Page 1

The ETL Symbol is a UK registered certification mark of the

Department of Energy and Climate Change

Authorised User: 03195

Installation & User Guide

Eden Power Tray

Installation Guide | Issue 2.0 | The Eden Power Tray Page 1

Page 2

Contents

The Eden Power Tray

Contents

1. INTRODUCTION 4

1.1 The Eden Power Tray Range 4

1.1.1 Variants / Part Codes for Ordering 5

1.1.2 Replacing Legacy Equipment 6

1.1.3 Eden Power Tray – Mating Connectors 6

2. CONNECTION DETAILS 7

2.1 EP3115 & 3116 10A Assisted Defrost / Major Tray Connectivity 7

2.2 EP3115 & 3116 10A Assisted Defrost / Major Tray Circuit Diagram 8

2.3 EP3113 & 3114 30A Assisted Defrost / KTUC09Tray Connectivity 9

2.4 EP3113 & 3114 30A Assisted Defrost / KTUC09Tray Circuit Diagram 10

2.5 EP3119 & 31110 Hot Gas Defrost / KTUC09 HG Tray Connectivity 11

2.6 EP3119 / 31110 Hot Gas Defrost / KTUC09 HG Tray Circuit Diagram 12

2.7 EP3117 & EP3118 External Defrost Contactor / KTUC09 Tray Connectivity 13

2.8 EP3117 & EP3118 External Defrost Contactor / KTUC09 Tray Circuit Diagram 14

2.9 EP3111 Minor Assisted Defrost Tray Connectivity 15

2.10 EP3111 Minor Assisted Defrost Tray Circuit Diagram 16

2.11 EP3110 & 3112 Off-Cycle Defrost Tray Connectivity 17

2.12 EP3110 & 3112 Off-Cycle Defrost Tray Circuit Diagram 18

2.13 All Variants – Sensor / Communication Network Connections 19

2.14 All Variants – Tray End View 20

3. SETTING THE CONTROLLER UP 21

3.1 Front panel display keys & icons 21

3.2 Using the front panel display & function keys 23

3.2.1 Set up menu 24

3.2.2 Controllers address & communications menu 26

3.2.3 Controllers refrigeration related parameter menu 28

3.2.4 Controllers defrost menu 30

3.2.5 Controllers fan related parameter menu 32

3.2.6 Controllers times related parameter menu 34

3.2.7 Controllers current status menu 36

3.2.8 Controllers current alarms menu 38

3.2.9 Controllers lights related parameter menu 40

3.2.10 Controllers sleep mode menu 41

3.2.11 Controllers self test menu 42

4. CLEANING INSTRUCTIONS 43

5. SPECIFICATION 44

5.1 Power requirements 44

5.2 Dimensions 44

5.3 Inputs 44

5.4 Communications 44

Installation Guide | Issue 2.0 | The Eden Power Tray Page 2

Page 3

Contents

The Eden Power Tray

6. REVISION HISTORY 45

7. DISCLAIMER 46

8. CONTACT DETAILS 47

9. APPENDICES 48

9.1 Cycle Time function (Times menu (Ti13) ` 48

9.2 Defrost Cycle (Fans Off) 49

9.3 Defrost Cycle (Fans On) 50

9.4 Integral Compressor Action 51

9.5 Remote Display 52

9.5.1 Panel Cut-out 52

9.5.2 Remote Display 53

9.5.3 Retaining Clips 53

9.5.4 Remote Display Module 53

10. EUROPEAN DECLARATION OF CONFORMITY 54

Installation Guide | Issue 2.0 | The Eden Power Tray Page 3

Page 4

Introduction

The Eden Power Tray

1. Introduction

The Eden Power Tray series of products are a range of complete refrigerated cabinet control solutions.

The extensive range provides prewired control panels suitable for both new installations and

replacement of legacy products. All of which utilise the intuitive RCS Eden Compact controller.

Each of the variants in the range delivers a powerful combination of connectivity, flexibility and ease of use in a

gear tray capable of safely supplying all required cabinet loads.

The Eden Power Tray range offers quality, high performance case control which will encompass and satisfy the

most stringent of refrigerated cabinet applications.

1.1 The Eden power Tray Range

All high current outputs are protected by re-settable MCB’s. Connector configurations where possible remain

identical to previous RCS cabinet control panels to safeguard easy replacement of legacy units. The assisted

defrost variants also provide an external connection for defrost heater klixons to provide further safety features.

The Eden Compact controller incorporated into each of the power tray variants was designed as the first all-inone compact refrigeration controller requiring no additional communication modules. The Eden Compact provides

easy configuration and the ability to set custom parameter sets.

The Eden Compact series covers the full range of evaporator inlet valve type and network connectivity options.

The user must choose at the point of ordering which of the following two basic options are required:-

Network compatibility

IP

RS485

Inlet Valve Type

LSV

EEV

Each model is easy to install and configure, thanks to features such as the standard two-part connectors for all

external wiring of Inputs/Outputs. All Eden Compact controllers provide the option of up to seven temperature /

analogue inputs for maximum flexibility, and multiple sensor types are also supported. (NB sensor types cannot

be mixed on a single controller).

Installation Guide | Issue 2.0 | The Eden Power Tray Page 4

Page 5

Part Codes

The Eden Power Tray

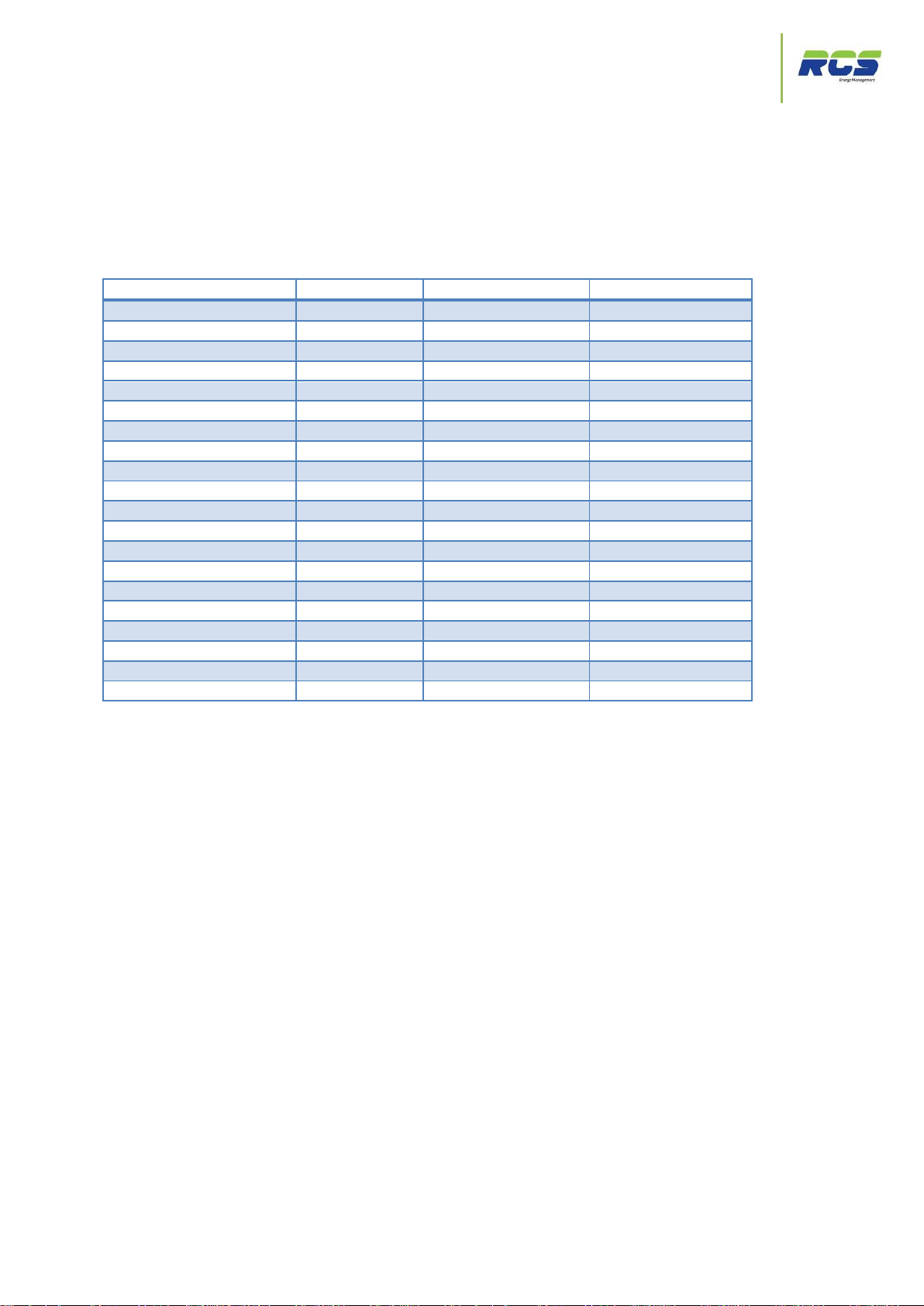

Variant

Inlet Valve Type

Communication Type

Part No

Off-Cycle defrost

LSV

RS485

EP3110

Off-Cycle defrost

EEV

RS485

EP3112

Off-Cycle defrost

LSV

IP

EP3120

Off-Cycle defrost

EEV

IP

EP3122

10A Assisted defrost

LSV

RS485

EP3115

10A Assisted defrost

EEV

RS485

EP3116

10A Assisted defrost

LSV

IP

EP3125

10A Assisted defrost

EEV

IP

EP3126

30A Assisted defrost

LSV

RS485

EP3113

30A Assisted defrost

EEV

RS485

EP3114

30A Assisted defrost

LSV

IP

EP3123

30A Assisted defrost

EEV

IP

EP3124

External Defrost contactor

LSV

RS485

EP3117

External Defrost contactor

EEV

RS485

EP3118

External Defrost contactor

LSV

IP

EP3127

External Defrost contactor

EEV

IP

EP3128

Hot Gas defrost

LSV

RS485

EP3119

Hot Gas defrost

EEV

RS485

EP31110

Hot Gas defrost

LSV

IP

EP3129

Hot Gas defrost

EEV

IP

EP31210

1.1.1 Variants / Part Codes for Ordering

This installation and set-up guide covers the complete Eden Power Tray range. The following part codes should

be used at the ordering stage:-

Remote display variants of each of the above are also available.

Please refer to each of the connection details and circuit drawings within this document to establish maximum

ratings for outputs for each variant.

Please note that warranty is void if any Eden power tray is used in any application that does not conform to the

tray specification.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 5

Page 6

Legacy Part Codes

The Eden Power Tray

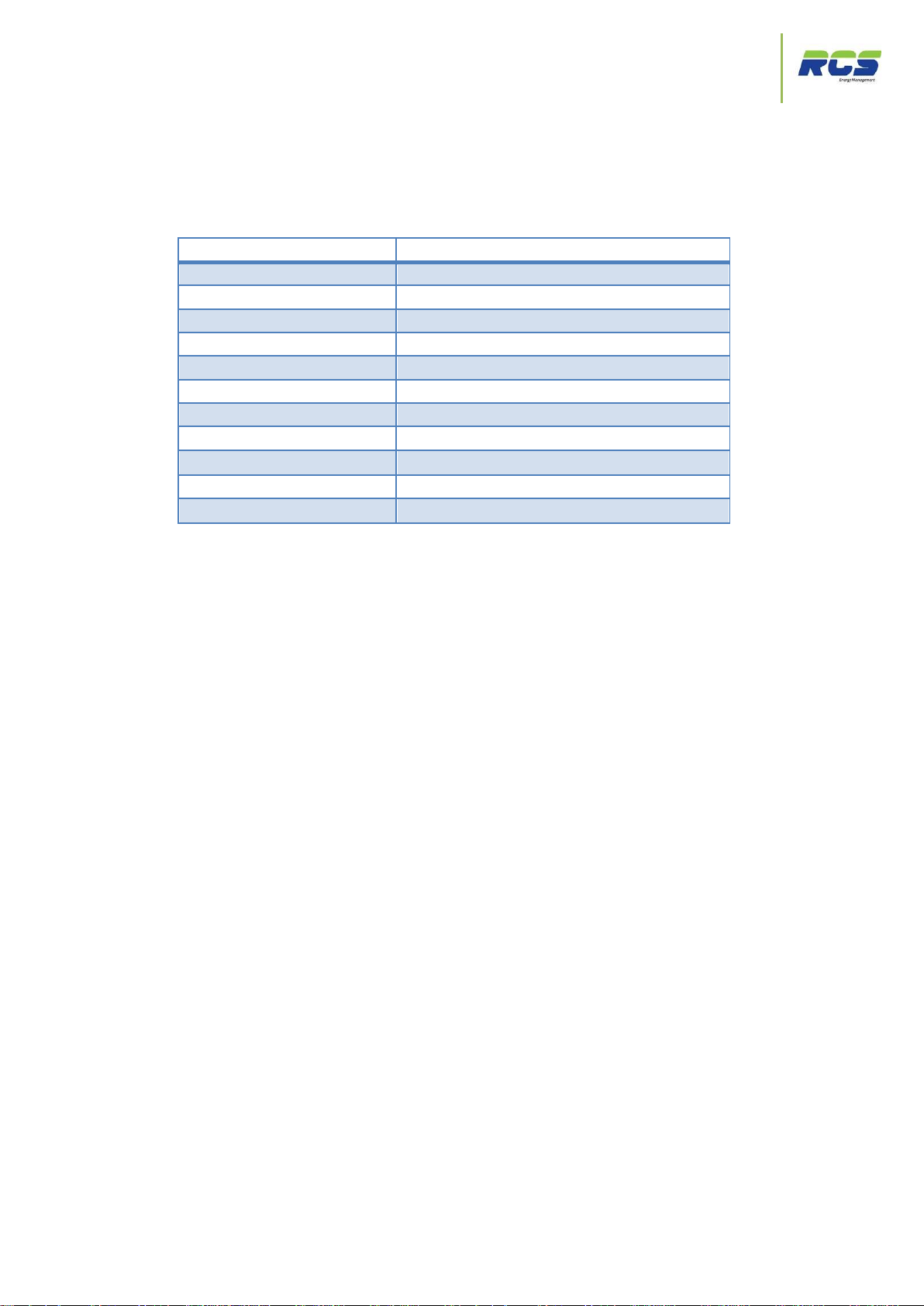

Part Number

Replacement For

EP3115 (LSV)

Major Assisted Defrost

EP3116 (EEV)

Major Assisted Defrost

EP3113 (LSV)

KTUC09 Assisted Defrost (Electric)

EP3114 (EEV)

KTUC09 Assisted Defrost (Electric)

EP3119 (LSV)

KTUC09 Hot Gas Defrost

EP31110 (EEV)

KTUC09 Hot Gas Defrost

EP3117 (LSV)

KTUC09 Tray (External Contactor)

EP3118 (EEV)

KTUC09 Tray (External Contactor)

EP3111 (LSV Only)

Minor Assisted Defrost

EP3110 (LSV)

Off-Cycle Defrost - ALL VARIANTS

EP3112 (EEV)

Off-Cycle Defrost – ALL VARIANTS

1.1.2 Replacing Legacy Equipment

The following part codes should be used at the ordering stage when replacing previous Powertray models:

1.1.3 Power Tray Mating Connectors

Eden Power Tray Mating Connectors:-

Incoming Mains Supply Connector, mates with: Weidmuller STVS3 161699 RCS Part Code KS3STVS00

Cable Clamp / Strain Relief for above connector: Weidmuller STVS3ZE 161387. RCS Part Code K00STV3ZE

STV1 / 2, mates with: Weidmuller STVS3 174367. RCS Part Code KP10STVS00

Cable Clamp / Strain Relief for above connector: weidmuller STVS10ZE 161394. RCS Part Code K010STV10ZE

Sensor / 485 Connector, mates with: Weidmuller BL12 126026 RCS Part Code KS12BL00

Klixon (Loop Back) RCS Part Code 300-00238

Installation Guide | Issue 2.0 | The Eden Power Tray Page 6

Page 7

Connection Details – 10A Assisted Defrost

The Eden Power Tray

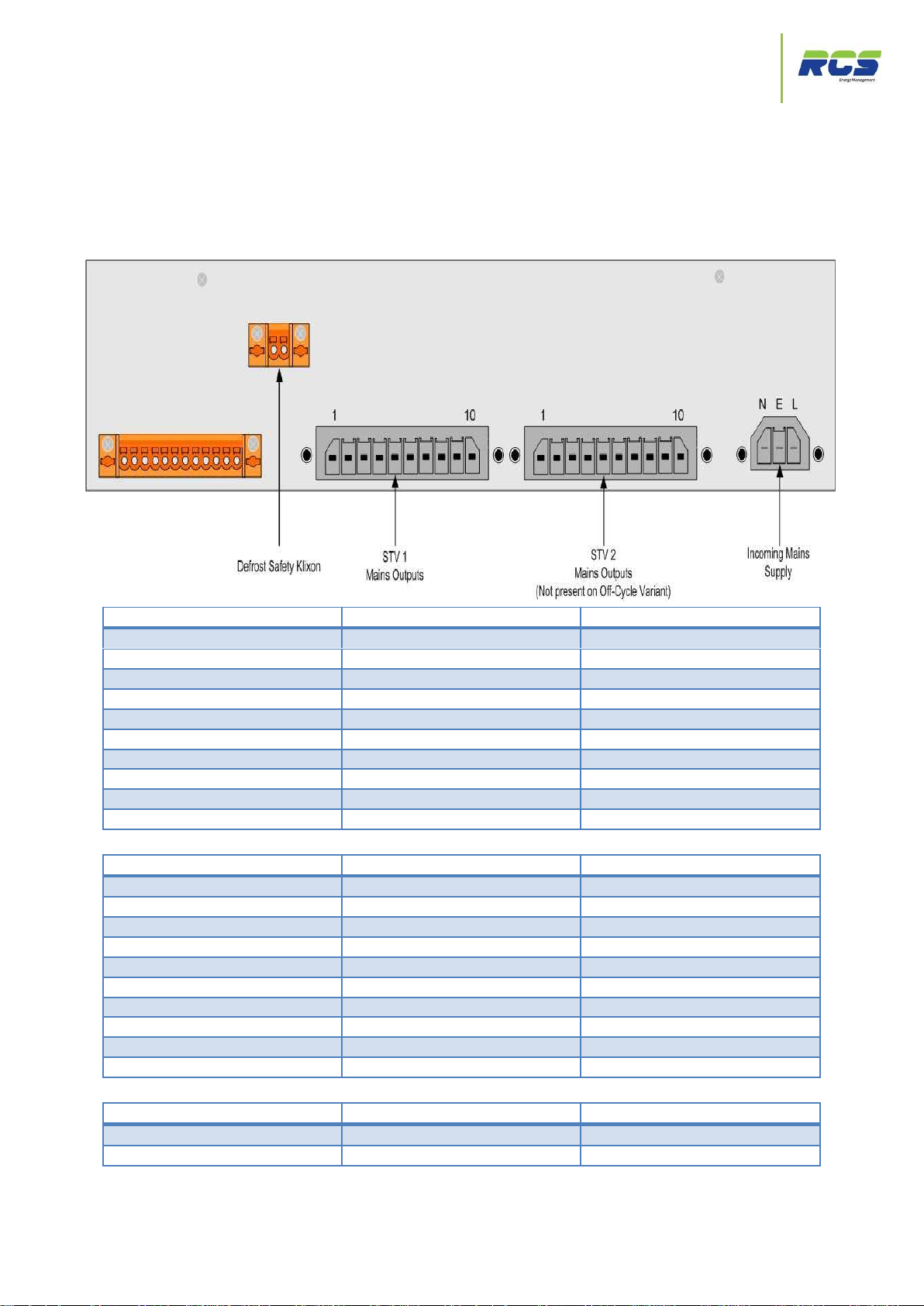

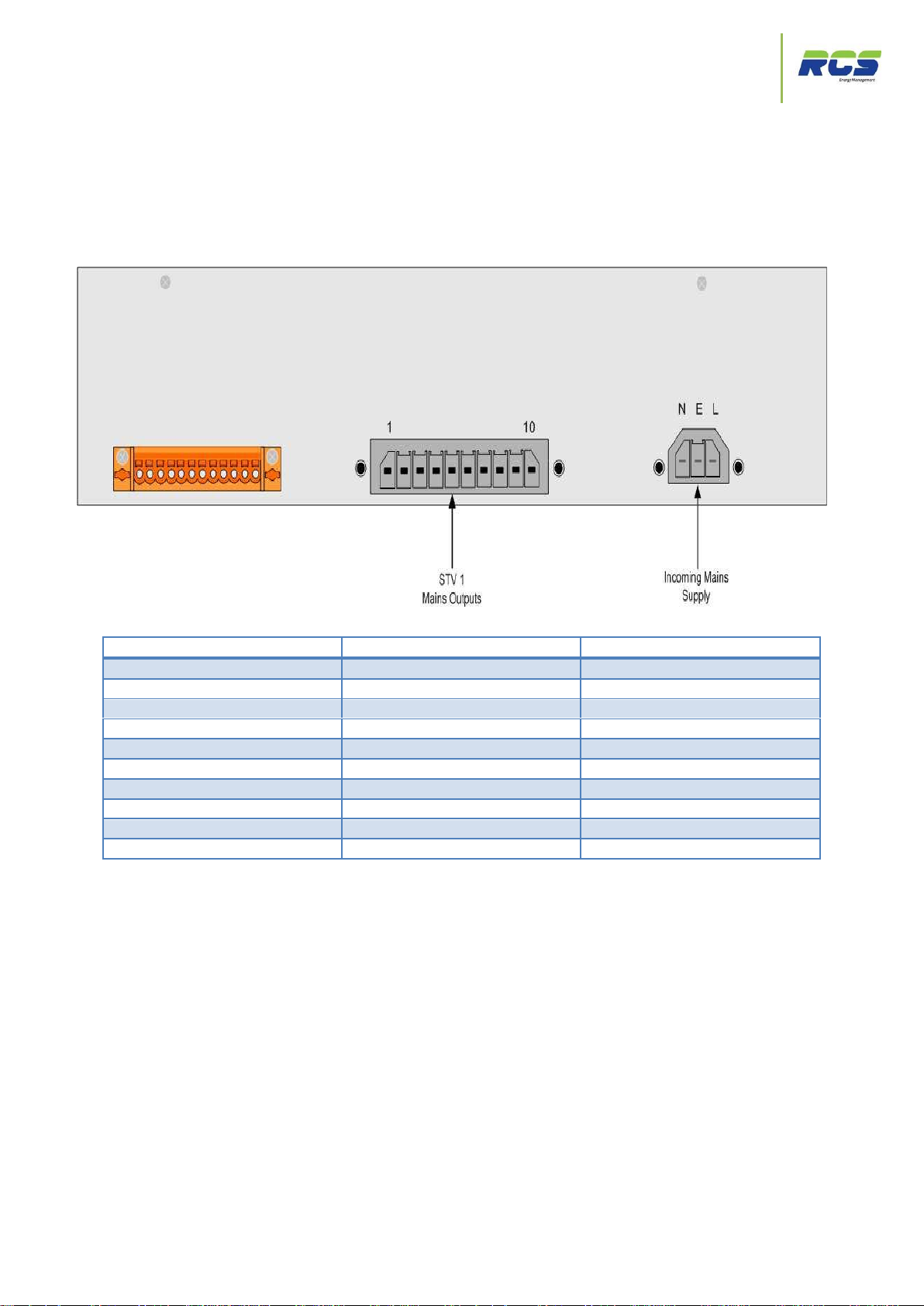

2. Connection Details

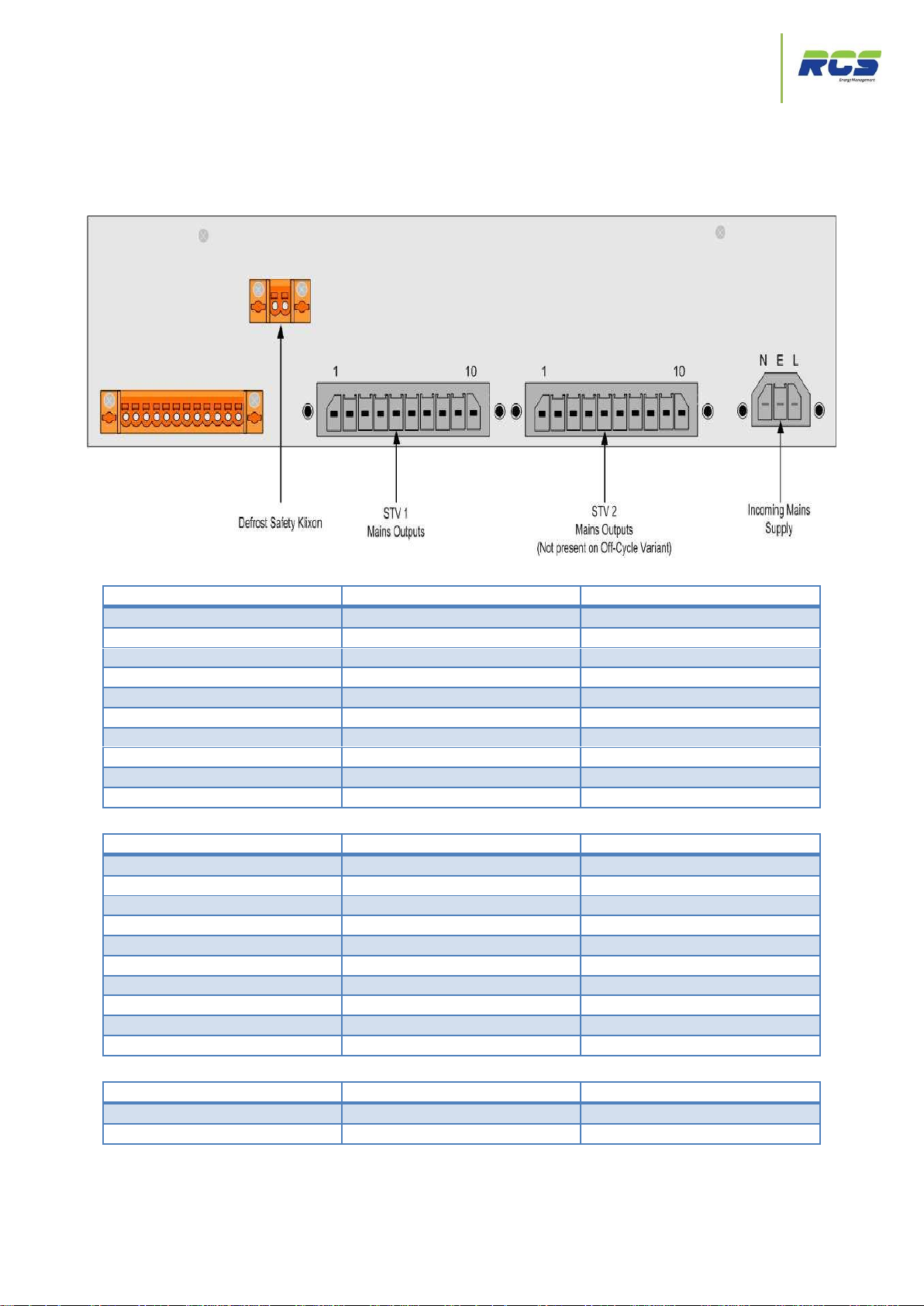

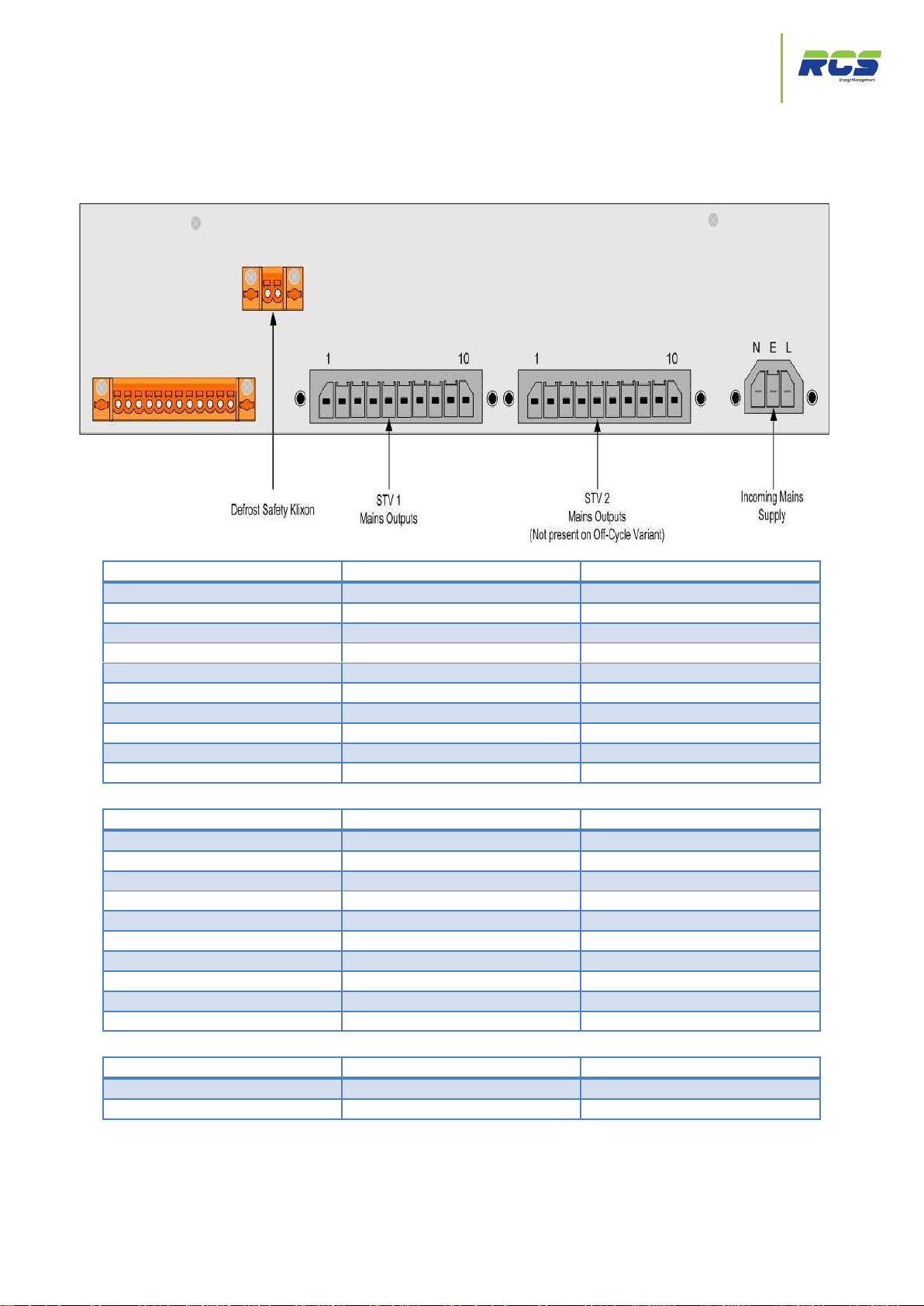

Pin Number

Function

Rating/Designation

1

Earth

2 Defrost Live

10A Internal MCB (CB 2)

3

Defrost Neutral

4

LSV/EEV Live

2A Internal MCB (CB 8)

5

LSV/EEV Neutral

6

Fans Live

4A Internal MCB (CB 9)

7

Fans Neutral

8

Lights Live

6A Internal MCB (CB 5)

9

Lights Neutral

10

Earth

Pin Number

Function

Rating/Designation

1

Earth

2 Suction Live

2A Internal MCB (CB7)

3

Suction Neutral

4 Not Used

5 Not Used

6 Not Used

7

Not Used

8

Trim Heater Live

10A Internal MCB (CB 6)

9

Trim Heater Neutral

10

Earth

Pin Number

Function

Rating Designation

1 Unit Supplied with loop fitted

2

2.1 EP3115, EP3125 (LSV) & EP3116, EP3126 (EEV)

(10A Assisted Defrost & Major Legacy replacement) - Connectivity Details

STV1

STV2

Defrost Safety Klixon

Eden controller power is supplied via an internal 2A MCB (CB 1)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 7

Page 8

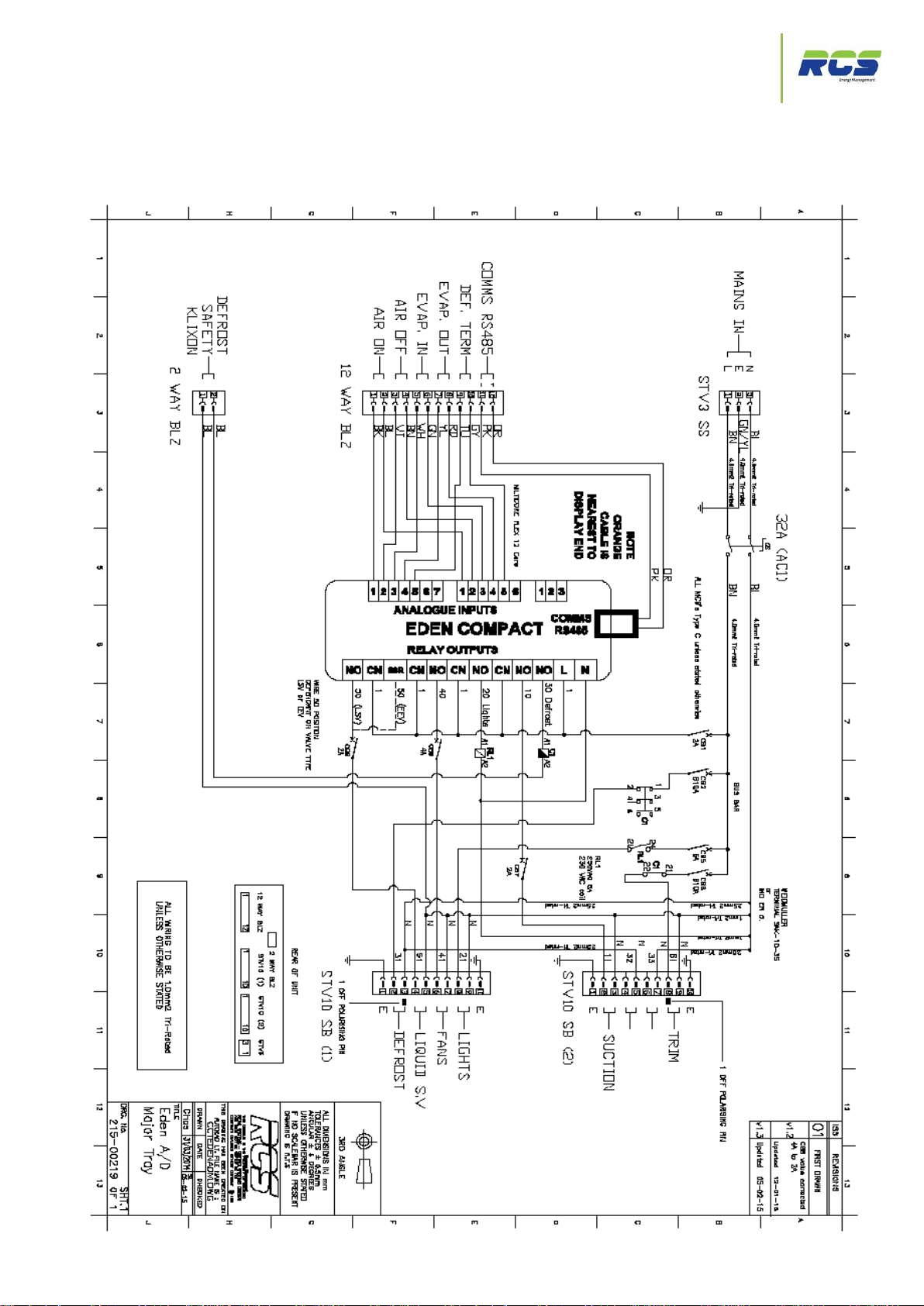

10A Assisted Defrost Circuit Diagram

The Eden Power Tray

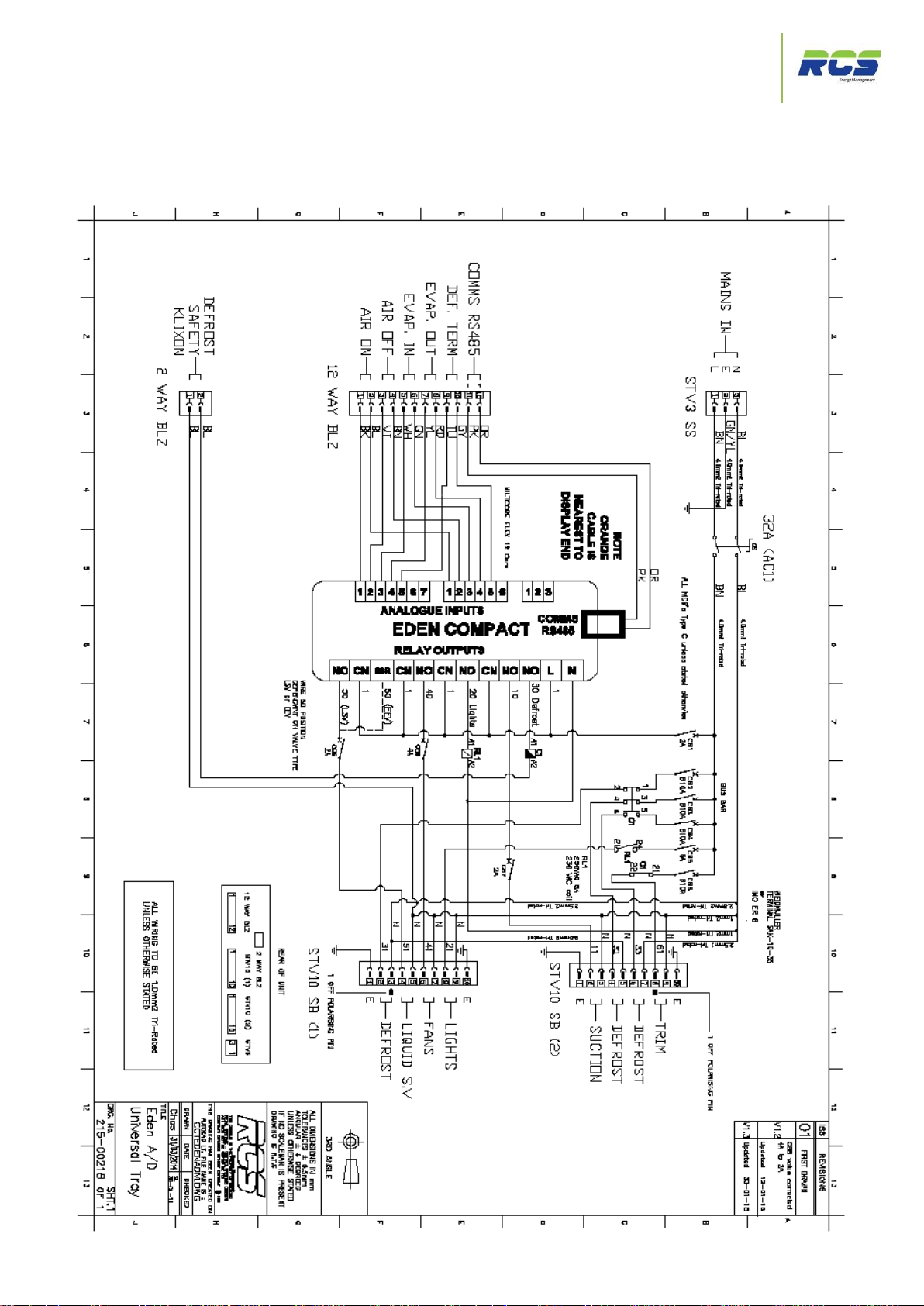

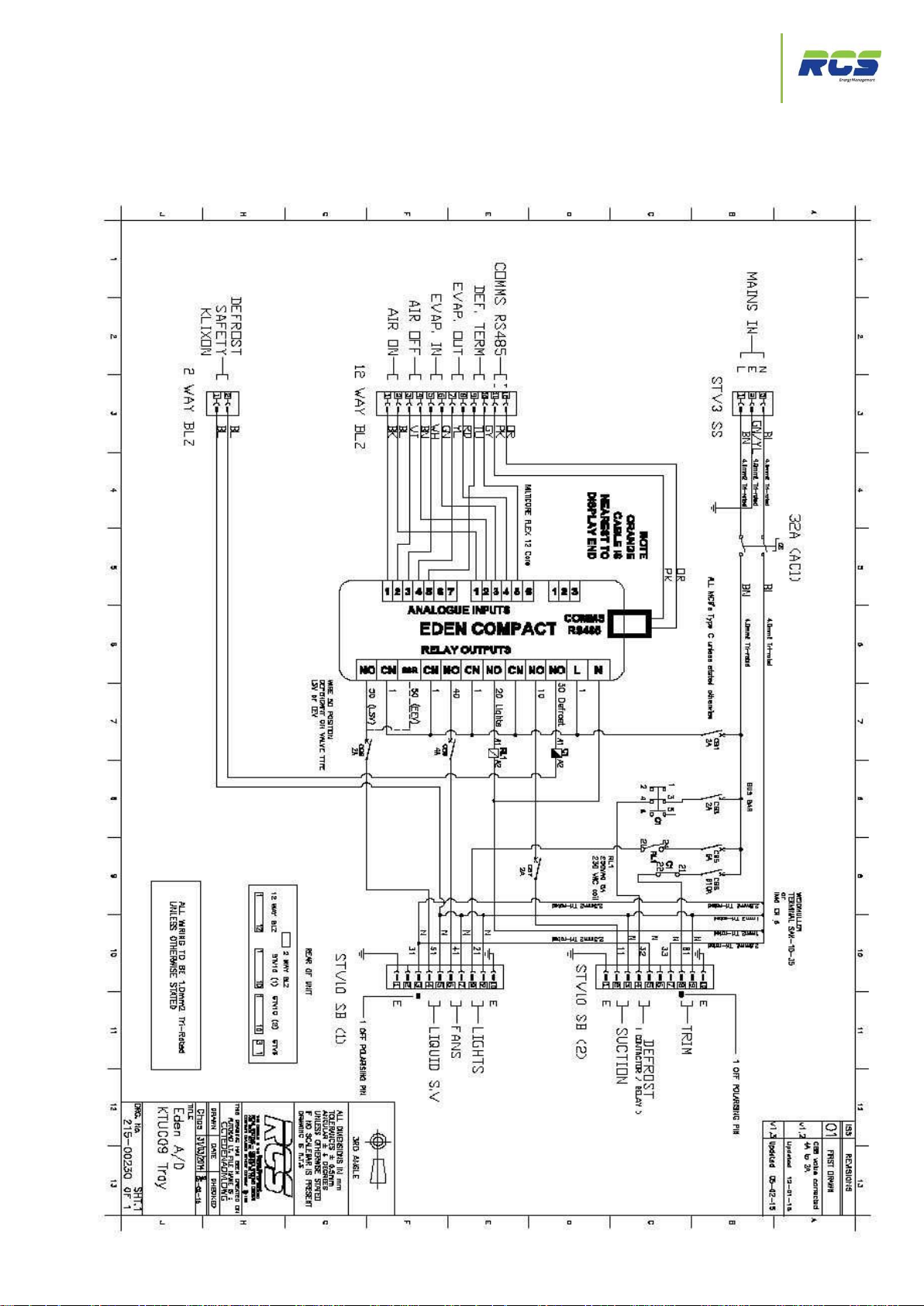

2.2 EP3115, EP3125 (LSV) & EP3116, EP3126 (EEV)

(10A Assisted Defrost & Major Legacy replacement) -Circuit Diagram

Installation Guide | Issue 2.0 | The Eden Power Tray Page 8

Page 9

Connection Details - 30A Assisted Defrost

The Eden Power Tray

2.3 EP3113, EP3123 (LSV) & EP3114, EP3124 (EEV)

Pin Number

Function

Rating/Designation

1

Earth

2

Defrost Live

10A Internal MCB (CB 2)

3

Defrost Neutral

4

LSV/EEV Live

2A Internal MCB (CB 8)

5

LSV/EEV Neutral

6

Fans Live

4A Internal MCB (CB 9)

7

Fans Neutral

8

Lights Live

6A Internal MCB (CB 5)

9

Lights Neutral

10

Earth

Pin Number

Function

Rating/Designation

1

Earth

2 Suction Live

2A Internal MCB (CB 7)

3

Suction Neutral

4 Defrost Live

10A Internal MCB (CB 3)

5

Defrost Neutral

6 Defrost Live

10A Internal MCB (CB 4)

7

Defrost Neutral

8

Trim Heater Live

10A Internal MCB (CB 6)

9

Trim Heater Neutral

10

Earth

Pin Number

Function

Rating Designation

1 Unit Supplied with loop fitted

2

(30A Assisted Defrost & KTUC09 Electric Defrost Legacy replacement) Connectivity Details

STV1

STV2

Defrost Safety Klixon

Eden controller power is supplied via an internal 2A MCB (CB 1)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 9

Page 10

30A Assisted Defrost Circuit Diagram

The Eden Power Tray

2.4 EP3113, EP3123 (LSV) & EP3114, EP3124 (EEV)

(30A Assisted Defrost & KTUC09 Electric Defrost Legacy replacement) –

Circuit Diagram

Installation Guide | Issue 2.0 | The Eden Power Tray Page 10

Page 11

Connection Details - Hot Gas Defrost

The Eden Power Tray

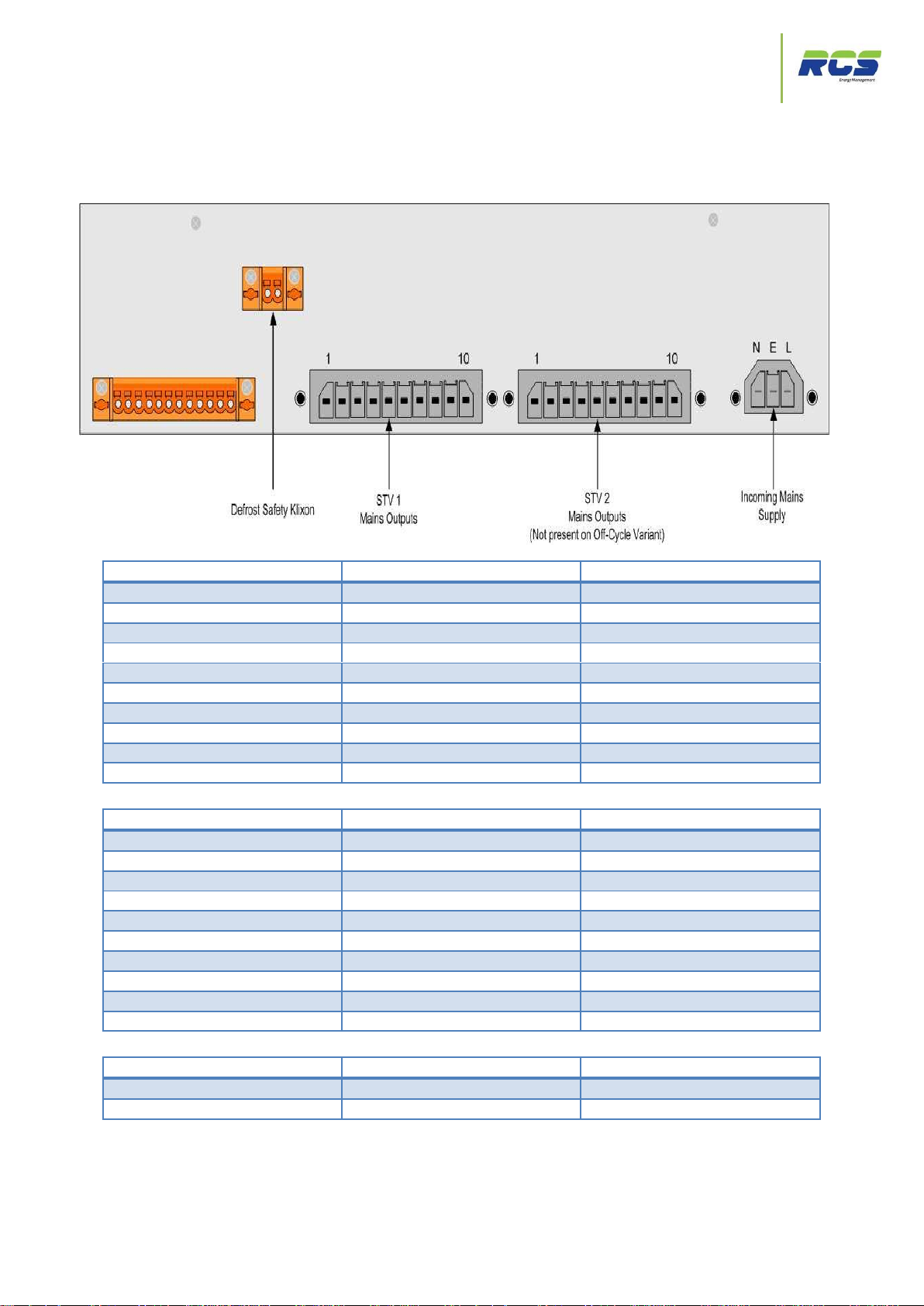

2.5 EP3119, EP3129 (LSV) & EP31110, EP31210 (EEV)

Pin Number

Function

Rating/Designation

1

Earth

2

Not Used

3

Not Used

4

LSV/EEV Live

2A Internal MCB (CB 8)

5

LSV/EEV Neutral

6

Fans Live

4A Internal MCB (CB 9)

7

Fans Neutral

8

Lights Live

6A Internal MCB (CB 5)

9

Lights Neutral

10

Earth

Pin Number

Function

Rating/Designation

1

Earth

2 Suction Live

2A Internal MCB (CB 7)

3

Suction Neutral

4 Hot Gas S/V Live

2A Internal MCB (CB 3)

5

Hot Gas S/V Neutral

6

Not Used

7

Not Used

8

Trim Heater Live

10A Internal MCB (CB 6)

9

Trim Heater Neutral

10

Earth

Pin Number

Function

Rating Designation

1 Unit Supplied with loop fitted

2

(Hot Gas Defrost & KTUC09 Hot Gas Defrost Legacy replacement) Connectivity Details

STV1

STV2

Defrost Safety Klixon

Eden controller power is supplied via an internal 2A MCB (CB 1)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 11

Page 12

Hot Gas Defrost Circuit Diagram

The Eden Power Tray

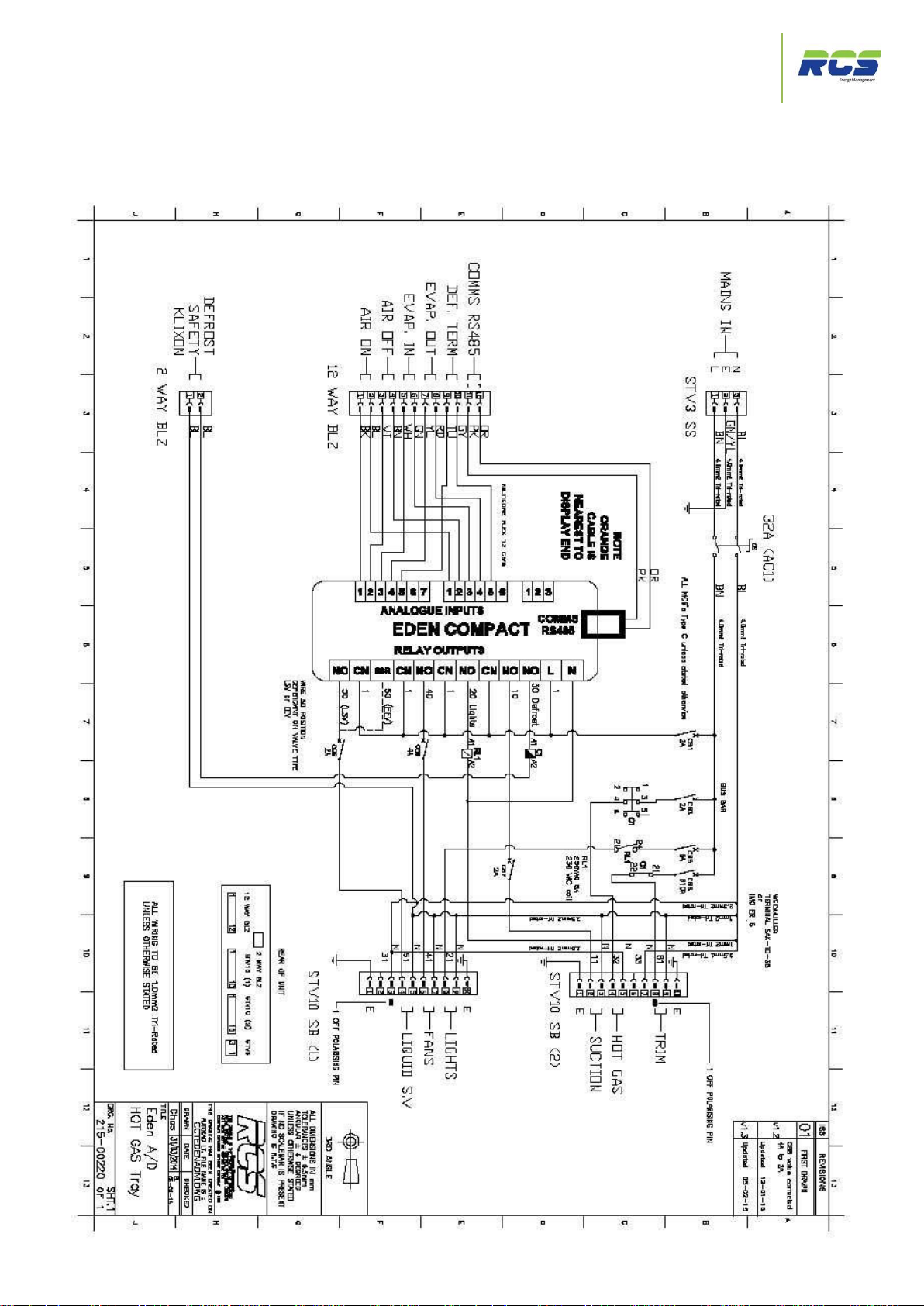

2.6 EP3119, EP3129 (LSV) & EP31110, EP31210 (EEV)

(Hot Gas Defrost & KTUC09 Hot Gas Defrost Legacy replacement) - Circuit

Diagram

Installation Guide | Issue 2.0 | The Eden Power Tray Page 12

Page 13

Connection Details - External Defrost Contactor

The Eden Power Tray

2.7 EP3117, EP3127 (LSV) & EP3118, EP3128 (EEV)

Pin Number

Function

Rating/Designation

1

Earth

2

Not Used

3

Not Used

4

LSV/EEV Live

2A Internal MCB (CB 8)

5

LSV/EEV Neutral

6

Fans Live

4A Internal MCB (CB 9)

7

Fans Neutral

8

Lights Live

6A Internal MCB (CB 5)

9

Lights Neutral

10

Earth

Pin Number

Function

Rating/Designation

1

Earth

2 Suction Live

2A Internal MCB (CB 7)

3

Suction Neutral

4 External Defrost Contactor Live

2A Internal MCB (CB 3)

5

External Defrost Contactor Neutral

6

Not Used

7

Not Used

8

Trim Heater Live

10A Internal MCB (CB 6)

9

Trim Heater Neutral

10

Earth

Pin Number

Function

Rating Designation

1 Unit Supplied with loop fitted

2

(External Defrost Contactor & KTUC09 “Tray” Legacy replacement) Connectivity Details

STV1

STV2

Defrost Safety Klixon

Eden controller power is supplied via an internal 2A MCB (CB 1)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 13

Page 14

External Defrost Contactor Circuit Diagram

The Eden Power Tray

2.8 EP3117, EP3127 (LSV) & EP3118, EP3128 (EEV)

(External Defrost Contactor & KTUC09 “Tray” Legacy replacement) – Circuit

Diagram

Installation Guide | Issue 2.0 | The Eden Power Tray Page 14

Page 15

Connection Details - Minor Assisted Defrost

The Eden Power Tray

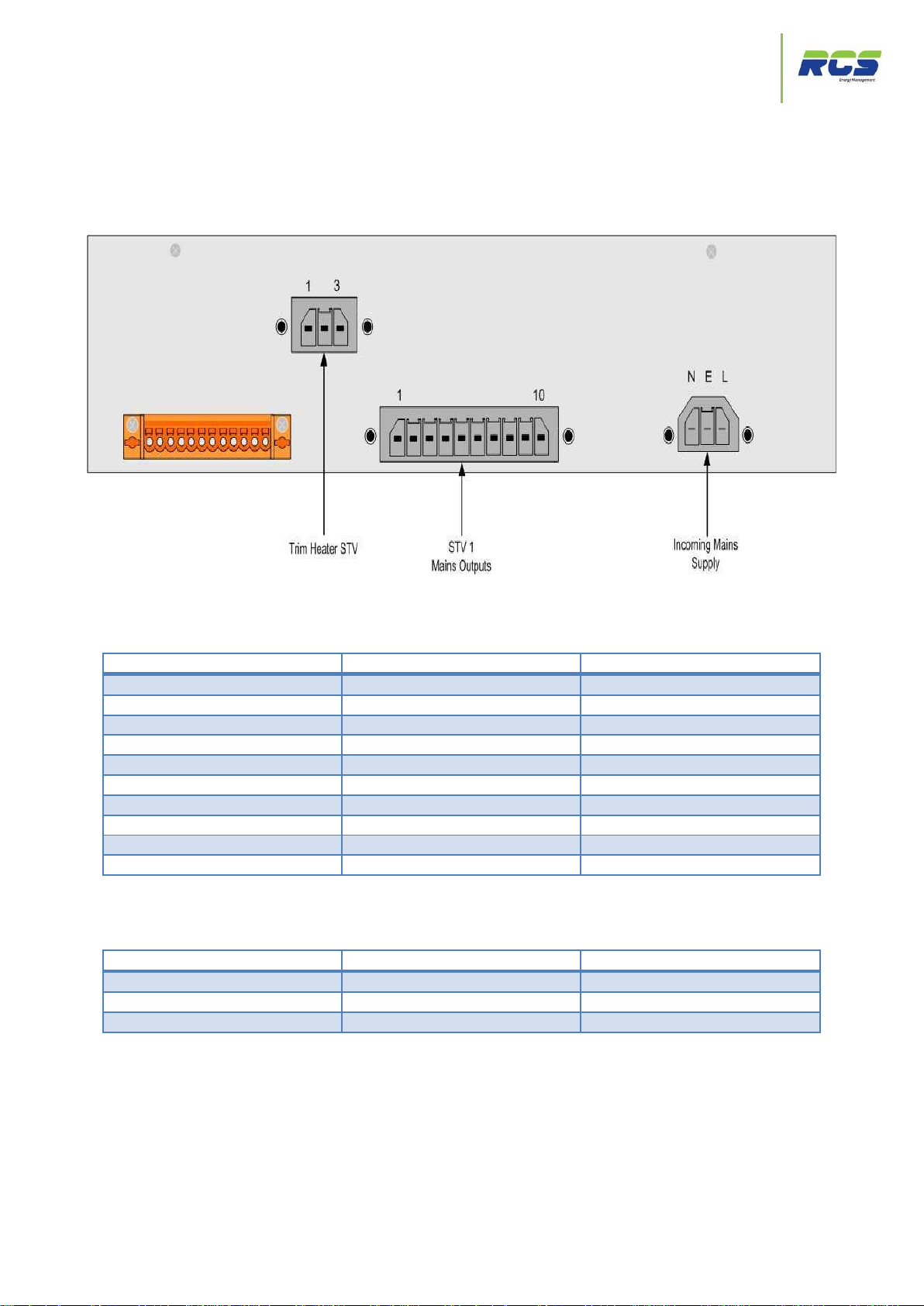

2.9 EP3111 (Minor Assisted Defrost Legacy replacement) –

Pin Number

Function

Rating/Designation

1

Earth

2

Defrost Live

16A Internal MCB (CB4)

3

Defrost Neutral

4 LSV/EEV Live

2A Internal MCB (CB 6)

5

LSV/EEV Neutral

6 Fans Live

2A Internal MCB (CB 5)

7

Fans Neutral

8 Lights Live

6A Internal MCB (CB 3)

9

Lights Neutral

10

Earth

Pin Number

Function

Rating/Designation

1

Trim heater Live

6A Internal MCB (CB 2)

2

Trim Heater Earth

3

Trim Heater Neutral

Connectivity Details

STV1

Trim Heater STV

Eden controller power is supplied via an internal 2A MCB (CB 1)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 15

Page 16

Minor Assisted Defrost Circuit Diagram

The Eden Power Tray

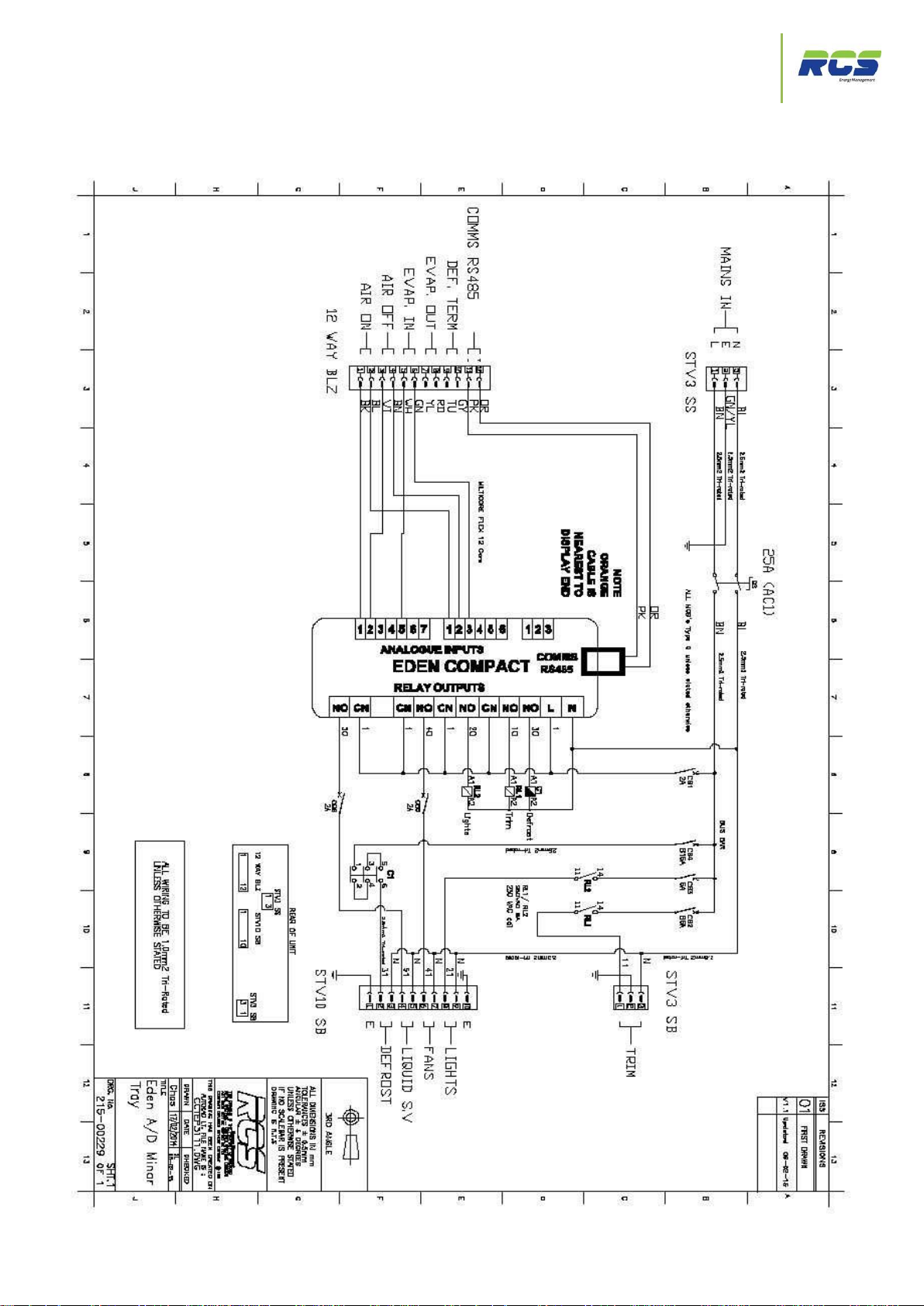

2.10 EP3111 (Minor Assisted Defrost Legacy replacement) – Circuit Diagram

Installation Guide | Issue 2.0 | The Eden Power Tray Page 16

Page 17

Connection Details – Off-Cycle Defrost

The Eden Power Tray

Pin Number

Function

Rating/Designation

1

Earth

2 Curtain Fan Live

4A Internal MCB (CB 3)

3

Curtain Fan Neutral

4 LSV/EEV Live

2A Internal MCB (CB 5)

5

LSV/EEV Neutral

6 Fans Live

4A Internal MCB (CB 4)

7

Fans Neutral

8 Lights Live

6A Internal MCB (CB 2)

9

Lights Neutral

10

Earth

2.11 EP3110, EP3120 (LSV) & EP3112, EP3122 (EEV) (Off-Cycle Defrost)

– Connectivity Details

STV1

Eden controller power is supplied via an internal 2A MCB (CB 1)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 17

Page 18

Off-Cycle Defrost Circuit Diagram

The Eden Power Tray

2.12 EP311, EP3120 (LSV) & EP3112, EP3122 (EEV) (Off-Cycle Defrost)

– Circuit Diagram

Installation Guide | Issue 2.0 | The Eden Power Tray Page 18

Page 19

Connection Details – Sensors & Comms.

The Eden Power Tray

Pin Number

Function

Rating/Designation

1

Air On – Signal

2

Air On – Ground

3

Air Off Sensor – Signal

4

Air Off Sensor – Ground

5

Evaporator In Sensor – Signal

Optional (Set-up option – see section

3.2.1) SU11

6

Evaporator in Sensor – Ground

7

Evaporator Out Sensor – Signal

Optional (Set-up option – see section

3.2.1) SU11

8

Evaporator Out Sensor – Ground

9

Defrost Termination Sensor – Signal

Optional (Set-up option – see section

3.2.4) DF8

10

Defrost Termination Sensor – Ground

11

RS485 Communication Network -

Omitted if IP Variant

12

RS485 Communication Network +

2.13 All Variants – Sensor / communication network connections

12 Way BLZ

Installation Guide | Issue 2.0 | The Eden Power Tray Page 19

Page 20

Chassis – End View

The Eden Power Tray

2.14 All Variants – End View

Installation Guide | Issue 2.0 | The Eden Power Tray Page 20

Page 21

Setting up the controller

The Eden Power Tray

3. Setting up the controller

The Eden Compact can be set up via a variety of different methods:

Through the front panel display and function keys

Through the RCS system manager

Directly via the controllers communication port using a PC

Across an IP network

Subsequent pages will identify and explain each menu group and individual parameter in detail when utilising the function keys

on the front of the Eden controller for set up purposes. Information has been presented in exactly the same format as it will

appear to the user on the display, and descriptions of each function are given along with the maximum, minimum and default

values for HT and LT variants.

If the user wishes to confirm / modify parameters using the RCS system manager then the Eden controllers will need to be

logged onto the system to achieve this, please complete the Setup and Address sections as identified on pages 8-11 before

proceeding to use the system manager.

Controllers can be pre-commissioned with identical non default parameter sets via the use of a PC connected directly into the

Eden controller’s communication port. To achieve this a simple software application is available from RCS upon request.

3.1 Front Panel Display Keys & Icons:-

The Eden Compact consists of a very attractive front panel display and a keypad. The display has 4 digits,

decimal point and icons. It shows temperatures, all parameter values, and the main unit status.

The silicon keypad ensures ease of use and reliability.

The front panel incorporates a blue LED 4 character display for indicating temperatures and status / alarm

messages. The four function keys are identified below:-

Installation Guide | Issue 2.0 | The Eden Power Tray Page 21

Page 22

Setting up the controller

The Eden Power Tray

Alarm

Critical alarm present, see Alarms Menu – Page 10

Service

See Parameter Ti9 – Page 18

HACCP

See Parameter Su9 – Page 9

Valve

Illuminated when Relay 1 is on – Pages 28-29

Fans

Illuminated when Relay 2 is on - Pages 28-29

Lights

Illuminated when Relay 3 is on - Pages 28 - 29

Defrost

Illuminated when Relay 5 is on – Pages 28-29

Network

Off = No Network attached / network failure

On = Network Established

Installation Guide | Issue 2.0 | The Eden Power Tray Page 22

Page 23

Setting up the controller

The Eden Power Tray

3.2 Using the front panel display and function keys

Display Text

Menu Group

Information

Set

Initial controller setup

Setup

Addr

485 / IP comms configuration

Address

rEF

Refrigeration Mode Parameters

Refrigeration

dEF

Defrost Mode Parameters

Defrost

FAnS

Fans parameters

Fans

ti

Time related Parameters

Times

StA

Unit Status Information

Status

ALAr

Unit Alarm Information

Alarms

LtS

Lights related Parameters

Lights

SLP

Sleep Mode

Sleep

SELF

Self Test Mode

Self

To enter setup press the FUNCTION and UP buttons simultaneously for greater than 3 seconds until the

message SEt appears. Pressing the ENTER key again at this point will allow access to the first item in the setup

menu (Su1). Pressing the FUNCTION button at any point will return the user to the previous menu. The UP /

DOWN buttons can be used to scroll through the available menu groups, as listed below. Once the required

menu group is displayed pressing the enter key again will allow access to that group as described above.

The following pages provide details of each menu group in order. It is recommended that the user follows this

sequence to ensure correct setup is achieved.

If no buttons are pressed for a period greater than 3 minutes the display will revert to indicating the actual cabinet

temperature. This applies to all menus.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 23

Page 24

Setting up the controller

The Eden Power Tray

3.2.1 Set Up Menu

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

Su1

Unit Type

0 = HT Integral

1 = LT Integral

2 = HT Remote

Case

3 = LT Remote

Case

4 = HT Coldstore

5 = LT Coldstore

4 4

Options 1 and 2 not valid if

EEV variant.

Su2

Control Probe Type

0 =Use Air On

Probe

1 = Use Log Probe

Air On

Air On

Selects between using the air

on, or the log probe as the

control temperature. If Su3 is

set to 0 (off) N/A will appear

Su3

Log Probe Type

0 = Off

1 = Logging

2 = Logging with

Alarm

0 - Off

0- Off

Selects the function of the log

probe. (if fitted)

Su4

Trim In Defrost

No

Yes

No

No

Selects the state (on or off) of

the trim heater output during

defrost.

Su5

Trim Output %

0 – 100

%

100

100

Selects the percentage output

level of the trim heater output

on a 100 second time base.

Example – if Su5 = 10% then

trim on for 10 seconds and off

for 90 seconds.

Su6

Relay 4 Function

0 = Suction

1 = Trim

2 = Compressor 2

Suction

Suction

If unit type 1 or 2 is selected

this parameter will default to 2

– compressor 2

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, at this point press the ENTER button again and the display will indicate Su1. This is the

first item in the set up menu. The UP and DOWN keys can be used to scroll through the entire list of set up items

– from Su1 through to Su12. See table below:-

Pressing ENTER whilst displaying any Su number will allow the user to view and modify that particular value by

using the UP / DOWN keys to either increment or decrement the default value. Once the desired value is

displayed press ENTER again to save, or use the FUNCTION key to return to previous menu without saving.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 24

Page 25

Setting up the controller

The Eden Power Tray

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

Su7

Digital Input 1

Function

0 = Case Clean

1 = Door Open

2 = C1 Fault

3 = Man Trapped

Case Clean

Case -

- Clean

Default for cabinet type 3 and

4 is case clean. If unit type 1

or 2 selected (su1) then

default value becomes 2 – C1

Fault. If unit type 5 or 6

selected (su1) then default

becomes 1 – Door alarm. All

digital inputs are contact sense

N/O. N/C for alarm.

Su8

Digital Input 2

Function

0 = Case Clean

1 = Door Open

2 = C2 Fault

3 = Man Trapped

Case -

- Clean

Case -

- Clean

Default for cabinet type 3 and

4 is case clean. If unit type 1

or 2 selected (su1) then

default value becomes 2 – C2

Fault. If unit type 5 or 6

selected (su1) then default

becomes 1 – Man Trapped

alarm. All digital inputs are

contact sense N/O. - N/C for

alarm.

Su9

HACCP Function

0 = Off

1 = On

2 = Flashing

0 - Off

0- Off

Selects the state of the front

panel HACCP icon.

Su10

Sensor Type

0 = PT1000

1 = 5K NTC

2 = 10K NTC

3 = 2K2 NTC

PT1000

PT1000

Selects the temperature

sensor type being used. Note

– sensor types cannot be

mixed on a single controller

Su11

Evaporator Probes

Fitted

0 = Not Fitted

1 = Fitted

1 - Fitted

1 - Fitted

Allows the user to select if

Evaporator In and Out sensors

are fitted.

Su12

Number of

Compressors

1 2 2 2

Selects the number of

compressors in use when unit

type 1 or 2 (integral) is

configured

Installation Guide | Issue 2.0 | The Eden Power Tray Page 25

Page 26

Setting up the controller

The Eden Power Tray

3.2.2 Controller address and communications menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

485A

Controller RS485

communication

address

(unit number)

0.0 – 499.9

0.0

0.0

Allows the user to set the

controllers network address for

RS485 legacy systems

485C

Controller RS485

communication baud

rate

0 = 9600

1 = 600

9600

9600

Allows the user to set the

controllers network baud rate for

RS485 legacy systems

IP-1

IP Address Byte 1

0 – 255

0 0

Allows the user to set the first

byte of the controllers IP

address. Note- If DHCP is set to

yes this value is not editable.

IP-2

IP Address Byte 2

0 – 255

0 0

Allows the user to set the

second byte of the controllers IP

address. Note- If DHCP is set to

yes this value is not editable.

IP-3

IP Address Byte 3

0 – 255

0 0

Allows the user to set the third

byte of the controllers IP

address. Note- If DHCP is set to

yes this value is not editable.

IP-4

IP Address Byte 4

0 – 255

0 0

Allows the user to set the fourth

byte of the controllers IP

address. Note- If DHCP is set to

yes this value is not editable.

Sn -1

Sub-Net Address Byte

1

0 – 255

0 0

Allows the user to set the First

byte of the controllers sub net

mask. Note- If DHCP is set to

yes this value is not editable.

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the DOWN key once - the display will indicate Addr at this point press the ENTER

button and the display will indicate 485A. This is the first item in the address menu. The UP and DOWN keys can

be used to scroll through the entire list of set up items – from 485A through to DGT. See table below:Pressing ENTER whilst displaying any item will allow the user to view and modify that particular value by using

the UP / DOWN keys to either increment or decrement the default value. Once the desired value is displayed

press ENTER again to save, or use the FUNCTION key to return to previous menu without saving.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 26

Page 27

Setting up the controller

The Eden Power Tray

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

Sn -2

Sub-Net Address Byte

2

0 – 255

0 0

Allows the user to set the

second byte of the controllers

sub net mask. Note- If DHCP is

set to yes this value is not

editable.

Sn -3

Sub-Net Address Byte

3

0 – 255

0 0

Allows the user to set the third

byte of the controllers sub net

mask. Note- If DHCP is set to

yes this value is not editable.

Sn -4

Sub-Net Address Byte

4

0 – 255

0 0

Allows the user to set the fourth

byte of the controllers sub net

mask. Note- If DHCP is set to

yes this value is not editable.

Gt1

Network Gateway

Address Byte 1

0 – 255

0 0

Allows the user to set the first

byte of the network gateway

address.

Gt2

Network Gateway

Address Byte 2

0 – 255

0 0

Allows the user to set the

second byte of the network

gateway address.

Gt3

Network Gateway

Address Byte 2

0 – 255

0 0

Allows the user to set the third

byte of the network gateway

address.

Gt4

Network Gateway

Address Byte 2

0 – 255

0 0

Allows the user to set the fourth

byte of the network gateway

address.

NtP1

NTP server Address

Byte 1

0 – 255

0 0

Allows the user to set the first

byte of the NTP server address

NtP2

NTP server Address

Byte 2

0 – 255

0 0

Allows the user to set the

second byte of the NTP server

address

NtP3

NTP server Address

Byte 3

0 – 255

0 0

Allows the user to set the third

byte of the NTP server address

NtP4

NTP server Address

Byte 4

0 – 255

0 0

Allows the user to set the fourth

byte of the NTP server address

dHCP

DHCP Enabled

Yes

No

Yes

Yes

Configures if DHCP is being

used

dntP

NTP server address

obtained via DHCP

Yes

No

Yes

Yes

Configures if the NTP server

address is automatically

obtained via DHCP

dGt

Network gateway

address obtained via

DHCP

Yes

No

Yes

Yes

Configures if the gateway

address is automatically

obtained via DHCP

If the user is unsure of any network related parameter please consult your network administrator

Installation Guide | Issue 2.0 | The Eden Power Tray Page 27

Page 28

Setting up the controller

The Eden Power Tray

3.2.3 Controllers Refrigeration related parameter menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

rF1 Force Refrigeration

No

Yes

No

No

Allows the user to force the

controller into a forced

refrigeration

state. During the force

refrigeration

state any scheduled defrosts will

be

ignored. The controller will

remain in

this state until either NO is

selected or a period of 60

minutes has elapsed.

rF2

Temperature

Setpoint

-40.0°C - +35.0°C

°C

1.0°C HT

-20°C LT

-1.0°C HT C/S

-20°C -

LT C/S

1.0°C HT

-20°C LT

-1.0°C HT C/S

-20°C LT C/S

Temperature at which inlet valve

or compressor/s will switch on

rF3

Temperature Diff.

0.2 – 5.0°C

°C

1.0°C HT

2.0°C LT

1.0°C HT

2.0°C LT

Differential temperature below

the temperature setpoint at which

the inlet valve or compressor will

switch off

rF4 Control Ratio

0 – 100%

%

66%

Cabinet

100%

Coldstore

66%

Cabinet

100%

Coldstore

Ratio of Air On temperature that

is used to calculate the estimated

cabinet temperature for control.

The remaining percentage used

is Air off temperature.

rF5 Display Ratio

0 – 100%

%

66

66

As above only applied to the front

panel display temperature.

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the DOWN key 2 times - the display will indicate rEF, at this point press the

ENTER button and the display will indicate rF1. This is the first item in the REFRIGERATION menu. The UP and

DOWN keys can be used to scroll through the entire list of the rEF menu – from rF1 through to Rf16. See table

below:Pressing ENTER whilst displaying any item will allow the user to view and modify that particular value by using

the UP / DOWN keys to either increment or decrement the default value. Once the desired value is displayed

press ENTER again to save, or use the FUNTION key to return to the previous menu without saving.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 28

Page 29

Setting up the controller

The Eden Power Tray

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

rF6 Superheat Setpoint

0.0 - 9.0

°C

6.0°C

6.0°C

The controller will attempt to

maintain this superheat setpoint

N/A will be displayed if LSV

version.

rF7 EEV Injection

percentage

0 – 100%

%

45%

45%

Sets the value of the EEV when

in a recovery state. N/A will be

displayed if LSV version.

rF8 Air On Alarm

Setpoint

-40.0°C - +35.0°C

°C

8.0 HT

-10.0 LT

8.0 HT

-10.0 LT

Sets the Air On alarm setpoint

rF9 Air Off Alarm

Setpoint

-40.0°C - +35.0°C

°C

4.0 HT

-20.0 LT

3.0 HT

C/S

-18.0 LT

C/S

4.0 HT

-20.0 LT

3.0 HT

C/S

-18.0 LT

C/S

Sets the Air Off alarm setpoint

rF10

Logging Probe OT

Alarm

Setpoint

-40.0°C - +35.0°C

°C

10.0 HT

-12.0 LT

10.0 HT

-12.0 LT

Sets the log probe over

temperature alarm setpoint.

NOTE – N/A will be displayed if

Su3 is not set to 2

rF11

Logging Probe UT

Alarm

Setpoint

-40.0°C - +35.0°C

°C

-5.0 HT

-35.0 LT

-5.0 HT

-35.0 LT

Sets the log probe under

temperature alarm setpoint

NOTE – N/A will be displayed if

Su3 is not set to 2

rF12

EEV Minimum

Opening

0 – 100%

%

15%

15%

Sets the minimum valve opening

during normal operation. The

controller will prevent the valve

from closing below this value.

N/A will be displayed if LSV

version.

rF13

Manual EEV Control

0 = No

1 = Yes

0 - No

0 – No

Allows the user to manually

control the EEV valve opening %

if set to Yes. Used in conjunction

with rF14 N/A will be displayed if

LSV version.

rF14

Manual EEV

Opening

0 – 100 %

% 0 0

If rF13 is set to yes, the manual

% opening value. The EEV will

remain at this percentage until

manual control is exited N/A will

be displayed if LSV version.

rF15

Air On setpoint

-40.0°C - +20.0°C

°C

-3.0 HT

-20.0 LT

-3.0 HT

-20.0 LT

Temperature at which inlet valve

or compressor/s will switch on.

Note N/A will be displayed if not

type 4 or 5 (coldstore)

rF16

Evaporator Offset to

allow injection state

-10.0°C - +10.0°C

°C

0.0 HT

2.0 LT

0.0 HT

2.0 LT

Temperature offset from the ECT

setpoint at which the injection

(recovery) state can be entered

Note N/A will be displayed if not

type 4 or 5 (coldstore)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 29

Page 30

Setting up the controller

The Eden Power Tray

3.2.4 Controllers DEFROST menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

dF1

First Defrost Time

00:01 – 23:59

hh:mm

01:00

01:00

Sets the first scheduled defrost

time

dF2

Number of Defrosts

per

Day

0 – 8 6 6 Sets the number of defrost

cycles per day. Automatically

spaced equally from the first

defrost time (dF1)

dF3

Maximum Defrost

Duration

00:00 – 01:59

hh:mm

00:30

00:30

Maximum time that a scheduled

defrost cycle can run. Note Timed from the end of defrost

Minimum (dF4)

dF4

Minimum Defrost

Duration

00:00 – 01:59

hh:mm

00:05

00:05

Minimum time that a scheduled

defrost cycle must run before

terminating. If termination

temperature is achieved during

this period the controller will turn

off the defrost output but not

return to refrigeration mode until

period has elapsed.

dF5

Pump Down

Duration

0 – 60

mm 0 0

Pump down time prior to

minimum defrost duration (dF4)

commencing

dF6

Drain Down Duration

0 – 60

mm

02

02

Drain down time after defrost has

terminated to allow water to be

cleared.

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the DOWN key 3 times - the display will indicate dEF, at this point press the

ENTER button and the display will indicate dF1. This is the first item in the DEFROST menu. The UP and DOWN

keys can be used to scroll through the entire list of the DEFROST menu – from dF1 through to dF13. See table

below:Pressing ENTER whilst displaying any item will allow the user to view and modify that particular value by using

the UP / DOWN keys to either increment or decrement the default value. Once the desired value is displayed

press ENTER again to save, or use the FUNCTION key to return to the previous menu without saving.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 30

Page 31

Setting up the controller

The Eden Power Tray

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

dF7

Defrost termination

Temperature

-40.0°C - +35.0°C

°C

8.0°C

8.0°C

Scheduled defrost will terminate

when the defrost termination

sensor reaches this temperature.

Note – If the defrost termination

sensor is not fitted (or faulty)

then defrost termination will

occur when the Evap. In sensor

reaches this temperature if fans

off, or the Air Off sensor reaches

this temperature if fans on.

dF8

Defrost termination

sensor in Use

0 = Defrost

1 = Air Off

2 Evap. In

0 =

Defrost

0 =

Defrost

Allows the user to select the

sensor used for defrost

termination.

dF9

Defrost Type

0 = Electric

1 = Hot Gas

0 Electric

0 –

Electric

Allows the user to select if

electric or hot gas defrost in

being used.

dF10

Suction Valve after

Hot

Gas defrost

Open

Closed

Closed

Closed

Allows the user to select if the

suction valve is open or closed

during the drain down period.

Only applicable if Hot Gas

defrost is selected at dF9

dF11

Force Defrost

Yes

No

No

No

Sets the controller into defrost.

The

controller will remain in this mode

until either No is selected or max

defrost duration (Df3) time

is exceeded.

dF12

Trigger Defrost

Yes

No

No

No

Allows the user to trigger a

defrost cycle additional to those

scheduled. All normal termination

criteria apply.

dF13

LSV during Hot Gas

Defrost

0 = Closed

1 = Open

0 Closed

0 –

Closed

Allows the user to select if the

evaporator inlet valve is open or

closed during a hot gas defrost.

Only applicable if Hot Gas

defrost is selected at dF9

dF14

Suppress Full Length

Defrost

Yes

No

No

No

Allows the user to prevent the

controller from entering a full

length defrost at the scheduled

time/s when the defrost

termination temperature is

above the termination setpoint

(df7) at the start of defrost.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 31

Page 32

Setting up the controller

The Eden Power Tray

3.2.5 Controllers Fan related parameter menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

Fn1 Fans Only Mode

0 = No

1 = Yes

2 = Lights and

Fans

Only

0 – No

0 – No

Allows the user to set the

controller

into Fans Only Mode. The

controller

will remain in this mode until No

is

selected.

Fn2

Maximum Fans off

Time

0 – 60

mm 0 0

Maximum time for which the fans

are switched off following

draindown.

Fn3

Fans Off

Temperature

During Defrost

-40.0°C - +35.0°C

°C 8.0°C

(HT)

-10.0°C

(LT)

8.0°C

(HT)

-10.0°C

(LT)

Allows the user to determine the

temperature at which fans will

turn off during defrost. Once

turned off by this setting fans will

remain off for the remaining

defrost duration.

NOTE If -40.0°C is selected fans

will be always off during defrost

Fn4 Fans Off Delay Time

0 – 60

ss 0 0

The delay time before fans are

switched off when a door open

state is entered. Note N/A will be

displayed if not type 4 or 5

(coldstore)

Fn5

Fans Holdoff End

setpoint

-40.0°C - +35.0°C

°C 0.0°C

(HT)

-10.0°C

(LT)

0.0°C

(HT)

-10.0°C

(LT)

Defrost termination sensor

temperature which when

achieved will allow fans to be

switched on.

Fn6

Fans Pulse In defrost

No

Yes

0 = No

0 = No

Allows the user to select if

evaporator fans pulse during

defrost

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the DOWN key 4 times - the display will indicate FAns, at this point press the

ENTER button and the display will indicate Fn1. This is the first item in the FANS menu. The UP and DOWN keys

can be used to scroll through the entire list of the FANS menu – from Fn1 through to Fn9. See table below:Pressing ENTER whilst displaying any item will allow the user to view and modify that particular value by using

the UP / DOWN keys to either increment or decrement the default value. Once the desired value is displayed

press ENTER again to save, or use the FUNCTION key to return to the previous menu without saving.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 32

Page 33

Setting up the controller

The Eden Power Tray

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

Fn7

Fans On setpoint

-10.0°C - +30.0°C

°C 50.0°C

(HT)

-1.0°C

(LT)

5.0°C

(HT)

-1.0°C

(LT)

Cold store Only.

Defrost termination sensor

temperature or Air On

temperature which when

achieved will allow fans to be

switched on. Note N/A will be

displayed if not type 4 or 5

(coldstore)

Fn8

Fans Pulse Time

5 – 600

ss

60

60

Time in seconds for which the

fans will alternate between on

and off if Fn6 is set to yes

Fn9

Door Open State

Closes

Valve

0 = No

1 = Yes

0 – No

0 – No

Allows the user to select if a door

open state closes the evaporator

inlet valve. Note N/A will be

displayed if not type 4 or 5

(coldstore)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 33

Page 34

Setting up the controller

The Eden Power Tray

3.2.6 Controllers time related parameter menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

ti1

Time of Day

00:00 –

23:59

hh:mm

00:00

00:00

Allows the user to set the correct

time of day into the controller. Note

on networked systems the time of

day will automatically be down

loaded from the host system

ti2

Current Date

01:01 –

31:12

dd:mm

00:00

00:00

Sets the controllers current date

ti3

Current Year

2012 -2100

0000

0000

Sets the controllers current year

ti4

Time of Next

Defrost

hh:mm

Allows the user to view the time of

the next scheduled defrost cycle.

ti5

Time Since last

defrost

hh:mm

Allows the user to view the time

since the last scheduled defrost

cycle occurred.

ti6

Duration of last

defrost

hh:mm

Allows the user to view the duration

time of the last scheduled defrost

cycle.

ti7

Duration of current

defrost

hh:mm

Allows the user to view the elapsed

time of a current defrost cycle.

ti8

Door Alarm Delay

0 – 120

mm

Delay after the door open input is

asserted before the alarm occurs.

Note N/A will be displayed if not

type 4 or 5 (coldstore)

ti9

Service Interval

Time

0 – 130

khrs

60

60

Running time in KHrs (1000x)

before the front panel service

(spanner) icon is illuminated. Reset

can be achieved by changing the

value to 0 then back to the desired

interval.

ti10

Air On Alarm Delay

0 – 120

mm

20

20

Delay for the Air On OT alarm

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the DOWN key 5 times - the display will indicate Ti, at this point press the ENTER

button and the display will indicate Ti1. This is the first item in the TIMES menu. The UP and DOWN keys can be

used to scroll through the entire list of the TIME menu – from TI1 through to Ti19. See table below:Pressing ENTER whilst displaying any item will allow the user to view and modify that particular value by using

the UP / DOWN keys to either increment or decrement the default value. Once the desired value is displayed

press ENTER again to save, or use the FUNCTION key to return to previous menu without saving.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 34

Page 35

Setting up the controller

The Eden Power Tray

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

ti11

Air Off Alarm Delay

0 – 120

mm

20

20

Delay for the Air Off OT alarm

ti12

Log Probe Alarm

Delay

00:00 –

02:00

hh:mm

00:20

00:20

Delay for the log probe alarm

NOTE – N/A will be displayed if

Su3 is not set to 2

ti13

Cycle Time

0 – 120

mm

60

60

Energy saving feature (LSV use)

see appendix 1.

ti14

EEV Injection Time

0 – 30

mm 4 4

Maximum period the controller can

be in an injection (stall prevention)

state. N/A will be displayed if LSV

version.

ti15

Pull Down Time

0 – 30

ss 8 8

Time after draindown, before an

injection state (recovery) state can

be entered

ti16

Door Open Time

0 – 60

mm

Displays the time a cold store door

has been continuously open for.

Note N/A will be displayed if not

type 4 or 5 (coldstore)

ti17

Door Interlock

Time

0 – 60

mm

0

(HT)

5

(LT)

0

(HT)

5

(LT)

Maximum time for which fans and

/or inlet valve are off / closed when

a cold store door is open. Note N/A

will be displayed if not type 4 or 5

(coldstore)

ti18

Compressor/s start

holdoff Time

0 – 15

mm 4 4

Time period following initial power

up of the controller before

compressors can be started –

Integral use only

ti19

Compressor/s

Restart

Time

0 – 15

mm 4 4

Anti – short cycle time for

compressor 1 and 2 – Integral use

only

Ti20

Compressor/s

stage Time

0 – 15

mm 4 4

Period which must elapse between

compressor A changing state and

subsequent change of state of

compressor B – Integral use only

Ti21

Compressor/s

Minimum On Time

0 – 15

mm 4 4

Minimum time compressor/s must

run once started – Integral use

only

Ti22

Compressor/s

Minimum Off Time

0 – 15

mm 4 4

Minimum time compressor/s must

be stopped once switched off –

Integral use only

Installation Guide | Issue 2.0 | The Eden Power Tray Page 35

Page 36

Setting up the controller

The Eden Power Tray

3.2.7 Controllers current status menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

St1

Air On Temperature

°C Displays the current Air On sensor

Temperature.

St2

Air Off Temperature

°C

Displays the current Air Off sensor

Temperature

St3

Evaporator In

Temperature

°C

Displays the current Evap. In sensor

Temperature

St4

Evaporator Out

Temperature

°C

Displays the current Evap. Out sensor

Temperature

St5

Superheat

°C

Displays the current superheat

Temperature

St6

Defrost sensor

Temperature

°C

Displays the current Defrost termination

sensor Temperature

St7

Estimated cabinet

Temperature

°C

Displays the current estimated cabinet

temperature. This is defined by the ratio

of air on temperature set within the rEF

menu at rF5 (Display Ratio)

St8

Log Probe

Temperature

°C

Displays the current log sensor

Temperature.

St9

Analogue channel 7

Displays the current value of analogue

input

channel 7. (Hardware configurable).

St10

Trim Output

percentage

% Displays the current percentage of the

controllers trim output.

St11

Digital Input 1

Open

Closed

Displays the current state of controllers

digital input 1. Function dependant upon

selection made in SETUP menu – Su7

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the UP key 6 times - the display will indicate StA, at this point press the ENTER

button and the display will indicate St1. This is the first item in the STATUS menu. The UP and DOWN keys can

be used to scroll through the entire list of the STATUS menu – from St1 through to St20. See table below: Pressing ENTER whilst displaying any item will allow the user to view that particular value. None of the items

within this menu are user editable. Use the FUNCTION key to return to previous menu.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 36

Page 37

Setting up the controller

The Eden Power Tray

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

St12

Digital Input 2

Open

Closed

Displays the current state of controllers

digital input 2. Function dependant upon

selection made in SETUP menu – Su8

St13

Case Clean

On

Off

Displays if the controller is currently in

case clean mode. (all outputs off)

St14

EEV percentage

open

% Displays the current percentage opening

of the EEV. .N/A will be displayed if LSV

version.

St15

Compressor 1 Fault

Yes

No

Displays the current fault status of C1

(Integral only)

St16

Compressor 2 Fault

Yes

No

Displays the current fault status of C2

(Integral only)

St17

Compressor 1

Running

Yes

No

Displays the current status of controllers

C1 output. (Integral only)

St18

Compressor 2

Running

Yes

No

Displays the current status of controllers

C2 output. (Integral only)

St19

Software Version

Displays controllers software version

St20

Display software

version

Displays controllers display version

Installation Guide | Issue 2.0 | The Eden Power Tray Page 37

Page 38

Setting up the controller

The Eden Power Tray

3.2.8 Controllers current alarms menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

AL1

Any Alarms

Yes

No

Allows the user to quickly

establish

if any alarm conditions are

currently

Active.

AL2

Air On OT

Yes

No

Indicates if the controller

currently has an Air On over

temperature alarm.

AL3

Air Off OT

Yes

No

Indicates if the controller

currently has an Air Off over

temperature alarm.

AL4

Air On Sensor

Failure

Yes

No

Indicates if the controller

currently has a faulty Air On

temperature sensor.

AL5

Air On Sensor

Failure

Yes

No

Indicates if the controller

currently has a faulty Air Off

temperature sensor.

AL6

Evaporator In

Sensor

Failure

Yes

No

Indicates if the controller

currently has a faulty Evap. In

temperature sensor.

AL7

Evaporator Out

Sensor

Failure

Yes

No

Indicates if the controller

currently has a faulty Evap.

Out temperature sensor.

AL8

Defrost Termination

Sensor Failure

Yes

No

Indicates if the controller

currently has a faulty Defrost

Termination temperature

sensor.

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the UP key 4 times - the display will indicate ALAr, at this point press the ENTER

button and the display will indicate AL1. This is the first item in the ALARMS menu. The UP and DOWN keys can

be used to scroll through the entire list of the ALARMS menu – from AL1 through to AL14. See table below:Pressing ENTER whilst displaying any item will allow the user to view that particular value. None of the items

within this menu are user editable. Use the FUNCTION key to return to previous menu.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 38

Page 39

Setting up the controller

The Eden Power Tray

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

AL9

Logging Sensor

Failure

Yes

No

Indicates if the controller

currently has a faulty Log

temperature sensor.

AL10

Door Open

(Cold store Only)

Yes

No

Indicates if the controller

currently has a Door Open

alarm Note N/A will be

displayed if not type 4 or 5

(coldstore)

AL11

Man Trapped

(Cold store Only)

Yes

No

Indicates if the controller

currently has a Man Trapped

alarm Note N/A will be displayed

if not type 4 or 5 (coldstore)

AL12

Insufficient Data

Yes

No

Indicates if the controller

currently has an Insufficient

Data alarm. Note – Usually

occurs when defrost time 1

has not been set.

AL13

Compressor 1

Alarm

(Integral Only)

Yes

No

Indicates if the controller

currently has a Compressor 1

Fault.

AL14

Compressor 2

Alarm

(Integral Only)

Yes

No

Indicates if the controller

currently has a Compressor 2

Fault.

AL15

Critical Probe Fault

Yes

No

Set if the controller currently

has more than one

temperature sensor in a fault

condition.

Note – All of the above alarms if present will cause the front panel Bell Icon to be illuminated.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 39

Page 40

Setting up the controller

The Eden Power Tray

3.2.9 Controllers lights related parameter menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

Li1

Lights control Mode

0 – Remote

1 – Local

2 – Off

3 – On

2 2

Allows the user to set the control

of

case lights:0 = Case lights controlled via

host

System manager.

1 = Case lights controlled via

controller schedule (see Li2 –

Li15)

2 = Always Off

3 = Always On

Li2

Sunday Lights On Time

00:00 – 23:59

hh:mm

08:00

08:00

Available if Li1 set to 1 - Local

Li3

Sunday Lights Off Time

00:00 – 23:59

hh:mm

22:00

22:00

Available if Li1 set to 1 - Local

Li4

Monday Lights On Time

00:00 – 23:59

hh:mm

08:00

08:00

Available if Li1 set to 1 - Local

Li5

Monday Lights Off Time

00:00 – 23:59

hh:mm

22:00

22:00

Available if Li1 set to 1 - Local

Li6

Tuesday Lights On Time

00:00 – 23:59

hh:mm

08:00

08:00

Available if Li1 set to 1 - Local

Li7

Tuesday Lights Off Time

00:00 – 23:59

hh:mm

22:00

22:00

Available if Li1 set to 1 - Local

Li8

Wednesday Lights On

Time

00:00 – 23:59

hh:mm

08:00

08:00

Available if Li1 set to 1 - Local

Li9

Wednesday Lights Off

Time

00:00 – 23:59

hh:mm

22:00

22:00

Available if Li1 set to 1 - Local

Li10

Thursday Lights On Time

00:00 – 23:59

hh:mm

08:00

08:00

Available if Li1 set to 1 - Local

Li11

Thursday Lights Off Time

00:00 – 23:59

hh:mm

22:00

22:00

Available if Li1 set to 1 - Local

Li12

Friday Lights On Time

00:00 – 23:59

hh:mm

08:00

08:00

Available if Li1 set to 1 - Local

Li13

Friday Lights Off Time

00:00 – 23:59

hh:mm

22:00

22:00

Available if Li1 set to 1 - Local

Li14

Saturday Lights On Time

00:00 – 23:59

hh:mm

08:00

08:00

Available if Li1 set to 1 - Local

Li15

Saturday Lights Off Time

00:00 – 23:59

hh:mm

22:00

22:00

Available if Li1 set to 1 - Local

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the UP key 3 times - the display will indicate LtS, at this point press the ENTER

button and the display will indicate Li1. This is the first item in the LIGHTS menu. The UP and DOWN keys can

be used to scroll through the entire list of the LIGHTS menu – from Li1 through to Li15. See table below:Pressing ENTER whilst displaying any item will allow the user to view and modify that particular value by using

the UP / DOWN keys to either increment or decrement the default value. Once the desired value is displayed

press ENTER again to save, or use the FUNCTION key to return to previous menu without saving.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 40

Page 41

Setting up the controller

The Eden Power Tray

3.2.10 Controller sleep mode menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

SP1

Sleep Mode

Yes

No

No

No

Allows the user to set the

controller

Into sleep mode (All outputs off).

The controller will continue to

report temperature values to the

host

Supervisory system during sleep

mode periods.

The controller will remain in sleep

mode if selected until the user

selects No.

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SLP, Press the UP key 2 times - the display will indicate SLP, at this point press the ENTER

button and the display will indicate SP1. This is the only item in the SLEEP menu. See table below:-

Pressing ENTER whilst displaying SP1 will allow the user to view and modify that particular value by using the

UP / DOWN keys to either increment or decrement the default value. Once the desired value is displayed press

ENTER again to save, or use the FUNCTION key to return to previous menu without saving.

Note: - Caution should be used when setting this value as the controller will remain in sleep mode indefinitely

once selected.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 41

Page 42

Setting up the controller

The Eden Power Tray

3.2.11 Controller self test menu.

I/D

Parameter

Range

Units

Deflt

LSV

Deflt

EEV

Information

SF1

Self Test

No

Yes

No

No

Allows the user to set the

controller into self test mode.

The controller will cycle all outputs

consecutively for a period of 2

minutes.

The order in which the outputs are

switched are:-

Liquid valve

Fans

Defrost

Suction / Trim

Lights

Accessed by pressing and holding the FUNCTION and UP keys simultaneously for greater than 3 seconds. The

display will indicate SEt, Press the UP key once - the display will indicate SELF, at this point press the ENTER

button and the display will indicate SF1. This is the only item in the SELF TEST menu.

See table below:Pressing ENTER whilst displaying SF1 will allow the user to view and modify the default value of NO to YES. If

YES is selected the controller will remain in self test for a period of two minutes, or until NO is selected, if sooner.

The FUNCTION key can be used to return to the previous menu.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 42

Page 43

Cleaning

The Eden Power Tray

4. Cleaning

Only use a soft lint-free cloth. Abrasive cloths, towels, paper towels and similar items may damage the Eden

controller. Keep any liquids away from the controller; don’t use aerosol sprays, solvents or abrasives.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 43

Page 44

Specification

The Eden Power Tray

5. Specification

5.1 Power requirements:

Supply Voltage Range: 220 – 240 Vac ±10%

Supply Frequency: 50 – 60 Hz

Maximum supply current: 32 Amps

Typical supply current: Loading Dependant

Operating temperature range: +5C to +50C

Operating Humidity: 80% maximum

Storage temperature range: -20.0C to +65.0C

Environmental: Indoor use at altitudes up to 2000m, IP30,

Installation Category II.

Voltage fluctuations not to exceed ±10% of nominal voltage

5.2 Dimensions:

Size 360mm (W) x 85mm (H) x 210mm (D)

Approx Weight: 3.80 K Grams (without free-end connectors)

Safety: EN60730-1

EMC: EN 55014-1:2006 A2

Ventilation: There is no requirement for forced cooling ventilation

Class 2 Insulation: This unit MUST be Earthed.

5.3 Inputs:

Analogue: (X5) Channels 1-6 = PT1000 or 5K or 10K or 2K2 (selectable)

5.4 Communications: On-board RS485 or Ethernet 10/100baseT or Wi-Fi

(order option

Installation Guide | Issue 2.0 | The Eden Power Tray Page 44

Page 45

Revision History

The Eden Power Tray

Revision

Date

Author

Amendments

Comments

1

06/08/14

SRL

First Draft

Issued for internal review

2

06/02/15

SRL

Various Amendments

Circuit Diagrams updated. Part Codes Updated.

General Text Corrections.

6. Revision History

Installation Guide | Issue 2.0 | The Eden Power Tray Page 45

Page 46

Disclaimer

The Eden Power Tray

7. Disclaimer

To allow for design and specification improvements, the information contained within this document is subject

to change at any time without prior notice. RCS Energy Management shall not be liable for any errors or

omissions, for incidental or consequential damages either directly or indirectly resulting from the misuse of

this product or associated document.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 46

Page 47

Contact Details

The Eden Power Tray

8. Contact Details

RCS Energy Management Limited

RMS House

Kennet Side

Newbury

Berkshire

RG14 5PX

UNITED KINGDOM

Tel: +44 (0) 1635 231600

Fax: +44 (0) 1635 231699

Email: sales@rcsenergymanagement.co.uk

Website: www.rcsenergymanagement.co.uk

Installation Guide | Issue 2.0 | The Eden Power Tray Page 47

Page 48

Appendices

The Eden Power Tray

9. Appendices

Appendix 1

9.1 Cycle Time function (Times menu (Ti13)

Minimum value = 0 Minutes

Default Value = 60 Minutes

Maximum value = 120 Minutes

This energy saving feature applies to HT cases with liquid solenoid valve control only, and operates within

the standard LSV control loop. The cycle time function will close the liquid solenoid valve if the valve has

been open for greater than the cycle time parameter (Ti13) and has been constantly within the dead band for

this period.

The diagram below (Fig 1) shows the cycle timer operation overlaid over the standard control loop.

The cycle time function can be disabled by setting Ti13 value to zero.

Fig 1

The benefits of using the cycle time function are realised by shorter defrost periods or less frequent defrost

periods, resulting in very stable product temperatures as a result of an ice free evaporator.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 48

Page 49

Appendices

The Eden Power Tray

Appendix 2

9.2 Defrost Cycle (Fans Off)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 49

Page 50

Appendices

The Eden Power Tray

Appendix 3

9.3 Defrost Cycle (Fans On)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 50

Page 51

Appendices

The Eden Power Tray

Appendix 4

9.4 Integral Compressor Action

Installation Guide | Issue 2.0 | The Eden Power Tray Page 51

Page 52

Appendices

The Eden Power Tray

71mm

29mm

Appendix 5

9.5 Remote Display

The Eden Power Tray range is available in configurations to support remote display requirements.

The Eden Compact remote display unit maintains exactly the same fascia dimensions as the compact

controller.

9.5.1 Panel Cut-out:

Please allow 35mm behind panel for display module and cable clearance.

Installation Guide | Issue 2.0 | The Eden Power Tray Page 52

Page 53

Appendices

The Eden Power Tray

9.5.2 Remote Display

The remote display unit is robustly held in position by the use of sprung clips at either end of the enclosure.

These have been designed to allow the fitment of the module through a panel cut-out from the front.

9.5.3 Retaining Clips:

The remote display unit maintains exactly the same functionality as the integral display variant of the Eden

Compact with menu access, parameter management and setup the same as previously described within this

document.

9.5.4 Remote Display Module: (Front view)

Installation Guide | Issue 2.0 | The Eden Power Tray Page 53

Page 54

Declaration of Conformity

The Eden Power Tray

10. European Declaration of Conformity

We of RCS Energy Management Limited

RMS House, Kennet Side, Bone Lane, Newbury, Berkshire, RG14 5PX

In accordance with the following directive(s):

EN 60730-1 (Fourth Edition) 2010 Automatic electrical controls for household and similar

use.

2006/95/EC Low voltage Directive

EN 55014-1: 2006 A2 EMC requirements for household appliances, electric

tools and similar apparatus – Emissions.

EN 55014-2: 1997 A2 EMC requirements for household appliances, electric

tools and similar apparatus – Immunity.

Hereby declare that:

Equipment Eden Power Tray

Model Number(s) EP3110, EP3111, EP3112, EP3113, EP3114,

EP3115, EP3116, EP3119, EP31110,

Is in conformity with the applicable requirements of the afore mentioned standards / directives.

The Technical construction file is maintained at RMS House, Kennet Side, Bone Lane, Newbury, Berkshire,

RG14 5PX by S. Liddiard (Product Manager)

I hereby declare that the equipment named above has been designed to comply with the relevant sections of

the above referenced directives. The unit complies with all applicable requirements of these directives.

Signed: S Liddiard

Name: Mr. Simon Liddiard

Position: Product Manager

Date: 06 August 2014

Installation Guide | Issue 2.0 | The Eden Power Tray Page 54

Loading...

Loading...