RCM S.p.A.

via Tiraboschi, 4 - 41043 Casinalbo - Modena - Italy

Tel. +39 059 515 311 - Fax +39 059 510 783

www.rcm.it - info@rcm.it

5/2015 Rev.00

INSTRUCTION AND MAINTENANCE HANDBOOK

EN

(33.KI.001)

KILO

KILO

2

KILO

3

INDEX PAGE

INTRODUCTION 6

• Purpose and contents of the manual 6

• Recipients 6

• Storage of the manual 6

• Declaration of conformity 6

• Identi cation data 6

• Other manuals of reference 7

• Spare parts and maintenance 7

• Changes and improvements 7

• Operational capabilities 7

• Conventions 7

UNPACKING/DELIVERY 7

SAFETY 7

• Symbols used 8

• General instructions 8

DESCRIPTION OF THE MACHINE 10

• Structure of the machine 10

• Steering wheel with control and commands panel 11

• Safety functions 12

• Electromagnetic brake 12

• Traction safety micro-switch 12

• Anti-rollover tubes 12

TECHNICAL FEATURES 13

ACCESSORIES AND COMPONENTS UPON REQUEST 14

WIRING DIAGRAM 15/16

PUSHING/TOWING THE MACHINE 17

USE 18

BATTERIES 18

• Check/Installation of the new batteries on a new machine 18

• Batteries installation/replacement 18

• Setting of type of batteries installed 18

PRELIMINARY OPERATIONS BEFORE STARTING THE MACHINE 19

ELECTROMAGNETIC BRAKE 19

BRUSHES 20

• Disc brushes (only for KILO versions with disc brush base) 20

• Assembly of disc brush 20

• Disassembly of disc brush 20

• Selection of type of disc brush 21

• Selection table of type of disc brushes 21

• Pad holder driving disc 22

• Assembly of pad holder driving disc 22

• Disassembly of pad holder driving disc 22

• Selection of type of pad holder driving disc 23

• Selection table of type of pads 23

4

INDEX PAGE

SQUEEGEE 24

• Assembly of squeegee 24

• Disassembly of squeegee 24

• Selection of type of squeegee rubbers 25

• Selection table of type of squeegee rubbers 25

• Installation/removal of squeegee rubbers 25

TANKS 26

• Checking recovery water tank 26

• Filling the detergent solution tank with water (or washing water) 26

• Inlet in basic version 26

• Inlet in version with lling kit 26

• Installation/Filling “5 Liter” detergent tank 27

(Version with "DETERSAVER" automatic detergent feeding system)

STARTING AND STOPPING THE MACHINE 28

• Starting the machine 28

• Stopping the machine 29

MACHINE IN OPERATION 29

• Adjustments and checks 29

EMPTYING OF TANKS 30

• Emptying of recovery water tank 30

• Emptying the detergent solution (or washing water) tank 30

•

• Emptying 5-litre detergent tank (DETERSAVER - UPON REQUEST) 31

• Detergent solution (or washing water) tank level 32

• Recovery water tank level 32

AFTER MACHINE USE 33

LONG DOWNTIME OF MACHINE 33

FIRST PERIOD OF USE 34

MAINTENANCE 34

• Planned maintenance table 34

• Check of machine operating hours 35

• Cleaning the squeegee 35

• Check of squeegee rubbers 36

• Replacement of rear squeegee rubber 36

• Replacement of front squeegee rubber 36

• Rearrangement of the squeegee 38

• Squeegee height adjustment 37

• Cleaning the disc brush 37

• Cleaning the recovery tank 38

• Cleaning the suction lter 39

• Cleaning the detergent solution (or washing water) lter 39

5

INDEX PAGE

• Cleaning the detergent solution supply nozzle to the disc brush 40

(KILO version with disc brush base)

• Opening/Closing of the batteries holder case and disconnection of the batteries connector 41

• Charging the batteries 42

• Charging the batteries, for machines without on-board battery charger (Using external battery charger) 42

• Charging the batteries, for machines with on-board battery charger (upon request) 43

• Check/Replacement of fuses 44

• Disassembly/assembly of vacuum motor 45

TROUBLESHOOTING 46

SCRAPPING 47

6

INTRODUCTION

Purpose and contents of the manual

This Manual has the purpose of providing the operator with all necessary information to be able to use the machine in

the most suitable, independent and safest way possible. It includes information on safety, technical aspect, operation,

machine stop, maintenance, spare parts and scrapping.

Before performing any operation on the machine, the operators and quali ed technicians must carefully read the

instructions in this manual. If in doubt on correct interpretation of the instructions, contact the Manufacturer RCM for

any explanations.

Recipients

This manual is for both the operator and quali ed maintenance technicians of the machine.

The operators must not perform operations reserved for quali ed technicians. RCM is not liable for damages resulting

from failure to observe this prohibition.

Storage of the manual

This manual must be stored next to the machine, in the special bag, protected from liquids and anything else that may

jeopardise readability.

Declaration of conformity

The declaration of conformity supplied with the machine certi es compliance of the machine with the provisions of

law in force.

NOTE:

The original CE declaration of conformity is in the documentation attached to the machine.

Identi cation data

The serial number and model of the machine are shown on the label (A) a xed to the frame and can be read after

having extracted the batteries case (B) (See Maintenance chapter to open the batteries case).

The machine's year of manufacture is shown on the declaration of conformity; it is also indicated by the rst four digits

of the machine's serial number.

This information is necessary when ordering spare parts for the machine. Use the following space to note the machine's identi cation data.

MACHINE model | MACHINE serial number

A

B

7

Other manuals of reference

Electronic battery charger manual (to be considered integral part of this manual)

Spare parts catalogue (provided with the machine)

Electromagnetic brake release instructions label

Spare parts and maintenance

Contact quali ed personnel or RCM Service Centres for any requirement regarding use, maintenance and repairs.

Only original spare parts and accessories must be used.

Contact RCM for assistance or to order spare parts and accessories, and always specify model and serial number.

Changes and improvements

RCM focuses on constant improvement of its products and reserves the right to make changes and improvements

when deemed necessary, without having to modify the machines previously sold.

Any change and/or addition of accessories to the machine must be explicitly approved and implemented by RCM.

Operational capabilities

This scrubber drier is designed and manufactured to clean (wash and dry) smooth and compact oors, in civil and

industrial environments, in veri ed safe conditions, driven by a quali ed operator.

The scrubber drier is not suitable for washing carpets and rugs.

Conventions

All references to forward, backward, front, rear, right, left indicated in this manual refer to the operator sitting in the

driving position on the operator's seat.

UNPACKING/DELIVERY

Carefully follow the instructions on the packaging to unpack the Machine.

Refer to the Pushing/towing the machine paragraph to manually push the machine.

When the machine is delivered, check that the packing and the machine were not damaged during transportation.

If the damage is evident, keep the packing and have it checked by the Courier that delivered it. Immediately call the

Courier to ll in a request for a compensation for damages.

Check that the following items have been supplied with the machine:

Technical Documentation:

• Scrubber drier instruction and maintenance manual.

• Electronic battery charger manual (if supplied).

• Scrubber drier spare parts catalogue.

• Electromagnetic brake release instructions label.

SAFETY

The following symbols are used to warn of any potentially dangerous conditions. Always read this information carefully and take the necessary precautions to protect people and objects.

To avoid injury, collaboration of the operator is essential. No injury prevention plan is e ective without the total collaboration of the person directly responsible for machine operation. Most accidents that occur in a company, at the

workplace or during transfer, are caused by failure to observe the most basic safety rules.

A careful and cautious operator is the best guarantee against accidents and is indispensable to complete any prevention program.

8

Symbols used

!

DANGER!

Indicates a danger with risk, even deadly, for the operator.

!

ATTENTION!

Indicates a potential risk of injury for people or of damage to objects.

!

WARNING!

Indicates a warning or a note on key functions or on useful functions. Pay close attention to text blocks indicated by this symbol.

NOTE!

Indicates a note on key functions or on useful functions.

CONSULTATION

Indicates the need to consult the Instruction and maintenance manual before performing any operation.

General instructions

Warnings and speci c attention are described below to highlight potential dangers of damage to the machine and

to people.

!

DANGER!

• Before performing any maintenance, repairs, parts replacement, disconnect the battery using the special connector and remove the ignition key.

• This machine must be used only by properly trained and authorised people.

• Keep sparks, ames and incandescent materials away from batteries. Explosive gases leak during normal use of the lead batteries (WET).

• Remove all jewellery when working near electrical components.

• Do not work under the lifted machine without adequate xed safety supports.

• Do not operate this machine in environments with dusts, liquids or vapours that are harmful, dangerous, ammable and/or explosive. This machine is not suitable for collecting dangerous dusts.

• When charging lead batteries (WET), highly explosive hydrogen gas is produced, therefore the operation must be carried out only in well-ventilated areas that are away from open ames.

!

ATTENTION!

• Before performing any maintenance/repairs, carefully read all relevant instructions.

• Before using the external battery charger, ensure that the frequency and voltage indicated on the machine's serial plate coincide with the mains voltage.

• Do not use the battery charger cable to pull or move the machine and do not use it as a handle. Do not let

the battery charger cable be crushed by a door, do not pull it over sharp surfaces or edges. Do not pass

over the battery charger cable with the machine.

• Keep the battery charger cable away from hot surfaces.

• Do not use the machine if the battery charger cable or its plug are damaged. If the machine does not

work properly, is damaged, left outdoors or has fallen in water, take it to a Service Centre.

• To reduce the risk of re, electric shock or injury, do not leave the machine connected to the electrical

mains when it is unattended. Disconnect the machine from the power socket when it is not used and

before performing maintenance.

• Do not smoke during battery charging.

9

!

ATTENTION!

• Remove the ignition key to prevent unauthorised use of the machine.

• Do not leave the machine unattended without being sure that the machine cannot move independently.

• Always protect the machine from the sun, rain and other weather when in operation or stopped status. Store the

machine indoors, in a dry environment: this machine is only for dry use and should not be used or kept outdoors in

humid conditions.

• Close all doors and/or covers before using the machine, as indicated in the Operator manual.

• Do not let the machine be used as a toy. Pay careful attention when using it near children.

• Do not use the machine for purposes other than those indicated in this manual. Only use accessories recommended

by the manufacturer RCM.

• Take the appropriate precautions so that hair, jewellery, and loose clothing are not caught by the machine's moving

parts.

• Do not use the machine on sloping surfaces with an angle greater than the one stated on the identi cation plate so

as not to jeopardise stability and safe operation.

• Do not use the machine in especially dusty environments.

• Only use the machine in su ciently-lit areas.

• If the machine is used in the presence of other people, in addition to the operator, use of the rotating light and reverse drive buzzer (optional) are necessary.

• Make sure people and objects are safely protected during use of this machine.

• Do not knock shelving or sca olding, especially if there is danger of falling objects.

• Do not place containers of liquid on the machine.

• The operating temperature of the machine must be between 0°C and +40°C.

• The storage temperature of the machine must be between 0°C and +40°C.

• The humidity must be between 30% and 95%.

• When using detergents to clean the oor, follow the instructions and warnings on their containers.

• Use suitable gloves and protective devices when handling oor cleaning detergents.

• Do not use the machine as a transport vehicle.

• Do not let the brushes operate with the machine stopped to avoid damaging the oor.

• In case of re, use a powder extinguisher instead of a water one.

• For no reason at all must you tamper with the protections provided for the machine; carefully follow the routine

maintenance instructions.

• Do not let any object enter the machine's openings. Do not use the machine if the openings are blocked; keep the

machine's openings free from dust, lint, hair and any other foreign body that may reduce air ow.

• Do not remove or alter the labels a xed by the machine's Manufacturer.

• Release the electromagnetic brake too manually push the machine.

• Never use the machine with the electromagnetic brake deactivated.

• If the machine is pushed (due to no batteries, at batteries, faults, etc.), never exceed a speed of 4 Km/h.

• This machine is not approved for use on public roads.

• When moving the machine with temperatures below freezing point, be careful as the water in the tanks or in the

tubes may freeze and seriously damage the machine.

• Only use brushes and pads supplied with the machine and those speci ed in the Instruction and maintenance manual. Use of other brushes or pads may compromise safety.

• If faults in operation occur, make sure they do not depend on lack of maintenance. Otherwise request intervention

by authorised personnel or by the Service Centre.

• For replacement of parts, request ORIGINAL spare parts from an authorised Dealer or Seller.

• For safety purposes as well as proper operation, planned maintenance must be carried out by authorised personnel

or by an authorised Service Centre as per the speci c chapter in this manual.

• Do not wash the machine with direct or pressurised water jets or with corrosive substances.

• If lead batteries (WET) are installed in the machine, do not incline it beyond 30° compared to the horizontal surface

in order to prevent any highly corrosive liquid leaks from the batteries. If the machine needs to be inclined for maintenance, rst remove the batteries.

• The machine must not be abandoned at the end of its life cycle due to the presence within of toxic and harmful

materials (batteries, etc.), which are subject to standards that require disposal in special centres (see the Scrapping

chapter in the Instruction and maintenance manual).

• In conditions of use compliant with the indications of proper use, vibrations are not liable to give rise to dangerous

situations. The machine's level of vibrations is within the limits provided by law.

10

DESCRIPTION OF THE MACHINE

Structure of the machine

1. Steering wheel.

2. Ignition key. “0” o , “I” on.

3. Gear start and acceleration pedal.

4. Detergent solution (or washing water) level indicator.

5. Front, traction and steering wheel with electromagnetic

brake.

6. Rear wheels.

7. Disc brush, or pad holder disc (KILO with disc brushes

base)

8. Batteries connector.

9. Squeegee.

10. Brush(es) base.

11. Detergent solution (or washing water) tank.

12. Recovery water tank.

13. Tanks cover.

14. Tanks cover lifting grip.

15. Operator's seat.

16. Protective panel of electrical-electronic compartment.

17. Detergent solution (or washing water) lter.

18. Heel cushion.

19. Recovery water tank pipe level

20. Detergent tank (DETERSAVER - upon request) (*).

21. Detergent tank cap (DETERSAVER - upon request) (*).

(*) = Automatic “5-litre tank” detergent feeding system (DETERSAVER) parts.

22. Detergent solution (or washing water) tank cap.

23. Recovery water emptying tube.

24. Washing water drain tap.

25. Batteries holder case.

26. Flashing light (upon request).

27. Slot for (recovery water), breakwater protection

wall (antisplash feature).

28. Storage container.

29. Side pins indicating brush(es) height.

30. Connector connecting the machine’s battery

charger to the electrical mains (upon request).

31. Recovery water tank.

32. Recovery water tank oat.

33. Suction inlet (with vacuum motor protection).

34. Recovery water inlet (with debris recovery tray).

35. Batteries.

31

32

33

34

27

35

8

30

1

2

3

5

6

9

7

10

11

12

13 14

15

16

18

17

4

24

26

20

21

22

23

25

28

29

19

11

Steering wheel with control and commands panel

1. Control and commands panel

2. Emergency stop button

3. Display showing:

• 3a = “Ready”: the machine is ready or “Sit Down” (sit in the seat)

• 3b = Total operating hours

• 3c = Power status of the batteries in %

• 3d = Power status of the batteries in graphic scale

4. Adjustment buttons (+ and -) for ow of detergent solution (or washing water) (*).

5. Luminous indication for ow of detergent solution (or washing water).

6. Adjustment buttons (+ and -) for percentage of detergent depending on the ow of washing water (upon

request) (*)

7. Luminous indication for percentage of detergent (upon request).

8. Button for turbo, activation of maximum ow of detergent solution (or washing water and detergent) ; activation remains operative for 30 seconds.

9. Luminous indication of the passage of 30 seconds.

10. Adjustment button for maximum machine speed; each time it is pressed, it increases the speed (*).

11. Luminous indication for machine instantaneous speed.

12. Button for activating lowering and rotation of the disc brush.

13. Luminous indication of the disc brush activated; the luminous indicator ashes when switching from deactivated to activated and vice versa.

14. Button to activate lowering of the squeegee and recovery water suction.

15. Luminous indication of the squeegee and suction activated; the luminous indicator ashes during switch from

deactivated to activated and vice versa.

16. Button for simultaneously activating the squeegee and suction and the disc brush.

17. Luminous indication of the squeegee, suction and disc brush activated; the luminous indicator ashes during

switch from deactivated to activated and vice versa.

18. Button to activate reverse drive. The speed is halved compared to the forward drive. For the time of activation

of the reverse drive, a horn sounds. During reversing, the squeegee automatically lifts to avoid damage.

19. Luminous indication of the reverse drive activated.

20. Button to activate the buzzer.

21. Button to release the disc brush.

(*): Upon machine start-up with the key, these adjustments are placed on the values set previously.

1

2

3

3A

3B

3C

3D

4

5

6

7

8

9

10

11

12

13

141516

17

18

19

2021

12

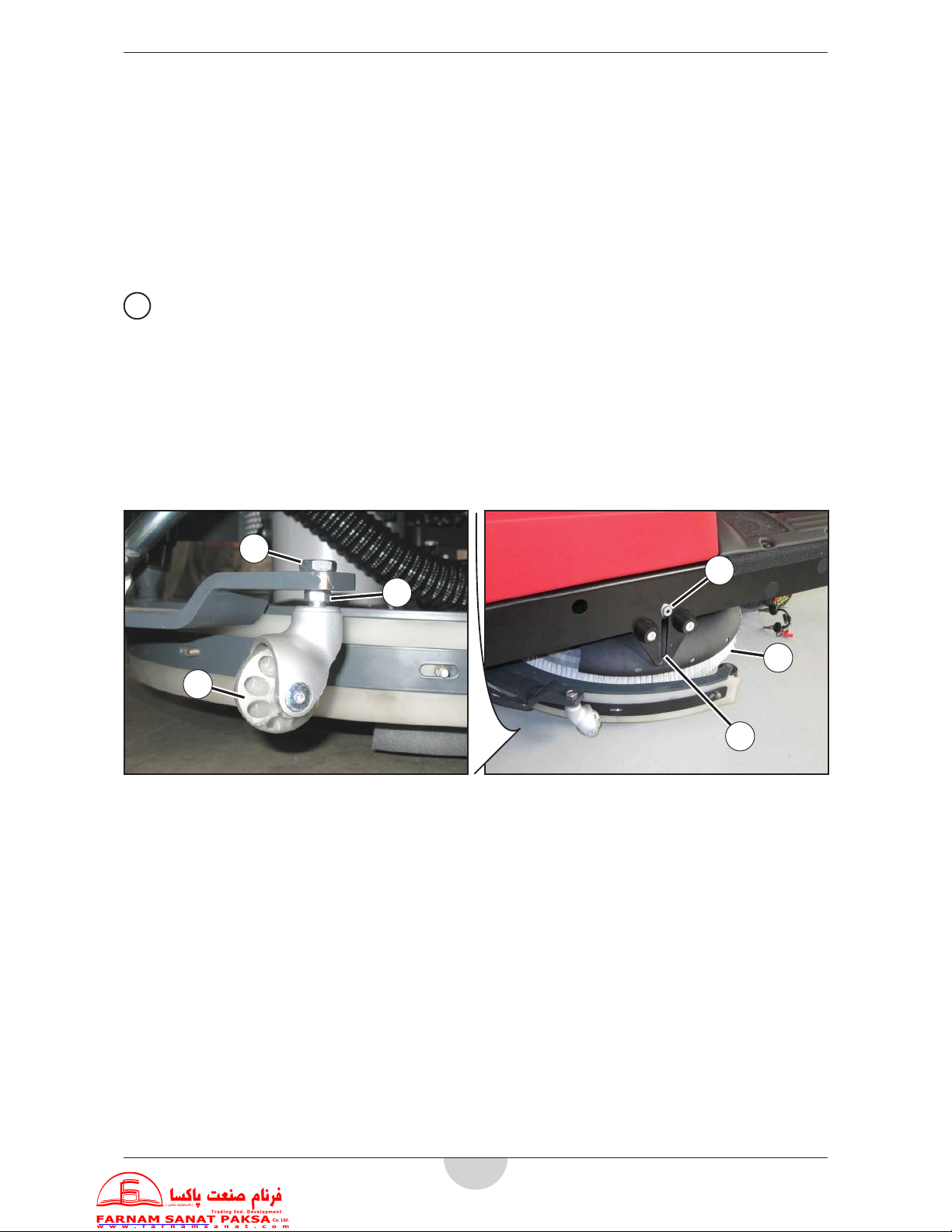

Safety functions

The machine is equipped with the safety functions described as follows.

Electromagnetic brake

The electromagnetic brake (A) is integrated in the front

wheel's traction system and keeps the machine braked

when it is turned o and when it is on but stopped.

The key (A1) locks/releases the brake.

(see chapters: “PUSHING/TOWING THE MACHINE” and

“ELECTROMAGNETIC BRAKE”.

Traction safety micro-switch

It is installed in the driver's seat in zone (B) and does not

allow any machine operation if the driver is not seated.

Emergency stop button

It is on the control and commands panel in position (C); it

is easily accessible by the operator.

It must be pressed rmly if urgently required in order to

stop all machine functions.

Turn it clockwise too release it and restore all machine

operations.

C

A

B

D

D

A1

A1

Anti-tipping tubes

These are two tubes (D) on the right and left front parts

of the frame that prevent the machine from tipping over.

13

TECHNICAL DATA

Description

S02

(Disc brush base)

Voltage 24V

Cleaning width 530 mm

Drying width 600 mm

Vacuum 1168 mm H2O

Detergent solution (or washing water) tank capacity 65 L

Disc brush rpm 175 rpm

Number of disc brushes 1

Disc brush pressure 23 Kg

Washing speed 4 Km/h

Maximum speed 5 Km/h

Maximum working angle 10%

Batteries (nr.) 2 - 118Ah

Built-in battery charger √ (Upon request)

Max. washing capacity 2120 m²/h

Autonomy (hours) based upon 118 Ah batteries 2. 30’

Detersaver √ (Upon request)

> Mixing ratio 1-5%

Machine body dimensions with squeegee and brush

(length x height x width)

1340 x 1130 x 600 mm

Basic weight of the empty machine in operation

(with 118Ah batteries, with tanks empty, without operator on board)

235 Kg

Gross weight of the ready machine

(with 118Ah batteries, with full solution tank, without operator on board)

300 Kg

Drive motor 400 W

Disc brush motor 400 W

Vacuum motor 400 W (3 stages)

Manufacturing legislation EC

Sound pressure level (A) in operating position 72.4 dB (A)

14

ACCESSORIES AND COMPONENTS UPON REQUEST

• Disc brushes in materials other than standard ones (See the chapter regarding Use the diagram for selection of

type of disc brush).

• Pad holder driving disc (A) and pad (B) (See the chapter regarding Use the diagram for selection of type of pad).

• Squeegee rubbers in materials other than standard ones (See the chapter regarding Use the diagram for selection of

type of squeegee rubbers).

• Front and rear wheels in di erent materials.

• Automatic detergent feeding system (C) (DETERSAVER based upon 5-Litre tank).

• Breakwater protection wall for the recovery water tank (antisplash feature).

• Flashing light (E).

• Kit (F) for lling the tank with detergent solution (or washing water).

• Lead batteries (WET) support

• Di erent types of batteries.

• Anti-tipping tubes (G)

B A

G

E

F

C

15

WIRING DIAGRAM 1/2

Description of electrical components

7CH4Q90A: Traction board

7CFI0000: Functions board

BA: Battery

CB: Battery charger

RC: Battery charger relay

FE: Emergency stop button

EV: Water solenoid valve (brushes)

TX2: Traction board TX serial connection

RX1: Battery charger RX serial connection

RX2: Traction board RX serial connection

K1: Brush contactor

K2: Suction contactor

K3: Brush release contactor

K4: Brush contactor NA contact

K5: Suction contactor NA contact

K6: Brush release contactor NA contact

M: Drive motor

M3: Chemical (detergent) pump

M4: Water pump

M1: Brush actuator

M2: Squeegee actuator

SP: Brush motor

ASP: Vacuum motor

SWC: Start-up key switch

SWG: Water oat

SWM: Seat micro-switch

BR: Reverse drive buzzer

LAMP: Flashing

P - SPEED REFERENCE: Accelerator potentiometer

F1: 80A midi fuse (traction)

F2: 10A blade fuse (auxiliaries)

F3: 30A midi fuse (vacuum)

F4: 40A midi fuse (brush)

16

WIRING DIAGRAM 2/2

17

PUSHING/TOWING THE MACHINE

When traction cannot be used (no batteries, at batteries, faults, etc.), the electromagnetic brake must be released as

follows to push/tow the machine:

• Insert the key (A1) in the appropriate seat (A2) and completely tighten it. During this operation, gently push

the machine back and forth to facilitate releasing the electric brake and thus be able to manually move the

machine.

Never exceed a speed of 3 Km/h during pushing/towing.

• When nished, unscrew and remove the key to apply the brakes again and bring the machine back to safe conditions. Store the key in a safe place and within reach in the event the machine has to be moved.

!

ATTENTION!

After having moved the machine and to reactivate the electromagnetic brake (A), always remember to remove

the key (A1). Check that the electromagnetic brake is reactivated by pushing the machine and verifying the

condition of the brakes.

!

ATTENTION!

Never turn the machine on with the key (A1) in released electromagnetic brake position. Release the electromagnetic brake only for the time required to move the machine.

AA1

A2

A1

18

USE

!

ATTENTION!

Adhesive labels are applied to some points of the machine, indicating:

• DANGER

• ATTENTION

• WARNING

• CONSULTATION

During reading of this manual, the operator must carefully understand the meaning of the symbols shown on the

labels. Do not cover the labels for any reason and immediately replace them if damaged.

BATTERIES

Check/Installation of batteries on a new machine

!

ATTENTION!

This machine's electrical components may become severely damaged if the batteries are not installed and

connected properly. The batteries must be installed only by quali ed personnel.

The machine must also be set, according to the batteries used: WET, GEL, AGM.

Check the batteries before installing them to make sure they are not damaged.

Disconnect the batteries connector and the battery charger's plug.

Handle the batteries carefully.

Install the protective caps of the batteries' terminals.

The machine can be supplied in one of the following con gurations:

• With batteries (WET or GEL or AGM) already assembled on the machine and ready for use.

• Batteries not supplied

Depending on the type of supply received, operate as follows.

a) Batteries (WET or GEL or AGM) already assembled on the machine and ready for use.

1. The machine is suitable for use.

b) Batteries not supplied

2. Purchase suitable batteries (See the Technical features paragraph).

Contact quali ed dealers of batteries for selection and installation.

Batteries installation/replacement

This intervention must be performed by a specialised technician; refer to the Authorized Service Center.

Setting of type of batteries installed

This intervention must be performed by a specialised technician; refer to the Authorized Service Center.

19

PRELIMINARY OPERATIONS BEFORE STARTING THE MACHINE

!

ATTENTION!

At each machine start-up, check that there are no foreign bodies between the brush base (A) and the machine,

or between the squeegee (B) and the machine, that may obstruct the brushes base and the squeegee from lifting. This check is necessary if the machine has been turned o without the brush holder base and the squeegee being lifted; when it is turned back on the brushes base and the squeegee automatically lift.

ELECTROMAGNETIC BRAKE

BRAKING is assisted by the electric brake (1). THE electric brake is integrated in the traction system of the front inwheel electric motor 2 and keeps the machine braked when it is o or when it is on but stopped. The electric brake is

equipped with a key 3 to unlock and manually move the machine when it is stopped. (for example: when the battery

is missing). Also see chapter: “PUSHING/TOWING THE MACHINE”.

!

ATTENTION!

The machine does not brake if the electromagnetic brake is released.

NEVER USE THE MACHINE WITH THE BRAKE RELEASED.

1

2

3

A

B

20

BRUSHES

Disc brushes (only for KILO disc brush base)

Proceed as follows for assembly/disassembly of the disc brush (A) on the machine provided with appropriate base:

!

ATTENTION!

Always check there are no foreign bodies between the base (J) and the machine, which can obstruct lifting of

the base, before activating the ignition key (B).

Assembly of disc brush

1. Sit on the machine seat and rotate the ignition key (B) to “I”, then wait a few seconds until the caption (D)

“Ready” appears on the display (C).

2. Wait for the brush base (J) to lift and the luminous indication (I) to turn o .

3. Rotate the ignition key (B) to “0” and extract it.

4. Position the disc brush (A) under the base (J), centring it on the coupling hub.

5. Sit on the machine seat and rotate the ignition key (B) to “I”, then wait a few seconds until the caption (D)

“Ready” appears on the display (C).

6. Press the activation button (E) to lower and rotate the brush.

7. Press the accelerator (F) lightly and only for an instant, thereby lowering the hub that will couple the brush.

If the brush is not coupled climb down from the machine and reposition the brush on the coupling hub,

which should have remained lowered (thereby easing alignment); then repeat the operations described in the

previous points 5, 6 and 7.

8. The disc brush (A) is coupled and ready for use; if necessary, turn the machine o by rotating the ignition key

(B) to “0” and extract it.

Disassembly of disc brush

1. Sit on the machine seat and rotate the ignition key (B) to “I”, then wait a few seconds until the caption (D)

“Ready” appears on the display (C).

2. Press the brush release button (G) and wait for a few seconds until the machine has released the brush after

having activated it for an instant.

3. Rotate the ignition key (B) to “0” and extract it.

4. Slightly move the squeegee (H) and recover the disc brush.

!

ATTENTION!

Use of the machine with the brush not perfectly assembled can cause injury to people and damage to equipment.

Always ensure all components have been assembled before starting the machine. Carefully

inspect the machine before using it.

A J

H

F

B

A

G

D

C

I

E

21

Selection of type of disc brush

Selection of the most appropriate brush is essential for cleaning surfaces.

You can clean more quickly with the proper brush; furthermore, the cost savings from this increase in productivity

can be substantial.

!

WARNING!

A less than optimal selection could damage the oor surfaces. If in doubt, contact the RCM representative.

NOTE!

The table below shows a selection of the most used products. For special requirements, contact the RCM representative.

SELECTION TABLE OF TYPE OF DISC BRUSHES

Type of disc brush

Union

Mix

Prolite Prolene

Aglite

Grit

500

MidGrit

240

MidLite

Grit

180

Dyna

Grit 80

Magna

Grit 46

Floors/Aggressiveness

Light

Medium

Light

Medium Medium

Medium

Strong

Strong

Ver y

Strong

Aggressive

Linoleum √√√√

Vinyl √√√√ √√

Rubber √√√

Polyole n √√

Ceramic √√√√√

Non-slip √√√√

Stone √√√√

Terracotta √√√√

Terrazzo √√√√√

Concrete √√√√√√

Marble √√

Granite √√

Floor in epoxy resin √√√

Concrete √√√√√

22

Pad holder driving disc (only for KILO versions with disc brush base)

Proceed as follows for assembly/disassembly of the pad holder driving disc (A) with pad (B) on the machine provided

with appropriate base:

Tighten/loosen the ring nut (C) to assemble/disassemble the pad (B) on the pad holder driving disc (A).

!

ATTENTION!

Always check there are no foreign bodies between the base (E) and the machine, which can obstruct lifting of

the base, before activating the ignition key (D).

Assembly of pad holder driving disc

1. Sit on the machine seat and rotate the ignition key (D) to “I”, then wait a few seconds until the caption (H)

“Ready” appears on the display (G).

2. Wait for the base (E) to lift and the luminous indication (I) to turn o .

3. Rotate the ignition key (D) to “0” and extract it.

4. Position the pad holder driving disc (A) with pad (B) under the base, centring it on the coupling hub.

5. Sit on the machine seat and rotate the ignition key (D) to “I”, then wait a few seconds until the caption (H)

“Ready” appears on the display (G).

6. Press the activation button (J) to lower and rotate the pad holder driving disc.

7. Press the accelerator (K) lightly and only for an instant, thereby lowering the hub that will couple the pad

holder driving disc.

If the pad holder driving disc is not coupled climb down from the machine and reposition the pad holder

driving disc on the coupling hub, which should have remained lowered (thereby easing alignment); then

repeat the operations described in the previous points 5, 6 and 7.

8. The pad holder driving disc (A) is coupled and ready for use; if necessary, turn the machine o by rotating the

ignition key (D) to “0” and extract it.

!

ATTENTION!

Use of the machine with the pad holder driving disc not perfectly assembled can cause injury to people and

damage to equipment.

Always ensure all components have been assembled before starting the machine. Carefully inspect the machine before using it.

Disassembly of pad holder driving disc

1. Sit on the machine seat and rotate the ignition key (D) to “I”, then wait a few seconds until the caption (H)

“Ready” appears on the display (G).

2. Press the pad holder driving disc release button (L) and wait for a few seconds until the machine has released

the pad holder driving disc after having activated it for an instant.

3. Rotate the ignition key (D) to “0” and extract it.

4. Slightly move the squeegee (M) and recover the pad holder driving disc.

A E

M

K

D

C

L

H

G

I

J

A

C

B

23

Selection of type of pad holder driving disc

Selection of the most appropriate pad is essential for cleaning surfaces.

You can perform the activity more quickly with the proper pad; furthermore, the cost savings from this increase in

productivity can be substantial.

!

WARNING!

A less than optimal selection could damage the oor surface. If in doubt, contact the RCM representative.

NOTE!

The table below shows a selection of the most used products. For special requirements, contact the RCM representative.

SELECTION TABLE OF TYPE OF PAD

FOR PAD HOLDER DRIVING DISC

Type of pad

Aggressiveness

Light

Medium

Light

Medium

Medium

Hard

Rough

Ver y

Rough

Crystallising

Polishing

Floors/Colour code

White Red Blue Green Brown Black Grey Beige

Linoleum √√√√ √

Vinyl √√√ √√ √

Rubber √√

Polyole n √

Ceramic √√√√

Non-slip √√√√

Stone √√√√

Terracotta √√√√

Terrazzo √√√√√ √√

Concrete √√√√√

Marble √√ √√

Granite √√√ √√

Floor in epoxy resin √√

24

SQUEEGEE

Proceed as follows for assembly/disassembly of the squeegee (A) on the machine:

!

ATTENTION!

Always check there are no foreign bodies between the squeegee (A) and the machine, which can obstruct lifting of the squeegee, before activating the ignition key (B).

Assembly of squeegee

1. Sit on the machine seat and rotate the ignition key (B) to “I”, then wait a few seconds until the caption (D)

“Ready” appears on the display (C).

2. Wait for the squeegee (A) to lift and the luminous indication (E) to turn o .

3. Rotate the ignition key (B) to “0” and extract it.

4. Operate on the left side of the machine to rotate the squeegee's support bracket (F) forward.

5. Position the squeegee (A) on the support bracket (F) and engage the pin (G) in the hole (H) of the squeegee.

Tighten the squeegee xing knob (I).

6. Connect the suction pipe (J) to the inlet (K) of the squeegee.

7. Rotate the squeegee unit inwards towards the machine, in a central work position.

8. The squeegee (A) is coupled and ready for use; if necessary, turn the machine o by rotating the ignition key

(B) to “0” and extract it.

!

ATTENTION!

Use of the machine with the squeegee not perfectly assembled can cause injury to people and damage to

equipment.

Always ensure all components have been assembled before starting the machine. Carefully inspect the machine before using it.

Disassembly of squeegee

1. Sit on the machine seat and rotate the ignition key (B) to “I”, then wait a few seconds until the caption (D)

“Ready” appears on the display (C).

2. Wait for the squeegee (A) to lift and the luminous indication (E) to turn o .

3. Rotate the ignition key (B) to “0” and extract it.

4. Operate on the left side of the machine to rotate the squeegee's support (F) forward and loosen its xing knob

(B).

5. Disconnect the suction pipe (J) from the squeegee's inlet (K).

6. Remove the squeegee (A) by disengaging its hole (H) from the pin (G) of its support.

D

C

E

K

H

A

B

JG

IA

I

J

25

Selection of type of squeegee rubbers

Selection of the most appropriate rubbers is essential for cleaning surfaces.

You can perform the activity more quickly with the proper rubbers; furthermore, the cost savings from this increase

in productivity can be substantial.

NOTE!

The table below shows a selection of the most used products. For special requirements, contact the RCM representative.

SELECTION TABLE OF TYPE OF RUBBERS FOR SQUEEGEE

Type of oor/Colour of

rubbers

(Polyure-

thane)

SH35

(Linatex)

SH35

(Natural

rubber)

SH33

(Natural

rubber)

SH37

(Natural

rubber)

SH40

Floor with fatty oil, acids. √

Quartz concrete oor, rough

oor and oor without joints

(without joints between the

tiles).

√

Floor with joints (with joints between the tiles); very thorough

drying of the oor.

√

Floor with joints (with joints between the tiles); average drying

of the oor.

√

Floor with joints (with joints between the tiles); light drying of

the oor.

√

Installation/removal of squeegee rubbers

See the procedure in the Maintenance chapter for installation/removal of the squeegee's rubbers.

26

TANKS

Checking the recovery water tank

Lift the cover (A) using its grip (B) and check that the recovery water tank (C) is empty, otherwise empty it as described

in the speci c paragraph “Emptying of tanks”.

Filling the detergent solution tank with water (or washing water)

The tank can be lled in one of the following ways, depending on the inlet version on the machine.

!

WARNING!

The temperature of the water inserted in the tank must not exceed 40°C (100°F).

!

WARNING!

Use a proper detergent for the type of cleaning to be carried out.

Only use low foam and non- ammable liquid detergents; suitable for the machine to be used.

During use of detergents for cleaning oors, follow the instructions and warnings on the labels.

Use suitable gloves and protective devices before handling oor cleaning detergents.

Inlet in basic version

1. Unscrew the cap (D) and pour water in through its inlet.

2. After lling, screw the cap (D).

Inlet in version with lling kit

1. Extract the lling kit (F), put the opening (G) under a water tap and ll the tank through the inlet (E)

2. After the lling stage, place back the kit (F) in its seat (E).

B

A

C

D

E

F

G

27

Installation/Filling 5-litre detergent tank (“DETERSAVER” - Upon request)

(version with automatic detergent feeding system)

!

WARNING !

Use a proper detergent for the type of cleaning to be carried out.

Only use low foam and non- ammable liquid detergents; suitable for the machine to be used.

During use of detergents for cleaning oors, follow the instructions and warnings on the labels. Use suitable gloves

and protective devices before handling oor cleaning detergents.

1. Put the tank (1) in its support (2).

2. Connect the detergent pump tube (3) to the tank’s lid (4).

3. Use the elastic strap (5) to x the tank (1) to the support (2).

4. Open the lid (4) and ll up the tank with detergent.

1

2

3

4 5

28

STARTING AND STOPPING THE MACHINE

Starting the machine

1. Prepare the machine as described in the previous paragraph.

2. Sit on the machine seat (A).

3. Rotate the ignition key (B) to “I”, then wait a few seconds until the caption (D) “READY” appears on the display

(C).

!

ATTENTION!

Do not rotate the ignition key (B) without rst sitting on the seat (A) as a safety system allows the machine to

be used only when the operator is sitting on the seat (A).

It is strictly forbidden to tamper with the seat's safety system or to simulate in any way the operator sitting on

the seat.

If the ignition key (B) is rotated without sitting on the seat, the caption “SIT DOWN” appears in zone (D) on the display

and no other machine function is available.

When the display shows indications other than those described, an intervention is required from the RCM Service

Centre.

4. Check the battery charging status by observing the percentage (E) and relative graphic (F).

Charge the batteries if necessary; see the procedure in the Maintenance chapter.

!

ATTENTION!

The machine is not suitable for use on uneven oors.

5. Go to the work area by starting the machine with your hands on the steering wheel and pressing the pedal

(G). The forward speed is adjustable from zero to its maximum set value, based on the pressure exerted on the

pedal (G).

6. To activate reverse drive of the machine when required, release the pedal (G) and when the machine has

stopped press button (H).

7. If required, use buttons (I) to adjust the ow of the detergent solution (or washing water).

8. (Upon request) If required, use buttons (J) to adjust the percentage of the washing detergent.

9. To start washing the oor, press button (L) to activate the brush(es).

10. To start drying the oor, press button (M) to activate the vacuum.

11. To start washing and drying the oor, press button (N).

12. To start polishing the oor with the pad, press button (L).

13. Start cleaning/polishing by moving the steering wheel (P) and moving the machine forwards by pressing the

pedal (G).

A

B

G

P

I

J

K

L

M N

F

CD

E

H

29

Stopping the machine

1. Release the pedal (G).

2. Press button (L) or (M) or (N) to deactivate and lift the respective active functions.

The vacuum stops a few seconds after the relative button has been pressed in order to vacuum all of the water

in the tube.

3. Rotate the ignition key (B) to “0” and extract it.

It is not necessary to lock the machine during stopping or parking as the electromagnetic brake on the front

wheel automatically brakes the machine when the accelerator is activated.

4. Empty the tanks, if necessary, as described in the speci c paragraph.

!

ATTENTION!

Do not leave the machine unattended without having removed the ignition key.

5. To immediately stop the machine in an emergency, press button (Q).

To release the emergency button (Q), rotate it clockwise until it is released from its lowered position.

MACHINE IN OPERATION

Adjustments and checks

1. Start the machine as described in the previous chapter.

2. If necessary, adjust the balance of the squeegee (T) (see the procedure in the Maintenance chapter).

3. If required, use buttons (I) to alter the ow of the detergent solution (or washing water).

4. (Upon request) If required, use buttons (J) to alter the percentage of the washing detergent.

5. If required, press the turbo button (R) to activate maximum ow of detergent solution.

6. If required, use button (K) to alter the maximum speed of the machine.

7. Periodically check the charging status of the batteries during work so as not to have at batteries in areas far

from any charging points. To charge the batteries, see the procedure in the Maintenance chapter.

8. If the recovery water tank lls during machine use, suction will automatically be stopped.

Empty the recovery water tank to restart suction (see the procedure in the speci c Paragraph).

9. Use the relative level indicator (S) to periodically check the residual quantity of detergent solution (or washing

water).

10. Empty the tank at the end of work if necessary (see the procedure in the speci c Chapter).

I

J

K

R

L

M N

Q

S

B

G

T

30

EMPTYING OF TANKS

Emptying of recovery water tank

1. Take the machine to the intended area for disposal of the recovery water, in compliance with the emission standards in force.

2. Rotate the machine's ignition key to “0” and extract it.

3. Disengage the tube (A) from its seat and lift it above the upper edge (B) of the tank until its zone (C) is free from

water, then keep it in this position and unscrew the cap (D).

4. Manually bend the tube in the zone (C) until a watertight bend (E) is obtained, then keep it bent and lower it on

the drain zone.

5. Gradually (to avoid unwanted splashes) release the bend (E) so that the dirty water ows from the tank into the

drain zone.

6. Use the grip (F) to lift the tank cover (G) and, if necessary, wash the recovery water from the tank (H) (see the

procedure in the Maintenance chapter).

7. Tighten the cap (D) and engage the tube (A) in the relative seat of the machine.

Emptying the detergent solution (or washing water) tank

1. Take the machine to the intended area for disposal of the detergent solution (or washing water), in compliance

with the emission standards in force.

2. Rotate the machine’s ignition key to “0” and extract it.

3. Open the tap (I) so that the detergent solution (or water) ows out from the tank into the drain zone.

4. If necessary, wash the detergent solution (or water for washing) tank after unscrewing the cap (P).

5. After washing the tank, close the tap (I) and screw the cap (P) back on.

!

Danger! Frost Hazard

With temperatures of 0°C or below, check and eventually fully remove water from tanks and hoses at the end

of each job or if the machine is unused for a certain period of time.

E

D

C

A

G

F

H

P

B

C

M

I

31

Emptying the 5-Litre detergent tank (Upon request - DETERSAVER)

To empty the tank 1, proceed as follows:

1. Remove the tube (3).

2. Remove the elastic strap (5).

3. Remove the tank (1) from its support (2).

4. Open the cap (4) and empty the tank in the area

designed for this purpose..

5. Clean the tube (3) and the parts of the detergent

feeding system (only in the event of prolonged inactivity of the machine).

6. Place back the tank by following the steps above

in reverse order.

1

2

3

4 5

32

Detergent solution (or washing water) tank level

• The level of the detergent solution (or washing water) in the relative tank is visible through the transparent

tube (A); the side indications (B) de ne the amount.

Recovery water tank level

• When the recovery water tank is full, the oat (C)

stops water suction; empty the tank to continue

suction (See the procedure on emptying the recovery water tank in the “Emptying of tanks” paragraph).

A

B

C

33

AFTER MACHINE USE

the following activities must be carried out at the end of work after machine use.

1. Remove and clean the brush(es) or pad holder, as described in the Maintenance chapter.

2. Empty the tanks, as described in the speci c paragraph.

3. Remove and clean the squeegee, as described in the Maintenance chapter.

4. Recharge the batteries if necessary, as described in the Maintenance chapter.

5. Store the machine in a dry and clean place with the brush(es) or pad holder and squeegee raised.

LONG DOWNTIME OF MACHINE

If the machine is not to be used for more than 30 days, you must:

1. Follow what is indicated in the “After machine use” paragraph.

2. Clean the detergent feeding system (DETERSAVER - upon request), as described in the “Emptying the 5-Litre

detergent tank” section.

3. Disconnect the connector of the batteries, as described below.

• extract the left pin (A), then rotate it a half turn to lock it in the extracted position.

• extract the right pin (B) and keep it in the extracted position.

• use the handle (C) to extract the batteries holder case (D).

• disconnect the connector (E) of the batteries.

• put the batteries case (D) in its seat, unlock it, and engage it to retainer (B) and to retainer (A).

4. Store the machine in a dry and clean place with the brush(es) or pad holder and squeegee removed or raised.

DA

B

D

C

E

34

FIRST PERIOD OF USE

After the rst 8 hours of use, you must:

• Check the tightening of the machine's fastening and connection parts.

• Check that the visible parts are intact and do not leak.

MAINTENANCE

The service life of the machine and its maximum operating safety are ensured by careful and regular maintenance.

The planned maintenance table is shown below. The schedule shown may vary depending on the particular work

conditions, to be de ned by the maintenance manager.

!

ATTENTION!

The operations must be carried out with the machine o and the batteries disconnected.

All instructions in the Safety paragraph must also be carefully read.

All planned maintenance or repairs must be carried out by quali ed personnel or be done at an Authorised Service

Centre.

Only the easiest and more frequent maintenance procedures are described in this manual, after the planned maintenance table.

NOTE!

For the procedures of the other maintenance operations foreseen in the planned maintenance table and for

the other repair procedures, contact the authorized technical service centre.

PLANNED MAINTENANCE TABLE

Operation

Daily

(after machine

use)

Monthly

(or every 100

hours)

Twice-yearly

(or every 400

hours)

Yearly

(or every 800

hours)

Cleaning the squeegee.

√

Cleaning the disc brush or pad holder driving disc.

√

Cleaning the tanks (see speci c chapter).

√

Charging the batteries

√

Checking/replacing the squeegee rubbers.

√

Cleaning the detergent solution (or washing water)

lter

√

Cleaning the detergent solution supply nozzle.

√

Checking the e ciency of the electromagnetic

brake.

√ (1)

Checking the screws and nuts are tightened.

√ (1) (2)

Checking the suction lter (Hepa).

√ (2)

Checking/replacing rotation belt of the brush(es)

√ (2)

Checking/cleaning traction chain

√ (2)

(1) :

and after the rst 8 hours of operation.

(2) : maintenance to be carried out by an authorised RCM Service Centre.

35

Check of machine operating hours

1. Sit on the machine seat.

2. Rotate the ignition key to “I”, then wait a few seconds until the caption (B) “READY” appears on the display (A).

3. Zone (C) displays the number of machine operating hours.

4. Rotate the machine's ignition key to “0” and extract it.

Cleaning the squeegee

NOTE!

The squeegee must be clean and the rubbers in good condition for the oor to be well-dried.

!

WARNING!

It is advisable to use protective gloves when cleaning the squeegee since there can be sharp debris.

1. Disassemble the squeegee, if necessary (See procedure in the speci c paragraph).

2. Wash and clean the squeegee (D); clean the compartments (E) and the recovery water passage hole (F) from

dirt and debris.

Check that the front rubber (G) and the rear rubber (H) are intact and have no cuts or tears, otherwise replace

them (see the procedure in the speci c paragraph).

3. Reassemble the squeegee if disassembled (See procedure in the speci c paragraph).

E

B

A

C

D

E

E

F

G

H

36

Check of squeegee rubbers

1. Disassemble and clean the squeegee, as described in the speci c paragraph.

2. Check that the front rubber (A) and the rear rubber (B) are intact and have no cuts and tears, otherwise replace them as described below.

Also check that the front edge (C) of the rear rubber (B) is not worn; otherwise detach the rubber and reverse

it, moving one of the other three edges (if still intact) to the front edge (C) position. Replace the rear rubber if

the other three edges are also worn, as described below.

Replacement of rear squeegee rubber

1. Disengage the safety retainer (D) and open the eccentric (E), then disengage it from the hook (I).

2. Loosen the terminal nuts (F).

3. Remove the retaining strip (G) by disengaging it from the pin nuts (F) and from the pins (H).

4. Remove the terminal strip (J).

5. Replace (or reverse) the rear rubber (B) then reassemble the removed parts, operating in reverse order to removal.

Replacement of front squeegee rubber

1. Unscrew the self-locking nuts (K) on the inside of the squeegee.

2. Remove the retaining strip (L).

3. Replace the internal rubber (A), then reassemble the removed parts, operating in reverse order to removal.

Rearrangement of the squeegee

1. Reassemble the squeegee, as described in the speci c paragraph.

2. Adjust the height of the squeegee if necessary, as described in the speci c paragraph.

B

F

F

J

I

D E

G

B

A

C

F

DE

G

H

K

L

A

H

H

K

A

L

B

37

Squeegee height adjustment

Adjustment of the squeegee height is necessary when the machine does not dry properly, leaving trails of water in

the central or external areas.

• To adjust the height, loosen the locknut (A) and adjust the height of the wheel (B) with the hex wrench (C);

tighten the locknut (A) when adjusted.

Repeat the operation on the wheel on the other side of the machine.

Cleaning the disc brush

!

WARNING!

It is advisable to use protective gloves when cleaning the disc brush because there can be

cutting debris.

1. Disassemble the disc brush if necessary (See procedure in the speci c paragraph).

2. Wash and clean the disc brush (D) from dirt and debris.

3. Reassemble the disc brush if disassembled (See procedure in the speci c paragraph).

4. The disc brush must be replaced for excessive wear when, with the brush lowered, the side pins (E) rest on the

lower ends (F) of the slots.

E

F

D

A

C

B

38

Cleaning the recovery tank

1. Take the machine to the intended area for disposal of the recovery water, in compliance with the emission

standards in force.

2. Rotate the machine's ignition key to “0” and extract it.

3. If there is recovery water in the tank, empty it (see procedure in the Use chapter).

4. Use the grip (F) to lift the tank cover (G) and wash the recovery water from the tank (H).

Remove the breakwater protection wall from its slots (P) and wash it, then put it back in its slots.

Also wash the underneath (I) of the cover and the entire perimeter gasket (J).

Check that the perimeter gasket (J) is intact: if it is damaged it may compromise correct operation of the recovery water suction.

!

WARNING!

Do not damage the oat (K)

5. Extract the recovery water inlet (L) from its seat and wash it, then put it back in its seat.

6. Extract the suction inlet (M) from its seat and clean and wash it; also clean its drain hole (N) from dirt.

Be careful that no water enters the suction inlet (M) seat (so as not to damage the vacuum motor).

Let the suction inlet (M) drip and then put it back in its seat.

7. Make all of the washing water ow from the tube (Q). Tighten the cap (R) and engage the tube (Q) in the relative

seat of the machine.

8. Close the tank cover (G).

G

F

J

I

H

P

M

K

L

N

M

R

Q

39

Cleaning the suction lter

1. Remove the vacuum motor (see procedure in the speci c paragraph).

2. Remove the suction lter (A) from the support (B).

3. Clean the suction lter with a brush and compressed air (max. 5 Bar). Replace the lter if worn.

!

ATTENTION!

Appropriately protect body parts (eyes, hair, hands, etc.) when cleaning with compressed air or water guns.

4. Assemble, following the disassembly operations in reverse.

Cleaning the detergent solution (or washing water) lter

1. With the machine's controls, lower the squeegee and the disc brush, then turn the ignition key to “0” and extract it (see Use chapter).

2. Operate on the right side of the machine to unscrew and remove the transparent cover with lter (D).

3. Remove the lter (E) from the transparent cover (F).

4. Clean the lter (E) and the transparent cover (F).

5. Replace the lter (E) in its transparent cover case (F).

6. Screw the transparent cover with lter (D) in its seat.

7. Rotate the ignition key to “I” and wait for the squeegee and the disc brush to lift, then rotate the ignition key to

“0” and extract it.

A

B

D

E

F

D

40

Cleaning the detergent solution supply nozzle to the disc brush

(KILO version with disc brush base)

1. Remove the brush (See procedure in the speci c paragraph).

2. By acting on the coupling hub (A) of the brush, unscrew the ring nut (B) and recover the nozzle (C) and the gasket

(D).

3. Clean the nozzle (C).

4. Place the nozzle (C) and the gasket (D) in their seat and then screw the ring nut (B).

5. Reassemble the brush (See procedure in the speci c paragraph).

!

ATTENTION!

Appropriately protect body parts (eyes, hair, hands, etc.) when cleaning with compressed air or water guns.

B

C

A

E

B E

C F

D

G

41

Opening/Closing of the batteries holder case and disconnection of the batteries connector

Proceed as follows to open the case and disconnect the connector:

1. Rotate the ignition key to “0” and extract it.

2. Operate on the rear side of the machine to extract the left pin (A), then rotate it a half turn to lock it in the extracted position.

3. Extract the right pin (B) and keep it in the extracted position.

4. Use the handle (C) to completely extract the batteries holder case (D), then engage the pin (B) on the relative

locking hole of the batteries case.

5. Disconnect the connector (E) of the batteries.

Proceed as follows for connection and closure of the case:

1. Reconnect the connector (E) of the batteries.

2. Disengage the pin (B) and carefully put the batteries case in its seat, then engage the pin (B) to the batteries

case.

3. Unlock and engage the pin (A) to the batteries case.

DA

B

D

C

E

42

Charging the batteries

!

WARNING!

Keeping the batteries charged lengthens their life.

!

WARNING!

When the batteries are at, make sure they do not remain in this condition for long as this would shorten their

life.

Check the battery charging status at least once a week!

!

WARNING!

For machines without on-board battery charger, use a battery charger suitable for the type of batteries installed.

!

ATTENTION!

Charging lead batteries with liquid acid (WET) produces highly explosive hydrogen gas. Only charge in areas

that are well-ventilated and far from open ames.

Do not smoke during battery charging.

Keep the batteries holder case in the extracted position during battery charging.

!

ATTENTION!

Be very careful when charging the lead batteries with liquid acid (WET) as small quantities of liquid could leak

from the batteries. This liquid is corrosive; if it comes into contact with the skin or eyes, wash abundantly with

water and immediately contact a doctor.

Charging the batteries, for machines with no on-board battery charger

(Using an external battery charger)

1. Take the machine to a suitable area to charge the batteries.

2. Open the batteries holder case and disconnect the batteries connector (see procedure in the previous paragraph).

3. Only for lead batteries (WET):

• check the correct level of the electrolyte inside the batteries (E); restore it through the cap (F) if necessary.

• leave all caps (F) open for subsequent charging.

• clean (if necessary) the upper surface of the batteries.

4. Check the suitability of the battery charger to be used by referring to its instructions. The nominal voltage of

the battery charger must be equal to 24V.

5. After disconnecting the batteries connector (G), connect the connector (H) to the external battery charger.

6. Connect the battery charger to the electrical mains.

The batteries start charging.

7. When they are charged, disconnect the battery charger from the electrical mains and from the batteries connector (H).

8. (only for lead batteries (WET)) Check the correct level of the electrolyte inside the batteries and close all the

caps (F):

9. Connect the batteries connector and close the batteries holder case (see procedure in the previous paragraph).

10. Charging is complete.

G

H

F

G

H

E

43

Charging the batteries, for machines with on-board battery charger (upon request)

1. Take the machine to a suitable area to charge the batteries.

2. Open the batteries holder case (see procedure in the previous paragraph) but do not disconnect the batteries

connector (D).

3. Only for lead batteries (WET):

• Check the correct level of the electrolyte inside the batteries (E); restore it through the cap (F) if necessary.

• Leave all caps (F) open for subsequent charging.

• Clean (if necessary) the upper surface of the batteries.

4. Connect the connector (G) to the electrical mains, after having checked that the mains nominal voltage is the one foreseen for charging the machine (Refer to the machine's technical data plate).

The batteries start charging.

NOTE!

When the battery charger is connected to the mains, all machine functions are automatically excluded.

5. Charging is complete when “100 %” is shown on the zone (H) of the display and the notches of the zone (I) are

all full.

6. Disconnect the electrical connection (G) from the mains.

7. Only for lead batteries (WET ) Check the correct level of the electrolyte inside the batteries and close all the caps (F).

8. Close the batteries holder case (see procedure in the previous paragraph).

9. Charging is complete.

E

F

G

D

H I

E

F

44

Check/Replacement of fuses

1. Open the batteries holder case and disconnect the batteries connector (see procedure in the previous paragraph).

2. Remove the screw (F) with a crosshead screwdriver and the panel (G) by taking it by the handle (as shown in the

photo) and disengaging it from its lower pins (H).

3. Check/replace the fuse:

• 10A fuse, for auxiliary services (I) protection

!

ATTENTION!

Request intervention of a quali ed technician or of the Service Centre for replacement of the other fuses.

4. Insert the panel (G) by engaging it in its lower pins (H).

5. Screw back the screw (F).

6. Extract the batteries case again and connect the batteries connector.

7. Connect the batteries connector and close the batteries holder case (see procedure in the previous paragraph).

I

G

H

F

45

Disassembly/assembly of the disc brush

• See the procedure in the “Use” chapter, “Preliminary operations before starting the machine” paragraph.

Disassembly/assembly of pad holder driving disc

• See the procedure in the “Use” chapter, “Preliminary operations before starting the machine” paragraph.

Disassembly/assembly of squeegee

• See the procedure in the “Use” chapter, “Preliminary operations before starting the machine” paragraph.

Disassembly/assembly of vacuum motor

Proceed as follows to disassemble the vacuum motor:

1. If available, place the machine on a raised platform, otherwise place it on a level oor.

2. With the machine's controls (as foreseen in the Use chapter), lower the brush and the squeegee, then rotate the

ignition key to “0” and extract it.

3. Open the batteries holder case and disconnect the batteries connector (see procedure in the previous paragraph).

4. Operate on the left side of the machine to unscrew the screws (A).

5. After having disconnected the electrical connector (C) of the vacuum motor, remove the support unit with the

vacuum motor and lter (B).

6. At the bench remove the soundproof gasket (D).

7. Cautiously remove the vacuum motor (E) by disengaging it from the suction lter (F).

Proceed as follows to assemble the motor:

• Reassemble, following the disassembly operations in reverse.

A

A

B

B

C

D

E

F

46

TROUBLESHOOTING

Problem Probable cause Solution

No luminous indicator lights up on

the panel; the motors do not work.

Battery connector (8 page 10) disconnected.

Connect connector.

Batteries at. Charge the batteries.

The emergency stop button (2 page

11) has remained pressed.

Release it.

Suction of the recovery water is insu cient.

Squeegee (9 page 10) dirty or squeegee rubbers worn or damaged.

Clean the squeegee or turn/

replace the rubbers.

Tank cover not closed

properly or gasket (J page 41) not

working.

Close the cover properly. Clean/replace the gasket.

There is no recovery water suction.

Recovery water tank full.

Empty the tank.

Hose (J page 26) disconnected from

the squeegee.

Connect hose.

Insu cient ow of detergent

solution (or washing water) to the

disc brush.

Detergent solution (E page 42) (or

washing water) lter dirty.

Clean lter.

Detergent solution (or washing water) outlet nozzle dirty.

Clean nozzle.

Detergent solution (or washing water) tank dirty.

Clean the tank.

No ow of detergent

solution (or washing water) to the

disc brush..

Detergent solution (or washing water) tank empty.

Fill the tank.

Detergent solution (E page 42) (or

washing water) lter clogged.

Clean the lter.

Detergent solution (or washing water) outlet nozzle clogged.

Clean the nozzle.

Insu cient/no ow of

washing detergent to the disc

brush. (For machine with DETER-

SAVER “upon request” detergent

feeding system).

Detergent ow percentage (%)

set too low

Increase percentage.

Detergent feeding system

clogged.

Clean the system.

The squeegee leaves dirty marks on

the oor.

Debris under the squeegee rubbers. Clean the squeegee.

Squeegee rubbers worn, chipped or

torn.

Turn the rubbers or replace them.

The squeegee does not lie correctly.

Adjust the height of the wheels

supporting the squeegee.

The disc brush does not clean.

Brushes excessively worn and do not

touch the oor, check:

Check the pins (E page 39) or the

pins (C page 40).

Replace the brushes.

For further information, contact RCM Service Centres.

47

SCRAPPING

!

ATTENTION!

This machine must not be disposed of with other domestic waste at the end of its life cycle.

To prevent any harm to the environment or to human health from uncontrolled waste disposal, we recommend the user to separate this product from other types of waste and recycle it responsibly to promote the

sustainable reuse of material resources.

Scrap this machine at an authorised demolition company.

Before scrapping the machine, remove and separate the following materials and send them to a waste collection

centre in compliance with the environmental health standards in force.

• Batteries

• Disc brush

• Tubes and parts in plastic

• Electrical and electronic parts (*)

(*): Especially for the scrapping of electrical and electronic parts, refer to the RCM area o ce.

Loading...

Loading...