Page 1

15

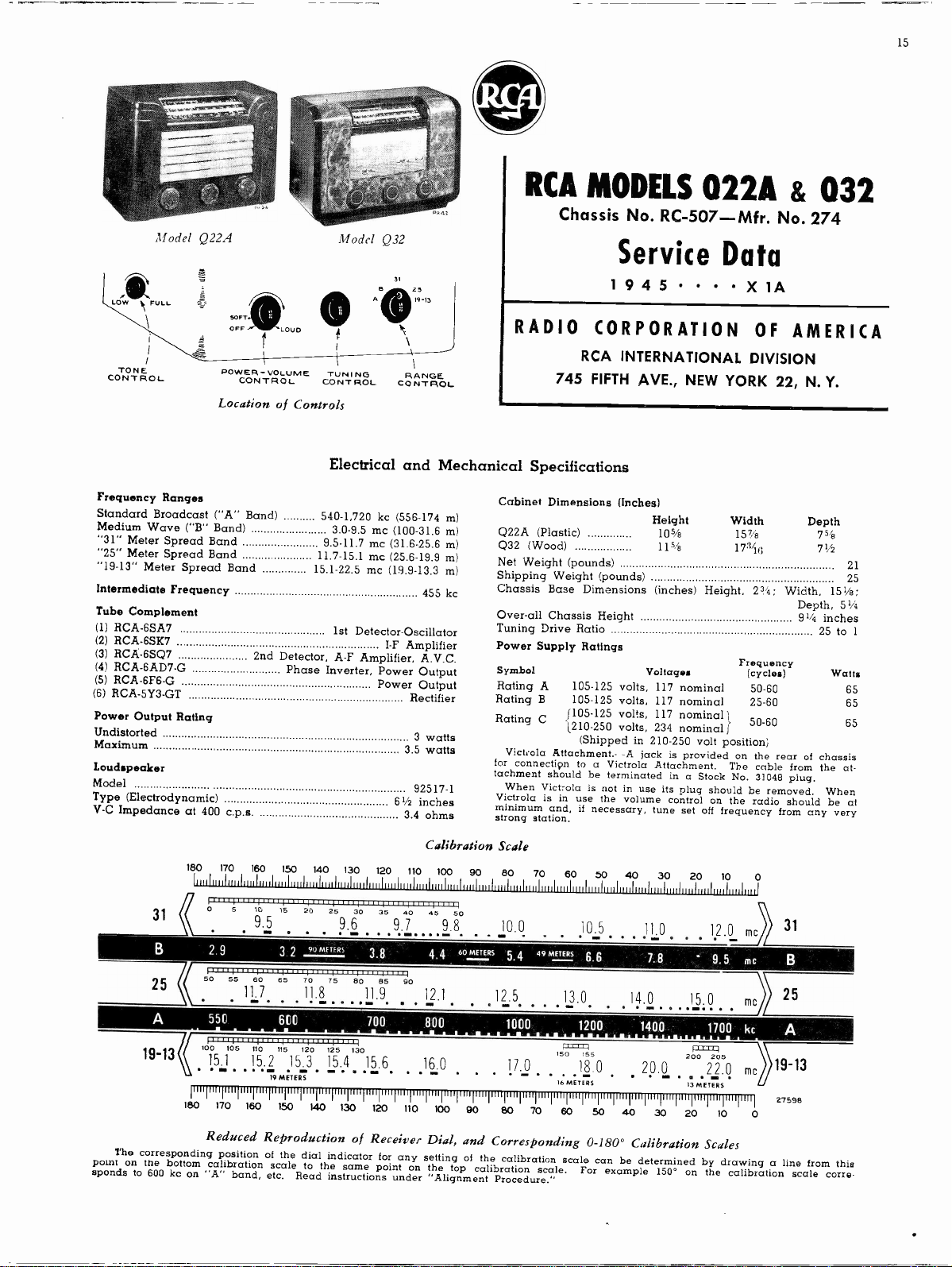

Model Q22A

LOW

TONE

CONTROL

SOFT

OFF

POWER -VOLUME

CONTROL

Location of Controls

Frequency Ranges

Standard Broadcast ("A" Band)

Medium Wave ("B" Band)

"31" Meter Spread Band

"25" Meter Spread Band

"19-13" Meter Spread Band

Intermediate Frequency

Tube Complement

(1) RCA-6SA7

(2) RCA-6SK7

(3) RCA-6SQ7

(4) ACA-6AD7-G

(5) RCA -6F6 -G

(6) RCA-5Y3-GT

Power Output Rating

Undistorted

Maximum

Loudspeaker

Model

Type (Electrodynamic)

V -C Impedance at 400 c.p.s.

Model Q32

31

61

25

A

19-13

LOUD

TUNING

CONTROL

RANGE

CONTROL

Electrical and Mechanical Specifications

540-1,720 kc (556-174 m)

3.0-9.5 mc (100-31.6 m)

9.5-11.7 mc (31.6-25.6 m)

11.7-15.1 mc (25.6-19.9 m)

15.1-22.5 mc (19.9-13.3 m)

455 kc

1st Detector -Oscillator

2nd Detector, A -F Amplifier, A.V.C.

Phase Inverter, Power Output

I -F Amplifier

Power Output

Rectifier

3 watts

3.5 watts

92517-1

61/2 inches

3.4 ohms

RCA MODELS 022A

& 032

Chassis No. RC -507 -Mfr. No. 274

Service Data

1 9 4 5

RADIO CORPORATION OF

RCA INTERNATIONAL DIVISION

745 FIFTH AVE., NEW YORK 22, N. Y.

Cabinet Dimensions (Inches)

Q22A (Plastic)

Q32 (Wood)

Net Weight (pounds)

Shipping Weight (pounds)

Chassis Base Dimensions (inches) Height,

Over-all Chassis Height

Tuning Drive Ratio

Power Supply Ratings

Symbol

Rating A

Rating B

Rating C

Victrola Attachment.- -A jack is provided on the

for connecti9n to a Victrola Attachment.

tachment should be terminated in a Stock No. 3104E1 plug.

When Victrola is not in use its plug should be removed. When

Victrola is

minimum and, if necessary, tune set off frequency from

strong station.

105-125 volts, 117 nominal

105-125 volts, 117 nominal

[105-125 volts, 117 nominal)

1210-250 volts, 234 nominal

(Shipped in 210-250 volt position)

in use the volume control on the radio should be at

Height

105/e

115e

Voltages

X

Width

151/2

17"i (1

Frequency

The cable from the

AMERICA

Depth

75S

71,1

23'4;

Width,

Depth, 51/4

91/4 inches

(cycles) Watts

50-60

25-60

50-60

rear of chassis

any very

151/2;

25 to

21

25

1

65

65

65

at-

180

170

160

150

140

130

120

31

25

A

11

0

5

10

15

9.5

=11

B

2.9

50

55

550

11111111111, 1,11 u.,,,111117

105

15.1

En

180

170

11.7

15.2

160

.41,1

60

110

3.2

65

600

115

19 METERS

150

17411

20

25

9.6

90 METERS

1111 ill 11111111

70

75

11.8

120

125

15.3

15.4

M

140

130

30

35

mi.

3.8

1...1

BO

85

11.9

_

700

130

15.6

m

120

Reduced Reproduction of Receiver Dial, and

The corresponding position of the dial indicator for

point on the bottom calibration scale to the same point

sponds to 600 kc on "A" band, etc.

Read instructions under "Alignment Procedure."

Calibration Scale

110

100

90

80

70

60

50

40

30

20

10

40

45

On

-

4,4

12.1

800

16.0

I=

100

50

9.8

60 METERS

90

10.0

5.4

09 METERS

12.5

eM=

1000

17.0

80

150

mi

16 METERS

70

13.0

FD=171

60

10.5

6.6

1200

155

18.0

11.0

7.8

14.0

1400

20.0

m.

50

40

30

'

15.0

12=1100

200

22.0

13 METERS

20

12.0

9.5

1100

205

10

9.7

90

110

Corresponding 0-180° Calibration Scales

any setting of the calibration scale can be determined by drawing

on the top calibration scale.

For example 150° on the calibration scale

0

31

me

mc

B

)

25

kc

19-13

mc

27598

0

a line from this

corre-

Page 2

16

Q22A & Q32

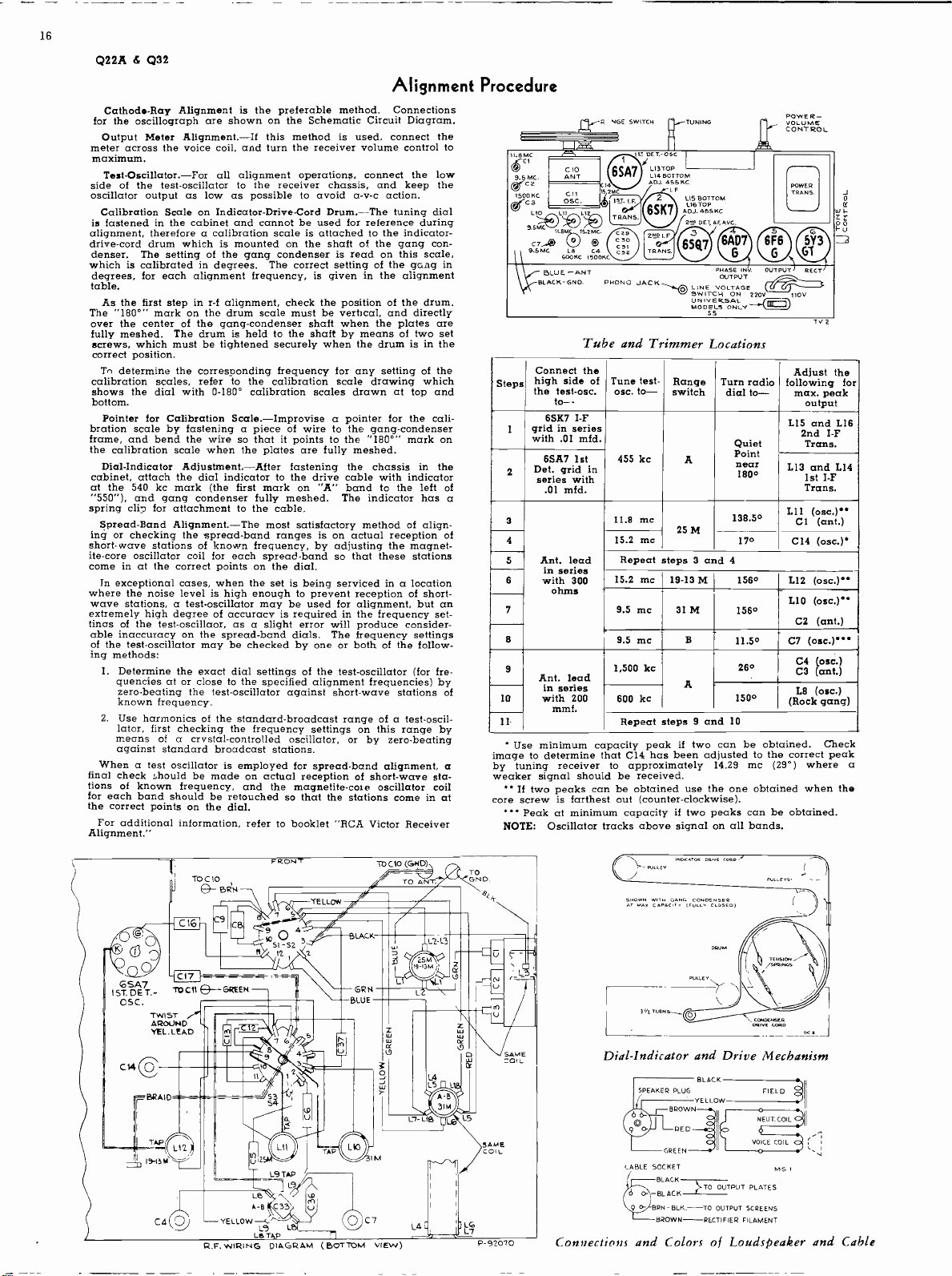

Cathode -Ray Alignment is the preferable method.

for the oscillograph are shown on the Schematic Circuit Diagram.

Output Meter Alignment.-If this method is used, connect the

meter across the voice coil, and turn the receiver volume control to

maximum.

Test-Oscillator.-For.

side of the test -oscillator to the receiver chassis, and keep the

oscillator output as low as possible to avoid a -v -c action.

Calibration Scale on Indicator -Drive -Cord Drum.-The tuning dial

is fastened in the cabinet and cannot be used for reference during

alignment, therefore a calibration scale is attached to the indicator -

drive -cord drum which is mounted on the shaft of the gang con-

denser.

which is calibrated in degrees. The correct setting of the gong in

degrees, for each alignment frequency, is given in the alignment

table.

The "1800" mark on the drum scale must be vertical, and directly

over the center of the gang -condenser shaft when the plates are

fully meshed.

calibration scales, refer to the calibration scale drawing which

shows the dial with 0-180° calibration scales drawn at top and

bottom.

bration scale by fastening a piece of wire to the gang -condenser

frame, and bend the wire so that it points to the "180°" mark on

the calibration scale when the plates are fully meshed.

cabinet, attach the dial indicator to the drive cable with indicator

at the 540 kc mark (the

"550"), and gang condenser fully meshed.

spring cliff for attachment to the cable.

ing or checking the spread -band ranges is on actual reception of

short-wave stations of known frequency, by adjusting the magnet-

ite -core oscillator coil for each spread -band so that these stations

come in at the correct points on the dial.

where the noise level is high enough to prevent reception of short-

wave stations, a test -oscillator may be used for alignment, but an

extremely high degree of accuracy is required in the frequency set-

tinas of the test-oscillaor, as a slight error will produce consider-

of the test -oscillator may be checked by one or both of the follow-

ing methods:

final check should be made on actual reception of short-wave sta-

tions of known frequency, and the magnetite -core oscillator

for each band should be retouched so that the stations come in at

the correct points on the dial.

Alignment."

The setting of the gang condenser is read on this scale,

As the first step in r -f alignment, check the position of the drum.

screws, which must be tightened securely when the drum is in the

correct position.

Tn determine the corresponding frequency for any setting of the

Pointer for Calibration Scale.-Improvise a pointer for the cali-

Dial -Indicator Adjustment.-After fastening the

Spread -Band Alignment.-The most satisfactory method of align-

In exceptional cases, when the set is being serviced in a location

1.

Determine the exact dial settings of the test -oscillator (for fre-

quencies at or close to the specified alignment frequencies) by

zero -beating the test -oscillator against short-wave stations of

known frequency.

2.

Use harmonics of the standard -broadcast range of a test -oscil-

lator,

first checking the frequency settings on this range by

means of a crustal -controlled

against standard broadcast stations.

When a test oscillator is employed for spread -band alignment, a

For additional information, refer to booklet "RCA Victor Receiver

all alignment operations, connect the low

The drum is held to the shaft by means of two set

first mark on "A" band to the left of

spread -band dials. The frequency settings

oscillator,

The indicator has a

Alignment Procedure

Connections

chassis in the

or by zero -beating

coil

a -c. NGE SWITCH

0.8

9 . ScivlaC

1500 SC

C3

LIO

9'SMC 11.8

3.5MC L8 C4

coons sop,

BL2'ALCUSE-G-NON. PHON 0 JACK

No

1.15 BOTTOM

LIE TOP

ADJ. 455 BC

EP SET, AE AVC.

PHASE

LINE VOLTAGE

SW ITCH ON

UN

MODEL. ONLY

OuTPVT

POWER -

CONTROL

POWER

TRANS.

OUTPUT

2204 1104

RECT.

Tv 2

Tube and Trimmer Locations

Connect the

high side of

Steps

the test-osc.

to--

6SK7 I -F

I

grid in series

with .01 mfd.

6SA7 1st

2

Det. grid in

series with

.01 mfd.

3

4

Ant. lead

5 Repeat steps 3 and 4

in series

6

with 300

ohms -

7

8

9

Ant. lead

in series

with 200

10

11 Repeat steps 9 and 10

image to determine that CI4 has been adjusted to the correct peak

by tuning receiver

weaker signal should be received.

core screw is farthest out (counter -clockwise).

mmf.

Use minimum capacity peak if two can be obtained.

** H two peaks can be obtained use the one obtained when the

Tune test-

osc. to-

455 kc

11.8 mc

15.2 mc

15.2 mc

9.5 mc

9.5 mc

Range

switch

A

25 M

19-13 M

31 M

B

1,500 kc

600 kc

A

to approximately

Turn radio

dial to-

Quiet

Point

near

1800

138.50

170

1560

1560

11.50 C7 (osc.)

260

-

1500

14.29 mc (29°) where a

*** Peak at minimum capacity if two peaks can be obtained.

Oscillator tracks above signal on all bands.

NOTE:

Adjust the

following

max. peak

output

1.15 and 1.16

2nd I -F

Trans.

1.13 and L14

1st I -F

Trans.

L11 (osc.)CI

(ant.)

C14 (osc.)

1.12 (osc.)

LIO (osc.)

C2 (ant.)

C4 (osc.)

C3 (ant.)

LB (osc.)

(Rock gang)

Check

for

6SA7

1ST. 06 T.-

CGC,

C141

r=BRAIDx =

TO C110

Twl5T

AROUND

YEL. LEAD

TAP

L12

173-751.1 -r-'

C4 2)

TOCIO

G- tmis

-7-

CI7

GREEN

11.1444:

-YELLOW

R.F. WIRING DIAGRAM

FRONT

tz,L:Amr,

-71

cL-p51

52

2

=

a

L9 L

Le TAP

r"7

( BOTTOM

LACK

GRN

BLUE

To CIO (GND)

IM

c

7

v7 )

TO ANT.

L2 LB

L4 E E;

D.

U

rr

z

SAME

COIL

CAME

COIL

L

P-92070 Connections and Colors of Loudspeaker and Cable

Dial -Indicator and Drive Mechanism

SPEAKER PLUG

LAKE SOCKET

0- -BLACK

BLACK

YELLOW

GREEN

BLACK

}TO OUTPUT PLATES

BRN-BLK.---TO OUTPUT SCREENS

BROWN -RECTIFIER FILAMENT

M5I

Page 3

6AD7G

PH INVER.

& OUTPUT

230V.

C

NC

30V,

OUTPUT

n2v6Fe_G

R16

0

470,000

VOLTAGES SHOULD

WITH RATED SUPPLY.

HOLD WITHIN ±2.0%

e-0RN,RED-

TI

oR voL-rownys-r.

* MEASURED WITH

CHANALY5T

TOTAL

7003, TOTAL

BRN. -

BRN.

RECT SEATER S Y.

60N .

C2g

9.511G.

11.9i1

-RED

0-v .R

25, .7-

BLUE

SEATER 0.3V.

EBLUE_

-RED

CONNECTIONS

117V. POWER TRANS.

Ad-

Remove feelers

R12.

65Q7

2t9-DET-A.F-A.V.C.

2ND I. F TRANS

I.F

65K7

1.r TRANS

455 KC

1sT.

330,000

455 KC

r

90V

56

F'

-- `"

56'

C20

100

CIA

01

F UU

RI

c25

030

C),0

11

.C21

D

A

IS LI

C 24

C 38

470,000

.005

_

220

ioo

E

RE C 34 -r

22,000

RS

22.4E3

.05

R9

IS

500,000

TONE CONTRT

R 6

500,000

VOL. CONTR.

IC

.01

C 28

MEG.

IRViA°

PHONO.

%319

JAc K

TAP AT 125,000

R-7

12poo

/

4

15,000

A

C 32

05 c ILLOG RA PH CONNECTIONS

.035

C22 -

}B

KC)} A

05oosC)

VERTICAL." 0" TO CHASSIS.

VERTIcAl2 HI° TO THIS POINT,

-7V. (GOO

-

-BV. (9 MC)

-5V. (3 MC)

BAND)

(19-13

- 7V. (31 BAND)

-6V. (25 BAND)

- 5V.

292 V.

LIT

FIELD

RECT.

5Y3-GT

GRNrRED TR .

Ti

RED

LIZ

LII

100

63MA

300V 1060

GRI4.7 BED

I9 -13M

ac,

E+ 1 C30

+

Ct,279D.-:

BEN

4. 525a.

go TOTAL

RED-BLICI

12EOTAL

it i

BRN

5eE4

0 V

2203.

BLU.

I

-Es-EEDI

ONLY

SO ON Tv .

220v mOCD_S

sG

0-13

T -9319I

DIAL LAMPS

MAZDA *44

ELI) TO HEATERS

Loudspeaker. --

-

grga6,_

with repeated applications of acetone.

suspension

Keep acetone from flowing to other parts of the loud-

(Caution:

Keep the outer edge of the suspension soaked, and lift the cone,

To center the loudspeaker voice coil, first remove the dust cover.

Then loosen the center suspension by thoroughly soaking the outer

edge of this

Insert 3 feelers, equally spaced, between the voice coil and the

speaker.)

near the voice coil, up and down until the suspension is pulled

when cement has hardened completely.

away from the cone housing.

pole piece, arid allow the center suspension to re -cement itself.

ditional cement should be applied if necessary.

65N7

15T DE T- OSC.

TUBE SOCKETS

BOTTOM VIEW OF

A

G

232V.

MEG

C 3S

05

L az

S 33poo II

C17

SG

- An

isC87

CONNECTED

2- bo

CI -ANT

Li

=

35(1

CB

A

2-10

PR

C8

47

C9

GB

Le

I

(R53ua)

12

1 1 -C4930

RANGE SWITCH

VIEWED FROM FRONT

AND SHOWN IN 'A'BAND

(MAX. COUNTER C LOC K-

WISR ) POSITION.

C33-151

9

NOTE:

COIL RESISTANCE

VALUES LESS THAN

ONE OHM ARE NOT

SHOWN.

C4

2-12

(FRONT)

TERMINALS ON S3

TO CORRESPONDING

3 SA.

2-12

CIA

68

C13

C11

All oscillatbr coil leads must be kept apart from each other and

other leads and parts.

Blue plate lead of 2nd I -F transformer should be dressed under

All leads between antenna coils and switch must be as short as

possible and kept away from oscillator coil, leads and switches.

Precautionary Lead Dress. -

2.

1.

other leads and against chassis.

3.

NOTE.-On some sets C23 may be .0015 mf., C25 may be .0025 mf.

4siic)1

Page 4

18

Q22A & Q32

Service Hint:

If minimum volume

reduced by dressing the yellow lead from hot

side of volume control (R6) away from the grid

coupling capacitor (C23).

Replacement Parts

STOCK

No.

Bracket-Drive cord pulley bracket complete with one (1) 30685

35640

35639

35622

37976

35642

12714

33014

34654

35646

36012

45465

70582

35644

39622

39632

70586

35645

39628

39636

70667

70687

70601 Capacitor-Tubular,

70624 Capacitor-Tubular, .003 mfd.,

70627 Capacitor-Tubular,

70648

70610 Capacitor-Tubular,

70631 Capacitor-Tubular,

70614

70615

70636 Capacitor-Tubular,

35631

35632

35623

35624

35625

35626

35619

35629

35620

32634

34662

12006

35788

31259

35627

35638

35641

35630

34761

30735

pulley

Bracket-Drive cord pulley bracket complete with three (3)

pulleys

Bracket-Flywheel support bracket

Bracket-Tone control support bracket 30652

Calibrator-Drive drum calibrator

Capacitor-Air trimmer (2-12 mmf.) (C4, C7, C14)

Capacitor-Electrolytic, consisting of three

10 mfd., 450 volts, and one (1) section of 20 mfd., 25 volts

(C29, C30, C3I, C32)

Capacitor-Mica trimmer, triple, 2.5-10 mmf, (C1, C2, C3)

Capacitor-Ceramic, 6 mmf. (C36)

Capacitor-Ceramic, 15 mmf. (C37)

Capacitor-Ceramic,

Capacitor-Ceramic, 47 mmf. (C8)

Capacitor-Ceramic, 47 mmf. (C12)

Capacitor-Mica, 56 mmf. (CI7)

Capacitor-Mica, 56 mmf. (C20, C21)

Capacitor-Mica, 68 mmf, (C9)

Capacitor-Ceramic, 68 mmf, (C13)

Capacitor-Mica, 100 mmf. (C15, C18, C34)

Capacitor-Mica, 220 mmf. (C16, C38)

Capacitor-Mica, 560 mmf. (C5)

Capacitor-Mica, 3000 mmf. (C6)

Capacitor-Tubular, .005 mfd., 1000 volts (C26, C27)

Capacitor-Tubular, .035

Capacitor-Tubular, .05

Coil-Antenna coil,

L2, L3)

Coil-Antenna coil, "A," "B" and 31 meter bands (L4, L5,

L6, L7, L18)

Coil-Oscillator coil, "A" and "B" bands (L8, L9)

Coil-Oscillator coil,

Coil-Oscillator coil, 25 meter band (L11)

Coil-Oscillator coil, 31 meter band (L10)

Condenser-Variable tuning condenser (C10, C11)

Control-Tone control (R9)

Control-Volume control and power switch (116, S6)

Cord-Drive cord (approx, 28 inches overall length)

Cord-Indicator cord (approx. 53 inches overall length)

Core-Adjustable core and stud assemblies for

formers

Core-Adjustable core and stud for "A" and "B" band os-

cillator coil

Core-Adjustable core and stud for 19-13 meter, 25 meter

and 31 meter oscillator coil

Drum-Drive drum less calibrator

Flywheel-Tuning knob shaft flywheel

Plug -4 contact female plug for speaker cable

5040

Pulley-Drive cord pulley

Pulley-Idler pulley located between the range switch and

tuning knob shafts

Resistor -10 ohms, 1/4 watt (R18)

Resistor -560 ohms, 1 watt (R15)

DESCRIPTION

CHASSIS ASSEMBLIES

RC -507

sections of

(3)

15 mmf. (C33) 31418

.002 mfd., 200

.005 mfd., 600

.01 mfd., 200

.01 mfd., 600 volts

mfd.,

mfd., 200 volts (C19)

.05 mfd., 600 volts

19-13 meter and 25 meter bands (LI,

volts (C23)

600 volts (C25) (T1)

volts (C24)

volts (C39)

200 volts (C22) STAMPED 92517-1J

(C28)

(C35)

19-13 meter band (L12)

I -F trans-

is too high, it

STOCK

No.

30436

35595

30492

30180

30493

14983

30648

30649

30992

14350

35633

35637

31364

14278

31251 Socket-Tube socket

12007

31261

35621

32827 Switch-Voltage switch (S5)

35636

35628

32852

35588

33726

2917 Washer-"C" washer for tuning knob shaft

70578 Cone-Cone and voice coil assembly

5118 Plug -4 -prong male plug for speaker

70583

70584 Transformer-Output transformer (T2)

35649

70579

35654 Dial-Glass dial scale

36658 Extension-Tone control shaft extension for Q32

35647 Frame-Dial frame complete less indicator

70581

X1611

70580 Indicator-Station selector indicator

35652 Knob-Range indicator knob

35651

35650

34489

11891 Lamp-Dial lamp (Mazda No. 44)

14270 Spring-Retaining spring for tone control, volume control,

4982 Spring-Retaining spring for range indicator knob

may be

DESCRIPTION

Resistor -12,000 ohms, 1/4 watt (I17)

Resistor -15,000 ohms, 3 watt (114)

Resistor -22,000 ohms, 1/4 watt (115)

Resistor -33,000 ohms, 1/4 watt (I12)

Resistor -120,000 ohms, 1/4 watt (1113)

Resistor-I50,000 ohms, 1/y watt (1114)

Resistor -330,000 ohms, I/4 watt (R12)

Resistor -470,000 ohms, 1/2 watt (R11, R16)

Resistor -1 megohm, 1/4 watt (R1)

Resistor -2.2 megohms, 1/4 watt (R3)

Resistor -10 megohms, 1/4 watt (R10)

Screw-:8-32 square head set screw for drive drum

Shaft-Range switch indicator knob shaft

Shaft-Tuning knob shaft

Socket-Lamp socket

Socket-Phono input socket

Spring-Drive cord

Spring-Retaining spring

stud assemblies

Spring-Retaining spring for oscillator coils' core and stud

assemblies

Switch-Range switch (SI, S2, S3, S4)

Transformer-First I -F transformer (L13, L14, C15, C18)

Transformer-Second I -F transformer (L15, LI6, C20, C21)

Transformer --Power transformer, 105-125 volts, 50/60 cycle

or 105-125/210-250 volts, 50/60 cycle (T1)

Transformer-Power transformer, 105-125 volts, 25/60 cycle

or indicator

cord spring.

I -F transformers' core and

for

Washer-"C" washer for idler pulley

SPEAKER ASSEMBLY

Speaker -61/2 -inch E.M. speaker complete with cone and

voice coil less plug and output transformer

Note: If

Back-Cabinet back for Q22A

Back-Cabinet back for Q32

Decal-Trade mark decal

Grille-Grille cloth for Q22A

Grille-Grille cloth for Q32

Knob-Range switch knob

Knob-Tone control knob

Knob-Tuning or volume control knob

stamping on speaker in instrument does not

agree with above speaker number, order replace -

ment parts by referring to model number of

strument, number stamped on speaker and full de scription of part required.

MISCELLANEOUS ASSEMBLIES

range switch and tuning knobs

in -

APPLY TO YOUR RCA DISTRIBUTOR FOR PRICES OF REPLACEMENT PARTS

Addition to Parts List under Mis-

cellaneous Assemblies:

for

Stock

Model Q32.

71083-Back-Cabinet

No.

back

Loading...

Loading...