Page 1

Copy Size А4

The fuel level sensor

"EPSILON"

Models EN and EZ

Instruction manual

EN.000 RE (EN)

Page 2

Copy Size А4

Page

EN.000 RE

2

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

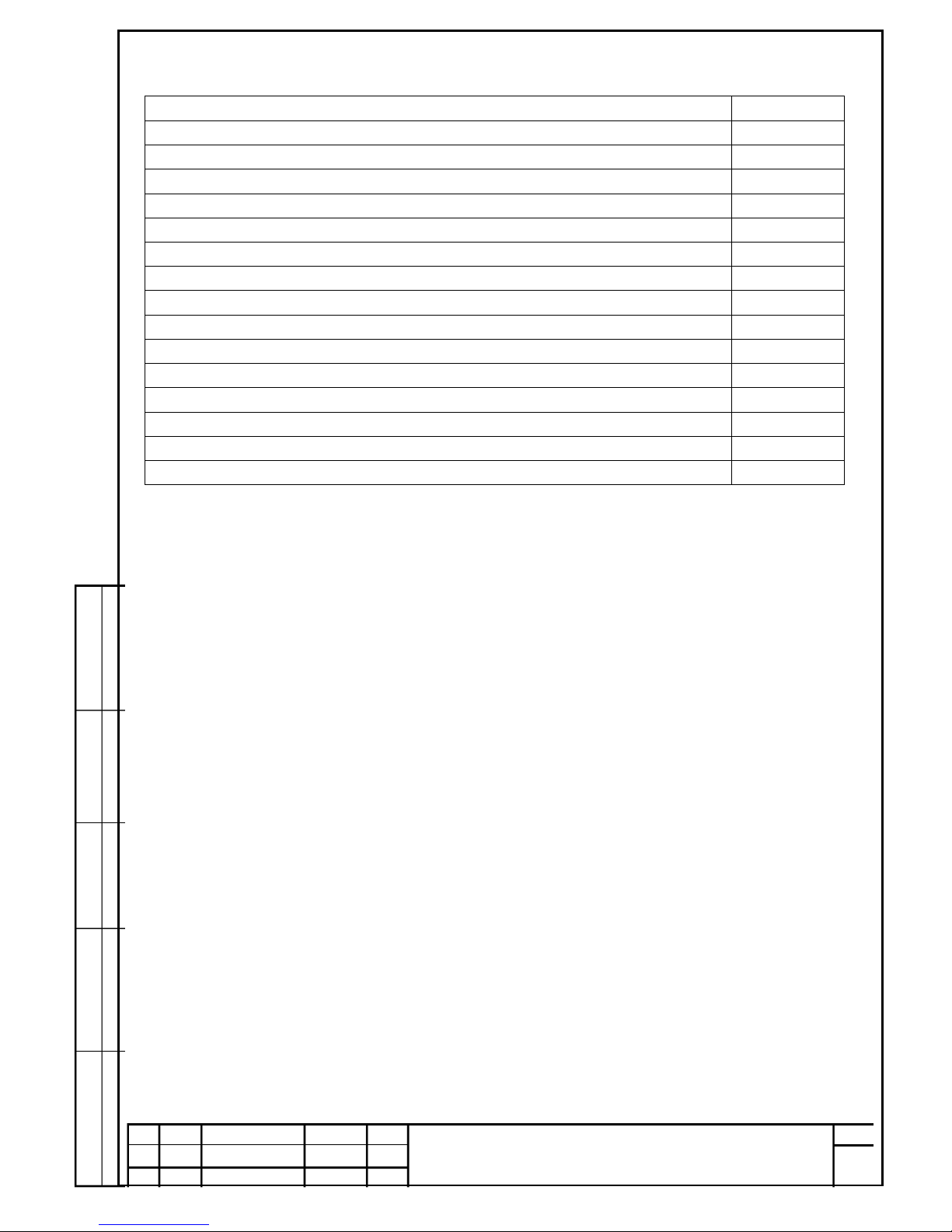

Content

Page

Introduction

3

1. Description and operation

3

1.1. Description of the sensor operation

3

1.2. Description of the components operation

18

2. Operations

20

2.1. Operation limits

20

2.2. Explosion-proofness

2.3. Preparation for use

21

2.4. Usage

22

3. Technical maintenance

23

3.1. Technical maintenance of the sensor

23

4. Current maintenance

26

4.1. Current maintenance of the sensor

26

4.2. Current maintenance of the components

26

5. Transportation and storing of the sensor

29

This instruction manual is designed to inform users about operation and maintenance

of the fuel level sensor "EPSILON" models EN and EZ, hereafter referred to as the

sensor or FLS.

The staff, which operates this sensor, must read this instruction manual carefully.

This instruction manual is referred to all the modifications of "EPSILON" models EN

and EZ.

This sensor doesn’t generate any hazardous emissions and doesn’t produce any other

negative effects on humans and the environment.

1. Description and operation

1.1. Description of the sensor operation

1.1.1. Product designation.

This sensor is designed to measure fuel level inside fuel tanks of vehicles and stationary

fuel storages. The sensor could be applied for measurement of any non-conductive

FLSids.

Page 3

Copy Size А4

Page

EN.000 RE

3

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

The sensor should be applied with equipment that supports a unified protocol of

Epsilon Data Exchange (hereafter referred to as EDE).

The sensor is compatible with various kinds of control units, concentrators and GPS

monitoring devices, such as:

- "Autograph";

- "Scout";

- "Locarus";

- "Intellitrac";

- "Patriot";

- "Teletrack";

- "Teltonika";

- "M2M – Cyber GLX";

- "Ruptela FM";

- "FM blue" and others.

1.1.2. Specifications.

Table 1.1.

Characteristic or parameter

Unit

of

meas

ure

ment

Value

Remark

1

2 3 4

General

Working temperature range

С

– 40 … + 75

Measuring head dust and moisture

protection level

IP67

Operating regime

Continuous

Measurement

Upper limit of the level measuring range,

depending on modification

mm

from 150 to

3000

(1)

The limits of reduced error level

measurement

%

±1.0

(2)

Page 4

Copy Size А4

Page

EN.000 RE

4

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

Relative electric permittivity range of values

for operating FLSid (ε)

1.5…3.3

Models

EXXxх-XXXX

1.5…5

Models

EXХRxх-

XXXX (3)

Averaging period of measurement results

с

0…32

Measurement information width

bit

10;12;16

(4)

Data rate of COM port

bits

per

seco

nd

2400, 4800,

9600, 19200,

38400,

57600,

115200

Selected by

program

Estimation of vehicle inclination

The range of vehicle inclination estimation

degre

e

±75

(5)

Resolving ability of vehicle inclination

estimation

degre

e

0.1

(5)

Data interpretative code width

bit

16

(5)

Estimation of measuring head

temperature

The range of measuring head temperature

estimation

°С

- 40…+ 85

The width of measuring head data

interpretative code

bit 8

Built-in data concentrator

Maximum number of connected external

FLS

pcs 7 (6)

Maximum number of calibration chart

records for all FLS

pcs

960

(7)

Maximum number of calibration chart

records for random FLS

pcs

960

(7)

Measurement information width

bit

10;12;16

Power

Supply voltage, operational range

V

from 9 till

36

Nominal

Useful current, no more than

m

50

Model EN

250

Model EZ

(8)

Page 5

Copy Size А4

Page

EN.000 RE

5

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

Permissible impact of impulse voltage

through power circuits

V

+160, 1 s

-1000,

continuous.

(8, 9)

Permissible short-time impact of electric

potential between signal ground and

measuring head cabinet

V

1500

(10)

Interface

Digital

RS-232

Model EN2

RS-485

Model EN4

RS-232 and

RS-485

(independent

)

Model EN6

RS-232 or

RS-485

(dependent)

Model EZ6 (11)

Connection dimensions, weight

Modification of flange

5 holes

diameter 4.5

mm

(12)

Type of fuel probe connecting thread

М36×1.5

Height of measuring head over tank surface,

including flange, no more than

mm

30

(13)

Sensor weight, no more than

kg

3.2

(14)

Notes

1 The level measuring range is the distance Ly between the cap claw (where there is)

or the cap bottom surface (without cap claw) of the fuel probe and drain port bottom

edge, which are minimum and maximum scale values respectively (see fig 1.1).

2 For fuel control with the same dielectric permittivity for the fuel, which used for

calibration. For other kinds of fuel, the personal should use calibration chart

(according to fuel dielectric permittivity table).

3 For level measurement of other dielectric liquids, it is necessary to use other

special fuel probe types, depending on the liquid parameters and operation

conditions.

Page 6

Copy Size А4

Page

EN.000 RE

6

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

4 There are two formats of data representation: 16 and 10; 12 bits. Capacity 10 or 12

bits is defined by programming controller. Default value is12 bit.

5 For both of two axes (lateral and transversal).

6 External FLS connections are possible for model EN6 only. For other models it is

possible to use internal calibration chart only. Quantity of external connected FLS

depends on ports functionality. If port RS-232 is mapped, maximal possible quantity

of connected external FLS is 1, otherwise (port RS-485) – 7.

7 Total amounts of calibration chart records could be distributed randomly between

any FLS. Calibration chart of any FLS could be absent (no records) or all records

could be belonged to single FLS.

Total amount of all FLS calibration chart records couldn't be more than 960.

If FLS doesn’t contain calibration chart for actual volume estimation, actual level

and volume of the tank are applied.

8 For the model EZ the parameter is shown for simultaneous usage of the FGU and

electrical protection unit BIZ-EZ.

9 Impulse parameters comply with requirements of State Standard 28751-90 (ГОСТ

28751-90) (unit class А, degree of fixity 3 for 24 V of supply-line voltage).

10 Exposure time is up to 1 second. For EZ model unit– voltage difference between

signal ground of spark protection block and measuring head cabinet.

11 For EZ model unit concurrent operating is possible by single interface only.

12 Other modifications of flange are possible by agreement with the customer.

13 Except packing washer.

14 Total weight of the sensor depends on the length and modification of its fuel prob.

Page 7

Copy Size А4

Page

EN.000 RE

7

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

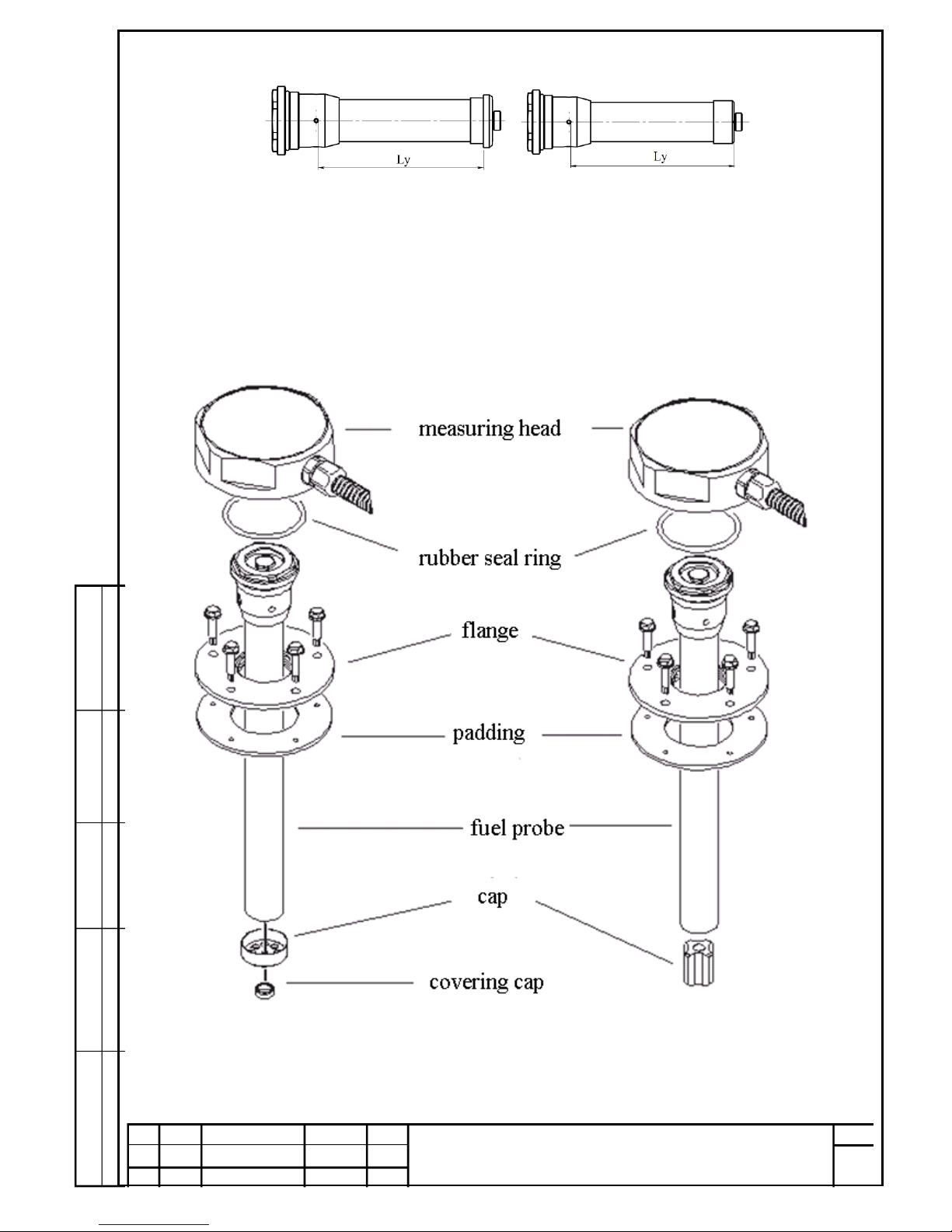

Fig.1.1

1.1.3. Contained parts.

1.1.3.1. Main contained parts.

The main contained parts are the probing device and attached detecting head, which

is fixed to FS tank surface with flange (Fig 1.2).

Fig.1.2. General view of FLS with string central contact (left) and pluggable central

contact (right).

1.1.3.2. Product designation and brief summary of the model range

Page 8

Copy Size А4

Page

EN.000 RE

8

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

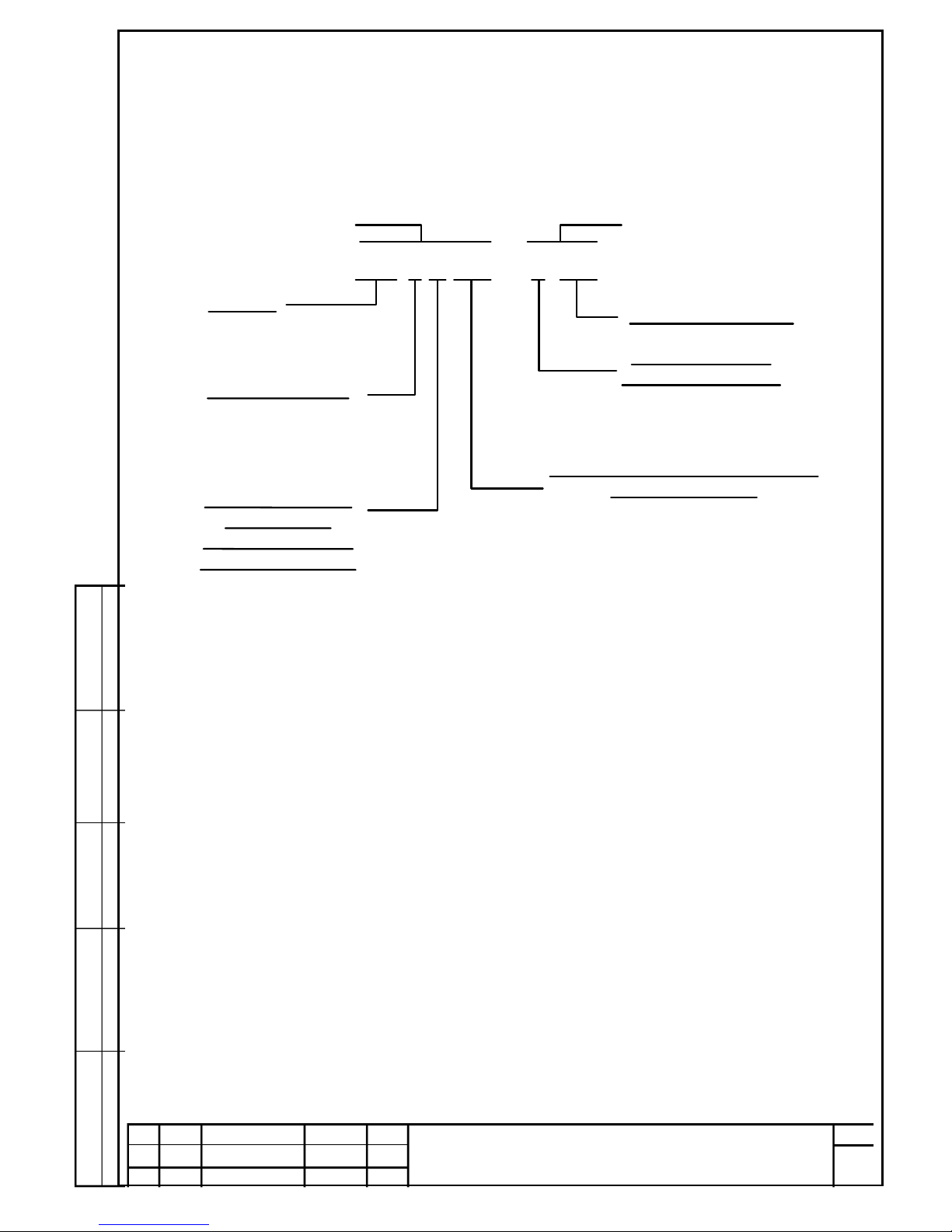

There are different identification marks of sensor, depending on the interface type,

measuring liquid dielectric permittivity, presence of tilt meter, probing device type

and length.

Fig. 1.3.

Epsilon EN2" – provides data exchange by RS-232 interface. "Epsilon EN4" provides data exchange by RS-485 interface.

"Epsilon EN6" – has two independent interfaces: RS-232 and RS-485. This sensor

is able to be a data concentrator for other FLS.

"Epsilon EZ6" – is operated only together with spark protection unit BIZ-EZ. Spark

protection unit BIZ-EZ - provides explosion protection of sensor model "EZ" and

data exchange by RS-232 and RS-485 interfaces.

1.1.3.3 Sensor identification to order.

1.1.3.3.1 Sensor identification contains of:

Designation;

space

- absent

i

- presence of tilt meter

m

- data processing considering

tank models

E Х 6 R i m - H 075

Identification of

measuring head

Identification

of fuel probe

Model

Interface type

2

- RS-232

4

6

- RS-232+RS-485

8

- CAN

For measurement

of liquids

dielectric

permittivity

space

- from 1.5 to 3.3

R

- from 1.5 to 5

operational characteristics

and combinations

Fuel probe design

space

- string

H

- pluggable

Fuel probe length (cm)

EN

EZ

Page 9

Copy Size А4

Page

EN.000 RE

9

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

Sensor type - "Epsilon"

Model designation;

Interface type;

Relative electric permittivity range of values for operating fluids;

Operational characteristics

Modification of fuel probe;

Fuel probe length (cm);

Identification of these specifications.

Page 10

Copy Size А4

Page

EN.000 RE

10

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

1.1.3.3.2 Example of "Epsilon" sensors’ identification recording when

ordering and in documentation of other products, where it can be applied:

Fuel level sensor

"Epsilon" EN6Ri-H075 TOR U30466754-07:2013,

where:

- " Fuel level sensor"– item;

- "Epsilon" – name;

- "EN" – model;

- "6" – RS-232 and RS-485 interfaces;

- "R" – for measuring in a liquid with dielectric permittivity between 1.5

and 5;

- "i" – presence of an inclinometer;

- "-" – separator character in an identification;

- "H" – plug-in probe;

- "075" – probe length is 75 cm;

1.1.3.3.3 Probe length determination when ordering (see fig. 1.4)

Required length of the probe is determined by formula

L of probe = extern. L of tank – ∆, where:

L of probe – length of probe upon ordering (see fig. 1.5, 1.6);

extern. L of tank – external height of tank in the place of sensor

installation;

∆ – size of gap between the probe and the bottom of the tank.

Recommended values of the gap:

- ∆ = 10…20 mm – for hard metallic tanks (higher elevation of the tank must

comply with higher value of gap);

- ∆ = 30 mm – for hard tanks having insufficient rigidity (such as plastic

tanks of considerable height).

Page 11

Copy Size А4

Page

EN.000 RE

11

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

Fig. 1.4 Probe length determination when ordering

Fig. 1.5 Probe with a string

Fig. 1.6 Probe with plug contact

It is recommended to use the probes having lengths, standardized by

manufacturer (see table 1.1) – this will eliminate additional works during

sensor installing or replacing.

22

L зонда

22

L зонда

Flange

Ext. L of tank

L of probe

L of probe

L of probe

Page 12

Copy Size А4

Page

EN.000 RE

12

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

Thus, for example, overall height of the tank semi-trailer tractors of such

widespread brands as DAF, MAN, Renault, Scania is 620 mm – it is necessary to

apply the sensor with 600 mm long probe for them.

Sensor manufacturer provides the following set of standardized lengths of

probes (Table 1.1)

Table 1.1

Recommended length

of the probe

Typical vehicle models

800

Special vehicles

600

Semitrailer tractors DAF, IVECO, MAN,

Mercedes-Benz, Renault, Scania etc., technique

on their platform.

510

KAMAZ, KrAZ trucks, technique on their

platform

420

MAZ trucks, technique on their platform

340

ZIL trucks

250

Light commercial vehicle, minibuses

In case if data on the length in the record is absent, measuring probe is

typically supplied 750 mm long.

Page 13

Copy Size А4

Page

EN.000 RE

13

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

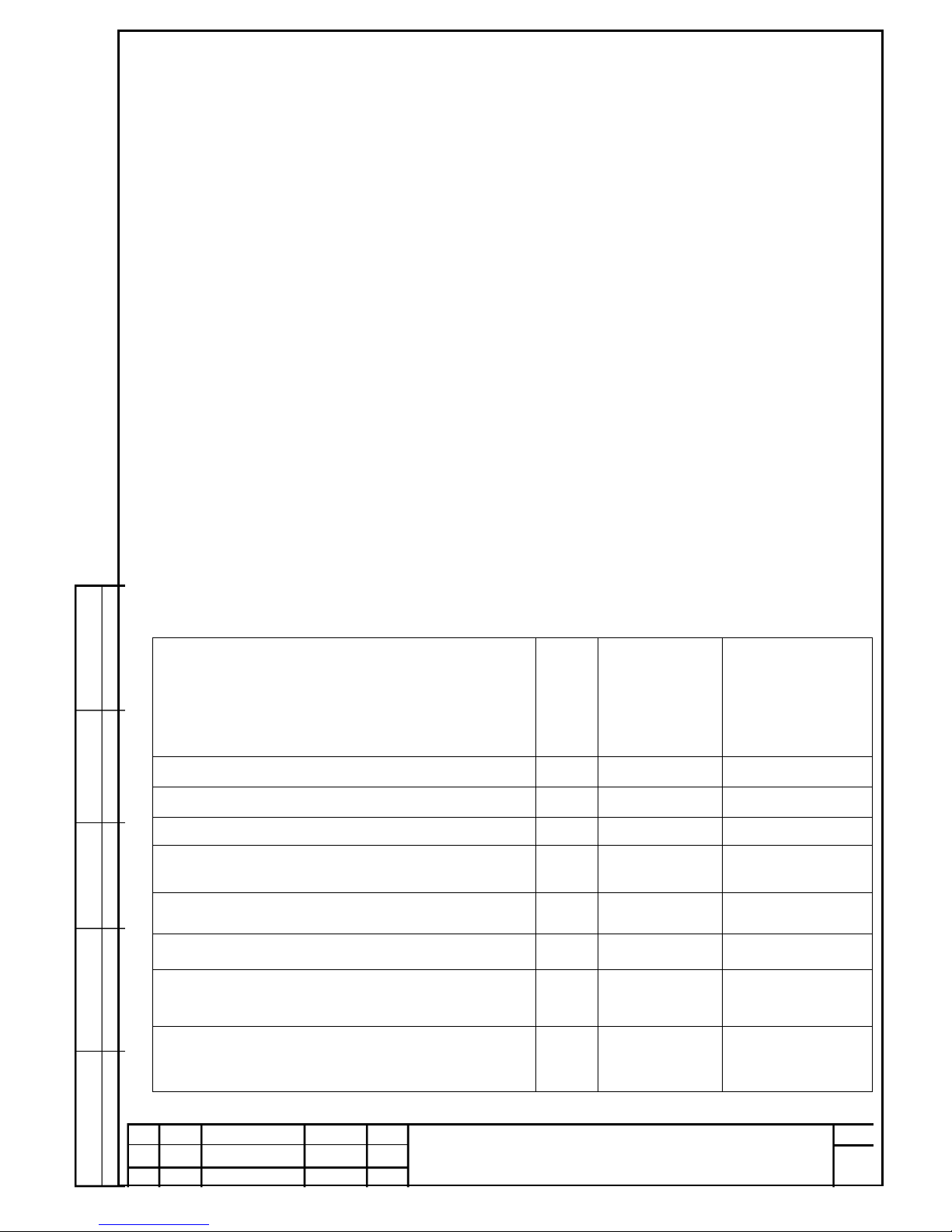

1.1.3.4 Delivery package

1.1.3.4.1 Basic delivery package

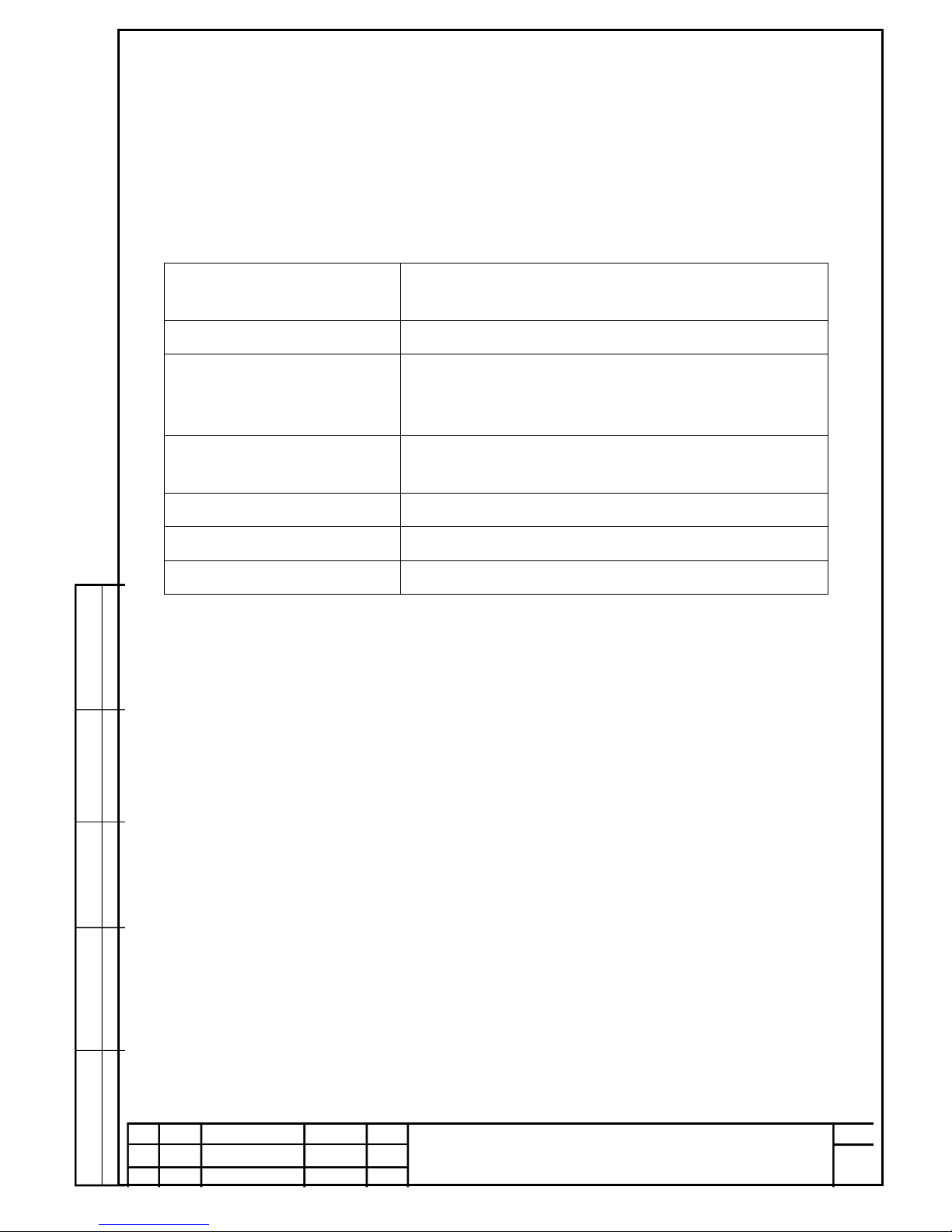

Table 1.2

Name

Models

Quantity,

pcs.

Notes

1

2

3

4

Measuring head

EN, EZ

1

Probe

EN, EZ

1

Flange

EN, EZ

1

Rubber seal ring

EN, EZ

1

Support of the probe

EN, EZ

1

Socket plug cap

EN

1

Self-drilling helical screw

EN, EZ

4

Ø 4.2х19 mm

Self-drilling helical screw

EZ

2

Ø 3.9х16 mm

Self-drilling helical screw for

sealing

EN, EZ

1

Ø 4.2х19, stainless, with an

aperture for sealing

Tamper-evident seal

EN

2

With wire for sealing

EZ

4

Interface cable EN2

EN2,

EN4

1

Length 7.5 m

Interface cable EN6

EN6

1

Length 7.5 m

Interface cable EZ

EZ

1

Length up to 300 m

manufactured upon request

Interface cable BIZ

EZ

1

Length 1.0 m

Cable tightening

EN, EZ

15

200х3.6 mm

Spark protection module BIZEZ

EZ

1

Grounding wire

EZ

1

Length 1 m

String

EN, EZ

with

string

1

SPTA

Page 14

Copy Size А4

Page

EN.000 RE

14

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

end of Table 1.2

1

2

3

4

Fuse strip 0.1 А 250V

EN

1

Ø 5х20 mm, quick-action

Fuse strip 0.5 А 250V

EZ

1

Ø 5х20 mm, quick-action

Insertion label

EN, EZ

with

string

1

Scheme of string fixing

Vehicular safety appliance 1А

EZ

1

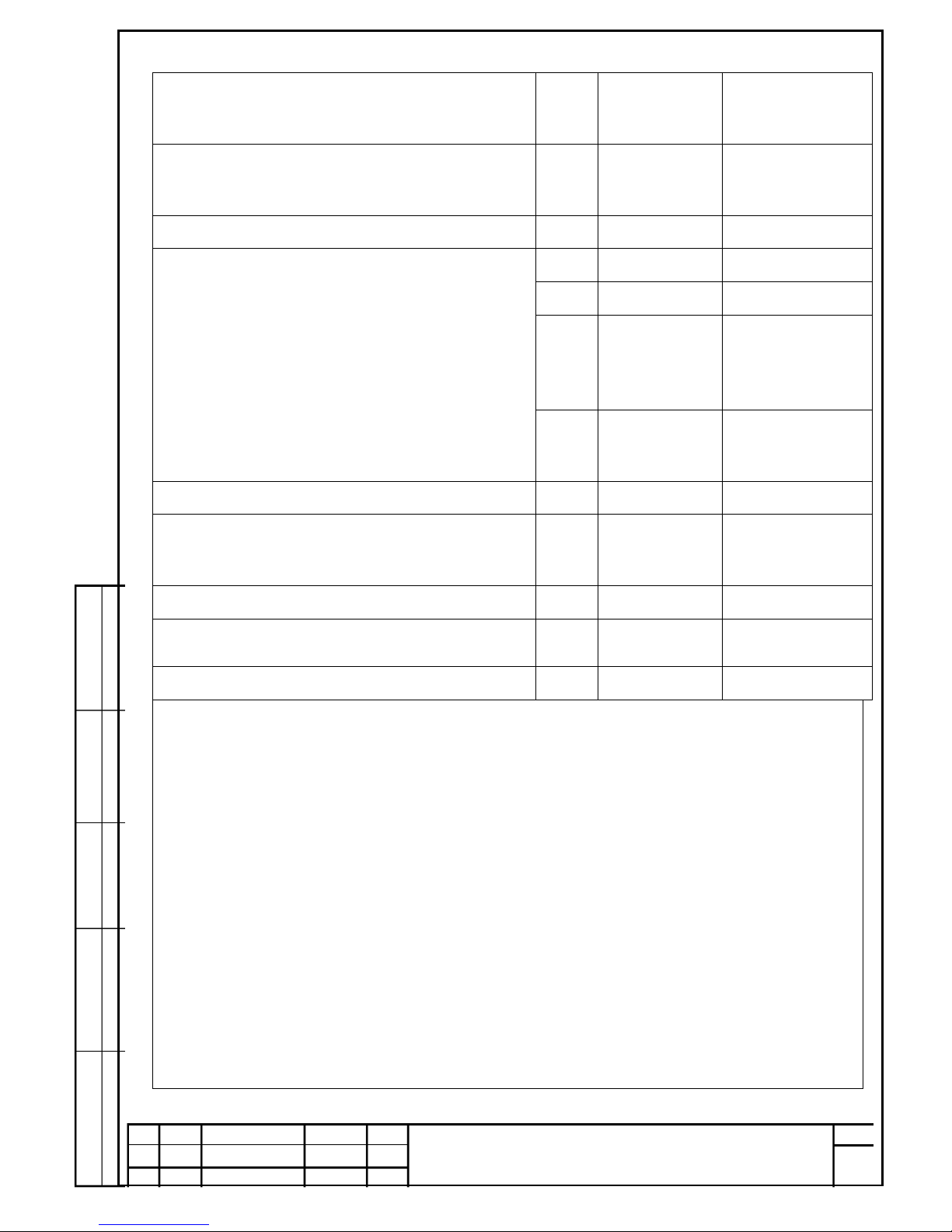

1.1.3.4.2 Additional accessories

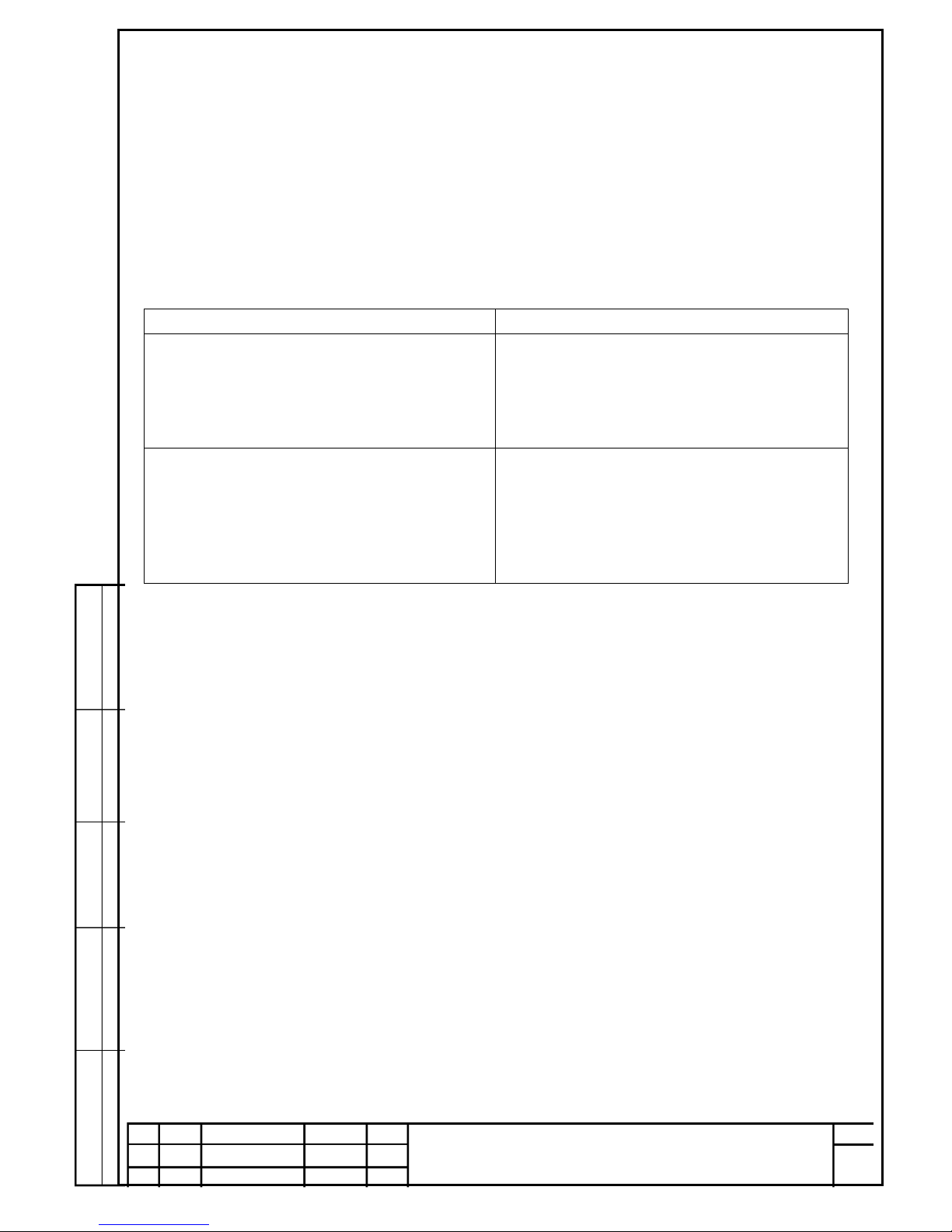

Table 1.3

Name

Indication

Quantity

Notes

Socket plug

IEC EN C.100

1

Installed on the tank after

complete dismantling of the

sensor

Socket plug-cover

IEC EN. 002.0

1

Installed on the tank after

removal of the measuring

head

EX2 cable for

connecting a

sensor to PC

IEC ES С.100

1

For models EN2

Supplied upon additional

request

EX4 cable for

connecting a

sensor to PC

IEC ES С.100-

01

1

For models EN4

Supplied upon additional

request

EX6 cable for

connecting a

sensor to PC

IEC EN СА.100

1

For models EN6, EZ6

Supplied upon additional

request

CD-ROM with

software

EN.000 CD1

1

Supplied upon additional

request

Page 15

Copy Size А4

Page

EN.000 RE

15

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

1.1.3.4.2 Operation documentation

Table 1.4

Name

Identification

Q-ty

Notes

Passport

EN.000 ПС 1 For model EN

Passport

EZ.000 ПС 1 For model EZ

Passport

BIZ-EZ.000 ПС

1

For spark protection module

Operation manual

EN.000 РЕ

1

1 copy per batch on a single

address

Installation

manual

EN.000 ИМ

1

Supplied upon additional request

1.1.4 Structure and Functioning

Measuring of fuel level is carried out by measuring head together with

probe immersed into the fuel.

When immersed into the fuel, probe of sensor performs the function of a

variable capacitor whose capacitance is linearly dependent on the filling level of

fuel.

Sensor’s measuring head performs a linear transformation of probe's

capacitance into a digital code of the fuel level, processing of obtained digital data

with averaging the measurement results, measurement of head’s temperature

and data output in unified EDE Protocol via RS-485 or RS-232 interface. Fuel level

data is outputted in form of 16-bit value, and optionally as 10- or 12-bit value

selectable, data about the temperature – in the form of 8-bit value. In order to

estimate acceleration and angle of vehicle's inclination, for purpose of estimation

of reliability of level value and its further compensation depending on the angle,

there is the inclinometer built in the head.

In order to define volume of controlled fuel, the procedure of the fuel tank

calibration should be performed, at which dependence between the volume of

fuel and level code is determined.

Calibration procedure control and establishing data exchange parameters

by means of "eS Install" software are described in Appendix А to the document

"EN.000 ИМ. Installation manual ".

EDE data exchange protocol is given in Appendix B of that document.

The embedded software update process, as well as saving and restoration

process of configuration data is described in Appendix C of that document.

Page 16

Copy Size А4

Page

EN.000 RE

16

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

1.1.5 Labeling and Sealing

1.1.5.1 Labeling

1.1.5.1.1 Labeling of measuring head:

- name and label for goods and services of the enterprisemanufacturer;

- name and conventional identification;

- explosion-proofing labeling;

- operational temperature range;

- serial (factory) number according to the system of enterprise-

manufacturer.

1.1.5.1.2 Labeling of spark protection module (for "EZ" models):

- name and label for goods and services of the enterprise-

manufacturer;

- name and conventional identification;

- explosion-proofing labeling;

- operational temperature range;

- lettering "Intrinsically safe circuits";

- serial (factory) number according to the system of enterprise-

manufacturer.

1.1.5.1.3 Labeling on sensor packaging:

- name and label for goods and services of the enterprisemanufacturer;

- name and conventional identification;

- production date (month, year);

- explosion-proofing labeling (for "EZ" model);

- type and length of the probe;

- operational temperature range;

- TOR number, according to which sensor is manufactured;

- lettering "Made in Ukraine";

- serial (factory) number in Arabic numerals;

- serial (factory) number in the form of barcode.

1.1.5.2 Sealing

In order to protect sensor and spark protection module against

unauthorized tampering, tamper-evident seals are installed.

One seal protects the measuring head from unscrewing, and the rest are installed

on separable interface cable connections.

Sealing procedure is described in section 4 of the document "EN.000 ИМ.

Installation manual".

Page 17

Copy Size А4

Page

EN.000 RE

17

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

1.1.6 Packing

Measuring head with attached probe is packed in polyethylene "sleeve" and

building kit from basic delivery package (see table 1.2) and spark protection

module (for models "EZ"), are packed in sealed polyethylene packages.

Page 18

Copy Size А4

Page

EN.000 RE

18

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

1.2 Description of product components

1.2.1 Measuring heads

Sensor’s measuring head (fig. 1.2) contains:

- capacitometer;

- inclinometer (in certain models);

- data concentrator with calibration tables;

- digital data processing circuit;

- data exchange device;

- galvanic barrier (for model EN);

- power stabilizer and scheme providing necessary protection of input

and output circuits.

Connection with external devices is provided through interface cable.

Capacitometer performs the conversion of current capacity of the probe

into digital code. Conversion is a linear function with variable parameters.

Inclinometer is present in the models of EXХXiх-XXXX version. Inclinometer

is executed on the basis of accelerometer with high resolution, and designed for

evaluation of acceleration and inclination angle of the vehicle, in order to estimate

reliability of the fuel level value and for possibility of its consequent compensation

depending on inclination angle.

Built-in data concentrator features in all listed models, however, using it

together with other sensors is possible only with EN6 model due to the presence

of two independent interfaces RS-232 and RS-485. Designation of master and

slave ports is set programmatically. Other models may only use embedded

calibration tables on the eigenvalues.

Digital data processing circuit performs control of capacitance meter (range,

zero offset, etc.) as well as temperature compensation, filtering and scaling the

obtained data. Data exchange device allows data exchange with the monitoring

device, saving / loading of calibration and configuration data of fuel level sensor,

remote upgrade of built-in software via serial interface.

Built-in galvanic isolation is an additional instrument fuel level sensor safety

system, and it is designed for isolation of measuring element’s and probe’s circuits

from the rest of electronics of the head.

This solution eliminates the possibility of passage interference currents on

circuits "case – signal ground”, increases interference immunity of measuring

element, enhances stability and reliability of the entire device.

For EZ model galvanic barrier is realized in spark protection module BIZ-EZ.

The measuring head is attached to the probe by means of a threaded

connection. Tightness of measuring head's attachment is provided by sealing ring

located in the end groove.

1.2.2 Probe

Page 19

Copy Size А4

Page

EN.000 RE

19

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

The probe is a coaxial capacitor formed by a pipe made of aluminum alloy

(outer electrode) and an insulated copper string or aluminum alloy pin (inner

electrode). Required string tension is supported by a spring that is located in

contact of the probe’s connector. Concentricity of a pin and an outer pipe is

provided by internal plastic inserts.

1.2.3 Spark protection module BIZ-EZ (for model "Epsilon EZ")

Intrinsic Safety Requirements for sensor of "EZ" model is provided by

connecting them via spark protection module, which is included in delivery

package.

Spark protection module is designed for power supply of the sensor with

type of explosion protection "intrinsically safe electrical circuit" of "ia" level, and

for exchange of information signals with a sensor via RS-485 interface. Spark

protection module has galvanic insulation both between inputs and outputs of

power supply, and between inputs and outputs of RS-485 interface.

Spark safety of electrical circuits of a unit, associated with equipment in

potentially explosive area, is provided by current and voltage limiting in electrical

circuits down to intrinsically safe values.

Spark protection module is designed for installation beyond the potentially

explosive areas. It relates to an apparatus of active type and is designed for the

protection of intrinsically safe circuits under the influence of a voltage up to

250 V.

Power supply of spark protection module is carried out from the source of

direct current with voltage of 9...36 V. Parameter values of intrinsically safe

circuits of spark protection module are given in Table 2.2.

1.2.4 Flange

Flange serves for hermetic fixing of the probe to the tank of vehicle. Fixation

of flange to the tank is realized by means of self-drilling screws. Tight seal

between tank and flange is provided by a rubber gasket.

1.2.5 Interface cable

Interface cable is designed for connecting measuring head to external

devices. Interface cable is protected against mechanical impacts with flexible

metal hose or corrugated pipe.

Page 20

Copy Size А4

Page

EN.000 RE

20

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

2 INTENDED USAGE

2.1 Operating restrictions

2.1.1 During operation of the sensor it is prohibited:

– to use the device inappropriately;

– to connect the sensors to devices, whose interface does not meet the

specifications indicated in this manual;

– to expose device to the impact of aggressive media;

– to supply power, exceeding the limit value of 36 V;

– to allow exposure to pulsed voltage on power circuits with values greater

than the values listed in the Table 1.1.

2.1.2 Using an item with fluids, preserving their aggregate state in the

operating temperature range, is allowed.

2.1.3 Dielectric permeability measured liquid should correspond to liquid

permeability, applied when calibrating. Failure to observe this results in an

increase in measuring errors.

2.2. Explosive safety

2.2.1 EN model sensors are explosion proof, have "1ExsiaIICT6 Х" explosion

proof mark and can be used in Class 1 and 2 explosion-hazardous areas – head,

and 0, 1, 2 – probe. Sign "Х" in explosion proofing labeling indicates specific

conditions of sensors’ safe application, lies in the following:

- sensors should be included in the electrical circuits of equipment, powered

only from the vehicle battery with a voltage not exceeding 36 V, and having

no electrical connections with electrical equipment which has other sources

of power;

- connection of sensors to the mains must be carried out via a fuse with a

nominal value of not more than 0.1 A.

EZ model sensors are explosion proof, have explosion proofing labeling "0

Ex ia IIВ T6" and can be used in Class 0, 1 and 2 explosion-hazardous areas.

Explosion proofing of EZ model sensor is provided by its connection via

spark protection module BIZ-EZ.

Page 21

Copy Size А4

Page

EN.000 RE

21

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

Table 2.1 Parameter values of intrinsically safe field circuits of model EZ sensor:

Name of feature or parameter

Meas.

unit

Value

Maximum input voltage, U0

V

8.0

Maximum input current, I

0

mA

100

Maximum internal capacitance, C

0

mfd

80

Maximum internal inductance, L

0

mH

0.2

2.2.2 Spark protection module "BIZ-EZ" has explosion proofing labelling

"ExiaIIВ" and can only be installed in explosion safe area.

Table 2.2 Parameter values of intrinsically safe field circuits of spark protection

module

Name of feature or parameter

Meas.

unit

Value

Maximum input voltage, U0

V

8.0

Maximum input current, I

0

mA

450

Maximum internal capacitance, C

0

mfd

80

Maximum internal inductance, L

0

mH

0.5

* - maximum values of L0, C0 spark protection module are established

considering 1.5-tuple safety factor

2.3 Preparation for use

Preparation of item for use is performed in accordance with "EN.000 ИМ

Installation manual".

Page 22

Copy Size А4

Page

EN.000 RE

22

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

2.4 Item application

2.4.1 Application of a sensor consists in obtaining electronic information on

the fuel level in tank from it by external device (such as onboard controller).

Sensor control is performed by external device via interface cable and does not

require any additional operator's intervention.

2.4.2 The list of possible malfunctions and their solutions

Table 2.1

Malfunction

Troubleshooting

Sensor transmits the data about the

maximum level of fuel in tank,

although the actual level of fuel is less

than the maximum value

Check the tank for the presence of

conductive liquid (water) and drain it

at presence

Sensor stopped transmitting data

about the level of fuel in the tank

Consult your authorized dealer or

manufacturer with request to replace

the measuring sensor head or the

complete set of sensor

2.4.3 Operation in extreme conditions

In case of fire, having occurred in the location of sensor, you must

disconnect onboard power supply and perform all standard procedures for

extinguishing fire in the vehicle.

Page 23

Copy Size А4

Page

EN.000 RE

23

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

3 MAINTENANCE

3.1 Item Maintenance

3.1.1 General guidelines

3.1.1.1 Sensor is a maintenance-free product, but if vehicle

maintenance regulation provides procedure of fuel tank prophylaxis, then

it is advisable to simultaneously perform preventive maintenance of sensor

as well.

Spark protection module is subject to examination at least once every

6 months (see 3.1.3.2).

3.1.1.2 Only personnel who are familiar with this operating manual and

the document "EN.000 ИМ. Installation manual" is admitted to sensor

maintenance.

3.1.2 Safety measures

3.1.2.1 During maintenance of fuel level sensor, organizational and technical

measures, providing safe operation of control and measuring equipment,

auxiliary equipment and consumables.

3.1.2.2 Responsibility for the implementation of security measures is

imposed on the technical staff carrying out the installation of fuel level sensor, as

well as on the personnel responsible for equipment of the work site.

3.1.2.3 Requirements of fire safety rules, acting on the territory of consumer,

must be observed on the work site.

3.1.2.4 Requirements of occupational safety regulations in accordance with

those, acting on customer’s site, must be observed on the vehicles on the work site

of sensor installation.

Page 24

Copy Size А4

Page

EN.000 RE

24

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

3.1.3 Order of item maintenance

3.1.3.1 Sensor maintenance

Complete dismantling of sensor must be performed in the following

consequence (fig. 3.1):

- to disconnect interface and connecting cable;

- to unscrew and remove measuring head, after that to unscrew sensor probe

from the flange;

- to close an aperture of flange with socket plug IEC EN C. 100 (see Table 1.3),

as shown in fig. 3.1;

Fig. 3.1 Complete dismantling of fuel level sensor and installing socket plug

- to wash entire part of probe with fuel (with which the sensor is

opertated) and to blow with compressed air;

- to control own parameters of the measuring head (using "eS Install"

software, according to procedure, described in appendix А of the

document "EN.000 ИМ. Installation manual ");

- to perform installation and sealing of the sensor according to

requirements 1.1.5.2.

3.1.3.2 Maintenance of Spark Protection Module

Maintenance of spark protection module consists in its examination and

elimination of violations during the operation.

During examination it is necessary to perform the following operations:

- to inspect the case and to identify mechanical damage;

- to clean the case of spark protection module from dust and dirt;

- to check labeling;

- to check the attachment of module;

Page 25

Copy Size А4

Page

EN.000 RE

25

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

- to check the quality electrical connection to the ground bus or to a vehicle

body;

- to check the quality of connection of external circuits;

- to check the integrity of protective seals.

In case of detecting damages it is necessary to eliminate them, and if it is

impossible to correct problems, to carry out the replacement of damaged parts.

It is forbidden to operate spark protection module with damages and

malfunctions, as well as its repair.

In case if it becomes necessary to disassemble spark protection module,

disassembling should be performed in the following consequence:

- to disconnect the power connector (from BIZ interface cable);

- to disconnect intrinsically safe circuit connector (from EZ interface cable);

- to disconnect the ground wire of spark protection module casing from

grounding bus terminal or vehicle body;

- to remove spark protection module from place of installation.

Page 26

Copy Size А4

Page

EN.000 RE

26

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

4 TEMPORARY REPAIR

4.1 Item temporary repair

4.1.1 General guidelines

4.1.1.1 Temporary item repair can be carried out only regarding

replacement of the measuring head. Sensor’s measuring head itself is nonrepairable item, and during guaranteed service life it retains stability of its

parameters.

4.1.1.1 Only personnel who are familiar with this operation manual and

with document "EN.000 ИМ. Installation instruction" is admitted to performance

of works.

4.1.1.3 Safety precautions during measuring head replacement are

similar to those during sensor maintenance (see 3.1.2)

4.2 Temporary repair of item components

4.2.1 Repair (replacement) of measuring head

4.2.1.1 In case of measuring head failure, and if vehicle operation before

installing another measuring head, it is necessary to make partial disassembling

of sensor.

4.2.1.1.1 Partial disassembling of sensor should be performed in the

following consequence (fig. 4.1):

- to disconnect the interface and connecting cables.

- to unscrew and remove the measuring head of sensor.

- if necessary, partially to screw on sleeve bearing of sensor probe into the

flange, as shown on fig. 4.1.

- to close sleeve bearing of sensor probe with cover-plug IEC EN. 002.0

(see table 1.3);

Page 27

Copy Size А4

Page

EN.000 RE

27

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

Fig. 4.1 Partial disassembling of fuel level sensor и and installation of cover-

plug

- to upload new configuration data in new measuring head (see appendix В

of the document "EN.000 ИМ. Installation manual");

- to install and connect new measuring head, to perform sensor sealing

according to requirements of 1.1.5.2.

4.2.1.2 In case if configuration data was lost, it is necessary to perform

operations on sensor configuration, described in appendix В of the document

"EN.000 ИМ. Installation manual". If configuration data was successfully restored,

then re-calibration of the tank is not required.

4.2.2 Probe string replacement

If it is necessary to replace the string, the following operations should be

performed:

- To disconnect measuring head from the probe, having performed

operations, described in the relevant section of the document "EN.000 ИМ.

Installation manual " in reverse order;

- To disconnect the string in lower part of the probe, having removed plug-

cap, and in the upper part of probe, as shown on fig. 4.3;

Page 28

Copy Size А4

Page

EN.000 RE

28

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

Fig. 4.3 Disassembling of string

- Install the string, having performed the operations, described in subsection

8.3 of the document "EN.000 ИМ. Installation manual" in reverse order.

Page 29

Copy Size А4

Page

EN.000 RE

29

Chg.

Page

Doc. #

Sign.

Date

Sign. and date

Rep. t

ag #

Inst. of t

ag #

Sign. and date

а

Script t

ag #

5 TRANSPORTATION AND STORAGE

Transportation of sensor in transport packaging of enterprisemanufacturer is allowed by all types of closed land and maritime transport (in

railway waggons, containers, covered trucks, holds, etc.).

Transportation in pressurized heated compartments of aircraft is allowed.

During transportation and storage, requirements of manipulation signs,

printed on group transport packaging, should be respected.

Loading...

Loading...