RS2640

SPECIFICATIONS (Subject to change without notice)

Line Voltage: 120vAC +/- 10% @ 60Hz

AMPLIFIER:

Power Bandwidth: 60-20,000 Hz

Frequency Response:

Main Channels: 60-16,000 Hz +0/-3dB

Hum, at Min Volume (unweighted): 1m Vrms @ 6 ohms

Muting Attenuation: 70 db

Signal to Noise:

Weighted: 65 db

Crosstalk: 50 db

Maximum Input: 2 Vrms

Power Output: 80W @ 10% THD

Headphone Output: 6 mW

AM RADIO PERFORMANCE

Tuning Range: 530-1710

Usable Sensitivity @ 20dB S/N: 600 uV/m

S/N: 40 db

Auto Stop Sensitivity @ 1kHz: 1000 mV/m

FM RADIO PERFORMANCE

Tuning Range: 87.5 – 107.9Mhz

Minimum Sensitivity: 26 dbf

Frequency Response: 100 – 10 KHz +/- 5 db

Stereo Separation @ 1kHz: 20 db

S/N Ratio stereo A-weighted: 55 dbf

Auto Stop Sensitivity @ 99MHz: 32 dbf

TAPE

Frequency Response: 63 – 8 kHz +/-5 db

S/N Ratio (Playback): 45 db

Channel Separation @1 kHz: 34 db

Wow & Flutter: 0.2%

CD

Frequency Response: 60 – 20,000 Hz +0/-3 db

S/N Ratio: 75 db

Eccentricity: 140 um

Vertical deviation: 780 mm

Page 1-3

RS2640 RS2640

DISASSEMBLY DISASSEMBLY

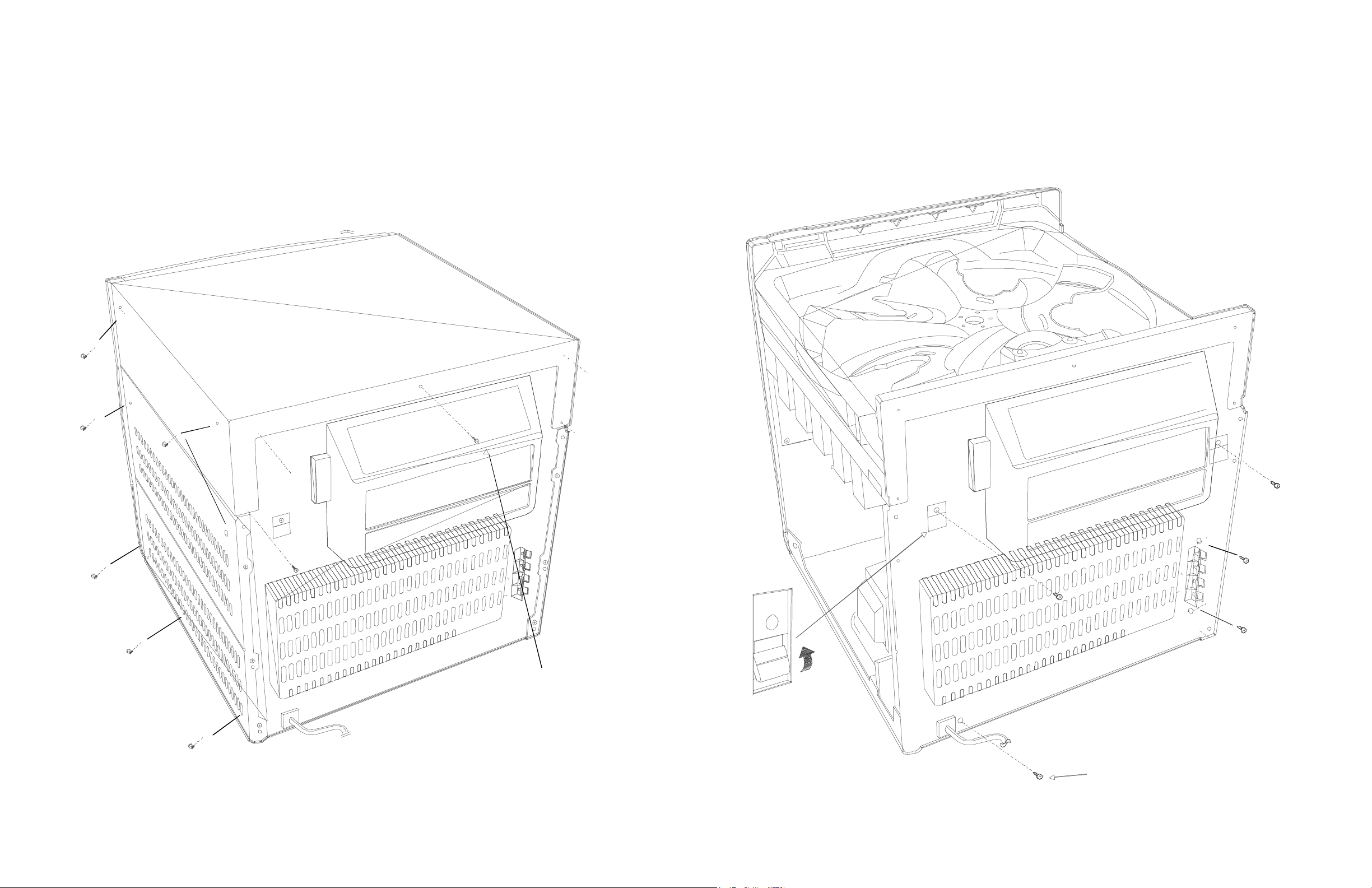

Cover Removal

Note: Perform all disassembly procedures in the order

presented. When reassembling, use the reverse

procedure. Make sure that all leads/wiring are

routed correctly when reassembling.

1. Remove the screw located on the backside of the unit as

shown in Figure 1. Remove seven (7) screws located on

the left and right side of the cover

2. Remove top panel by lifting upward from rear and

separating tabs from backside of front plate.

Back Panel Removal

1. Remove cover.

2. Remove thirteen (13) screws from the back of unit as

shown in Figure 2.

3. Lift CD tray to release tabs on back panel as shown in

Figure 2.

Fig. 1 Cover Removal

1/2 PAN HEAD SCREW

1 OF 5

Remove screws

Located on the Back of Unit.

Fig. 2 Back Panel Removal

Page 2-2Page 2-1

RS2640 RS2640

DISASSEMBLY DISASSEMBLY

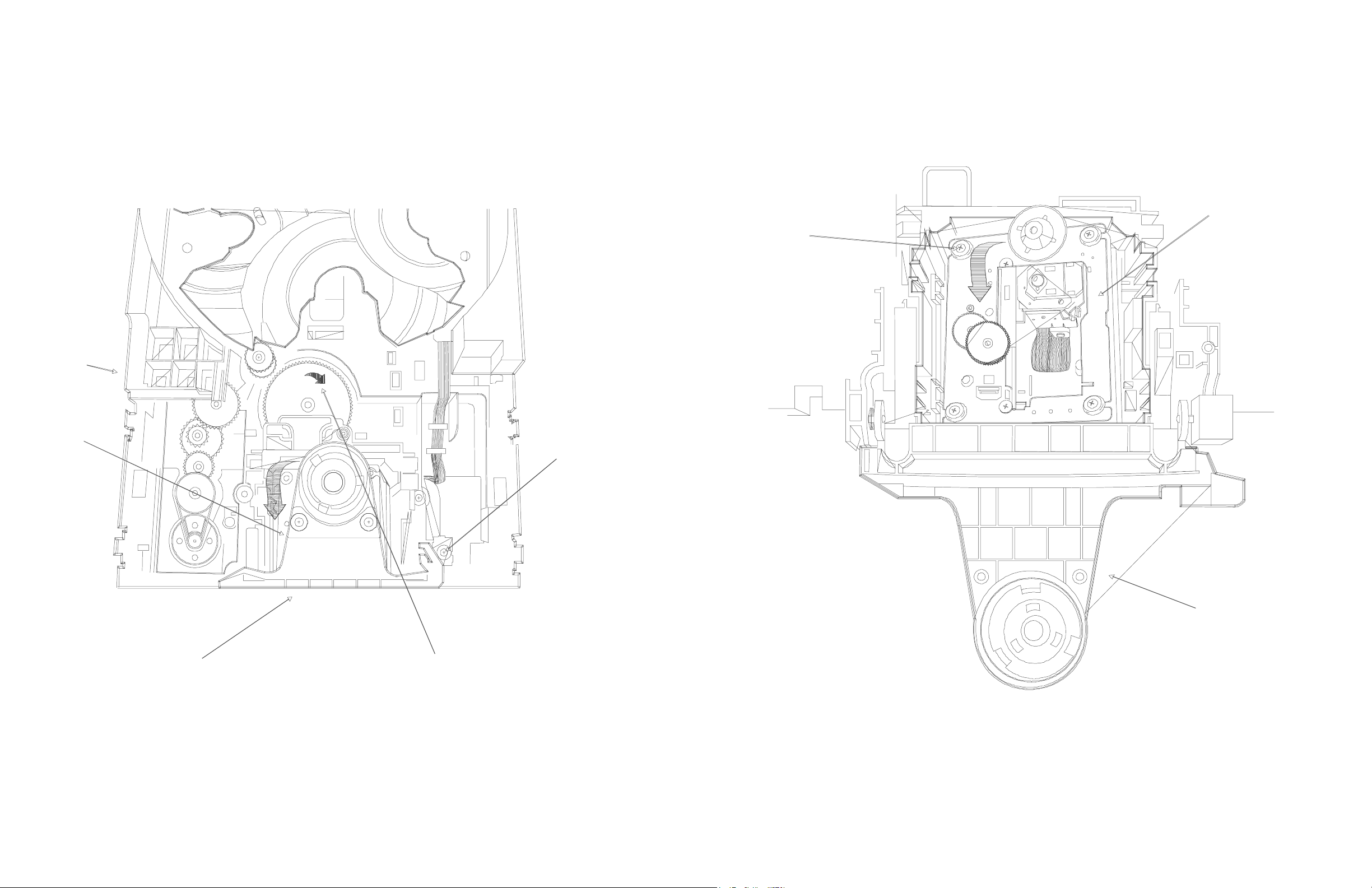

CD Mechanism Removal

1. Plug unit in and extend the CD tray. While extended unplug the unit.

2. Remove top cover.

3. Remove side panels.

4. Remove the back panel

5. Remove one (1) screw from the CD Arm Stop as shown

in Figure 3.

CD Mechanism Removal (Cont’d)

7. Remove four (4) srews fron CD Mechanism Assembly

as shown in Figure 4.

8. Release one (1) wire from catch on bottom of CD Tray.

9. Release CD Mechanism Assembly from mount by pulling towards the rear and lifting gently.

Remove (4) screws

CD Tray

CD Mechanism Assembly

CD Arm

Rear of Unit

Remove (1) screw

CD Arm

Rotate Gear Clockwise

Fig. 3 CD Mechanism Removal

Fig. 4 CD Mechanism Removal

Page 2-3

Page 2-4

RS2640 RS2640

DISASSEMBLY DISASSEMBLY

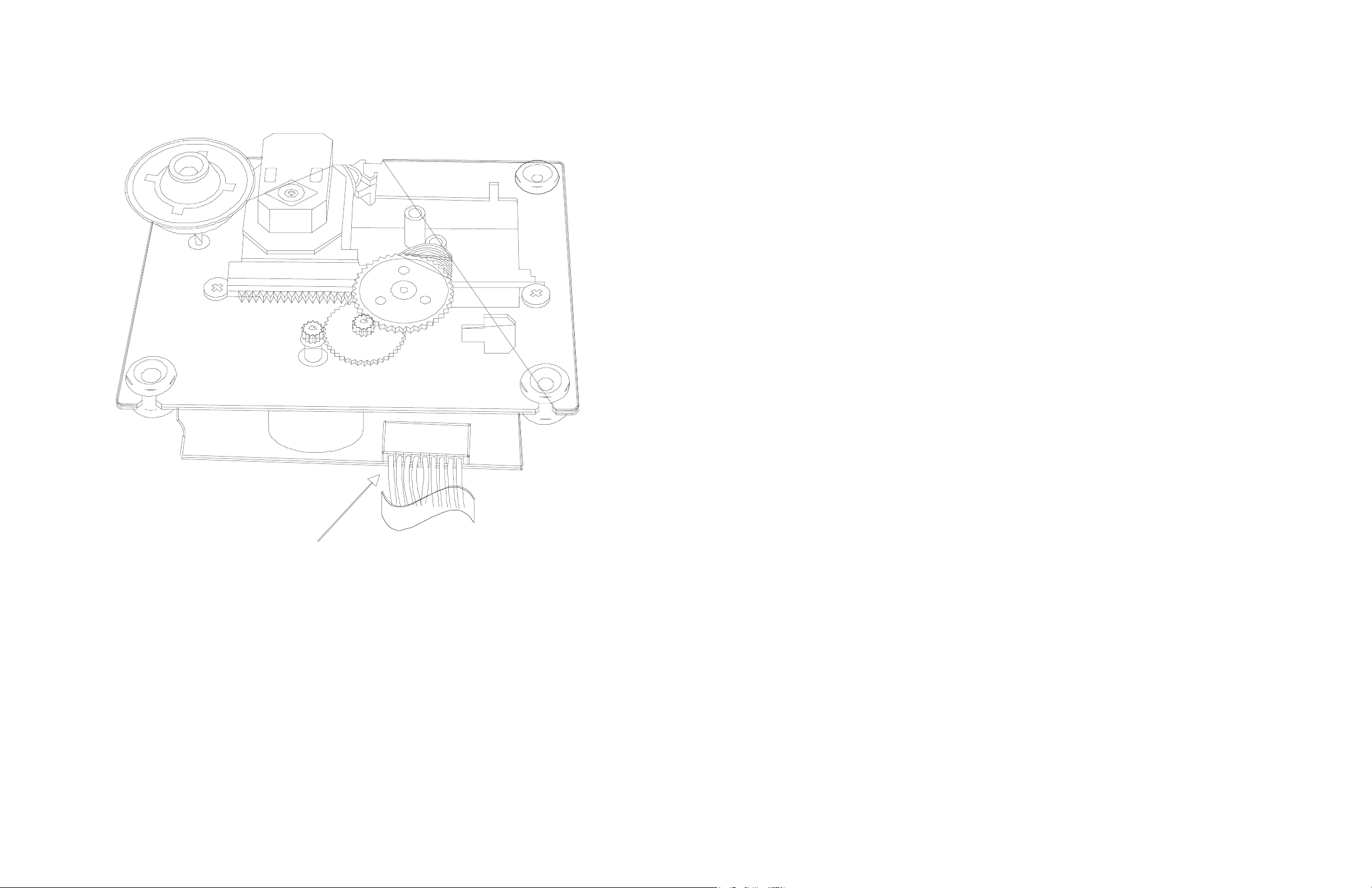

CD Mechanism Removal (Cont’d)

10. Disconnect one (1) Ribon wire from CD Mechanism

Assembly as shown in Figure 5.

Risconnect Wire from

CD Mechanism Assembly

Fig. 5 CD Mechanism Removal

Page 2-5

Page 2-6

RS2640 RS2640

ALIGNMENT PROCEDURES

Operating Conditions

Unless otherwise noted, the following conditions must be

observed when aligning the RS2640:

1. Chassis must be operated from a 120VAC isolation

transformer, with line voltage set to 120VAC (±2.0V).

2. Set controls (Volume, Tone, Balance, etc.) to mid-range.

3. Procedures must be performed in the sequence given.

4. A 10X probe must be used for oscilloscope and frequency measurements.

5. Minimum warm-up time is 10 minutes

Required Test Equipment

Personal Computer: IBM or Compatible 486DX 66 meg

PC (or LAPTOP) with 16 MEG Memory, VGA Monitor, one

3 1/2” floppy drive, 540 Meg or larger hard drive, compatible mouse, one parallel port dedicated for service interface

box and one port for mouse, Windows 95, 4X CD ROM,

Printer and Sound Card.

Isolation Transformer:

Digital Voltmeter: Range .1V DC to 1000V DC, Accuracy: ±

.5%/

True “RMS” Voltmeter: Range: 01 to 1000 Volts ± .5% Ac-

curacy

DC Voltage Supply: Range: 0 to 50V, 2A—Well Filtered

Temperature Controlled Soldering Station: Grounded Tip

Type—Tip Temperature 500F to 800F Adjustable

Frequency Counter: Range: 50Hz to 100 MHz Sensitivity:

25mV to 5V. Equipped with Lo-Cap Probe (10:1 Attenuation)

AC Variac: Continuously Variable. Isolation Type Preferred

NTSC Video Signal Generator: Must provide 1V P-P Nega-

tive Sync, Video into 75-OHM input. Produce, standard NTSC

75% Saturated Color Bars with 100% White Window. (B&K

1249, or equivalent)

RF Signal Generator: 100 kHz to 150 MHz .1V RMS, Int.

Mod. 1KHz 30%

TAG001 Tuner Alignment Generator (stock # 215568) or

equivalent: Equivalent Generator must have RF output capa-

bilities for cable channels 1-125.

Cross Hatch Generator: Must have RF output.

S-Video Source: Must provide standard Y-C separated sig-

nal. SVHS output of VCR, DSS or DVD will suffice

Dual Trace, Delayed Sweep Oscilloscope: 25 MHz with

Channel invert capability. Sensitivity’ 5mV/cm Maximum

Sweep Rate: .1us/cm.

Hot Air Desoldering Station:

MTS TV Stereo Generator: Must produce L-R, L+R, SAP at

300 Hz, 1KHz, 8KHz(B&K 2009, or equivalent).

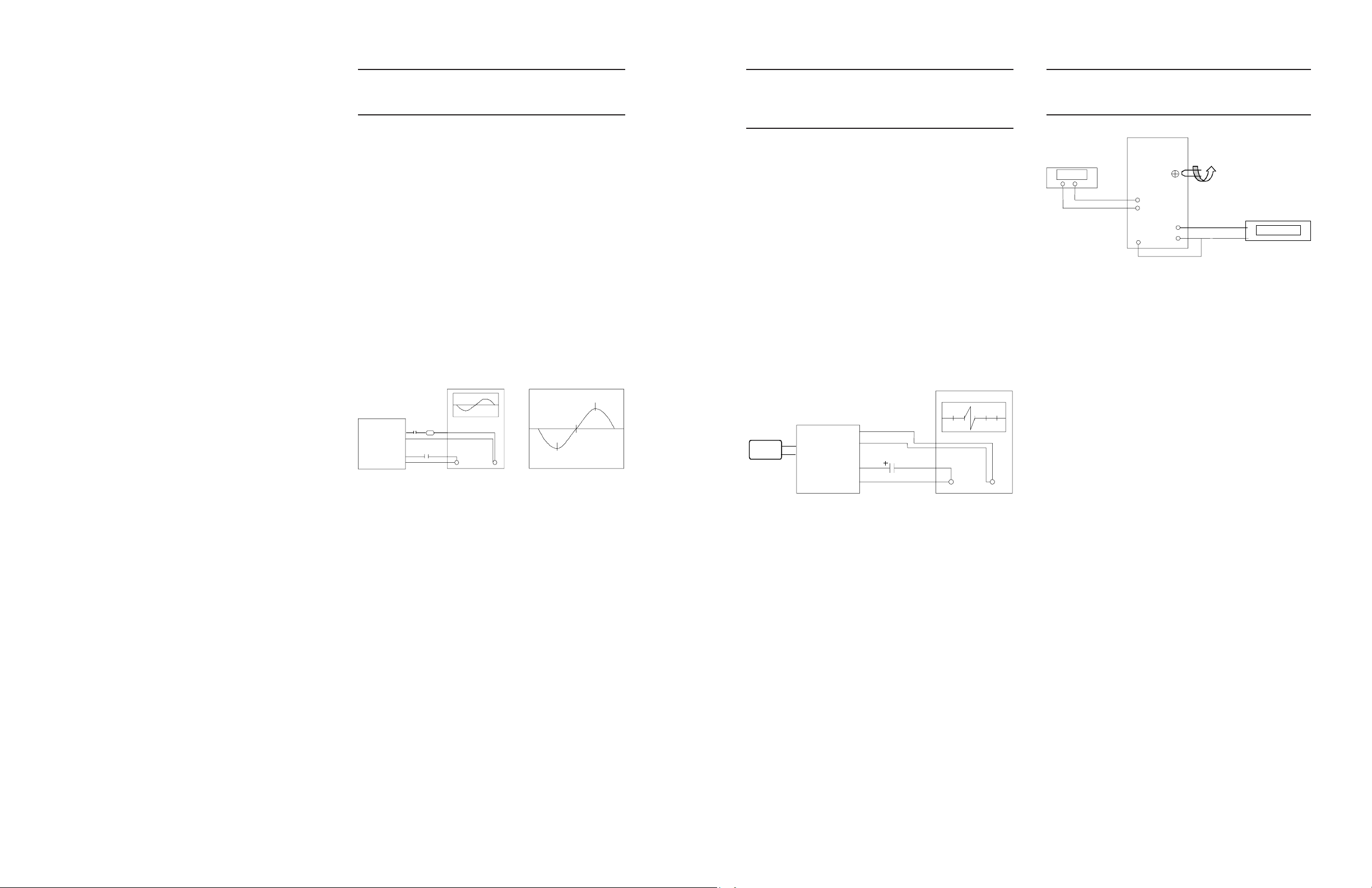

FM IF ALIGNMENT

Test Points:

Input: TP 001 TP001G (RFGND)

Output: TP 003 TP001G (AGND)

1. Connect an FM IF signal to TP004 (Pin 39 of UIC001)

and TP004G (IFGND) through a 1nF capacitor in series

with a 10K resistor.

2. Connect an Oscilloscope to the IF signal output at TP009

(Pin 10 of IC001) and TP009G (AGND) through a 4.7

uF capacitor.

3. Align TF006 to obtain a clear display on the oscilloscope

without any interference.

4. Ensure that the curve is not saturated.

5. Tune the set to 98.10 MHz

6. Apply an un-modulated mono RF signal at 98.10 MHz

with RF input level of 1 mV to TP001 and TP001G

(RFGND).

7. Connect a frequency counter to TP003 (Pin 33 of IC001)

thru a capacitor 0.1 uF

8. Check TP003 and align TF006 to get 10.7 MHz ± 10

KHz.

TUNER

SECTION

TP-004G

TP-009G

TP-004

TP-009

1 nF 10K

4.7uF

Figure 1.

IN

OUT

10.60

10.70

10.80

Figure 2.

ALIGNMENT PROCEDURES

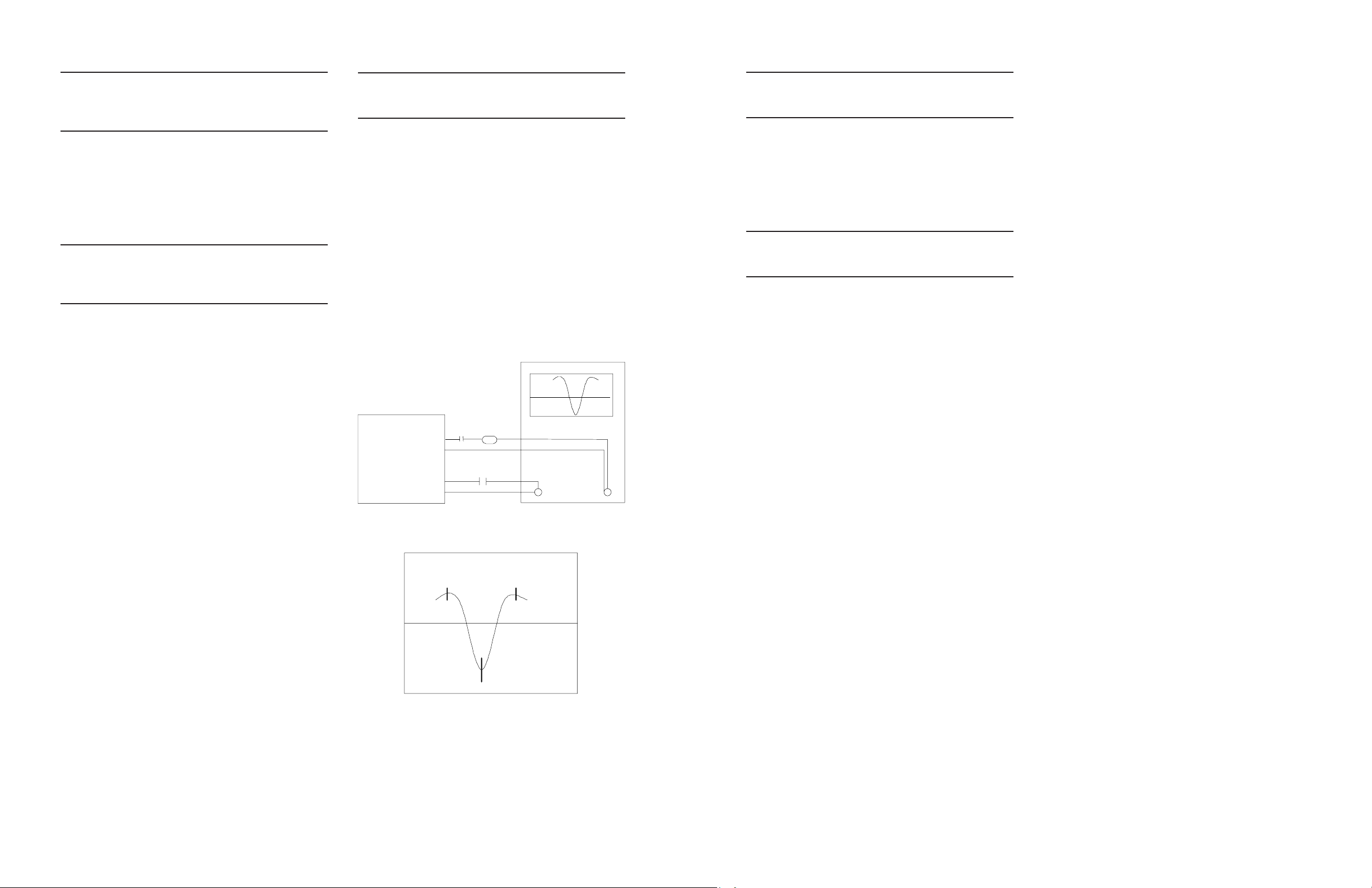

FM OSCILLATOR AND RF ALIGNMENT

Test Points:

Input: TP001 TP001G (RFGND)

Output: TP007/TP008 TP009G (AGND)

Tuning(VT):TP002 TP009G (AGND)

1. Set frequency to 87.5 MHz.

Adjust FM Osc coil (L004) to obtain 1.0 to 1.05V at

TP002 (VT) and TP009G (AGND).

2. Set frequency to 108.10 MHz.

Adjust Vari-Cap (CV002) to obtain 7.0V ±0.5 at TP002

and TP009G (AGND).

3. Repeat steps 1 and 2 above until the band coverages falls

within the specified VT voltage.

4. Feed a FM RF signal to a matching balanced pad (50

ohm - 75 ohm) at TP 001 and TPR001G (RFGND).

5. Use the circuit in figure 3 to detect the signal from TP

007/008 and TP009G (AGND).

6. Set frequency to 90.10 MHz and adjust L003 until maximum amplitude is reached.

7. Set frequency to 106.10 MHz to see whether approximate amplitude is the same as in step 6.

8. Set frequency to 98.10 MHz and check for approximate

amplitude.

1.00V

DC Voltmeter

TUNER

TP-001G

TP-002

TP-001

TP-001G

TP-007/008

TP-009G

OSC ILLOSCOP E

4.7uF

FIGURE 3

IN OUT

FM STEREO ALIGNMENT

Test Points:

Input: TP001 TP001G (RFGND)

Output: TP005 TP010G (DGND)

TUNER SECTION

FM Signal Generator

TP-0 10

RV-001

TP-001

TP-001G

TP-006

TP- 005

FIGU RE 4

Frequenc y Counter

152.000kHz

98.10M Hz

1. Apply an un-modulated mono RF signal at 98.10 MHz

with RF input level of 1 mV to TP001 and TP001G

(RFGND).

2. Search to 98.10 MHz (Remove the VT probe during

search)

3. Connect a 10K from TP005 to TP010G (DGND).

4. Connect a frequency counter to TP005 (Pin 24 of IC001)

and TP010G (DGND), short TP010 (Pin 27 of IC001)

to TP010G (DGND, Pin 26 of IC001).

5. Check TP005 and align RV001 to get 152 KHz ± 1 KHz.

6. Apply a stereo 98.10 MHz signal to the set. Ensure the

Stereo indicator lights up. Signal strength must be less

than 32dB.

7. Remove the 10K resistor from TP005 and TP010G installed in step 3.

Page 3-2Page 3-1

RS2640 RS2640

ALIGNMENT PROCEDURES ALIGNMENT PROCEDURES

AM OSCILLATOR ALIGNMENT (MW)

Test Points:

Input: AM Antenna Loop TP001G (RFGND)

Output: TP007/TP008 TP009G (AGND)

Tuning(VT):TP002 TP009G (AGND)

1. Set frequency to 530 KHz .

2 Adjust MW Osc coil (TF003) to obtain 1.4 ± 0.05V at

TP 002 and TP009G.

3. Set frequency to 1710 KHz. Ensure the MW-VT at TP002

and TP009G is 8.0 ± 1 V

AM OSCILLATOR ALIGNMENT (LW)

Test Points:

Input: AM Antenna Loop TP001G (RFGND)

Output: TP007/TP008 TP009G (AGND)

Tuning(VT):TP002 TP009G (AGND)

1. Set frequency to 150 KHz.

2. Adjust MW Osc coil (TF003) to obtain 1.51 ±0.01V at

TP 002 and TP009G.

3. Set frequency to 283 KHz. Ensure the MW-VT at TP002

and TP009G is 4.6 ± 1V

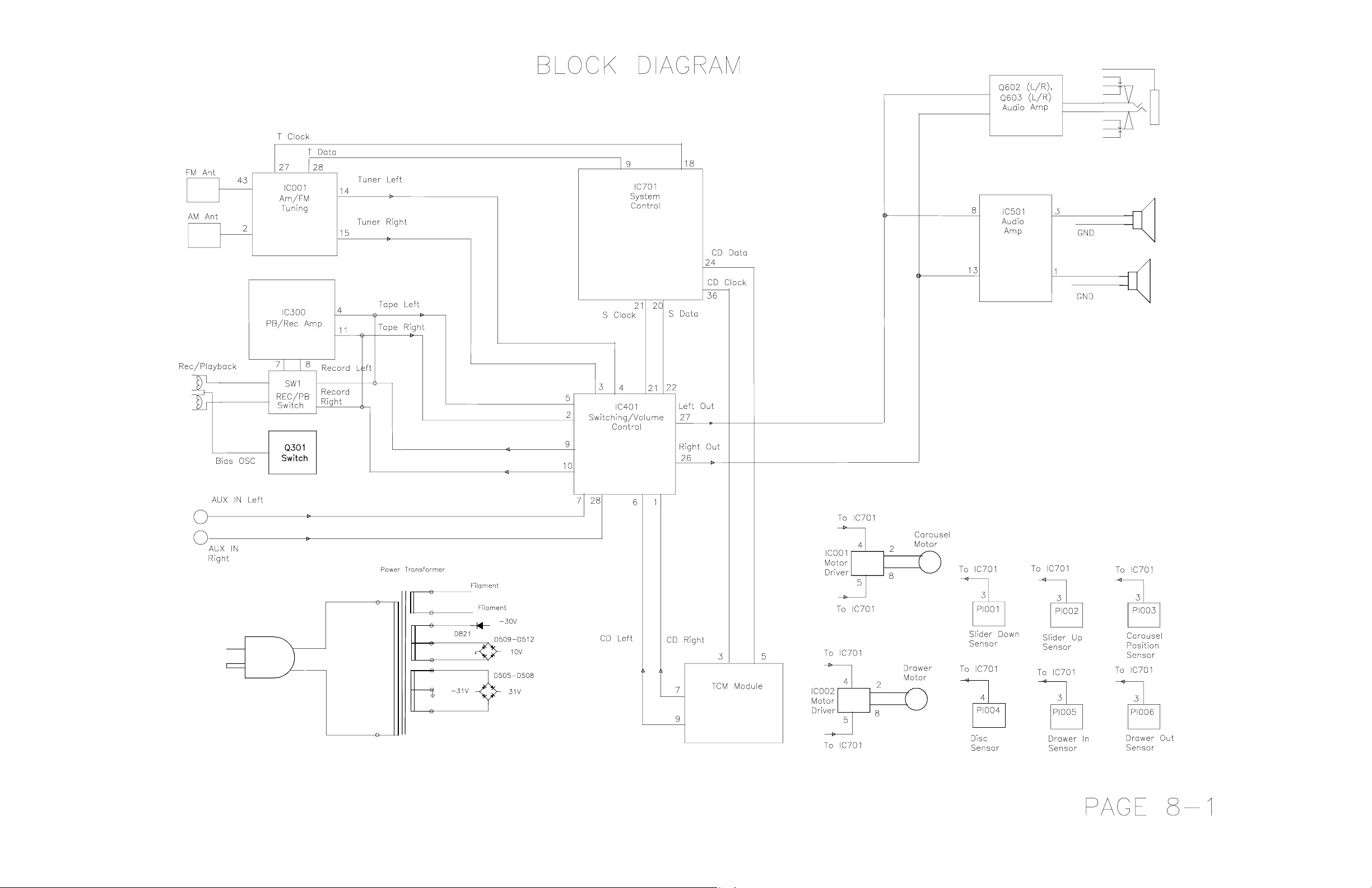

AM IF AND AFC ALIGNMENT

Test Points:

Input: AM Antenna Loop TP001G (RFGND)

Output: TP011 TP004G (IFGND)

1. Connect an AM IF signal to AM OSC, TP012 (pin 6 of

IC001) and TP001G (RPGND).

2. Detect the output signal at TP009 (pin 10 of IC001) and

TP009G (AGND) as shown below in figure 5.

3. Adjust TF005 & TF008 until maximum amplitude is

reached

4. Send an un-modulated RF signal at 1000 KHz with RF

level of 100mV.

5. Tune the receiver to search up/down (remove the VT

probe during search). It will stop after acquiring this

signal.

6. Connect a frequency counter to TP011 (pin 36 of IC001)

and TP004G (IFGND) thru a capacitor 1uF

7. Check TP011 (pin 36 of IC001) and align TF007 to get

450 KHz ± 1 KHz.

AM RF ALIGNMENT (MW)

Test Points:

Input: AM Antenna Loop TP001G (RFGND)

Output: TP007/TP008 TP009G (AGND)

1. Apply a modulated (400 Hz) MW RF signal at 630 KHz

with low RF level of 300 uV.

2. Detect the signal from TP 007/008 and TP009G

(AGND). Adjust TF001 for the maximum amplitude.

AM RF ALIGNMENT (LW)

Test Points:

Input: AM Antenna Loop TP001G (RFGND)

Output: TP007/TP008 TP009G (AGND)

1. Apply a modulated (400 Hz) MW RF signal at 170 KHz

with low RF level of 300 uV.

2. Detect the signal from TP 007/008 and TP009G (AGND.

Adjust TF001 for the maximum amplitude.

MAIN BOARD TAPE ALIGNMENT

Alignment for the cassette portion should be done at the

semi - encased stage.

TUNER

TP012

TP004G

TP009

TP009G

445

AZIMUTH ALIGNMENT

1uF

4.7uF

FIGURE 5

IN

OUT

455

1. In tape transport 1, playback a test tape (TCC-153) freq.

10 KHz.

2. Connect the speaker outputs to a dual trace oscilloscope.

3. Adjust the azimuth screw at the tape head to obtain the

maximum amplitude on both channels. (Both channels

must be in phase).

TAPE SPEED ADJUSTMENT

1. Rewind the test tape (MTT-111 DN 3khz) until both the

spools on the left and right hubs are equal.

2. Connect the output to the WOW -FLUTTER METER.

3. Adjust the trimmer in the motor to obtain a playback

freq. of 3KHz ± 60 Hz.

RECORD BIAS OSCILLATOR ALIGNMENT

1. Place a tape inside the set. Ensure that the tape is not

450

record protected.

2. Select Tape mode and engage the Record button.

3. Monitor TP60 and TP60G (ground). Ensure that the

scope/meter does not have an activated low pass filter.

Adjust L302 & L303 to obtain a voltage of 12Vrms±5%.

Page 3-4Page 3-3

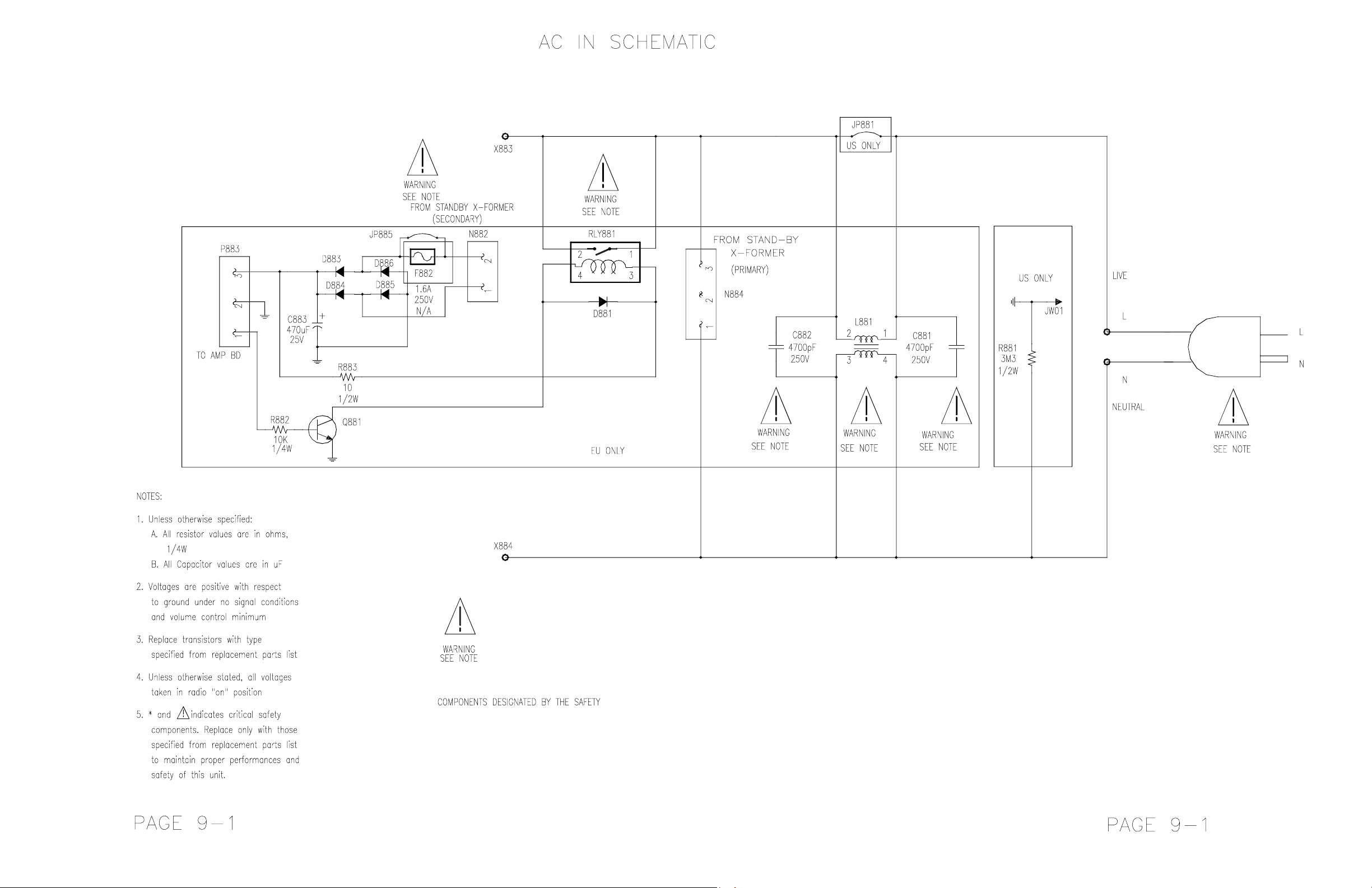

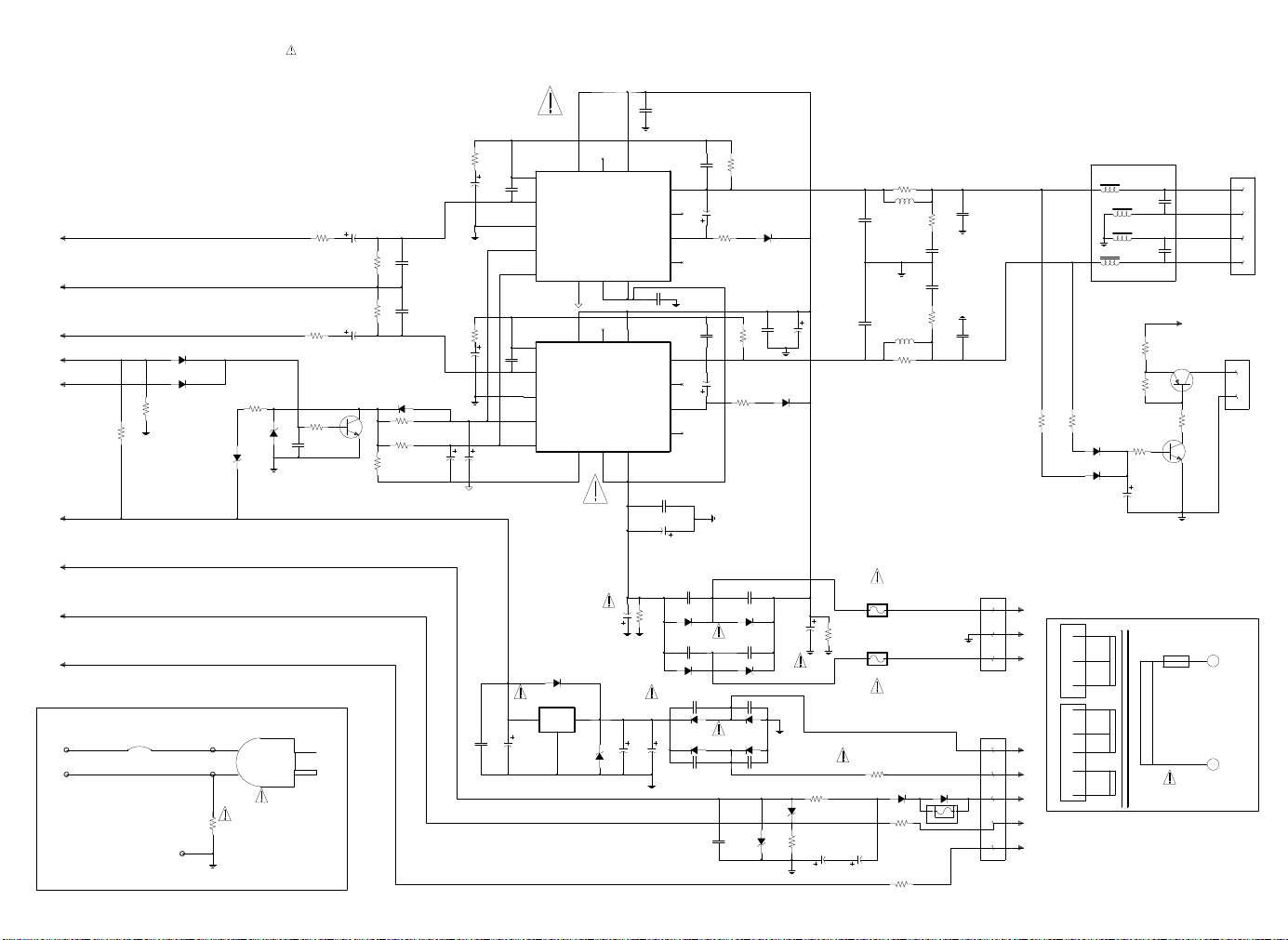

NOTES:

1. Unless otherwise specified:

A. All resistor values are in ohms

B. All Capacitor values are in uF

2. Voltages are positive with respect

to ground under no signal conditions

and volume control minimum

AUDIO_L

AGND

AUDIO_R

R512

6K8

1/16W

1N4148

1N4148

D515

D516

AMP_MUTE

H/P_IN

H/P_MUTE

1/16W

R511

10K

+10V

-30V

FIL+

FIL-

X883

X884

LIVE

JP881

NEUTRAL

R881

3M3

1/2W

X885

SHIELD_GND

On transformer BD

3. Replace transistors with type

specified from replacement parts list

4. * and indicates critical safety

components. Replace only with those

specified from replacement parts list

to maintain proper performances and

safety of this unit.

R502L

C502L

33K

1uF

1/16W

50V

R507L

100K

1/16W

R507R

100K

1/16W

C502R

R502R

1uF

33K

50V

1/16W

WARNING

SEE NOTE

R502

470

1/16W

D501

1/2W

2V4

D504

L

N

WARNING

SEE NOTE

R510

5V1

1K 1/16W

1/2W

100pF

C502

50V

L

N

KTC3875GR

Q501

1/16W

1N4148

D503

R525

33K

1/16W

R529

10K

1/16W

1K5

R532

C507L

470pF

50V

C507R

470pF

50V

10uF

C534

50V

R503L

1/16W

R503R

C509R

390

C509L

50V

1/16W

47uF

50V

4

AMPLIFIER\POWER SUPPLY SCHEMATIC

C518

100nF

111213

BOOT_LOADER

BUFFER_DRIVER

-VS

-PWVS +PWVS

8

111213

BOOT_LOADER

BUFFER_DRIVER

-VS

-PWVS +PWVS

8

-POWER_SUPPLY

C512

4700uF

50V

2200uF

C516

22uF

25V

AGND

BOOTSTRAP

CLIP_DET

15

BOOTSTRAP

CLIP_DET

15

100uF

50V

R530

1/2W

WARNING

SEE NOTE

C514

25V

63V

C501L

R501L

5pF

33k

50V

OUT

14

5 6

C524

100nF

63V

C501R

OUT

14

5 6

C520

100nF

1/16W

C537

22uF

25V

R505L

D501L

2K2

1N4148

1/16W

C533

1/16W

33k

R505R

2K2

1/16W

100nF

100uF

63V

50V

C539

D501R

1N4148

R501R

5pF

50V

C538

22uF

25V

63V

C505L

1NF

50V

C505R

1NF

50V

R510L

L501L

0.5uH

L501R

0.5uH

R510R

10

1/4W

C518L

10

1/4W

100nF

R512L

1/16W

16V

C518R

100nF

R512R

1/16W

C521L

330nF

50V

4R7

16V

4R7

C521R

330nF

50V

C540

+POWER_SUPPLY

C532

1N5402

D510

D512

100nF

50V

50V

C807

100nF

C526

100nF

100V

D506

C513

1N5402

4700uF

C528

WARNING

SEE NOTE

100nF

D508

WARNING

SEE NOTE

C531

50V

1N4001

1N4001

1.3W

D509

D511

27V

100V

1N5402

C530

100nF

50V

D820

100nF

50V

7.5V

1/2W

R885

50V

WARNING

SEE NOTE

220 1/2W

D819

10k

1/4W

R886 D821

C806

100uF

WARNING

SEE NOTE

F503

5S_5A_125V

US:

R531

4K7

1/2W

F504

5S_5A_125V

US:

WARNING

SEE NOTE

RF505

WARNING

1W

0.27

SEE NOTE

D822

1N4001

1N4001

R888

1 2

PF01

1

1/4W

C805

100uF

50V

50V

R889

1

1/4W

N/A

C525

100nF 100V

D505

4K7

1N5402

C527

100nF 100V

D507

C529

100nF

1N4001

1N4001

WARNING

SEE NOTE

7

IN-

+VS

C535

10uF

50V

C523

100nF

25V

C522L

1NF

50V

C522R

234

IN+

SGND

IC501

TDA7293

MUTE

STBY-GND

STBY

9 10

234

1NF

50V

9 10

WARNING

SEE NOTE

3

C515

22uF

16V

IN-

IN+

SGND

MUTE

STBY

OUT

D513

1N4148

IC503

KIA7812

GND

2

IN

1

7

+VS

IC502

TDA7293

STBY-GND

1

WARNING

SEE NOTE

1

D514

>25V

1/2W

WARNING

SEE NOTE

47uF

390

L502L

5uH

N801A

1 2 3

12345

N801B

JW3

JW2

JW1

JW04

JW05

JW06

JW07

JW08

R506L

22k

1/16W

1/16W

TO N801B TO N801A

2 3 4 51 321

L

L503L

R

L502R

5uH

R506R

22k

D502R

1N4148

D502L

1N4148

TRANSFORMER (EI76X50)

L503R

EU only

C519L

5uH

100nF 16V

5uH

C519R

100nF

R509

10

1/4W

R505

10K

1/16W

R503

10K

1/16W

KTC3875GR

Q503

C503

47uF

25V

FUSE INSIDE X`MER

WARNING

SEE NOTE

L OUTPUT

16V

R OUTPUT

+10V

KTA1273

Q502

R504

1K

1/4W

ON X'FORMER BD

FROM

BOARD

AC

NJ501

TO FAN

12

X883

X884

MAIN OUTPUT

1 2 3 4

N501

Loading...

Loading...