Page 1

USER MANUAL

UP 9501

UP 9502

UP 9504

- DXT 9000

SYSTEM AMPLIFIERS

Page 2

Page 3

SAFETY PRECAUTIONS

NOTES ABOUT AUDIO SIGNAL CABLES

DXT 9000 SYSTEM DESCRIPTION

UP 9500 SERIES AMPLIFIER MAIN FEATURES

INSTALLATION INTO A 19” RACK CABINET

FRONT PANEL

REAR PANEL

LOUDSPEAKER CONNECTION

OPERATING AS DXT 9000 SYSTEM COMPONENTS

USE AS GENERIC AMPLIFIER

AUDIO SET MENU

CALIBRAT MENU

ROUTING MENU

SYSTEM MENU

INFO MENU

DISPLAY TEXT MESSAGES

INTERNAL JUMPER SETTINGS

CONNECTION EXAMPLE

SPARE AMPLIFIER (UP 9501) CONNECTION EXAMPLE

GUIDANCE ON THE MEASUREMENT OF THE SPEAKER LINE IMPEDANCE

SPECIFICATIONS

APPENDIX

4

5

6

10

11

12

16

20

21

21

22

25

25

25

25

26

27

28

29

30

34

35

TABLE OF CONTENTS

Page 4

4

ENGLISH

IMPORTANT

WARNING

SAFETY PRECAUTIONS

IMPORTANT

Before connecting and using this product, please read this instruction manual carefully and keep it

on hand for future reference.

The manual is to be considered an integral part of this product and must accompany it when it

changes ownership as a reference for correct installation and use as well as for the safety precautions.

RCF S.p.A. will not assume any responsibility for the incorrect installation and / or use of this product.

WARNING: To prevent the risk of re or electric shock, never expose this product to rain or humidity.

This device is intended for indoor use only.

SAFETY PRECAUTIONS

1. All the precautions, in particular the safety ones, must be read with special attention, as they

provide important information.

2.1 PRIMARY POWER SUPPLY FROM MAINS

- The mains voltage is sufciently high to involve a risk of electrocution: never install or connect this

product when its power cord is plugged in.

- Before powering up, make sure that all the connections have been made correctly and the voltage

of your mains corresponds to the voltage shown on the rating plate on the unit, if not, please

contact your RCF dealer.

- This apparatus can be connected to either TT or TN earthing arrangements only.

- The metallic parts of the unit are earthed by means of the power cord. An apparatus with CLASS

I construction shall be connected to a mains socket outlet with a protective earthing connection.

- This apparatus shall be connected to a facility equipped device to protect against earth faults,

appropriately sized for the type and power of the installed line (RCD).

- Protect the power cord from damage. Make sure it is positioned in a way that it cannot be stepped

on or crushed by objects.

- To prevent the risk of electric shock, never open this product: there are no parts inside that the

user needs to access.

- The mains plug is used to disconnect the device and it shall remain readily operable.

2.2 SECONDARY (/ EMERGENCY) POWER SUPPLY THROUGH BATTERIES

- The apparatus operating voltage is 48 V dc (therefore, it is necessary to connect in series several

batteries having a lower nominal voltage, example: 4 x 12 V, 2 x 24 V).

- Always use rechargeable batteries, which need to be chosen according to the maximum possible

load.

- Verify the polarity of batteries is correct.

- Do NOT short-circuit batteries (i.e. connecting the 2 opposite poles together with metallic wires).

- The 48 V dc plug is used to disconnect the device and it shall remain readily operable.

- The 48 V dc power supply does not go beyond the fact that there are dangerous voltages inside

the unit.

- Throw empty batteries away according to your country laws about ecology and environment

protection.

3. Make sure that no objects or liquids can get into this product, as this may cause a short circuit.

This apparatus shall not be exposed to dripping or splashing. No objects lled with liquid (such as

vases) and no naked sources (such as lighted candles) shall be placed on this apparatus.

4. Never attempt to carry out any operations, modications or repairs that are not expressly described

in this manual.

Contact your authorized service centre or qualied personnel should any of the following occur:

- The product does not function (or functions in an anomalous way).

- The power cord has been damaged.

- Objects or liquids have got into the product.

- The product has been subject to a heavy impact.

5. If this product is not used for a long period, disconnect its power cord and batteries.

6. If this product begins emitting any strange odours or smoke, switch it off immediately and

disconnect its power cord and batteries.

Page 5

5

ENGLISH

NOTES ABOUT AUDIO SIGNAL CABLES

7. The terminals marked with the symbol are HAZARDOUS LIVE and their connection is to be

made by an INSTRUCTED PERSON or the use of ready-made cables is required.

8. Do not connect this product to any equipment or accessories not foreseen.

For suspended installation, only use the dedicated anchoring points and do not try to hang this

product by using elements that are unsuitable or not specic for this purpose.

Also check the suitability of the support surface to which the product is anchored (wall, ceiling,

structure, etc.), and the components used for attachment (screw anchors, screws, brackets not

supplied by RCF etc.), which must guarantee the security of the system / installation over time, also

considering, for example, the mechanical vibrations normally generated by transducers.

To prevent the risk of falling equipment, do not stack multiple units of this product unless this

possibility is specied in this user manual.

9. RCF S.p.A. strongly recommends this product is only installed by professional

qualied installers (or specialised rms) who can ensure correct installation and certify

it according to the regulations in force.

The entire audio system must comply with the current standards and regulations

regarding electrical systems.

10. Supports and trolleys

The equipment should be only used on trolleys or supports, where necessary, that are recommended

by the manufacturer. The equipment / support / trolley assembly must be moved with extreme caution.

Sudden stops, excessive pushing force and uneven oors may cause the assembly to overturn.

11. Mechanical and electrical factors need to be considered when installing a professional audio

system (in addition to those which are strictly acoustic, such as sound pressure, angles of coverage,

frequency response, etc.).

12. Hearing loss

Exposure to high sound levels can cause permanent hearing loss. The acoustic pressure level that

leads to hearing loss is different from person to person and depends on the duration of exposure. To

prevent potentially dangerous exposure to high levels of acoustic pressure, anyone who is exposed

to these levels should use adequate protection devices.

When a transducer capable of producing high sound levels is being used, it is therefore necessary to

wear ear plugs or protective earphones.

See the technical specications in loudspeaker instruction manuals to know their maximum sound

pressure levels.

13. Do not obstruct the ventilation grilles of the unit. Situate this product far from any heat sources

and always ensure adequate air circulation around the ventilation grilles.

14. Do not overload ampliers. Check that amplier outputs are not shorted.

15. Never force the control elements (keys, knobs, etc. ).

16. Do not use solvents, alcohol, benzene or other volatile substances for cleaning the external parts

of this product.

Use a dry cloth.

To prevent the occurrence of noise on microphone / line signal cables, use screened cables only and

avoid putting them close to:

- Equipment that produces high-intensity electromagnetic elds.

- Mains cables.

- Loudspeaker lines.

WARNING:

Any change made by unauthorized

personnel to the product and / or the

system (in which it is installed and

congured, including rack cabinet and

wiring) may invalidate the CE marking

(certication EN54-16: 2008) and also

the product warranty.

Page 6

6

ENGLISH

RCF S.P.A. THANKS YOU FOR PURCHASING THIS PRODUCT, WHICH HAS BEEN

MADE TO GUARANTEE RELIABILITY AND HIGH PERFORMANCE.

DXT 9000 is a monitored digital paging / evacuation system in compliance with EN 54-16

and ISO 7240-19 that allows a completely scalable and versatile range of congurations

and solutions.

It features a double-ring topology approach: a rst simple ring for the small and medium

size systems and a second larger ring supported by main units with router (MU 9186/R) for

large and extra-large applications, always plug & play and easy-congurable.

For instance, a small system can be designed by using only one MX 9502 / MX 9504

main unit, which already includes all the necessary controls and two 250 W (MX 9502)

/ four 125 W (MX 9504) class D power ampliers (having 100 V / 70 V constant voltage

loudspeaker lines).

A system that requires a higher output power or a larger number of zones can be obtained

by adding one or more system ampliers model UP 9501 (1 x 500 W), UP 9502 (2 x 250

W) or UP 9504 (4 x 125 W) to the MX 9502 / MX 9504, connected through the dedicated

RCF FLEXCOM data-link port.

MU 9186 is another main unit model similar to MX 9502 / MX 9504, but without internal

power ampliers.

Since data wiring may have critical connections, for instance due to cable type and length,

RCF FLEXCOM bus can adapt the data communication speed to the wiring characteristics

and available data band.

Only a few devices are necessary to design the simplest and the most complex projects,

centralized or distributed: no matter if a supermarket or a theatre, an airport or a shopping

centre, a fast-food or an underground, a school or a hospital.

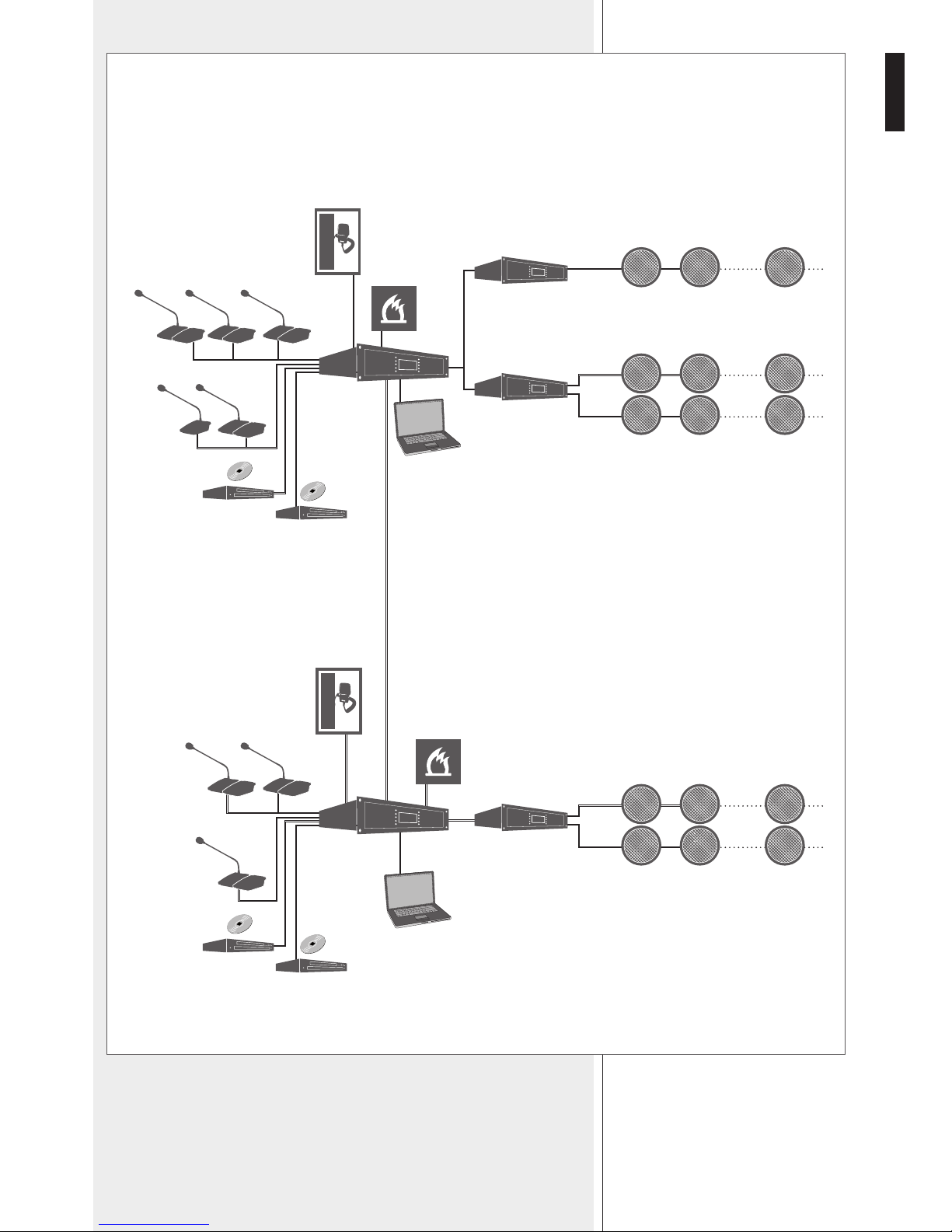

DXT 9000 SYSTEM DESCRIPTION

100 V / 70 V LINES

100 V / 70 V LOUDSPEAKERS

MX 9504

100 V / 70 V LINES

100 V / 70 V LOUDSPEAKERS

100 V / 70 V LOUDSPEAKERS

MX 9504

UP 9501

100 V / 70 V LINES

Page 7

7

ENGLISH

Diagnostic functions and fault reporting meet all evacuation system requirements.

Wiring is limited to a twin pair J-type re-rated cable for most of connections and to a fourpair J-type re-rated cable to link paging microphones.

The system conguration can be edited on the main unit front panel (for small systems),

but it can also be made through a local or remote PC, by using a dedicated graphic user

interface software.

The dual power supply allows both AC and DC operation.

The ‘RCF D+ Class’ power amplier technology and recover-fall-back built-in facility make

the DXT 9000 a highly secure, reliable and safe system.

Each DXT 9000 unit is equipped with an RS 485 serial port to be used for the dedicated

system programmable remote controls. Noise detection devices work on RS 485 port as

well.

Two pre-recorded messages can be simultaneously played and sent to the DXT 9000

network from main units, which can store both emergency messages (to a checked

dedicated memory) and routine messages (on separated SD cards).

Another SD/USB support is used as MP3 player (to play background music).

The Ethernet port (on main units) allows to get the complete remote control of the entire

system.

The Ethernet port (on main units) allows to get the complete remote control of the entire

system.

DXT 9000 devices have programmable logic inputs and outputs, checked by the system

itself or by the connected security/emergency devices, such as re alarm systems.

Each component has its own digital address.

DXT 9000 includes high quality digital components already in use for RCF professional

audio systems, obtaining high performances and qualifying the DXT 9000 system for

installations in places that require a very good sound reproduction, such as theatres and

auditoriums.

DXT 9000 SYSTEM COMPONENTS

- MX 9502 Main unit including two 250 W class D ampliers inside

- MX 9504 Main unit including four 125 W class D ampliers inside

- MU 9186 Main unit (no power ampliers inside)

- MU 9186/R Main unit with router (no power ampliers inside)

- UP 9501 Unit with a single 500 W class D amplier

- UP 9502 Unit with two 250 W class D ampliers

- UP 9504 Unit with four 125 W 500 W class D ampliers

- BM 9804 Paging microphone with zone selection

- BM 9802 Paging microphone with zone selection through numeric keyboard

- BE 9808 Additional 8-zone keyboard for paging microphones

- TS 9918 Remote level control and programme selector

Page 8

8

ENGLISH

100 V / 70 V LOUDSPEAKERS LINES

EXAMPLE: SYSTEM WITH MX 9504 MAIN UNIT

EXAMPLE: SYSTEM WITH MU 9186 MAIN UNIT

FALLBACK

EMERGENCY

MIC.

PAGING MIC.

BM 9802

BM 9804

+ BE 9808

MUSIC SOURCES

FIRE ALARM

SYSTEM

MX 9504

PC

FALLBACK

EMERGENCY MIC.

PAGING MIC.

BM 9802

BM 9804

+ BE 9808

MUSIC SOURCES

FIRE ALARM

SYSTEM

MU 9186

PC

100 V / 70 V LOUDSPEAKERS LINES

UP 9501

UP 9502

UP 9504

Page 9

9

ENGLISH

100 V / 70 V LOUDSPEAKER LINES

UP 9502

UP 9501

EXAMPLE: SYSTEM WITH NETWORK

100 V / 70 V LOUDSPEAKERS LINES

UP 9502

FALLBACK

EMERGENCY MIC.

PAGING MIC.

BM 9802

BM 9804

+ BE 9808

MUSIC SOURCES

FIRE ALARM

SYSTEM

MU 9186/R

PC

FALLBACK

EMERGENCY

MIC.

PAGING MIC.

BM 9802

BM 9804

+ BE 9808

MUSIC SOURCES

FIRE ALARM

SYSTEM

MU 9186/R

PC

Page 10

10

ENGLISH

UP 9500 series ampliers are based on RCF ‘Class D+’ technology and have a FALL BACK

emergency audio input, making the DXT 9000 system highly safe and reliable.

These can operate as either DXT 9000 system components (linked to MU 9186 / MX 9502

/ MX 9504 main units) or generic ampliers (with limited functionality) for other audio

systems.

The three models differ in the number of channels, the power per channel and the number

of amplied outputs.

UP 9501 has a single 500 W internal amplier, UP 9502 has two 250 W internal ampliers,

UP 9504 has four 125 W internal ampliers.

The UP 9501 model has 2 amplied outputs (1 channel only), the UP 9502 model has 2

amplied outputs for both channels, the UP 9504 model has a single amplied output per

each channel.

Every amplied output is a monitored 100 V / 70 V loudspeaker line.

The only model UP 9501 (1 x 500 W) can be set as the spare amplier (for one or more

ampliers) that automatically replaces the faulty one.

The spare amplier (of a system / system part) shall be necessarily installed into the same

rack cabinet where ampliers to be replaced (in case of fault) are already placed.

A local FALL BACK input is available to link a dedicated and independent paging microphone

(or another audio source) for emergency announcements.

Another local input is available to link a device for background music (e.g. CD / MP3

player).

Diagnosis is in compliance with EN 54-16 and ISO 7240-19.

Front panel control with LCD display.

RCF-FLEXCOM digital audio bus.

12 GPI logic inputs (8 monitored and 4 optical) and 8 GPO logic outputs (relays).

RS 485 serial port (screw terminals) for interfacing and monitoring.

AC and DC power supply.

UP 9500 SERIES AMPLIFIER MAIN FEATURES

Page 11

11

ENGLISH

INSTALLATION INTO A 19” RACK CABINET

BLOCK DIAGRAM

Fix every amplier to the front side of a 19” rack cabinet through 4 screws.

UP 9500 series ampliers have forced ventilation controlled by a thermostat and can be

stacked without spaces or ventilation panels.

Air ventilation is horizontal, so it is necessary to keep open the lateral sides.

Rack cabinets shall have:

- At least an IP 30 rating.

- A door with glass (or a thin metal mesh), through which the warning and emergency

light indications are clearly visible (according to regulations).

Page 12

12

ENGLISH

FRONT PANEL

1

SYSTEM ON button: press and hold to turn amplier on (when off).

This button also works as fault acknowledge: press it to remove the displayed fault

indication.

The

SYSTEM ON

buTTon does noT Turn The uniT off. To swiTch The uniT off, make sure The 48 V

dc power supply (baTTeries) is noT presenT and use eiTher The proper sofTware funcTion or The main

power 41 swiTch on The rear panel.

2

ESC (‘Escape’) button: press to quit the displayed menu.

3

Six buttons to select the respective functions shown on the display.

4

CONTROL / SELECTION: rotary encoder and push-button to select.

Turn the control clockwise to scroll the displayed downwards or increase the selected

parameter value.

Turn it counterclockwise to scroll the menu upwards or decrease the selected parameter

value.

Press to select.

5

Display (LCD)

1 2

11 19

13 21

16 24

12 20

15 23

14 22

17 25

18 26

33

33

5

4

33

7 8 9 106

28

a

28

b

27

Page 13

13

ENGLISH

6

÷ 26 LEDs

Nr. SILK SCREEN COLOUR

iT works as

Generic

amplifier

INDICATION (WHEN LIT) FURTHER INFORMATION

6

AC PWR Green Yes

The mains power (AC) is present

and the respective fuse is intact.

If the LED is off, the mains power is

not available (or out of range).

7

DC PWR Green Yes

48 V dc power supply is present

and the respective fuse is intact.

If the LED is off, 48 V dc is not

available (or out of range).

8

AUX PSU Green Yes

The main unit is turned on and

its stand-by power supply unit

operates properly.

9

SYSTEM OK Green Yes

No detected faults:

the entire system is operating

properly.

The LED is lit when no faults are

detected on any system device.

10

GENERAL

FAULT

Yellow No

One or more faults have been

detected, including problems

on power supply, so it can be lit

even if the AC PWR

6

and DC

PWR

7

green LEDs are off.

The LED gets lit even in case of

failure of any peripheral unit.

If a logic input (GPI) is set to obtain

a fault remote indication of an

external device, a possible problem

is indicated by the GENERAL FAULT

LED.

11

FALL BACK

EVENT

Red No

An emergency announcement

(with highest priority) is in

progress through the FALL BACK

INPUT

29

.

12

ALARM Red No

The evacuation message is

currently played. This LED also

indicates the play of a message

from a microphone or an external

source activated as EMERGENCY

(e.g. GPI set to EMERG).

Page 14

14

ENGLISH

Nr. SILK SCREEN COLOUR

It works as

GENErIC

amplIfIEr

INDICATION (WHEN LIT) FURTHER INFORMATION

13

ALERT Yellow No

The alert message is currently

played. This LED also indicates

the play of a message from a

microphone or an external source

activated as ALERT (GPI set to

ALERT).

14

QUIESCENT Green No

The device is switched on but not

playing any audio signal.

It simply indicates an idle state, as

there is no audio signal.

15

DISABLEMENT Yellow Yes

One or more device inputs, outputs

or peripherals are disabled.

This LED is lit only in case of one or

more circuits and/or devices used for

evacuation/emergency are disabled.

In the case, for example, of a nonmonitored paging microphone, its

disabling will not make the LED get

lit.

16

MESSAGE

FAULT

Yellow No

Main unit emergency message

player fault.

Faulty memory or problems on the

audio path (the internal message

player is not properly linked to the

system audio outputs).

17

SYSTEM FAULT Yellow No Internal microprocessor reset.

After rebooting, the LED will be off,

but the reset event will remain in

the SYSTEM / FAULT LOG.

18

PWR SUPPLY

FAULT

Yellow Yes

Power supply fault (internal power

supply, internal boards or external

power supply).

A logic input (GPI) needs to be

linked to the logic output of the

external power supply unit and set

to EXTERNAL EVENT FAULT.

A possible external power supply

unit fault is displayed as EXTERNAL

PSU FAULT.

19

LOCAL FAULT Yellow Yes

Amplier fault. This LED gets lit even

in case of mains power fault.

This LED is lit in the fault device

only.

For instance, if an amplier is faulty

and the MASTER unit is properly

operating, this LED is lit on the

amplier only, while the SYSTEM

FAULT

17

LED is lit on both

MASTER and ampliers.

If a logic input (GPI) is set to signal

a possible fault of an external

system, this will be indicated by

the LOCAL FAULT LED (only in the

unit where the logic input has been

activated).

20

MICROPHONE

FAULT

Yellow No

An emergency paging microphone

(among those connected to the FALL

BACK INPUT

29

is faulty.

21

AMPLIFIERs

FAULT

Yellow Ye s One or more ampliers are faulty.

22

SPKR

CIRCUITs

FAULT

Yellow Ye s

One or more loudspeaker lines are

faulty.

23

EARTH FAULT Yellow Ye s Loudspeaker line earth leakage.

Page 15

15

ENGLISH

27

MONITOR: 6.3 mm jack input (TRS) for headphones.

28

a

Internal loudspeaker (monitor).

28

b

Internal buzzer for fault alert (or evacuation message in progress).

It can be muted by pressing the SYSTEM ON

1

button.

when used as Generic amplifiers (noT linked To a dXT 9000 sysTem main uniT), only a few leds

are enabled.

Nr. SILK SCREEN COLOUR

It works as

GENErIC

amplIfIEr

INDICATION (WHEN LIT) FURTHER INFORMATION

24

COMM. PORT

FAULT

Yellow No

Hardware / RS 485 serial port (for

linking to a re alarm system) fault.

This indication depends on either a

broken / short-circuited cable or no

data transmission (for example, due

to a damaged serial port) or remote

device unavailable.

25

LOGIC INPUT

FAULT

Yellow No

GPI fault. The LED gets lit when

the logic input is monitored and its

respective line is open or shorted.

A logic input (GPI) needs to be

monitored when linked to a re

alarm system (to activate prerecorded messages remotely).

26

LOGIC

OUTPUT

FAULT

Yellow No

GPO fault. The LED gets lit when the

logic output is monitored and its

respective line is open or shorted.

A logic output (GPO) needs to be

monitored when linked to a re

alarm system (for example, to signal

an audio system fault to the re

alarm system).

Page 16

16

ENGLISH

REAR PANEL

29

FALL BACK INPUT: monitored audio input (balanced, ‘line’ level, for removable

connector) to be used for emergency announcements. This input can be used even in case

of software crash.

AUDIO

– Audio signal (cold)

+ Audio signal (hot)

GND Audio signal ground

CMD

–

Activation and monitoring contacts

of the FALL BACK audio input.

+

UP 9502

UP 9501

36 34

383739

35404142

3233

a

33

b

31 30 29

UP 9504

MAX OUTPUT POWER 500 W RMS

MINIMUM LOAD IMPEDANCE

70 V (20 Ω) - 100 V (40 Ω)

UP

4x125W CLASS D+ POWER AMPLIFIER

AC VOLTAGE SELECTOR

AND FUSE INSIDE,REFER

TO INSTRUCTION MANUAL

WARNING

TO REDUCE THE RISK

OF FIRE OR ELECTRIC SHOCK, DO NOT

EXPOSE THIS EQUIPMENT TO RAIN OR

MOISTURE. DO NOT REMOVE COVER.

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED PERSONNEL.

WARNING

RISK OF ELECTRIC SHOCK DO NOT OPEN

CAUTION

SERIAL NUMBER

GENERAL PURPOSE OUTPUTS

1 2 3 4 5 6 7 8

RELAY OUTPUTS (contact load 0,3A - 24V DC)

BGM 3AUX INPUT

GND

FALL BACK INPUT

CMD

GND

AUDIO

GENERAL PURPOSE INPUTS

Max 100 mA

1 2 3 4 5 6 7 8 9 10 11 12

PHOTO-COUPLED INPUTSMONITORED INPUTS

24V DC

MADE IN ITALY

POWER 115/230V ~ 50-60Hz - 800 W max48 V 15 A max

EN54-16

COMPLIANCE STICKER

Series

SPEAKER LINE OUT

LINE A LINE B

- + - + - +

- +

LINE C LINE D

SPARE AMP BUS

INPUT

- + - +

OUTPUT

GND

28V

GND

BUS OUT

BUS IN

FLEXCOM BUS C TRL RS485

1 2 3 4 1 2 3 4

36 34

383739

b

35404142

3233

a

33

b

31 30 29

36 34

3837

35404142

3233

a

33

b

31 30 29

39

a

39a39

c

39b39

d

Page 17

17

ENGLISH

30

BGM 3 audio input (dual RCA connector) for a ‘line’ level signal (i.e. CD / MP3

player, tuner).

The Two channels (lefT / riGhT) of The

BGM 3

sTereo siGnal are miXed in mono inside The deVice.

31

AUX INPUT balanced audio input (removable connector).

32

CTRL RS485: RS 485 serial port (removable connector).

33

a

FLEXCOM BUS IN: data bus input (removable connector).

33

b

FLEXCOM BUS OUT: data bus output (removable connector).

34

GENERAL PURPOSE INPUTS

12 logic inputs (removable connectors), of which the rst 8 are monitored and the last 4

with opto-isolators.

The loGic inpuTs are enabled only if The deVice is linked To a dXT 9000 sysTem main uniT.

T

he loGical inpuTs 9 To 12 can be acTiVaTed by connecTinG The 24 V dc

35 ouTpuT To each loGic

inpuT. possible loGic sTaTes: inacTiVe / acTiVe.

+ Hot

– Cold

GND Ground

For monitoring purposes, the two CMD contacts should normally be powered by 24 V dc

(voltage available from the 24 V DC

35

. FALL BACK input state depends on presence

and polarity of the voltage at the two CMD contacts.

STATE VOLTAGE AT THE CMD CONTACTS DESCRIPTION

COMMAND KO No voltage The FALL BACK INPUT is not connected

IDLE 24 V dc, direct polarity The FALL BACK INPUT is connected, but inactive

ACTIVE 24 V dc, reverse polarity The FALL BACK INPUT is activated

+ RS 485 B (non-inverting)

– RS 485 A (inverting)

GND RS 485 (reference ground)

28V Power supply + 28 V dc

GND Power supply ground

Page 18

18

ENGLISH

A B

470 Ω 10 kΩ

LOGIC INPUT 1 ÷ 8 STATES:

STATE DETECTED RESISTANCE VALUE (R)

OPEN Open line or too high resistance R > 15 kΩ

SHORT Short-circuit or too low resistance R < 390 Ω

IDLE Used logic input, but inactive 3.4 kΩ < R < 15 kΩ

ACTIVE Activated logic input 390 Ω < R < 1.17 kΩ

SUGGESTED RESISTORS TO BE ADDED TO GET LINE MONITORING:

A B

GPI

(1-8)

35

24 V DC: 24 V dc output, max. 100 mA.

36

GENERAL PURPOSE OUTPUTS

8 logic outputs (relay dry contacts, removable connectors).

Each logic output has two resistors that can be inserted by setting the respective jumper

(JP1 to JP8) to the AB position. These two resistors are necessary when the logic output

(GPO) is linked to a logic input (GPI) of another device and the line monitoring is

required.

The rst resistor (470 Ω) is used to get the ACTIVE state, the second (10 kΩ) to get the

IDLE state.

If a jumper is set to the BC position, the two resistors are overridden (the internal relay

contact is directly connected).

The loGic ouTpuTs are enabled only if The deVice is linked To a dXT 9000 sysTem main uniT.

inTernal jumper seTTinG needs To be carried ouT direcTly by eiTher rcf or an auThorised serVice

cenTre.

warNING:

do noT direcTly power a loGic ouTpuT (

GPO

) when The respecTiVe inTernal jumper

is seT To The

AB

posiTion (inserTed resisTors), as The maX. currenT is only 25 ma. if The jumper is

seT To The

BC

posiTion, The maX. currenT is 1 a.

GPO

B

C

JP 1 ÷ 8

10k

470

A

Page 19

19

ENGLISH

37

SPARE AMP BUS – INPUT

Input to link the spare amplier 100 V / 70 V output.

38

SPARE AMP BUS – OUTPUT

If the amplier is not faulty (and so the spare amplier is not inserted), this 100 V / 70 V output

is directly linked to the SPARE AMP BUS – INPUT

37

and can be used to connect a dummy

load.

39

(UP 9501) SPEAKER LINE OUT

Two 100 V / 70 V loudspeaker line outputs (LINE A1 and LINE A2) of the internal 500 W

amplier.

PAGING IN 2 PAGING IN 1

ROUTINE MESSAGES ETHERNET

MAIN IN

BGM 2 BGM 1

GND

GND

28V

GND

BUS IN

BUS OUT

FLEXCOM BUS

CTRL RS485

1234 1234

MX

2x250W MASTER UNIT

EN54-16

COMPLIANCE STICKER

Series

SPARE AMP BUS

INPUT

- + - +

OUTPUT

39

a

(UP 9502) SPEAKER LINE OUT

Two 100 V / 70 V loudspeaker line outputs (LINE A1 and LINE A2) of the internal

amplier channel A (250 W).

39

b

(UP 9502) SPEAKER LINE OUT

Two 100 V / 70 V loudspeaker line outputs (LINE B1 and LINE B2) of the internal

amplier channel B (250 W).

39

a

(UP 9504) SPEAKER LINE OUT

100 V / 70 V loudspeaker LINE A output of the internal amplier channel A (125 W).

39

b

(UP 9504) SPEAKER LINE OUT

100 V / 70 V loudspeaker LINE B output of the internal amplier channel B (125 W).

39

c

(UP 9504) SPEAKER LINE OUT

100 V / 70 V loudspeaker LINE C output of the internal amplier channel C (125 W).

39

d

(UP 9504) SPEAKER LINE OUT

100 V / 70 V loudspeaker LINE D output of the internal amplier channel D (125 W).

40

Power cord input (to be connected to a mains earthed socket only).

41

POWER switch (0 = OFF, I = ON).

42

Input for 48 V dc power supply (removable screw terminals) through batteries.

noTe: accordinG To en 54-16 sTandard, The backup power supply uniT shall be insTalled inTo The

same rack cabineT where There is The audio sysTem wiTh emerGency purposes (or a sysTem parT) To

which iT is connecTed.

The deTecTion of 48 V dc power supply inVolVes The impliciT condiTion ThaT The sysTem is

always

Turned on, Thus noT allowinG shuTdown of The main uniT ThrouGh The respecTiVe funcTion in

The menu, nor ThrouGh The

POWER

swiTch

41

.

PAGING IN 2 PAGING IN 1

ROUTINE MESSAGES ETHERNET

GND

28V

GND

BUS IN

BUS OUT

FLEXCOM BUS

CTRL RS485

1234 1234

MX

2x250W MASTER UNIT

EN54-16

COMPLIANCE STICKER

MAX OUTPUT POWER 500 W RMS

MINIMUM LOAD IMPEDANCE

70 V (20 ) - 100 V (40 )

Series

SPEAKER LINE OUT

LINE A1 LINE A2

- + - + - + - +

LINE B1 LINE B2

SPARE AMP BUS

INPUT

- + - +

OUTPUT

PAGING IN 2 PAGING IN 1

ROUTINE MESSAGES ETHERNET

GND

28V

GND

BUS IN

BUS OUT

FLEXCOM BUS

CTRL RS485

1234 1234

MX

1x125W MASTER UNIT

EN54-16

COMPLIANCE STICKER

MAX OUTPUT POWER 500 W RMS

MINIMUM LOAD IMPEDANCE

70 V (20 ) - 100 V (40 )

Series

SPEAKER LINE OUT

LINE ALINE B

- + - + - + - +

LINE C LINE D

SPARE AMP BUS

INPUT

- + - +

OUTPUT

Page 20

20

ENGLISH

LOUDSPEAKER CONNECTION

Connect all loudspeaker respecting the phase.

Every loudspeaker shall have a matching transformer, which input is suitable for the line

voltage (70 / 100 V).

The output voltage setting (either 100 V or 70 V) can only be made by an authorised RCF

service centre.

UP 9501

Connect the positive wire of the loudspeaker line to the ‘+’ contact to one of the two amplier

outputs (either LINE A1 or LINE A2)

39

and the negative wire to the respective ‘–’ contact.

The total power of all connected loudspeakers shall not exceed (500 W).

UP 9502

This model has 2 independent channels (A and B), each with 2 outputs (1 and 2):

LINE A1 and LINE A2

39

a

;

LINE B1 and LINE B2

39

b

].

The total power of all connected loudspeakers of a single channel shall not exceed 250 W.

See the UP 9501 model for loudspeaker connection.

UP 9504

This model has 4 independent

channels (A, B, C, D):

LINE A

39

a

;

LINE B

39

b

;

LINE C

39

c

;

LINE D

39

d

.

The total power of all connected loudspeakers of a single channel shall not exceed 125 W.

See the UP 9501 model for loudspeaker connection (note: only one output per channel).

70/

100 v0

70/

100 v0

70/

100 v0

LOUDSPEAKER LOOPED LINE ('RING MODE')

If ampliers are linked to a DXT 9000 system main unit (i.e. MU 9186, MX 9502, MX

9504), in the (only) UP 9501 and UP 9502 models the loudspeaker line can wired as

a loop (by using both channel outputs, to ensure continuity of service even in case of

interruption of the line in a point).

In the DXT 9000 system main unit DXT 9000 (MU 9186, MX 9502, MX 9504), the

SET RING parameter (DISABL-SURV > CALIBRAT > amplier > SET RING) of every

amplier with looped loudspeaker lines shall be set to 'A Ring B Out'.

Page 21

21

ENGLISH

If used as DXT 9000 system components, UP 9501, UP 9502 and UP 9504 ampliers

are controlled by the main unit (MU 9186, MX 9502, MX 9504) to which they are

linked and their displays indicate REMOTE CONTROLLED.

All settings regarding their use as generic independent ampliers (see the next manual

section) are disabled.

OPERATING AS DXT 9000 SYSTEM

COMPONENTS

USE AS GENERIC AMPLIFIER

(NOT LINKED TO DXT 9000 SYSTEM)

Beside the display, there are 6 buttons

3

(3 on the left, 3 on the right) to select the

correspondent displayed options.

The ESC

2

button (below the display, on the right) allows to quit the displayed menu.

Turn and press the CONTROL SELECTION

4

encoder to select parameters and change

their values.

The software initial main menu is shown as MAIN in the top left-hand corner of the

display.

The complete menu path is indicated in the top of the display.

up 9501 model: The selecTions

oUt 2, oUt 3

and

oUt 4

are disabled.

up 9502 model: The selecTions

oUt 3

and

oUt 4

are disabled.

1 4

2 5

3 6

70/

100 v0

70/

100 v0

70/

100 v0

– + – +

LINE A1 LINE A2

Page 22

22

ENGLISH

AUDIO SET > INPUT SUBMENU

The INPUT submenu allows to edit audio inputs.

Select either BGM 3 or AUX IN to access audio input parameters.

AUDIO SET > INPUT

SUBMENU

HPL/LPF 3-BAND EQ LO CUT 5-BAND EQ COMPRESSOR LEVEL

BGM 3 √ √ √

AUX IN √ √ √ √

HPF / LPF (hi-pass lter, low-pass lter)

The hi-pass lter (HPF) cuts low frequencies (below its cutoff frequency), the low-pass

lter (LPF) cuts high frequencies (above its cutoff frequency).

PARAMETERS

FREQ HPF Setting of the hi-pass lter cutoff frequency.

FREQ LPF Setting of the low-pass lter cutoff frequency.

BYPASS Select either ON (lters bypassed) or OFF (lter inserted).

3-BAND EQ

The three bands are semi-parametric equalizers that allow to choose the centre frequency

and adjust its level.

AUDIO SET MENU

SOTTOMENU DESCRIPTION

1 INPUT Audio input settings.

2 OUTPUT Audio output settings.

3 MONITOR Audio monitoring level.

Menu that allows to set input / output parameters and audio monitoring.

MENU DESCRIPTION

1 AUDIO SET Input / output / monitor settings.

2 CALIBRAT Amplier calibration.

3 --- ------

4 ROUTING Audio matrix.

5 SYSTEM LED test, system reset and shutting down.

6 INFO

Information about the device, its internal ampliers and its

rmware.

Functions managed by each menu are briey described in the following table:

Page 23

23

ENGLISH

BAND n

(I, II, III)

FREQ Centre frequency setting.

GAIN Gain setting.

BYPASS EQ Select either ON (equalizer bypassed) or OFF (equalizer inserted).

BAND n

(I, II, III, IV, V)

FREQ Centre frequency setting.

GAIN Gain setting.

BYPASS EQ Select either ON (equalizer bypassed) or OFF (equalizer inserted).

LO CUT (hi-pass lter)

Filter that cuts low frequencies below the cutoff frequency.

It has a single parameter: the cutoff frequency.

5-BAND EQ

The ve bands are semi-parametric equalizers that allow to choose the centre frequency

and adjust its level.

PARAMETERS

COMPRESSOR

The compressor does not modify a signal having a level lower than the predetermined

threshold and compresses a signal (ratio 3:1) with a higher level.

The threshold can be set to three different levels:

–30 dBu (curve 1), –20 dBu (curve 2), –10 dBu (curve 3).

CURVE 2CURVE 1 CURVE 3

PARAMETERS

ATTACK Adjusts the compressor attack time.

POST GAIN

Adjusts the output gain (useful to minimize the signal

attenuation due to compression).

HOLD

Adjust how long the compression is held after the audio

signal returns below the predetermined threshold.

DECAY Adjusts the compressor release rate.

CURVE

Curve selection:

- Curve 1

- Curve 2

- Curve 3

BYPASS

Select either On (compressor bypassed) or Off (compressor

inserted).

PARAMETERS

Page 24

24

ENGLISH

LIMITER

The limiter limits a signal having a higher level than the predetermined threshold.

It is in fact a compressor having a high compression ratio.

It can be really useful to avoid signal distortion due to too high levels.

PARAMETERS

DECAY Adjusts the limiter release rate.

BYPASS Select either ON (limiter bypassed) or OFF (limiter inserted).

DELAY (OUT 1 only)

Audio output delay time setting.

LEVEL

Audio output level setting.

AUDIO SET > MONITOR SUBMENU

LEVEL setting of the internal loudspeaker (MONITOR)

28

a

, which allows to listen to

the audio channel (chosen by the MONITOR parameter in the ROUTING menu) among:

OUT 1/2/3/4 (audio outputs), INT.SINE (internal sine wave), BUS 1/2/3/4 (internal

buses), BGM3 or AUX IN (audio inputs), ZERO (no selection).

AUDIO SET > MONITOR

SUBMENU

AUDIO SET > OUTPUT

SUBMENU

BAND n

(I, II, III, IV, V)

FREQ Centre frequency setting.

GAIN Gain setting.

BYPASS EQ Select either ON (equalizer bypassed) or OFF (equalizer inserted).

LEVEL

Audio input level setting.

AUDIO SET > OUTPUT SUBMENU

Audio output parameter settings.

Select an audio output among OUT 1, 2, 3, 4, to access its parameter list.

Select MUTE ALL to mute or UNMUTE ALL to unmute all audio outputs.

5-BAND EQ

The ve bands are semi-parametric equalizers that allow to choose the centre frequency

and adjust its level.

PARAMETERS

Page 25

25

ENGLISH

FUNCTION DESCRIPTION

1 LED TEST

Check of all LEDs, which light up for a few seconds (a text

message will be displayed).

2 SYSTEM RESET Reset / re-initialization of the device.

3 SYSTEM OFF Device shut-down command.

FUNCTION DESCRIPTION

1 BOARD Hardware notes.

2 AMPL Information about the proper operation of internal ampliers.

3 ACCESSORY

Information about the A, B ports for accessories (i.e. TS 9918

remote controls).

4 ABOUT Firmware notes.

SYSTEM MENU

INFO MENU

ROUTING MENU

Calibration of each audio output (necessary for detecting line faults).

Select one of the audio output OUT 1/2/3/4 (that correspond to its respective internal

amplier) to carry out its calibration.

Menu concerning the audio matrix, where to match sources and destinations.

After selecting an audio output (OUT 1, OUT 2, OUT 3, OUT 4), use the CONTROL

SELECTION

4

encoder to choose an audio channel (to be sent to the selected output)

among: BGM 3, AUX IN, BUS 1, BUS 2, BUS 3, BUS 4 or ZERO (no selection).

Choose MONITOR to select (by using the CONTROL SELECTION

4

encoder) the

audio channel sent to the internal loudspeaker

28

a

(MONITOR).

The choice is made among: OUT 1/2/3/4 (audio outputs), INT.SINE (internal sine wave),

BUS 1/2/3/4 (internal buses), BGM3 or AUX IN (audio inputs), ZERO (no selection).

LED test, system reset and shutting down.

Information about the device.

CALIBRAT MENU

Page 26

26

ENGLISH

DISPLAY TEXT MESSAGES

DISPLAY TEXT MESSAGES DESCRIPTION

REMOTE CONTROLLED Device controlled by a DXT 9000 system main unit.

AC NOT AVAILABLE Mains AC power supply not available.

AC HIGH Mains AC power supply: too high voltage.

AC LOW Mains AC power supply: too low voltage.

AC FUSE FLT Mains AC power supply: blown or not present fuse.

DC NOT PRESENT 48 V DC (batteries) power supply not available.

DC HIGH 48 V DC (batteries) power supply: too high voltage.

DC LOW 48 V DC (batteries) power supply: too low voltage.

DC FUSE FLT 48 V DC (batteries) power supply: blown or not present fuse.

STND-BY PSU VOLTAGE NOT

AVAILABLE

Faulty internal ‘stand-by’ power supply unit.

STND-BY PSU VOLTAGE HIGH Internal ‘stand-by’ power supply unit: too high voltage.

STND-BY PSU VOLTAGE LOW Internal ‘stand-by’ power supply unit: too low voltage.

STND-BY PSU VOLTAGE FUSE FLT Internal ‘stand-by’ power supply unit: blown or not present fuse.

SYS OK System operating properly.

SPEAKER LINE xx DISABLED Loudspeaker line disabled.

AMPLIFIER xx DISABLED Amplier disabled.

MICROPROCESSOR xx FLT Microprocessor fault.

MAIN POWER SUPPLY FAULT Internal main power supply unit fault.

MAIN POWER SUPPLY OVERHEAT Internal main power supply unit overheat.

MAIN POWER SUPPLY OVERLOAD Internal main power supply unit overload.

LOCAL FAULT Local fault.

AMPLIFIER xx OVERLOAD Amplier overload.

AMPLIFIER xx OVERHEAT Amplier overheat.

FANs FLT Amplier cooling fan failure.

IMPEDANCE HIGH Loudspeaker line: too high impedance.

IMPEDANCE LOW Loudspeaker line: too low impedance.

LINE OPEN Loudspeaker line: open circuit.

LINE SHORTED Loudspeaker line: short circuit.

SPKR LINE GND LEAKAGE Loudspeaker line: earth leakage.

all displayed TeXTs (buT remoTe conTrolled) are possible only when amplifiers are noT linked

To a dXT 9000 sysTem main uniT.

Page 27

27

ENGLISH

JP1 to JP8

AB position: the two resistors for monitoring are

inserted in the respective logic output (GPO).

BC position: the two resistors for monitoring are not

inserted (‘dry contact’) in the respective logic output

(GPO).

JP 9

Jumper inserted (ON): normal operation of the rst

logic input (GPI 1), which can be connected to a dry

closing contact.

Jumper removed (OFF): the rst logic input (GPI 1) can

be linked to an external device having its own output

voltage.

JP 10

Jumper inserted (ON): normal operation of the second

logic input (GPI 2), which can be connected to a dry

closing contact.

Jumper removed (OFF): the second logic input (GPI 2)

can be linked to an external device having its own output

voltage.

ImportaNt:

inTernal jumper seTTinG shall be carried ouT only by eiTher rcf or an auThorised

serVice cenTre.

Remove the lid and look at the back GPI / GPO board (in this drawing, the 10 jumpers

are marked in grey inside the rectangle):

INTERNAL JUMPER SETTINGS

ZOOM:

Page 28

28

ENGLISH

MP3

+ –

MU 9186

MU 9186/R

MX 950x

UP 950x

BUS IN

BUS OUT

A1 B2

A2 B1

CONNECTION EXAMPLE

Page 29

29

ENGLISH

SPARE AMPLIFIER (UP 9501) CONNECTION EXAMPLE

UP 9501

/ 9502

/ 9504

UP 9501

/ 9502

/ 9504

SPARE UP 9501

Page 30

30

ENGLISH

GUIDANCE ON THE MEASUREMENT

OF THE SPEAKER LINE IMPEDANCE

In the DXT 9000 system, monitoring of the integrity of speaker lines is made through

impedance measurement at subsonic frequency (20 Hz).

This method was chosen because of its good stability and accuracy of calculated values,

which avoids false line fault reports that often occur with impedance measurements

faster at supersonic frequencies, but more prone to interferences and errors.

To use the DXT 9000 line monitoring properly, so that it fully complies with the European

Safety Standard EN 54-16, it is strictly necessary to consider the functional limitations of

all devices.

The two main limitations are:

- Measurable impedance range.

- The minimum / maximum tolerance compared to the calibration value of the

measurement for the line fault detection.

Let us now analyse in detail these two limitations.

MEASURABLE IMPEDANCE RANGE

There are three amplier models that differ in their power, so each has its own

measurable impedance range:

- Single channel amplier (max. power: 500 W).

- Dual channel amplier (max. power: 250 W per channel).

- Four-channel amplier (max. power: 125 W per channel).

In a 100 V (or 70 V) constant voltage line, the minimum measurable impedance Zmin

can be estimated (in all the three cases) considering a load having double the maximum

output power Pmax on a single line (and ignoring the efciency of speakers and

approximating the impedance at 20 Hz with the real one; the phasor impedance at 20 Hz

is only 9 degrees out of phase with the real axis ).

MEASURABLE

IMPEDANCE RANGE

The results are:

1 x 500 W → Zmin = 10 Ω (at 100 V), Zmin = 5 Ω (at 70 V)

2 x 250 W → Zmin = 20 Ω (at 100 V), Zmin = 10 Ω (at 70 V)

4 x 125 W → Zmin = 40 Ω (at 100 V), Zmin = 20 Ω (at 70 V)

The maximum measurable impedance Zmax can be estimated considering lines loaded

to a quarter of the maximum output power Pmax.

The results are:

1 x 500W → Zmax = 80 Ω (at 100 V), Zmax = 40 Ω (at 70 V)

2 x 250W → Zmax = 160 Ω (at 100 V), Zmax = 80 Ω (at 70 V)

4 x 125W → Zmax = 320 Ω (at 100 V), Zmax = 160 Ω (at 70 V)

Zmin =

100V

(100 V)

2

2 Pmax

Zmin =

100V

(100 V)

2

0.25 Pmax

Zmin =

70V

(70.7 V)

2

2 Pmax

Zmin =

70V

(70.7 V)

2

0.25 Pmax

or

or

Page 31

31

ENGLISH

TOLERANCE COMPARED

TO THE CALIBRATION VALUE

Ampliers are protected and designed to operate at their maximum rated power.

The best impedance range (Zmon), in which its measurement is more stable,

immune to errors and repeatable, is from 50% to 100% of the load corresponding

to the maximum power of the channel.

With 100 V lines:

1 x 500 W → 20 Ω ≤ Zmon ≤ 40 Ω

2 x 250 W → 40 Ω ≤ Zmon ≤ 80 Ω

4 x 125 W → 80 Ω ≤ Zmon ≤ 160 Ω

With 70 V lines:

1 x 500 W → 10 Ω ≤ Zmon ≤ 20 Ω

2 x 250 W → 20 Ω ≤ Zmon ≤ 40 Ω

4 x 125 W → 40 Ω ≤ Zmon ≤ 80 Ω

Note that (depending on ampliers and tolerances of sensors) measures higher or

lower than the indicated limits can be similarly accurate and valid. These values shall be

considered as ‘condence thresholds’ of the line control.

In fact, sensors could measure impedances (at 20 Hz) in the 5 ÷ 400 Ω range.

Measuring of impedances out of that range may be prone to errors and interferences.

TOLERANCE COMPARED TO THE CALIBRATION VALUE

The choice of the speaker line impedance tolerance is important in order to avoid these

two cases:

- Too low tolerance: every little interference will cause a false line fault.

- Too high tolerance: the system will not report any fault even with a line damage that

excludes most speakers.

EN54-16 standard requires the system to indicate speaker line faults (short or open

circuits) and not a single speaker fault. Therefore, a single speaker fault is tolerable, but

not the loss of a line section.

In a 100 / 70 V line all speakers are linked in parallel, so a short circuit (total impedance

tends to zero) leads to the opening of the entire speaker line.

The choice of the tolerance (ve options: 5%, 10%, 15%, 20%, 25%) is important to get

a proper speaker line monitoring.

Consider the following general rule:

“The recommended tolerance value is the highest of the available options,

but lower than the weight of the smallest percentage change in impedance,

usually due to the disconnection of the speaker having the highest

impedance and installed at the end of a line branch.”

A COUPLE OF EXAMPLES:

1. Two speaker lines are linked in parallel and connected to a 250 W amplier output.

The total impedance is 40 Ω (Ztot).

The line 1 ends with a speaker having an impedance 600 Ω (Zmaxend).

The line 2 ends with a speaker having an impedance 200 Ω.

Since all speakers are linked in parallel, in case of disconnection of the 600 Ω

speaker, the line total impedance will change from 40 Ω (Ztot) to 42.8 Ω (Znoend).

Page 32

32

ENGLISH

The following formula is basically the calculation of the impedances in parallel:

NotE

: The line im pedance here is cons idered aT The frequenc y of 20 hz (wh ich is noT equal To

The one mea sured b y an impedance meTer aT 1 khz)!

The percentage difference between the two impedances is 7.14%, so it is necessary

to set the tolerance to the 5% option.

2. Three speaker lines are linked in parallel and connected to a 500 W amplier output.

The total impedance is 50 Ω (Ztot).

The line 1 ends with a speaker having an impedance 140 Ω.

The line 2 ends with a speaker having an impedance 220 Ω.

The line 3 ends with a speaker having an impedance 350 Ω.

Since all speakers are linked in parallel, in case of disconnection of the 350 Ω

speaker, the line total impedance will change from 50 Ω to 58.3 Ω.

The percentage difference between the two impedances is 16.6%, so it is necessary to

set the tolerance to the 15% option.

However, there are many cases where the weight percentage of the last speaker is less

than 5%, often making impossible to detect any damage to the line.

Moreover, there are speakers (e.g. horns) that are virtually open circuits at the frequency

of 20 Hz, making it impossible to measure the line impedance.

In these cases, it is strictly necessary to connect (at the end of lines) devices having an

impedance (at 20 Hz) that allows the calibration (in the proper range of each channel)

and low enough to make it possible to detect the opening of the last line segment.

These devices are just named ‘End Of Line’, hereafter abbreviated as EOL.

EOL (‘END OF LINE’): FEATURES AND USE GUIDELINES

EOL are reactive loads having an impedance 200 Ω at the resonance frequency (20 Hz).

Absorbing reactive power only, EOL can be added to a speaker line without affecting

the rated power of its amplier. However, this is valid if considering the dynamic of the

impedance meter, which can properly measure up to a maximum load of twice the rated

amplier power.

To ensure proper line monitoring when the constrain of the last speaker of various line

branches (explained in the previous paragraph) is not respected, it will be necessary to

add an EOL at the end of each line branch.

For each amplier model, there is a maximum number of EOL (and line branches) that

can be added to a single line. This is due to problems of dynamics of the impedance

measuring circuit and the amplier (eddy currents need to be considered, as these can

overload the amplier).

- Max. 5 EOL for each line linked to a 500 W amplier output.

- Max. 4 EOL for each line linked to a 250 W amplier output.

- Max. 2 EOL for each line linked to a 125 W amplier output.

Znoend =

Zmaxend

Ztot

Zmaxend – Ztot

EOL (‘END OF LINE’):

FEATURES AND USE

GUIDELINES

Page 33

33

ENGLISH

Within the system operation limits, the result is equal to 1 in almost all cases.

The only exception is given by a line with two branches including horn speakers only and

connected to a 500 W amplier. In this case, it is advisable to add two EOL (in parallel) to

the end of each line branch (to fall within the correct measurement range).

Anyway, to know how many EOL are needed in a line, it is necessary to calculate the total

impedance (Ztot) by applying the following formula (parallel impedances), adjusted with

the EOL number (Neol):

NotE:

The line im pedance (

Zline

) he re is c onsider ed aT Th e frequ ency of 20 hz (which is noT

equal To The o ne meas ured by an im pedance meTer aT 1 khz )!

The total impedance must respect the constraints about EOL.

EOL number shall not exceed the maximum amount (as indicated previously).

NotE:

The line im pedance (

Zline

) he re is c onsider ed aT Th e frequ ency of 20 hz (which is noT

equal To The o ne meas ured by an im pedance meTer aT 1 khz )!

In case of a single line having a particularly low impedance load or lines including

horn speakers (open circuits at 20 Hz), it will be necessary to add more EOL in

parallel.

In case the line is divided into more branches, in each branch the EOL number

needs to be the same, in order to guarantee a proper monitoring and respect

the following formula:

Ztot =

Zline

Zeol

Zline – Zeol

Neol > =

200 Ω

Ztot (21 – Nbranch)

Ztot = total impedance

Nbranch = line branch number

Neol = EOL number

Ztot =

Zline

Zline +

200 Ω

Neol

200 Ω

Neol

The total impedance (Ztot) resulting from the parallel between the load impedance

already present in the line (Zline) and EOL (Zeol = 200 Ω) is easily obtainable by the

following formula:

Page 34

34

ENGLISH

–50 ÷ +6 dBu

20 Hz ÷ 20 kHz

25 kΩ

104 dB

24 V dc

–50 ÷ +6 dBu

20 Hz ÷ 20 kHz

25 kΩ

94 dB

–50 ÷ +6 dBu

20 Hz ÷ 20 kHz

25 kΩ

100 V / 70 V (selectable by RCF only)

1 (UP 9501), 2 (UP 9502), 4 (UP 9504)

500 W (UP 9501), 250 W (UP 9502), 125 W (UP 9504)

[100 V] 20 Ω (UP 9501), 40 Ω (UP 9502), 80 Ω (UP 9504)

[ 70 V] 10 Ω (UP 9501), 20 Ω (UP 9502), 40 Ω (UP 9504)

A1 - A2 (UP 9501)

A1 - A2 - B1 - B2 (UP 9502)

A - B - C - D (UP 9504)

20 Hz ÷ 20 kHz

≤ 0.1%

8

4

24 V dc

0.3 A

4

24 bits

44.1 kHz

100 mA

FALL BACK INPUT audio input

- Input sensitivity:

- Frequency response (±3 dB):

- Input impedance (1 kHz):

- Signal / noise ratio:

- FALL BACK command voltage:

AUX INPUT

- Input sensitivity:

- Frequency response (±3 dB):

- Input impedance (1 kHz):

- Signal / noise ratio:

BGM 3 audio input

- Input sensitivity:

- Frequency response (±3 dB):

- Input impedance (1 kHz):

Loudspeaker line outputs

- Output voltage:

- Number of internal ampliers:

- Max. power of each amplier:

- Load minimum impedance for each amplier:

- Loudspeaker line outputs:

- Frequency response (±3 dB):

- Distortion (THD+N @1W, 1kHz):

GPI (logic inputs)

- Monitored GPI number:

- Photo-coupled GPI number:

GPO (logic outputs)

- Max. applicable voltage:

- Max. current:

RCF FLEXCOM BUS

- Channels:

- Resolution:

- Sampling frequency:

24 V DC output

- Max. output current:

SPECIFICATIONS

Page 35

35

ENGLISH

DATA LINK

- 1 RS485 EUROBLOCK connector

- 2 RCF FLEXCOM BUS EUROBLOCK connectors

ELECTRICAL SPECS.

- Operating voltage:

- Max. consumption (power):

- Operating temperature:

- Relative humidity:

MECHANICAL SPECS.

- Dimensions (w, h, d):

- Net weight:

115/230 V ac (50-60 Hz), 48 V dc

800 W

–5 ÷ +50 °C (23 ÷ 122 °F)

20 ÷ 90% (non-condensing)

485 mm, 88 mm, 365 mm (19” rack - 2 units)

7.8 kg (UP 9501), 8.0 kg (UP 9502), 8.3 kg (UP 9504)

APPENDIX

DXT 9000 - COMPLIANCE OPTION LIST WITH EN 54-16 REQUIREMENTS

7.3 Audible warning

7.6.2 Manual silencing of the voice alarm condition

7.7.2 Manual reset of the voice alarm condition

7.8 Output to re alarm devices

8.3 Indication of faults related to the transmission path to CIE

9. Disablement condition

10. Voice alarm manual control

11. Interface to external control device(s)

12. Emergency microphone(s)

13.14 Redundant power ampliers

Page 36

0068

RCF S.p.A. - Via Raffaello 13, 42124 Reggio Emilia, ITALY

14

0068-CPR-002/2014

EN 54-16:2008

Voice alarm control and indicating equipment for fire detection and

fire alarm systems for buildings

DXT 9000

Provided options:

Other technical data: see DXT 9000 operational manuals.

7.3

7.6.2

7.7.2

7.8

7.9

8.3

9

10

11

12

13, 14

Audible warnings

Manual silencing of the voice alarm condition

Manual reset of the voice alarm condition

Output to fire alarm devices

Voice alarm condition output

Indication of faults related to the transmission path to the CIE

Disablement condition

Voice alarm manual control

Interface to external control device(s)

Emergency microphone(s)

Redundant power amplifiers

Page 37

Page 38

Page 39

Page 40

10307285 revD_EN 2014 / 07

www.rcfaudio.com

HEADQUARTERS:

RCF S.p.A. Italy

tel. +39 0522 274 411

e-mail: info@rcf.it

RCF UK

tel. 0844 745 1234

Int. +44 870 626 3142

e-mail: info@rcfaudio.co.uk

RCF France

tel. +33 1 49 01 02 31

e-mail: france@rcf.it

RCF Germany

tel. +49 2203 925370

e-mail: germany@rcf.it

RCF Spain

tel. +34 91 817 42 66

e-mail: info@rcfaudio.es

RCF Belgium

tel. +32 (0) 3 - 3268104

e-mail: belgium@rcf.it

RCF USA Inc.

tel. +1 (603) 926-4604

e-mail: info@rcf-usa.com

Except possible errors and omissions.

RCF S.p.A. reserves the right to make modications without prior notice.

Loading...

Loading...