1/10 Scale 4WD Electric off-road buggy

maintain and replace the spare parts,please keep and take it for reference.

The user who is not familar with the assembling,please contact with the

wholesaler,nominated model shops and the Special after-sale service

outlets.

This manual expatiate the structure of the model. In order to better

B - 10 E S pecification s

Leng th:

4 1 7m m

Width: 25 0 / 25 2 m m

Heig ht: 1 51m m

Whee l Base: 2 90m m

Gear R atio:9 .47:1

Tire Typ e: Φ8 7 x3 4 m m ( F ) Φ 8 7x39 m m ( R )

The Ma x. Ground Clearance: ( F/ R ):2 9 / 3 0m m

The act ual v ersio n is su bject t o the r eal standa rd. It woul d be va ried

becau se of d iff erent v ers ions.

Manual

B R U S H LE S S /B R U S H E D

B-10E

B-10E Specific ations

Leng th:

Width: 250/252mm

Dimensiones: 417mm x 250/252mm x 151mm

Heig ht: 151mm

Distancia entre ejes: 290mm

Whee l Base: 290mm

Ruedas (D/T): ø 87x34mm / ø 87x39mm

Gear R atio:9.47:1

Altura del suelo (D/T): 29/30mm

Tire Typ e: Φ87x34mm(F) Φ87x39mm(R)

The Max. Ground Clearance: (F/R):29/30mm

This manual expatiate the structure of the model. In order to better maintain and replace the spare parts, please keep and take it for reference. The

user who is not familar with the assembling,please contact with the wholesaler,nominated model shops and the Special after-sale service outlets.

The spare parts,appearanc e of this model will be tiny re vised and changed befor e totally upgrade into a ne w

vers ion,ZD reserve this rig hts,and no further noti ce.

The actual version is subject to the real standard.It would be varied because of different versions.

417mm

R

Scale

1:10

Ready To Run

This manual expatiate the structure of the model. In order to better

maintain and replace the spare parts,please keep and take it for reference.

The user who is not familar with the assembling,please contact with the

wholesaler,nominated model shops and the Special after-sale service

outlets.

The act ual v ersio n is su bject t o the r eal standa rd. It woul d be va ried

becau se of d iff erent v ers ions.

Electric

4WD

2.4G

Radio

1. Don't operation the models close to open fires or near heat source.

2. Operation must be in the open and dry site .

3. The thunderstorm weather is forbidden to operate this product.

4. Away from the high voltage cables.

5. Some of the parts will be exothermic or burning after operated.

6. Please do not use hand or foreign body contact activities of the parts before cut off

the power supply, .

7. During the operation, if foreign matter or liquid get into eyes, please timely with

plenty of water flush eyes, and immediately consulting professional doctor. As the

body is injured, please seek imm

ediate medical attention.

8. Keep out of the reach of children, this is not toy, strongly suggest adult supervision.

9. Placed in ventilated and dry place, do not use, take the battery out.

10.The product items do not diet or swallowed.

SAFETY GUIDELINES

3

B-10E

IN T R ODU CE

B - 1 0 E

INTRODUCE

Thank you fo r ch oo sing the ZD racing series products. Our company take th e ta rg et of offering the t op

Than y k o f u o c r hoosin t g h MCR e s er ie p s roduc ts O . u c r ompan t y ak t e h t e arge o t o f fferin t g h t e o p

quality an d be st service. Th ro ugh attending the competitions and repeated testing the p ro ducts,

qualit a y n b d es s t ervice . Throug a h ttendin t g h c e ompetiti on a s n r d epeate t d estin t g h p e roducts ,

constant ly e nhancing our experience,then further improvin g th e de sign and quality control. Only for

constant l e y nhancin o g u e r xp erience,the f n urthe i r mprovin t g h d e esig a n n q d u al it c y o ntrol O . nl f y o r

showin g th e gr eat performance products. This manual including all the important mat te r be fore operating

showin t g h g e rea p t erformanc p e roducts . Thi m s anua i l ncludin a g l t l h i e mportan m t atte b r e for o e peratin g

the car. We advise studying and k no wi ng the control system before assembling or playing it . As we ll a s

th c e a W .r a e dvis s e tudyin a g n k d nowin t g h c e ontro s l yste b m efor a e ss emblin o g p r layin i g t . A w s el a l s

the furthe r up gr ade and maintenance. Please feel free t

th f e urthe u r pgr ad a e n m d a in tenance P . leas f e ee f l re t e c o onsul o t u a r uthorize d d eale ,r nominate m d ode l

shop or spec ia l after-sale service station if any question refer to the pla y or u se. Our website

sho o p s r pecia a l fter-sal s e er vic s e tatio i n a f n q y ue st io r n efe t r t o h p e la o y u r se O . u w r ebsite

is:www.xi ng yaohua.com. We a re wholeheartedly for your service.

is se.ocitimcr.www//:ptth : W a e r w e holeh ea rt edl f y o y r ou s r ervice.

QUALITY ASSURANCE

Our compan y ta ke the fully responsibility to the quality defect during th e ma nufacturing process.

This assur an ce is only subject to the product only and its spare parts.

These situat io n be low are not included:

The breaka ge c aused by using,assembling or adjustment.

The other br ea kage not related to the quality itself.

o consult ou r au th orized dealer,nominated model

IMPORTANT STATEMENT

The Mode l Car is not a toy. It is the casual item combine a lot of high tec hnology produ ct s. If using

improp er may brin g serious damage. Please read the manual de ta il ed before using, and keep your se lf

safe.

Attentio n: Any ope ra tion of the Model car,the manufacturer and dealers are incapable of take the

respon si bility of the accidents caused by wear out or abnormal asse mb le.

This product is p ro vided to those who have o pe ra tion remote control model c ar experience or a

technica l personnel in the guidance of the local legal field, in ha s to ensure the saf e and correct operation

under th e condition of use.Our company wi ll not accept an y operation and use the control o n any

performa nc e and safety responsibility

The RC products are belong to consum ab le goods,if disasse mb le,it may caus

use of goods caused by bad or not satisfied, will not be able to replace or return, such as in case of

operatio n maintenance problems, t he company designat ed national distribut or model shop a nd special

after-sa le s ervice store will provide technical guidance, and s pe cial parts supply services.

e the spare parts loss,Any

Warning: because of the neglect of these operating ins tr uctions, and use wrongly may cause

property dam ag e or serious injury.

Note: beca us e of the neglect of these operating instructions, and u

dangerou s.

Ban: in any pr oh ibited environment, do not try to operation.

se wrong ly c ou ld be

2

2

SAFETY GUIDELINES

1. Don't operation the models close to open fires or near heat source.

2. Operation must be in the open and dry site .

3. The thunderstorm weather is forbidden to operate this product.

4. Away from the high voltage cables.

5. Some of the parts will be exothermic or burning after operated.

6. Please do not use hand or foreign body contact activities of the parts before cut off

the power supply, .

7. During the operation, if foreign matter or liquid get into eyes, please timely with

plenty of water flush eyes, and immediately consulting professional doctor. As the

body is injured, please seek imm

ediate medical attention.

8. Keep out of the reach of children, this is not toy, strongly suggest adult supervision.

9. Placed in ventilated and dry place, do not use, take the battery out.

10.The product items do not diet or swallowed.

3

3

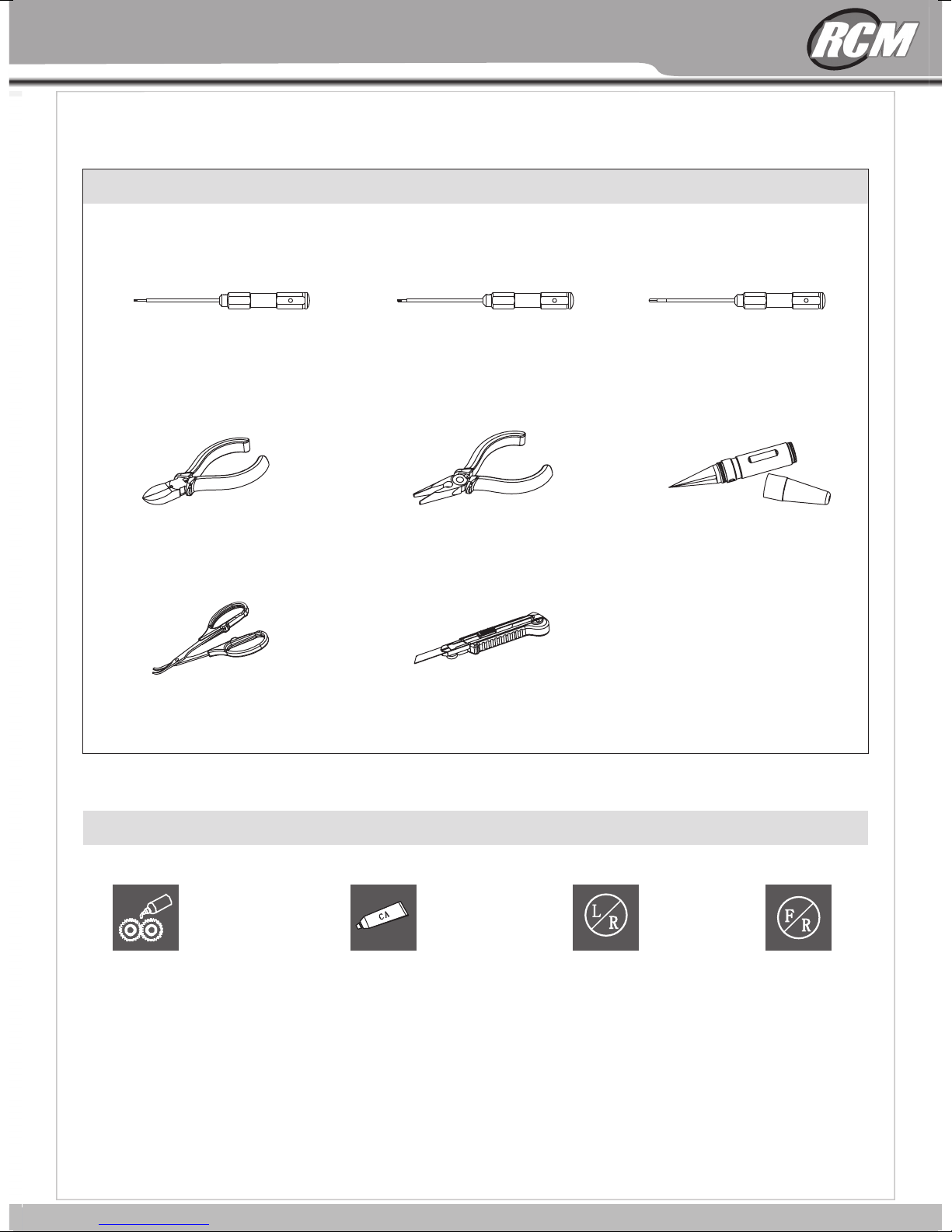

2.5 Assorted Screwdrivers

8F5-200250-00-00

2.0 Assorted Screwdrivers

8F5-300200-00-00

1.5 Assorted Screwdrivers

8F5-300150-00-00

Hobby Scissors

6Y7-000001-00-07

Hobby Knife

6X0-000028-00-00

Wire Cutters

6Y7-000001-00-00

Needle Nose Pliers

6T4-000096-00-00

Reamer

Recommended maintenance tools(not included)

8PT-040001-71-00

Symbols used throughout the instruction manual

Assemble both

L/R sides

Assemble both

F/R sides

Apply CA glue

(not included)

All kinds of grease

(not included on the

products)

5

EB10

5

5000 mAh 30C

2

Li-po battery

EB10

2

4

Recommended maintenance tools(not included)

1.5 Assorted Screwdrivers

8F5-300150-00-00

Wire Cutters

6Y7-000001-00-00

Hobby Scissors

6Y7-000001-00-07

2.0 Assorted Screwdrivers

8F5-300200-00-00

Needle Nose Pliers

6T4-000096-00-00

Hobby Knife

6X0-000028-00-00

2.5 Assorted Screwdrivers

8F5-200250-00-00

Reamer

8PT-040001-71-00

Symbols used throughout the instruction manual

All kinds of grease

(not included on the

products)

Apply CA glue

(not included)

Assemble both

L/R sides

5

5

Assemble both

F/R sides

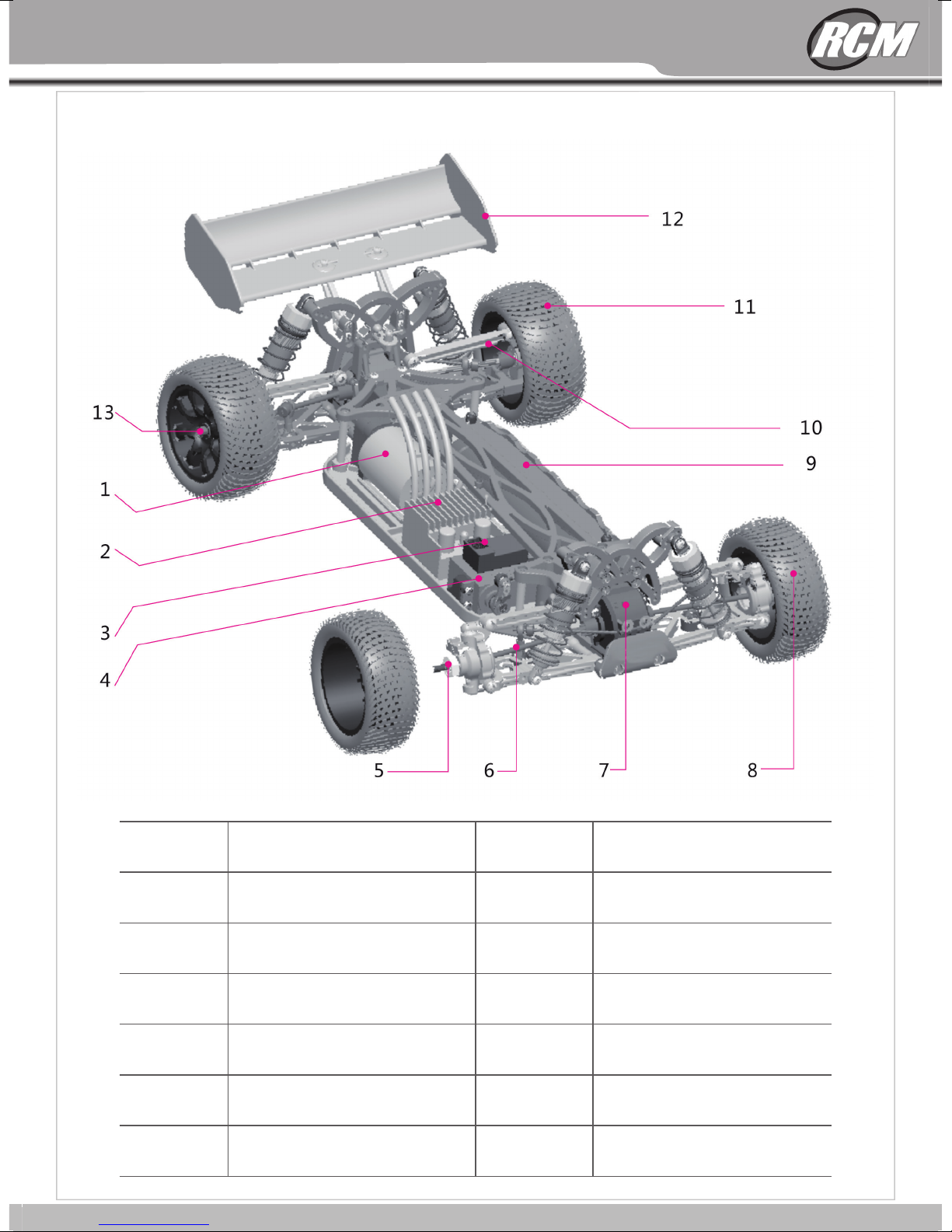

2

3

4

1

5

6

8

9

10

7

11

12

Tail

13

Brushed Motor

Brushed ESC

Receiver

Servo

Gear Box

Front Ti re

Battery

Drive Shaft

Rear Tir e

Locknut

Wheel Hub

Drive Shaft

B-10E Brushed Car

1

2

3

4

5 6 7 8

9

10

11

12

13

7

B-10E

13

1

2

B-10E Brushless Car

EB10 Brushless Car

12

11

10

9

3

4

Brushless Motor

1

2

3

4

5

Brushless ESC

Receiver

Servo

Wheel Hub

5 6 7 8

Front Ti re

8

9

10

11

12

Battery

Drive Shaft

Rear Tir e

Tail

6

7

Drive Shaft

Gear Box

Locknut

13

6

6

B-10E Brushed Car

EB10 Brushed Car

12

11

13

1

2

3

4

10

9

5 6 7 8

1

Brushed Motor

8

Front Ti re

2

3

4

5

6

7

Brushed ESC

Receiver

Wheel Hub

Drive Shaft

Gear Box

Servo

9

10

11

12

13

7

7

Battery

Drive Shaft

Rear Tir e

Tail

Locknut

MID

1 2 3

4 5 6

7 8 9

Racing Steps

Open the cap of the r ad io

Put 4 AA batteries in to t he battery tank

(Please note th e Po sitive and Nega ti ve )

Note: 1. In order t o ge t the better cont rol effect, w e recommend you to us e AA1.5 V alkaline bat teries (not inc lu ded in the

product), the r at io of 1.2 V recharg ea ble battery effect is better. 2. Battery if ins ta llation error s of t he pole, or long ti me

no management wil l lead leakage.3. D o not use the old bat te ry and new batter y hy brid together. 4 .If long time idle, d o not

leave the batte ry i n the remote cont ro l.

Racing Operation Steps

Cover the cap of th e ra dio

Properly inst a

lled antenna tu be pu t the battery into th e battery tank cover the batte ry b ox

Adjust the thro tt le, steering ve rn ier

adjustment kn ob b utton to median

(MID) directi on . big/small rud de r

Angle knob butt on t o 120%

Be sure to first op en t he remote contr ol p ower, and then ope n th e model car

power supply, switch on the pow er, t he motor delive ri ng a diz ~ diz ~ ~ ~ sounds ,

it means the moto r fo r standby state . open radio button , the motor will be gi n to run.

Finish racing note

Turn off the E SC a nd disconnect

the power plug.

Turn off the r ad io

Put out the batte ry

B-10E

10

C H A R G IN G T H E B A T T E R Y P A C K

1

2

3

A Once the battery r ea dy to be charged, first plug the AC quick c ha rger into the outlet of AC power

source, an d th en connect the battery input/output harness to the charger.

B. Continu ed t o monitor the battery as it is being charged. As soon as the battery is full y ch arged,

discon ne ct the battery. from th e ch ar ger plug (Over-charging or charging incorrectly usi ng i nadequate

chargers m ay c ause the battery pack to become dangerouslyhot).

C. For best re su lts, let the battery pack cool before charging. Heat may preven t th e battery pack from

chargi

ng to full cap ac ity and also decreases the performance of the battery.

.

Lithium Po ly mer (Li-Po) batteries are becoming popular for use in R/C m od els due to their compact size,

high ene rg y density, andhig h- current output. However, these types of batteries require sp ec ial care and

handli ng p rocedures for long life and safe operation.

A F TE R C H A R G E T IME E X P IR E S , D I S C ON NE C T

B AT TE R Y P L UG F R O M C H AR G E R P L U G .

P L UG I N TO A C O U TL E T.

C O NN E C T B AT T E R Y P L U G

T O D C O UT LE T P L UG F R O M C H A R G E R .

L iP o B A T T E R IE S

CHARGING THE BATTERY PACK

A Once the battery r ea dy to be charged, first plug the AC quick c ha rger into the outlet of AC power

.

source , an d th en connect the battery input/output harness to the charge r.

B. Continu ed t o monitor the battery as it is being charged. As soon as the battery i s fu ll y charged,

discon ne ct the battery. from th e ch arger plug (Over-charging or charging incorrect ly u sing inadequate

charge rs m ay c ause the battery pack to become dangerouslyhot).

C. For best re su lts, let the battery pack cool before charging. Heat may prev en t the battery pack from

chargi ng t o fu ll capacity and also decre

1

PLUG INTO AC OUTLET.

ases the per fo rmance of the battery.

3

CONNECT B ATTE RY PLUG

TO DC OUT LET PLU G FROM CH ARGER .

2

AFTER CHA RGE TIM E EXPIR ES, DIS CONNE CT

BATTERY PLUG FRO M CHARG ER PLUG .

LiPo BATTERIES

Lithium Po ly mer (Li-Po) batteries are becoming popular for use in R /C m odels due to their compact size,

high ene rg y density, andhig h- current output. However, these types of batteries requir e sp ec ial care and

handli ng p rocedures for long life and safe operation.

Warning: Lithium Polymer (Li-Po) batteries are int en de d only for advanced users that are educated on

Wa r ni ng : Lithium Polymer (Li-Po) batteries are inten de d only for advanced users that are educated on

the risks as so ciated with Li-Po battery use. THUNDER TIG ER/ACE RC does not recommend

Important: D o no t use NiCd/Ni-MH battery chargers for Li-PO batteries . If y ou d o not use a special

Impo

the risks as so ciated with Li-Po battery use. www.rcmitico.es does n ot r ec ommend

that anyon e un der the age of 16 use or handle Li-Po battery packs without the sup er vision of a

that anyon e un der the age of 16 use or handle Li-Po battery packs without the sup er vision of a

knowle dg eable and respo

knowle dg eable and responsible adult.

r ta nt: Do not use NiCd/Ni-MH battery chargers fo r Li -P O batteries. If you do not use a special

charge r fo r Li -PO battery,they wi ll b e damaged.

charge r fo r Li -PO battery,the y wi ll b e damaged.

nsible a du lt.

Please not e! C on sumers for use or installation of lipo battery in the remote control model be lo ng s

and cause any Di re ct or indirect damages, our company will not bear any legal liability.

8

9

B-10E

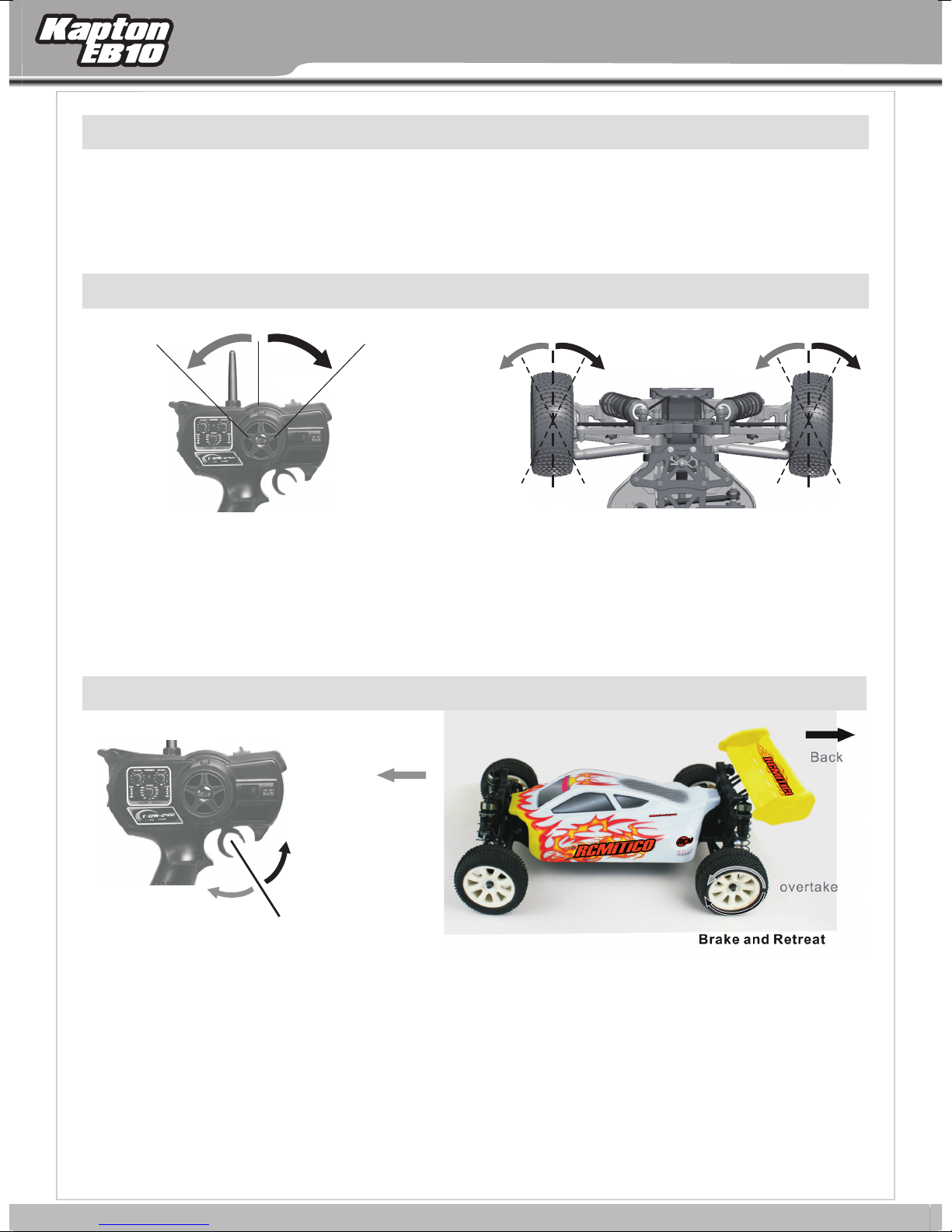

Racing Operation Steps

Racing Steps

1 2 3

Open the cap of the r ad io

Note: 1. In order t o ge t the better cont rol effect, w e recommend you to us e AA1.5 V alkaline bat teries (not inc lu ded in the

product), the r at io of 1.2 V recharg ea ble battery effect is better. 2. Battery if ins ta llation error s of t he pole, or long ti me

no management wil l lead leakage.3. D o not use the old bat te ry and new batter y hy brid together. 4 .If long time idle, d o not

leave the batte ry i n the remote cont ro l.

Put 4 AA batteries in to t he battery tank

(Please note th e Po sitive and Nega ti ve )

Cover the cap of th e ra dio

4 5 6

Properly inst a

lled antenna tu be pu t the battery into th e battery tank cover the batte ry b ox

MID

7 8 9

Adjust the thro tt le, steering ve rn ier

adjustment kn ob b utton to median

(MID) directi on . big/small rud de r

Angle knob butt on t o 120%

Finish racing note

Turn off the E SC a nd disconnect

the power plug.

Be sure to first op en t he remote contr ol p ower, and then ope n th e model car

power supply, switch on the pow er, t he motor delive ri ng a diz ~ diz ~ ~ ~ sounds ,

it means the moto r fo r standby state . open radio button , the motor will be gi n to run.

Turn off the r ad io

10

9

Put out the batte ry

The adjustment of Radio

Speed cont ro l over heats

Car has a prob le m on power

If you have trouble starting or keeping your love car running, here's a

quick checklist of what to look for first.

TROUBLESHOOTING

Car dies or sl ow s

Car is glitc hi ng

Motor is ove rh eats

No power

No throttl e

No steerin g

Revers in g

Descript io n

Goes backw ar ds when you pull the

trigger or g oe s right when turning the

wheel le ft

Servo no t pl ug ged in

Locked up st ee ring linkage

Servo fail ur e

Motor not pl ug ged in

Motor fail ur e

No throttl e, o nl y steering

Motor keep s ru nning

Gear mesh is t oo t ig ht

Battery is d is charged

Che

ck for loose wires, dead radio batteries

or loose crystals.Check motor capacitors,

losse wires or crystals.

Check thro tt le / steering reversing

switches o n tr ansmitter

Plug ser vo i nto ESC unit

Free up stee ri ng linkage

Replac e se rv o

Plug motor i n

Replac e mo to r

A-T-L function works;turn off the vehicle

first and fo ll ow the guide to turn on the

radio. (Ra di o first, vehicle second!!!)

Check if the t hr ottle trim knob is in neutral

position .

Charge b at te ry

Charge b at te ry

Let motor co ol a nd check recommended

gearin g fo r mo tor type. Reset g

ear mesh

Let it cool an d tr y la ter

Solution

Problem

13

First open the t ra nsmitter powe r,c onnect the Lipo battery power output plugs and electronic g overnor

power input plug. Then turn on the ESC. (The 1 ps 7.4 V battery on t he car,when turning on t he power

supply must pay attention to the positi ve and ne ga ti ve pole), hearing the tone or the power indicator

light is lit .

Steering operation guide

turn left

1) slo wly rotating around the s te ering wheel, the car

will be slow to the right or to the left accordingly (when

there is no c

control ST direction and rud de r sw itch).

2) when the cars can't run straight, you can adjust te

directio n of the remote con tr ol on the median knob,

until the ve hi cle can run straight.

onsisten t please toggle on the remote

turn right

Throttle operation

overtake

turn left

Center Positi on Center Positi on

◆

◆

turn right

Adjust the Medi an t rimming to keep t he

front wheel in th e ce nter position

When testing th e di version of the ca r,p lease

keep the front wh ee l hang in the air.

turn left

turn right

Back

overtake

(1) Slowly p re ss the throttle operation lever, the cars will be slow to over ta ke.

(2) When the throttle leve r to

action, the car will ma ke back action. when there is not consistent, please strike on th e remote control of

TH (oil Door ) an d rudder switch.

(3) When the throttle machine didn't do any action, wheels ap pe ar to be automatic for wa rd or b ac kw ard

rotation ,y ou can adjust the throttle median knob on the remote control, u nt il the car static.

(4) When pr ess the throttle lev er, but the car no any reaction (perhaps with diz d iz diz ~ ~ ~ ~ th

sound) , but the rudder function is normal, it shows that the car drive syst em get into safe mode, now

please cor re ct TH (throttle) a k no b, u ntil the gas operation normal or buzzing sound stop.

Brake and Retre at

push up, the car will be brakin g action. w he n making brake - median - brake

10

Brake and Retre at

overtake

e buzzing

TROUBLESHOOTING

If you have trouble starting or keeping your love car running, here's a

quick checklist of what to look for first.

Descript io n

Car dies or sl ow s

Car is glitc hi ng

Motor is ove rh eats

No power

No throttl e

Problem

Speed cont ro l over heats

Car has a prob le m on power

Gear mesh is t oo t ig ht

Battery is d is charged

Motor not pl ug ged in

Motor fail ur e

No throttl e, o nl y steering

Motor keep s ru nning

Solution

Let it cool an d tr y la ter

Che

ck for loose wires, dead radio batteries

or loose crystals.Check motor capacitors,

losse wires or crystals.

Let motor co ol a nd check recommended

gearin g fo r mo tor type. Reset g

Charge b at te ry

Charge b at te ry

Plug motor i n

Replac e mo to r

A-T-L function works;turn off the vehicle

first and fo ll ow the guide to turn on the

radio. (Ra di o first, vehicle second!!!)

Check if the t hr ottle trim knob is in neutral

position .

ear mesh

No steerin g

Revers in g

Servo no t pl ug ged in

Locked u p st ee ring linkage

Servo fail ur e

Goes backw ar ds when you pull the

trigger or g oe s right when turning the

wheel le ft

13

Plug ser vo i nto ESC unit

Free up stee ri ng linkage

Replac e se rvo

Check thro tt le / steering reversing

switches o n tr ansmitter

11

3.REAR GEAR BOX ASSEMBLY

4.FRONT LOWER SUSPENSION ARM ASSEMBLY

7181

7247

7180

7181

7248

7178

7182

7180

7247

7179

0.10m m

7182

50mm

50mm

51mm

7181

7181

7251

x2

x2

7271

7270

x2

x1

7272

x1

7248

x6

7247

1:1

7175

26.2m m

7176

7175

7272

7177

7177

7251

7271

7271

7270

7270

7170

7175

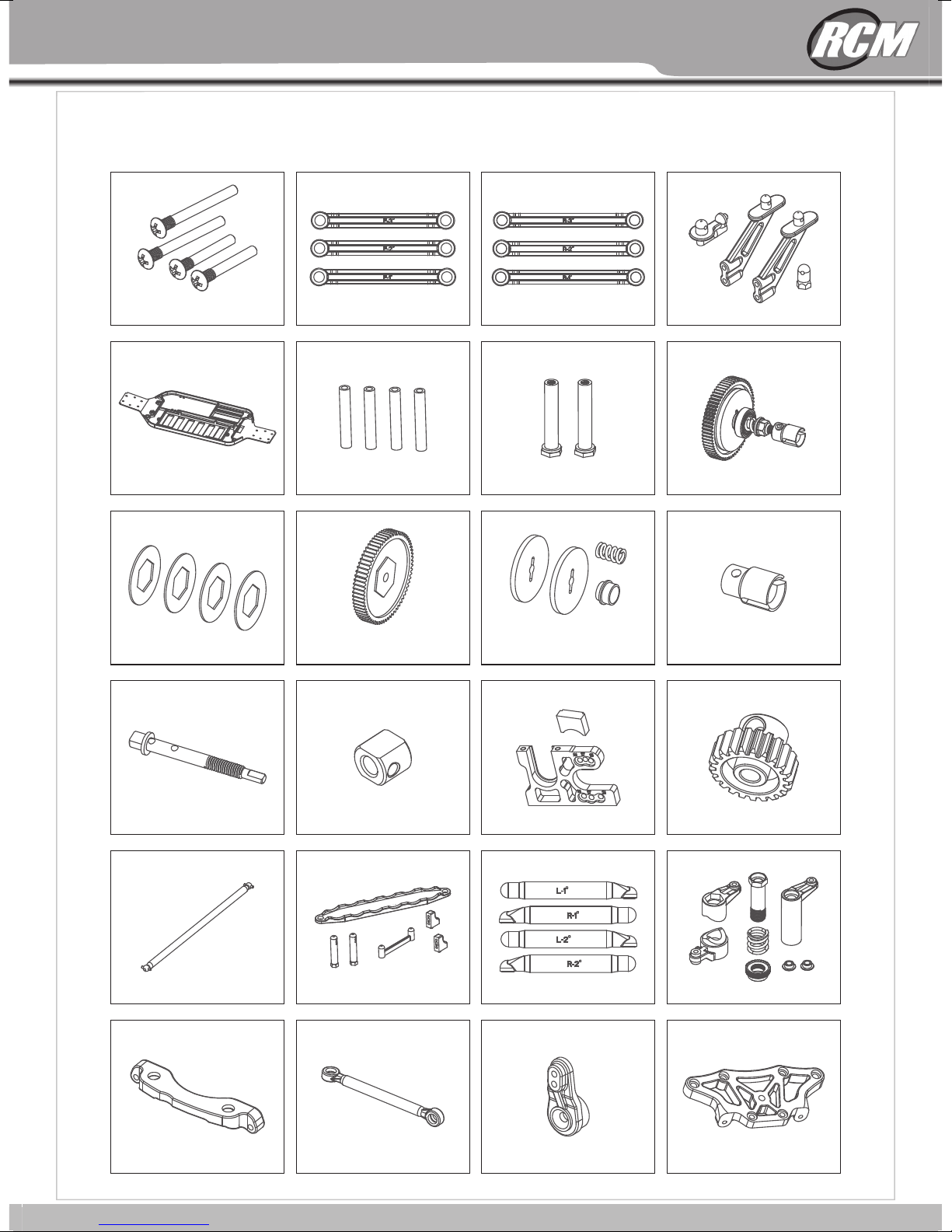

M3X10 P an Se lf- tapping Sc rew S et

M3X12 F lat H ead S elf-tapp ing

Screw S et

M3X20 F lat H ead S elf-tapp ing

Screw S et

1:1 Scale

Ball bear ing φ15 x10x4

Ball bear ing φ10 x5x4

E butto n φ2.5x0. 4

Add app rop ria te

amoun t of oi l

Susp. Ar m Hin ge

Pin Bra ce fr ont

3x30m m Hin ge Pi n

Susp. Ar m Hin ge

Pin Bra ce fr ont

15

with a ga p of 0. 10m m

B-10E

1:1 Scale

7244

M2x10 S ock et Ca p Screw

7276

φ10xφ5.5x0.3 Washers

7275

φ8xφ5.1x0.3 Washers

x8

x2

x6

x4

1.DIFFERENTIAL ASSEMBLY

Add app rop ria te

7244

amoun t of oi l

7174

7171

7172/ 7279

7275

7171

7171/ 7280

13T大伞齿

7171

7172

7279

7173

Add app rop ria te

amoun t of oi l

7173

7173

7271

7172

7276

7173

7172

Add app rop ria te

amoun t of oi l

7275

7272

E button φ2.5x0. 4

M3X10 P an Se lf- tapping Sc rew S et

Ball bear ing φ15 x10x4

Ball bear ing φ10 x5x4

Set Scr ew M4 x4

E button φ2.5x0. 4

7251

7271

7270

7260

7272

7173

7173

7170

x2

x2

x2

x1

x1

2.FRONT GEAR BOX ASSEMBLY

1:1

7171

Add app rop ria te

amoun t of oi l

7251

28mm

7175

7271

7177

7175

7271

7270

7175

7175

7272

7177

7171

7172

7279

7270

7174

7260

Put a lit tle

screw g lue

7176

The scr ew sh oul d

be lock ed in t he

plani met ric p osition

of shaf t

12

14

1:1 Scale

x2

7251

M3X10 P an Se lf- tapping Sc rew S et

x2

7271

Ball bear ing φ15 x10x4

x2

7270

Ball bear ing φ10 x5x4

x1

7272

E butto n φ2.5x0. 4

3.REAR GEAR BOX ASSEMBLY

26.2m m

7175

1:1

7175

7175

7272

7271

7251

Add app rop ria te

amoun t of oi l

7177

7271

7170

7176

7270

7177

7270

x1

7248

M3X20 F lat H ead S elf-tapp ing

Screw S et

x6

7247

M3X12 F lat H ead S elf-tapp ing

Screw S et

4.FRONT LOWER SUSPENSION ARM ASSEMBLY

7247

7180

7182

3x30m m Hin ge Pi n

7181

Susp. Ar m Hin ge

Pin Bra ce fr ont

7181

Susp. Ar m Hin ge

Pin Bra ce fr ont

7248

7178

7247

7179

7182

7180

7181

with a ga p of 0. 10m m

0.10m m

7181

50mm

50mm

51mm

15

13

7.THE ASSEMBLY OF FRONT ANTI-SWAY BAR

7192

7258

7192

7192

7192

7250

7192

7192

128.6 1mm

7253

7192

7259

7192

7277

7194

7192

7259

7192

7193

7250

7193

7277

7193

7192

7191

7267

7191

7194

7189

136.7 8

7189

10253

7193

7258

7194

7191

7267

8.THE ASSEMBLY OF REAR ANTI-SWAY BAR

2.00m m

0.00

0.00

2.00

x2

7194

x2

7259

7258

x2

x2

7250

x2

7253

7277

x2

x2

7259

7258

x2

x2

7250

x2

7253

7277

x2

7278

7268

x2

7267

x4

7194

x2

7270

x2

x4

1:1

3mm

1mm

1:1

7270

7190

7270

7189

7190

7278

7188

7268

Set Scr ew M3 x3

M3X6 Pa n Sel f-t apping Scr ew Se t

M3X14 P an Se lf- tapping Sc rew S et

Set Scr ew M3 x10

Set Scr ew M3 x3

M3X6 Pa n Sel f-t apping Scr ew Se t

M3X14 P an Se lf- tapping Sc rew S et

φ8xφ3.2x0.5 Washers

φ8xφ3.2x0.5 Washers

Φ7.5xΦ5.1x2.1

Rear Wheel Shaft Washers

1:1 Scale

Front Swa y Bar

right

Left

Rear Sway B ar

Set Scr ew M3 x10

Front Low er Susp ensio n Pins

Rear Lowe r

Suspens ion Pin s

Ball bear ing φ10 x5x4

φ2x11 Pin S et

φ2x10 Pin Se t

Add app rop ria te

amoun t of oi l

Anti- rol l bar i s installe d up

the tra nsm iss ion shaft.

Anti- rol l bar i s installe d up

the tra nsm iss ion shaft.

17

B-10E

5.REAR LOWER SUSPENSION ARM ASSEMBLY

1:1 Scale

7247

M3X12 F lat H ead S elf-tapp ing

Screw S et

M3X16 P an Se lf- tapping Sc rew S et

7254

x6

x2

with a ga p of 0. 10m m

0.10m m

50mm

54.9m m

50.8m m

3x30m m Hin ge Pi n

7184

7182

7181

Susp. Ar m Hin ge

Pin Bra ce re ar

Susp. Ar m Hin ge

Pin Bra ce re ar

7181

7181

7247

7183

7247

7182

7254

7181

7184

Ball bear ing φ15 x10x4

Ball bear ing φ10 x5x4

Steer ing B all S crews φ4.7 -M3

7263

M3x4. 1 Scr ew ro d

7271

7270

7265

6.STEERING ARMS ASSEMBLY

x4

7268

φ2x11 Pin S et

7267

φ2x10 Pin Set

x2

7266

φ2x9.7 Pin S et

x2

7185

7267

x2

7185

x2

x2

x2

Add app rop ria te

amoun t of oi l

7185

1:1

7185

7266

7185

7185

7187

79.70mm

right

7263

7263

7271

7186

7265

7270

Left

7268

7188

14

16

1:1 Scale

7.THE ASSEMBLY OF FRONT ANTI-SWAY BAR

7258

Set Scr ew M3 x3

x2

x2

7250

M3X6 Pa n Sel f-t apping Scr ew Se t

x2

7253

M3X14 P an Se lf- tapping Sc rew S et

x2

7277

φ8xφ3.2x0.5 Washers

x2

7259

Set Scr ew M3 x10

Front Low er Susp ensio n Pins

7194

x2

7259

Set Scr ew M3 x10

3mm

1:1

7192

7192

7259

7192

7250

x2

right

7192

7277

Front Swa y Bar

7192

7192

Anti- rol l bar i s installe d up

the tra nsm iss ion shaft.

7192

7258

7194

2.00m m

128.6 1mm

7192

Left

Add app rop ria te

amoun t of oi l

7253

0.00

7258

Set Scr ew M3 x3

x2

x2

7250

M3X6 Pa n Sel f-t apping Scr ew Se t

x2

7253

M3X14 P an Se lf- tapping Sc rew S et

x2

7277

φ8xφ3.2x0.5 Washers

x4

7278

Φ7.5xΦ5.1x2.1

Rear Wheel Shaft Washers

8.THE ASSEMBLY OF REAR ANTI-SWAY BAR

7194

Rear Lowe r

Suspens ion Pin s

x2

7268

φ2x11 Pin S et

x4

7267

φ2x10 Pin Set

x2

7270

Ball bear ing φ10 x5x4

Rear Sway B ar

x2

7192

7192

7259

7192

0.00

7194

1mm

1:1

7193

7193

7277

7193

2.00

7250

Anti- rol l bar i s installe d up

the tra nsm iss ion shaft.

7190

7191

7267

7194

7270

7189

7193

7258

7191

10253

7190

7278

7191

7267

7268

7270

7189

7188

7189

136.7 8

17

15

11.THE ASSEMBLING OF THE UPPER

DECK PILLAR, PIVOTING POINT AND CHASSIS

7200

7199

7249

7198

7246

x4

7249

x4

7246

7200

x2

7199

x2

M3X8 Fl at He ad Sc rew Set

M3X10 F lat H ead S elf-tapp ing

Screw S et

Alumini um stru t

Servo Sav er Post

1:1 Scale

Add app rop ria te

amoun t of oi l

Add app rop ria te

amoun t of oi l

Hexag on of t he

pivot ing p oin t should

align t o tha t of ba seboard

19

B-10E

1:1 Scale

7264

M3x4. 8 Scr ew ro d

9.FRONT UPPER ROD SET ASSEMBLY

The cam ber o f tir e can be chang ed wh en yo u adjust the l eng th of t he pull r ods

Different dri vin g fee ling ap pea rs wi th diffe rent pull- r od le ngt h

You ca n cho ose approp ria te pu ll rods b ase d on th e fie ld

x4

7264

7195

The fro nt up p ull -rod 3°(se lec tiv e use)

The f ront up pull -ro d 2°( stand ard U se)

The fro nt up p ull -rod 1°(se lec tiv e use)

7195

7264

x4

7264

M3x4. 8 Scr ew ro d

x4

M3X10 P an Se lf- tapping Sc rew S et

M3X12 F lat H ead S elf-tapp ing

Screw S et

7251

x1

7247

7264

7264

10.REAR UPPER ROD SET ASSEMBLY

7251

7197

7196

7264

7195

7196

7247

7197

The rear up pu ll- rod 3°( sel ect ive use)

The up pu ll- rod 2°(sta nda rd Us e)rear

The up p ull -ro d 1°(selec tiv e use ) rear

7264

The cam ber o f tir e can be chang ed wh en yo u adjus t the l eng th of the pull r ods

Different dri vin g fee ling ap pea rs wi th diffe rent pull- r od le ngt h

You ca n cho ose approp ria te pu ll rods base d on th e fie ld

16

18

1:1 Scale

x4

7249

M3X8 Fl at He ad Sc rew Set

x4

M3X10 F lat H ead S elf-tapp ing

Screw S et

7246

x2

7200

Servo Sav er Post

11.THE ASSEMBLING OF THE UPPER

DECK PILLAR, PIVOTING POINT AND CHASSIS

7199

7199

Alumini um stru t

Hexag on of t he

x2

pivot ing p oin t should

align t o tha t of ba seboard

Add app rop ria te

amoun t of oi l

7200

7249

7198

Add app rop ria te

amoun t of oi l

7246

19

17

14.REAR SUSPENSION ASSEMBLY

15.STEERING ASSEMBLY

x2

7260

x4

7246

x6

7275

x2

7245

x2

7265

7260

7207

7260

7275

7246

7214

7212

7212

7213

7213

7265

7213

7245

7212

转向拉杆左1 °(标配使用)

转向拉杆右1 °(标配使用)

转向拉杆左2 °(选用配件)

转向拉杆右2 °(选用配件)

1:1

6.00m m

1:1

3.5mm

Set Scr ew M4 x4

M3X10 F lat H ead S elf-tapp ing

Screw S et

M3X8 Fl at He ad Se lf-tappi ng

Screw S et

Steer ing B all S crews φ4.7 -M3

φ8xφ5.1x0.3 Washers

1:1 Scale

Add app rop ria te

amoun t of oi l

Put a lit tle

screw g lue

The scr ew sh oul d be locked in t he

plani met ric p osition of s haf t

The toe -in a ngl e of the front t ire c an be c hange d whe n you a djust the le ngt h of th e pull rods

Different dri vin g fee ling ap pea rs wi th diffe rent steer ing p ull r od leng th

You ca n cho ose approp ria te pu ll rods base d on th e fie ld

21

1:1 Scale

Set Scr ew M4 x4

M3X8 Pa n Hea d Scr ew Set

B-10E

7260

7256

12.REDUCTION GEAR AND MOTOR ASSEMBLY

x1

x2

7202

7203

7202

7256

Put a lit tle

screw g lue

7260

7209

The scr ew sh oul d be locked in t he

plani met ric p osition of s haf t

7208

7285

7289

Ball bear ing φ15 x10x4

7262

Lock Nu t M4

7271

7249

M3X8 Fl at He ad Sc rew Set

7268

7206

x1

x2

7204

Adjusti ng spri ng Φ7.6xΦ1.4x 14.5

13.REDUCTION GEAR ASSEMBLY

x5

7208

7204

x1

7210

7268

6.00m m

7204

1:1

7204

7271

7204

7262

7260

7205

x2

7245

M3X8 Fl at He ad Se lf-tappi ng

Screw S et

7251

M3X10 P an Se lf- tapping Sc rew S et

7199

Alumini um stru t

x2

x2

7199

7201

Put a lit tle

screw g lue

7245

18

20

7211

7249

Put a lit tle

screw g lue

7245

7251

Insta llm ent o f

the bac kbo ne

of the bo dys hel l

1:1 Scale

Set Scr ew M4 x4

7260

x2

x6

14.REAR SUSPENSION ASSEMBLY

The scr ew sh oul d be locked in t he

6.00m m

plani met ric p osition of s haf t

7275

φ8xφ5.1x0.3 Washers

x4

M3X10 F lat H ead S elf-tapp ing

Screw S et

7246

x2

7245

M3X8 Fl at He ad Se lf-tappi ng

Screw S et

7275

1:1

Put a lit tle

screw g lue

7260

7207

15.STEERING ASSEMBLY

7260

7246

x2

7265

Steer ing B all S crews φ4.7 -M3

The toe -in a ngl e of the front t ire c an be c hange d whe n you a djust the le ngt h of th e pull rods

Different dri vin g fee ling ap pea rs wi th diffe rent steer ing p ull r od leng th

You ca n cho ose approp ria te pu ll rods base d on th e fie ld

3.5mm

Add app rop ria te

amoun t of oi l

7213

7212

1:1

7213

7213

7245

19

21

7265

7214

7212

7212

转向拉杆左1 °(标配使用)

转向拉杆右1 °(标配使用)

转向拉杆左2 °(选用配件)

转向拉杆右2 °(选用配件)

18.FRONT SHOCK ABSORBER ASSEMBLY

19.REAR SHOCK ABSORBER ASSEMBLY

7221

7231

7231

7222

7227

O

i

l

≈

7228

7272

7228

7224

7228

7261

7232

7273

7230

7226

7228

7228

7229

7228

7230

7273

7228

7229

7225

30.3m m

107.45m m

x2

7261

x4

7273

x2

Φ7.9x2.5

7228

x2

Φ9.5x2

7228

x4

7273

x2

Φ7.9x2.5

7228

x2

Φ9.5x2

7228

Φ3.35

7228/72 29

x4

Φ8.1xΦ3.35

7228/72 29

x4

x2

7261

53.50 mm

1:1

48.80 mm

1:1

55.00 mm

1:1

67.00mm

1:1

Lock Nu t M2. 5

Lock Nu t M2. 5

Ball Head S et

Ball Head S et

Rear Shoc k Rods

Front Sho ck Rods

7221 Fron t Shock S pring (blac k)

7221 Rear S hock Sp ring( black )

1:1 Scale

7228

7272

7228

7229

7228

7228

7261

7223

7228

7229

7228

O

i

l

≈

7228

7226

7230

7273

7232

7273

7230

7225

7227

24. 3mm

91.8mm

The nut s hou ld no t be

locke d too t igh tly,

or the E bu ckl e may

fall of a fte r ext rusion

Add the S hoc k oil

Move sl owl y and w ait

the bub ble c ome o ut

from th e liq uid

The nut s hou ld no t be

locke d too t igh tly,

or the E bu ckl e may

fall of a fte r ext rusion

Add the S hoc k oil

Move sl owl y and

wait th e bub ble

come ou t fro m

the liq uid

23

1:1 Scale

7264

M3x4. 8 Scr ew ro d

7269

Ball bear ing φ8x 5x2.5

B-10E

x4

x4

16.STEERING SET ASSEMBLY

7264

7269

7269

7215

Add app rop ria te

amoun t of oi l

7264

7216

转向组

x5

7251

M3X10 P an Se lf- tapping Sc rew S et

x8

7257

M3X10 P an He ad Sc rew Set

7215

Add app rop ria te

amoun t of oi l

Steerin g Servo Tu rnbuc kle

17.UPPER DECK ASSEMBLY

7197

7251

7217

7251

7257

Put a lit tle

screw g lue

7218

Put a lit tle

screw g lue

7257

7251

20

22

1:1 Scale

Lock Nu t M2. 5

7261

x2

x4

18.FRONT SHOCK ABSORBER ASSEMBLY

7230

7228

7261

The nut s hou ld no t be

locke d too t igh tly,

or the E bu ckl e may

fall of a fte r ext rusion

Add the S hoc k oil

l

i

O

7225

7228

7229

7273

7273

Ball Head S et

7228

Φ7.9x2.5

7228

Φ9.5x2

7228/72 29

Φ8.1xΦ3.35

7261

Lock Nu t M2. 5

7273

Ball Head S et

x2

x2

x4

x2

x4

7228

7228

7272

7223

53.50 mm

7221 Fron t Shock S pring (blac k)

7232

7228

7229

7230

7273

7228

7226

7228

Move sl owl y and w ait

the bub ble c ome o ut

from th e liq uid

1:1

24. 3mm

≈

7227

7221

7231

48.80 mm

Front Sho ck Rods

91.8mm

1:1

19.REAR SHOCK ABSORBER ASSEMBLY

7228

7261

7228

7228

7272

The nut s hou ld no t be

locke d too t igh tly,

or the E bu ckl e may

fall of a fte r ext rusion

7232

Add the S hoc k oil

l

i

O

7225

7228

7229

7230

7273

x2

7224

7228

Φ7.9x2.5

x2

7228

Φ9.5x2

x4

7228/72 29

Φ3.35

7221 Rear S hock Sp ring( black )

55.00 mm

Rear Shoc k Rods

67.00mm

23

21

1:1

7228

7229

1:1

7228

7228

7273

7230

30.3m m

≈

7226

Move sl owl y and

wait th e bub ble

come ou t fro m

the liq uid

107.45m m

7227

7222

7231

22.SERVO\ RECEIVER ESC\ ASSEMBLY

23.BATTERY ASSEMBLY

7233

7283

7287

7245

7250

7246

Rec eiver

90. 00°

Ins tallm ent of th e ser vo ar m.

2.A djust t he serv o in the middl e, th en

adj ust the s teeri ng syst em to the s ame

sit uatio n. The se rvo r ock er sho uld k eep a n

ang le of 90° ± 5°wit h the hor izon

1.P ress th e F crank s et into s ervo

whe el(Th e tooth p rofil e of the cr ank set

sho uld aim at tha t of se rvo )

3.P ress th e servo rock er in to th e out to oth

of th e crank s et(Th e tooth p rofil e of the

ser vo rock er shou ld aim at the to oth p rof ile

of th e crank s et), fi nally l ock the scre w.

7274

7284

7288

7211

7274

x4

7252

x1

7245

x1

7250

x1

7246

x2

7274

7252

7211

7286

7286

7286

M3X12 P an Se lf- tapping Sc rew S et

M3X8 Fl at He ad Se lf-tappi ng

Screw S et

M3X6 Pa n Sel f-t apping Scr ew Se t

M3X10 F lat H ead S elf-tapp ing

Screw S et

R-Pin S et

Spong e dou ble -

sided t ape

Spong e dou ble -

sided t ape

25

1:1 Scale

B-10E

1:1 Scale

M3X20 P an Se lf- tapping Sc rew S et

7255

20. SHOCK ABSORBER ASSEMBLY FRONT

x2

M3X16 P an Se lf- tapping Sc rew S et

7254

7230

Shock E nd Se t

Φ7x4.5

x2

x2

21.REAR SHOCK ABSORBER ASSEMBLY

7255

7219

7254

7219

7230

x2

M3X20 P an Se lf- tapping Sc rew S et

7255

7254

M3X16 P an Se lf- tapping Sc rew S et

Shock E nd Se t Φ7x4.5

x2

x2

7230

7220

7230

7255

7220

7254

22

24

1:1 Scale

x4

7252

M3X12 P an Se lf- tapping Sc rew S et

22.SERVO\ RECEIVER ESC\ ASSEMBLY

7211

Rec eiver

x1

M3X8 Fl at He ad Se lf-tappi ng

Screw S et

M3X6 Pa n Sel f-t apping Scr ew Se t

M3X10 F lat H ead S elf-tapp ing

Screw S et

7245

x1

7250

x1

7246

7283

7287

Spong e dou ble sided t ape

7245

Spong e dou ble sided t ape

7250

7233

7286

7246

7286

7286

90. 00°

Ins tallm ent of th e ser vo ar m.

1.P ress th e F crank s et into s ervo

whe el(Th e tooth p rofil e of the cr ank set

sho uld aim at tha t of se rvo )

2.A djust t he serv o in the mi ddle, then

adj ust the s teeri ng syst em to the s ame

sit uatio n. The se rvo r ock er sho uld k eep a n

ang le of 90° ± 5°wit h the hor izon

3.P ress th e servo r ocker into t he ou t too th

of th e crank s et(Th e tooth p rofil e of the

ser vo rock er shou ld aim at the to oth p rof ile

of th e crank s et), fi nally l ock the scre w.

7252

7274

R-Pin S et

x2

23.BATTERY ASSEMBLY

7211

7274

7284

7288

7274

25

23

26.BODY ASSEMBLY

7243

7239/ 7240/724 1

7274

7274

7274

7274

7238

7238

7274

x4

R-Pin S et

27

1:1 Scale

B-10E

24.TIRE ASSEMBLY

7236

7237

2. La rgen th e tire set an d cover i t

on the tire r im ( Note : You need to

disting uish th e right s ide and

reverse s ide acc ordin g to the

texture o f the tir e becau se the ri ght

and left ti re shou ld be ins talle d and

used symm etric ally)

Insta nt

adhes ive

7236

7237

1 put the compres se d sponge

into the tire( No ti ce: the tire,

sponge, of the fr on t tire is

narrower than t he b ack tire

7234

7235

3.Wid en th e tou ch part of the t ire a nd

rim, an d the n dro p in the unive rsa l glu e(

note: The air sho uld f low w ell whe n you

use the u niv ers al glue. The oper ato r

shoul d wea r res pirator, go ggl e and

glove s to av oid t he acciden t. Th e

juven ile s sho uld op

super vis e of th e adults

erate u nde r the

1:1 Scale

25.TIRE ASSEMBLY

x4

7262

Lock Nu t M4

Note: You n eed t o dis tinguish t he ri ght s ide and r eve rse

side ac cor din g to the textu re of t he ti re beca use t he ri ght

and lef t tir e sho uld be insta lle d and u sed sym met ric ally

7262

7235/ 7237

7262

7234/ 7236

7234/ 7236

7262

7235/ 7237

24

7262

26

1:1 Scale

R-Pin S et

26.BODY ASSEMBLY

x4

7274

7239/ 7240/724 1

7243

7274

7274

7274

7238

7238

7274

27

25

726 4

719 9

724 9

719 9

719 9

720 0

724 9

721 0

724 6

719 8

721 1

728 2/728 6

725 1

721 1

721 1

721 1

724 5

724 5

727 4

727 4

728 1/728 5

719 6

719 6

726 4

726 4

718 2

725 4

724 7

719 7

727 4

727 4

719 3

725 0

719 3

727 7

719 3

725 4

725 5

725 2

727 7

728 4

728 4

721 1

724 5

接收机

725 1

717 7

721 9

725 4

725 5

723 0

727 1

727 1

724 7

717 0

717 5

717 5

727 2

717 5

717 9

726 4

719 5

726 4

726 4

727 0

727 0

717 7

726 2

719 4

718 4

719 2

719 2

719 2

725 8

725 3

726 3

726 3

718 7

723 4/723 6

718 5

727 1

718 6

727 0

726 8

718 8

718 5

718 5/726 6

718 5

726 7

718 5

717 6

726 0

718 1

724 6

724 7

7

245

726 5

726 5

726 5

726 5

721 3

721 3

721 2

721 2

721 4

725 3

719 2

725 8

721 3

721 3

721 3

721 3

721 3

726 9

726 9

726 9

721 3

102 46

721 6

721 6

726 4

726 4

726 0

724 9

720 4

726 2

720 5

728 3/728 7

721 8

723 8

727 4

719 7

725 7

725 7

725 1

725 1

725 7

725 7

723 5

723 7

722 0

723 0

719 3

725 8

723 5/723 7

726 2

726 0

720 7

726 0

720 6

720 4

720 4

720 2

720 2

720 3

726 8

726 8

720 4

727 1

725 6

720 8

720 9

720 4

719 1

719 0

719 0

727 8

727 0

727 0

718 9

718 9

718 9

719 4

726 8

718 8

726 2

722 0

725 4

725 5

723 0

724 7

718 1

727 5

727 0

719 3

719 3

725 8

718 4

717 7

727 0

717 6

717 5

71

71

717 1

717 5

727 2

717 0

717 7

725 1

727 4

725 1

719 7

725 1

718 3

718 1

B-10E

ZD10421-S

718 2

724 8

717 8

718 1

725 0

727 7

719 2

723 0

725 5

725 4

721 9

726 4

719 5

726 2

723 4/723 6

29

B-10E

Diagram of bod ys he ll tags

26

28

725 0

719 3

725 4

727 7

719 3

718 2

719 3

727 4

719 7

724 7

727 4

725 1

727 4

725 1

717 7

717 1

718 1

718 3

717 0

727 2

717 5

717 6

725 1

725 5

719 7

722 0

717 5

717 1

725 4

727 0

717 7

718 4

725 5

723 0

725 8

719 3

719 3

719 6

727 5

727 0

725 4

722 0

718 8

726 8

719 4

718 9

718 9

727 0

726 4

721 1

719 1

727 0

727 8

719 0

718 9

727 4

719 0

721 1

724 5

726 2

723 7

723 5

728 2/728 6

721 1

726 2

720 7

726 0

725 1

725 7

725 1

B-10E

ZD10421-S

EB10

723 0

725 8

719 3

723 5/723 7

719 6

726 4

719 9

726 0

720 6

720 4

720 2

720 3

721 8

723 8

719 7

727 4

725 7

728 1/728 5

726 8

726 8

720 2

720 4

720 9

726 0

720 4

725 6

720 8

725 7

725 7

724 7

718 1

726 4

724 9

721 1

724 5

727 7

728 4

接收机

726 4

721 6

721 6

721 3

726 9

720 4

727 1

728 3/728 7

724 6

720 0

728 4

725 2

726 4

724 9

720 4

720 5

719 8

721 3

721 3

721 3

726 9

721 3

102 46

721 3

726 9

721 3

721 4

726 2

726 5

721 2

726 5

721 3

721 2

725 8

719 2

726 5

726 2

723 4/723 6

724 7

718 1

726 0

717 6

726 5

727 0

724 5

717 7

719 2

725 3

717 9

726 4

719 5

726 4

725 1

726 2

723 4/723 6

721 1

719 9

721 0

724 6

719 9

718 5

726 7

718 5

725 8

719 2

727 0

717 5

717 5

727 2

717 5

717 0

724 7

721 9

723 0

727 4

724 5

718 8

724 9

718 5/726 6

718 5

725 3

725 5

726 3

719 2

718 4

726 4

727 1

727 1

717 7

725 1

719 2

725 4

726 8

727 0

718 6

727 1

718 5

718 7

726 3

719 4

726 4

719 5

721 9

723 0

725 5

727 7

725 0

724 8

718 1

717 8

725 4

718 2

29

27

721772157214

7213

7216

721272117210

7209720872077206

7205720472037202

7201720071997198

7197719671957194

Front /Re ar Lowe r

Suspens ion Pin s

o

Front Upp er rod se t 1 / 2 / 3

o o

Rear Uppe r rod set 1 /2 /3

o o o

Wing Moun t Plast ics

Chassis

Alumini um stru t (4pcs )

Servo Sav er Post

Slipper C lutch c omple te

with Main G ear

Asbesto s paper f ricti on plat e

Reducti on Gear

Adjusti ng spri ng/

Adjusti ng spri ng moun t/

Asbesto s briqu ettin g

Dogbone -Outd rive

Slipper C lutch

Reducti on gear s haft Gear Con necti ng cups

Alumini um Mot

or Mount

21T Mot or Gear

Alumini um Cent er Driv eshaft

Battery Tr ay and Po sts Steerin g Rods Se rvo Sav er/St eering Arm s

Steerin g Conne cting P late Steerin g Servo Tu rnbuc kle

Servo Arm Pla stic

Front Upp er Chas sis Bra ce

REPLACEMENT PARTS

31

B-10E

REPLACEMENT PARTS

71717170

Complet e Differen tial Set

7174 7175 7176 7177

Diffe renti al Outd rives

front+r ear

7178 71817180

Front Bum per

Diffe renti al Crow n Gear

38T+Sea ling

Diff Pi nion Ge ar 13T (2 pcs) O utdri ve Gear B ox fron t Gea r Box (1p cs)

7179

Front Sho ck Towe r

Diffe renti al Case a nd Sealin g

Front Sus pensi on Arm Set

71737172

Diffe renti al Gear S et (4pcs)

Susp. Arm Hin ge Pin Br ace

front&r ear

71837182 7185

3x30mm Hi nge Pin ( 4pcs)

Steerin g Knuck les

Rear Shoc k Tower

C-Hubs wi th Inse rts

71917190

7184

Rear Susp ensio n Arm Set

7192

Wheel Hex N uts

Univers al Dri

7189718871877186

Rear Hub Ca r.+ Hex

Wheel-A d.(ea ch with 2 pcs)

7193

ve shaft

Rear Hub Ca rrier Ax le

Horizon tal dri ve shaf ts

28

30

Front Swa y Bar Set Rear S way Bar Set

REPLACEMENT PARTS

7197719671957194

Front /Re ar Lowe r

Suspens ion Pin s

Chassis

Asbesto s paper f ricti on plat e

o

Front Upp er rod se t 1 / 2 / 3

o o

Alumini um stru t (4pcs )

Reducti on Gear

Rear Uppe r rod set 1 /2 /3

o o o

Servo Sav er Post

Adjusti ng spri ng/

Adjusti ng spri ng moun t/

Asbesto s briqu ettin g

Wing Moun t Plast ics

7201720071997198

Slipper C lutch c omple te

with Main G ear

7205720472037202

Dogbone -Outd rive

Slipper C lutch

7209720872077206

Reducti on gear s haft Gear Con necti ng cups

Alumini um Cent er Driv eshaft

ng Connec ting Pl ate Steeri ng Servo Tur nbuck le

Steeri

Battery Tr ay and Po sts Steerin g Rods Se rvo Sav er/St eering Arm s

Alumini um Moto r Mount

721272117210

7216

Servo Arm Pla stic

29

31

21T Mot or Gear

7213

721772157214

Front Upp er Chas sis Bra ce

7249

726672657264

7260 7261 7262 7 263

7259725872577256

7251

7253 7 254 72 55

7248 7250

7247

7252

72467244 7245

7267

REPLACEMENT PARTS

M2x10 Soc ket Cap S crew

M3X8 Flat H ead Sel f-

tapping S crew Se t

M3X10 Fla t Head Se lf-

tapping S crew Se t

M3X12 Fla t Head

Self-tapping S crew Se t

M3X20 Fla t Head

Self-ta pping S crew Se t

M3X8 Flat H ead Scr ew Set

M3X6 Pan Se lf-ta pping

Screw Set

M3X10 Pan S elf-t appin g

Screw Set

M3X12 Pan S elf-t appin g

Screw Set

M3X14 Pan S elf-t appin g

Screw Set

M3X16 Pan S elf-t appin g

Screw Set

M3X20 Pan S elf-t appin g

Sc

rew Set

M3X8 Pan He ad Scre w Set M3X10 Pa n Head Sc rew Set Set Screw M 3x3 Set Screw M 3x10

Set Screw M 4x4

Lock Nut M2 .5

Lock Nut M4

M3x4.1 Sc rew rod

M3x4.8 Sc rew rod

Steering Ball Screws φ4.7-M3

φ2x9.7 Pin Set φ 2x10 Pi n Set

33

B-10E

REPLACEMENT PARTS

Middle Up per Cha ssis Pl ate

Rear Shoc k Sprin g(bla ck)

Front Sho ck Set Rear Shoc k Set

Front Sho ck Rods Rear Shoc k Rods

7221722072197218

Front Sho ck Spri ng(bl ack)

7225722472237222

Shock cap

7229722872277226

Shock sea l cover

Shock End S et Uppe r/Low er

Front Tire R im Set Fr ont Tire R im Set

7238

Shock adj ustme ntrin g Shoc k absor ber pisto n group Shock Sea ling Se t (4pcs )

Shock spr ing low er seat

Front/Rear sho ck abso rber

cylinde r block

Tyre+Ins erts fr ont (2p cs) Tyre+Ins erts re ar (2pc s)

Φ8xΦ5x2.5 x4

7233723272317230

Server cr ankse t

723772357234 7236

728272817280

8 8 15 2 9 4 5 5 5 4

Asbesto s paper f ricti on

Antenn

a tube/an tenna c ap

plate φ25 .5x17 .5x1. 0

Φ10xΦ5x4 x10

Φ15xΦ10x4 x7

Complet e Beari ng Set

30

32

4 5 7 4 13 4 6 2 4

Complet e Screw S et

REPLACEMENT PARTS

72467244 7245

M2x10 Soc ket Cap S crew

7248 7250

M3X20 Fla t Head

Self-ta pping S crew Se t

7252

M3X8 Flat H ead Sel ftapping S crew Se t

7249

M3X8 Flat H ead Scr ew Set

7253 7 254 72 55

M3X10 Fla t Head Se lftapping S crew Se t

M3X6 Pan Se lf-ta pping

Screw Set

7247

M3X12 Fla t Head

Self-ta pping S crew Se t

7251

M3X10 Pan S elf-t appin g

Screw Set

M3X12 Pan S elf-t appin g

Screw Set

M3X8 Pan He ad Scre w Set M3X10 Pa n Head Sc rew Set Set Screw M 3x3 Set Screw M 3x10

7260 7261 7262 7 263

Set Screw M 4x4

M3X14 Pan S elf-t appin g

Screw Set

Lock Nut M2 .5

M3X16 Pan S elf-t appin g

Screw Set

Lock Nut M4

726672657264

M3X20 Pan S elf-t appin g

Screw Set

7259725872577256

M3x4.1 Sc rew rod

7267

3x4.8 Scr ew rod

M

Steering Ball Screws φ4.7-M3

33

φ2x9.7 Pin Set φ 2x10 Pi n Set

31

7284 72 86

7288 7 289

7283 7285

7287

REPLACEMENT PARTS

Brushed E SC Ni-MH 300 0mAh 7. 2V 15C Brus hed Motor 540 3.5 KG Serv o

Brushle ss ESC 60 A Li-Po 320 0mAh 7. 4V 18C Brushle ss Moto r Kv360 0

35

/

/

B-10E

REPLACEMENT PARTS

7271727072697268

φ2x11 Pin S et

E butto n φ2.5x0. 4

φ10xφ5.5x0.3 Washers φ8xφ3.2x0.5 Washers

7239/72 40/7241

Ball bear ing φ8x 5x2.5 Ball beari ng φ10x 5x4 B all bea ring φ1 5x10x 4

7275727472737272

Ball Head S et R-Pin Set

7279727872777276

Rear Whee l Shaft Wash ers

7243

φ8xφ5.1x0.3 Washers

Diffe renti al seal ring

Body (whi te)72 39

Body(ye llow) 7240

Body tran spare nt 7241

7242

Body and ta il stic ker

32

Tail Wing(W hite/ y ellow / black )

7290

Dust cove r

34

REPLACEMENT PARTS

R E P L A C E ME N T P A R T S

7 2 8 3 7 2 8 5

7283 7285

Brushed E SC Ni-MH 300 0mAh 7. 2V 15C Brus hed Motor 540 Servo 6-15kgs

Brushed E SC Ni-MH 300 0mAh 7. 2V 15C Brus hed Motor 540 3.5 KG Serv o

7 2 8 7

7287

Brushless ESC 45A-120A

Brushle ss ESC 60 A Li-Po 320 0mAh 7. 4V 18C Brushle ss Moto r Kv360 0

7 2 8 4 7 2 8 6

7284 72 86

7 2 8 8 7289

7288 7 289

LiPo 3600-6000mAh -

7.4v-11.1v

Motor Brushless 4 Poles

3000-3900kv

35

33

Por medio de la presente RC MITICO S.L. declara que el equipo de radiocontrol cumple los

requisitos esenciales y cualesquiera otras disposiciones aplicables o exigibles de la Directiva

1999/5/CE.

Hereby, RC MITICO S.L. declares that this Radio Control Equipment is in compliance with the

essential requirements and other relevant provisions of Directive 1995/5/EC.

IMPORTADOR:

CIF.: B-86452125

28914, Leganés - Madrid (España)

+14

Loading...

Loading...