ Ошибка! Закладка не определена.

4.3 Consumables and tools for sensor's installation and calibration ...................................... 8

5. LIST OF DOCUMENTS AND SOFTWARE FOR SENSOR'S INSTALLATION AND CALIBRATION 9

6.

LIST OF DEVICES AND EQUIPMENT FOR SENSOR'S INSTALLATION AND CALIBRATION

.............. 9

6.1 Instrumentation ...................................................................................................................... 9

6.2 Equipment, tools and consumables

..........................................................................................................

9

7. STRUCTURE AND WORK OF SENSOR ......................................................................................... 10

7.1 Structure of FLS ................................................................................................................... 10

7.2 Work of FLS

.......................................................................................................................................................

11

8. INSTALLATION ............................................................................................................................... 13

8.1 Preparation of fuel tank for sensor's installation ............................................................... 13

8.2 Preparation of sensor for installation ................................................................................. 15

8.2.1

Measuring of probe's length ................................................................................ 15

8.2.2 Changing of probe's length

....................................................................................................

15

8.3 Installation of sensor on fuel tank....................................................................................... 17

8.4 Connection of sensor to control units ................................................................................ 17

8.5 Sealing of sensor ................................................................................................................. 20

9. CALIBRATION .............................................................................................................................. 20

10. MAINTENANCE ............................................................................................................................ 21

Page 3

EPSILON ES2,ES4

3

11. TRANSPORTATION AND STORAGE ........................................................................................... 23

12. WARRANTY .................................................................................................................................. 23

Appendixes

1 SOFTWARE APPLICATION ES INSTALL ..................................................................................... 24

2 UNIFIED PROTOCOL EPSILON DATA EXCHANGE (EDE). ........................................................... 35

3 MEASURING HEAD MARKING. ...................................................................................................... 46

4 CONNECTION OF SENSORS ES2 AND ES4 TO CONCENTRATOR OF FUEL LEVEL SENSORS

«DALCON» .......................................................................................................................................... 47

5 CONNECTION OF SENSORS ES4 TO ONBOARD MONITORING CONTROLLERS OF

TRANSPORT SERIES «АВТОГРАФ-GSM» ........................................................................................ 48

6 CONNECTION OF SENSORS ES4 TO CONTROL UNIT OF MANAGEMENT SYSTEM OF

TRANSPORT NAVIGATION "TELETRACK" ....................................................................................... 50

7…CONNECTION OF SENSORS ES2 TO TRANSPORT MONITORING APPLIANCE "INTELLITRAC

A1" ....................................................................................................................................................... 51

8 CONNECTION OF SENSORS ES2 TO TRANSPORT MONITORING APPLIANCE TELTONIKA

MF4100(4200) -. .................................................................................................................................... 58

9 Connecting sensors to the subscriber terminal ES2……………………………….……….58

10 Connecting sensors to the subscriber terminal ES2……………………………….……….58

11

Using frequency output mode

……………………………….……………………………....67

Page 4

4

Safety requirements on installation and maintenance of fuel level sensor

During installation of the fuel level sensor you should take organizational and technical

measures for ensuring safe work with instrumentation, accessories and consumables.

Responsibility for the implementation of security measures is imposed to technical personnel

that install the fuel level sensor, and to the staff that is responsible for the equipment of place

where the work will be performed.

At the place of work fire safety rules should be kept in accordance with GOST (Ukrainian: ГОСТ

12.1.004 "ССБТ. Fire Safety. General requirements", and rules of electrical safety in

accordance with ГОСТ 12.1.019" ССБТ. Electrical safety. General requirements. "

On motor transport at the place of work labour safety rules should be kept in accordance with:

ДНАОП 0.00-1.28-97 "Rules of safety on motor transport" (in Ukraine) or ПОТ РM 027-2003

"Inter-sectoral labour safety rules on motor transport» (in Russian Federation).

Page 5

EPSILON ES2,ES4

5

1. Use

Fuel level sensor Epsilon (hereinafter referred to as the FLS or sensor) is used to measure the

fuel level in containers and fuel tanks (hereinafter - the tanks) of vehicles (hereinafter – the

vehicles).

The sensor can be used in conjunction with the equipment that supports a unified

communications protocol Epsilon Data Exchange (hereinafter - EDE) and (or) processing of the

analog signal.

The sensor is compatible with different control units, concentrators and equipment of GPS -

monitoring, such as follows:

Autograph

Ruptela

Dalcon

Pointer

Intellitrac

M2M Telematics

BCE

Teletrack

Teltonika… etc.

Model Epsilon ES2 provides data exchange on the interface RS-232, ES4 – on the interface

RS-485. The add-on device (digital to analog converter EG4x) ensures the formation of an

analog signal and exchange on the interface RS-485.

2. Explosion Protection

The sensor is explosion-protected and it has such explosion protection marking:

1Exm[ia]IICT6 Х - for use in Russian Federation.

1ExsiaIICT6 X - for use in Ukraine;

The sign "X" in the marking of explosion protection shows special conditions of safe use of

sensors as follows:

sensors should be connected to the electrical circuits of equipment that feeds only from the car

battery with voltage not more than 36 V and has no electrical connections with electrical

equipment that has other sources of supply, including the network ones;

connection of sensors to the mains supply should be carried out via a fuse rated at no more

than 0.1 A.

Documents confirming compliance of the sensor with the requirements of explosion protection:

Certificate of conformity of the Russian Federation State Standard № РОСС.UA.ME92.B02278

and certificate № 2703 of the State Testing and Certification Center of Explosion-Protected and

Mine Electrical Equipment (Donetsk, Ukraine).

Page 6

6

3. Main Technical Characteristics

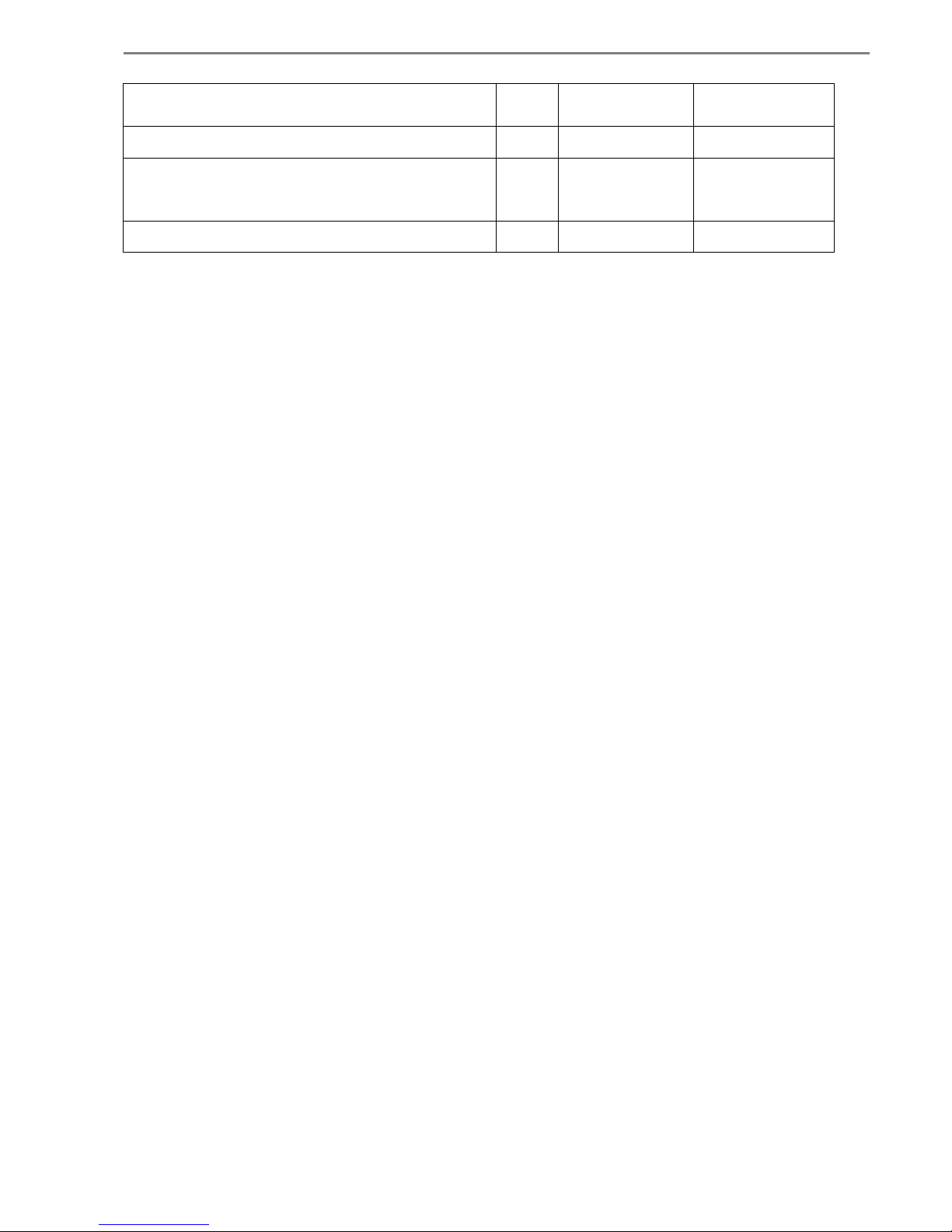

Table 1.

Name of characteristic or parameter Units Value Notes

General

Accepted values of electrical conductivity of

controlled fuel, not more

Cm/

m

10

-8

1

Limit range of operating temperature

0

С – 40 … + 75

Climatic range

1.1

ГОСТ15150-69

Degree of protection

IP56

Measurement

Range of measured values of level of

controlled fuel

mm

from 10 to 800

2,3,4

from 800 to

3000

Resolution of measurement of diesel fuel

level in static mode, not worse

mm

0,05

5

Basic permissible error in level measuring in

static mode, no more

mm

0,5

6

The period of measurement results averaging

in a dynamic mode

s 8

Bit code representation of measurement

results

bit

10/12/16

Level (8)

8

Temperature

Supply

Voltage supply, operating range V

+8

-10%

÷

+36

+20%

Rated

Current consumption мА

5,5±0,5

with 12V

2,5±0,2

with 24V

Operating mode

Long-term

Permissible effect of pulsed voltage supply to

circuits

+ 160В, 1с

-1000V

8

Interface

Digital

RS-485

Model ES4

RS-232

Model ES2

Analog (using a digital-analog converters

EG-41 (8 bits)

EG-42 (12 bits)

мВ

25…3175 9

25…4000 9

Accession size, weight

Page 7

EPSILON ES2,ES4

7

Kind of bumper ring

5 holes.

4.5mm

10

Type of probe’s thread M25х1,5

Height of measuring head above surface of

tank, including bumper ring, no more

mm 29

11, 12

Weight, no more g 250

12

Notes for table 1:

1. Allows you to measure different sorts of fuel with high electrical conductivity (which

contain anti-electrostatic additives).

2. The position of the upper (maximum) value of the measured level corresponds to the upper

edge of the drain hole of the probe.

3. Version of more than 800 mm is carried out to an additional order.

4. For version of "0800" (800 mm) it is allowed to shorten the probe "at the time of execution"

without restrictions on the minimum length.

5. During use of 16 bits representation of measurement results.

6. For a version of "0800" in the normal climatic conditions in accordance with ГОСТ15150-

69. In order to ensure a given accuracy in all working range of temperatures, the

adjustment of the calibration table should be applying (according to the temperature

dependence of the dielectric permeability of fuel).

It is also possible to adjust the calibration table with use of fuel with a dielectric permeability

different from the dielectric permeability of fuel which was used for calibration.

When testing the fuel with the same dielectric permeability as of the fuel used for calibration.

To ensure measurements with other sorts of fuel the adjustment of calibration table should

be used (according to dielectric permeability of the sort of fuel).

7. Data are given into two formats: 16 and 10/12 bits. Capacity of 10 or 12 bits is switched

according to the program. 12 bits value is set by default.

8. Pulse parameters in accordance to ГОСТ 28751-90 (product of A class, the degree of

severity 3 for 24V on-board power use).

9. With use of an additional inverter EG41 (42) U-mode or I – mode are possible. The

maximum output voltage Umax = U Power is 4 (V).

10. Other versions of conjunctive flange are possible after coordination with the customer.

11. Sealing gasket is not included.

12. For the indicated version of flange.

Page 8

8

4. Delivery set

4.1 Main delivery set

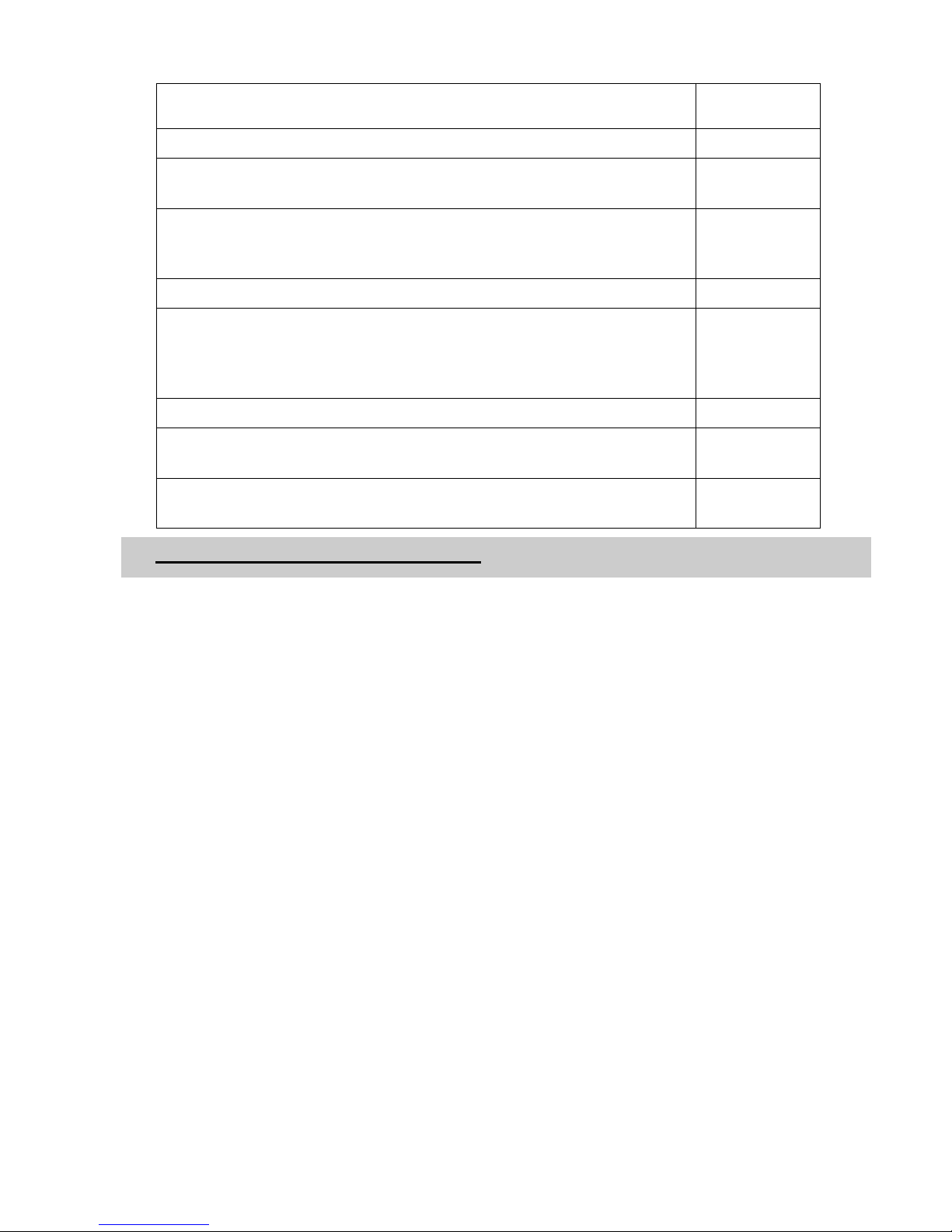

Table.2

Name Decimal number Quantity

Notes

1 Measuring head ES.100 1

2 Probe ES.200 1

3 Connecting cable ES.300 1

4 Flange ES.001 1

5 Cap ES.002 1

6 Self-drilling screw ES.004 1 With a hole for

sealing

7 Self-drilling screw 9Т64219-2 4

8 Gasket 5320-382713 1

9 Passport ES.402 ПС 1

10 Indicator’s seal SILTECH 2 With wire for

sealing

11 ZIP String

1

4.2

Extra Accessories

Table 3.

Name Decimal number

Notes

1) Service manual ES.401 RE

2) Compact disk CD-R ES.000 CD1 With program "eS Install" for

sensor’s setting

3) Cap М25х1.5 Installed on the tank after

removal of the sensor

4) Plug IEC ES.002.0 Installed on the tank after

removal of measuring head

5) Fuse 0,1А 250V Ø5х20 mm, high-speed

Page 9

EPSILON ES2,ES4

9

4.3 Сonsumables and tools for sensor’s installation and calibration

Consumables and tools for sensor’s installation and calibration can be supplied on special

request (see section 6).

5. LIST OF DOCUMENTS AND SOFTWARE FOR SENSOR’S

INSTALLATION AND CALIBRATION

● Passport ES.402 ПС.

● Service manual* ES.401 РЭ.

● User’s software on CD disk** ES.000 CD1

* - 1 manual with 10 sensors is supplied

** - supplied on special request

6. LIST OF DEVICES AND EQUIPMENT FOR SENSOR’S

INSTALLATION AND CALIBRATION

6.1

Instrumentation

Table.4

Name Quantity

1) Multimeter M890G 1

2) Tape measure 3 m

1

3) Measuring cup or flow meter, providing measuring errors of fuel

volume not worse than ± 0,1%

1

6.2 Equipment, tools and consumables

Table.5

Name Quantity

1) Metal cutting tool for holes making Ø22 ± 0,5 mm in the

sheet material of the tank surface. Preferably produced by RUKO:

a. For hydraulic hole punching:

a set 5 hydraulic, article 109 009,

b. For drilling:

carbide crown drill Ø22, article 105 022.

1 set

2) Electric drill with holder of clamping of the tool shank with

diameter NLT 10 mm.

1

3) The network extender in polyurethane insulation, 220V, 4А.

1

4) Pipe cutter is used when necessary to reduce the length of the 1

Page 10

10

probe (preferably produced by ROTHENBERGER company:

"MINIKAT II PRO", Art. 7.0402 or similar).

5) Spanner with 7 mm gap amount. 1

6) Spanner with 36 mm gap amount (can be ordered at your

sensor provider). Note for order IEC ES.002.0.

1

7) Special spanner for probe (can be ordered at your sensor

supplier).

Note for order IEC ES.003.0.

1

8) Auto Sealant Loctite 5900. 0,1 ml

9) Laptop (PC), minimum requirements: Pentium 500 MHz, 64 MB

RAM, MS Windows 98/2000/XP, MS Office not higher than 2003,

not less than 10MB of free hard disk space, the manipulator

"mouse", a free USB-port.

1

10) Adapter for connecting of the sensor eS2 to the PC

1

11) The converter USB/RS-485 model MOXA UPort 1130 (for

calibration of the tank with the sensor eS4).

1

12) The converter USB/RS-232 model MOXA UPort 1110 (for the

calibration of the tank with the sensor eS2).

1

7. Structure and work of sensor

7.1

Structure of FLS

The measuring head of the sensor (Pic. 7.1) consists of a level converter, a digital circuit of

signal processing, the device of data exchange, the voltage balancer and circuit which provides

necessary protection for input and output circuits.

Connection to external devices is providing with help of interface cable.

Page 11

EPSILON ES2,ES4

11

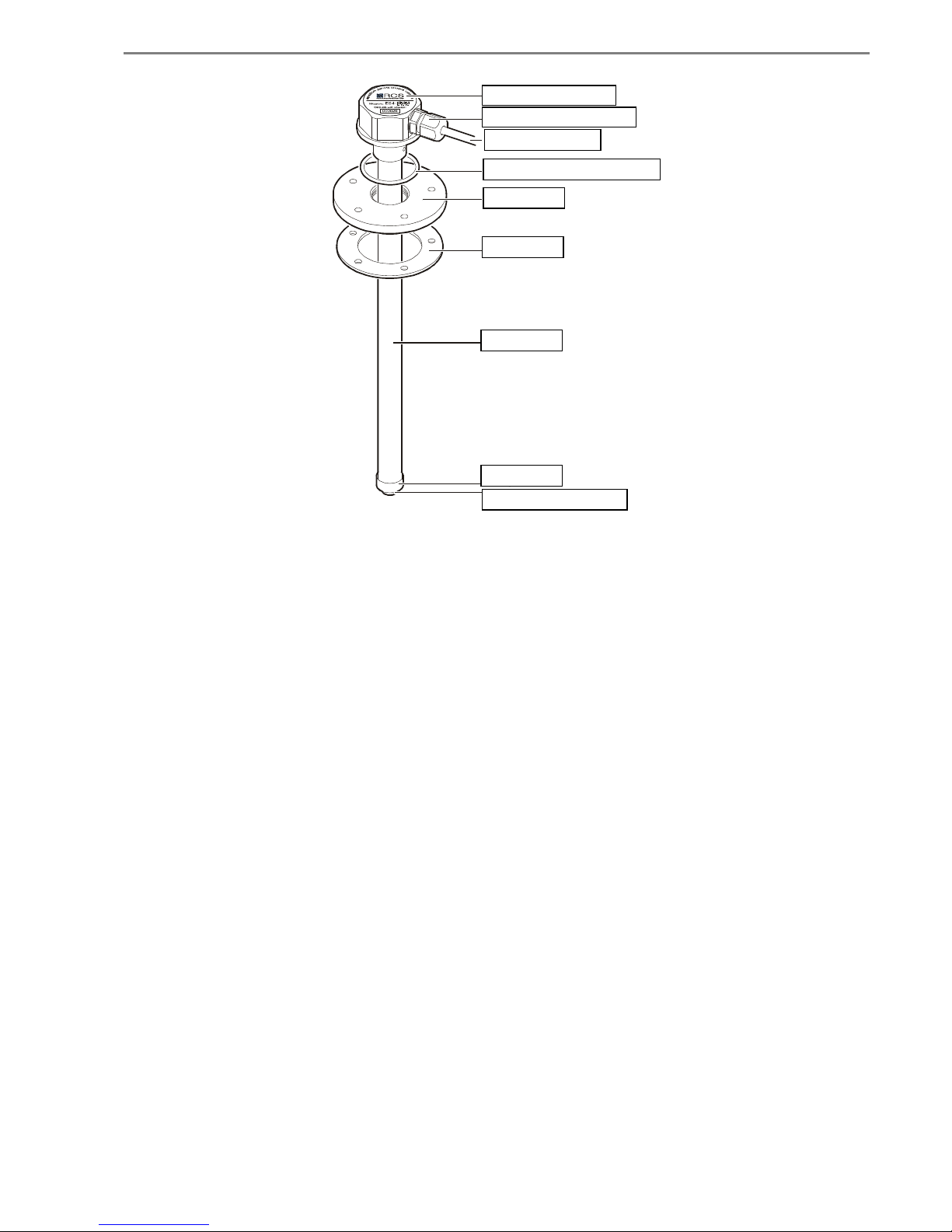

Pic. 7.1 The general view of the “Epsilon” FLS

Measuring of fuel level is made with help of measuring head with the probe, immersed into the

fuel. The probe is a coaxial capacitor, which is made of an aluminum tube (external electrode)

and insulated copper string (internal electrode). The required tension of the string is supported

by a spring which is situated in contact of the probe’s connector.

Mounting of the sensor is performed with help of self-drilling screws, which fix the sensor’s

flange on the tank. Impermeability of the fit of measuring head is provided by sealing ring,

located in the front groove.

The interface cable is protected from mechanical damage by a flexible metal sleeve or

corrugated pipe.

The sensor safety is provided by such facilities:

fuse for protection against overloads and short circuits;

intrinsically safe measuring circuit with normalized values of voltage, inductance,

capacitance and resistance;

multi-level protection of charging and interface circuits;

metal sheath with a proper degree of protection (IP56 according to ГОСТ14254);

compound filling of the measuring head’s membrane.

7.2 Work of FLS

The sensor’s probe during the immersing into fuel perform the function of a variable capacitor

whose capacitance linearly depends on the level of it’s filling by fuel.

The measuring head of the sensor performs a linear transformation of the probe’s capacitance

to digital code of fuel level, the processing of received digital data with averaging of

measurement results, taking the temperature of the fuel tank and delivery of the data in a

Measurement head

Hermetic cable input

Interface cable

Sealing rubber ring

Flange

Gasket

Zonde

Plug

Cap of Plug

Page 12

12

unified protocol EDE of bus RS- 485 or RS-232 or in an analog signal (only the level),

depending on the model.

Data about fuel level may be issued in the form of 10-, 12-or 16-bits value, the temperature data

- in the form of 8-bits value.

For determination of the amount of controlled fuel the procedure of calibration of fuel tank

should be carried out. During this procedure the dependence between the amount of fuel and its

level, measured by sensor (by the code of the level), is set.

Controlling of the calibration procedure and setting of parameters of data exchange with the

help of eS Install program are described in details in Appendix 1.

Protocol of data exchange EDE is shown in Appendix 3.

Page 13

EPSILON ES2,ES4

13

8. Installation

8.1 Preparation of fuel tank for sensor’s installation

The sensor is installed in the center of the fuel tank, as shown on Pic 8.1.

Only in this case, when vehicle is inclined, during acceleration or deceleration the fuel level at

the measuring point is the least volatile for fluctuations. The measuring probe should be set

vertically down. Improper installation of the probe may be the reason of accuracy loss in

determining of fuel amount.

If the top of tank is difficult to access, it is necessary to remove the tank from the vehicle for

proper installation of the sensor.

.

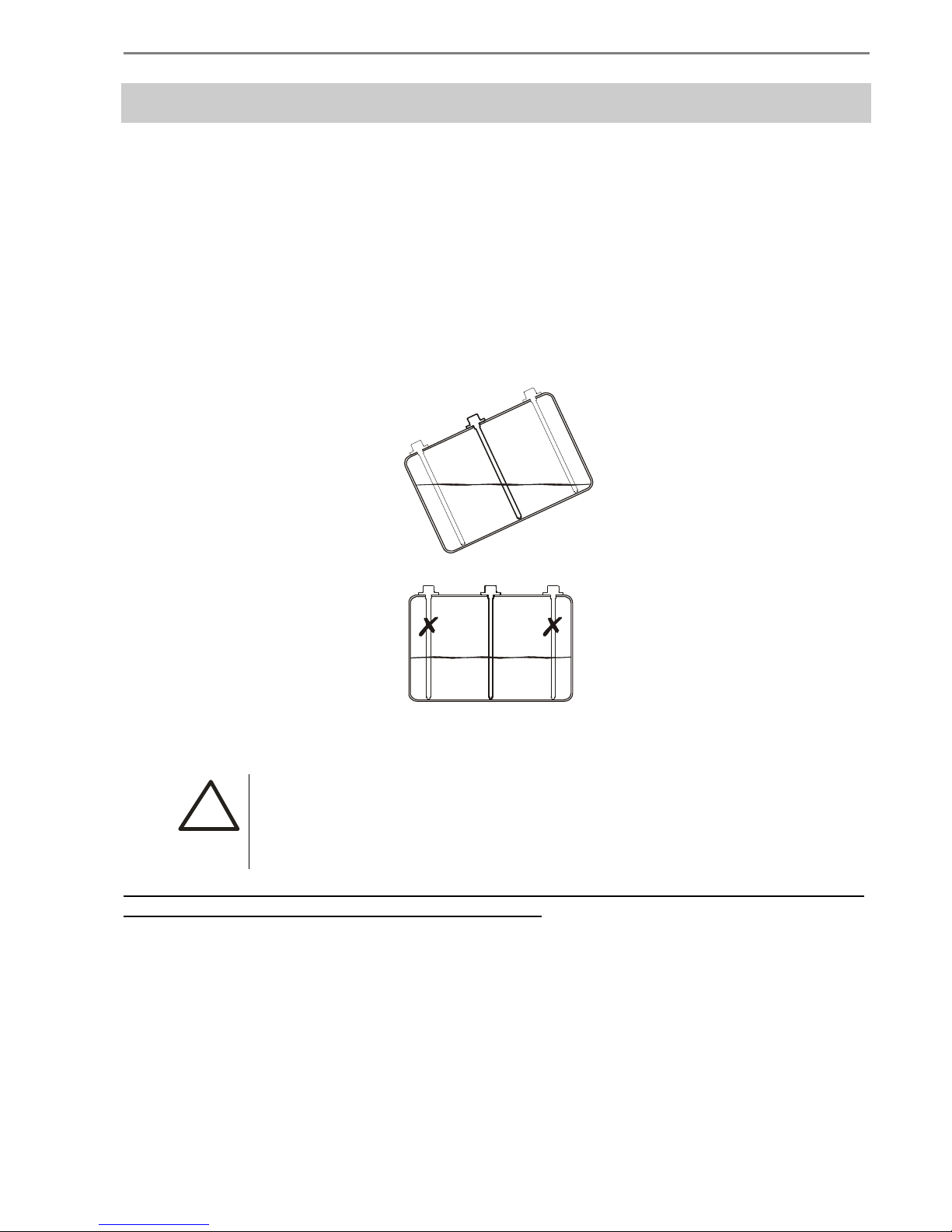

Pic. 8.1 Proper position of sensor on fuel tank

It is necessary to clean the fuel tank in the place of sensor’s installation.

!

WARNING! Before sensor’s installation on the tank, firstly you should fill

it with water or drain fuel and oil lubricants and clean the tank to the

complete removal of flammable liquids and vapors.

To ensure proper position of the sensor cable entry of the sensor and preparation of making the

procedure of sealing, we recommend following steps:

Determine the optimal orientation of the sensor. Cable entry of the sensor and the direction

of the interface cable should be oriented to the side of stowage and setting of connecting

cable on the car body.

Mark on the tank the position of flange holes and position of cable entry.

Set the flange on the sensor.

Page 14

14

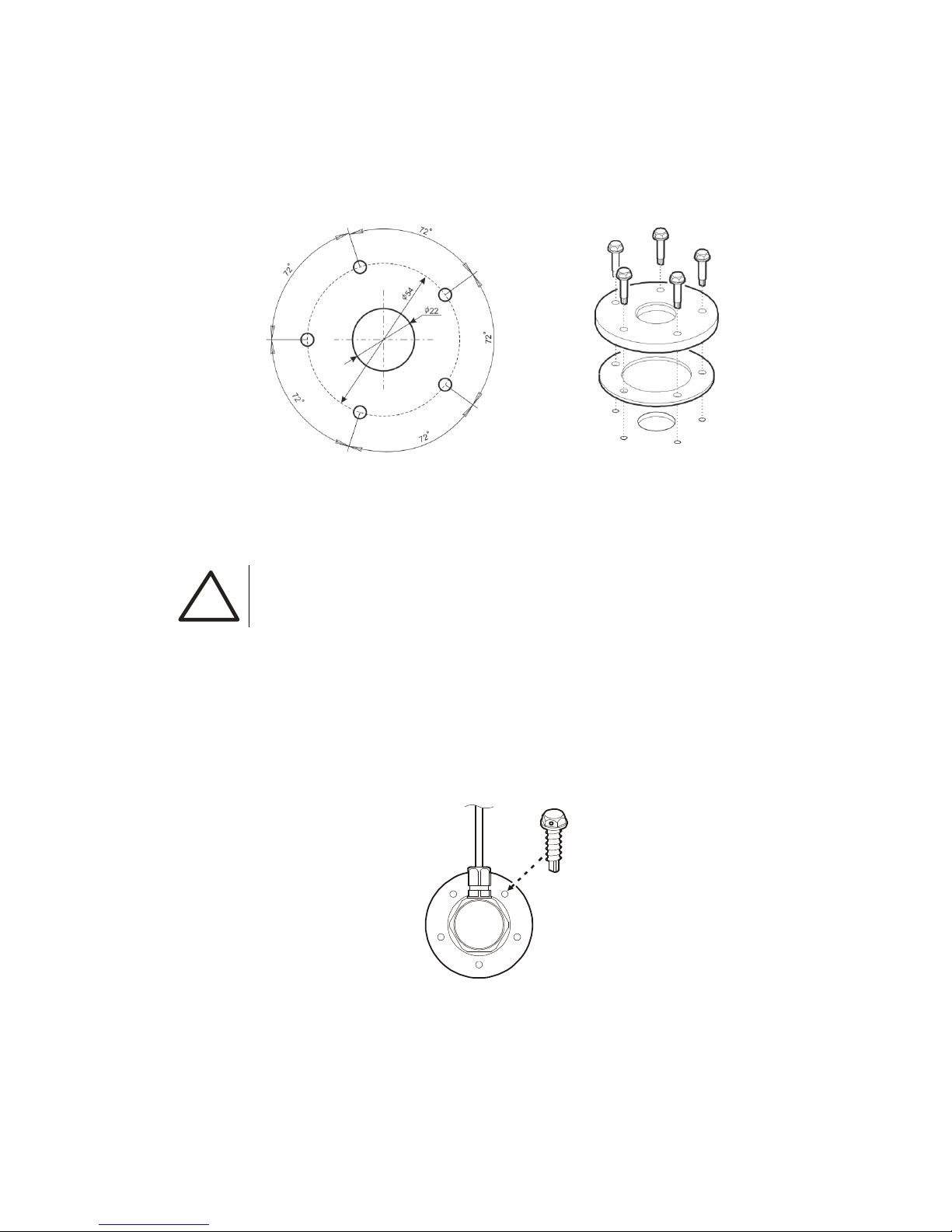

Drill or punch a central hole Ø22 and put the sensor with a flange into it.

Drill in the tank body 5 holes for flange setting (it is possible to make holes by self-drilling

screws). Example of holes drilling for self-drilling screws installation is the flange ES.001,

shown in Pic. 8.2. This picture also shows the reference sizes of flange setting.

Pic. 8.2 Size and method of flange setting on fuel tank

Remove the sensor with flange.

!

WARNING!

You must remove the chip from drilling of the holes, and

also make sure that there are no foreign objects and trash on the tank

bottom.

Lubricate both sides of the gasket 5320-382713 and self-drilling screws with sealant. The

type of sealant is shown in Table 5.

Set the flange ES.001 and gasket to the prepared surface of the fuel tank with help of a self-

drilling screw ES.004 (with an extra hole, provided for sealing). The screw should be placed

on the right side from the cable input, as shown in Picture 8.3.

Fix the flange with four self-drilling screws 9Т64219-2.

Pic. 8.3 Position of screw with a hole for sealing

Page 15

EPSILON ES2,ES4

15

8.2 Preparation of sensor for installation

8.2.1 Measuring of probe’s length

It is strongly recommended, whenever possible, to apply probes unified by a manufacturer - this

will eliminate extra work during installation or replacement of the sensor. As a rule, unified

sensors correspond to the outer height of tanks of the most encountered sizes. For example,

the overall height of the tank of trucks of such popular brands as DAF, MAN, Renault, Scania is

620 mm – the sensor with a probe of 620 mm should be applied for them.

The manufacturer of the sensor provides the following range of unified types of sensors.

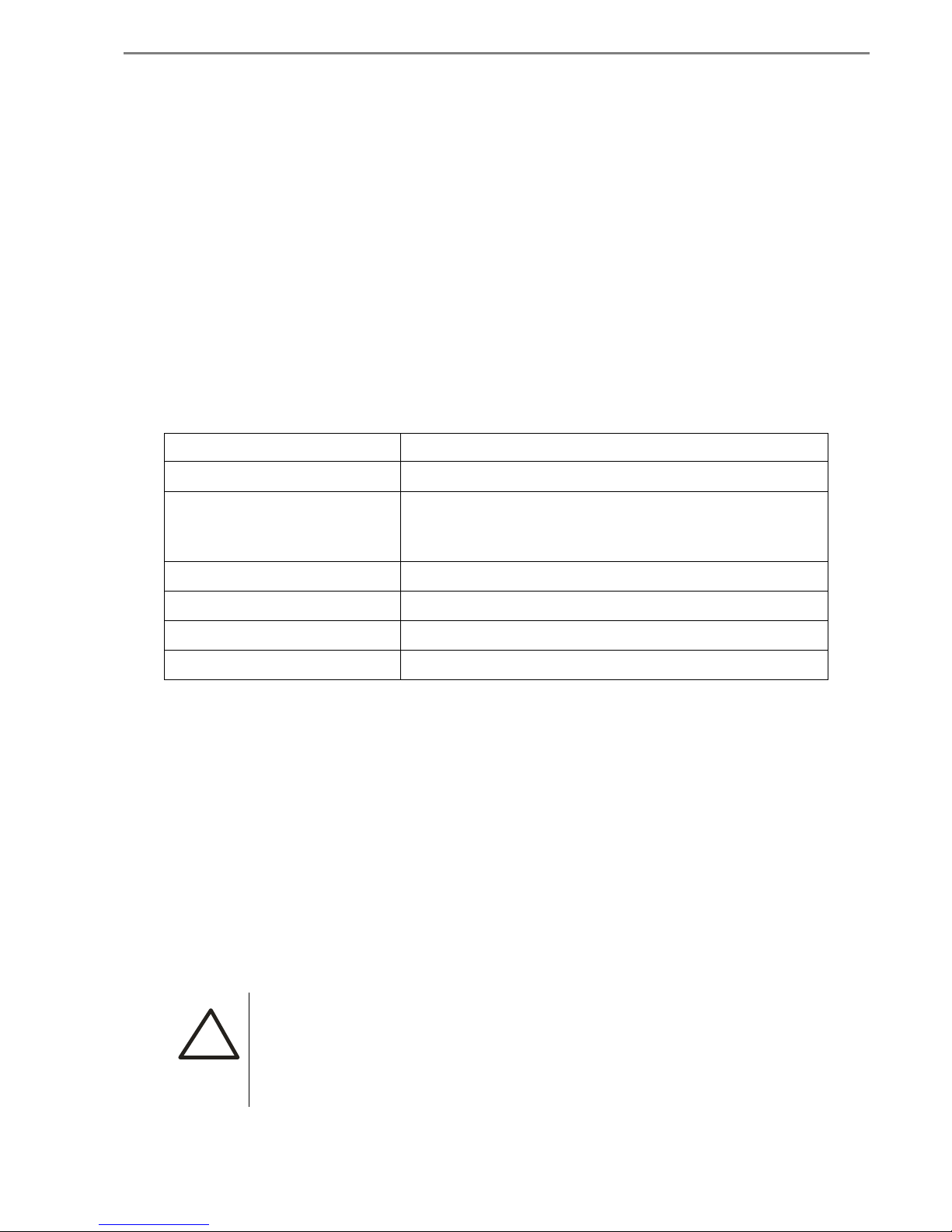

Table 6.

Probe’s length* Typical models of vehicles

800 Special machinery

620 Truck tractors DAF, IVECO, MAN, Mercedes-Benz,

Renault, Scania and others, machinery on their

base.

530 Trucks КАМАЗ, КрАЗ, machinery on their base.

440 Trucks МАЗ, machinery on their base

350 Trucks ЗИЛ

260 Light trucks and vans

*

corresponds to outer height of tank, mm, in place of sensor’s installation)

Type of the probe is indicated in the description of the sensor at the time of ordering.

In case of absence of type, as a rule, the length of delivering probe is 770 mm.

Description of measuring head and the index correspondence in the description of probe’s

length are shown in Appendix 3.

8.2.1 Changing of probe’s length

If there is no necessary length in the range of unified types, you will have to cut the unified

probe by yourself on the spot. To do this, you should measure the depth of the fuel tank L, as

shown on Pic. 8.4, then measure the length on the probe (L-15) mm, to ensure the gap of 10

mm between the probe and the bottom of the tank during the sensor use.

!

WARNING! For tanks with a lack of stiffness (for example - plastic

tanks of considerable height) it is recommended to increase the gap

between the probe and the bottom of the tank up to 30 mm. This is

due to changes of sizes of the tank because of changing of

temperature, poured fuel mass, and deformation during the motion.

Page 16

16

Pic. 8.4 Determining of measuring probe’s length

Next:

1) Cut the meted part of the probe’s tube. The cut must be made carefully, burrs must be

removed. The plane of the cut should be perpendicular to the guide line of the pipe. We

recommend using a special tool for cutting pipes. Type of the instrument is listed in Table 5.

2) Install an insulating cap ES.217 at the end of the probe, as shown on Picture 8.5, on the left:

Pic. 8.5 Method of fastening of string on the end of probe

3) Fix the central conductor of the probe. To do this, you should pull up to the stop (the length

of free movement of compressing spring 5 mm), fold and put the central conductor to the

grooves of stub, as shown on Pictures 8.5 and 8.6.

Pic. 8.6 Way of placement of central conductor on the stub

4) Check the quality of the tension. To do this, you should gently tap with your finger on the

probe (probe should be screwed to the measuring head against the stop) – you should feel the

vibration of the string taut (central conductor).

Cut the remained part of the conductor in the way that the cut was roughly in the center of a

stub.

5) Apply a drop of sealant (type shown in Table 5) on the place of conductor’s cut for providing

protection of the end of the conductor from water that may accumulate in the tank.

Page 17

EPSILON ES2,ES4

17

Install the plug on the cap, shown in Picture 8.5, on the right, and push until it clicks.

Preparation of the sensor for installation is complete. If the sensor is supplied with a probe of

unified or special length, the sensor assembly and preparation for installation is performed in

factory conditions.

8.3 Sensor’s installation on fuel tank

The sensor is screwed into the threaded hole of the flange as it shown in Pic. 8.7. Tightness of

connection is ensured by a sealing ring located in the front groove of the measuring head.

Before installing the sensor it is recommended to put a thin layer of grease or engine oil to the

ring.

Pic. 8.7 Installation of assembled sensor on fuel tank

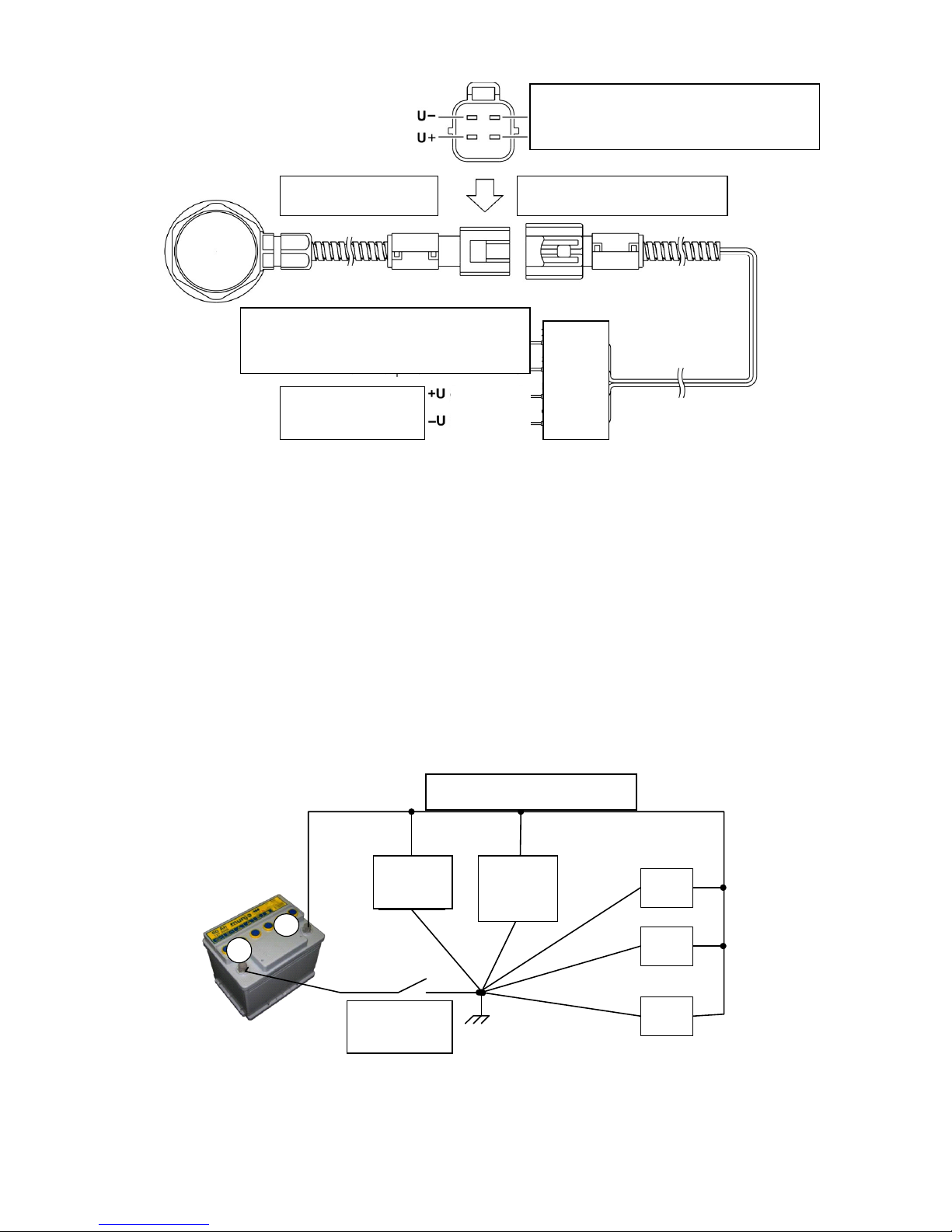

8.4 Connection of sensor to control units

To connect the sensor to different control units, concentrators and equipment of GPS monitoring it is recommended to use the original sensor’s cable system, which consists of an

interface cable ES.120 (0.45 m) and a connecting cable ES.300 (7,5 m).

The interface cable is connected to the measuring head of the sensor with help of permanent

connection and ends with slot M (6188-0442) (plug, set).

Connecting cable is supplied with the sensor. It begins with slot F (6189-0656) (socket, set) and

ends with four pressed wires, which should be connected to the appropriate type of the input

connector of a device.

Scheme of connection of interface and connecting cables and the wires description as well are

shown in Pic. 8.8.

!

WARNING! Do not twist the cable entry or otherwise violate the integrity

of the measuring head from the input of interface cable.

The connecting cable is stretched from the sensor which installed on the fuel tank, to the control

unit, that is usually located in the driver’s cab through the technologic holes, provided by the

construction of a vehicle. The cable is fixed with ties on immovable parts of the construction

every 50-60 cm.

Rubber sealing ring

Page 18

18

Pic. 8.8 Scheme of connection of interface and connecting cables

Additional instructions of connecting of the sensor to different control units, concentrators and

equipment of GPS - monitoring are in the appendixes of this Manual:

- for "Dalcon" concentrator – Appendix 4

- for "АвтоГРАФ –GSM" system – Appendix 5

- for "Teletrack" system – Appendix 6

- for "IntelliTrac" system – Appendix 7

- for "Teltonika" system – Appendix 8

Common earth conductors of the sensor (black wire) and of a control unit must be connected to

a single point on the chassis of a vehicle, to which "mass" or "earth" of the other electrical

appliances of a vehicle are connected (Pic. 8.9).

ДУТ

БУ

-

Выключатель

массы

1

2

...

n

Электроприборы ТС

+

Pic. 8.9 CORRECT connection of common wire

Interface cable Connecting cable

Yellow

Green

Red

Blac

k

embedded networ

k

general

ES4 ES2

Channel A (RS485) Rx(RS232 output 2 DB9)

Channel B (RS485) Tx(RS232 output 3 DB9)

ES4 ES2

Channel B (RS485) Tx(RS232 output 3 DB9)

Channel A (RS485) Rx(RS232 output 2 DB9)

FLS

Disconnect

Switcher

Electrical appliances of a vehicle

Control

block

Page 19

EPSILON ES2,ES4

19

!

If there is a disconnect switcher on a vehicle, for prevention of the

fuel level sensor (FLS) EPSILON failure and a control unit (CU) it is

strictly forbidden to connect the common (black) power wire of the

sensor in the area between the battery and disconnect switcher!

(Pic.8.10)

Pic. 8.10 INCORRECT connection of common wire.

The resistance between the body of installed sensor and the point of connection of its common

wire to the "mass" should not exceed 0.5 Ohms. In any case, the total resistance of the earth

wires from the sensor to the control unit should not exceed 0.5 Ohms.

During installation of the sensor to the vehicle with switched "mass" and necessity to save

functionality when ”mass” is switched off, additionally a galvanic isolated voltage stabilizer or

other galvanic power supply is set (Pic.8.11).

ДУТ

БУ

-

Выключатель

массы

1

2

...

n

Электроприборы ТС

+

Гальвани-

ческая

развязка

питания

+

Pic. 8.11 Installation of sensor on vehicle if it is necessary to save functionality when ”mass” is

switched off.

FLS

Control

Block

Disconnect

Switcher

Disconnect

Switcher

common

common

black

FLS

Control

Unit

Galvanic

Power

Supply

Page 20

20

8.5 Sealing of sensor

To protect the sensor from unauthorized interference you should install two seals. The first

seal prevents the measuring head from twisting and the second one is set on a detachable

connection of interface and connecting cables.

For sealing of the measuring head (look pic. 8.12):

make a wire loop;

tightly wrap the hermetic input;

make a twist of wire and thread the wire through the hole of the screw ES.004;

place the ends of the wire in the seal (using СИЛТЕК seal ends of the wire should go

through the holes of the seal on the side opposite to marking);

Select the wire slack and snap the seal.

Pic. 8.12 Method of sealing of the installed fuel level sensor

For additional mechanical fixation of the seal we recommend to drag it to hermetic output and

press with a plastic electro technical clamp tie.

9. Calibration

To ensure the most accurate control of fuel level, tank calibration is performed - initially empty

(full) tank is filled (merged) by equal portions of fuel and with the help of special software "eS

Install" the sensors statements are measured and fixed after adding (pluming) of each portion.

Portion sizes should be chosen depending on configuration of a tank: if horizontal crosssectional area of the tank in height is sharply changing the portion should be the less. (For

example, the recommended portion for a 500 l tank of КамАЗ should be 10 l).

You must also take into account the time of level balancing level in tanks of complex

configuration (for example, in 2-tank systems) due the fuel flow.

Requirements to a measuring cup or a flow meter that provides a measurement of portions are

shown in Table 4.

Page 21

EPSILON ES2,ES4

21

!

WARNING!

Calibration of the tank must be made using the same type of fuel,

with which the sensor will be operating (for example, you can not use petrol

for calibration, if you intend to operate with diesel fuel).

To achieve the most accurate operating features of the sensor it is desirable to make “training”.

It is sufficient to perform the calibration procedure not immediately after installation of a sensor,

but after some time of car’s usage, when 50 – 70% of tank’s fuel capacity is used. During this

time, mechanical clearances will normalize, guaranteed by the rubber gasket flange and a

polymer sealant, and on the entire surface of the probe a stable dielectric fuel film is formed.

If the "training" of the sensor can not be performed, before the calibration of the tank by filling it

with use of a new sensor (probe), the probe must be immersed into the fuel than removed and

you should allow the fuel to drain for 20-30 minutes. If the calibration is performed by the

method of draining, this procedure is not performed.

At the time of calibration you must disconnect the sensor from the on-board controller and

connect it to the port of used PC (requirement to PC and port converter are shown in Table 5).

At the end of calibration a connection to the on-board controller should be restored.

The result of calibration in the form of tank calibration table and user’s data about work

executed is storing on the PC in a format which guarantees the data exchange into Dispatch

Software. Detailed procedure of calibration using software application eS Install is described in

Appendix 1.

10. Maintenance

The sensor is unattended product, but if the rules of vehicle maintenance provide the procedure

of fuel tank prevention; it is advisable to execute simultaneously preventive service of the

sensor.

For sensor’s preventive service you have to:

Perform a complete removal of the sensor (see Pic.10.2);

Wash the probe from inside by the fuel (in which sensor is operating) and blow with

compressed air.

Check own parameters of the measuring head (by using "eS Install").

Perform installation and sealing of the sensor according to the requirements of section 8.

Measuring head of the sensor is not repairable product and during the warranty period

preserves the stability of its metrological parameters.

In the case of failure of the measuring head you must perform the following:

If you want to use vehicle before a new measuring head is installed, it is necessary to make

a partial removal of the sensor (see Pic. 10.1).

Page 22

22

For new measuring head you have to install (by using eS Install) an appropriate unified type

(indicated in the calibration protocol).

If you use User’s type, it is necessary to perform automatic zero installation again, and then

by additional manual zero installation (see Appendix 1) to set for an empty probe (firstly you

should remove the probe from the fuel and wait until the fuel drain) the same level code as

specified in the calibration protocol of this tank.

Install and connect a new measuring head, make the sensor sealing in accordance with the

requirements of section 8.

Partial removal of the sensor is made as follows:

Disconnect the interface and connecting cables.

Remove only the measuring head of the sensor.

If necessary, partially tighten the sleeve of the sensor’s probe into the flange, as shown in

Pic. 10.1.

Close the sleeve of the sensor’s probe by a cap.

Pic. 10.1 Partial removal of fuel level sensor

Complete removal of the sensor is made as follows:

Disconnect the interface and connecting cables.

Remove the measuring head and then the sensor’s probe from the flange.

Close the hole of the flange by the plug M 25 x 1.5 (see Table 3), as shown in Pic. 10.2.

Pic. 10.2 Complete removal of fuel level sensor

Page 23

EPSILON ES2,ES4

23

11. Transportation and Storage

Transportation of the sensor in transport package of the manufacturer is allowed by all means of

closed land and sea transport (railway cars, containers, closed vehicles, holds, etc.). It is

possible to transport in sealed heated compartments of airplanes. Transportation and storage

must be done in terms that correspond to conditions of storage 3 according to ГОСТ 15150-69.

During transportation and storage requirements of manipulation signs, printed on transport

package must be complied.

12. Warranty

Warranty period of operation of the sensor is 18 months from the date of entry into operation of

the sensor, but not more than 24 months from the date of production. Date of entry into

operation should be fixed in accordance with the requirements assigned in passport of the

sensor. If there is no such data in the passport the warranty period begins on the date of

shipment of the sensor to the consumer.

Manufacturer's warranties are valid if the consumer follows the requirements of this service

manual. In case of violation, or if there is any mechanical or electrical damage caused by

influence of factors, not provided by this service manual, warranty is considered to be expired.

Page 24

24

APPENDIXES

Appendix 1

Software Application "eS Install" (v. 1.0.1.18)

The software application "eS Install" (hereinafter - the Program) is designed to provide

calibration process of a fuel tank and to make a calibration table that describes the dependence

of the output code of the sensor on the fuel level.

The program is included to users software (SW), supplied on compact-disk (name ES.000

CD1). To install on a personal computer (PC) it is enough to copy the program into the desired

folder. In addition, ports RS-485 (for a model eS4) or RS-232 (model eS2) must be installed on

PC For a laptop it is recommended to use converters MOXA: USB/RS-485 UPort 1130 or

USB/RS-232 UPort 1110.

To get started with the program you need to connect the sensor to correct port (complying the

polarity of interface and the supply conductors) and provide sourcing of the sensor from an

onboard network of the vehicle or from an external source (power settings - in accordance with

Table 1 of section 3 of this manual).

After launch, in the window "eS Install" you have to select the desired COM port and set the

exchange speed. By default, the sensor with factory settings has the exchange speed of 19200.

Windows RTS and DTR you have to leave unchecked (engineering view).

In the same window there are available menu options such as "Файл (File)", "Опции (Options)",

"Вид (Type)" and «Help» (their purpose is described below).

At the bottom of the window the status of the port is displayed:

If you see message "Port is closed" you have to press active bottom and

program is ready for use.

“COM port N 5 is open“ this message means that COM port is open and works correctly.

“Error in port 257 opening” - message indicates that the COM port is opening with an

error. In this case, you should check and set up the functionality of the port on the level of

drivers or check the condition of the COM port itself.

For beginning of the process (calibration), press the button .

The presence of the symbol "Search", marked by the frame in the picture above, shows that a

device (sensor) is not connected to the specified COM port.

In case of normal program start the tab “Information” will be shown.

Page 25

EPSILON ES2,ES4

25

It has 2 panels:

Panel "Passport information" displays information about the factory settings and

configurations of the product.

• The panel "Complex Information" displays the data received from the measuring head at

present time and the data received from the calibration protocol saved before.

This tab is interesting as for beginning of calibration and for calibrated sensor as well. In the first

case, the user can check the availability and conformity of the product. In the second case, after

loading of calibration data, with the help of a button “Load calibration data”

you can analyze the efficiency of the product in real terms. If you

download calibration data you will be able to estimate the fuel level not only in the level code or

in capacity code, but also in quantitative units of measurement, in liters. Pressing the button

“Show the diagram” you’ll open a window where you can see and edit the

diagram and the calibration table. The process for editing will be described below, in the chapter

about window “Monitoring of fuel tank calibration”.

Percentage value is calculated:

• if there is a protocol attached to the application – from the maximum value recorded in the

protocol;

• in there is no before saved protocol – from the maximum possible value.

Page 26

26

To continue, press the button “NEXT”

On the tab "Sensor’s general options” you can see parameters of data exchange with an

external controller.

Meaning of parameters:

"Turn on a text format" - activates the data output in text format (takes effect when you click

"APPLY" and restart the sensor by power reset). By default is not activated.

"Turn on periodic issuance" - activates the periodic issuance of the data. By default is not

activated.

"Repeat Interval" - defines the repeat interval during periodic issuance in seconds.

"Turn on averaging "- activates averaging of the data.

«Exchange speed on UART» - allows you to install one of the seven proposed exchange

speeds.

«Device network address" - may have value from 0 to 255. Defines the network address of

the sensor. By default is 1. If the system uses several sensors, they must have unique

addresses, each of them must to be made individually for each sensor.

"Capacity" - the capacity of data that determine the fuel level.

Page 27

EPSILON ES2,ES4

27

On the panel "Parameters of data exchange" factory settings are shown. Pressing the button

“APPLY” you will save changed parameters, and pressing the button “RESET”

you will cancel changes. When you click on “FACTORY SETTINGS”

all settings will be reset to initial state that corresponds to the factory

settings.

To continue the work you have to press “NEXT” , to return to the previous tab - pres

the button “BACK”.

Next, to continue the work (calibration) you should choose the length of the probe, after

measuring the depth of the tank. After that you need to screw the probe to the measuring head.

If the probe has a standard factory length, in the window "Type of probe" you have to select the

type, appropriate to the length of the connected probe.

If the probe was cut, it is necessary to make the procedure of measuring of the length of the

probe. For this you need to press “Auto detection of probe’s type”

. After that, the program will automatically determine the length

of the probe and offer a suitable type of the probe.

Page 28

28

If the probe is shorter than 185 mm or longer than 725 mm, you will be offered to install the type

"User’s L» or «User’s H», respectively. In this case, you will have to make zero installation of a

measuring head.

Attention!

Effective range is 846 mm, the probe type

“User’s H” will be set.

OK

Zero installation is recommended to make in automatic mode, for this you should press button

“MAKE”. If necessary, you can make more correct manual setting, increasing or decreasing the

value in the box "Exact". In this case the deviation of the relative position of range start will be

indicated in the lower field in the form of a line with an indication of percentage value (from the

value of the full range). Allowable deviation is within the whole window; going beyond its limits

will be displayed by flashing, colored in red, figures of percentage value.

Sensors of modifications ES2X, ES2XL, ES2XXL, ES4X, ES4XL, ES4XXL are produced

according to given ranges of probes’ length and do not need calibration. The program

automatically determines the model of the sensor. If the connected sensor’s model is one of

listed above, there is not the tab "Calibration".

To continue the work and transfer to the tab "Calibration" it is necessary to select the protocol

and filling the data of calibration protocol. By pressing to the button “NEXT” the

program will offer you to select the protocol. If everything is done right, on your screen the

window of protocol select will appear.

Next, you have to create a file calibration protocol or select a necessary one of created before

(if the calibration, for whatever reason has not been completed and it is necessary to continue

it). In the window "Protocol select", the newly created protocols are available. To view those

saved before use the button

and navigate to the choice of protocol by

operating system tools.

Page 29

EPSILON ES2,ES4

29

The data of calibration will be saved in this protocol file; in the case of abnormal power

disconnection of PC data will not be lost.

After selecting the protocol the tab «Data Protocol" will open.

Data made on this tab are complementary and they are used by technical support service. They

do not affect to the calibration, but are saved in the "cap" of calibration table.

To start the calibration it is necessary to fill all the fields on the tab "Data Protocol" and press

button “NEXT” .

“Monitoring of fuel tank calibration”

Page 30

30

Then you need to choose the initial volume of fuel in the tank in the window "Starting value, l":

- if the tank is empty - "0";

- Current value, in the case if the calibration does not begin from "zero" (has not been

completed before, or starts with a full tank by draining method). However, if the vehicle was in

operation and the fuel level is not the same as the last point of calibration, you should

add/reduce fuel to the nearest calibration point, guiding by code of level “N”.

In the window "Step, l" you need to set the volume size of fuel portion (calibration cup), at that:

• sign "+" corresponds to adding portion (set by default)

• sign "-" corresponds draining the portion of fuel.

By pressing on the button «Start» you have to initiate monitoring procedure.

Page 31

EPSILON ES2,ES4

31

To record the point of calibration, press the button «Rec», to pause the scrolling (with

long pauses) – press «Pause». In the box "Next value, l" you will see the prompt - the

expected amount of the fuel in the tank. If this value is in the process of calibration will exceed

the tank amount, indicated in the protocol, the window will be colored in orange for warning.

Code level, N is the result of measuring the fuel level by sensor eS4. It is displayed in decimal

format. If you will have 12-bit representation a typical value (in empty tank) is: for unified types

and for "User’s L" - N = 625, for "User’s H" - N = 100. During the rising of fuel level in the tank N

increases, the maximum value for type 710 is N = 4095.

The information about each saved calibration point is displayed on the graph. For taking extend

information you have to click the left mouse button on the relevant position in the table on the

right (or on the graph), this will give you transition to a selected point on the graph (and in the

table). For editing of selected point you have to press the right mouse button and select one of

listed menu items.

«Change fuel level of selected point» - if you choose this item you will see a dialog box "Fuel

Level" in which you have to enter a new value in liters for the selected point. After pressing the

button you will be offered to change the values all next points to quantity of values difference.

Pressing the button , changes all next values. To change only selected point you have

to press , to complete without changes press .

Page 32

32

«Delete selected point» - when you select this item a dialog box "Information" will be shown.

Here all the properties of the deleting point will be listed. If you will press the selected

point will be deleted. – log out without changes.

"Properties" - when this option is selected you will see a dialog box in which all the properties

of the point will be listed.

Left overhead there are buttons of the graph scroll to the left/right.

Scaling is performed by selection of appropriate window (to fix an angle - press the left mouse

button, then draw:

to increase - from left to right, from top to bottom;

to decrease - from right to left, from bottom to top).

Page 33

EPSILON ES2,ES4

33

To complete the calibration, press «Stop» button (right in bottom), before exit you will

be offered to export calibration file into Excel format.

The exported file in Excel format is a calibration table that can be used to control the fuel level.

It should be noted that the table may contain data (if they were saved), obtained as Auto save

points. They can duplicate the data got in the calibration points (User save). Auto save points

are required only for saving of calibration history, in the calibration table they are not used and

should be filtered.

Changing of the auto save parameters is available in the menu:

"Options \ Settings \ Control of operation mode."

The parameter "Auto save constant" determines the amount of code N level change that

causes the point auto save. Auto-saving is not set by default, but at the beginning and at the

end of work with the calibration protocol the endpoints will always be stored in Auto save mode.

For saving the history and increasing the accuracy of the data processing it is recommended to

allow auto save, especially in the tanks of complex shape.

Changing of parameters of the probe length control is available in the menu

"Options \ Settings \ Settings of probe length measuring." The values of these parameters are

determined by the manufacturer, and to change them is not recommended.

To control the data exchange protocol of the sensor with a controller a terminal box can be

used, it is available in the menu "Options \ Display terminal box”. Selection of another protocol

may be made in the menu "File \ Connect a new protocol."

Export of a protocol file into Excel, if it was not executed at the end of calibration, can always be

done in the menu "File \ Export protocol into Excel". The latter variant should be considered

preferable, because the protocol files in a special format of eS Install (*.esi) take less space and

are not available for correction by ordinary tools.

After exporting of a protocol file into Excel, calibration curve is calculated automatically (for a

general visual estimation of correctness of work done).

Page 34

34

Appendix 2

UNIFIED PROTOCOL Epsilon Data Exchange (EDE)

A2.1 General Provisions

This document describes a protocol of data exchange of fuel level sensors «Epsilon»

(hereinafter referred to as FLS) with external devices.

Two types of exchange protocols are supported: in a binary form (HEX) or in a symbolic form

(ASCII-sequences transfer). For work it is recommended to use a binary exchange protocol.

After powering of FLS and before issuing the first command of request you should wait not less

than 250 ms. The command, sent in 250 ms after switching on, will not be accepted by FLS. It is

also possible do not get the answer to the request if the FLS is busy (data processing is

running). In this case, the command should be repeated in 100 ... 200 ms.

The reaction time on the received reading command (except a reading command of supply

voltage) does not exceed 5.5 ms. Reaction time to reading command of supply voltage is

approximately 250 ms. The reaction time to the command of parameters saving is no more than

200 ms. To avoid "hanging" during an unexpected serial interface disconnection timeout on

symbol receiving is used - about 100 ms. If during this time the expected symbol is not received,

FLS does not answer and goes into standby mode to next command.

A2.2 Serial port settings.

Exchange speed corresponds to the parameter set in the sensor (19 200 bit/s by default).

Data capacity - 8 bits.

Parity - not checked.

Stop bit - 1.

Flow control – switched off.

A2.3. Description of commands for binary exchange protocol.

A2.3.1 Message format for binary exchange protocol.

All commands of a binary exchange protocol have the same standardized form:

Commands and messages format for binary exchange protocol.

Field serial number

Name of field

Size of field, Bytes

Description

1 Prefix 1

Field is a marker of message

beginning.

Incoming messages must have

prefix 31h,

and outgoing message must be

issued by a program with prefix

3Eh.

Page 35

EPSILON ES2,ES4

35

2 Network address 1

Field contains:

- network address of acceptor for

prefix 31h;

- network address of message

sender for prefix 3Eh;

3 Command code 1

Field contains:

- for prefix 31h – code of

command code, that FLS has to

comply;

- for the prefix 3Eh – code of

command, on which FLS gives

the answer.

4

Command

parameters

Depends on the

command code

The data composition and the

format of the field depends from

the command code.

5 CRC8 1

This field is used to control data

integrity. Calculated from all the

previous bytes in accordance with

Application Note 27 from Dallas.

Multi-byte command parameters are transferred in order from a junior byte to a senior one(«low

endian»).

A2.3.2 Description of computer code.

A2.3.2.1 Common commands for FLS of all modifications.

A2.3.2.1.1. Single data reading (command 06h).

The command is designed for reading of current data: user’s value of fuel level (10 or 12 bits),

technological value of fuel level (16 bit), temperature (8 bits).

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 06h Command code

+3 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 06h Command code

+3 1 -128…127

Temperature in degrees

of centigrade

Page 36

36

+4 2

0000h…03FFh

or 0000h…0FFFh

User’s value of fuel level

+6 2 0000h…FFFFh

Technological value of

fuel level

+8 1 00h…FFh CRC8

A2.3.2.1.2 Unsolicited (periodic) data output (command 07h).

In message current data is transferred: User’s value of fuel level (10 or 12 bits), technological

value of fuel level (16 bit), temperature (8 bits).

Message format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 07h Command code

+3 1 -128…127

Temperature in degrees

of centigrade

+4 2

0000h…03FFh

or 0000h…0FFFh

User’s value of fuel level

+6 2 0000h…FFFFh

Technological value of

fuel level

+8 1 00h…FFh CRC8

Turning on of the periodic data output is performing by command 55h. In case of receiving of

any valid command periodic data output is disabled, for it’s turning on you have to restart FLS

(switch off and switch on of power supply).

P2.3.2.1.3 Reading of technological parameters (command 41h).

The command is designed for reading of technological parameters of FLS: date of production,

serial number, model code, embedded software version, current calibration data, network

address, period of data output, data output mode.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 41h Command code

+3 1 00h…FFh CRC8

Answer format:

Page 37

EPSILON ES2,ES4

37

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 41h Command code

+3 1 00h…FFh

Year of production: 00h

corresponds to 2000

+4 1 00h…0Bh

Month of production:

00h – January, … , 0Bh

- December

+5 1 01h…1Fh

Day of production:

1…31

+6 3 000005h…FFFFFFh

Serial number

(000005…1048575)

+9 1 01h…92h

Model code

(see next table)

+10 1 01h…FFh

Embedded software

version

+11 1 00h…3Fh Rough calibration

+12 1 00h Reserved

+13 2 0000h…FFFFh Exact calibration

+15 1 F1h Reserved

+16 1 00h Reserved

+17 1 00h…FFh Network address

+18 1 00h…FFh

Period of data output -1

s

+19 1 See table 4.2 Data output mode

+20 1 00h…FFh CRC8

FLS model decoding:

Model code (HEX) Model name Range of probe length, mm

01 ES4-0800 0…800

11 ES4X-1208 800…1200

21 ES4X-1412 1200…1400

31 ES4X-1514 1400…1500

41 ES4XL-1914 1400…1900

51 ES4XL-2119 1900…2100

61 ES4XL-2221 2100…2200

71 ES4XXL-2722 2200…2700

81 ES4XXL-2927 2700…2900

91 ES4XXL-3029 2900…3000

02 ES2-0800 0…800

12 ES2X-1208 800…1200

22 ES2X-1412 1200…1400

32 ES2X-1514 1400…1500

Page 38

38

42 ES2XL-1914 1400…1900

52 ES2XL-2119 1900…2100

62 ES2XL-2221 2100…2200

72 ES2XXL-2722 2200…2700

82 ES2XXL-2927 2700…2900

92 ES2XXL-3029 2900…3000

A2.3.2.1.4 Reading of serial number and date of production (command 42h).

The command is designed for reading of following FLS parameters: date of production, serial

number, model code, embedded software version.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 42h Command code

+3 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 42h Command code

+3 1 00h…FFh

Year of production: 00h

corresponds to 2000

+4 1 00h…0Bh

Month of production:

00h – January, … , 0Bh

- December

+5 1 01h…1Fh

Day of production:

1…31

+6 3 000005h…FFFFFFh

Serial number

(000005…1048575)

+9 1 01h…92h

Model code

(see table 4.1)

+10 1 01h…FFh

Embedded software

version

+11 1 00h…FFh CRC8

A2.3.2.1.5 Reading of supply voltage (command 50h).

Command is designed for getting current value of voltage of built-in stabilizer.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

Page 39

EPSILON ES2,ES4

39

+1 1 00h…FFh

Network address of

acceptor

+2 1 50h Command code

+3 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 50h Command code

+3 2 Vcc=0000h…7FFFh

Formula evaluation of

supply voltage:

U=Vcc/4667,8.

+5 1 00h…FFh CRC8

A2.3.2.1.6 Installing of the period of data output (command 54h).

The command is designed for setting of period of data output.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 54h Command code

+3 1 00h…FFh

Value of the period of data

output -1 s

+4 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 54h Command code

+3 1 00h or 01h

Return code: 00h -

command is complied

successfully, 01h -

Error

+4 1 00h…FFh CRC8

A2.3.2.1.7 Installing of data output mode (command 55h).

The command is designed for setting of following parameters: data output capacity (10 or 12

bits), periodic data output (On/Off), resolution

Page 40

40

of a symbol protocol LLS (On/Off), averaging of data (On/Off) exchange rate on a serial port

(2400 ... 115 200 bit /s).

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 55h Command code

+3 1 00h…FFh See table….

+4 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 55h Command code

+3 1 00h or 01h

Return code: 00h -

command is complied

successfully, 01h -

Error

+4 1 00h…FFh CRC8

Data output mode decoding:

Bit(s)

Use

Description

Value by default

Notes

7 Output data capacity

0: 10 bit

1: 12 bit

ES2 – 10 bit

ES4 – 12 bit

Value by

default can be

changed

according to

order

6 Data averaging

0: ON

1: OFF

0 (ON)

5 Reserved - 0

Changes are

not allowed

4,3,2

Exchange speed on

serial port

000 – speed

does not change;

001 – 2400 bit/s;

010 – 4800 bit/s;

011 – 9600 bit/s;

(setting by

default);

100 – 19200

bit/s;

101 – 38400

bit/s;

110 – 57600

bit/s;

111 – 115200

bit/s;

100 (19200 bit/s)

Value by

default can be

changed

according to

order

Page 41

EPSILON ES2,ES4

41

1 Symbol protocol LLS

0: denied

1: allowed

0 (denied)

Value by

default can be

changed

according to

order

0

Periodic data output after

restart

0: OFF

1: ON

0 (OFF)

Value by

default can be

changed

according to

order

NOTES.

Setting of exchange speed and resolution of data output in symbol format is used in FLS ES2,

ES4 with software versions 1.8 and higher, as well as in ES2X, ES2XL, ES2XXL, ES4X,

ES4XL, ES4XXL with embedded software versions: 4.6, 4.7, 4.10 and higher.

Periodic data output mode is used in ES2, ES4 with software versions: 1.3, 1.4, 1.7 and higher,

as well as in ES2X, ES2XL, ES2XXL, ES4X, ES4XL, ES4XXL with embedded software

versions: 4.6, 4.7, 4.10 and higher.

For ES2, ES4 with software versions 1.3, 1.4, ; bits 1 ... 6 in the command parameter must be

equal to 0.

A2.3.2.1.8 Setting of network address (command 56h).

Command is designed for setting of network address of FLS for work of several fuel level

sensors on one line.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 56h Command code

+3 1 00h…FFh

New network address of

FLS

+4 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 56h Command code

+3 1 00h or 01h

Return code: 00h -

command is complied

successfully, 01h -

Error

+4 1 00h…FFh CRC8

A2.3.2.2 Special commands for FLS models ES2-0800, ES4-0800.

A2.3.2.2.1 Rough calibration (command 45h).

Page 42

42

Command is designed for rough calibration («zero installation») in the process of FLS

installation. If the length of probe is within (150…710) mm, «zero installation» is not required.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 45h Command code

+3 1 00h…3Fh

Value of parameter of

rough calibration

+4 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 45h Command code

+3 1 00h or 01h

Return code: 00h -

command is complied

successfully, 01h -

Error

+4 1 00h…FFh CRC8

A2.3.2.2.2 Exact calibration (command 49h).

Command is designed for exact calibration («zero installation») in the process of FLS

installation. If the length of probe is within (150…710) mm, «zero installation» is not required

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 49h Command code

+3 2 0000h…FFFFh

Value of parameter of

exact calibration

+5 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 49h Command code

+3 1 00h or 01h

Return code: 00h -

command is complied

successfully, 01h -

Error

Page 43

EPSILON ES2,ES4

43

+4 1 00h…FFh CRC8

A2.3.2.2.3 Reading of probe’s length parameter (command 4Dh).

Command is designed for reading of current value of probe’s length parameter.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 4Dh Command code

+3 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 4Dh Command code

+3 1 00h…07h

Parameter of probe’s

length

+4 1 00h…FFh CRC8

Probe’s length parameter decoding

Value of probe’s

length parameter

Manufacturer's type

mark

Allowable length of

probe, mm

Notes

0 User’s L 0…260

Calibration is made

during installation

1 User’s H 710…800

Calibration is made

during installation

2 260 150…340

Manufacturer’s

calibration

3 350 270…430

Manufacturer’s

calibration

4 440 360…520

Manufacturer’s

calibration

5 530 450…610

Manufacturer’s

calibration

6 620 540…650

Manufacturer’s

calibration

7 710 630…710

Manufacturer’s

calibration

A2.3.2.2.4 Select of probe’s length parameter (command 4Eh).

The command is designed for selecting of probe’s length in a line from 0 to 7.

Page 44

44

The parameter values from 2 to 7 correspond to the factory calibration for the standard series of

probe length. In these cases the calibration of FLS during the installation is not required, you

just have to select the parameter of probe’s length according to Table 4.3.

The value of "0" is applied if the probe’s length is less than 150 mm, the value "1" is applied if

the length of the probe is in the range of (710 ... 800) mm. In these cases, the calibration of FLS

is made during its installation.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 4Eh Command code

+3 1 00h…07h

Parameter of probe’s

length (look table 4.3)

+4 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

+1 1 00h…FFh

Network address of

sender

+2 1 4Eh Command code

+3 1 00h or 01h

Return code: 00h -

command is complied

successfully, 01h -

Error

+4 1 00h…FFh CRC8

A2.3.2.2.5 Storing of calibration data for set-up probe’s length parameter

(command 4Fh).

The command is designed for storing in non-volatile memory of parameters, set by commands

45h and 49h during calibration («zero installation») for a set-up probe’s length parameter.

Command format:

Drift, byte

Size of field, byte

Value Description

0 1 31h Prefix

+1 1 00h…FFh

Network address of

acceptor

+2 1 4Fh Command code

+3 1 00h или 01h

Parameter of probe’s

length

+4 1 00h…FFh CRC8

Answer format:

Drift, byte

Size of field, byte

Value Description

0 1 3Eh Prefix

Page 45

EPSILON ES2,ES4

45

+1 1 00h…FFh

Network address of the

sender

+2 1 4Fh Command code

+3 1 00h или 01h

Return code: 00h -

command is complied

successfully, 01h -

Error

+4 1 00h…FFh CRC8

A2.3.2 Support for symbol protocol LLS.

A2.3.2.1 Format of data output (example):

F=FFFF t=1A N=03FF.0<CR><LF> , where:

F – 16-bit code of measured capacity.

t – temperature, °C

N – user code of the measured capacity (always 10 bits despite the parameter set by command

55h).

A2.3.2.2 Supported commands of symbol protocol LLS.

DO – request for one-time data output. At the moment of receiving this command FLS shows

data 1 time in the format described in P 5.1.

DP – switching on of periodic data output. This command is sent only once, after which FLS

shows data in the format described in Section 5.1., with interval set by command 54h. This

mode does not depend on the resolution of periodic data output set by command 55h and is

stored until receiving any valid command of EDE protocol or to the turning off and restart of

FLS.

For work with a symbol protocol, bit 1 must be installed in the parameter of command 55h.

Otherwise, commands DO and DP are ignored, and the periodic data output, if installed, is

made in a binary format in accordance with p.4.1.2.

Page 46

46

Appendix 3

Measuring head marking.

Example of measuring head marking:

Without index - normal, value of division 1Δ (~ 0.20 mm/un. code);

Х - long, value of division 2Δ, the same;

ХL - long, value of division 3Δ, the same;

ХXL - long, for work with a thickened probe; value of division 3,75Δ

Correspondence of index in head marking to the length of the probe:

Used head Used probe

Marking of

model and

interface

Marking of

measuring

range

Marking of

maximum

probe’s

length

Coaxial ratio,

D/d (mm/mm)

Probe’s length, mm

maximum minimum

ES2; ES4 - 0800* 13/0.4 800 30

ES2; ES4 X 1208 13/0.4 1200 800

ES2; ES4 X 1412 13/0.4 1400 1200

ES2; ES4 X 1514 13/0.4 1500 1400

ES2; ES4 XL 1914 13/0.4 1900 1400

ES2; ES4 XL 2119 13/0.4 2100 1900

ES2; ES4 XL 2221 13/0.4 2200 2100

ES2; ES4 XXL 2722 31/0.4 2700 2200

ES2; ES4 XXL 2927 31/0.4 2900 2700

ES2; ES4 XXL 3029 31/0.4 3000 2900

Minimum allowable length, mm

Probe, Maximum allowable length, dm

Interface type

Correspondence

Page 47

EPSILON ES2,ES4

47

Appendix 4

CONNECTION OF SENSORS ES2 AND ES4 TO CONCENTRATOR

OF FUEL LEVEL SENSORS “DALCON”

Concentrator of fuel level sensors "LLS DALCON" is designed for evaluating of current volume

of liquid in one or two tanks and for organization of interface of interaction with external devices

of data collection (recorders).

The concentrator also has the ability to control external status displays (needle indicator of fuel

level and light indicator "reserve").

A4.1 Connection

For connection of sensors to the concentrator you need to use the "Manual for installation of

concentrator of fuel level sensors LLS DALCON" (Ed. 1.3, Omnicomm 2008,

http://rega78.ucoz.ru/_ld/0/9_Installation_DA.pdf or later) and this appendix.

You can connect two sensors with the same interfaces RS485 (pic.A4.1) or different interfaces

RS485 or RS232 (Pic. A4.2) to connector MF-20F on the concentrator’s body.

To connect three or more sensors to concentrators DALCON cascading connection is used.

(see afore-mentioned manual).

Page 48

48

Pic. A4.1. Connection of sensors with the same interfaces RS485.

Pic. A4.2. Connection of sensors with different interfaces RS485+RS232

A4.2. Configuration of sensor «Epsilon ES4»

(

see pic. A 4.3, pic. A4.4).

Data output capacity – 10 bits.

Periodic data output is switched off.

Network address – 1 for 1st sensor and 2 for 2nd sensor (other values can be applied, from 0

to 15, but necessarily different).

Black

Yellow

Green

Red

Red

Yellow

Green

Black

Black

Yellow

Green

Red

Black

Yellow

Green

Red

Page 49

EPSILON ES2,ES4

49

Before connection to DALCON sensors must pass the calibration in accordance with Appendix

1.

A4.3. Configuration of concentrator DALCON

(see Pic. A4.5, Pic. A4.6).

Periodic data output - optionally.

Sensor 1 – ask.

Sensor 2 – ask.

You have to install network addresses of sensors in accordance with paragraph A.4.2.

Pic A4.5. Typical DALCON configuration for devices using a digital protocol.

Page 50

50

Pic. A4.6. A typical DALCON configuration for devices using a text protocol

The value of tank volume should be set a little bit higher than real (for example, 1000 l when the

real volume of the tank is 900 l). This is due to calibration table – there must be a point

corresponding to the value of code equal to 1023. In the case of FLS LLS, this point always

corresponds to a full tank, and in case of FLS "Epsilon" value of the code for a full tank does not

reach this point.

A4.4. Entry of calibration table

(see pic. A4.7, pic. A4.8).

For empty tank 2 values of code are entered: 0 (automatic) and the value got during the

calibration (for latter you have to establish the fuel volume of 1 l). Next, values from a calibration

table are entered until the code value for a full tank. Next, you have to enter a value of the tank

volume, set earlier, and the value of the code for it, equal to 1023. Conversion level table is

stored in memory of DALCON by pressing “Record conversion level table”

Pic. A4.7. Entry of calibration table for the 1st sensor.

Automatically

set zero value

Initial value of

fuel level code

Relative tank

volume for code

1023

Real tank’s

volume

Page 51

EPSILON ES2,ES4

51

Pic. A4.8. Entry of calibration table for the 2nd sensor.

To use all the settings, you need to switch off and restart DALCON.

Page 52

52

Appendix 5

CONNECTION OF SENSORS ES4 TO ONBOARD MONITORING

CONTROLLERS OF TRANSPORT SERIES «AвтоГРАФ-GSM»

The on-board transport monitoring controller "AвтоГРАФ-GSM” is an electronic recorder that

registers vehicle movements by recording the route in the form of points with coordinates

received from satellite system GPS (NAVSTAR) or GLONASS.

Additionally, it makes records of some other device parameters: speed, fuel level and condition

of different vehicle sensors.

To connect to FLS RS485 port is used.

For connecting of 1 on more fuel level sensors to the range of devices ""AвтоГРАФ-GSM” you

have to use manufacturer’s manual " WORK_RS485 User manual.pdf", and also the following

scheme:

ES4

RS485

черный

зеленый

желтый

красный

ES4

RS485

черный

зеленый

желтый

красный

ES4

RS485

черный

зеленый

желтый

красный

...

+U

16 17 18 11 12 5

6

7 8

F C

13 14 15 9 10 1 2 3 4

E B

A

B

-U

You can also use additional installation manuals on the site of the manufacturer:

http://snavi.ru/instrykciya-po-ystanovke/index.html.

red

red

red

Green

Yellow

Black

Green

Yellow

Black

Green

Yellow

Black

Page 53

EPSILON ES2,ES4

53

Appendix 6

CONNECTION OF SENSORS ES4 TO ON-BOARD CONTROLLER OF

TRANSPORT NAVIGATION "Teletrack TT-221"