Page 1

A-PDF MERGER DEMO

SERVICE MANUAL

FILE NO. SM-CTV-O-039A

COLOR TELEVISION

MODEL NO. MCR61TF30/MCR66R400

MCR68R420/MCR68TF800

CHASSIS NO. CH-10C5

Please read this manual carefully before service.

Page 2

SERVICE MANUAL

TABLE OF CONTENTS

SAFETY INSTRUCTIONS AND MAINTENANCE........................................................... 1

X-Ray Radiation Precaution.........................................................................................1

Safety Precaution......................................................................................................... 1

Product Safety Notice .................................................................................................. 2

Maintenance ................................................................................................................2

KEY ICS AND ASSEMBLIES ......................................................................................... 3

BLOCK DIAGRAMS FOR CHASSIS .............................................................................. 4

Structure Block Diagram ..............................................................................................4

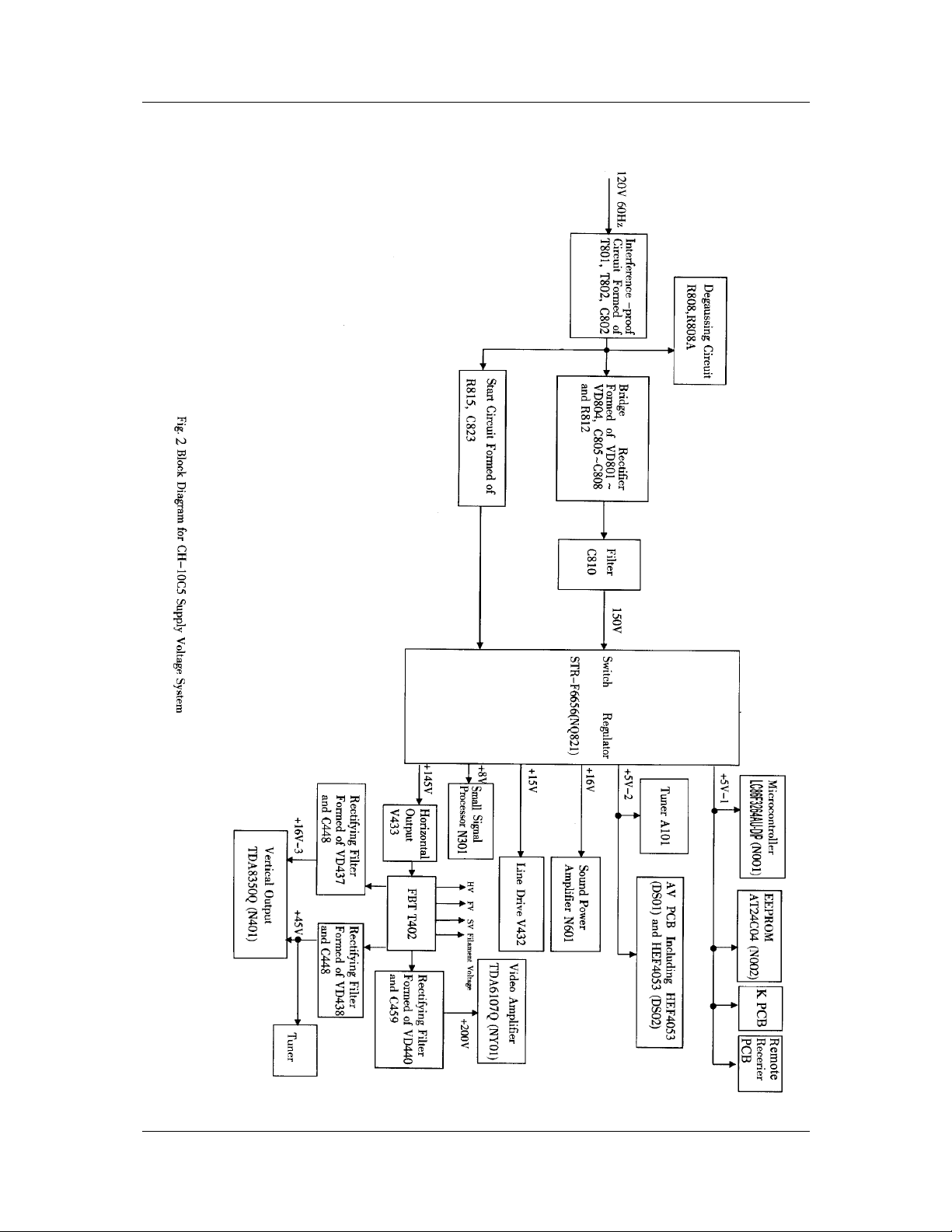

Block Diagram for Supply Voltage System................................................................... 5

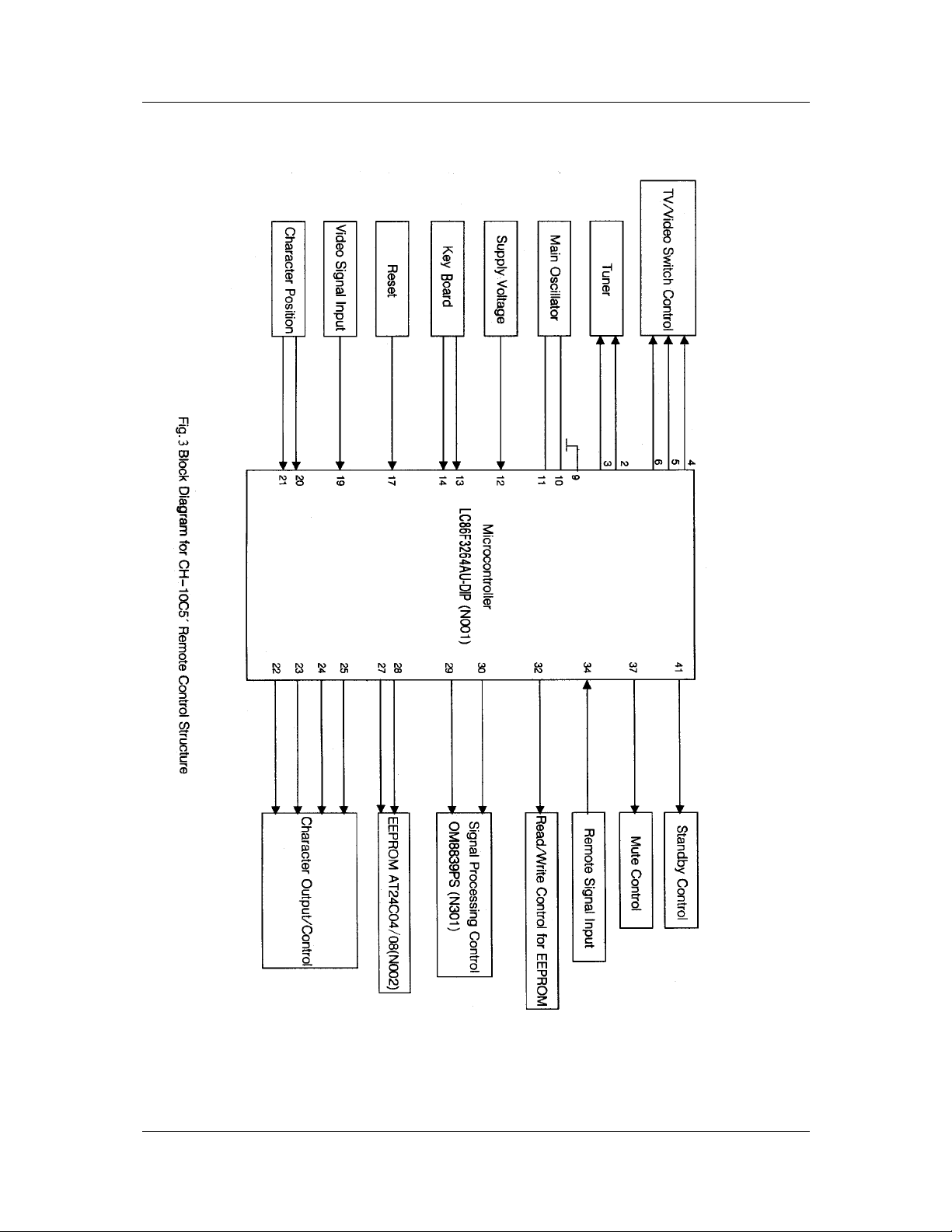

Block Diagram for Remote Control Structrre................................................................ 6

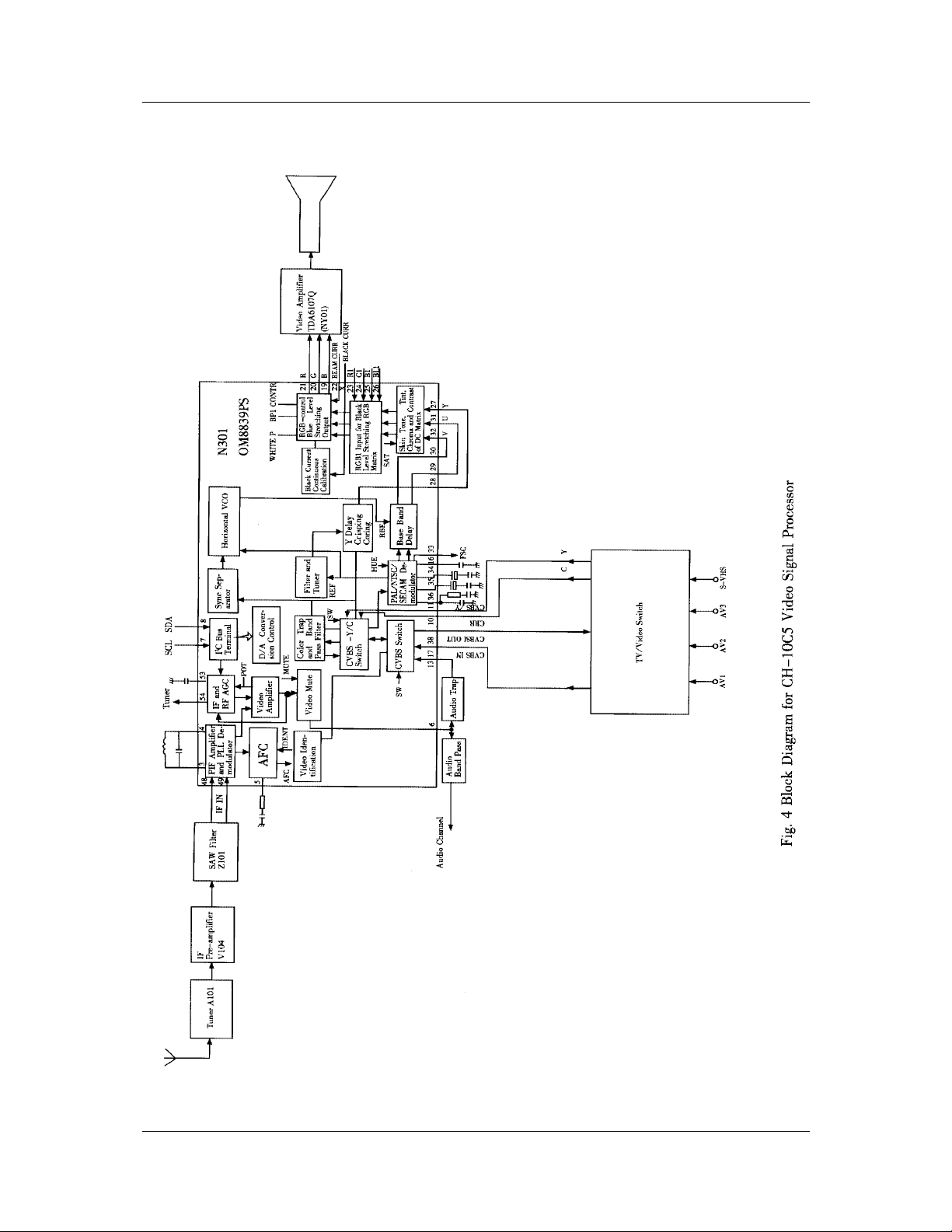

Block Diagram for Video Signal Processor ..................................................................7

SERVICE DATA .............................................................................................................................8

Technical Data of Key ICs ............................................................................................ 8

Service Data of Key ICs............................................................................................. 22

Waveforms of Key Points ........................................................................................... 28

ADJUSTMENTS............................................................................................................ 32

Set-up Adjustments.................................................................................................... 32

Circuit Adjustments .................................................................................................... 34

Service Mode and Bus Data ...................................................................................... 36

APPENDIX

1. Circuit Diagram

2. Final Wiring Diagram

3. Exploded View

4. Printed Circuit Board Diagrams

1

Page 3

SERVICE MANUAL

SAFETY INSTRUCTIONS AND MAINTENANCE

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE X-RAY RADIATION PRECAUTION ,

SAFETY PRECAUTION AND PRODUCT SAFETY NOTICE INSTRUCTIONS-BELOW.

X-RAY RADIATION PRECAUTION

1. The EHT must be checked every time the receiver is serviced to ensure that the CRT does not emit

X-ray radiation as result of excessive EHT voltage. The nominal EHT for this receiver is 29KV (for

25”TV) or 30KV (for 29”TV) at zero beam current (minimum brightness) operating at AC 120V. The

maximum EHT voltage permissible in any operating circumstances must not exceed 32KV (for

25”TV) or 33KV (for 29”TV). When checking the EHT, use the High Voltage Check procedure in this

manual using an accurate EHT voltmeter.

2. The only source of X-RAY radiation in this receiver is the CRT. To prevent X-ray radiation, the

replacement CRT must be identical to the original fitted as specified in the Parts List.

3. Some components used in this receiver have safety related characteristics preventing the CRT

from emitting X-ray radiation. For continued safety, replacement component should be made after

referring the PRODUCT SAFETY NOTICE below.

SAFETY PRECAUTION

1. The receiver has a nominal working EHT voltage of 29KV (for 25”TV) or 30KV (for 29”TV). Extreme

caution should be exercised when working on the receiver with the back removed.

1)

Do not attempt to service this receiver if you are not conversant with the precautions and procedures

for working on high voltage equipment.

2) When handling or working on the CRT, always discharge the anode to the receiver chassis before

removing the anode cap in case of electric shock.

3) The CRT, if broken, will violently expel glass fragments. Use shatterproof goggles and take extreme

care while handling.

4) Do not hold the CRT by the neck as this is a very dangerous practice.

2. It is essential that to maintain the safety of the customer all power cord forms be replaced exactly

as supplied from factory.

3. Voltage exists between the hot and cold ground when the TV is in operation. Install a separation

transformer during repairing or connecting to any testing equipment for the sake of safety. The

power of the separation transformer should exceed the rated overall power.

4. Replace blown fuses within the receiver with the fuse specified in the parts list.

5. When replacing wires or components to terminals or tags, wind the leads around the terminal

before soldering. When replacing safety components identified by the international hazard symbols

on the circuit diagram and parts list, it must be the company-approved type and must be mounted

as the original.

6. Keep wires away from high temperature components.

1

Page 4

SERVICE MANUAL

PRODUCT SAFETY NOTICE

Many electrical and mechanical components in this chassis have special safety-related characteristics.

These characteristics are often passed unnoticed by a visual inspection and the X-ray radiation

protection afforded by them cannot necessarily be obtained by using replacements rated at higher

voltages or wattage, etc. Components which have these special safety characteristics in this manual

and its supplements are identified by the international hazard symbols in the circuit diagram and parts

list. Before replacing any of these components read the parts list in this manual carefully. Substitute

replacement components which do not have the same safety characteristics as specified in the parts

list may create X-ray radiation.

Safety Symbol Description

The lightning symbol in the triangle tells you that the voltage inside this product may be

strong enough to cause an electric shock. Extreme caution should be exercised when

working on the TV with the back removed.

This is an international hazard symbol, telling you that the components identified by the

symbol have special safety-related characteristics.

FDA This symbol tells you that the critical components identified by the FDA marking have

special safety-related characteristics.

UL This symbol tells you that the critical components identified by the UL marking have special

safety-related characteristics.

VDE This symbol tells you that the critical components identified by the VDE marking have

special safety-related characteristics

.

Maintenance

1. Place the TV set on a stable stand or base that is of adequate size and strength to prevent it from

being accidentally tipped over, pushed off, or pulled off. Do not place the set near or over a radiator

or heat register, or where it is exposed to direct sunlight.

2. Do not install the TV set in a place exposed to rain, water, excessive dust, mechanical vibrations or

impacts.

3. Allow enough space (at least 10cm) between the TV and wall or enclosures for proper ventilation.

4. Slots and openings in the cabinet should never be blocked by clothes or other objects.

5. Please power off the TV set and disconnect it from the wall immediately if any abnormal condition

are met, such as bad smell, belching smoke, sparkling, abnormal sound, no picture/sound/raster.

Hold the plug firmly when disconnecting the power cord.

6. Unplug the TV set from the wall outlet before cleaning or polishing it. Use a dry soft cloth for

cleaning the exterior of the TV set or CRT screen. Do not use liquid cleaners or aerosol cleaners.

2

Page 5

SERVICE MANUAL

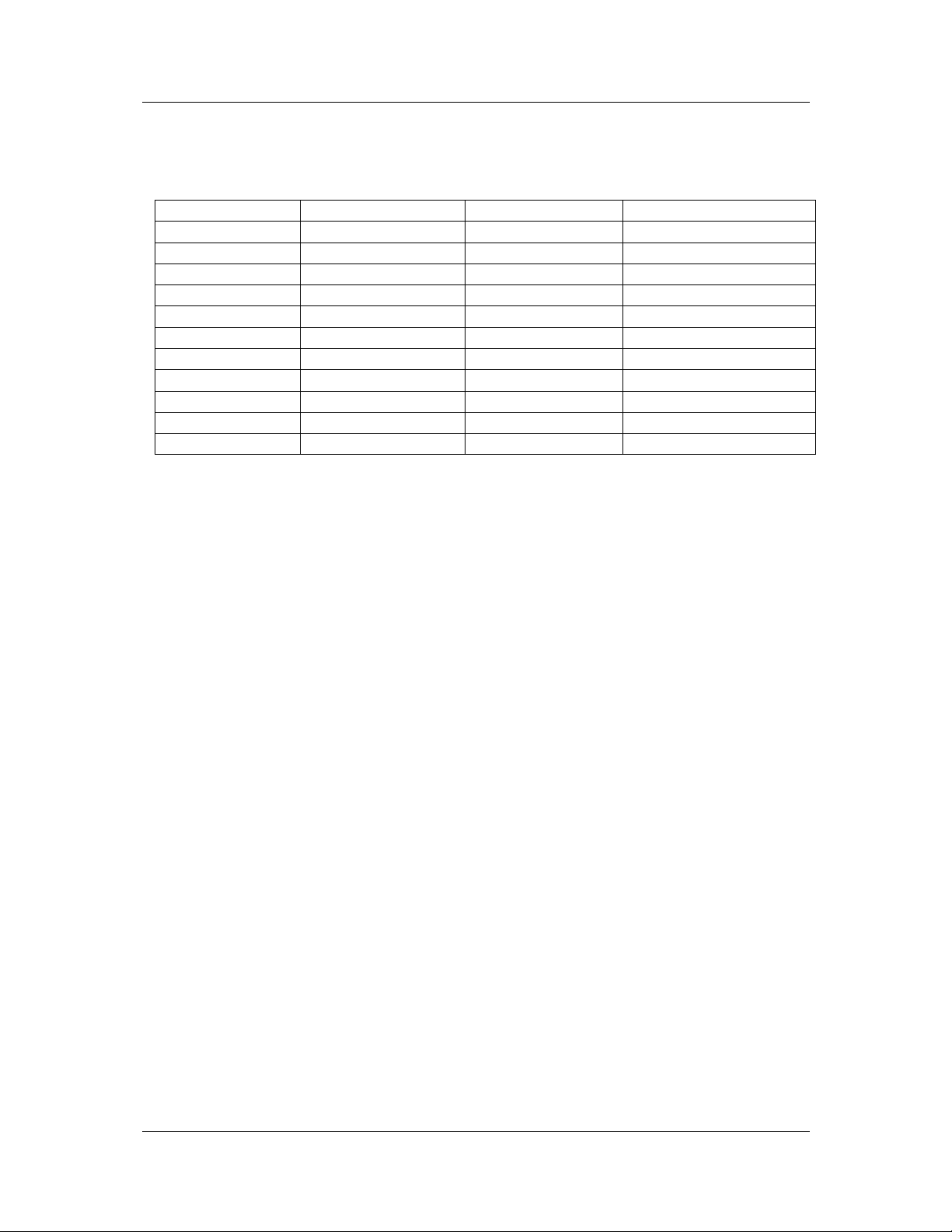

KEY ICS AND ASSEMBLIES

Table 1 Key ICs and Assemblies

Serial No. Position No. Model No. Function Description

1 N301 OM8839PS Small signal processor

2 N401 TDA8350Q Vertical output circuit

3 N852 LM317T Tri-terminal regulator

4 N601 TDA7057AQ Sound power amplifier

5 N001 LC86F3264AU-DIP Microcontroller

6 N002 AT24C04/AT24C08 EEPROM

7 NY01 TDA6107Q Video amplifier

8 DS01 HEF4053 Analog switch circuit

9 DS02 HEF4053 Analog switch circuit

10 N606 TDA9859 Audio processor

11 A101 TDQ-6F2M Tuner

Notes: AT24C04 (N002) is for MCR61TF30 only;

AT24C08 (N002) is for MCR66R400/MCR68R420/MCR68R800.

3

Page 6

SERVICE MANUAL

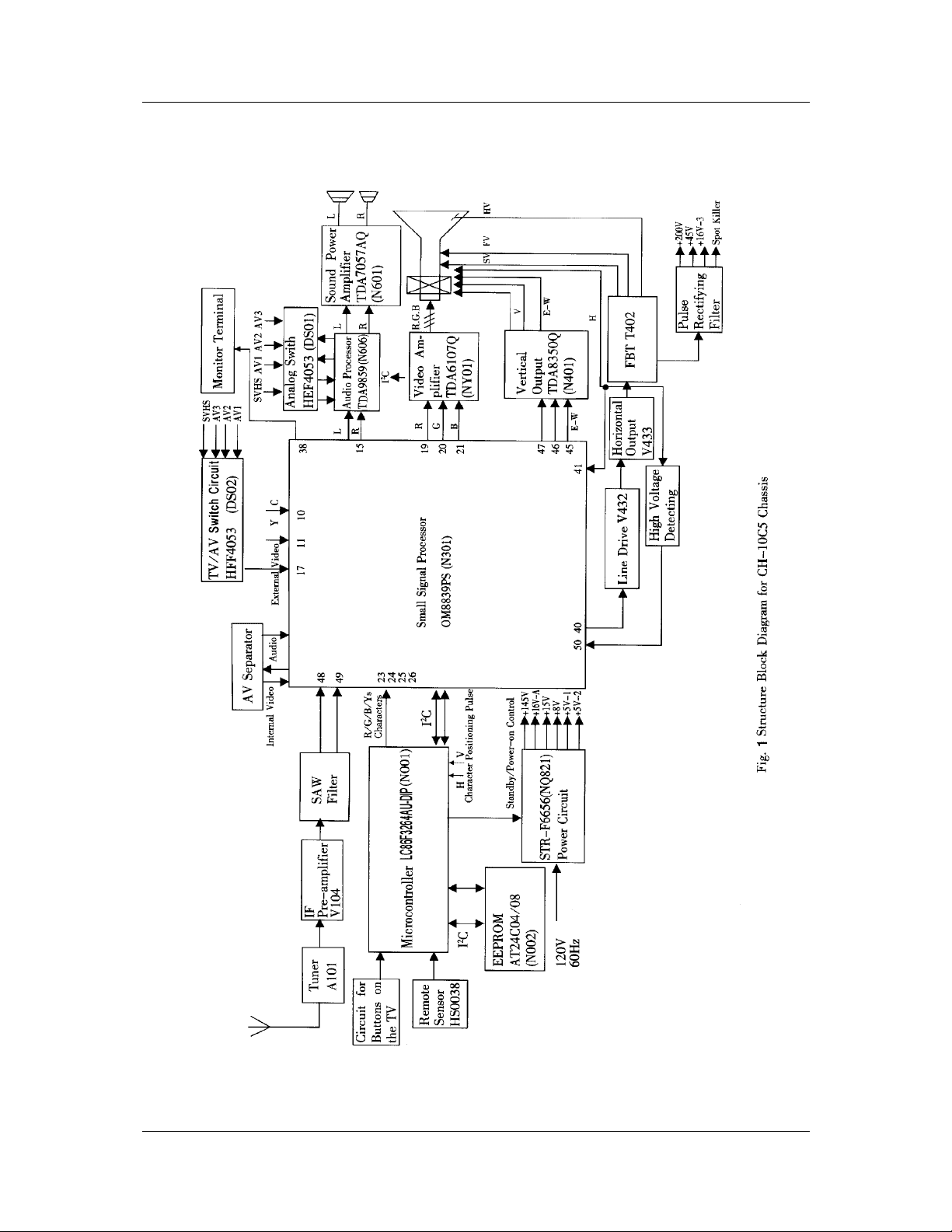

BLOCK DIAGRAMS FOR CHASSIS

Structure Block Diagram

4

Page 7

SERVICE MANUAL

Block Diagram for Supply Voltage System

Fig.2 Block Diagram for CH-10C1(S) Supply Voltage System

5

Page 8

SERVICE MANUAL

Black Diagram for Remote Control Structure

6

Page 9

SERVICE MANUAL

Block Diagram for Video Signal Processor

7

Page 10

SERVICE DATA

Technical Data of Key ICs

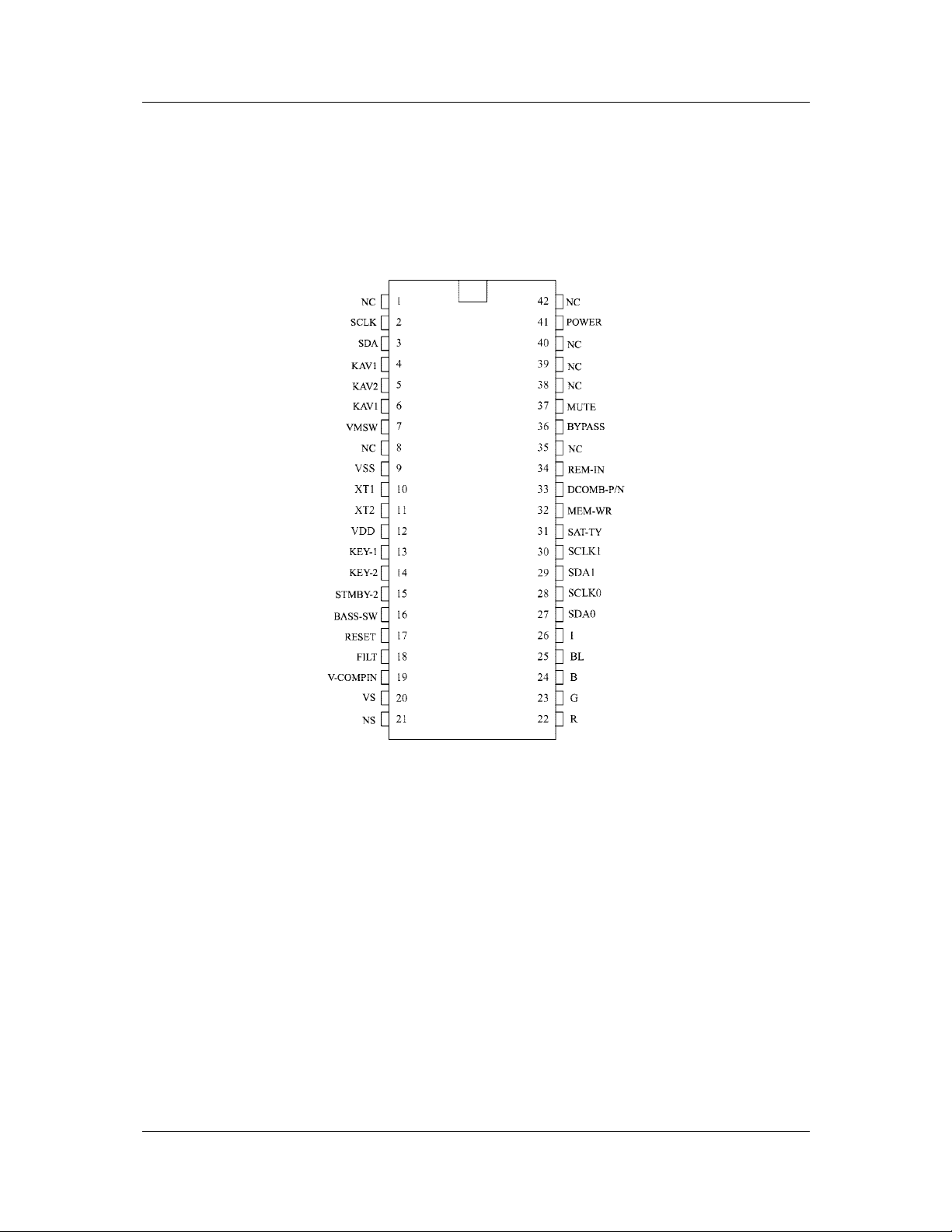

LC86F3264AU-DIP (N001)

1. Terminal Assignment Layouts

SERVICE MANUAL

Fig. 5 LC86F3264AU-DIP DIP42S Terminal Assignment Layout

8

Page 11

SERVICE MANUAL

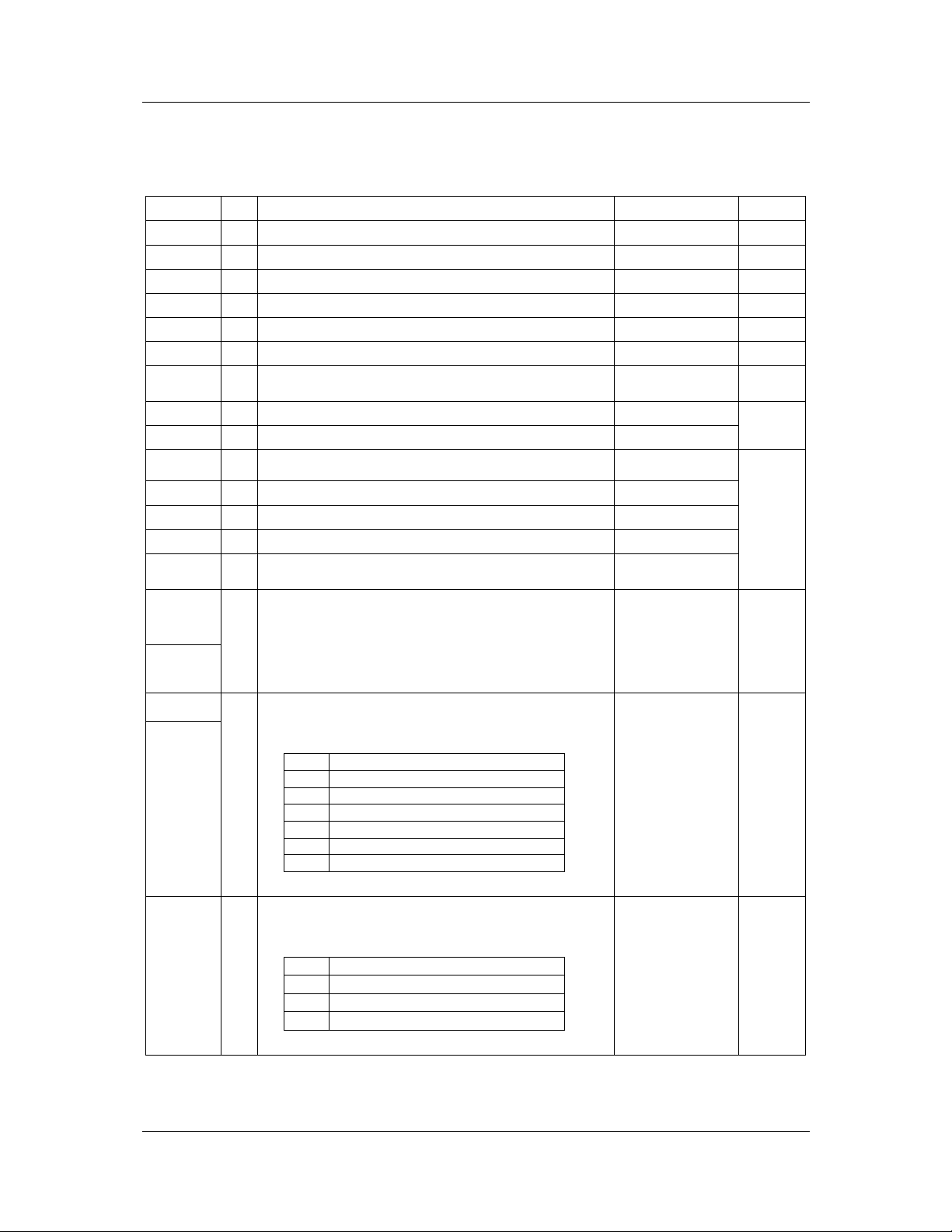

2. Terminal Function

Table 2 Terminal Function Table

Terminal I/O Function Description Option Format

VSS - Negative power supply

XT1 1 Input terminal for crystal oscillation

XT2 O Output terminal for crystal oscillation

VDD - Positive power supply

RES I Reset terminal A

FILT O Charge-pump output terminal N

CVIN I

VS I

HS I

RO

GO

B O Blue (B) output terminal of RGB imagee

I O Intensity (I) output terminal of RGB image

RL O

Part 0

P00-P07

Port 1

P10-P17

Image signal input terminal

(available only in CH04T1002)

Vertical synchronization signal input terminal

Horizontal synchronization signal input terminal

Red (R) output terminal of RGB image

Green (R) output terminal of RGB image

Fast blanking control signal

Switch TV image and caption/OSD image signal

8-bit input/output port

Input/output can be specified in nibble unit

I/O

I/O

Other functions:

Hold release input

Internal input

8-bit input/output port

Each bit can be independently programmable

Other functions:

P10 SIO0 data output

P11 SIO0 data input/bus input/output

P12 SIO0 clock input/output

P13 PWM1 output

P14 PWM2 output

P15 PWM3 output

P17 Timer 1(PWM) output

Pull-up resistor

provided/not

provided

Output format

CMOS/Nch-OD

Output format

CMOS/Nch-OD

M

A

O

E

F

Port 6 I/O

4-bit input/output port

Each bit can be independently programmable

Other functions:

P60 IIC0 data input/output

P61 IIC0 clock output

P62 IIC1 data input/output

P63 IIC1 clock output

9

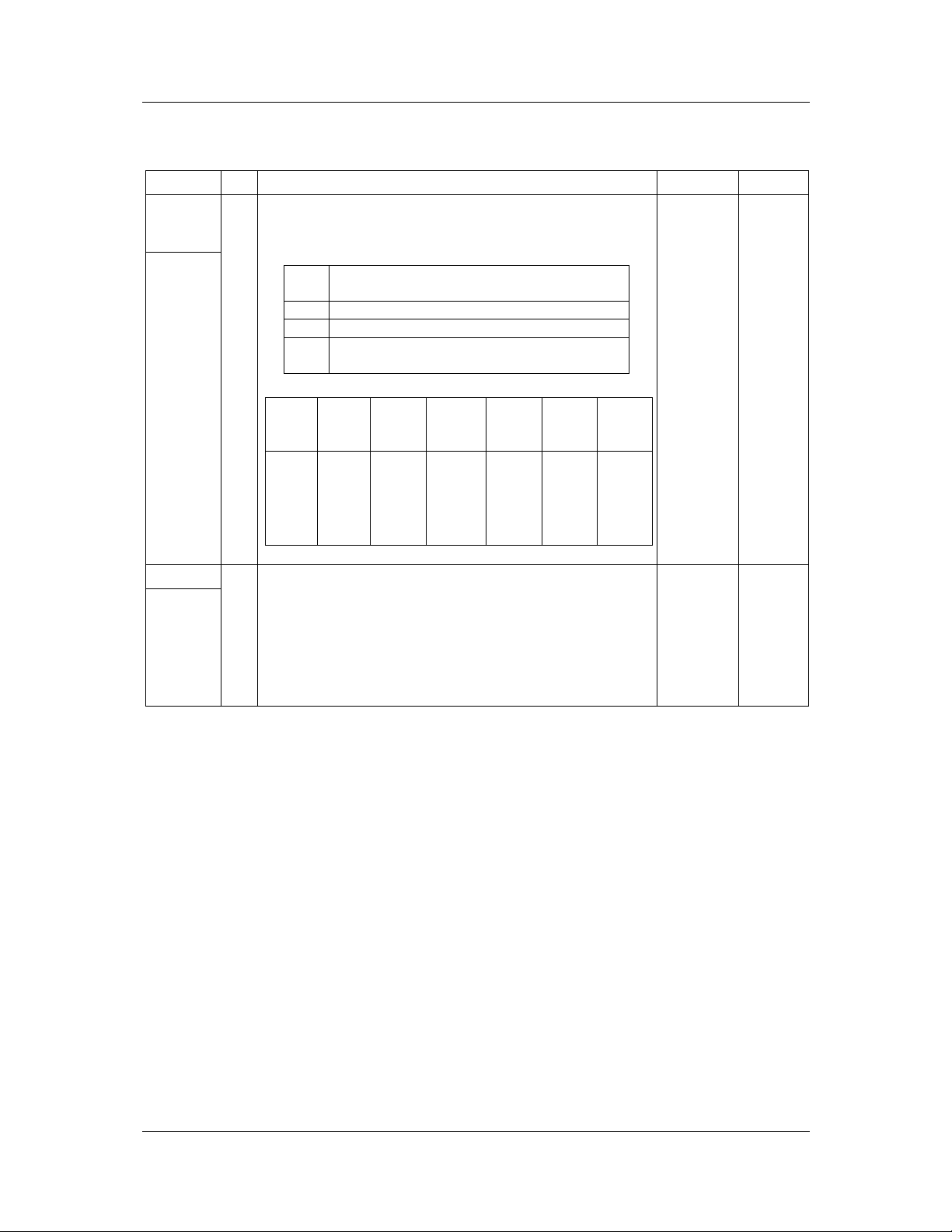

Page 12

SERVICE MANUAL

Terminal I/O Function Description Option Format

4-bit input/output port

Port 7

I/O

P71-P73

Each bit can be independently programmable

Other functions:

INTO input/HOLD release input

P70

/Nch-Tr. output for watchdog timer

P71 INT1 input/HOLD release input

P72 INT2 input/timer 0 event input

INT3 input (noise rejection filter attached

P73

input)/timer 0 event input

Interrupt receiver format vector address

INTO

INT1

INT2

INT3

Rising Falling

yes

yes

yes

yes

yes

yes

yes

yes

Rising

/

Falling

no

no

yes

yes

H

levelLlevel

yes

yes

no

no

yes

yes

no

no

Vector

03H

0BH

13H

1BH

P70

W

P71-P73

V

Port 8

P83

P84-P87

Port options can be specified independently for each bit.

The programmable pull-up resistors are provided depending on whether CMOS or Nch-OD (Nch open

drain ) is selected as the port 1 option.

3. Refer to Table 3 about Functions and Data of the IC’s Each Pin.

I/O

1-bit input port

(P83 is set only in CH04T1002)

I

4-bit input/output port(P84-P87)

Each bit can be independently programmable

Other function:

AD converter input port

P83

B

P84-P87

X

10

Page 13

SERVICE MANUAL

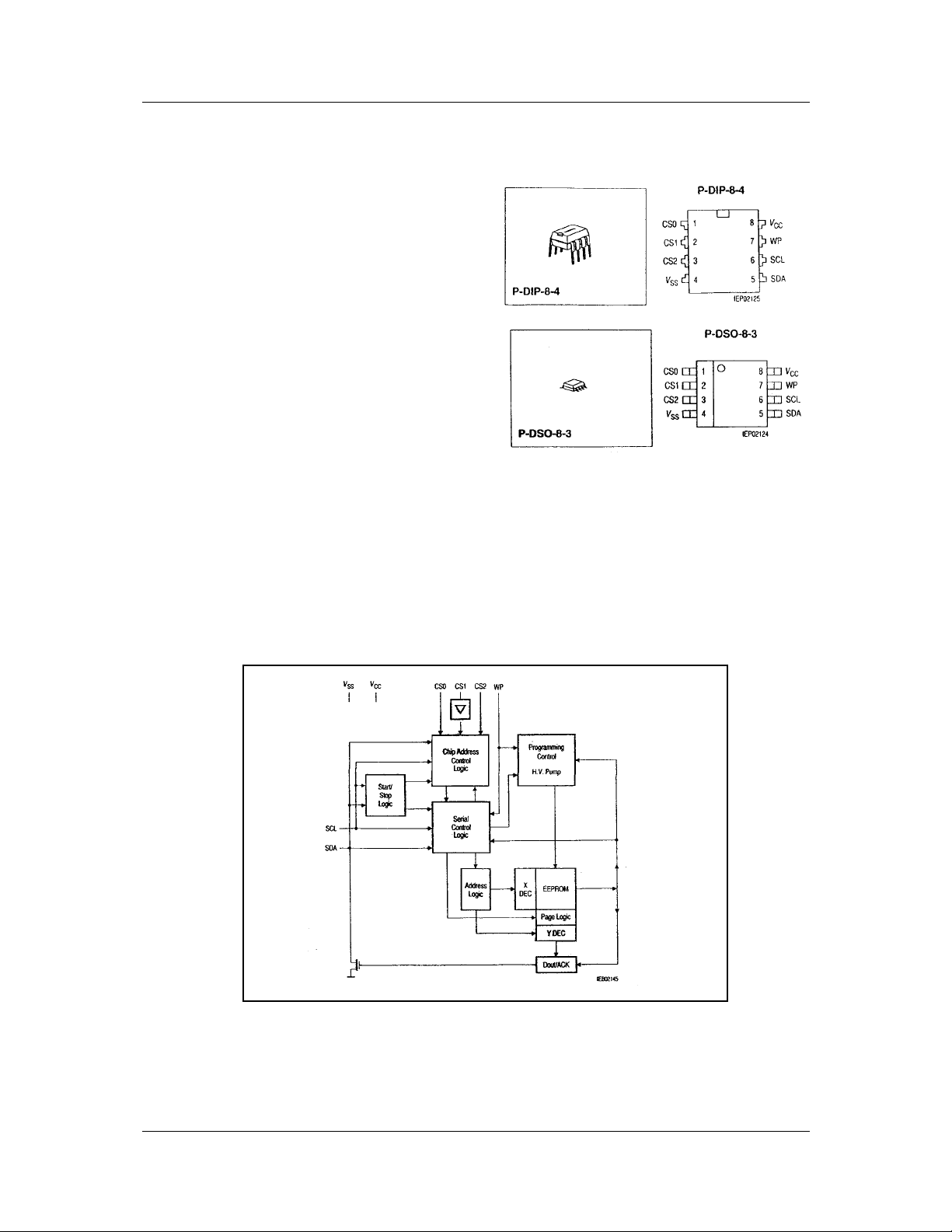

EEPROM AT24C04 (N002)

1. Features

Data EEPROM internally organized as 512

bytes and 32 pages×16 bytes

Low power CMOS

Vcc=2.7 to 5.5V operation

Two wire serial interface bus I

compatible

Filtered inputs for noise suppression with

Schmitt trigger

Clock frequency up to 400 kHz

High programming flexibility

-Internal programming voltage

-Self timed programming cycle including erase

-Byte-write and page-write programming

between 1 and 16 bytes

-Typical programming time 6 ms(<10ms) for up

to 16 bytes

High reliability

-Endurance 10

-Data retention 40 years

6

cycles

1)

1)

-ESD protection 4000 V on all pins

8 pin DIP/DSO packages

Available for extended temperature ranges

-Industrial -40 to +85

-Automotive -40 to +125

3. Block Diagram

2

C-Bus

2. Pin Configuration

Fig. 6

Fig. 7

4. Refer to Table 4 about Functions and Data of the IC’s Each Pin

11

Page 14

SERVICE MANUAL

OM8839PS (N301)

I2C-bus Controlled PAL/NTSC/SECAM TV Processors

1. Features

The following features are available in all IC’s:

·Multi-standard vision IF circuit with an

alignment-free PLL demodulator without external

components

·Alignment-free multi-standard FM sound

demodulator (4.5 MHz to 6.5 MHz)

·Audio switch

·Flexible source selection with CVBS switch and

Y(CVBS)/C input so that a comb filter can be

applied

·Integrated chrominance trap circuit

·Integrated luminance delay line

·Asymmetrical peaking in the luminance channel

with a (defeatable) noise coring function

·Black stretching of non-standard CVBS or lumina-

nce signals

·Integrated chroma band-pass filter with switchable

centre frequency

·Dynamic skin tone control circuit

·Blue stretch circuit which offsets colours near

white towards blue

·RGB control circuit with “Continuous Cathode

Calibration” and white point adjustment

·Possibility to insert a“blue back” option when no

video signal is available

·Horizontal synchronization with two control loops

and alignment-free horizontal oscillator

·Vertical count-down circuit

·Vertical driver optimised for DC-coupled vertical

output stages

2

·I

C-bus control of various functions

2. General Description

The various versions of the TDA 884X/5X

series are I

2

processors which are intended to be applied in

PAL, NTSC, PAL/NTSC and multi-standard

television receivers. The N2 version is pin and

application compatible with the N1 version,

however, a new feature has been added which

makes the N2 more attractive. The IF PLL

demodulator has been replaced by an

alignment-free IF PLL demodulator with

internal VCO (no tuned circuit required). The

setting of the various frequencies (33.4, 33.9,

38, 38.9, 45.75 and 58.75 MHz) can be made

via the I

2

C-bus.

Because of this difference the N2 version is

compatible with the N1, however, N1 devices

cannot be used in an optimised N2 application.

Functionally the IC series is split up in 3

categories, viz:

·Versions intended to be used in economy TV

receivers with all basic functions (envelope:

S-DIP 56 and QFP 64)

·Versions with additional features like E-W

geometry control, H-V zoom function and

YUV interface which are intended for TV

receivers with 110° picture tubes (envelope:

S-DIP 56)

·Versions which have in addition a second

RGB input with saturation control and a

second CVBS output (envelope: QFP 64)

The various type numbers are given in the

table below.

C-bus controlled single chip TV

3. Survey of IC Types

Envelope S-DIP 56 QFP 64

TV receiver category Economy Mid/High end Economy Mid/High end

PAL only TDA 8840 TDA 8840H

PAL/NTS TDA 8841 TDA 8843 TDA 8841H

PAL/SECAM/NTSC TDA 8842 TDA 8844 TDA 8842H TDA 8854H

NTSC only TDA 8846/46A TDA 8847 TDA 8857H

12

Page 15

4. Block Diagram

SERVICE MANUAL

5. Refer to Table 5 about Functions and Data of the IC’s Each Pin.

13

Fig .8 Block Diagram “Economy Versions” (S-DIP 56 Envelope)

Page 16

SERVICE MANUAL

TDA8350Q (N401)

DC-coupled Vertical Deflection and East-West Output Circuit

1. Features

Few external components

Highly efficient fully DC-coupled vertical

output bridge circuit

Vertical flyback switch

Guard circuit

Protection against

- short-circuit of the output pins

- short-circuit of the output pins to Vp

High EMC immunity due to common mode

inputs

3. Block Diagram

Temperature (thermal) protection

East-West output stage with one single

conversion resistor.

2. General Description

The TDA8350Q is a power circuit for use in 90°

and 110° colour deflection systems for-field

frequencies of 50 to 120 Hz. The circuit

provides a DC driven vertical deflection output

circuit, operating as a highly efficient class G

system and an East-West driver for sinking the

diode modulator current.

Fig. 9 Block Diagram

4. Refer to Table 6 about Functions and Data of the IC’s Each Pin.

14

Page 17

SERVICE MANUAL

TDA7057AQ (N601)

2×8W Stereo BTL Audio Output Amplifier with DC Volume Control

1. Features

·DC volume control

·Few external components

·Mute mode

·Thermal protection

·Short-circuit proof

·No switch-on and switch-off clicks

·Good overall stability

·Low power consumption

·Low HF radiation

·ESD protected on all pins.

3. Block Diagram

2. General Description

The TDA7057AQ is a stereo BTL output amplifier with DC

volume control. The device is designed for use in TVs and

monitiors, but is also suitable for battery-fed portable

recorders and radios.

Missing Current Limiter (MCL)

A MCL protection circuit is built-in. The MCL circuit is

activated when the difference in current between the

output terminal of each amplifier exceeds 100 mA (typical

300 mA). This level of 100 mA allows for single-ended

headphone applications

Fig. 10 Block Diagram

4. Refer to Table 7 about Functions and Data of the IC’s Each Pin.

15

Page 18

SERVICE MANUAL

TDA6107Q (NY01)

Triple Video Output Amplifier

1. Features

·Typical bandwidth of 5.5 MHz for an

output signal of 60 V (p-p)

·High slew rate of 900 V/S

·No external components required

·Very simple application

·Single supply voltage of 200 V

·Internal reference voltage of 2.5 V

·Fixed gain of 50

·Black-Current Stabilization (BCS) circuit

·Thermal protection.

3. Ordering Information

2. General Description

The TDA6107Q includes three video output amplifiers

in one plastic DIL-bent-SIL 9-pin medium power

(DBS9MPF) package (SOT 111-1), using high-voltage

DMOS technology, and is intended to drive the three

cathodes of a colour CRT directly. To obtain maximum

performance, the amplifier should be used with

black-current control.

Type

Number

TDA6107Q DBS9MPF

4. Block Diagram

Name Description Version

Package

Plastic DIL-bent-SIL medium power package with fin; 9

leads

SO T111-1

Fig. 11 Block Diagram (One Amplifier Shown)

5. Refer to Table 8 about Functions and Data of the IC’s Each Pin.

16

Page 19

SERVICE MANUAL

STR-G5653/6454R (NQ821)

Power Module

The Series STR-G5653/F6654 is specifically designed to satisfy the requirements for increased

integration and reliability in off-line quasi-resonant flyback converters. The series incorporates a

high-precise error amplifying control and drive circuit with discrete avalanche-rated power MOSFET,

featuring fewer external components, small-size and standard power supply.

Covering the power range from below 25 watts up to 300 watts for 100/115/230 VAC inputs, and up to

150 watts for 85 to 265 VAC universal input, these devices can be used in a range of applications,

from battery chargers and set top boxes, to televisions, monitors, and industrial power supply units.

Cycle-by-cycle current limiting, under-voltage lockout with hysteresis, over-voltage protection, and

thermal shutdown protects the power supply during the normal overload and fault conditions.

Low-current startup and a low-power standby mode selected from the secondary circuit completes a

comprehensive suite of features. The series is provided in a five-pin overmolded SIP style package,

affording dielectric isolation without compromising thermal characteristics.

1. Features

Flyback Operation with Quasi-Resonant Soft Switching for Low Power Dissipation and EMI

Rugged Avalanche-Rated MOSFET

Soft drive circuit MOSFET

Adjustable MOSFET switching speed

Choice of MOSFET Voltage and rDS(on)

Full Over-Current Protection (no blanking)

Under-Voltage Lockout with Hysteresis

Over-Voltage Protection

Direct Voltage Feedback

Low Start-up Current (100 Amax)

Low-Frequency, Low-Power Standby Operation

Overmolded 5-Pin Package

2. Circuit Block Diagram

Fig.12

17

Page 20

3. Pin Configuration and Functions

SERVICE MANUAL

Dwg MK-003-50mm

Fig.13

3.1) Pin function for STR-G5653

Pin No. Symbol Function Description

1 D MOSFET drain

2 S MOSFET source

3 GND Ground

4VINSupply voltage input for control circuit

5 OCP/FB Over-current protection detection signal/voltage-limiting signal input

3.2) Pin function for STR-F6654

Pin No. Symbol Function Description

1 OCP/FB Over-current protection detection signal/voltage-limiting signal input

2 S MOSFET source

3 D MOSFET drain

4VINSupply voltage input for control circuit

5 GND Ground

4. Difference between STR-G5653 and STR-F6654

a.Different size: STR- F6654 is larger

b.Different pin functions

c.Different electric characteristics: Larger power output, switching current, avalanche-rated and

internal allowable power consumption for STR-F6654

18

Page 21

SERVICE MANUAL

TDA9859 (N606)

Universal Hi-Fi Audio Processor for TV

1. Features

Multi-source selector switches six AF inputs

(three stereo sources or six mono sources).

Each of the input signals can be switched to

each of the outputs (crossbar switch).

Outputs for loudspeaker channel and peri-TV

connector (SCART).

Switchable spatial stereo and pseudo stereo

effects

3. Block Diagram

(1) For extended bass control, the capacitor between CBR/L1 and CBR/L2 should be replaced by the

Audio surround decoder can be added

externally

Two general purpose logic output ports

2

I

C-bus control of all functions.

2. General Description

The TDA9859 provides control facilities for the

main and the SCART channel of a TV set. Due

to extended switching possibilities signals

from three stereo sources can be handled.

Fig. 14 Block Diagram and Application Circuit.

extended bass control network.

4. Refer to Table 9 about Functions and Data of the IC’s Each Pin.

19

Page 22

SERVICE MANUAL

HEF4053 (DS01/DS02)

Triple 2-channel Analog

Multiplexer/Demultiplexer

1. Description

The HEF4053 is a triple 2-channel analog

multiplexer/demultiplexer with a common enable

input (E). Each multiplexer/demultiplexer has two

independent inputs/outputs (Y

common input/output (Z) and select inputs (Sn).

Each also contains two-bidirectional analog

switches each with one side connected to an

independent input/output (Y

other side connected to a common

input/output(Z).

With (E) LOW one of the two switches is

2. Block Diagrams

and Y1) a

0

and Y1) and the

0

selected (low impedance ON-state) by Sn. With

E HIGH all switches are in the high impedance

OFF-state independent of S

V

and VSSare the supply voltage connections

DD

for the digital control inputs (S

The V

inputs/outputs (Y

V

limit. V

to VSS range is 3 to 15V.The analog

DD

and Z) can swing between

0Y1

as a positive limit and VEE as a negative

DD

may not exceed 15 V.

DD-VEE

to SC.

A

to SC and E).

A

For operation as a digital multiplexer/demultiple-

xer V

is connected to VSS (typically ground).

EE

Fig. 15 Functional Diagram

20

Page 23

SERVICE MANUAL

Pinning

Y

to Y0C Independent inputs/outputs

0A

Y

to Y1C Independent inputs/outputs

1A

S

to S

A

c

E Enable input (active LOW)

to Z

Z

A

C

Select inputs

Common inputs/outputs

Fig. 16 Pinning Diagram

HEF4053P(N): 16-lead DIL ; plastic

(SOT38-1)

HEF4053D(F): 16-lead DIL; ceramic

(cerdip)

(SOT74)

HEF4053T(D): 16-lead S0; plastic

(SOT109-1)

( ): Package Designator North America

3. Function Table

Inputs Channel

E Sn On

L L Y

L H Y

on-Zn

ln-Zn

H X none

Notes

H=HIGH state (the more positive voltage)

L=LOW state (the less positive voltage)

X=STATE is immaterial

Fig. 17 Schematic Diagram (One Switch)

Ratings

Limiting values in accordance with the Absolute Maximum System(IEC 134)

Supply voltage (with reference to V

)V

DD

-18 to + 0,5 V

EE

Note

To avoid drawing V

current out of terminal Z, when switch current flows into terminals Y, the voltage

DD

drop across the bidirecctional switch must not exceed 0,4 V. If the switch current flows into terminal Z,

no V

current will flow out of terminals Y, in this case there is no limit for the voltage drop across the

DD

switch, but the voltages at Y and Z may not exceed V

DD

or V

EE

4. Refer to Table 10 about Functions and Data of the IC’s Each Pin.

21

Page 24

SERVICE MANUAL

Service Data of Key ICs

Table 3 Functions and Service Data of LC86F3264AU-DIP (N001)’s Pins

Pin

No.

1 Not connected 0 9.62 5.35

2 Clock line 4.89 9.56 5.08

3 Data line 4.87 9.56 5.06

4 AV1 control 5 6.84 5.22

5 AV2 control 0 6.89 5.16

6 AV3 control 0 7.28 5.29

7 Not connected 0 9.61 5.4

8 Not connected 0.92 9.6 5.4

9 Ground 0 0 0

10 Input terminal for clock oscillating signal 1.88 9.55 6.12

11 Output terminal for clock oscillating signal 2.63 9.05 6.08

12 Power supply 5 3.64 3.33

13 Button-control voltage input terminal 5 8.91 5.21

14 Button-control voltage input terminal 5 8.93 5.21

15 Not connected 5 9.45 5.45

16 Not connected 4.9 9.53 5.45

17 Reset 4.96 4.64 4.48

18 Filter 2.76 9.52 5.31

19 Video signal input terminal 3 9.51 5.92

20 Input terminal for vertical flyback pulse 4.74 8.73 5.03

21 Input terminal for horizontal flyback pulse 4.27 8.81 5.01

22 R character output terminal 0 2.08 2.08

23 G character output terminal 0 2.1 2.1

24 B character output terminal 0 2.08 2.08

25 Output terminal for fast blanking signal 0 1.97 1.97

26 Character level clamping 0 9.54 5.73

27 Clock line 0 5 7.12 4.91

28 Data line 0 5 7.12 5.18

29 Clock line 1 4.52 7.05 5.12

30 Data line 11 4.41 7.03 5.09

31 Overload detecting input terminal 5 6.95 5.13

32 Input terminal for selectable production modes 5 9.62 5.29

33 Not connected 0 9.56 5.46

34 Remote control input 4.64 9.22 5.33

35 Not connected 0 9.58 5.4

36 Not connected 0 9.58 5.42

37 Mute 0 9.58 4.3

38 Not connected 0 9.58 5.36

39 Not connected 0 9.59 5.28

40 Not connected 0 9.59 5.36

41 Standby control 0 7.43 4.9

42 Not connected 0 9.6 5.36

Function Description

Reference

Voltage (V)

Digital Multimeter

Positive

Resistance (K )

Negative

Resistance (K )

22

Page 25

SERVICE MANUAL

Table 4 Functions and Service Data of AT24C04 (N002)'s Pins

Pin

No.

1 Address input 0 0 0

2 Address input 0 0 0

3 Address input 0 0 0

4 Common ground 0 0 0

5 Clock line 5 7.05 4.82

6 Data line 5 7.06 5.24

7 Write protect 4.99 9.58 5.49

8 Power supply 5 3.64 3.33

Function Description

Reference

Voltage (V)

Digital Multimeter

Positive

Resistance (K )

Negative

Resistance (K )

Table 5 Functions and Service Data of OM8839PS (N301)’s Pins

Pin

No.

1 SIF signal input 0 2.21 2.21

2 External audio signal input 3.65 9.02 6.04

3 Reference frequency resonant coil terminal 0

4 Reference frequency resonant coil terminal 0

5 PLL filter 2.51 8.92 5.82

6 Video detection output 3.06 2.2 2.2

7 Clock line 4.4 7.15 5.15

8 Two-way transmission data line 4.52 7.15 5.15

9 Gap decoupling 6.7 7.52 5.68

10 SVHS chroma signal input 1.35 9 6

11 SVHS luminance signal input 3.4 9.04 5.91

12 Supply voltage 8.24 2.78 1.96

13 Composite video signal input terminal 4.32 9.15 5.94

14 Ground 0 0 0

15 Audio signal output 3 9.24 5.98

16 Decoupling capacitor connection 0

17 Video input 3.4 9.12 5.94

18 Black current control input 5.81 9.22 5.88

19 Blue(B) signal output 3.04 6.19 5.2

20 Green(G) signal output 3.1 6.19 5.23

21 Red(R) signal output 3.2 6.2 5.26

22 Beam current control 2.1 8.22 6.04

23 Red(R) signal output 3.6 9.01 6.12

24 Green(G) signal output 3.61 9.01 6.12

25 Blue(B) signal output 3.6 9.01 6.12

26 Selectable primary color signal input control 0.1 1 1

27 Luminance signal input 3.26 9.25 5.87

28 Luminance signal input 3.26 9.25 5.87

29 B-Y color difference signal output 2.38 8.5 5.91

30 R-Y color difference signal output 2.37 8.5 5.91

31 B-Y color difference signal output 2.38 8.5 5.91

Function Description

Reference

Voltage (V)

Digital Multimeter

Positive

Resistance (K )

Negative

Resistance (K )

23

Page 26

SERVICE MANUAL

32 R-Y color difference signal output 2.37 8.5 5.91

33 Sub-carrier output for SECAM demodulation 0.35 6.78 5.96

34 3.58MHz crystal oscillator 2.54 8.02 6.04

35 4.43MHz crystal oscillator 2.53 8.02 6.04

36 APC low pass filter 4.99 9.37 6

37 Horizontal starting supply voltage 8.22 2.64 2.56

38 Composite video output 3.68 7.52 6.11

39 Black level stretch 4.95 9.26 4.93

40 Line drive pulse output 3.55 3.5 3.49

Horizontal flyback pulse input/sandcastle pulse

41

output

42 Line discriminator 3.66 8.81 6.04

43 Line discriminator 3.92 9.31 6.04

44 Ground 0 0 0

45 Vertical frequency parabola output 0.73 9.05 5.97

46 Field drive signal output 2.32 9.3 5.97

47 Field drive signal output 2.35 9.3 5.97

48 IF signal input 4.62 8.52 6.2

49 IF signal input 4.62 8.52 6.2

50 High voltage detection input 2.05 8.04 6.14

51 Vertical sawtooth generation 3.8 8.65 6.09

52 Vertical reference bias setting 3.9 8.89 6.05

53 AGC filter for IF amplifier 4.49 9.25 6

54 AGC output for IF amplifier 0.67 10.05 5.82

55 Audio deemphasis 2.93 8.93 6.12

56 Audio decoupling 4.02 9.37 6.08

0.76 8.82 5.92

Table 6 Functions and Service Data of TDA8350 (N401)’s Pins

Pin

No.

1 Vertical drive input (positive) 2.32 9.4 5.84

2 Vertical drive input (negative) 2.3 9.4 5.87

3 Feedback input 8.15 5.81 4.72

4 Supply voltage 16.27 7.99 7.62

5 Output 1 8.14 5.88 4.72

6 Not connected 0

7 Ground 0 0 0

8 Pump supply voltage input 46.94 4.29

9 Output 1 8.22 5.92 4.71

10 Guard output 0.28 8.51 5.899

11 Pincushion output 16.99 9.45 4.16

12 Pincushion input (negative) 0.25 9.12 5.93

13 Pincushion input (positive) 0 0 0

Function Description

Reference

Voltage (V)

Digital Multimeter

Positive

Resistance (K )

Negative

Resistance (K )

24

Page 27

SERVICE MANUAL

Table 7 Functions and Service Data of TDA7057AQ (N601)’s Pins

Pin

No.

1 Volume control input 1.03 6.88 6.15

2 Not connected 0

3 Audio R signal input 2.45 12.68 6.5

4 Supply voltage 16.18 0.46 0.46

5 Audio L signal input 2.45 12.6 6.5

6 Ground 0 0 0

7 Volume control input 1.03 6.88 6.15

8 Left channel in-phase signal output 7.64 6.48 5.6

9 Ground 0 0 0

10 Left channel inverting signal output 7.71 6.47 5.6

11 Right channel inverting signal output 7.76 6.47 5.6

12 Ground 0 0 0

13 Right channel in-phase signal output 7.79 6.48 5.6

Function Description

Reference

Voltage (V)

Digital Multimeter

Positive

Resistance (K )

Negative

Resistance (K )

Table 8 Functions and Service Data of TDA6107Q (NY01)’s Pins

Pin

No.

1 G inverting input 2.94 5.72 4.96

2 R inverting input 3 5.72 4.96

3 B inverting input 2.91 5.72 4.96

4 Ground 0 0 0

5 Black level current input 6.5 19.28 5.68

6 Supply voltage 198.65 4.53

7 B output 103 5.48

8 R output 98.6 5.48

9 G output 100.6 5.48

Function Description

Reference

Voltage (V)

Digital Multimeter

Positive

Resistance (K )

Negative

Resistance (K )

25

Page 28

SERVICE MANUAL

Table 9 Functions and Service Data of TDA9859 (N606)’s Pins

Pin

No.

Function Description

Reference Voltage (V)

Digital Multimeter

Positive Resistance

(K )

Negative

Resistance (K )

1 Audio input 4.14 7.62 5.85

2 Output 1 0 7.86 6.26

3 Audio input 4.14 7.61 5.84

4 Reference voltage for filtering

capacitor

8.18 7.46 5.94

5 Audio output 4.14 7.62 5.83

6 Supply voltage 8.26 1.62 1.62

7 Audio output 4.15 7.41 5.95

8 Ground 0 0 0

9 Audio output 4.15 7.36 5.79

10 Audio input 8 4.15 7.36 5.79

11 Channel 1 audio compensation 4.15 7.38 6.12

12 Channel 2 audio compensation 4.15 7.61 6.03

13 Audio output 8 0

14 Treble compensation 4.15 7.48 6.24

15 Audio output 4.13 6.78 5.66

16 Clock line 4.33 7.02 5.25

17 Serial data line 4.53 6.98 5.21

18 Audio output 4.13 6.78 5.65

19 Treble compensation 4.14 7.48 6.24

20 Audio output 0

21 Bass2 compensation 4.15 7.59 6.04

22 Bass1 compensation 4.15 7.37 6.12

23 Audio input 4.15 7.34 5.77

24 Audio output 4.15 7.34 5.77

25 Mode address selection 0 0 0

26 Audio output 4.15 7.38 5.96

27 Audio compensation 1 4.14 7.64 6.22

28 Audio input 4.14 7.59 5.83

29 Audio compensation 1 4.14 7.61 6.24

30 Audio input 4.14 7.57 5.83

31 Output 2 0 7.84 6.24

32 Audio input 4.14 7.57 5.83

26

Page 29

SERVICE MANUAL

Table 10 Functions and Service Data of HEF4053 (DS01/DS02)’s Pins

Pin

No.

1 Signal input 0 9.81 6.15

2 Signal input 0 0 0

3 Signal input 0 9.81 6.15

4 Signal output 0 6.66 6.21

5 Signal input 0 0 0

6 Ground 0 0 0

7 Ground 0 0 0

8 Ground 0 0 0

9 Control signal input 0.12 7.97 5.7

10 Control signal input 0.12 7.99 5.7

11 Control signal input 4.98 7.8 5.6

12 Signal input 0 0 0

13 Signal output 0 9.81 6.15

14 Signal input 0 6.9 6.4

Signal output

15 0 6.95 6.4

16 Supply voltage 5.09 6.98 4.44

Function Description

Reference

Voltage (V)

Digital Multimeter

Positive Resistance

(K )

Negative

Resistance (K )

Table 11 Functions and Service Data of TDQ-6F2M’s Pins

Pin

No.

1 AGC 0.98 9.56 6.04

2 NC 26.73 6.85

3 NC 0.61 9.79 7.39

4 SCL 4.89 9.58 5.13

5 SDA 4.88 9.58 5.12

6 VDD 5 2.2 2.2

7 NC 4.9 2.2 2.2

8NC 0 0 0

9 BT 30.21 13.07

10 NC 0 0 0

11 IF 0

Function Description

Reference

Voltage (V)

Digital Multimeter

Positive Resistance

(K )

Negative

Resistance (K )

27

Page 30

Waveforms of Key Points

SERVICE MANUAL

IC DATA AND WAVEFORMS OF KEY POINTS (continued)

28

Page 31

SERVICE MANUAL

29

Page 32

SERVICE MANUAL

30

Page 33

SERVICE MANUAL

31

Page 34

SERVICE MANUAL

ADJUSTMENTS

Set-up Adjustments

The following adjustments should be made when a complete realignment is required or a new CRT is

installed. Perform the adjustments in order as follows.

1. Colour purity

2. Convergence

3. White Balance

Note:

The purity/convergence magnet assembly and rubber wedges need mechanical positioning. Refer to

Fig. 18.

1. Colour Purity Adjustment

Note:

Before attempting any purity adjustment, the TV should be operated for at least 15 minutes.

1) Demagnetize the CRT and cabinet using a degaussing coil.

2) Set the brightness and contrast to maximum.

3) Receive the green raster test pattern.

4) Loosen the clamp screw holding the deflection yoke and slide it backward or forward to display

vertical green belt (zone) on the screen.

5) Remove the rubber wedge.

6) Rotate and spread the tabs of the purity magnet around the neck of the CRT until the green belt is on

the center of the screen.

7) Slowly move the deflection yoke forward or backward until a uniform green screen is obtained.

Tighten the clamp screw of the yoke temporarily.

8) Check purity of the red and blue raster.

Deflection Yoke

Dummy Wedge

Glass Cloth Tapes

Purity/Convergence

Magnet Module

Rubber Wedge

Adhesive

Deflection Yoke

Fig. 18

32

Page 35

SERVICE MANUAL

Fig. 19

2. Convergence Adjustment

Note:

Before attempting any convergence adjustment, the TV should be operated for at least 15 minutes.

Center convergence adjustment

1) Receive the crosshatch test pattern.

2) Set the brightness and contrast properly.

3) Adjust two tabs of the 4-pole magnet to change the angle between them and red and blue vertical

lines are superimposed on the center area of the screen.

4) Turn both tabs at the same time keeping the angle constant to superimpose red and blue horizontal

lines on the center of the screen.

5) Adjust two tabs of 6-pole magnet to superimpose red/blue line and green line. Adjusting the angle

affects the vertical lines and rotating both magnets affects the horizontal lines.

6) Repeat steps 3) 5) keeping in mind red, green and blue movement. 4-pole magnet and 6-pole

magnet interact each other, resulting in complicating and dot movement.

Circumference convergence adjustment

1) Loosen the clamping screw of the defection yoke slightly to allow it to tilt.

2) Temporarily put a wedge as shown in Fig.18. (Do not remove cover paper on adhesive part of the

wedge.)

3) Tilt front of the deflection yoke up or down to obtain better convergence in circumference.

Push the mounted wedge into the space between the CRT and yoke to fix the yoke temporarily.

4) Put other wedge into bottom space and remove the cover paper to stick.

5) Tilt front of the deflection yoke right or left to obtain better convergence in circumference.

6) Keep the deflection yoke position and put another wedge in either upper space. Remove cover paper

and stick the wedge on the CRT to fix the yoke.

7) Detach the temporarily mounted wedge and put it in another upper space. Stick it on the CRT to fix

the yoke.

8) After fixing three wedges, recheck overall convergence.

Tighten the screw firmly to fix the yoke and check if the yoke is fixed.

33

Page 36

SERVICE MANUAL

9) Stick three adhesive tapes on wedges as shown in Fig. 18.

Fig. 20

Circuit Adjustments

1. General Description

All adjustments are thoroughly checked and corrected before the TV outgoing. Therefore the TV

should operate normally and deliver proper colour pictures upon installation. However, several

minor adjustments may be required depending on the particular location where the TV is operated.

This TV is shipped completely in carton. Carefully take out the TV from the carton and remove all

packing materials. Connect the power cord into a 120V AC, 60Hz two-pin power outlet. Turn on the

TV. Check and adjust all the customer controls such as brightness, contrast and colour to obtain

natural colour pictures.

2. Automatic Degaussing

A degaussing coil is mounted around the CRT so that external degaussing after moving the TV is

generally unnecessary, providing it is properly degaussed upon installation. The degaussing coil

operates in about 1 second after power on. If the set is moved or faced to a different direction, the

power switch must be switched off for a few minutes in order that the automatic degaussing circuit

operates properly. Should the chassis or parts of the cabinet become magnetized to cause poor

colour purity, use an external-degaussing coil. Slowly move the degaussing coil around the screen,

the sides and front of the TV and slowly withdraw the coil to a distance of about 2m before unplug it.

If colour shading still exists, perform the Colour Purity Adjustment and Convergence Adjustment

procedures.

34

Page 37

SERVICE MANUAL

3. Supply Voltage Adjustment

Caution: +B voltage has close relation to high voltage. To avoid X-ray radiation, +B voltage should be

+145V.

1) Set R801 to the mechanical center and AC power supply to 120±2V.

2) Connect a digital voltmeter to two pins of C838, and then turn on the TV.

3) Receive Philips test pattern signals.

4) Make the voltmeter read 145±0.5V.

4.High Voltage Inspection

Caution: No high voltage adjustment should be done in the chassis.

1) Connect a precise high voltmeter to the second anode of the CRT.

2) Turn on the TV and set the brightness and contrast to minimum (i.e. set beam current of the CRT

to zero).

3) The high voltage tested should be 29±0.5KV(for 25” TV) or 30±0.5KV(for 29” TV)

4) Set the brightness to minimum or maximum, and ensure high voltage not beyond limitation of

30KV (For 25” TV) or 33KV (For 29” TV) in any case.

5. Focus Adjustment

1) Use the remote control to set the contrast to maximum and the brightness, chroma to medium.

2) Set H. V. lines near Philips pattern center to thinnest with the FCB on the FBT. After finishing

adjustment, ensure that no poor focusing exists near the center or around of the frame.

BeforeAdjusting AfterAdjusting

35

Page 38

SERVICE MANUAL

Service Mode and Bus Data

1. How to Enter the SERVICE Mode with the Remote control.

Decrease the volume to 00. Press the MUTE button on the remote control and “Mute”appears on the

TV screen. Then press and hold the MUTE button on the remote control and MENU on the TV at the

same time for 3 seconds and the TV enters the S mode.

Press the or button to select data in turn and or button to decrease or increase data. Press

the button on the remote control or MAIN POWER SWITCH button on the TV to exit from the mode.

Description Data Description Data Description Data Description Data Description Data

AFW:240KHz 1 De interta 0 S CORRECT 20 AUTO ADJUST 0 OPT SPKON 0

IF-PLL 1 H shift 40 V SHIFT 32 SUB BRIGHT 27 OPT SPATAL 1

AGC over f 9 H shift-50 32 V SHIFT-50 32 LOUDNESS 18 OPT COLOR 0

IFS 0 E/W WIDE 45 V 200M 25 CNTRST MAX 52 OPT V-CHIP 1

MOD 0 PARABOLA 32 V SCROLL 31 CONTRST MID 21 OPT CCD 1

Fixed Avd 1 E/W CORNER 63 V HALF 0 CNTRST MIN 0 OPT PWR- ON 1

Sound Mute 0 TRAPZIUM 23 SPK PRESCL 55 COLOR CORE 31 SRCH SPEED 0

Auto Limit 0 OSDH POS 13 AV PRESCAL 66 SPATIAL 32 ROM CORREC 0

VOLUME 0 V CENTER 31 ST SPECTRL 31 SUB TINT 31 0

Blank HOB 0 V AMP 30 ST TIM CVR 7 OPT STEREO 1

2. DS01 DS02 Door Turnover Control

DS01 DS02

910119 1011

TV H H L L H

AV1 H H L L H

AV2 L L L H L

AV3 L L H L L

S-VIDEO L L H L L

36

Page 39

3. Bus data (for MCR61TF30 only)

SERVICE MANUAL

Item

Description Bus data Remarks

MENU 00 IF

AFW:240KHZ AFC window 0=125KHz 1=275KHz 1

IF-PILL: IF-PILL frequency 1

AFA:Inside AFC window 0=Outside 1=Inside (output) 1 Changeable

AFB:Below AFC reference level 0=Below 1=Above (output) 1 Changeable

AGC over f RF AGC 7 Set to the optimal mode

IFS IF sensitivity 0=Normal 1= 20dB loss 0

MOD Modulation mode: 0=Negative 1=Positive 0

MENU 01 Audio

Fixed Aud. 0=Adjustable volume 1=Fixed volume 1

Sound Mute 0=Not mute 1=Mute FM demodulation 0

Auto Limit

Auto volume adjustment 0=Disable (limited to

8841/42/46)

0

FLNG1 Language options 0

FLNG2 000 English, French, Spanish 0

FLNG3

Other options are available for TVs to South

America.

0

OPT.STEREO 1: AV stereo (TDA9859) 0: AV mono 1

OPT.SPATAL Surround: 1=Yes 0=No 1

OPT.S-VHS 1 0 for other mode

MENU 02 Horizontal scan

Blank HOB

Upper and lower useless parts of 16:9 image

blanked 0=Disable

0

De interla 0=Interlace 1=Non-interlace 0

H shift Horizontal center (vertical frequency: 60Hz) 45 Set to the optimal mode

H shift-50 Horizontal center (vertical frequency: 50Hz) 31

E/W WIDE Horizontal amplitude 41 Set to the optimal mode

PARABOLA East-West pincushion correction 27 Set to the optimal mode

E/W CORNER Quadricorn correction 39 Set to the optimal mode

TRAPZIUM Trapezoidal distortion 40 Set to the optimal mode

OSD H.POS OSD horizontal position 3

MENU 03 Vertical scan

VER MODE:

0=Auto/60Hz 1=60Hz compulsory

2=Auto/hold

0

(continued)

37

Page 40

SERVICE MANUAL

VER OUT: 0=Normal 1=Vertical scan off 0

OVERSCAN: 1

VER Protec 0

BLANK FIX

VER Dividr

Vertical blanking: 0=50/60HZ adaptive 1=50HZ

compulsory

Vertical frequency divider 0=Normal 1=Wide range

sync

0

0

MENU 04 Vertical output

V HALF 1=Only first half vertical scan 0

V CENTER Half vertical center (vertical frequency: 60Hz) 31 Set to the optimal mode

V CENTER50 Half vertical center (vertical frequency: 50Hz) 31

V AMP Vertical amplitude (vertical frequency: 60Hz) 31 Set to the optimal mode

V AMP-50 Vertical amplitude (vertical frequency: 50Hz) 31

S CORRECT S correction 16

V SHIFT Vertical center (vertical frequency: 60Hz) 31 Set to the optimal mode

V SHIFT-50 Vertical center (vertical frequency: 50Hz) 31

V ZOOM Vertical amplitude compensation for 16:9 and 4:3 25

V SCROLL Center shift when 16:9 shifted to 4:3 31

MENU 05 RGB

WHIT P RED Red bright balance 31

WHIT P GRE Green bright balance 31 Set to the optimal mode

WHIT P BLU Blue bright balance 31 Set to the optimal mode

AKB Auto white (dark) balance 1

Y-De la y

0ns~320ns step40ns(9 steps unchangeable in

event of even)

8

Cathod Lev Monochrome peak voltage: 57~107V 5

MENU 06 Brightness channel

BLUE Stret Blue level stretch: 1=On 1

BLACK stret Black level stretch: 1=On 1

Y-VA LU E Brightness channel gain: 0=Normal 1=High 0

SKIN ANGLE

Skin tone correction angle: 0=123°(more red)

1=117°(more blue)

0

SKIN TONE Skin tone correction switch 1=On 1

B.B LEVEL

Blue back brightness

40

MENU 07 Color channel

ACL Auto color saturation control: 1=On 1

(continued)

38

Page 41

SERVICE MANUAL

CB

Center frequency of color band pass: 0=1Fsc

1=1.1XFsc

CMB 1=3 line comb filter enable (auto) 0=Disable 0

BPS 0=Base band delay line used 1=Bypassed (auto) 0

MAT 0=PAL/NTSC matrix 1=PAL matrix compulsory 0

OPT.DW4MIN

OPT.OVPT

1: Not degaussing again within 4 minutes after auto

degaussing with power on

Over voltage protection (spot killer when power off)

1=Yes 0=No

OPT.BBK 1: BBK on 0 BBK off 1

AUTO ADJST 1: Auto adjustment 0

MENU 08 Analog

SUB BRIGHT Sub brightness 31

AV PRESECL AV output amplitude (for BTSC stereo only) 75

VOLUME 0

CONTRST

MAX

Sub contrast Max. 63

CONTRST MID Mid. 31

CONTRST MIN Min. 0

0

1

1

COLOR Core Sub saturation 31

SUB TINT Sub tint 28

MENU 09 Selector

AKB start-up characteristic 0=Picture displayed

BCO

XA.XB

without delay 1=Picture displayed through inner

delay

Horizontal scan crystal oscillator: 0=TWO 3.6MHZ 0

1: ONE 3.6MHZ(PIN34)

2: ONE 4.43MHZ(PIN35)

3: 3.6 (PIN34)/4.43 MHZ (PIN35)

STB 0=Standby 1=Normal 1

POC Sync separation 0=On 1=Off 0

CM2.1.0

Crystal oscillator operation selection (color system

selection)

MENU 10 Selector

VIM

Video identification mode 1=Coupled to video after

switchover

1

0

1

(continued)

39

Page 42

SERVICE MANUAL

STM 1=Reducing identification sensitivity during tuning in 0

High voltage fluctuation compensation

HCO

0=Compensating vertical output 1=Compensation

horizontal/vertical output

1

EVG

PRD

Vertical protection 1=Identification and protection

0=Identification only

High voltage (X-ray protection ) 1=Identification

and protection 0=Identification only

COR Coring: 1=On 0=Off 1

MENU 11 Others

OSO 1=Switch-off in vertical overscan function 1

CS1.CS0

CVBS-2 OUTPUT ( for TDA885X only)

AST Auto Startup 0=AUTO 1=Startup by MUCH 1

FFI IF-PILL time constant 0=Normal 1=Fast 0

EBS Expanding blue level stretch 1=ON 1

FCO Color killer 0=Normal 1=Not kill 0

MENU 12 Option switch

OPT.AV2 1=With AV2 1

OPT.AV3 1=With AV3 1

OPT.YCbCr YUV component input 1 Yes 0=No 0

OPT.COLOR Color system 0=NTSC 1=PAL M/N—NTSC 1

OPT.V-CHIP V-CHIP 1=Yes 1

0

1

0

OPT.CCD CCD 1=Yes 1

OPT.PWR-ON 0=Soft on 1=Instant on 0

SRCH SPEED 0=Slow search 1= Fast search 0

ROM CORREC ROM correction (fixed to 0) 0

MSP/TDA 1 BTSC(MSP3440) 0=STEREO/ MONO 0

Notes: (1) For MCR68TF800 and MCR68420, OPT.AV3 should be changed to 0, POT.DVD should be

changed to 1; For MCR66R400, OPT.SHS should be changed to 0.

(2) The data sheet may differ dependent on different modes.

(3) The data sheet may differ dependent on different CRTs for the same model.

2

(4) Do not adjust I

C data with the remote jig unless necessary.

(5) The remote jigs on neighboring work position cannot affect each other.

40

Page 43

FINAL WIRING DIAGRAM FOR MCR61TF30

From Right Speaker

Black

Wired Connector B

Wired Connector XV602

cord

r

powe

From

XP800

To Speaker's Positive

Blue

From Degaussing Coil

XP901A

Wired Connector XP804

Power PCB Assembly

Power Switch Assembly

VDR801

XS804

XP804

XS803

Wired Connector XP803

XP803

XPK01A

Wired Connector XS803

Wired Connector XPY03

XS402

Wired Connector XPK01

XSK02XSK02

XSK01A

Main PCB Assembly

From Deflection Yoke

XSW01

XSY01

Control Buttons PCB Assembly

XPK02

To Speaker's Positive

XK01

From Left Speaker

Black

hite

W

Wired Connector A

Wired Connector XV602

Wired Connector XPK02

CRT RGB PCB Assembly

XPY01

Soldered on Copper-foil Grounding Land

VG2

GND2

GND1

XPY03

From CRT's Ground Wire

Grey

C Wire (Red)

Wired Connector XPY03

XSY03

A Wire

XPS06

Wired Connector XV602

XSA02

XSA01A

Connected to L Male Connector on AV PCB Assembly

XPA03

AV PCB Assembly

XPA02 XAS01

CUI

CVI

SPO

GND

SCI

SYI

GND

CYI

GND

GND

SCI

5V

VI

GND

GND

SYI

VI

5V

GND

GND

Connected to L Female Connector on Main PCB Assembly

CUI

CVI

GND

SPO

GND

CYI

Wired Connector XPY01

Page 44

FINAL WIRING DIAGRAM FOR MCR66R400

Page 45

FINAL WIRING DIAGRAM FOR MCR68R420

Control PCB Assembly

XPK01

Wired Connector XPK01

Power Switch PCB Assembly

From Right Speaker

Wired Connector A

Wired Connector XP205

Black Red

From Power Cord

XP800

Power PCB Assembly

From Degaussing Coil

XS08

XP901A

Wired Connector XP804

XP804

XP803

XS804

From Deflection Yoke

XS803

Wired Connector XP803

XS402

XSY03

Wired Connector XS803

XSK01

XS402

Main PCB Assembly

From Deflection Yoke

XPS06

Wired Connector XP205

XS08

XS06

Side AV PCB Assembly

XSY01

From Left Speaker

Black

Red

Wired Connector B

Wired Connector XP205

Wired Connector XPY01

From Ground Wire (Soldered)

XPY01

CRT RGB PCB Assembly

GND2

GND1

XPY03

AV PCB Assembly

Wired Connector XPY03

Wired Connector XPK02

Page 46

FINAL WIRING DIAGRAM FOR MCR68TF800

KK05KK06

KK04

P-

P+

TV/AV

XK02

Wired Connector AD-04-120

XS08

From Left Speaker

Wired Connector A

Black Red

From Power Cord

From Degaussing Coil

XP800

Wired Connector AD-05-200

XSK02B

XP901A

Wired Connector XP804

Wired Connector XS01

XSK02

XSK02A

XS804

Control PCB AssemblyPower Switch PCB Assembly

KK03

KK01

KK02

V-

V+

MENU

XPK02

From Right Speaker

Black Red

Wired Connector B

Wired Connector XP205's A

Power PCB Assembly

Wired Connector XPY01

From Ground Wire (Soldered)

XS804

Wired Connector XP803

XS803

XS803

XSY03

Main PCB Assembly

XS402

From Deflection Yoke

XPS06

Wired Connector XP205

XSY01

Wired Connector XPK02

Wired Connector XP205's B

Wired Connector XPY03

XPY01

GND1

GND2

XPY03

CRT RGB PCB Assembly

AV PCB Assembly

Page 47

MCR66R400 (Main Diagram)

Chassis : CH-10C5

Page 48

MCR66R400

(A/V I/O Board, Kine Board, Power Supply and others)

Chassis : CH-10C5

Loading...

Loading...